4 minute read

CUTTING EMISSIONS BY UP TO

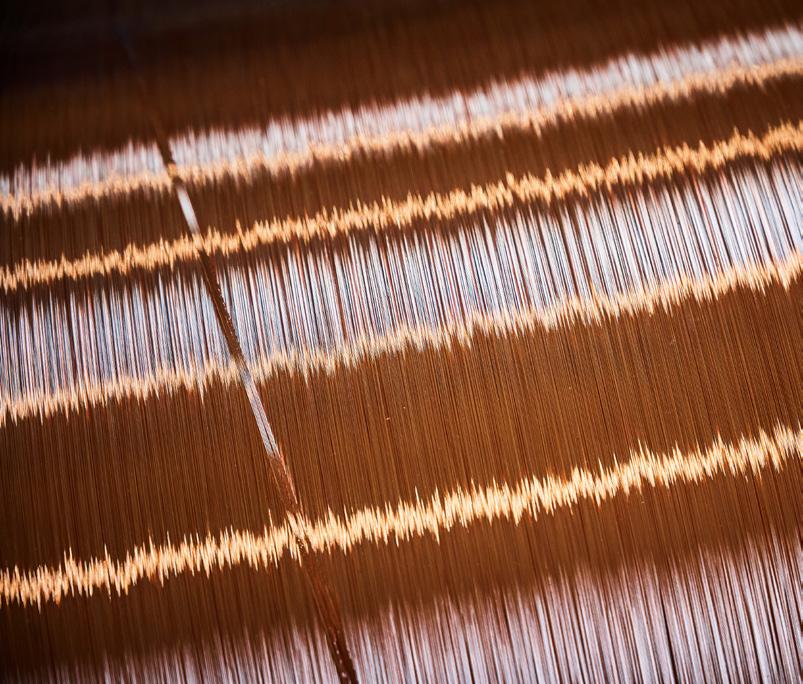

Elcowire & Doncaster Cables cowork on Low-carbon Copper

Doncaster Cables have chosen to use Low-carbon Copper from Swedenbased company Elcowire for its cable solution EV Ultra®. The lowered CO2-emissions in the Low-carbon Copper that will be used for the entire charging cable, will help to electrify Britain.

EV Ultra®: Power and data connectivity combined in one cable Hard wired data connectivity is a superior and secure alternative to using WiFi, resulting in a faster, neater and easier installation process. Available in both PVC Tuff-Sheath and SWA variants.

The introduction of Low-carbon Copper is a significant step for both, contributing in a significant way towards society’s goal of zero emissions by 2050.

Both companies add their expertise to this cable solution – Low-carbon Copper causes less than half of the carbon emissions over its processes from cradle to gate, compared to the global average footprint for standard copper. The collaboration between Elcowire and Doncaster Cables goes back more than 40 years.

When calculating the low-carbon copper footprint, all the parts of the products lifecycle, from sourcing the copper, manufacturing the copper wire and producing the final cable to recycling is covered.

encapsulating them in a double sheathed design. Whilst especially helpful in the installation of electric vehicle charge points, the cables also provide benefits in other electrical systems where power and data are required, including but not limited to gate entry, CCTV, caravan parks and home offices. These cables are designed to be installed in air, clipped to surface, on cable tray/ladder and direct burial. The cables are also third party approved by the British Approvals Service for Cables (BASEC).

The carbon emissions reductions from using Low-carbon Copper include:

Step 1: Copper mining process

Step 2: Producing the copper wire rod (Elcowire)

Step 3: Producing the ready-to-use cable EV Ultra® (Doncaster Cables)

Read more about the emissions reductions on next page.

WHAT IS LOW-CARBON COPPER AND HOW IS IT ACHIEVED?

The copper cathodes that Elcowire uses in its production comes from mines and smelters that has developed their sustainability agenda and have very low carbon footprint. These suppliers has undergone a substantial transformation due to electrification and automation of various stages in the process.

The Low-carbon Copper has also been made possible by a very efficient ore concentration process and a world-class green energy mix.

”Elcowire sets an example by producing semifinished and finished products that have a low impact on nature and the climate. We are proud to be in the lead for this transition,” says Paul Gustavsson, Elcowire’s CEO.

EV-ULTRA® INNOVATIVE CABLE SOLUTION

EV-Ultra® provides a quicker, neater an easier solution for electricians who are looking to install power and data. The cable combines power conductor with either 2 core signal or 4 pair data cables, whilst

How the carbon footprint is lowered in the EV Ultra® cables:

1

The first part of the process behind Lowcarbon Copper takes place in the north of Sweden. Elcowire’s suppliers has developed an efficient mining process with electrified vehicles and only fossil-free energy sources –mainly from hydropower – throughout its lean, and very efficient processes. Finally, there are also sustainable transports to Elcowire’s facilities.

2

An electrified train travels 1,350 km through Sweden to deliver the raw material, copper cathodes, to copper solutions company Elcowire’s advanced production facility where the Low-carbon Copper wires to be used in the final cable solution are produced.

3 4

Deliveries in the UK and all over the world through fast access to all major business regions.

The third step takes place at cable manufacturer Doncaster Cables in Doncaster where the Lowcarbon Copper wire is drawn to the desired dimension in a lean production method with sustainable measures taken in consideration in all means regarding energy, water, waste and recycling.