SUDESH KISSUN sudeshk@ruralnews.co.nz

are being urged to deliver a strong and clear mandate on the proposed $4.22 billion sale of consumer and related businesses to Lactalis.

Fonterra Co-operative Council chair John Stevenson says the proposed sale is a strong proposal for Fonterra shareholders to consider and he wants shareholders to attend farmer meetings and webinars over the coming weeks to learn more about the divestment – seen as one the biggest decisions since Fonterra’s formation.

“The divestment proposal is very significant for our co-op given its size and value,” he told Dairy News.

“It will also change what Fonterra looks like post any divestment.”

Stevenson says the council is of the view that it is really important that shareholders look at the proposal when it comes out in the notice of meeting, understand what it means, and vote.

“The decision we are being asked to make is important for the future of our co-op.

“A decision of this scale demands a strong and clear mandate, both in terms of voting participation and the level of support. Fonterra has a comprehensive plan for engaging with farmers, so I encourage all shareholders to try to attend one of the farmer meetings or webinars,

and when the time comes to exercise their voting entitlement.”

Fonterra will issue a notice of meeting next month and a special general meeting is likely in the first week of November.

Lactalis, a family-owned business headquartered in France, will buy Fonterra’s global consumer business (excluding Greater China) and consumer brands; the integrated foodservice and Ingredients businesses in Oceania and Sri Lanka; and the Middle East and Africa Foodservice business, plus Bega licences held by the Australian business.

The Bega licence issue was resolved last week, boosting the sale price by $375m. Fonterra will return $2/share to farmer shareholders.

Stevenson says it is great to have the dispute with Bega Cheese resolved and for farmers to have certainty around the inclusion of the Bega licences in the sale.

Fonterra chairman Peter McBride expects a strong mandate from farmers shareholders. For the sale to go ahead, 50.1% of voting Fonterra farmer shareholders must vote yes.

McBride says a series of webinars are being held where the co-op will brief farmer shareholders.

Fonterra directors and management will also use their roadshow meetings, scheduled after its annual result announcements next month, to sell the proposal. McBride expects strong farmer interest at the meetings.

“Often with farmers, when you have a good set of results, you don’t get a good turnout, but I think we’re going to get one this time,” he says. He also expects an easier round of consultation compared to its capital structure in 2021.

“When I compare this consultation to capital structure, I’d say this would be an easier road to go down, so we’re looking forward to it.

“We require 50.1% approval to go ahead with the sale, but we’re looking for much more than that, and we’re looking for a really high turnout. That’s an important part of this.”

McBride says, since the announcement, he has received a flurry of texts and messages – all positive. “They’ve obviously heard about some of the value that’s been bandied around. Now they’ve seen a real number, so I think it’s starting to hit home in terms of now they have a decision to make.”

Stevenson says the council has also received generally positive feedback from farmers on the proposed sale so far.

“Farmers have also told council that they have a deep connection to Fonterra brands, and that they are looking to understand the details of what Fonterra’s business looks like post any divestment.

He says shareholders will welcome a $2 return of capital.

“This is also big news for the economy of the rural communities within which we all operate.”

@dairy_news facebook.com/dairynews

CONVERTING A Banks

Peninsula farm to dairy is expected to reduce its environmental footprint by 46%, say its owner and manager.

Willesden Farm, in the Kaituna Valley, is part of a recent surge in dairy conversions prompted by the healthy milk payout.

Equipped with a brand-new composting feed barn and state-ofthe-art rotary shed, the farm has recently started milking 700 cows in its first production season.

Owner Brent Thomas says it’s a formula that will vastly reduce the farm’s footprint while ensuring financial viability.

The composting feed barn that captures animal effluent and helps preserve the pasture will be a key to the new venture’s success.

It will allow them to exclude the animals from the pasture in adverse weather – most often when it’s particularly wet in winter but also when too hot in summer.

“We can afford to do that under dairy because of the revenue that’s generated out of dairy,” said farm general manager Matt Iremonger.

He said it was a struggle to be financially viable

ON THE rest of the farm, there is forestry, sheep and beef, and extensive native vegetation, both planted and regenerating naturally.

Brent Thomas says his late mother was an environmentalist who set up the Prices Valley Reserve under a QE2 Covenant. They also did a lot of planting.

“We’ve got an environmental background and passion, and I don’t think you meet any farmers who don’t want to leave it better for their family than when they took it over.”

Construction of the new barn and shed was hoped to begin late last year but was delayed first by consenting delays then bad weather during construction in April.

Cows were introduced to the barn in late July and milking began in Mid-August.

With the construction running late, early calving cows were able to be managed on the group’s two other farms near Leeston.

Thomas said that whole “ecosystem” of consenting takes longer than it should - pointing out that it took a week just to get the permits from three different councils to transport an oversize earthmoving machine up the highway from Ashburton.

“It was consenting, then weather, and so it’s been a difficult and frustrating process,” he said.

With the current uptick in dairy conversions, the pair describe composting barns as a “systems change” likely to become increasingly common in the New Zealand dairy industry, although every farm is different and they would not be for everyone.

They say automation collars are another technology that will become commonplace over time. Two out of the group’s three dairy farms already run Halter collars and they will assess the Kaituna herd over the season to potentially fit collars next year.

The new dairy shed also includes “a whole lot” of automation and they say their choice of systems means it is future proofed for further adaptation going forward.

“It reduces workload on staff, improves power efficiency and comfort in the shed, and also improves water usage, all those types of things,” says Matt Iremonger.

on the farm’s land type under irrigation.

“So, we looked at several alternatives and dairy

environment and it’s the best farm system for the natural assets that we have here.”

Iremonger said that environmental and financially sustainability were inextricably linked.

“The assets that we have here are the soil, the fertility, the pasture and the water. If we protect our soil and our fertility, we minimise the environmental impact, but we also minimise the financial impact and maximise the profitability.”

He said they submitted at a lower number in the consenting process to ensure a buffer, but the numbers are “quite achievable”.

“We suggested conditions that required monitoring and so we’re monitoring now through that process. So, we’ll be able to develop a whole lot of data, that demonstrates that we’ve having a net improvement across those metrics.”

tling ponds, then “flying” into the stream.

“The first thing was we put an effluent treatment system in there.”

That ran as a dry land dairy until 2005. Across the wider farm, the family has also tried various crops, and a vineyard and orchard, now both gone.

was the best fit because of its pastoral nature.

“It’s the best for the soil, it’s the best for the

Iremonger said rigorous modelling indicated the new system would give 25 to 30% reduction in P loss, 60 to 70% reduction in N loss and 60 to 70% reduction in E coli loading in the streams.

Thomas said his family had been in the Valley since 1975. In 1987 they added to their holdings by buying a dairy farm close to the Okana Stream, a tributary of the Kaituna River, with about 180 cows. Thomas said that at that time, the effluent was going to set-

With the farm’s water originally coming from poor quality shallow wells, the discovery of good quality deep water in 2009 allowed extensive irrigation but Thomas said it was still a struggle to leverage the assets to make a profit, despite the various ventures.

“If you start going backwards, you’ve got to make a change,” he said.

The dairy conversion applies to about 300ha

of the most productive irrigated land in the Kaituna Valley, only a small part of the farm’s total 4000ha, which extends high into the Kaituna and Prices Valley catchments. Of the 300ha, 200ha is now the dairy platform and the rest dairy support, sheep & beef finishing.

It is consented for 820 animals and has started with 700 but will settle on 800 in the longer term. Previously that land was farmed as intensive dairy support, beef and lamb finishing, and some summer and winter cropping.

“Now it’s grass 12 months of the year and that allows us to ensure that we have no exposed soils,” said Iremonger.

their organic milk price forecasts.

ON TRACK for a fifth consecutive year of organic milk price increases, Fonterra is seeking more suppliers to meet growing global demand.

