X-RAD

1. X-ONE

STRUCTURAL ENGINEERING (page 24)

INSTALLATION (page 34) TRANSPORT (page 36)

2. X-PLATE

X-PLATE CONNECTION PLATES SYSTEM (page 40)

STRUCTURAL ENGINEERING (page 48) FROM MODELLING TO THE BUILDING SITE (page 54)

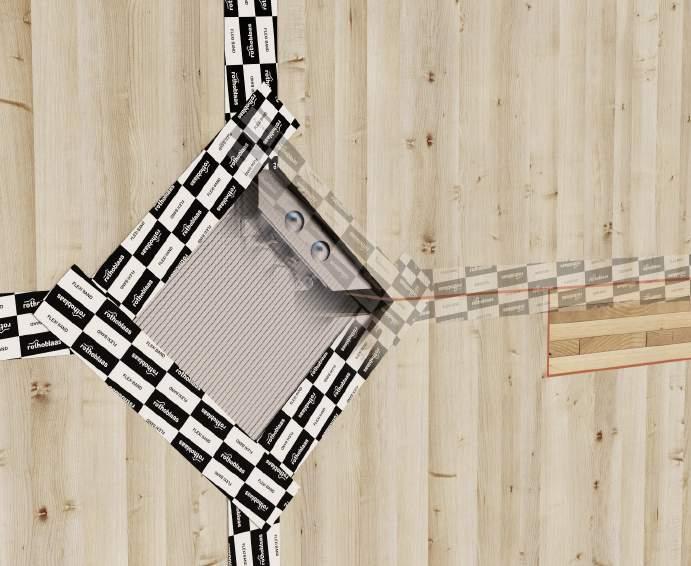

3. X-SEAL

DESCRIPTION OF THE SYSTEM (page 66)

THERMO-HYGROMETRIC PERFORMANCE (page 68)

ACOUSTIC PERFORMANCE (page 70)

FIRE REACTION (page 76)

page 20

page 38

page 64

X - RAD: THE POWER OF SIMPLICITY

X-RAD is a complete connection system for all types of CLT buildings. Extremely simple, it is made up of 3 parts: X-ONE, X-PLATE and X-SEAL. Designed to simplify on-site operations, ensuring precision and quick assembly. Mechanical, thermal and acoustic behaviour optimised to ensure maximum performance.

PRECISE COMPLETE SIMPLE QUICK

X-SEAL

X-PLATE

X-SEAL

X-PLATE

A system that ensures simplicity, rapidity and safety

Universal connector for CLT panels

Complete range of connection plates

Complete system for air tightening and thermal-acoustic comfort

X - RAD: CREATED BY DESIGNERS, DEDICATED TO DESIGNERS

A new connection system, simple and revolutionary. With the professionalism of the Rothoblaas Technical O ffice, everything is simple: rely on specialist consultants who are always at your service to solve any design or building site issues.

6

3

INVOLVED IN THE DEVELOPMENT

3

ARTICLES TO ANSWER ANY QUERIES

10 TECHNICAL INTERNATIONAL CONSULTANTS UNIVERSITIES PUBLICATIONS

PUBLISHED IN SPECIALISED

RECORDED AT MAIN IN 5 LANGUAGES AND TESTING STAGES SCIENTIFIC JOURNALS

279 TECHNICAL TO SUPPORT YOUR DESIGN ACTIVITY

5

AWARDS DRAWINGS

IN RECOGNITION OF THE INNOVATIVE

CHARACTER OF THE SYSTEM

INTERNATIONAL CONFERENCES

ARE YOU READY TO DESIGN DIFFERENTLY?

The Rothoblaas Technical O ffice guarantees all of the support you may need for your first creation with the X-RAD system, from design to the construction phases. Together, it is easy to be leaders in the future of wooden buildings.

MY PROJECT

MyProject is the software for calculating and verifying the connections, with the precise aim of simplifying the designer’s job. Simple and intuitive, it allows you to quickly develop the calculation and choice of application and products, leading you to print the calculation report in just a few steps.

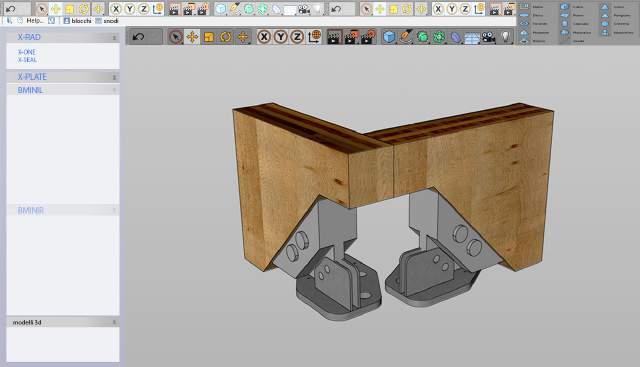

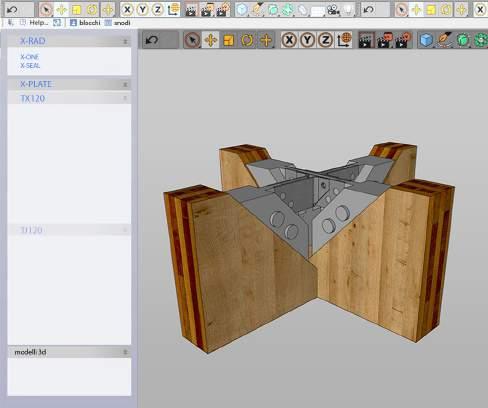

You can find the geometry of the X-RAD system and its components already implemented in the most common CAD CAM design software for wooden structures (page 57)

CALCULATION REPORT

Calculation report including product verifications and specifications

PRACTICAL AND INTUITIVE

Instruction manual and final report with plenty of graphs and pictures

PARAMETERS

Step-by-step instructions on how to correctly enter the data

Possibility of creating a user database and saving ones own projects CUSTOMISED

In the catalogue you can also find a method for modelling wooden structures with X-RAD connections using traditional structural engineering software (page 32)

THE FUTURE OF WOODEN BUILDINGS

Thinking and contributing to the evolution of wooden buildings means identifying innovative technological solutions, developing specific connections for CLT structures, and adopting new simple and quick construction systems: X-RAD is the answer to all of these requirements.

The greatest innovation in the field of timber connections

A system that allows you to build easily and quickly

Standard machining on a CLT panel whatever the panel thickness

A connection as simple as genius

The answer to many architectural and engineering questions

ADVANTAGES OF THE X - RAD SYSTEM

The innovative nature of X-RAD lies in its ability to invalidate the standards of wooden constructions thanks to the advantages it offers: higher precision, reduced installation time, greater safety on site, reduced number of components needed for fastening, excellent static performance.

More precise and safer installation

Quicker execution

Reduced number of connections

Reduced error margins for operators More order and cleanliness on site

Reduced time and physical effort for operators

The right system to deal with the challenges of wooden buildings

CONSTRUCTION TIMES

Standardising and reducing the overall number of joints makes the X RAD system a winner when the construction times are a key factor in implementation of the work. These advantages were actually demonstrated when the first buildings were constructed using the X RAD system, where the time required for all of the operations needed to assemble the structure were carefully recorded and documented, and then by comparing it at the end with that required by a solution using traditional anchors.

COMPARISON OF FASTENING TIMES BETWEEN THE X RAD SOLUTION AND TRADITIONAL ANGLE BRACKETS

Average time required to install 1 X-ONE: about 5 minutes

Total time required to fully position and assemble a wall (4 X-ONE in the factory + 4 X-PLATE on site): about 30 minutes

TRADITIONAL SYSTEM

Total time required to fully position and assemble a wall on site (fastening 4 WHT440 + 4 TCN240 + 4 TTN200): about 60 - 70 minutes

HOLD-DOWN AND ANGLE BRACKET

COMPARISON PARAMETER

X-RAD SYSTEM

total construction time

incidence of total labour costs (2)

transporting the panels machining in the factory connections fastening time (1)

The X-RAD system moves most of the work from the building site to the factory, with increased prefabrication, greater efciency, reduced times and optimisation of costs

TRADITIONAL

Total assembly time

unloading installation fastening

Connection systems

NOTES: (1) Compared with the total construction time (2) Compared with the overall cost (materials + labour)

These assessments resulting from analyses carried out on real building sites are approximate and generic estimates and, if necessary, shall be updated according to the specific case and type of construction involved.

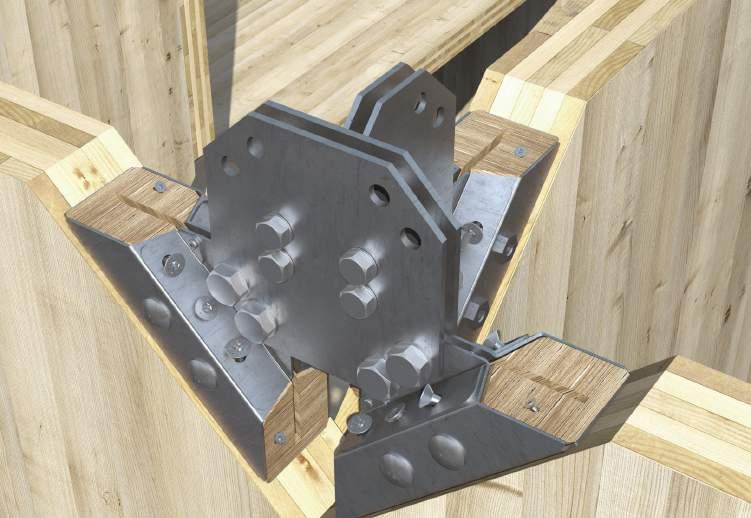

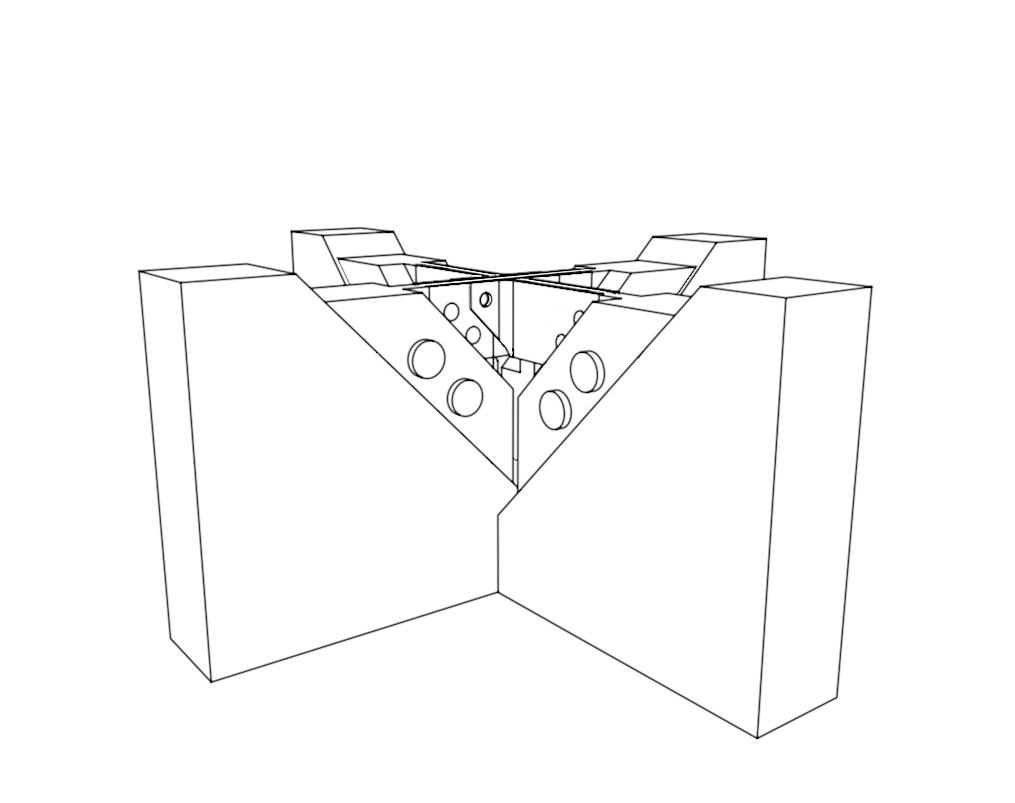

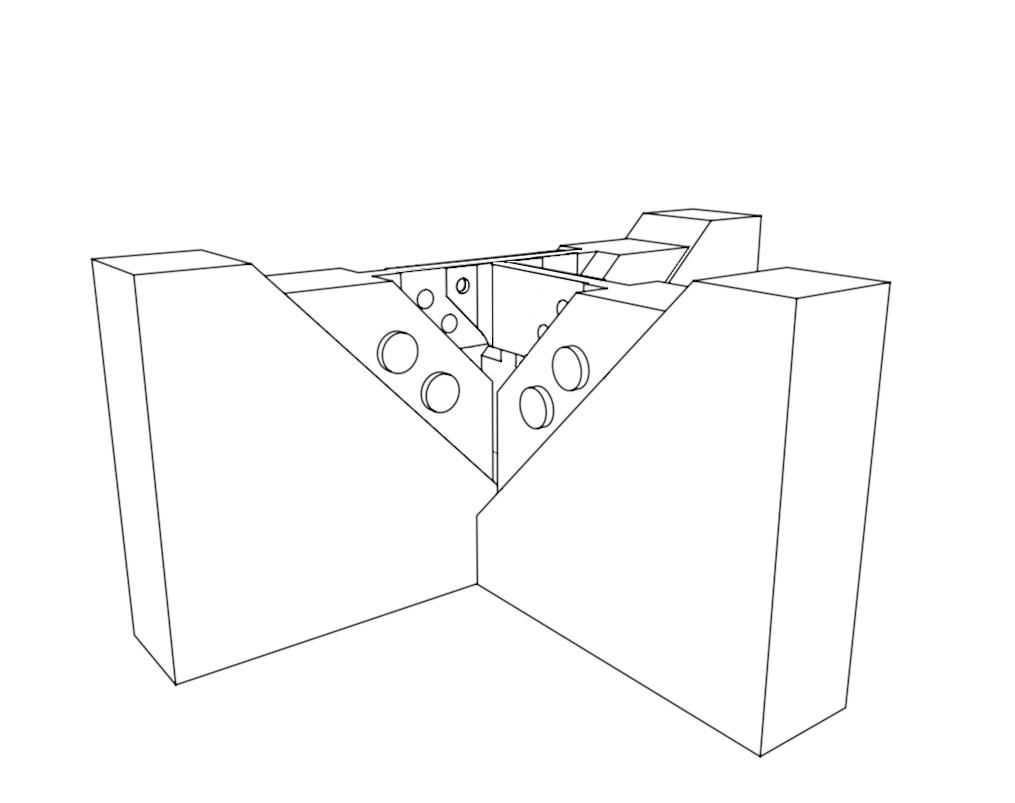

SPECIAL APPLICATIONS

The X-RAD system opens new frontiers in the field of connections for CLT structures.

High resistance and extreme rigidity allow you to increase the level of use of CLT panels, thus optimising performance of the wood and connections.

Innovative solutions, such as hybrid structures (wood-concrete, wood-steel), irrigated core structures and modular structures are emerging.

