5 minute read

Test & Measurement

How testing equipment is evolving to make the installers’ job easier

Mark Johnson, Marketing Consultant to Metrel UK, discusses the evolution of testing equipment amidst a challenging economic backdrop.

Advertisement

J

ust recently the economic news has not been great. Consumer inflation in the UK has risen to its highest level in 40 years. The pound has dropped in the last six years making any commercial transactions, such as buying oil, about a third more expensive.

Then there is the impact of Covid, exacerbating the shortage of various manufactured items such as silicon chips. This has meant that manufacturers are competing with different industries to grab a supply of components simply so they can build their testers. At the start of 2019 copper was $27,218 per ton, three short years later it was 63% higher. And that’s not all, as we can also add President Putin’s war to all of this.

Taken altogether, the bottom line of the situation is that we will all feel the pinch in the coming weeks and months ahead.

Thankfully, the positive is that we are working in the construction industry, the industry that our governments see as the driver for economic development and as the tangible proof of their ‘levelling up agenda’, whether it is great infrastructure projects like HS2, large housing estates or converting buildings into decent accommodation.

There is money to invest and money to be made in our industry. However ‘the aggregation of marginal gains’ philosophy of British Cycling’s Sir Dave Brailsford applied to our processes is no longer enough in a world of big cost increases.

The test equipment sector has been through a torrid time, with a chipset shortage. A fire in an American factory limited the supply for some major manufacturers’ multifunction testers. In an effort to circumnavigate this shortage, one manufacturer changed components, however reports suggested that it compromised their testers’ quality. Meanwhile, all manufacturers are now fighting for supplies in the

world markets against much richer businesses. The inevitable result will be significant price rises.

There is plenty of work around, not just in pure construction, but with the installation of the charging infrastructure required for electric vehicles. At the last count there were less than a quarter of a million EV chargers and about 33 million cars on the roads. There is great opportunity servicing these chargers post-installation. In fact, one source claims that at least 50% of the early installations were incorrectly installed!

Since Metrel were evangelising the testing of EVSE equipment, most manufacturers have launched EVSE testing adapters. Some are more reliable than others – in other words, you get what you pay for. Because of the desire to speed through the testing process, only a few multifunction testers actually test to IEC 62955, which requires a slower rise time to the 6 mA DC breaker test. For EVSE testing, on-board storage of results and certification are vital as in the future engineers are likely to be testing large numbers of chargers one after another.

The marginal gains referred to above can be seen quite clearly during installation testing, as at least two manufacturers’ offer an alternative to performing a trial insulation resistance test at 250 V, followed by a certification test at 500. Instead, as long as no vulnerable components are found, the machines from those manufacturers have a pre-test that will warn of low impedance in the circuit before doing a voltage test, which will halve the time for an insulation test.

Additionally, some manufacturers’ machines are able to give installers a number of results in a single shot by running a prescribed sequence of tests to expedite the process. Repeatable results, particularly on loop tests, also help so you don’t have to keep repeating the test and can move on.

Making sure your tester is running on the latest firmware is another marginal gain. Manufacturers are continuously improving the firmware that drives the testers to make them faster, and perform tests better. Some firmware changes even deliver new tests. Most of these upgrades are done at calibration but there are companies who free-issue them for customers to do for themselves.

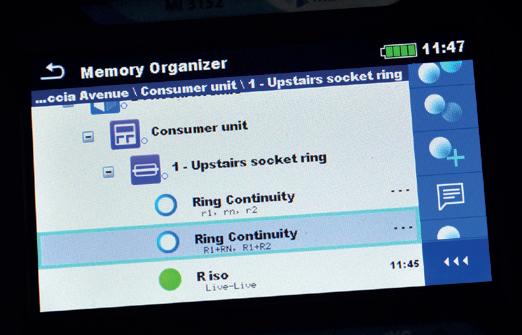

One recently released product that could give a more solid gain is a ring circuit adapter, which claims to save you more than 60% of your time testing ring final circuits. In two steps it delivers all the end-toend continuities, r1, rn and r2, followed by R1+R2 and R1+Rn using some clever communication through the conductors between tester and adapter to change the connections without needing to return to the distribution board. The calculated results of (r1+rn)/4 and (r1+r2)/4 are displayed for comparison.

The final area for making serious gains has been heralded for at least 20 years, downloading and automated certification. The way most professionals work right now seems to be to get the data away from their tester as soon as possible, maybe because the tester memory system is just too difficult to negotiate. Until recently they completed a rough document by hand and then made a fair copy either on a computer or paper form for passing on.

That is beginning to change, as now many have a representation of a certificate loaded on to a memory device of some kind, usually a tablet and type the test results in the form. While having the merit of having a completed Certificate when the engineer leaves the premises, it still is a laborious process risking error in the transferring of a result from one device to another.

But there’s still room for improvement, as a better alternative is to store the test results on-board the tester, in a schematic representation of the circuits under test. Multifunction testers capable of doing this allow you to add comments too. When the results are downloaded into the certificate, the comments have the option of being entered too. Additional tests that have been performed, which are not required for the certificate, like a snapshot of the harmonic distortion, can also be stored as part of the customer’s account.

In conclusion, we cannot do much to mitigate the effect of inflation by the automation of testing and information handling. But we are lucky to be in the vanguard of a bipartisan drive to net zero. We may or may not go to hell, but in a new EV.

Most manufacturers have launched EVSE testing adapters. Some are more reliable than others – in other words, you get what you pay for A better alternative is to store the test results on-board the tester, in a schematic representation of the circuits under test