This month the cooperative announced a new mid-point record forecast organic milk price of $13/kgMS for this season – with a range of $12 to $14/kgMS.

Last season’s forecast range was also revised upwards to a new range of $12.30 to $12.40/kgMS, with a midpoint of $12.35/ kgMS, which would be a record high. Fonterra will confirm the final milk price for last season as part of its annual results later this month. Fonterra’s highest organic milk price to date was in 202324 season - set at $10.92/ kgMS.

Fonterra’s general manager for organics, Andrew Henderson, told Dairy News that that its organic farmers are entering spring with a lift in

The organic milk price for last season has largely been driven by significant demand increases in recent months, with American consumers in particular prepared to pay a premium price for grass-fed, organic dairy from New Zealand, Henderson says.

“The strong demand, combined with our team’s hard work, has led to a 27% increase in sales year on year.”

The organic sales forecast for FY26 is up 8.5% compared to the previous year on a kgMS basis.

The US continues to be the largest and highest value market for Fonterra’s organics programme. However, looming large over the record milk price are new tariffs imposed by the Trump administration.

Henderson says the co-operative is keeping a close eye on overall supply and demand dynamics, including how tariff rates may affect the US market.

“We hope this latest

announcement is welcome news for our organic farmers and we will keep them updated through the rest of this season if we think things have materially shifted.”

Henderson adds that the co-operative is focused on opportunities to grow its North Island organic milk supply, especially in and around the Waikato region.

“Demand for organic products continues to grow and to keep up with this we are looking to further expand our organics programme.

“We’re encouraging farmers to get in touch with us if they want more information.

“There are support options available to convert to organic, and we look forward to sharing

more with any farmers who are interested.”

Henderson says the record forecasts and potential to grow the programme wouldn’t be possible without farmers’ ongoing dedication to organic practices.

“These exceptional results are a direct reflection of the care and attention co-op farmers invest in their land, animals and milk production, and we’re looking forward to building on their hard work and success as the 2025/26 season progresses.”

Fonterra’s organics business has been running since 2002 and continues to grow in supply, product range and value.

Over the last 4-5 years, the programme has more than doubled in size and currently includes more than 100 farms.

Organic farmers earn a premium, and there’s also a benefit to all Fonterra farmers because around 20% of the programme’s revenue goes back to the co-op as a contribution to shared overheads and earnings.

RURAL SUPPORT Waikato is inviting farmers, growers, and rural communities to take a well-earned break and join us for ‘Brunch on Us’ – a series of all-sector, relaxed drop-in events across the region.

The events started two weeks ago and run through to Friday 19th of September. The events are a chance for rural people to come together, enjoy brunch, and connect with others who understand the unique challenges of life on the land.

“You don’t have to register, and there are no speeches or presentations – just a warm welcome and some delicious food,” says Wanda Leadbeater from the Trust.

Rural Support Waikato will be hosting brunch at local locations from Pollok to Tirohanga, with support from local networks and organisations.

For full dates and venues, visit: rural-support.org. nz/events

LIC HAS reaffirmed its sponsorship of the New Zealand Dairy Industry Awards (NZDIA) by signing up as a national sponsor for another three years.

The herd improvement co-operative has confirmed its support and sponsorship across the regional and national awards through to 2028.

LIC has also added an impressive GeneMark Genomics prize to the pool for the national winner of the LIC Animal Wellbeing Recording and Productivity Award.

LIC chief executive, David Chin says the co-operative is honoured to continue the long-standing involvement with the awards.

DAIRYNZ HAS announced the date for its six-yearly Milksolids Levy vote, which will take place from Monday, 16 February to Friday, 13 March 2026.

DairyNZ chair Tracy Brown says the levy underpins sector science, research, on-farm support, and advocacy to ensure a positive future for dairy.

“Voting ‘yes’ in the Milksolids Levy vote ensures we can continue to invest in the activities that matter most to farmers – both now and into the future,” she says.

“Later in the year and into 2026, our board and management team will be visiting regions to meet with farmers, discuss the levy, and answer any questions.

“We value the opportunity to share the progress we’re making at a pivotal time for dairy. It’s important we continue to work with farmers and partners to secure the continued success of our sector,” Brown says.

Further details about the voting process and regional engagement events will be shared closer to the voting period.

The Milksolids Levy supports DairyNZ’s work in delivering world-leading science and research, extension, and evidence-based policy and advocacy.

AFTER SERVING three as a DairyNZ director, Waikato farmer Chris Lewis is ready for another term.

The former Federated Farmers national dairy chair says his focus at DairyNZ remains on ensuring the board provides strong governance direction that reflects farmers’ realities and invests levypayer funds wisely.

Nominations closed last week. This year, two farmer director positions are open, with Lewis and board chair Tracy Brown and Chris Lewis retiring by rotation. Brown is also seeking re-election.

DairyNZ has a governing board of eight directors. Five are farmer-elected and three are indepen-

“From freshwater farm plans to climate policy and biosecurity, the board must provide direction that is practical.”

dent, professional directors.

Lewis milks about 930 cows on a 330ha eff farm at Pukeatua, south of Hamilton.

He told Dairy News that DairyNZ must pursue practical, “paddock-first solutions” while safeguarding farm viability and being accountable to levypayers.

“Farmers need answers that work in

the paddock, not just on paper,” he says.

“My focus is on ensuring the board keeps DairyNZ connected to the realities of running a farm, so that strategies, research, and policy translate into tangible,

measurable outcomes on-farm that are positive for both production and profit.”

Lewis believes the board must take a strategic view of the cost pressures, regulatory demands, and labour

315

-

shortages impacting the sector.

“I will ensure DairyNZ’s priorities support profitability, resilience, and long-term confidence for the next generation of farmers.

“Sound governance

means testing every decision against operational realities. I will continue to ensure board decisions are informed by robust analysis and farmer input, not just theoretical models — and that all directors are able to bring their expertise effectively to the table.”

He says directors are accountable to farmers and the board must maintain a strong and credible voice in discussions with government, industry partners, and the public — representing farmer interests with integrity and authority.

“From freshwater farm plans to climate policy and biosecurity, the board must provide direction that is practical, costeffective, and achievable. I will ensure we face these issues head-on, balancing environmental, economic, and social outcomes.”

Lewis served as a Federated Farmers’ official for over 18 years, starting at Otorohanga branch chair culminating as national dairy chair. He stepped down four years ago to allow younger Feds members to take on leadership roles.

He remembers telling fellow Feds executives of the need to focus on ‘three Fs’ – family, farming then Feds.

“After a year we added another ‘F’ – fun; you must have some fun while you’re doing these roles.

“And so I always said to the guys, when we get together at the conferences, do not get things mixed up – family first, then your farm. If you’ve got time, do your volunteer work with Feds.”

@dairy_news

facebook.com/dairynews

homes in a

for intending purchasers is available to view. Options to purchase include: - the entire 193.2 ha property.

- the homestead block or 123ha (approx) including the second home and multiple supporting shed infrastructure. - the bareland block of 70ha (approx), including woolshed and cattle yards.

Greig Moore

027 205 9702 greig@redhotrealestate.nz

say support is required to shift away from the copper network that has been the only source of internet connection for some parts of rural New Zealand.

Last month, telecommunications commissioner Tristan Gilbertson wrote to Minister for Media and Communications, Paul Goldsmith, recommending the complete deregulation of New Zealand’s copper network.

Gilbertson says the Commerce Commission’s final recommendation reconfirms what was set out in the draft recom-

ADVERTORIAL

mendation released earlier this year, that copper regulation is no longer needed to promote competition in the areas where it remains and that it should be omitted from Schedule 1 of the Telecommunications Act.

“We have concluded that competition from alternative technologies is now sufficient to justify removing copper regulation,” he writes.