Transfer

Creation

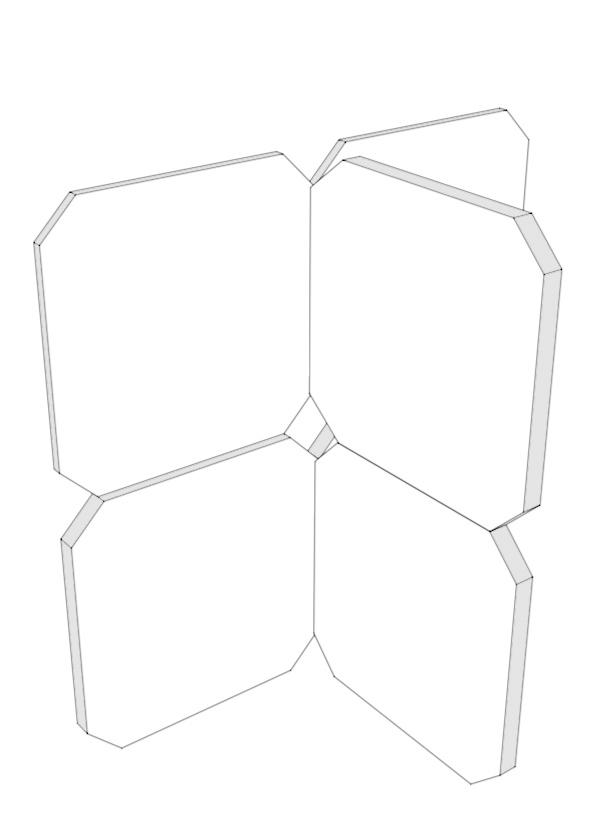

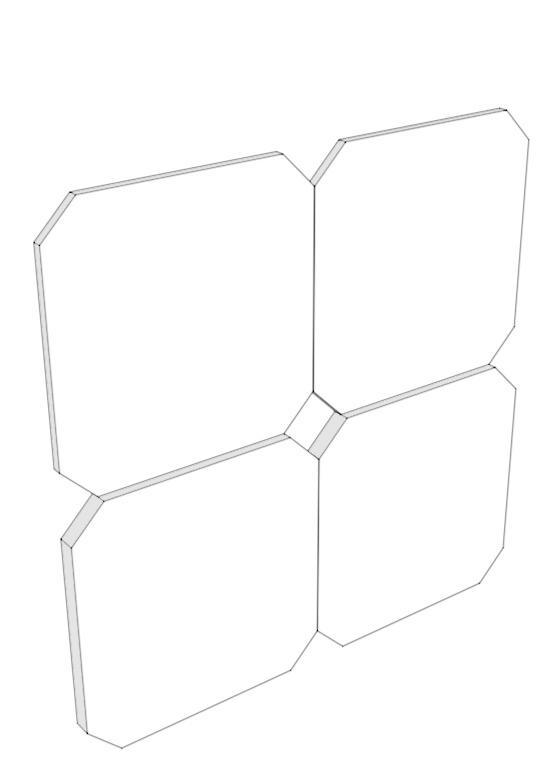

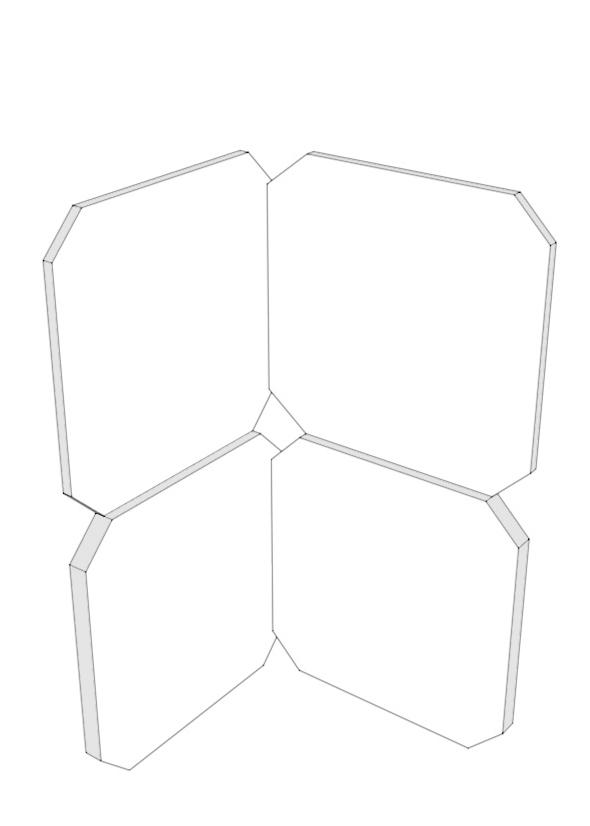

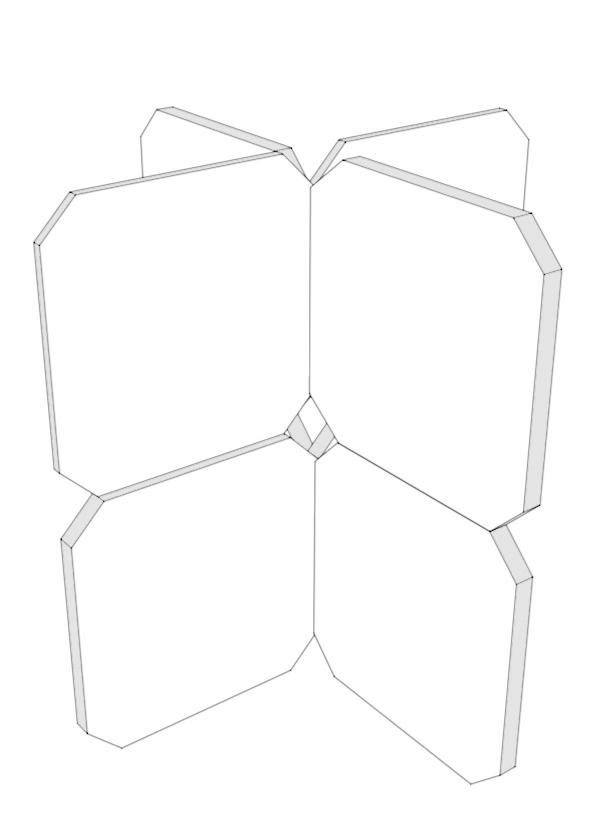

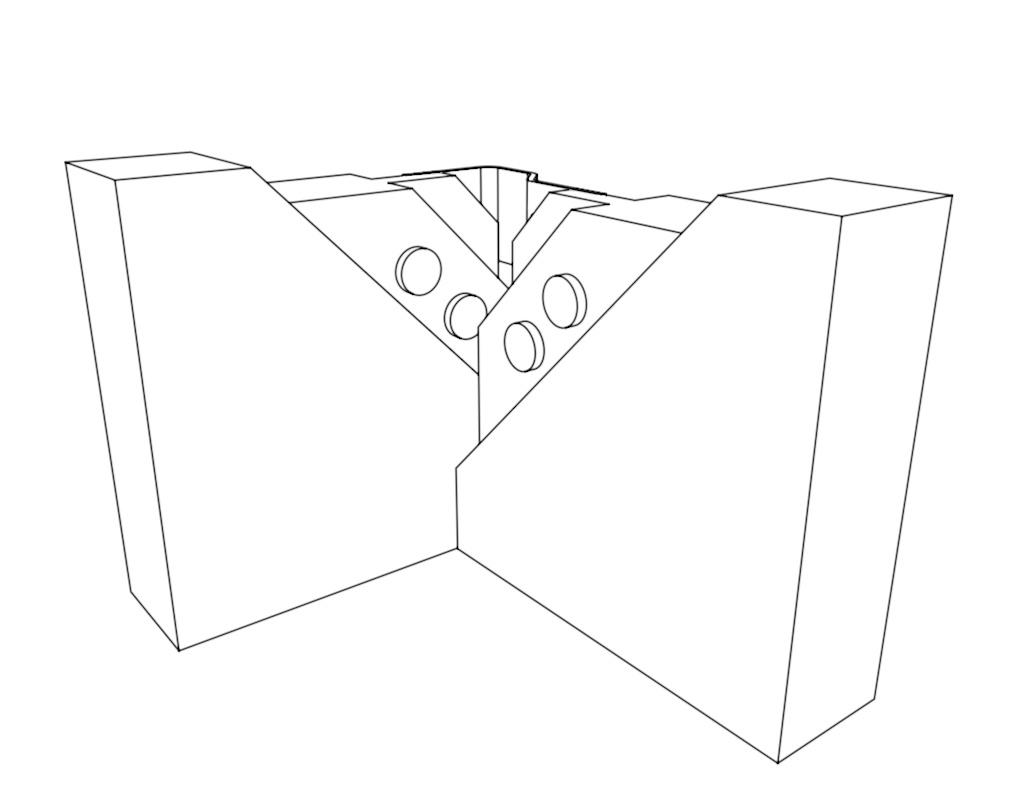

Interlocking solution

of rigid cores in CLT, with multi-storey vertical panels

of high horizontal plane forces to concrete core structures

for shear walls with CLT panels

Joint when connecting shear walls in CLT

Composition of modular systems with CLT panels, created with X-RAD connections, developed for the lifting, transport and assembly work on site

Use of CLT panels as a bracing system for steel frame structures

A new era for wooden multi-storey buildings

High resistance and rigidity give life to innovative solutions

Steel profile for vertical traction connection of CLT panels

Rigid restraint of diaphragms in high impact concrete

CLT shear wall suspension of the vertical loads from the slabs

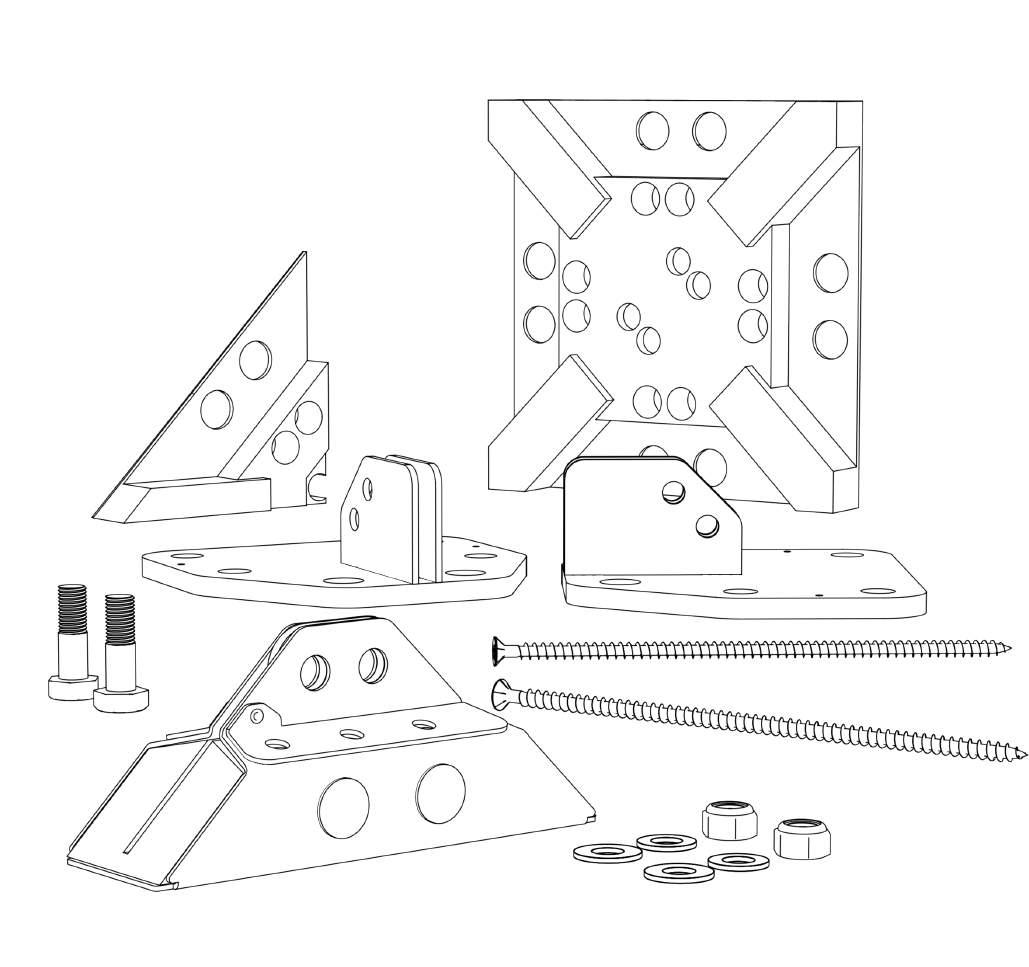

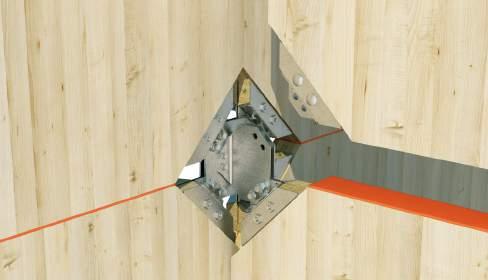

Universal connector for CLT panels

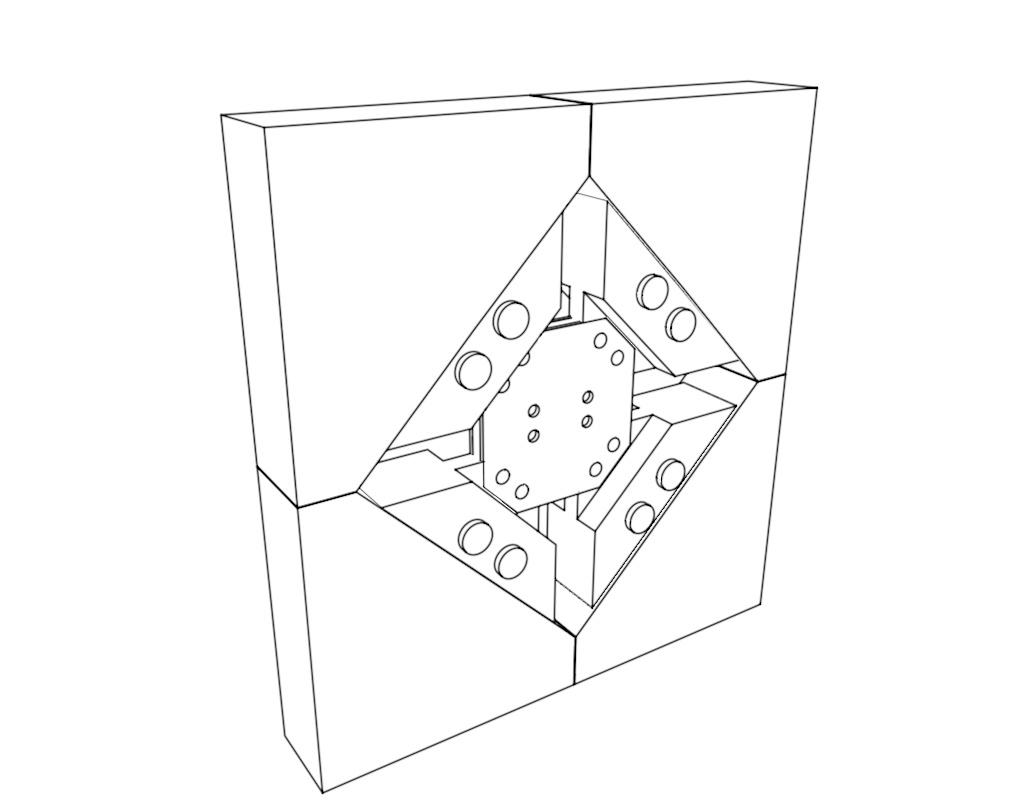

UNIQUE SOLUTION

One element for transferring the shear and traction stresses, for lifting, handling, positioning and fastening all thicknesses of CLT panels

STRONG

The insertion of 6 full thread screws with large diameter, with radial distribution and symmetric inclination enables the transfer of extremely high stresses in every direction

STRUCTURAL SAFETY

Connection system ideal for seismic design with tested and certified values of ductility

DID YOU KNOW THAT...?

X-ONE is the main component of the X-RAD system, it is the first connection in the world designed and optimised to make the most out of the mechanical resources of the CLT. It can be used in the complete X-RAD system for multi-storey buildings and in all applications that require the transfer of strong stresses.