In the letter, Gilbertson says that approximately 97% of rural consumers have three broadband alternatives available – LEO satellite, GEO satellite, and Fixed Wireless Access.

“These alternatives are often cheaper and better performing than copper, which is increasingly less

reliable and more expensive to operate and maintain,” he argues.

New Zealand is not alone in decommissioning its copper network. Spain has recently shut down its copper network while Singapore and Sweden are also nearing full retirement of the technology.

Meanwhile, Sandra

Matthews, national president of Rural Women New Zealand (RWNZ), says that while members of her organisation understand and accept the Commission’s reasoning, there are still concerns about the consequences for people in rural communities, “particularly those without access to alternative

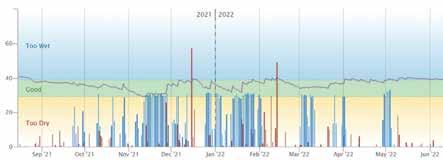

The Anderson family have been farming in Otorohanga since 1969. Today, second-generation farmer Alby Anderson and his wife Mary run their 160 hectare dairy farm in a split calving operation, with 300 cows calving in the spring and 200 in the autumn.

With no access to irrigation, the farm is reliant on the weather, and the famously dry Waikato autumn presents the biggest challenge for Alby.

“We grow fodderbeet to mitigate the autumn dry, we start feeding it from the end of March and we winter our cows on it as well. It’s a high yielding crop that enables us to extend the lactation for the spring calving cows. They transition onto fodderbeet at the end of March or early April, and they milk through on it until we dry off.”

Record breaking yields.

Growing the CONVISO® SMART fodderbeet has been a game-changer for the Andersons. It’s beaten

technologies, with medical needs, or for whom digital literacy remains a barrier”. She says that as copper services are withdrawn, those who still rely on them will risk rising costs as the remaining network becomes more expensive to maintain.

“For many rural families and older residents, copper is not just a communications service, it’s their lifeline.”

She says that Chorus needs to commit to a well-resourced, transparent public education campaign in order to ensure a successful transition away from copper.

“This will help users understand their options, support them in moving to new technologies, and

the weeds, has been a lot easier and has delivered unbelievably impressive yields of 35 tonnes of dry matter a hectare.

The variety behind the crop’s success is the SMART JOSINA and it has outperformed anything Alby has grown in the past:

“SMART JOSINA has performed outstandingly well this season. Our yields have probably been 30% at least above what we’ve grown in the past for fodderbeet.”

The final surprise for the Andersons was just how well the CONVISO SMART crop fared in the summer dry.

“We’d had no substantial rainfall since December, so this crop went three months without significant rain. It was still growing and still green, so it’s quite amazing how it weathered the drought,” concludes Alby.

ensure they are aware of the limitations of new technologies, such as the possible loss of service during power outages,” Matthews adds.

“Connectivity is no longer a luxury, it is fundamental to the livelihoods, safety and personal wellbeing of all New Zealanders.”

Federated Farmers rural connectivity spokesperson Mark Hooper says that currently rural connectivity is not up to standard, with cellular reception “patchy at best”, meaning the withdrawal of the copper network adds to concerns from many rural New Zealanders about connectivity. “All it’s going to do is widen the connectivity gap between those who

live in main centres like Auckland and Wellington, and the rest of us who live in the provinces,” he says.

Chorus general counsel Kristel McMeekin says the infrastructure company is committed to ensuring a smooth transition to more reliable and fit for future technologies.

“We will work closely with the Commerce Commission to make sure there are clear processes in place to support people as the copper network is retired over the next few years,” she says.

Consumers can visit the copper retirement section of the Chorus website to check their address and explore available alternatives.

DAIRY FARMERS around the country are into the busy spring calving period.

A dairy farmer’s workload typically increases at this time of year, and according to ACC data, so do their injury claims.

In 2024, ACC accepted over 23,000 new farming-related injury claims and spent around $120 million to help people recover from farmingrelated injuries.

Over 6000 of these claims were received during the busy spring period, says ACC workplace injury prevention manager Paula Wood.

“Exhaustion, lack of sleep, the stresses of farming, isolation from friends and family, and being unable to take a break all add to the risks that a farmer or farm worker will have an accident,” says Wood.

“This is something we want farmers and farm workers to keep in mind, as they go through the busy spring calving season this year.”

Agriculture is among the top five industries for ACC injury claims alongside manufacturing, construction, forestry and fishing. These industries accounted for 38 percent of all workplace injuries in 2024.

One way to prevent injury is to simply stop and think, says Wood.

“Most injuries, in the first instance, are avoidable. ‘Have a Hmmm’ before moving on to your next job.

“When you’re tired and rundown it effects your decision-making, so take a break when you need it so you can go home safe at the end of every workday.”

New Zealand has some

of the best farmers in the world, but we also have higher rates of workplace fatalities and injuries in agriculture, says Wood.

“Injuries can have a big impact on the individual, their whānau and friends, their community, and their workmates.

“We’re focused on reducing harm, injuries

and fatalities and on driving positive, long-term change.

“Our partnerships are key to supporting this. We partner with Safer Farms and our $11 million investment into the Farm Without Harm programme, as well as Farm Strong, a wellbeing programme which encourages farmers to farm well

by living well.

“There’s always going to be inherent risks in an industry that involves operating heavy machinery and handling livestock, but by working with our partners and farmers on how they can implement practical safety practices on their farm, we can help to mitigate those risks.”

■ In 2024, ACC accepted over 23,000 new farmingrelated injury claims and spent around $120 million to help people recover from farming-related injuries.

■ During Spring last year, ACC received over 6000 new claims for injuries on farms. The cost to help people recover from these injuries was $31.6 million.

■ ACC announced a new partnership with Safer Farms earlier this year. The new partnership will see over $11 million invested by ACC over the next five years to improve safety practices and reduce risks on the ground and in our farming communities.

■ An ACC-funded study for Farmstrong shows 58% of recently injured farmers linked their injuries to stress associated with farm work. A quarter of them said it was a major factor.

■ Over 15,000 farmers and growers every year are doing the things that keep them Farmstrong.

■ Waikato regional had the highest number of claims in 2024 - 4141 claims and cost of active claims for injuries topped $20.7m for the region. Canterbury had 3993 claims (419m), Auckland, 2051 claims ($11m).

FARMSTRONG SHARES practical tips from farmers for farmers so they can perform at their best, says Farmstrong programme director Gerrard Vaughan.

“Tips that keep you focused and calm, habits that help you to look after the most important asset in any business, which is the people that work in it,” says Vaughan.

There’s a strong connection between your wellbeing and your risk of accident and injury, says Vaughan.

“It’s important to look after your mind and body, so you can bring you’re A-game every day to the work you do on the farm.”

Over 10 years, Farmstrong has built up a collection of practical tools to help farmers improve their wellbeing. This includes a new ‘toolbox’ of mental fitness skills for farmers to maintain a clear headspace and perform under pressure.

“We encourage farmers to check these out, find out what works for you, and lock it in.”

There is a lot of great advice available to farmers through the Farm Without Harm and Farmstrong websites, which both offer a range of practical resources and guidance.

AGFIRST, NEW Zealand’s largest independent agribusiness consultancy, is turning 30 - celebrating three decades of “trusted advice, practical solutions, and innovative thinking”.

Formed in 1995 by 14 consultants with a shared vision of independence and practicality, AgFirst has grown into a nationwide network of over 100 specialists. Its expertise spans sheep and beef, dairying, engineering, horticulture, environmental management, and valuation — with many consultants bringing more than 20 years’ experience to their work.

“Our strength lies in our independence, our experience, and our commitment to helping clients succeed,” says Erica van Reenen, AgFirst chair.

“For 30 years, we’ve

stood alongside farmers, agribusinesses, and industry organisations to help them navigate challenges, seize opportunities, and achieve their goals.”

From Cape Reinga to Bluff, the AgFirst team work directly with farmers and growers to improve productivity, profitability, and sustainability.

Alongside client services in governance, HR, compliance, and financial planning, the team also partners with industry and government to deliver research, technical expertise, and policy support.

A hallmark of AgFirst’s story is the continuity of its leadership. Of the 14 original shareholders, nine remain active today — still working directly with clients and mentoring the next generation.

Founding member Ross Wilson reflected: “Us old buggers had a vision, and 30 years later that vision is front of us – a team of dynamic, skilled, and passionate agribusiness professionals all striving towards the

vision of leading a successful New Zealand primary industry. It is now time to pass the baton, and we implore the new wave of AgFirst leaders to strive to reach heights that we could only dream of being possible.”

To mark the milestone, the AgFirst team gathered in Taupo recently for their annual conference. The celebrations provided time to reflect on progress, share insights on the future of farming, and acknowl-

edge the people who have shaped the business.

Another founding member Peter Livingston told the conference that for the originals, AgFirst has always been more than a business — it’s been an extension of our families.

“We’ve shared professional successes and personal milestones, and it’s special to see the next generation coming through, with some of the originals’ children now part of the business.”

AgFirst says the night was a fitting tribute to the journey so far, as consultants from across the country came together to honour the contribution of both past and present team members — while also turning their sights to the future.

That future is increasingly shaped by agri-

technology and artificial intelligence, from precision feeding and environmental monitoring to data-driven financial modelling, it says.

AgFirst is working alongside clients to trial and adopt these tools, ensuring they deliver practical value on-farm while supporting sustainability and efficiency.

“As we celebrate 30 years, we’re focused on the future,” said James Allen, AgFirst chief executive.

“Our vision remains clear — to lead a smarter, sustainable, high-performing primary sector. The challenges ahead are significant, but so are the opportunities. We’re excited to continue working alongside our clients and industry partners for the next 30 years and beyond.”

DRIVEN BY a lifelong passion for animals, Amy Toughey’s journey from juggling three jobs with full-time study to working on cutting-edge dairy research trials shows what happens when hard work meets opportunity – and she’s only just getting started.

If you were to ask Bachelor of Animal Science graduate Amy Toughey what she’s most proud of, she’d say it’s that title – graduate.

“Study isn’t my strong point, and I worked three jobs alongside my fulltime degree, so the fact that I not only passed my papers with grades I’m happy with but stuck it out and graduated with no hiccups – I’m proud of that!”

Growing up against the backdrop of the beach and mountains surrounding Nelson, Amy knew from a young age she wanted to work with animals and help make life better for them and their owners.

“Massey was everything I was looking for. I majored in genetics and breeding and chose this path because it allows for long-term improvement in animals and helps create a better understanding of where New

headed.”

Prior to starting her degree, Amy completed a Certificate of University Preparation which she says helped her transition from college to university.

“It helped me adjust my study techniques and navigate the university’s resources, such as the library, making the move to university much smoother.”

Alongside her partner Caleb, who helped

her navigate the ups and downs of balancing work, life and study, Amy says her lecturers also played a key role in guiding her to where she is today.

“They provided real insight into what my future might look like, and the different pathways I could choose. I’ve just completed a threemonth internship that taught me so many amazing things about the industry in ways I never expected.”

Amy completed an internship with Aviagen,

where she learned firsthand about the different stages of a chicken’s life, from how genetics are selected, through to adulthood, and the processes that ensure a healthy chicken is produced.

“My time with Aviagen allowed me to see the amount of work that goes into raising the chickens everyday New Zealanders consume. It taught me some valuable lessons on how quickly the industry can change, and how to adapt in ways that

keep New Zealand’s food industry at such a high standard.

“It was such an incredible experience, and I’m now moving into the workforce, ready to make a difference.”

Amy is currently working on a research dairy farm, where she also provides tech support for a new trial.

“It’s an amazing role where I get to be very hands-on with the animals, while also learning about trial ethics, standards and the different

methods and measurements for data collection.

“My animal science degree equipped me with all the tools I’ve needed in the early stages of my career. It taught me how to use a range of data collection techniques, most of which I’m using now and will continue to use for our upcoming trials.

One day, I hope to run a trial with the farm I’m working on – they’ve made massive progress within the dairy industry, and I hope to make my own mark on it.”

Another highlight during Amy’s study was getting to work closely with some of the department’s woolly residents. Volunteering with classmates, she helped rear orphan lambs and would often head down after class for cuddles.

“It was great stress relief! I also reared calves as one of my jobs, feeding them early in the morning before lectures. They became so friendly you could lie down with them for cuddles, and they would curl up with you. It was the highlight of my day!”

When she’s not working, Amy loves to get out in nature and hike. Over summer, she ticked another mountain off her to-do list when she reached the summit of Mt Taranaki.

Throughout her journey, Amy says the biggest lesson she’s learned is that you’re always capable, no matter what the challenge is.

“While it can feel overwhelming in the moment, no challenge is too big and there’s nothing that can’t be done so long as you take a few breaths and get stuck into it.”

@dairy_news

facebook.com/dairynews

I RECENTLY had the pleasure of attending an AgFirst event in Hamilton where the results of the 2024-25 Waikato-Bay of Plenty Dairy Financial Survey were shared.

Based on a 136ha farm milking 379 cows, average farm profit before tax was $405,892, an incredible 286% increase on the 23-24 season.

The session also provided an outlook for 25-26, which confirmed what many have been sensing: a profitable season lies ahead.

With the milk price forecast sitting at $10/kgMS, improved cash flow and lower interest rates, farmer sentiment is optimistic.

But confidence alone won’t feed cows. Feed reserves are tight across much of the country. Now is the time to lock in your maize silage procurement strategy. Whether you’re planning to grow maize onfarm and/or buy it in, early planning will give you more flexibility and ensure you are well placed to take advantage of this season’s positive economic outlook.

Feed budget first

Regardless of whether you’re growing or buying, a basic feed budget is a good starting point.

Understanding how much feed is needed to fill the seasonal deficits on your farm is essential, particu-

larly with less surplus in reserve carried forward from last season.

Plan to carry a buffer of maize silage

The big problem with feed budgets is that they rely on average pasture growth rates, and half the time, pasture growth rates are below average.

The most resilient farm systems I have seen, carry a buffer of additional maize silage in stock. There are several benefits of doing this:

If pasture growth rates are below average, you still have enough feed to ensure cows are well fed.

In periods of extreme shortages, you are not waiting for feed deliveries, which can be hampered by the supply of feed and/or trucking capacity.

The starch digestibility of maize silage increases in the stack.

It is more efficient to have a buffer so that you do not have to feed maize silage immediately after harvest.

Maize silage, when well-compacted, covered,

and sealed, will maintain its quality for several seasons.

Tight feed reserves, strong demand

Last season’s prolonged summer dry in the North Island and cooler winter conditions in the South Island means many farmers have worked through their feed reserves. Without a strong spring and a good pasture silage harvest, they may head into summer with little onfarm supplement. So, there’s more pressure than ever to get this season’s feed strategy locked in early.

The Pioneer team are reporting strong demand for maize silage this season, and that demand could catch late buyers off guard, particularly those relying on the spot market.

If you’re planning to buy silage, now is the time to talk with your contractor or grower to confirm availability. Delaying those conversations may leave you scrambling later or paying a premium when demand increases.

Growing on farm? Don’t delay

For those choosing to grow maize on farm, it’s

equally important to start planning now.

That means determining the appropriate area required, identifying paddocks, and beginning any remedial actions needed for a successful crop. This includes addressing soil fertility, and possible preplanting fertiliser and/or effluent applications.

Maize remains one of the most cost-effective feeds to grow, but the best results are achieved when the crop is wellplanned and established under the right conditions.