EFFECTIVE

The system involves simple tightening of a few bolts. In the foundation solution, connection with X-PLATE plates is extremely fast and effective

FUNCTIONAL

The mid-floor and top nodes are created simply and quickly with predefined bolted joints

AIRTIGHT

Coupling with the X-SEAL element guarantees the highest air, water and wind resistance, while also ensuring good acoustic performance

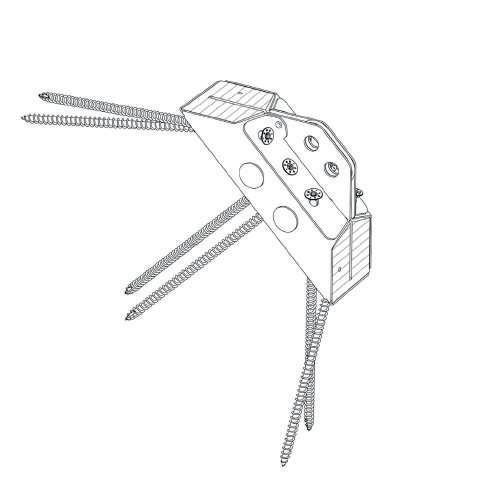

DESCRIPTION

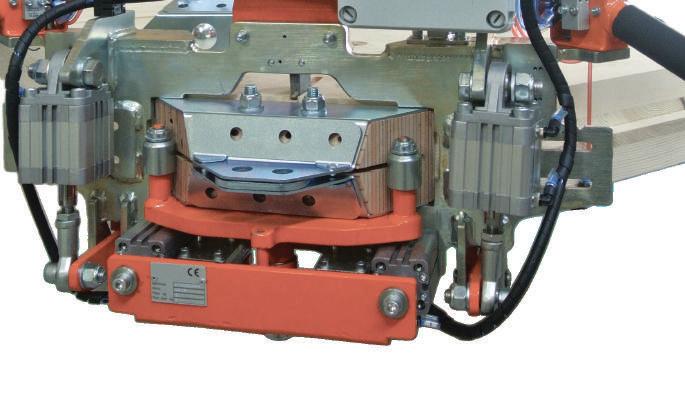

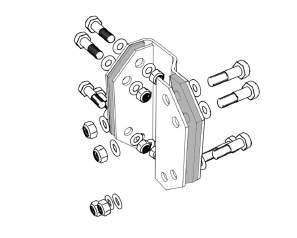

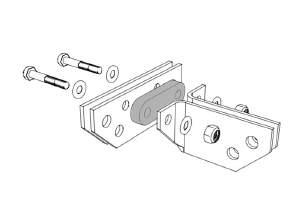

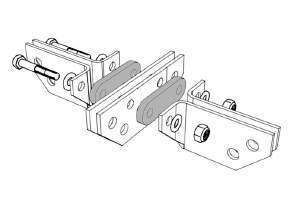

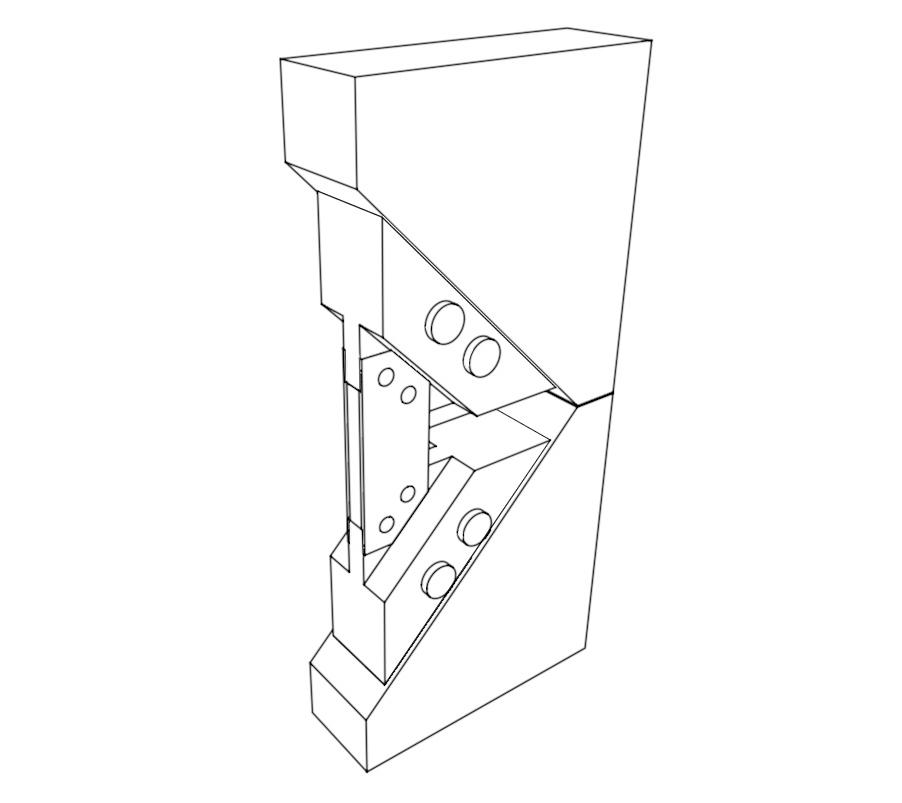

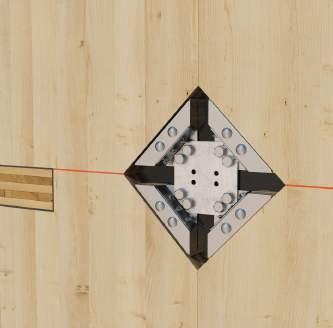

X-ONE is a light and compact connection element, capable of ensuring excellent mechanical performance. Its geometry allows it to be used in the X-RAD system and as a single connection element for particularly demanding applications.

X-ONE is fastened to the CLT panel by 6 XVGS11350 connectors inserted through oriented prebored holes. The fixing of the screws in the CLT according to the direction dictated by the X-ONE guide holes ensures extremely resistant fastening in every stress direction.

6x self-tapping screws of diameter 11 mm code XVGS11350

X-ONE connector

plane surface on which X-ONE can be fastened

CLT panel

CODES AND DIMENSIONS

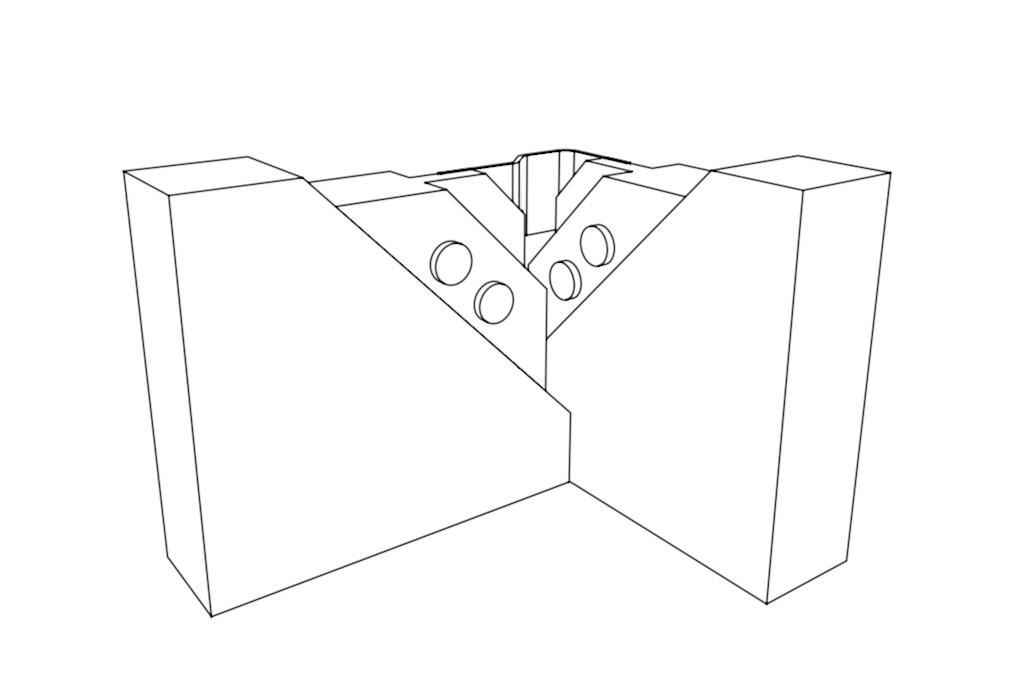

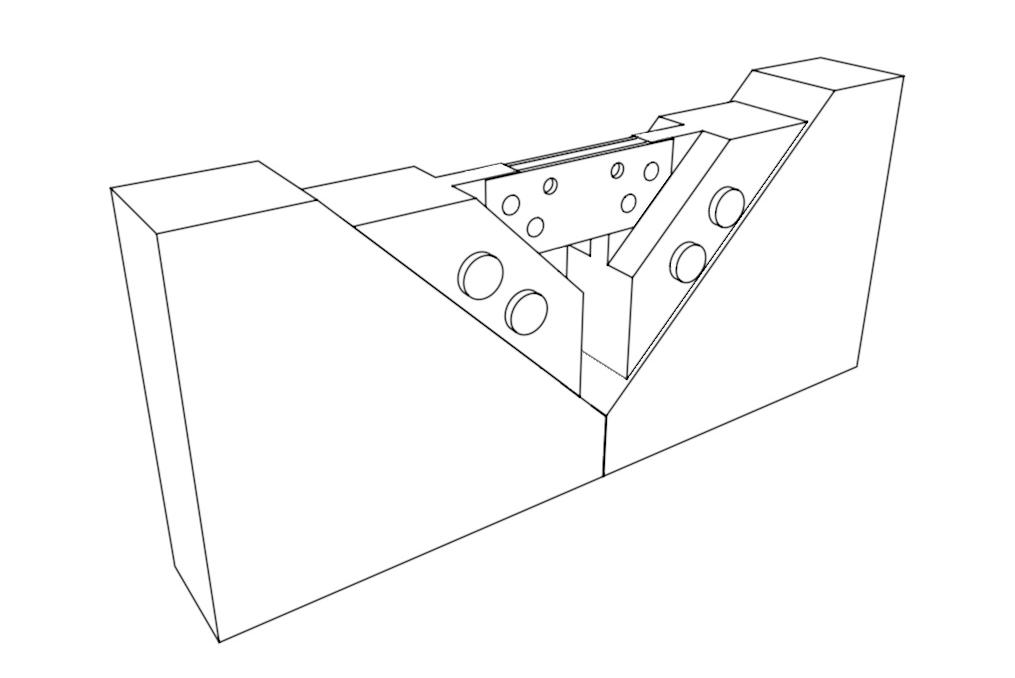

POSITIONING

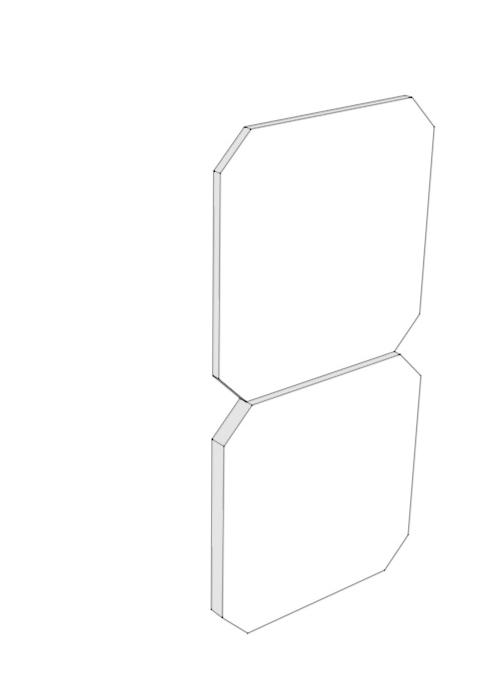

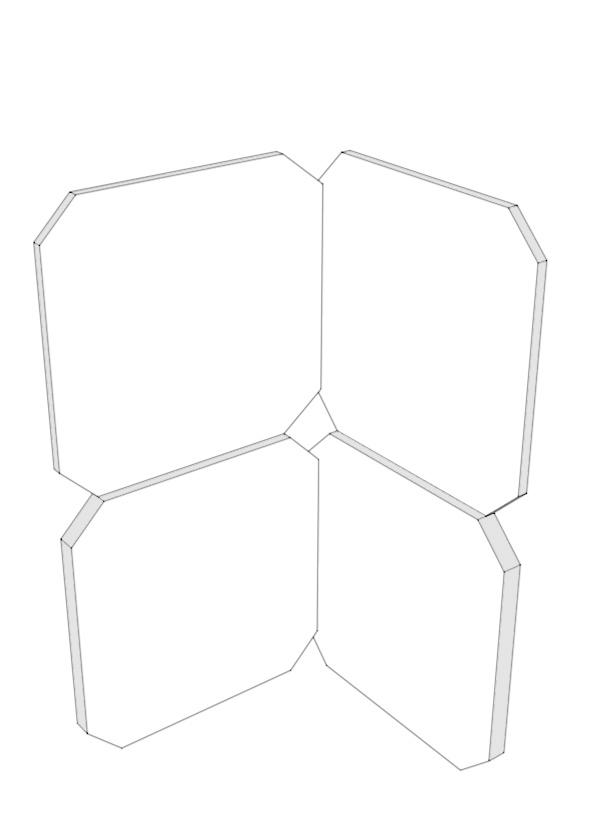

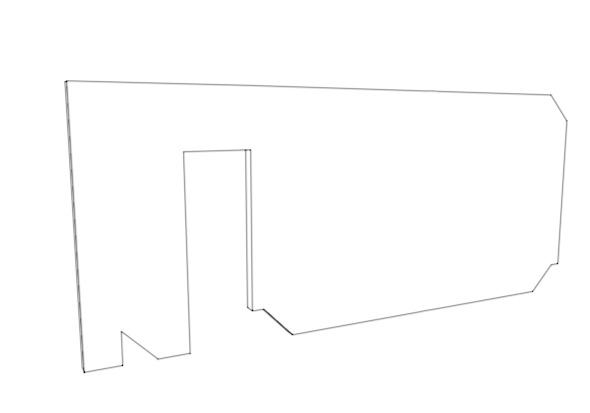

Independently of the thickness of the panel and its location on the site, the cut for the fastening of X-ONE is made at the tops of the walls, at 45°, and it is 360,6 mm long.

STANDARD MID FLOOR AND TOP NODES CUT (1)

STANDARD BASIC NODES CUT (1)

X-ONE is fixed on the inclined surface in a central position, both with respect to the length of the cut and in the direction of the panel thickness (s). This rules holds for all the thicknesses of the panel.

The creation of a specific housing for the floor panels avoids the interposition of the slabs between the wall panels and the resulting problems related to compression at right angles to the fibres. It thus allows direct transmission of vertical loads between the wall panels in concentrated zones at the ends of them.

NOTES: (1) For non-standard cases see pages 62-63. (2) We recommend not making cuts in and processing the CLT panel within a radius of 300 mm from the tops of X-ONE, in order to avoid damaging the fastening screws and cutting tools.

STRUCTURAL ENGINEERING

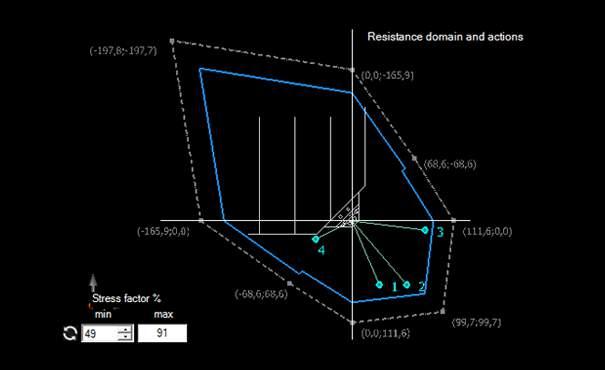

The objective of this section is to provide the designer with a resistance domain (characteristic and design) which describes the resistance of the X-ONE element stressed in different directions.

The pre-assembled X-ONE component, fixed to the CLT panel by means of special connectors and made up of:

1.external box in bent metal plate, thickness 2.5 mm

2.internal stiffening plate, thickness 6 mm, with fastening holes for M16 bolts

3.insert in Laminated Veneer Lumber (LVL)

4.washer-plates, thickness 2.5 mm

5.internal M12 bolts with nuts

6.VGS full thread fasteners Ø11 mm (code XVGS11350)

X ONE AND CONNECTORS

PLACING OF CONNECTORS WITH VARIABLE INCLINATION

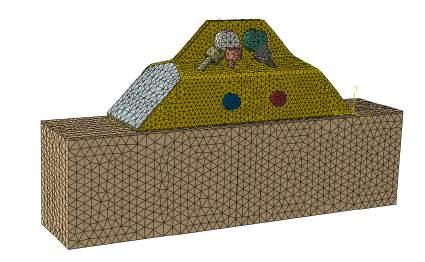

The failure domain of X-ONE in a stress field variable between 0° and 360° (in the CLT panel plane) is determined according to 3 approaches: experimental investigations: load tests on the connection with different stress directions analysis of the fnite elements (FEM): extension of the experimental results to different stress directions analytical models: confirmation of the experimental results and of the FEM analysis and simplification of the design approach

FOR MORE INFORMATION

A. Polastri, A. Angeli, “An innovative connection system for CLT structures: experimental - numerical analysis“, 13th World Conference on Timber Engineering 2014, WCTE 2014, Quebec City, Canada.