Growing maize on effluent areas not only

helps manage excess nutrients but can also produce feed for as little as 16-22c per kg drymatter.

Flexibility for uncertain weather events

Building some feed certainty into your system will put you in good shape to manage any weather challenges thrown at you during the season.

As weather patterns become more volatile, having a stored, highenergy feed like maize silage in your system provides flexibility. It offers support during dry spells, helps extend lactation,

and reduces pressure on autumn pastures. This season presents an opportunity to capitalise on strong economic signals, but that only happens when you’re prepared.

Your next step

Whether you’re growing or buying, the earlier you plan, the more control you’ll have. Talk to your grower, contractor or Pioneer area manager now to secure your feed and avoid the scramble later.

• Wade Bell is Genetic Technologies farm systems manager. Contact him at wbell@genetic.co.nz

FINANCE MINISTER Nicola Willis could have saved her staff and MBIE time and effort over ‘buttergate’ recently by not playing politics with butter prices in the first place. Despite already knowing, from her time as a Fonterra executive, that international commodity prices drive the domestic price of dairy products, Willis had her staff urgently press officials for international dairy price comparisons in the hours before her meeting with Fonterra’s chief executive.

Emails obtained by RNZ under the Official Information Act show a last-minute scramble for hard data prior to the performative meeting she arranged to “look into” butter prices. On the day before Willis was due to sit down with Miles Hurrell, the minister’s private secretary John Creech asked the Ministry of Business, Innovation and Employment (MBIE) for “some facts and figures... so that the Minister has solid info”.

FONTERRA’S $4.22 BILLION consumer business sale to Lactalis is ruffling a few feathers outside the dairy industry.

Milking It was surprised to read former Prime Minister Helen Clark’s comments about “a number of concerning aspects of Fonterra’s iconic dairy brands”.

In a social media post, Clark asked whether an investment programme was planned for the proceeds. “Or will there be just a one-off cash distribution to shareholders which could well end up being priced into the value of farmland?”

Dairy farmers have done it tough for the past few years with low milk price and soaring input costs. The $2/share capital return will help farmers reduce debt and catch up on maintenance work on farms. And, by the way, how farmers spend this money is their call.

Gene Bill rumours

THE GENE Technology Bill has divided the farming community with strong arguments on both the pros and cons of GM.

So when the Health Select Committee’s report on the Gene Tech Bill was extended by a month, the rumour mill went into overdrive.

Organics Aotearoa suggests in a newsletter to members that this could mean that the coalition Government is struggling to agree on the Bill in its current form.

It is urging members to use the extra time to advocate for the Bill to be fundamentally changed.

They may be disappointed because all three parties in the coalition back the use of gene technology and it seems it’s only a matter of time before the Bill becomes law.

Buttery prize

WESTLAND MILK may have won the contract to supply butter to Costco NZ but Open Country Dairy is having the last laugh when it comes to cashing in on NZ grass-fed butter.

Open Country’s new automated butter plant began churning out butter last month.

And Milking It understands that the country’s second largest milk processor has already locked in a major customer –Costco Global in the US.

With Costco NZ – with turnover of around $360 million – buying its butter from Westland Milk in Hokitika, Open Country has gone for the big prize. Costco Global owns over 828 warehouse stores, mostly in the US, plus some in Canada and Mexico.

Owned by the Talley’s Group, Open Country Dairy butter could soon be appearing on Costco shelves in North America.

THE PHASING out of copper network from communications is understandable. However, the move risks leaving rural people with uncertainty as to where to go for a phone or internet connection.

The legacy copper network has played a valuable role serving New Zealand’s communications needs, however, it’s now endof-life technology with many parts of the network prone to faults. With modern technologies like fibre, wireless and satellite able to deliver fast and reliable phone and internet, Chorus will retire the copper network from service over the next few years. The Commerce Commission agrees.

But with some 100,000 homes and businesses still using the copper network, the removal of copper leaves a lot of people unsure as to what to move to – particularly those without access to alternative technologies, with medical needs, or for whom digital literacy remains a barrier.

As copper services are withdrawn, those who continue to rely on them may face rising costs as the remaining network becomes more expensive to maintain.

Rural Women New Zealand (RWNZ) wants Chorus needs to commit to a wellresourced, transparent public education campaign.

There is a worry that rural communities could be left behind as technology shifts. Poor rural connectivity has always been a concern for farming leaders. This played out in real time last month when Federated Farmers telecommunications spokesperson Mark Hooper, doing a radio interview from his Taranaki farm on the very issue, saw the connection dropping out midinterview.

Hooper says rural connectivity isn’t up to scratch, cellular reception is patchy at best, and Chorus’s withdrawal of the copper network only adds to concerns many rural residents have about connectivity. He rightly says the rural community deserves better.

Head Office: Lower Ground Floor, 29 Northcroft St, Takapuna, Auckland 0622

Phone 09-307 0399.

Postal Address: PO Box 331100, Takapuna, Auckland 0740

by: Inkwise NZ Ltd Contacts: Editorial: sudeshk@ruralnews.co.nz

: davef@ruralnews.co.nz

Publisher: Brian Hight Ph 09-307 0399

General Manager: Adam Fricker Ph 021-842 226

Editor: Sudesh Kissun Ph 021-963 177

Machinery Editor: Mark Daniel Ph 021-906 723

markd@ruralnews.co.nz

Reporters: Peter Burke Ph 021-224 2184 peterb@ruralnews.co.nz

Subscriptions: Julie Beech Ph 021-190 3144

Production: Becky Williams Ph 021-100 4831

Digital Strategist: Jessica Marshall Ph 021 0232 6446

AUCKLAND SALES CONTACT: Stephen Pollard Ph 021-963 166 stephenp@ruralnews.co.nz

WAIKATO & WELLINGTON SALES CONTACT: Lisa Wise Ph 027-369 9218 lisaw@ruralnews.co.nz

SOUTH ISLAND SALES REPRESENTATIVE: Kaye Sutherland Ph 021-221 1994 kayes@ruralnews.co.nz

OVER THE years, I’ve seen firsthand how much our farms and farming systems have changed.

Herd sizes have grown, pasture and feed systems have evolved, and technology is now fundamental to everyday operations. But nothing captures this transformation, quite like the DairyNZ Economic Survey.

We recently celebrated its 60th birthday and I see it as one of the more significant stories in our sector’s history.

I may be more prone to economic nostalgia given my first job out of university was as an agricultural economist at the Meat & Wool Board’s Economic Service in Wellington in the 1990s.

But I’m not the only one.

Malcolm Ellis from Fonterra shared the following.

“Right through the ‘90s and into the early 2000s, I would await the annual publication with real anticipation and study it cover to cover. I’d regularly extract ‘good oil’ from the survey for our farming interests, my teachings, or an article I was writing. Roll forward to today, and the online version is still open on my computer. The Microsoft Snipping Tool often hovers over aspects of this truly cherished, celebrated, and highly valued publication.”

In a world full of data and everyone looking to harness it, the Economic Survey serves as a source of independent dairy truth – for many beyond our sector as well as in it.

That’s part of why I’m incredibly proud to celebrate the recent 60th anniversary of DairyNZ’s Economic Survey. This milestone is more than just a number - it represents six decades of progress, resilience, and innovation in one of New Zealand’s most important sectors.

Since 1963–64, the Economic Survey has provided a clear window into how our sector is tracking. It began life as the Economic Survey of Factory Supply Dairy Farmers, back when the average herd was just 92 cows. Today, that number has more than quadrupled, and milksolids per cow have nearly doubled – gains made possible through science, innovation, and a relentless drive from farmers to adapt and improve.

But the survey doesn’t just show how things have changed, it helps explain why.

It offers valuable insights into farm performance, cost structures, income trends, and sector-wide challenges. It’s one of New Zealand’s most comprehensive dairy datasets, used by farmers, economists, banks, and policymakers to benchmark performance and guide evidence-based decisions.

It supports national and international reporting and underpins economic modelling and tools like DairyNZ’s Econ Tracker. It also directly informs the direction of DairyNZ’s research, extension, and advocacy work on behalf of farmers.

Importantly, the Economic Survey is built on real-world data, volun-

tarily shared by farmers through DairyBase – a free, confidential tool that helps farmers better understand their farm system. That data then feeds directly into the Economic Survey, creating a full-circle benefit: individual insights for farmers, and collective value for the entire

sector.

Importantly, this work is not only valued by DairyNZ — it’s recognised right across the sector. Earl Rattray of Dairy Link Ltd calls the Survey a “vital component of the dairy sector’s knowledge infrastructure,” saying it enables better decisions and

smarter policy.

Sixty years on, we’re proud to continue this work for farmers. The Economic Survey is more than a report - it’s a living legacy, built with information from farmers, for farmers, that continues to guide us forward.

• Tracy Brown is DairyNZ chair Tracy Brown

THE TEAM meeting at the Culverden Hotel was relaxed and open, despite being in the middle of calving when stress levels are at peak levels, especially in bitterly cold and wet conditions like today.

Dairy News was invited to sit in on the weekly meeting Craigmore Farming Northern Operations manager Hayden Fletcher holds with the managers of the four Craigmore farms he is responsible for – Landsend, Darnley, Riverend, and Caithness.

Outside on the farms, the grass growth is slow, the ground is sodden and muddy, and the wind bitingly cold with snow on the surrounding hills. Calving is well underway, so Hayden’s team is busy and stress levels are high when they convened for their weekly team meeting over lunch with Hayden at the pub.

However, the fire is

going and Hayden runs a very open meeting, with each manager giving him their topline numbers –such as number of cows calved so far – and providing feedback on everything from animal health issues to staff problems and machinery breakdowns.

These notes go into his minutes, but the team meetings are not really about ‘reporting up’ to Craigmore operations.

“My original purpose for these meetings was really to get the guys off the farm for a while and share any concerns or problems,” says Hayden.

Hayden managed Darnley for nine years before moving up to a role overseeing all four farms for Craigmore. He has been in the position his team is now in and so knows the pressures they face and is able to offer assistance, advice and try and guide them to a solution.

His philosophy is very focused on the team find-

ing the right balance of work and lifestyle, but he is clear that nobody gets to enjoy the benefits of this without earning it.

He says being stuck on the farm with your problems, they can seem

insurmountable, especially during busy times like calving. Sitting down with the others is a reminder that everyone is going through the same issues as you.

“I’ve made no secret

of the fact that I’ve had my own struggles, so I know what it’s like.”

Part of Hayden’s transition from managing one farm to overseeing the managers on four required him to “sit on

his hands” and not try and do everything himself. The job is to delegate and guide the managers he has employed on the farms. His style seems more about asking the managers if they need help rather than telling them what to do, and his empathy and ability to listen to his team is obvious.

As part of a corporate, the team obviously have to produce good numbers. His focus though is primarily on the wellbeing of his team. Getting this right naturally leads to good performance for the company.

With average performance per cow of 570 kgMS across the four farms, across about 2850 total cows, and a top result of 605 kgMS on Darnley, at the current payout, and with good animal and fertility results, they are certainly achieving that.

The four farms are also part of the Pahau Drain Catchment Group

– a group of farmers from across the Amuri Basin between the Waiau and Hurunui Rivers in North Canterbury – who are working together to improve irrigation efficiency, nutrient management and biodiversity through riparian planting.

Culverden and the surrounding region itself represents a tight concentration of extremely productive dairy farms and was one of the first areas in North Canterbury to convert from drystock to dairy some 30 years ago.

“There’s a lot of progressive and forwardthinking farmers around here,” says Hayden.

Using a bit of ‘back of the fag packet maths’, he estimates that within a 30-minute radius of Culverden township, there’s a tight cluster of top dairy farms producing well north of $250m in economic activity.

“Dairy farming is a very efficient way of distributing money into the community,” he says.

HAYDEN FLETCHER’S approach to management on the four Culverden farms he is responsible for is to put the well-being of people and, crucially, the cows front and centre.

Getting the second part right through proper cow nutrition helps massively with achieving the first part: better cow condition, fertility, in-calf rates and fewer animal health problems all make life easier for the staff – and put more milk in the vat.

All four farms use in-shed feeding, plus some feeding in the paddock. From J Swap Stockfoods they buy in a blended meal of mid-range proteins with a custom mineral pack to feed in the sheds, plus they buy palm kernel to feed to their springers in mobile troughs. They also have silos for locally-sourced grain which they put through their own in-line crusher and add into the feeding regime when the cows need a bit more – such as post mating.

The blends are calculated by Hayden, working in with his J Swap Stockfoods representative Dean Weastell to get the right mix at a good price and ensure the orders are processed and delivered on time, using blower or augur trucks to keep the silos full.

Hayden says while each farm operates independently, according to its own particular needs, some things like the feed blends are standardised across the four farms.

Dean says Hayden is known for his carefully considered feed regimes, which are formulated after carefully working through farm and herd data with a nutritionist.

“He is focused on animal health as well as production,” says Dean.

“And that focus has resulted in fewer animal health issues, which fits with Hayden’s philosophy of looking after the staff, because they spend less time and stress dealing with animal health issues.”

most

BY SEPTEMBER,

herds are already calved and are heading towards mating. The window to influence pre-calving minerals has passed, and decisions made in the transition period are only just becoming obvious.

How well the cows cycle, express heats, and conceive this spring is a direct reflection of the mineral balance they received during the allimportant transition period.

Watching for and understanding those signals now can help farmers improve outcomes for the rest of this season and build a better plan for next year. Why transition still matters now

The three weeks before and after calving will set up the cow’s reproductive system for the whole season. Mineral imbalances in that window, even when clinical milk fever and ketosis may not have been evident, can lead to silent heats, delayed cycling, or low submission rates months later.

By the time mating starts, those imbalances can’t be completely undone. But they can be measured, managed, and used to improve both current and future mating performance.

What to look for in the herd

1. Heat expression

Weak or silent heats can indicate trace element imbalances, particularly copper and selenium, which influence hormone production and uterine repair. If heat activity seems low despite good energy levels, it’s worth checking mineral status.

2. Cycling patterns

Delayed cycling, cows not showing heats by the planned start of mating, often stems from mineral-related disruptions to ovarian function. These cows often look healthy, but are hormonally

The three weeks before and after calving will set up the cow’s reproductive system for the whole season. Mineral imbalances in that window, even when clinical milk fever and ketosis may not have been evident, can lead to silent heats, delayed cycling, or low submission rates months later.

behind.

3. Retention of latecalvers

Cows calving late are already under pressure to get back in-calf. Any mineral issues from transition can compound that challenge. Tracking latecalvers’ heat activity can help flag if minerals were part of the problem. Checking mineral status now

Blood tests taken in early lactation that assess both mineral status and liver function enzymes can show whether transition minerals have been adequately dosed. While this won’t change what’s already happened pre-calving, it does two things: Firstly, it guides supplementation during mating, i.e., correcting copper or selenium levels to support conception now, and secondly, it informs next year’s dry cow and transition plan, avoiding the same gaps

repeating.

Pasture and feed tests are useful, but they don’t always reflect what cows absorbed. Liver testing gives the clearest picture of trace element reserves heading into mating. Managing reproduction for the rest of this season

While pre-calving minerals can’t be changed at that late stage, there’s still value in supporting cows through mating:

Targeted trace elements: If testing shows low levels, supplementing during mating can help improve conception rates later.

Body condition checks: Thin cows take longer to cycle. Although minerals won’t fix this, knowing which cows are behind helps prioritise management.