A. Polastri, A. Angeli, G. Dal Ri, “A new construction system for CLT structures“, 13th World Conference on Timber Engineering 2014, WCTE 2014, Quebec City, Canada.

A. Polastri, “An innovative connector system for fast and safe erection with CLT“, 20. Internationales Holzbau-Forum 2014, Garmisch Partenkirchen, Germany.

A. Polastri, R. Brandner, D. Casagrande, “Numerical analyses of high- and medium- rise CLT buildings braced with cores and additional shear walls, Structures and Architecture: Concepts, Applications and Challenges“, Proceedings of the 3nd International Conference on Structures and Architecture, ICSA 2016.

A. Angeli, A. Polastri, E. Callegari, M. Chiodega, “Mechanical characterization of an innovative connection system for CLT structures“ , 14th World Conference on Timber Engineering 2016, WCTE 2016, Vienna, Austria.

A. Polastri, C. Loss, L. Pozza, I. Smith, “CLT buildings laterally braced with core and perimeter walls“, 14th World Conference on Timber Engineering 2016, WCTE 2016, Vienna, Austria.

A. Polastri, I. Giongo, S. Pacchioli, M. Piazza, “Structural analysis of CLT multi-storey buildings assembled with the innovative X-RAD connection system: case-study of a tall-building“, 14th World Conference on Timber Engineering 2016, WCTE 2016, Vienna, Austria.

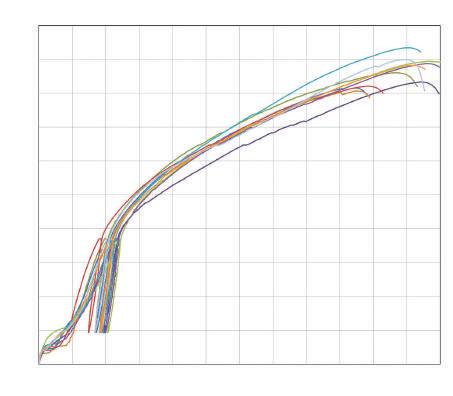

EXPERIMENTAL INVESTIGATIONS

The laboratory tests were carried out in three different research centres:

TU-GRAZ (Lignum Test Centre of the University of Graz - AT): monotonic tests to identify the resistance and rigidity parameters

CNR-IVALSA (Trees and Timber Institute in San Michele A.A - IT): monotonic and cyclic tests to define ductility and behaviour from a seismic perspective

DICAM (Department of Civil, Environmental and Mechanical Engineering of the University of Trento - IT): tests on the overall wall-connection system

MONOTONIC TEST

CYCLICAL TEST

Example of output from monotonic test: force-movement for stress curves α = 45°

Displacement [mm]

Example of output from cyclical test: diagram force-movement for stress diagram α = 135° - 315°

The experimental study of X-ONE made it possible to design and perform, at the University of Trento, cyclic failure tests on complete wall systems where the CLT panel was fastened to the ground using the X-RAD system. The experimental campaign ended with the testing of a complex system with multiple X-RAD connections between 4 CLT panels which made it possible to analyse the interaction among the various components (X-ONE, X-PLATE, CLT panels).

Example of output from cyclical test on wall system: force-displacement diagram and test setup for single panel

In all the tests performed the connection was taken to breakage in order to observe the behaviour of the system as the stress direction applied changed.

At the end of the experimental phase the resistance diagram of the connection was defined through interpolation of the data collected.

S chematisation of the failure modes observed with changes in stress (0° ≤ α < 360°)

α = 0° - 90° - 135° - 315° tension VGS connectors

α = 45° block tearing of the plates

α = 180° - 225° - 270° wood side failure mechanisms

Experimental resistance domain

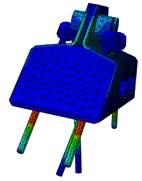

FINITE ELEMENT ANALYSIS

The results collected in the experimental tests and observation of breaking characteristics led to the creation and validation of a finite-element model, capable of describing the overall behaviour of the X-ONE connection subject to movements in different directions.

Analyses of the push-over type were simulated; these were then linearised through bilaterals in order to provide the values of maximum resistance to changes in the direction of movement.

of the X-ONE element and of the connectors

Example of capacity curve with linearisation

The points representing maximum resistances found by the FEM analyses enable the definition of a further resistance domain for the connection.

FEM modelling of the X-ONE connector and CLT panel

Resistance domain obtained from the FEM simulations

FEM

ANALYTICAL MODELS

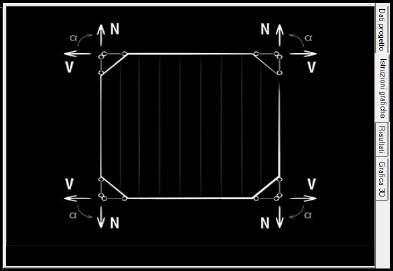

The experimental campaign and the finite-element model show how the X-ONE + CLT panel system has different ways of failure on changes in the stress direction. For the purposes of defining calculation models, 8 main stress directions were identified within a x-z reference system, in which the behavioural symmetries of the connection can be noted.

Starting from observation of the experimental collapse characteristics, the balance configurations of the connection were identified for each stress direction in accordance with the static theorem of the limit analysis. By way of example the resistant mechanisms for two configurations are shown:

Confguration for α = 45°

Confguration for α = 135° - 315°

On the basis of the analytical model, it is possible to generate a further resistance domain very close to those identified experimentally and through the FEM model. This confirms the stability of the behaviour of the connection and the validity of the analysis methods adopted.

Resistance domain from analytical calculation

2RVGS,t

2RVGS,t

2RVGS,t

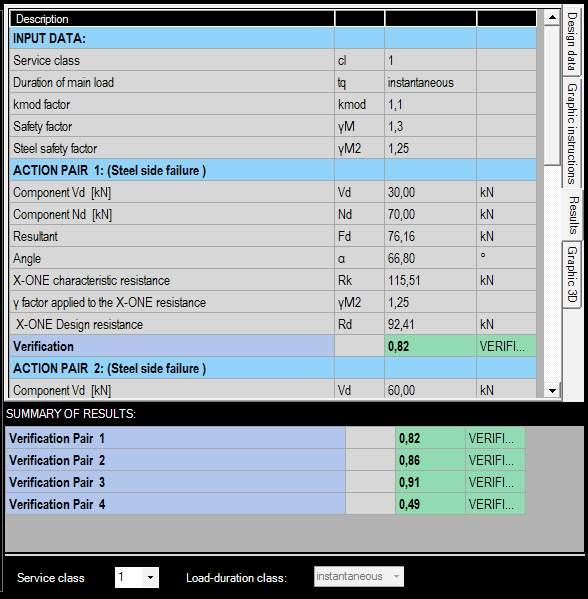

DESIGN RESISTANCES

For the purposes of the design verifications, the resistances are used, supplemented by the analytical resistances, thus identifying the characteristic resistance domain of X-ONE

Through a system design in accordance with the concepts of resistance hierarchy, with the over-sizing of a number of elements constituting X-ONE, thus facilitating certain failure modes:

tension of the VGS connectors block tearing in correspondence with the M16 holes on the box + internal plate system wood failure (extraction of VGS connectors or wood compression)

Characteristic resistance domain

A summary table of the characteristic resistances is presented, in the various stress configurations together with a reference to the related safety coefficient according to the breaking characteristics (steel or wood).

NOTES: In order to obtain the maximum performances of X-ONE connector and to avoid the splitting of the wood panel, it is recommended to insert 2 full thread connectors VGZ perpendicular to the CLT panel (picture right - page 24).

(1) The partial safety coefficients should be taken according to the current regulations used for the calculation. The table shows the steel-side values in accordance with EN1993-1-8 and the wood-side figures in accordance with EN1995-1-1.

Checks at the Ultimate Limit State are carried out using the design resistance domain of X-ONE, defined starting from the characteristic resistance values (1)

The design resistance values are obtained as follows: steel-side:

wood-side:

with the coefficients kmod and γM to be taken according to the failure modes and the current regulations used for the calculation.

Verification of the X-ONE connection is considered achieved when the point representing the stress Fd falls within the design resistance domain:

Fd ≤ Rd

Design resistance domain in accordance with EN1995-1-1 and EN1993-1-8

The design domain of X-ONE refers to the resistance values and to the γM coefficients shown in the table and for loads with instantaneous duration class (earthquake and wind) (2)

NOTES:

(1) The full report on experimental analysis of the X-ONE connection can be downloaded from www.rothoblaas.com or from the MyProject software.

(2) Connection by means of X-ONE works as a connection between CLT walls to prevent their tipping and sliding in the presence of seismic and wind phenomena (instantaneous duration class). The static vertical forces are transmitted directly by wall-wall contact, without stressing the connection.

The use of X-ONE in the presence of loads with brief, medium or permanent duration class (kmod < 1) requires a re-assessment of the design domain, because the resistance hierarchy may change. In these cases, in the interests of safety, we suggest treating all design resistances as wood-side resistances, applying opportune kmod and γM coefficients.

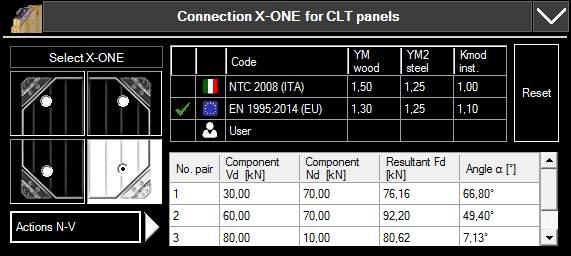

CALCULATION WITH MY PROJECT

Selection of the module for verification of the X-ONE connector from the verification modules available (connections with screws, retractable junctions, structural reinforcements, thermo-hygrometric verifications).

Resistance domain and graphic output of results (position of stress values with respect to the perimeter of the domain and indication of the percentage of use).

Full report with product rendering, initial assumptions, input data, graphs, synthetic and extensive verifications.

Selection of the calculation standard (NTC 2008, EN 1995 or user).

Definition of the type of CLT panel top.

Input of nodal loads (possibility of inserting infinite pairs of shear-tension forces, directly imported from the modelling software calculation table).

Summary report of the numerical results with indication of the safety coefficients adopted based on the failure mode and verification degree specification for each stress pair input.

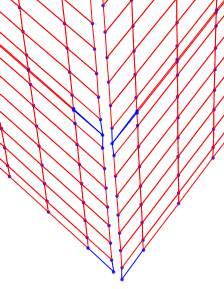

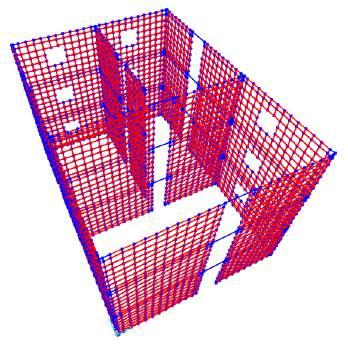

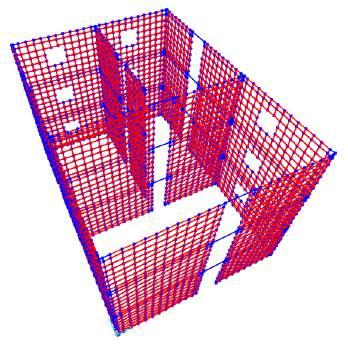

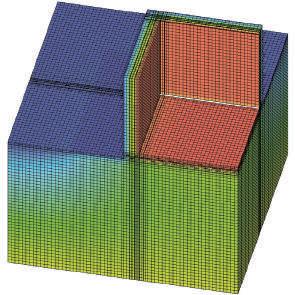

GUIDELINES FOR MODELLING THE X RAD SYSTEM

Modelling starts with the definition of the base panel and the X- ONE connectors at the corners. The CLT panel can be modelled with “shell” elements as the rigidity of the CLT / X-RAD system is controlled by the deformability of the connection.

The connector can be modelled with two square steel connecting rods with side measuring l = 5.51 mm and length 255 mm (“frame” elements placed at the corners of the panel). So a final X-RAD rigidity is obtained of k = 25 kN/mm.

The representation of each X-RAD with two connecting rods allows a traction/compression force to be linked to the vertical frame element and a shearing force to the horizontal frame element.

TENSION COMPRESSION

In order to simulate contact between panel-panel and panelfoundation, nonlinear gap springs are defined. These have infinite compression rigidity and no traction.

NOTE: The full guidelines for modelling the X-RAD system can be downloaded from www.rothoblaas.com or from the MyProject software. These guidelines give an example of a possible sequence of useful tips to help you model CLT structures with the X-RAD system. It is the responsibility of the designer to define and study in depth the modelling process details needed for proper structural design.

A spring (C) is provided at each end of the panel, both vertically and horizontally, to simulate contact between CLT panels. The springs at the base of the walls simulate contact between the panel and the foundation.

The wall panels arranged at right angles are supposedly free. Plates that in reality will connect the orthogonal walls are entered as a construction connection outside the calculation.

Final definition of the FEM model.

The analysis considers a solution method for the nonlinear finite element model, given the presence of springs that only work with compression.

START EARTHQUAKE

NONLINEAR MODEL STATIC ANALYSIS

REGULARIT Y IN HEIGHT + T1 < 2.5 Tc

NONLINEAR MODEL

VERIFICATION OF ALL STRUCTURAL ELEMENTS, INCLUDING CONNECTIONS

The stresses deriving from the analysis, which can be obtained in each node from reading the forces of the two connecting rods simulating the X- ONE connector, can be exported to the MyProject software for automatic verification of all connections.

STEP 7

STEP 9

STEP 6

STEP 8

MANUAL INSTALLATION

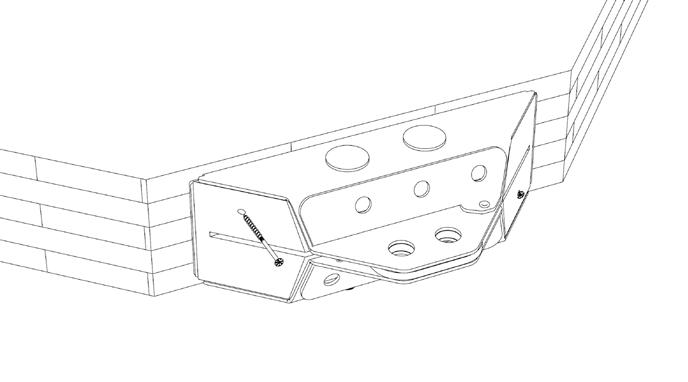

For use of X-ONE not in series and for applications which do not provide for the use of the manual or automatic template, it is possible to install X-ONE manually.

1. place X-ONE on the corner surface of the panel

2. fix X-ONE temporarily to the CLT panel using 2 HBS5120 screws in order to prevent movement of the component during the definitive fastening operations

3. proceed to the definitive fastening of X-ONE with 6 XVGS11350 connectors

At the end of the definitive fastening, the positioning screws can be removed

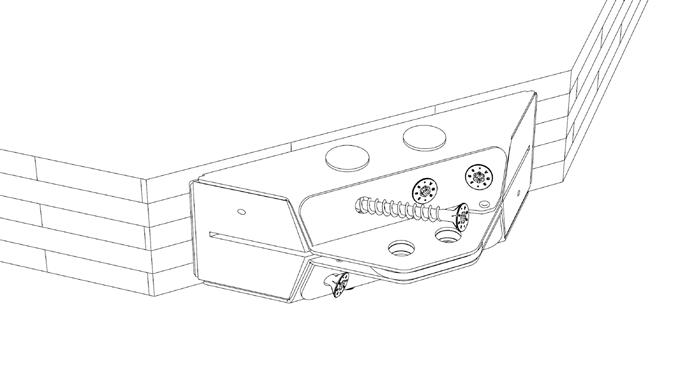

INSTALLATION WITH MANUAL AND AUTOMATIC TEMPLATE

MANUAL TEMPLATE

The manual template system enables X-ONE to be positioned quickly and precisely. IT can be used for thicknesses between 100 and 220 mm. The steps are the following:

1. bring the template close to the corner of the panel so as to bring the template against the oblique side. Fasten the template to the panel with the screws already installed in the template body.