Focus on heat detection: Heats can be harder to spot when expression is weak. Supplementing

with key trace elements such as iodine and selenium supports increased thyroid hormone production, which in turn stimulates better liver function, leading to stronger heats and better conception. Learning for next season

The biggest gain from monitoring now is in planning ahead. If low heat expression or late cycling is widespread, it’s a signal that transition nutrition, especially minerals, needs reviewing.

Questions to ask:

■ Were cows blood- or liver-tested before calving?

■ Were key minerals, calcium, magnesium, selenium, copper, and phosphorus levels within the target range?

■ Did conserved forages or feed changes shift mineral profiles?

■ Were pre-calving and post-calving blends

aligned, or did they stay static despite changing feed rations? Answering these helps

build a more accurate mineral plan for the next dry period, reducing the risk of repeat issues.

Why it pays to act on the signals

Poor reproduction is expensive, with more empties, late-calvers, and replacements to rear. Earlier conceptions tighten the calving pattern, boost days in milk, and reduce workload. Fixing mineral gaps doesn’t just avoid metabolic disease, it also improves fertility and herd longevity.

For many farms, even a modest lift in firstround in-calf rates translates to significant gains in milk and fewer headaches at mating time. This spring, watch how cows are cycling. Weak heats or slow returns aren’t just bad luck; they’re a message from last season’s mineral management. The sooner that message is understood, the better decisions can be made for the season ahead.

• Chris Balemi is founder of Agvance

technology company

FORSI Innovations Ltd may be headquartered in the rural town of Matamata but the business is anything but provincial in its ambitions.

This family-owned water treatment manufacturer has quietly become a pioneering force in the filtration industry, with a growing portfolio of advanced, high-performance systems deployed across New Zealand and as far afield as Hong Kong.

Founded in 2002, FORSI says its origins lie in agricultural water treatment—specifically, the removal of iron and manganese from water used on dairy farms. Over the past two decades, the company has evolved into a sophisticated engineering and R&D-led organisation focused on solving complex water treatment challenges across industries.

Its most technologically advanced system to date is a proprietary dairy effluent treatment

plant, capable of converting raw effluent into three valuable outputs: a compostable solid fertiliser, a concentrated liquid nutrient suitable for targeted land application, and potable water that meets New Zealand drinking water standards. The result is a closed-loop system that exemplifies sustainability, resource recovery, and operational efficiency for the agrisector.

In 2023, FORSI initiated a breakthrough research programme into Silicon Carbide flat sheet ceramic membrane technology—a next-generation filtration medium prized for its durability, chemical resistance, and energy efficiency. After two years of development, FORSI commissioned its first commercial system, designed to treat high iron and manganese content from a mixed bore water source feeding a new residential development.

“Our ceramic membrane trials have demonstrated exceptional performance and versatility across a wide range of water treatment scenarios,” says Craig Hawes, operations manager at FORSI Innovations.

“To our knowledge, we are the only New Zealand-based company to successfully commercialise this specific membrane technology.”

The implications are significant, according to Howe.

Flat sheet ceramic membranes offer a compelling value proposition for industries under increasing pressure to comply with environmental regulations and water reuse mandates. Capable of filtering out suspended solids, oil emulsions, and bacteria, these membranes are ideally suited to sectors such as municipal water supply, landfill management, industrial wastewater treatment, and food and beverage processing.

Advantages of FORSI’s ceramic membrane technology:

• Exceptional robustness and lifespan

• Chemical and thermal resistance

• Low maintenance and operational costs

• High filtration precision and scalability Applications currently in development or operation include:

• Drinking water filtration

• Membrane bioreactors (MBR)

• Liquid waste recycling

• Sludge concentration

• Landfill leachate treatment

• Oil-water separation

• Process fluid recovery

Hawes says every FORSI system is fully customised.

www.forsi.co.nz

EXHIBITED AT the Verona Trade Fair in Italy in 1958, the pendulumtype fertiliser spreader system, invented by Italian fertiliser merchant Luigi Steffenino, was seen for the first time and currently has 67 years under its belt. An agreement for worldwide manufacture and marketing was signed with Vicon, which after what could be described as a slow start, the pendulum spreader became a common sight on many

Transpread have designed a compact, single-axled version of its Contractor trailer engine-driven pump system, offering reduced dimensions for ease of access through tight gateways or confined yards.

The compact format, at only 6.3 metres long, is over two metres shorter than the tandem-axle version, yet the new unit carries everything needed for an umbilical spreading system, with a self-contained engine-driven pump unit, a compressor for blowing out the drag hose, hose spool carrying cradle and

storage for tools, couplings and sundries.

The single-axle model can be supplied with a 175hp or 238hp, six-cylinder FPT engine, Bauer, Doda or Cri-Man pumps, 140 or 180CFM output compressors, alongside optional GSM or radio-type remote control systems.

A 900-litre capacity fuel tank is repositioned underneath the engine and pump assemblies, while the 1000m hose spool is loaded into a carrying cradle from the front and quickly and located with a locking pin system.

The sprung, single axle is fitted with 50km/h rated 435/50R19.5 tyres and air brakes. Meanwhile, the drawbar is designed to allow the towing tractor to also carry a dribble bar on its three-point linkage, while towing the trailer, allowing one operator to move an entire umbilical system.

A range of options includes a suction hose transport kit, a sponge ball (pig) launcher for clearing the delivery pipework when work is finished, and a new 360-degree camera system for remote monitoring.

@dairy_news facebook.com/dairynews

• Cost competitive

• Utilise your existing site

• Control contamination and gas

• 20 year material warranty

• Reliable seam testing

• Proven performance

• Full QA report

farms, not only for fertiliser application, but also seeding, typically at half rates at ninety degrees to each pass. At its peak, the Dutch facility in NieuwVennep made over 1000 units each week and achieved a tally of more than one million units being sold globally.

The Kverneland Group has recently confirmed

that production of the iconic Vicon pendulum fertiliser spreader will finish for good at the end of this month. Dairy News understands the decision to pull the pin was made because a major investment would be required to bring the 47-yearold assembly line up to date, while the company also notes it is becom-

ing increasingly difficult to maintain the specialised skills needed for production.

In addition, modern environmental and safety standards require significant changes in the production process, and the non-recyclable polyester hopper would also need to be replaced by recyclable polyethylene.

ENVIRONMENT SOUTHLAND’S catchment improvement funding is once again available for innovative landowners in need of a boost to get their project going.

Funding is available to all landowners within the Southland region looking to do projects that enhance water quality, with up to 50% of the costs covered by the council. The total funding available is $140,000.

Environment Southland’s general manager community and engagement Sam Rossiter-Stead says the funding is designed to support landowners who want to take action on environmental improvements.

“If you’ve identified ways to improve the environment on your property but haven’t had the means to follow through, this funding could be the key to making it happen.”

The Environment Southland funding is divided into two categories, one for land management and the other for native planting.

The Land Sustainability Mitigations Fund is designed to support landowners in implementing practical mea-

sures that contribute to improved freshwater outcomes. Projects eligible for funding include fencing for critical source areas, constructing and fencing wetlands, building detainment bunds, fencing gullies, planting erosion-control poles, installing bark chip bioreactors, and undertaking wetland restoration. Through this fund, Environment Southland will cover 50% of project costs, up to a maximum of $5,000.

The Southland Native Planting Fund also covers 50% of project costs, up to $3,000. It supports native planting adjacent to waterways, in wetlands, for forest restoration, in critical source areas, and on retired farmland.

To be eligible for funding, projects must be discussed with an Environment Southland land sustainability officer before submitting an application.

All projects must be completed within the financial year, with invoices submitted by 15 June, 2026.

For more information contact Environment Southland to discuss your projects with a land sustainability officer on 0800 76 88 45.

EFFLUENT CAN be a source of nutrient loss, contaminants entering waterways, and greenhouse gas emissions. However, it can also be a valuable resource that, when managed well, increases pasture production, and reduces fertiliser costs, says DairyNZ.

It suggests ways to improve management of effluent on farm:

• Consider developing an effluent management plan. This is a handy tool for bringing together all effluent needs on a farm, including regional rule requirements, location of waterways, buffer exclu-

sions, and system maintenance schedules.

• Spread effluent during appropriate soil conditions and at lowapplication rates to minimise nutrient loading, match plant requirements, and minimise ponding and runoff to waterways.

Foranyquotesorenquiriescontactuson: 03-308 4816

Or call into the yard at: Grove Farm Rd, Tinwald, Ashburton •

Practice deferred effluent irrigation and store effluent during inappropriate soil conditions.

• This will also help reduce the N-surplus and therefore the nitrous oxide emitted from the soil.

• Test effluent regularly so that nutrient concentrations are known, and application rates can be adjusted.

• Use all effluent applications as a substitute for fertiliser applications, enabling reduced fertiliser on effluent application areas.

• Practice deferred effluent irrigation and store effluent during inappropriate soil conditions.

• Avoid storing effluent in anaerobic conditions, as this will increase methane emitted. Options to reduce this include stirring, covering, or adding treatments like polyferric sulphate.

• Ensure careful man-

agement of effluent from housing and stand-off pads due to volume created of both liquids and solids. Ensure that it doesn’t lead to increased risk of nutrient loss and increased emissions from application and storage.

CRITICAL SOURCE areas are features in the landscape where water flows or accumulates, and there is a connection to waterways. This includes point source discharges such as tile or mole drains.

■ Identify critical source areas on your farm and their connection to waterways.

■ Develop actions that reduce or mitigate contaminant

REDUCED EROSION leads to improved grass growth and milk production. It enhances water quality and if planting is undertaken for erosion control, it can also provide shade and shelter for stock.

■ Think about the suitability of each paddock for cultivation and assess the risk of soil erosion before work is undertaken, e.g. topography and soil type, proximity to waterways, and erosion susceptibility.

■ Plan crop rotations and re-sowing to minimise the time that soils are bare, especially during the highrisk winter months.

■ Use catch-crops to reduce contaminant loss to water and improve soil.

loss through critical source areas, such as:

■ Excluding stock from critical source areas during times of high contamination risk.

■ Minimising effluent or fertiliser to critical source areas during high-risk periods.

■ Retiring and planting areas to filter contaminants.

■ Ensure stock crossings are bunded to prevent runoff and move gates and tracks away from waterways.

■ Consider direct drilling, strip-tillage, or non-invasive tillage to reduce risk of contaminant loss.

■ Manage or retire and plant erosion-prone land to minimise soil losses.

■ Plan and prepare a winter grazing plan to minimise soil damage and erosion during the winter months. Select appropriate paddocks for intensive winter grazing that are away from waterways, 10° or less slope and are not vulnerable to pugging or erosion.

■ Graze pastures and crops from top to bottom or strategically, to minimise sediment and contaminant loss to critical source areas and waterways.

THE DESIGN and construction of an effective dairy effluent system is a complex process.

It requires the assistance of experts who are qualified and experienced in the field. Communication with the system designers, installers and contractors will be crucial to ensure the result is fit-forpurpose in your farming situation.

According to DairyNZ, a good effluent service provider will offer:

• certainty that their product will perform

• guarantees and producer statements

• after-sales care, service and support, and

• farm team training on the operation and maintenance of the system.

DairyNZ recommends that designers and installers should be involved in the project from start to finish supervising the quality and standard of workmanship during the installation and commissioning of the system. They should be willing to stand by their work.

DairyNZ also recommends farmers use suitably qualified and accredited effluent system designers. Make sure the system will be up to the job, it says.

A poorly designed system will be expensive and frustrating in the long term, particularly for the farm team. Like milking too many cows through a dairy, it can be done, but it takes longer and the likelihood of

fatigue, breakdown and general frustration is extremely high.

A system which is poorly designed may result in problems such as:

• high risk of noncompliance with regional

council requirements

• no contingency for adverse weather events, staff absence or system breakdown

• high demand on labour and time

• expensive to operate and maintain

We connect your water meter data with climate, soil moisture to give a real basis to irrigate or use water with:

• The right amount

• At the right time

• Tailored Presentation

• Real Time Data

• Action Alerts

• Mobile Friendly

• Tank level – Axroma meters - pipe 15-50mm

• Good Value... cost effective data

• Easy setup and easy to use

• the need to irrigate on days when ponding, runoff, and leaching risk is high

• additional pressure on the farm team during calving or wet weather

• unrealised investment in the system

if it is not user-friendly or doesn’t achieve compliance, and

• little room for future expansion.

“It is important to think about potential changes to the farm system, especially intensification, including an increase in cow numbers, greater use of standoff and feed pads or the addition of wintering facilities.

“If these are desired but finances don’t allow you to accommodate these now, plan for a staged expansion to the system as you require it. Get the system designed with the changes in mind – it can save a big expenditure in the future.”

• Uncomplicated presentation giving simple farm management decisions

• Nationwide service and backup

• We are well established being the leading provider of water measuring systems

• Equipment is reliable land well proven to perform

• We support you in your audit and environmental reporting

DAIRYNZ HAS pulled together tactics that will help farmers improve on-farm efficiency and have positive benefits for the environment. These tactics are based on research, data, and lessons from leading farmers.

It says that every farm is different, so farmers are urged to take time to consider their options and find out what works best for their business.

Managing fertiliser and feed use can help minimise losses to waterways and improve the efficiency of pasture and crop production. These efficiency improvements may also reduce greenhouse gas emissions if the

Balancing pasture growth and utilisation is key to optimising stocking rates that result in the same or higher profit with lower inputs.

total feed eaten on-farm is decreased or production is increased from the same inputs.

• Prepare an annual nutrient budget based on regular soil tests with your trusted farm consultant or fertiliser represen-

Geosil 150 is a highly effective drinking water disinfectant designed to keep your water free of pathogens & bacterias.

It is tasteless and odourless, will not produce undesirable disinfection by-products, cause skin irritations or other allergic reactions & safe for septic tanks.

For more info or to purchase

tative.

• Minimise surplus nitrogen through reduced use of nitrogen fertiliser and supplementary feed.

• Use urease-coated fertilisers which reduce losses of ammonia from urea use and maximise

the nitrogen available for plant uptake. This means less nitrogen needs to be used and less nitrous oxide is emitted.

• Manage the timing and placement of nitrogen fertiliser to reduce the amount of nitrogen

applied while still increasing pasture growth.

• Consider the use of plantain in your pasture sward. Research has shown it can help reduce nitrogen surplus.

• Monitor and maintain soil phosphorus levels below or within the target ranges for the soiltype and crop.

• Match feed demand with pasture growth and utilisation. Balancing pasture growth and utilisation is key to optimising stocking rates that result in the same or higher profit with lower inputs.

• Manage pasture and crop husbandry to optimise production through fertility, rotation, and inputs, while minimising damage from compaction, diseases, and pests

• Store fertiliser in a contained system to minimise losses and calibrate and maintain fertiliser spreading equipment.

FORSI are specialists in customised treatment systems for all types of water quality issues.

WE OFFER CUSTOMISED SOLUTIONS FOR THE REMOVAL OF:

Iron, manganese & turbidity removal

pH correction

Effluent management solutions ❱❱ Car & Truck wash recycling systems

Effluent recycling systems

Irrigation filtration

Specialists in ceramic filtration technology Let’s talk about how we can help make your water Quality Water.

enhances HVAC (heating, ventilation, and air conditioning) performance.

THE ALL-NEW 2026

Can-Am Defender HD11 looks likely to raise the bar in the highly competitive side-by-side category.