2. position X-ONE in the special housing and fasten X-ONE to the panel with 6 XVGS11350 connectors

The side supports of the template are fastened with bolts so that they can be easily removed for installations in non-standard or particularly complex positions.

See the installation on the geometry of the base nodes in figures 1 and 2 below.

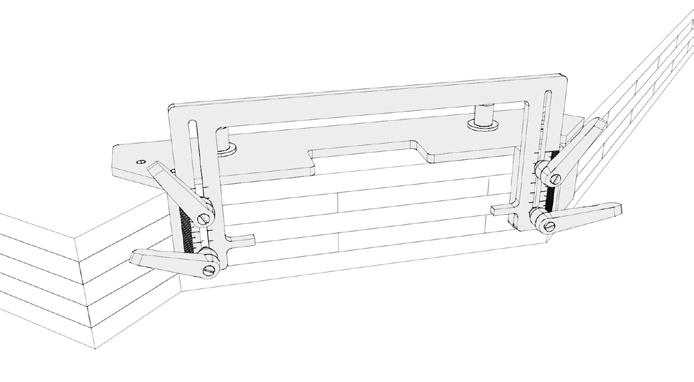

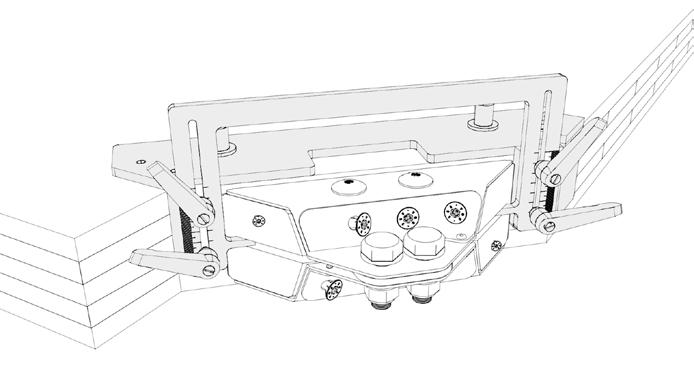

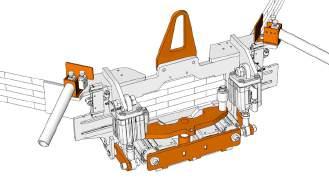

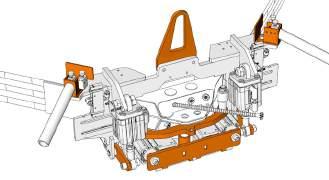

AUTOMATIC TEMPLATE

The automatic template system is the ideal solution for assembling X-ONE in industrial manufacturing processes of CLT panels.

I t can be used for panels with a thickness between 100 and 160 mm. The steps are the following:

1. bring the side tracks close to the orthogonal sides of the panel so as to bring the body of the template against the oblique side. Lock the template on the panel

2. position X-ONE in the special housing on the pneumatic template, lock it into position and fasten X-ONE to the panel with 6 XVGS11350 connectors

CODES AND DIMENSIONS

HBS SCREW

MANUAL TEMPLATE

AUTOMATIC TEMPLATE

INSERTS

SCREW GUN

TRANSPORTING THE WALLS

HORIZONTAL LIFTING

A specific lifting system has been developed to lift panels on which X- ONE connectors have been installed, including from the horizontal plane (process of certification in progress under the terms of the machinery directive 2006/42/EC) (1)

HANDLING PANELS AT THE END OF THE PRODUCTION CYCLE

TRANSPORTING AND LOADING CLT PANELS ONTO TRANSPORT VEHICLES

NOTE: To ensure safe lifting operations and to prevent the wood from splitting due to orthogonal stresses to the fibres, it is recommended to insert VGZ full thread connectors perpendicular to the CLT panel (see page 24).

VERTICAL LIFTING

The CLT walls are assembled on site by positioning bolted steel plates, developed to make structural nodes in all geometric configurations of the panels. With the X-RAD system the CLT panels are lifted, handled and mounted directly from the transport vehicles to the structure under construction, thus avoiding drop-off and storage phases.

The X-RAD system is certified according to machinery directive 2006/42/EC for additional use as a vertical lifting point for transporting CLT panels (1)

In function of the weight of the panel and the angle between the lifting ropes (β), it is possible to compare the force acting on each hook point (T). By applying the appropriate security factors, it is therefore possible to compare the stress acting on the lifting point with the resistance of X- ONE

NOTES: (1) When lifting with hooks for ropes or chains, it is recommended to use high resistance omega grills with pin Ø = 16 mm. (2) If the α angles are excessive, use lifting slingbars.

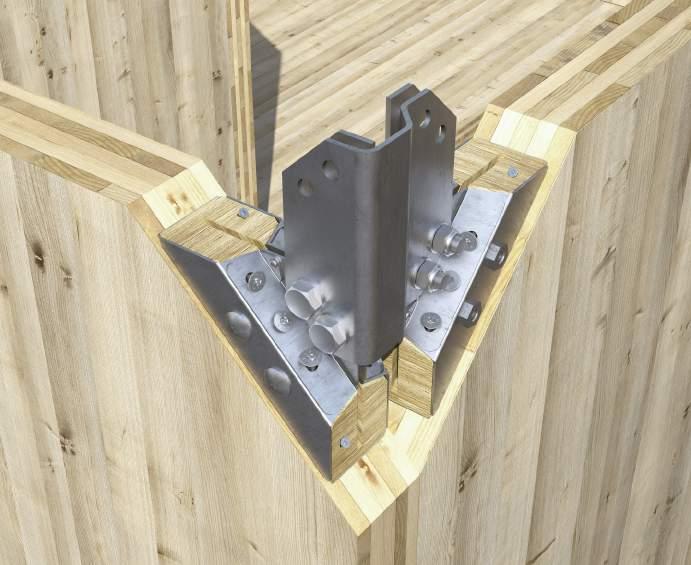

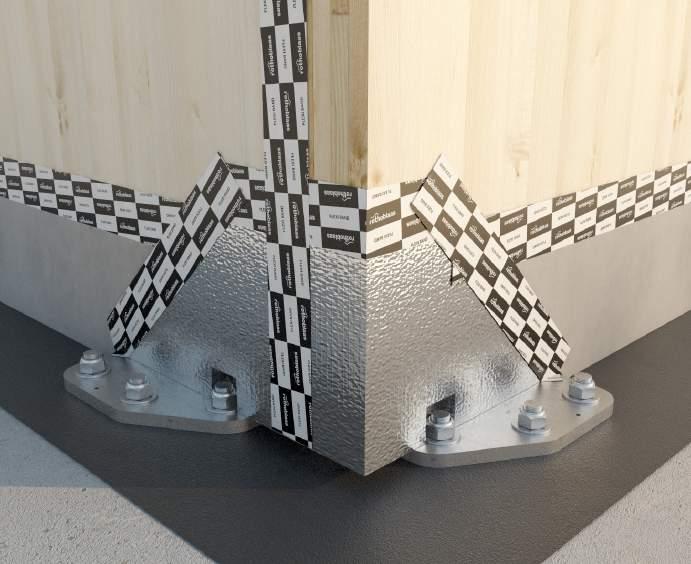

PLATE

Complete range of connection plates

SIMPLE

The panels are mounted at the site through the simple tightening of steel bolts

COMPLETE

The range meets every on-site need, from attachment to the ground, to connection between walls at different levels and with different thicknesses, to fastening the walls at top level

CERTIFIED

High quality guaranteed by the CE marking according to EN1090 of the X-PLATE components

DID YOU KNOW THAT...?

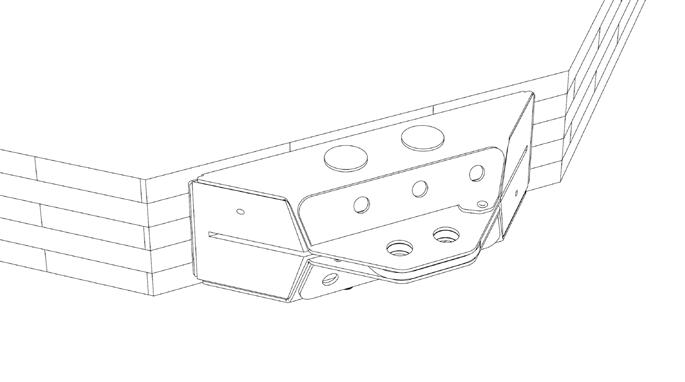

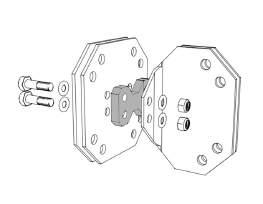

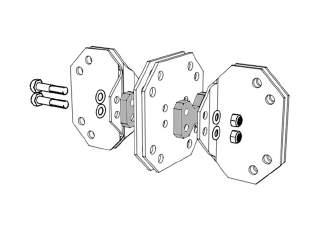

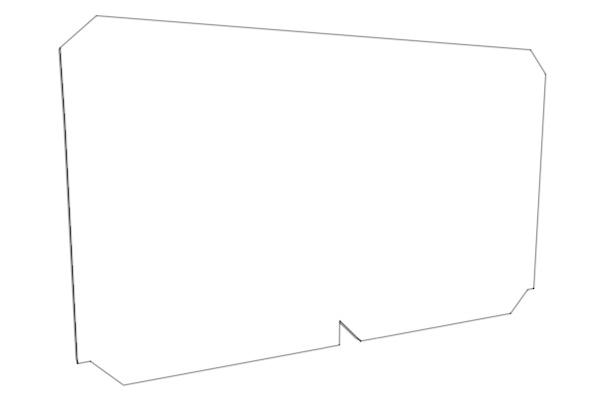

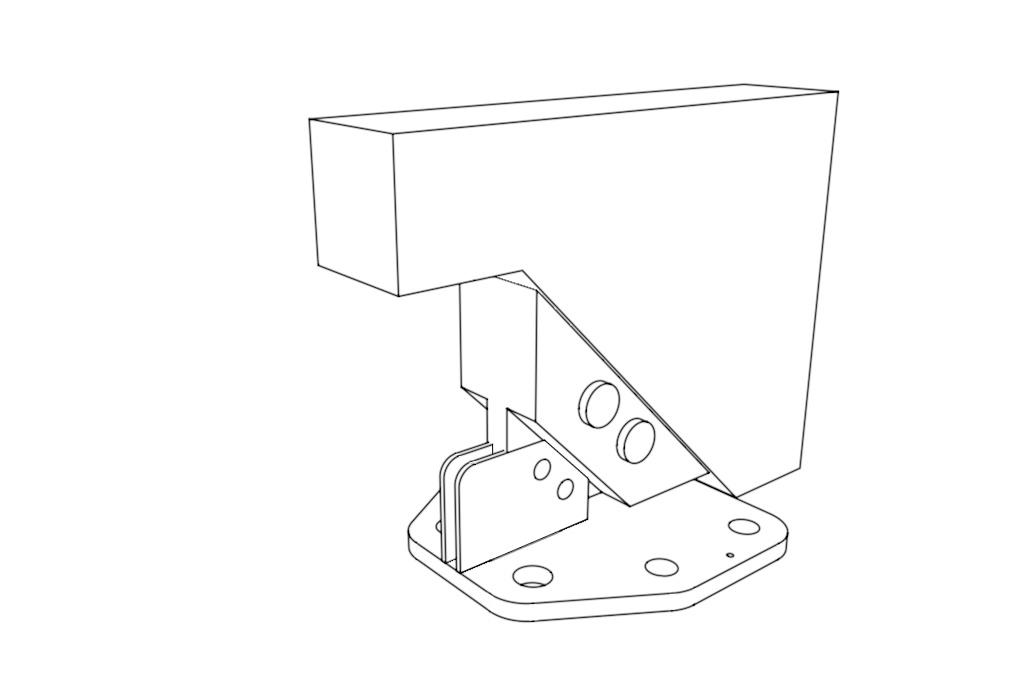

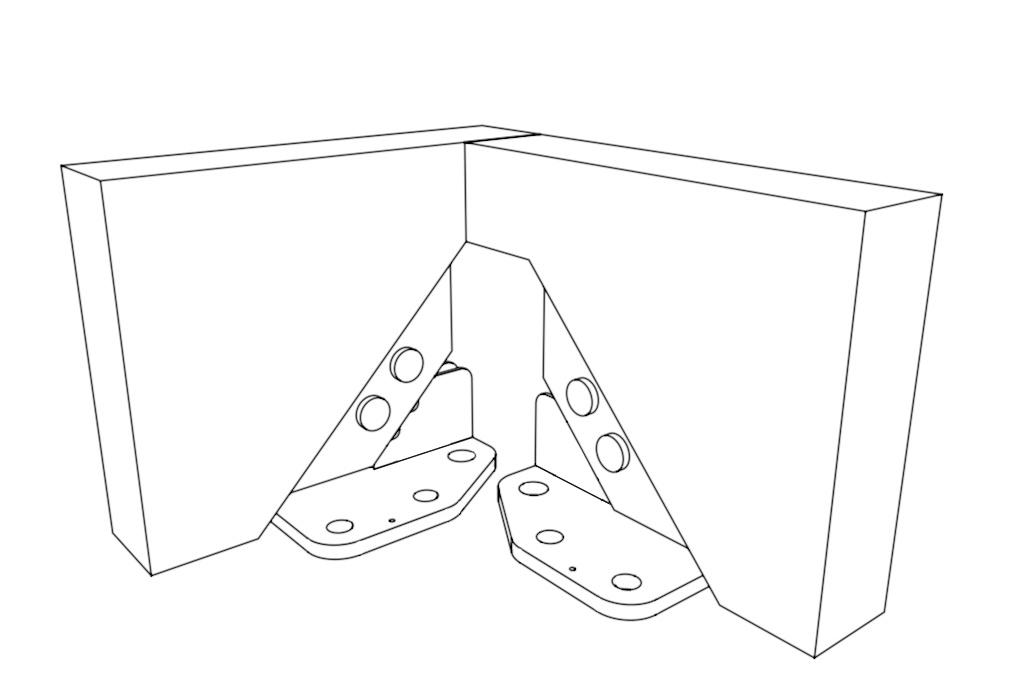

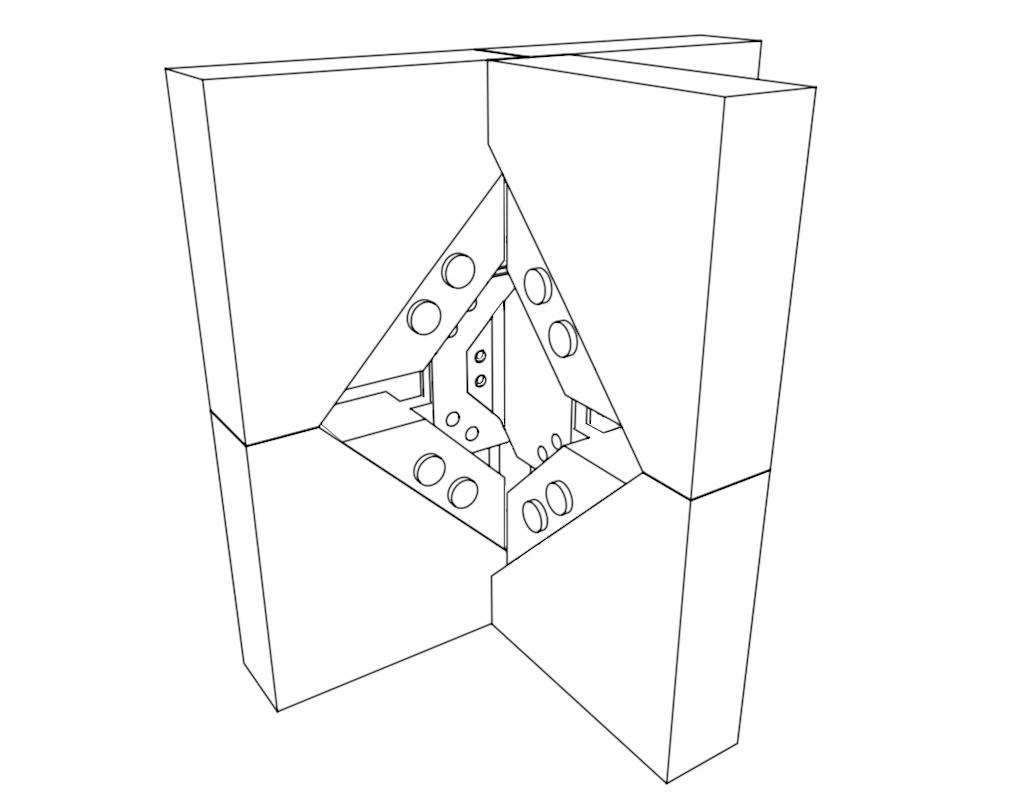

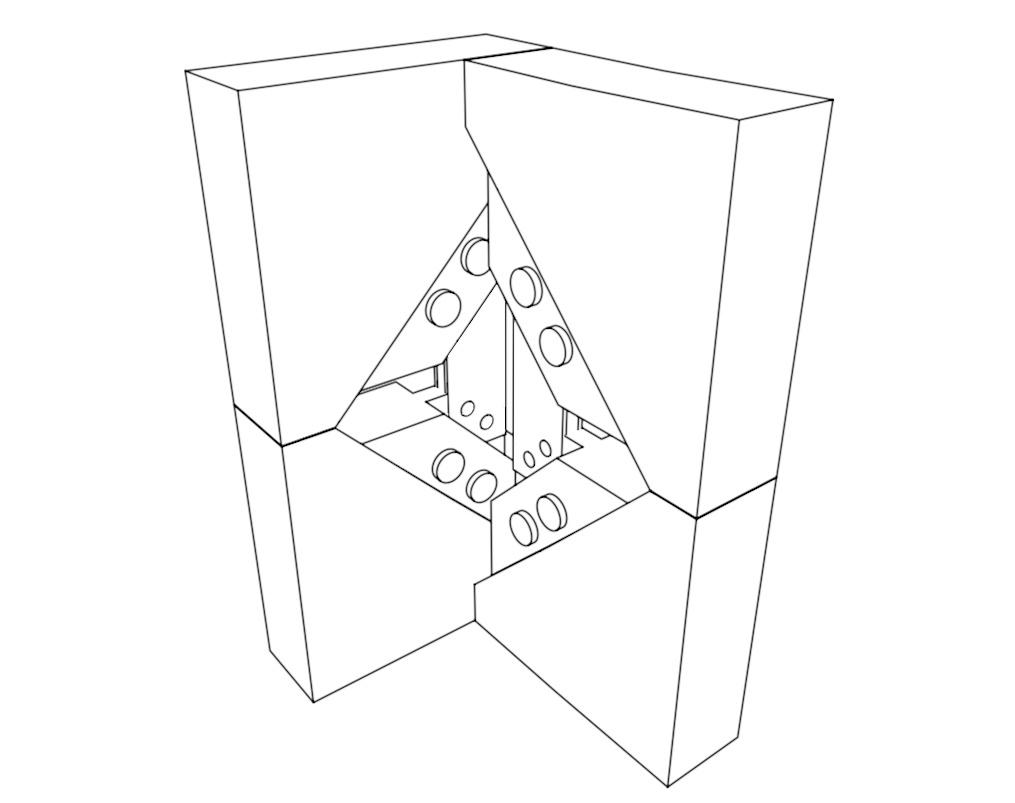

X-PLATE is the range of certified steel plates for mounting the CLT panels on the building site, made up of X-BASE, X-MID and X-TOP.

The connectable panel thicknesses vary from 100 mm to 200 mm.

X-BASE plates introduce a new concept of ground alignment and creating the attachment to the ground, making the mounting of the walls extremely precise and quick, with a saving in building times of between 50% and 70%.

INTUITIVE

The reference holes on the base of the plate make it possible to avoid any installation mistakes, for precise attachment of the system to the ground

ADVANCED

The system guarantees a high degree of prefabrication; it also solves problems relating to positioning, levelling and anchoring in the foundation of the CLT panels

PRACTICAL

The panels are quickly connected to each other using X-PLATE plates. A practical solution suitable for every building site

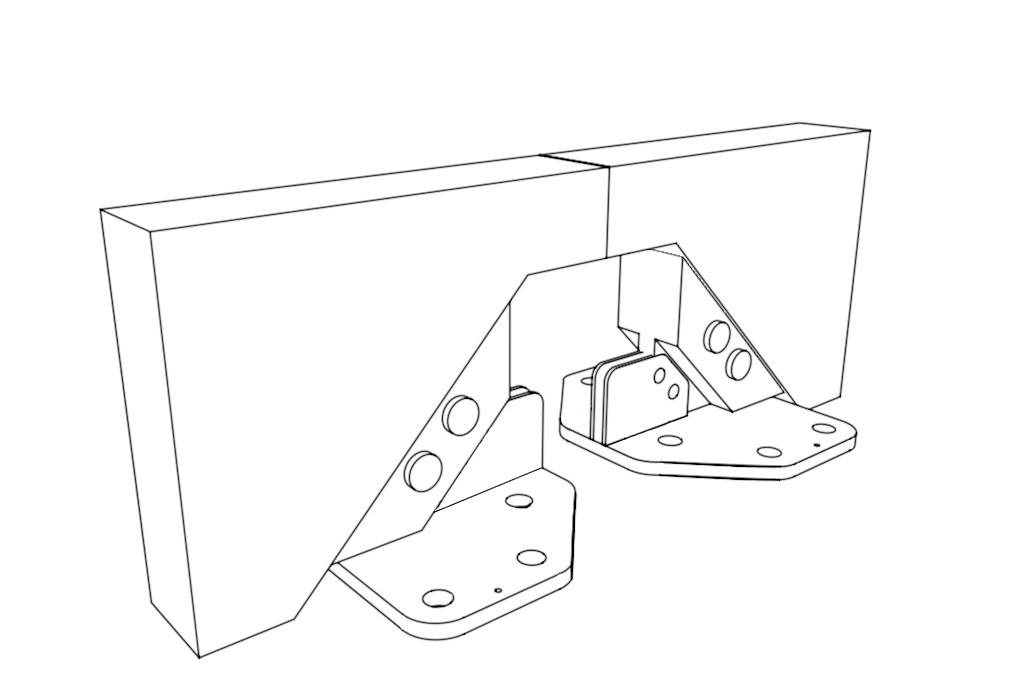

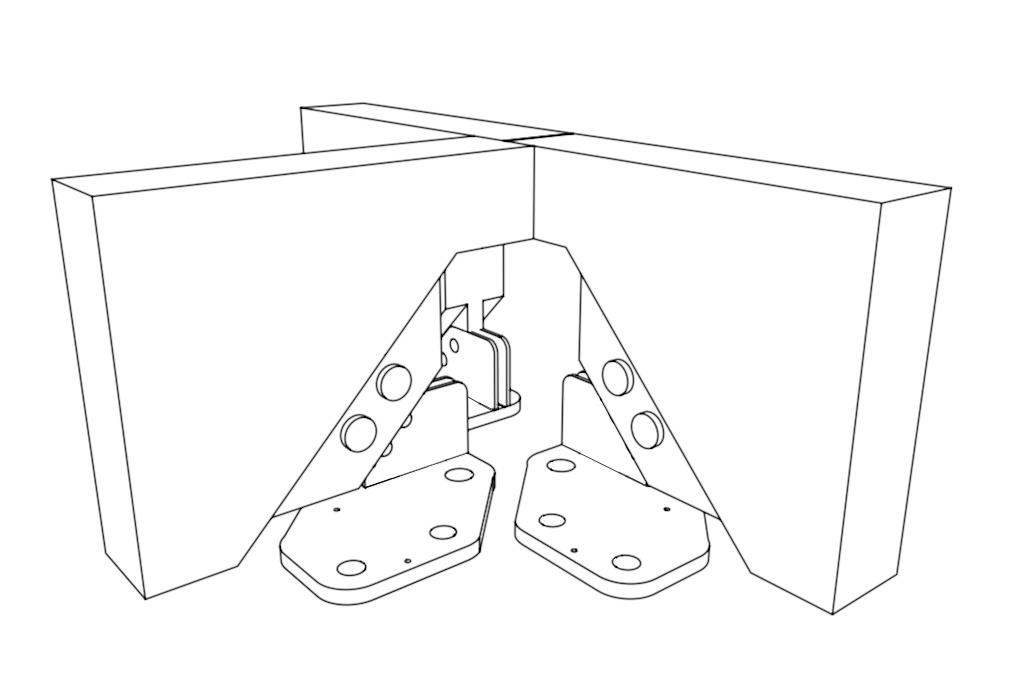

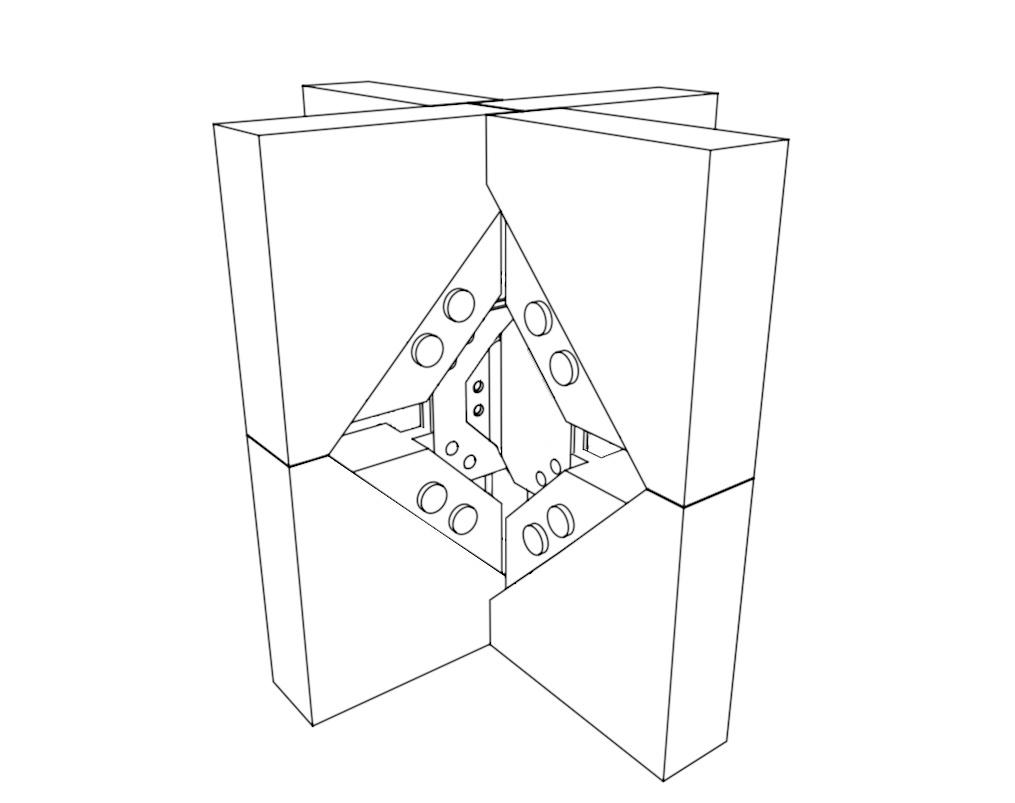

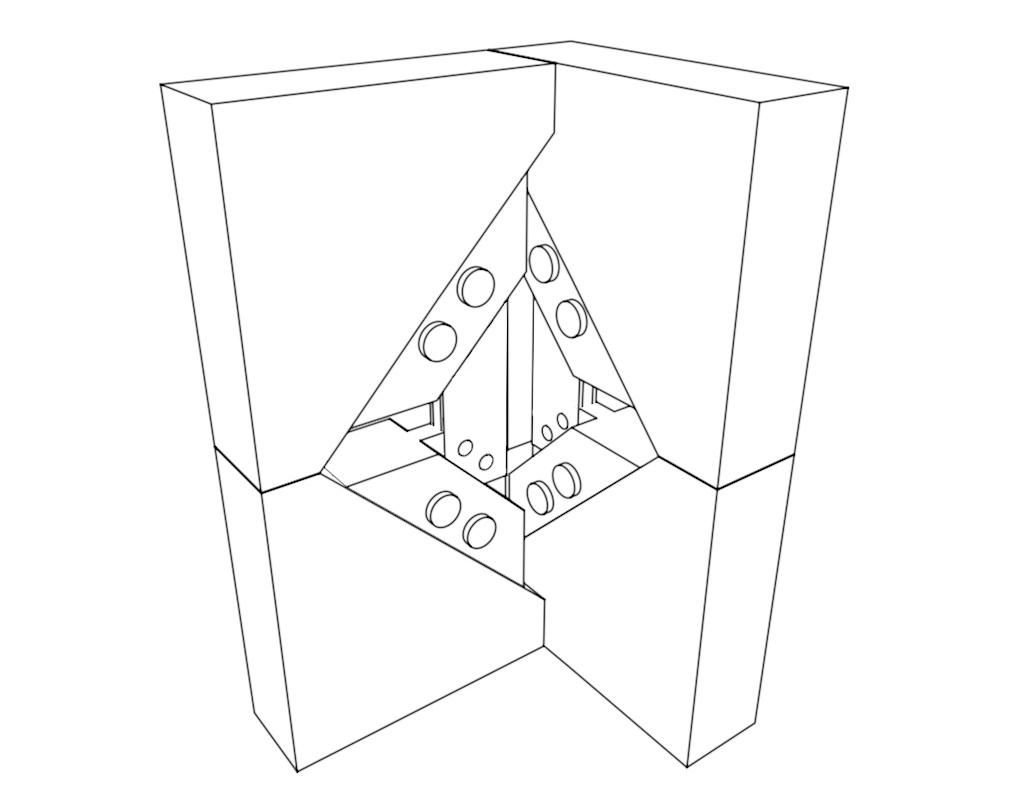

X-ONE makes the CLT panel a module provided with specific connections for fastening. X-PLATE enables the modules to become buildings. Panels with a thickness between 100 and 200 mm can be connected.

X-PLATE plates are the ideal solution for every building site situation, developed for all geometric configurations. The X-PLATE plates are identified according to their placing at the level of the building (X-BASE, X-MID, X-TOP) and according to the geometric configuration of the node and to the thickness of the panels connected.

X-PLATE BASE CODE COMPOSITION

CODES = level + thickness + orientation

LEVEL: B indicates that these are base plates

THICKNESS: indicates the interval of thickness of the panel that can be used with that plate. There are two families of plates, the first designed for thicknesses between 100 and 130 mm (code BMINI), the second for thicknesses between 130 and 200 mm (code BMAXI)

ORIENTATION: indicates the orientation of the plate with respect to the wall, right/left (R/L), indication only for asymmetric plates

CODES = level + node + thickness

LEVEL: indicates that these are mid-floor MID (M) and TOP (T) plates

NODE: indicates the type of node (X, T, G, J, I, O)

THICKNESS: indicates the thickness of the panel that can be used with that plate. There are three families of standard thickness, 100 mm - 120 mm - 140 mm. IT is possible to use all thicknesses of panels between 100 mm and 200 mm, with universal plates for the G, J, T and X nodes, in conjunction with SPACER plates, developed ad hoc. Universal plates are available in MID-S and TOP-S versions for panels with a thickness between 100 and 140 mm and in MID-SS and TOP-SS versions for panels with a thickness between 140 and 200 mm.

Examples:

MG140 = M + G + 140

TT120 = T + T + 120

/ TX120 / TX140

4 XONE no. 3 XONE

X PLATE TOP

/ TI120 / TI140

2 XONE

no. 2 XONE no. 24 XVGS11350 no. 18 XVGS11350 no. 12 XVGS11350 no. 12 XVGS11350 no. 12 XVGS11350 no. 8 XBOLT1660 no. 6 XBOLT1660 no. 4 XBOLT1660 no. 4 XBOLT1660 no. 4 XBOLT1660 no. 2 XBOLT1260 no. 2 XBOLT1260

X-PLATE_MID

X PLATE MID

no.

8 XONE

XVGS11350

no.

XVGS11350 no. 8 XBOLT1665 no. 8 XBOLT1665 no. 8 XBOLT1660 no. 8 XBOLT1660 no. 8 XBOLT1665

no. 8 XBOLT1660 no. 4 XBOLT1660

no. 4 XBOLT1260 no. 4 XBOLT1260

X PLATE BASE

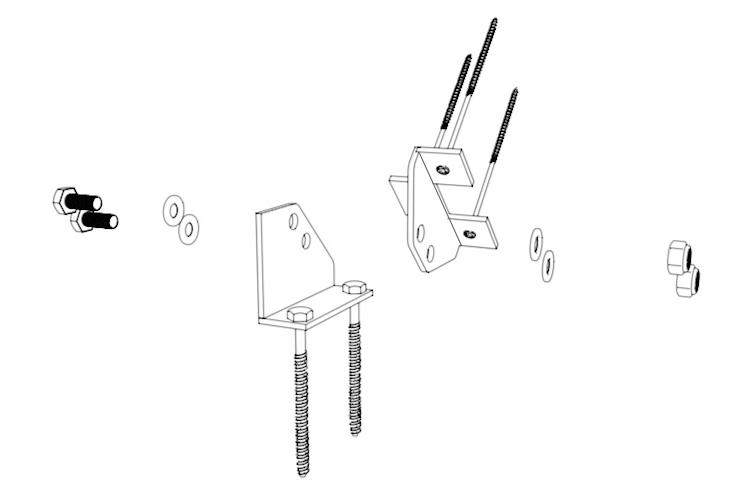

ADDITIONAL PRODUCTS FOR FASTENING X - PLATE PLATES

PRODUCTS FOR ASSEMBLING X - PLATE / X - ONE

head bolt with nut

PRODUCTS FOR ANCHORING IN FOUNDATION OF X - PLATE BASE

NOTE:

ACCESSORIES: EXAMPLE OF A SOLUTION WITH X-PLATE PLATES FOR NON-STANDARD WALL THICKNESSES

Below are the J (or G), T and X geometric configurations for MID and TOP levels, where the wall thickness affects the geometry of the X-PLATE plate. As an example, we have analysed panels with a thickness of 130 mm (so different to standard thicknesses of 100 - 120 - 140 mm), solved with MID-S and TOP-S universal plates, in combination with SPACER plates.

XPLATE MJS

no. 2 MJSPACER (1 MJ50S + 1 MJ150S) no. 4 XBOLT1675 no. 4 XBOLT1665

XPLATE MTS

no. 1 MTSPACER (1 MT150S) no. 12 XBOLT1665 no. 4 XBOLT1275

XPLATE MXS

no. 2 MTSPACER (2 MT150S) no. 16 XBOLT1665 no. 4 XBOLT1290

XPLATE TJS

no. 2 TJSPACER (1 TJ50S + 1 TJ150S) no. 2 XBOLT1675 no. 2 XBOLT1665

XPLATE TTS

no. 1 TTSPACER (1 TT150S) no. 6 XBOLT1660 no. 2 XBOLT1275

XPLATE TXS

no. 2 TTSPACER (2 TT150S) no. 8 XBOLT1660 no. 2 XBOLT1290

ACCESSORIES: EXAMPLE OF A SOLUTION WITH X-PLATE PLATES FOR CHANGES OF WALL THICKNESS AT MID-FLOOR LEVEL

All of the mid-floor geometric configurations are shown below, where the change of wall thickness from the floor below to the floor above affects the geometry of the X-PLATE plate. On a schematic level, you can understand how every variation in thickness can be solved using MID-S (or MID-SS) universal plates, in combination with the appropriate SPACER plates.

MO (2 TJSPACER)

MG (4 TJSPACER)

(4 TJSPACER + 1 MTSPACER)

MJ (4 TJSPACER)

(4 TJSPACER + 1 MTSPACER)

NOTE: For any doubts or assistance on X-PLATE plates and SPACER plates to be used in specific cases, contact Rothoblaas Technical O ffice.

MT

MI (4 TJSPACER)

MX

* supplied upon request

UNIVERSAL PLATES

Where foundation fastening for non-structural walls or temporary fastening for correct wall alignment (e.g. walls of considerable length) is required, a BEASYT plate (as an alternative to X-ONE) can be installed on the bottom corner of the CLT panel (with simple 45° cut without horizontal cut) and a BEASYC plate (as an alternative to X-PLATE BASE plates) can be installed on the mat foundation (1)

BEASYT BEASYC

The CLT panels are fastened with 3 HBS+ evo screws 8 x 200 mm and the reinforced concrete base is fastened with 2 SKR 12 x min 100 mm or alternatively 2 AB1 M12 x 103 mm.

CODES AND DIMENSIONS

RELATED PRODUCTS

NOTE: (1) The BEASYT plate is always assembled on the inclined surface in a central position, the same as X-ONE, both with respect to the length of the cut and in the direction of the panel thickness.

STRUCTURAL ENGINEERING

The aim of this section is to provide the resistance specifications for X-PLATE connection plates. The plates, of varying thickness according to the type, are all made of S355JR steel, CE marked according to EN1090 in EXC2 execution class. Each plate has been designed and verified by applying the maximum stresses transmitted by the X- ONE connector, according to three classes of strengths (1):

1. OVERALL STRENGTHS OF THE PLATE (with FEM analysis): shear; pure traction; pure compression; buckling stress or flexural stress.

2. LOCAL STRENGTHS: shear strength of the bolt (EN 1993-1-8 §3.6.1); bearing strength of the plate (EN 1993-1-8 §3.6.1); block tearing strength of the plate (EN 1993-1-8 §8.10.2); strength of the welds.

3. FASTENING STRENGTH ON THE FOUNDATION SUPPORT

X-PLATE BASE PLATES

The X PLATE BASE plates can be used under the following conditions: use of vinyl ester chemical anchor and 20 mm diameter threaded rod - steel strength grade 8.8 minimum strength class for C25/30 concrete

X-PLATE BMINI and BMAXI plates fully restore the resistance of the X- ONE connector.

X-PLATE BMINIL/R and BMAXIL/R plates partially restore the resistance of the X- ONE connector. This aspect is illustrated by the resistance domains shown below (2)

RESISTANCE DOMAINS OF X - PLATE PLATES COMPARED TO THE RESISTANCE DOMAIN OF THE X - ONE CONNECTOR

X-ONE

X-PLATE BMINI local strengths

X-PLATE BMINI overall strengths

X-PLATE BMINI foundation fastening strength (uncracked concrete hef = 200)

X-PLATE BMINI foundation fastening strength (cracked concrete hef = 200)

X-PLATE BMINI - Design resistance domain

NOTE: (1) The full report on structural design of the X-PLATE plates can be downloaded from www.rothoblaas.com or from the MyProject software. (2) The domains are shown according to the reference system for the X-ONE connector. To refer to the reference system for the X-PLATE plates, by applying forces on the X-PLATE plates that are equal and opposite to those applied on the X-ONE connector, these domains must be mirrored with respect to the bisector of the first quadrant.

X - PLATE

X-ONE

X-PLATE BMAXI local strengths

X-PLATE BMAXI overall strengths

X-PLATE BMAXI foundation fastening strength (uncracked concrete hef = 200)

X-PLATE BMAXI foundation fastening strength (cracked concrete hef = 200)

X-PLATE BMAXI - Design resistance domain

X-ONE

X-PLATE BMINILR local strengths

X-PLATE BMINILR overall strengths

X-PLATE BMINILR foundation fastening strength (uncracked concrete hef = 200)

X-PLATE BMINILR foundation fastening strength (cracked concrete hef = 350)

X-PLATE BMINIL/R - Design resistance domain

X-ONE

X-PLATE BMAXILR local strengths

X-PLATE BMAXILR overall strengths

X-PLATE BMAXILR foundation fastening strength (uncracked concrete hef = 200)

X-PLATE BMAXILR foundation fastening strength (cracked concrete hef = 350)

X-PLATE BMAXIL/R - Design resistance domain

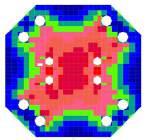

FEM ANALYSES ON X-PLATE BASE PLATES

The following FEM analyses, performed controlling displacement and assuming a final displacement of 15 mm, were conducted by analysing the 5 main load directions (positive/negative pure shear, positive/negative shear-traction and pure traction). The results of these simulations are as follows: diagram showing force-displacement for every load direction (0° ≤ α ≤ 180°) 3D deformation of the system in stress contours (von Mises) for α = + 90°

Displacement [mm]

Force-displacement diagram

Displacement [mm]

Force-displacement diagram

X - PLATE BMINI PLATE

X - PLATE BMAXI PLATE

3D deformation in stress contours (von Mises) - α = + 90°

3D deformation in stress contours (von Mises) - α = + 90°

Displacement [mm]

Force-displacement diagram

3D deformation in stress contours (von Mises) - α = + 90°

Displacement [mm]

Force-displacement diagram

deformation in stress contours (von Mises) - α = + 90°

X

3D

X - PLATE BMAXIR PLATE

DESIGN RESISTANCES - X-ONE / X-PLATE GROUND ATTACHMENT

X-PLATE BMINI / BMINIL / BMINIR

STRESS

X-PLATE BMAXI / BMAXIL / BMAXIR

ANCHOR INSTALLATION PARAMETERS

ANCHOR TYPE

x 400

(1) Rods 1000 mm long to be cut to size and used with a MUT nut and ULS washer (page 43).

GENERAL PRINCIPLES:

•The design values are in compliance with EN 1995:2014 in compliance with EN1993-1-8 and in compliance with the product certificates.

•The total resistance of the connection is obtained as follows:

• During calculation a C24 strength class for the CLT panel plates and a C25/30 strength class for the concrete were considered. There must be no annular space between the holes in the plate and the anchor (holes filled).

• Dimensioning and verification of the wooden and concrete elements must be done separately.

• Concrete strength values are valid for the calculation assumptions defined in the table; conditions with different contour conditions (e.g. minimum distances from the edges) must be checked.

RESISTANCE OF CONNECTIONS IN ELEVATION: X-PLATE MID AND TOP PLATES

The mid-floor nodes are made with X-PLATE MID plates, starting from the MI and MO element plates and ending with the most complex MT and MX plates, natural evolution and combination of the MI and MO plates. At a structural level:

MI PLATE: shear and traction strength

the MI plate fully restores the shear and traction strength of the 4 X- ONE connectors converging in the node and is verified for every possible stress combination transmitted by the connectors

MO, MG, MJ PLATES: traction strength

the MO and MG/MJ plates restore the traction strength (vertical stress at 90°) of each X- ONE connector connected to it

TI PLATES: shear strength

the TI plate restores the shear strength (horizontal stress at 0°) of each X- ONE connector connected to it

MX, MT, TX, TT PLATES

the MX, MT, TX and TT plates are the simple composition of the single MI, MO and TI plates, where each plate maintains its original structural performance

Von Mises stresses - traction and compression at 45°

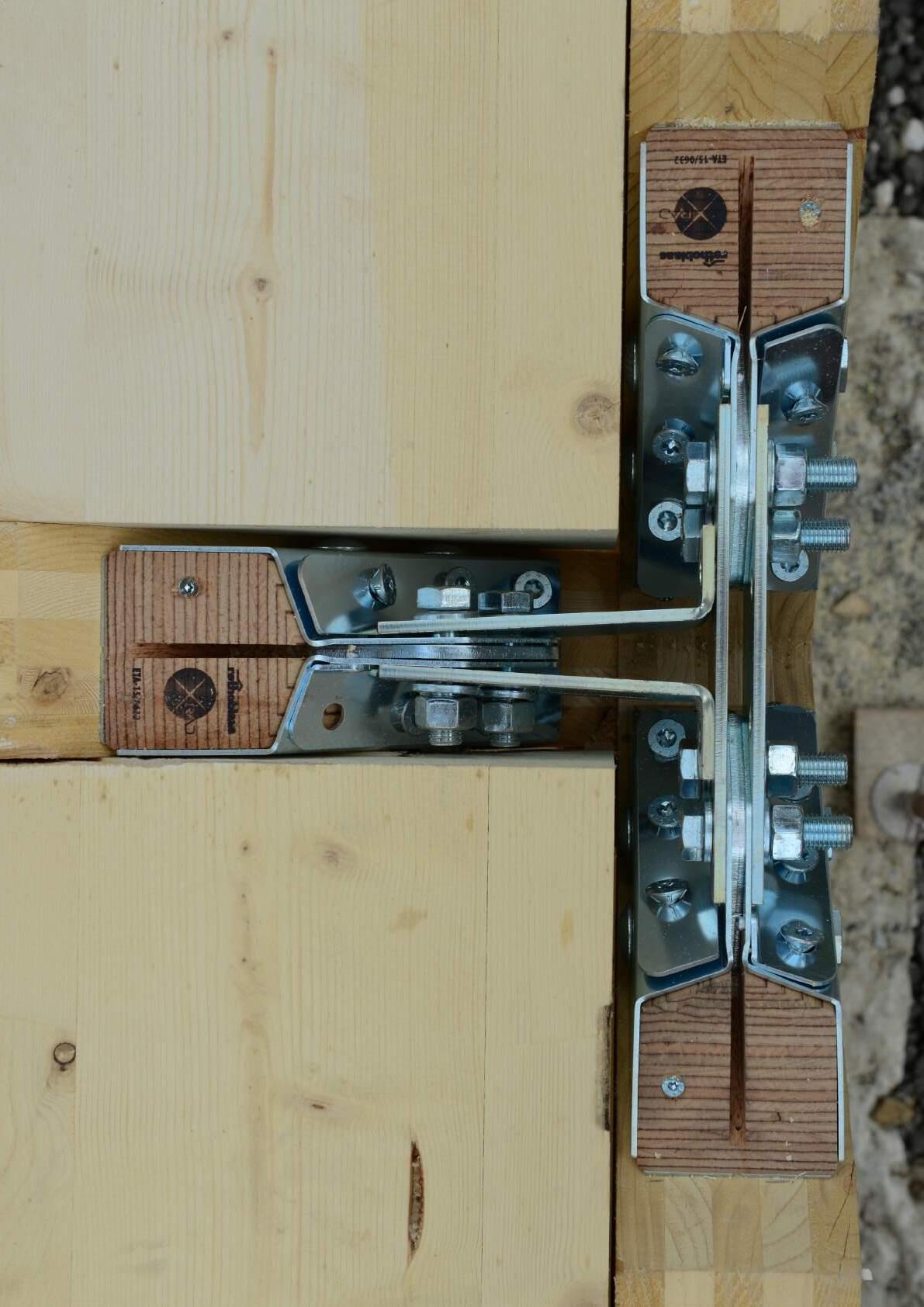

FROM MODELLING TO THE BUILDING SITE

STEP 1

Structural design and verification of the X-ONE connectors and X-PLATE plates (page 32).

STEP 3

Automatic import of the shear/machining geometry for the X-ONE model and the X-PLATE from the design software database.

STEP 5

Positioning the X-PLATE BASE plates on the ground floor wall plan using import CAD file on rothoblaas website or using CAD-CAM software database.

STEP 2

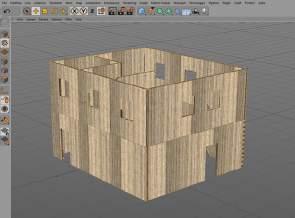

Realisation of the final drawing of the CLT panels forming the structure with 3D CAD/CAM software.

STEP 4

Export of the full list of connections (X-ONE, X-PLATE) from the design software.

STEP 6

Identification of the X-PLATE plates tracing holes (l1, l2) to position the reference points to be traced on site.

STEP 7

Tracing the positioning holes for the X-PLATE plates on site.

STEP 9

The X-PLATE plates are positioned and levelled to the required height. The CLT panel, with the bottom edge aligned with the intrados of the plate, will continue to support the foundation.

STEP 8

Positioning the X-PLATE plates on the foundation base in reinforced concrete.

STEP 10

Once the plates have been positioned, the operator will drill a Ø24 mm hole in the reinforced concrete support for the subsequent insertion of the Ø20 mm chemical anchors. The fasteners adjacent to the vertical wings of the plate (A) must be installed before assembling the CLT walls, those furthest away (B) can be installed later. The tolerance between the diameter of the anchor and the hole in the plate, to be filled with structural resin, allows the position of the plate to still be adjusted.

STEP 11

Positioning the base walls: X-ONE housing in the X-PLATE plates and connection with bolts, nuts and washers.

STEP 12

Positioning the mid-floor walls and roof: X-ONE housing in the X-PLATE plates and connection with bolts, nuts and washers.

ALTERNATIVE GROUND ATTACHMENT SOLUTIONS

PRE-INSTALLED X-PLATE PLATES AND PRE-CAST ANCHORS

Maximum assembling and prefabrication speed using tracing and installation of pre-cast anchors in the foundation slab casting and subsequent assembly of the CLT walls with the X-PLATE plates already fitted to the X-ONE connectors. In this case, it is recommended to use counterplates or templates embedded in the cast in order to correctly position the anchor bars.

To ensure perfect levelling, correct transmission of the vertical loads and protection from moisture rising from the foundation plane, it is advisable to space the CLT walls and the X-PLATE plates by a few centimetres and then to cast by filling with expansive structural cement mortar with a high degree of impermeability.

NON-STANDARD X-PLATE PLATES

If X-PLATE plates are required with geometries (see examples below) and capacities that are not standard, contact the Rothoblaas Technical O ffice.

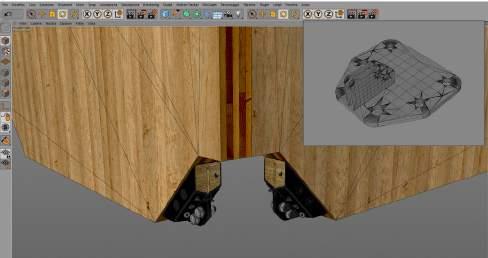

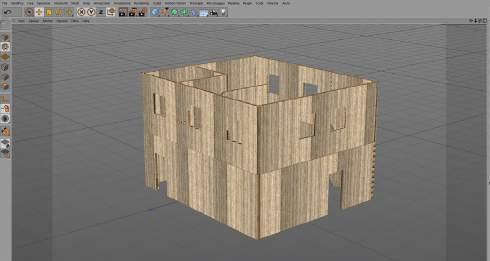

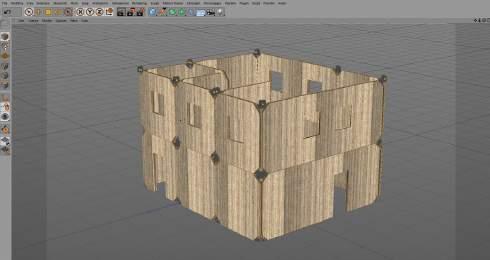

CAD/CAM CONSTRUCTION DESIGN

Using the most common CAD/CAM 3D software, it is possible to automatically define the machining geometry required on the CLT panels and to automatically insert the X-RAD system into the structure model. It is therefore immediately possible to preview the overall dimension of X-ONE and X-PLATE, the correct positioning and the components’ list and calculation.

BASE NODES

(„J“ NODE)

BMAXIL/R („T“ NODE)

BMINI („O“ NODE)

BMINIL/R

BMAXI („I“ NODE)

MG100

MJ100

MO100

MI100

TG100

TJ100

TI100

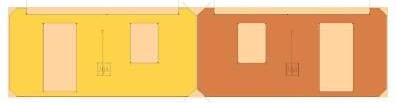

FROM THE PRODUCTION DRAWING TO PROCESSING CLT PANELS

Optimisation of the raw panel, on which all of the machining processes required for openings, slab housing and insertion of X- ONE connectors have been identified.

Cutting operations with circular saw and candle cutter to create the geometry required for positioning the X- ONE.

Examples of finished machining with detail on the inclined cut for assembling 1 X- ONE connector (fig. 1) and on the whole panel with cuts on the corners and housing for insertion of the slab (fig. 2).

fig. 1

2

STEP 3: MACHINING WITH CNC MACHINES

STEP 4: CLT PANEL AFTER THE CUTTING AND MACHINING OPERATIONS

STEP 1: SOFTWARE MODEL

STEP 2: NESTING PHASE

EXAMPLES OF CONSTRUCTION DETAILS CREATED

The X-RAD system is extremely flexible, providing a wide range of design solutions and adapting to complex and articulate structural configurations.

Connection of slab panels for the creation of rigid planes

Single machining for insertion of single X-ONE connector

Difference in height overcome with disjointed panels and double X-ONE connector

Vertical rigid connection between the front walls for the creation of a single monolithic wall

Continuous support of roof panels without specific machining on the vertical walls

Examples of machining and arrangement of the X-ONE connector at ground, slab and roof nodes

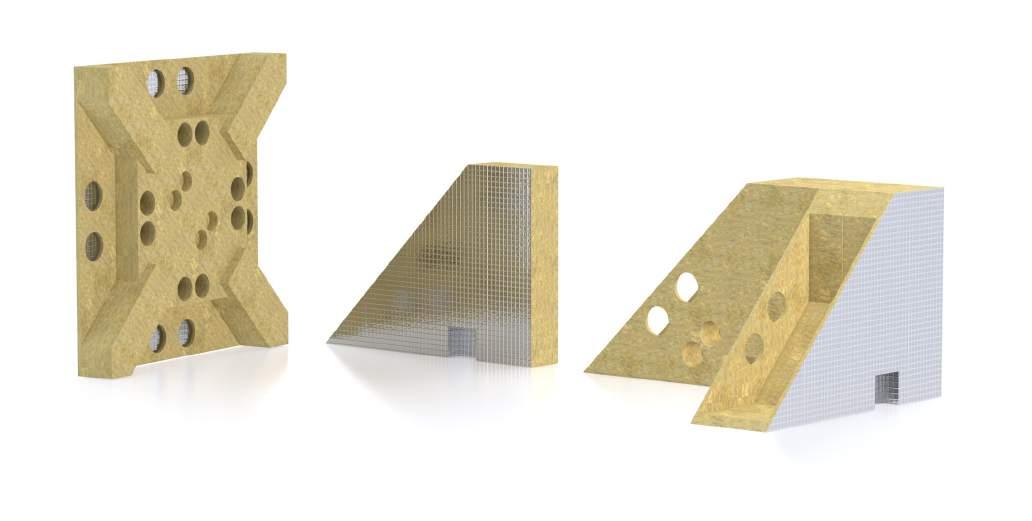

COMFORT AND DURABILITY

The rock wool structure and aluminium finish ensure acoustic and hermetic performance while protecting the heart of the X-RAD system

PRE SHAPING

Thanks to the shape which perfectly fits X-ONE and X-PLATE, the quick closure of the construction node is optimal and does not need further filling materials

PRACTICAL

The use of X-SEAL in combination with the range of rothoblaas acrylic tapes ensures quick execution and a perfect preservation over time of the seal characteristics against air and wind

DID YOU KNOW THAT...?

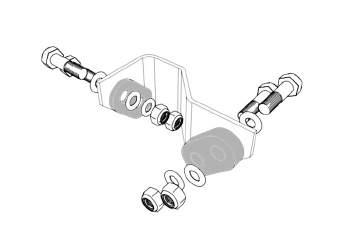

X-RAD is an innovative system that requires intelligent, fast and practical solutions also to optimise thermo-hygrometric and acoustic performance. For this reason X-SEAL has been developed. This is a pre-shaped closure that is suited to the morphology of the X-ONE and X-PLATE components. X-SEAL guarantees air and wind tightening, reduces the transmission of acoustic vibrations through the air and attenuates the single-point thermal bridge.

INSULATION

The specific density of rock wool in the X-SEAL system optimally solves the single-point thermal bridge

HERMETIC

The system components are all perfectly pre-shaped, thus guaranteeing, together with acrylic tapes sealing, perfect air tightness of the node

PROTECTION

At the ground connection, the use of X-SEAL and self-adhesive protection membranes for the CLT panels guarantees durability to the structure

SEAL TOP

code XSEALTX100 / TX120 / TX140

8 components

XSEALMX100 / MX120 / MX140

X SEAL MID

XSEALMT100 / MT120 / MT140

XSEALMG100 / MG120 / MG140 no. 16 components no. 9 components no. 6 components

SEAL BASE

The X-SEAL system uses the same logic as the X-PLATE plates. Each configuration is characterised and described by:

LEVEL: indicates whether it is base level B (BASE), mid-floor M (MID) or roof T (TOP)

NODE: indicates the type of node (X, T, G, J, I, O)

THICKNESS: indicates the thickness of the panel that can be used. There are three families of standard thickness: 100 mm - 120 mm - 140 mm. It is possible to use all thicknesses of panels between 100 mm and 200 mm, combining the base components for standard thicknesses with SPACER elements, with thicknesses between 5 and 10 mm.

X-SEAL BASE X-SEAL MID X-SEAL TOP

INSTALLATION MANUAL FOR THE X - SEAL SYSTEM Can be downloaded from www.rothoblaas.com or using the QR-CODE on the box.

X SEAL TOP

code XSEALTJ100 / TJ120 / TJ140

code XSEALTI100 / TI120 / TI140 no. 4 components no. 2 components

X SEAL MID

code XSEALMJ100 / MJ120 / MJ140

code XSEALMI100 / MI120 / MI140

code XSEALMO100 / MO120 / MO140 no. 6 components no. 3 components no. 3 components

X SEAL BASE

code XSEALBJ100 / BJ120 / BJ140

code XSEALBI100 / BI120 / BI140

code XSEALBO100 / BO120 / BO140 no. 4 components no. 2 components no. 2 components

X-SEAL SPARE 50 / 60 / 70

code XSEALSPARE50 / 60 / 70

X-SEAL SPACER 5 / 10

NOTES: With the X-SEAL SPARE elements, with thicknesses of 50 - 60 - 70 mm, all components of the X-SEAL system can be obtained THE X-SEAL MID components belonging to the walls of the floor below must always be assembled before installing the slab panels.

code XSEALSPACER5 / 10

The thermal analysis of the X-RAD system is carried out in order to quantify and verify the thermal bridge associable with the single-point element so that it can be used in the calculation of the building’s thermal performance. The most unfavourable conditions on which to concentrate the study and the verification are the attachment to the ground of the BASE G element near to the corner (A) and the node of the wall and roof slab attachment, TOP G (B)

The study is carried out using a FEM - 3D model and the calculation software Psi-Therm 3D. An overview of the study with some of the results is provided below.

To obtain the report of the complete study and further information contact the Rothoblaas Technical O ffice.

The stratigraphy of reference considered represents a possible standard situation which we can find in current building practice. The 3D simulation of the thermal bridge is done with X-RAD in the configuration without X-SEAL and with X-SEAL. In the image (fg. 1) we can observe the construction package and the materials considered. The choice of specific materials makes it possible to contextualise the checks and does not exclude the use of different products. Reference can be made to the complete test report to assess the different executive choices.

8.

9.

The thermal simulations are conducted varying the thicknesses of the insulation (12 cm, 16 cm and 24 cm), trying to identify possible values that would also roughly identify possible energy classes and the related performance. The simulations are carried out in 3 different climatic contexts that reflect the most frequent weather conditions in the northern and southern temperate zones, referring to a minimum average temperature of the coldest month (Te).

1. 10 cm CLT

2. 5 cm wood-fibre insulation

3. Plasterboard

4. Wood floor

5. Concrete screed

fig. 1

6. XPS extruded polystyrene 12 cm

7. 12 cm wood-fibre insulation

Concrete

Ground

The analysis provided various data and information, including isotherms, the Χ (Chi) value and the fRsi value.

Χ (Chi) represents the additional thermal flow of the three-dimensional thermal bridge with respect to the transmittance of the construction elements involved and two-dimensional thermal bridges of the attachments between them. The value is universal and independent of the climate data, but is affected by the insulation of the construction elements (see final report available at Rothoblaas Technical O ffice).

Reference Standard: EN 10211 fRsi represents the universal instrument for calculating the internal surface temperature (Tsi) in any place. While the fRsi is universal for calculated node, the internal surface temperature depends on the external climate. Using the Tsimin the danger of mould and condensation is assessed.

Reference Standard: EN 13788

NODE 1: GROUND ANCHORING

Node 1 thermal fow: Chi value

Node 1 mould danger: Tsi

NODE 1: SLAB-ROOF ATTACHMENT

Node 1 thermal fow: Chi value

Node 1 mould danger: Tsi

ACOUSTIC PERFORMANCE

With X-RAD the structural nodes are concentrated in single and distinct points. As regards the acoustics a targeted and calibrated study was carried out within the Flanksound Project on this new building concept in order to achieve the acoustic characterisation of the structural nodes created with X-RAD.

Rothoblaas has therefore supported research aimed at measuring the vibration reduction index Kij for a variety of joints between the CLT panels, with the dual objective of providing experimental data specific to acoustic design of buildings in CLT and contributing to development of the calculation methods.

Vibration reduction index measurements were performed in accordance with EN ISO 10848. For more information and details on the design and measurement methods, see “Catalogues / Soundproofing“ section in www.rothoblaas.com website.

X-SEAL avoids direct acoustic transmission through the air caused by the “emptying” of the mass of the node due to the 45° cut on the CLT panel.

SUMMARY OF THE CONFIGURATIONS TESTED WITHIN THE FLANKSOUND PROJECT

KEY

Data estimated from the experimental measurements

FOR MORE INFORMATION

A. Speranza, L. Barbaresi, F. Morandi, “Experimental analysis of fanking transmission of diferent connection systems for CLT panels“ in Proceedings of the World Conference on Timber Engineering 2016, Vienna, August 2016.

L. Barbaresi, F. Morandi, M. Garai, A. Speranza, “Experimental measurements of fanking transmission in CLT structures“ in Proceedings of the International Congress on Acoustics 2016, Buenos Aires, September 2016.

L. Barbaresi, F. Morandi, M. Garai, A. Speranza, “Experimental analysis of fanking transmission in CLT structures“ of Meetings on Acoustics (POMA), a serial publication of the Acoustical Society of America - POMA-D-17-00015.

ATTENTION TO DETAIL

Thanks to the precise location of the structural nodes at the tops of the CLT walls, X-RAD enables the non-interposition of the slabs between the walls. This entails significant benefits from the acoustic point of view, which increase with the adoption of specific profiles, providing the spaces shown in fig. 1.

mm spaces

I t is always advisable to have an interposition between the walls and slabs for the following acoustic profiles: resilient acoustic profles in PUR: XYLOFON (fig. 1)

Hermetic closure of the attachment between the structural elements and damping of the sound vibrations irrespective of the static or dynamic load applied, maintaining great elasticity and performance over time. resilient acoustic profles in EPDM: ALADIN STRIPE (fig. 1)

Hermetic closure of the attachment between the structural elements and damping of the acoustic vibrations between slab and wall. The resilient layer created dampens the sound wave otherwise transmitted by the structure vertically and horizontally. All these materials must be provided for at the stage of designing and cutting the panels.

XYLOFON

ALADIN STRIPE

5 mm spaces

XYLOFON

XYLOFON / ALADIN STRIPE 1

WALL - WALL JOINTS

DETAIL 45 | VERTICAL T JOINT

FASTENING SYSTEM

X PLATE BASE T, X-PLATE TOP T

RESILIENT PROFILE no

DETAIL 46 | VERTICAL X JOINT

FASTENING SYSTEM

X PLATE BASE X, X-PLATE TOP X

RESILIENT PROFILE

WALL - CEILING JOINTS

DETAIL 47 | HORIZONTAL L JOINT

FASTENING SYSTEM X PLATE BASE O

RESILIENT PROFILE no

DETAIL 48 | HORIZONTAL L JOINT

FASTENING SYSTEM X PLATE BASE O

RESILIENT PROFILE XYLOFON*, ALADIN STRIPE**

DETAIL 49 | HORIZONTAL T JOINT

DETAIL 50 | HORIZONTAL T JOINT WALL - CEILING JOINTS FASTENING SYSTEM

FASTENING SYSTEM X PLATE BASE O, X PLATE MID O RESILIENT PROFILE

WALL - CEILING JOINTS

DETAIL 51 | HORIZONTAL X JOINT

FASTENING SYSTEM

PLATE BASE O, X PLATE MID O

RESILIENT PROFILE no

DETAIL 52 | HORIZONTAL X JOINT

SYSTEM

PROFILE

The X-RAD system involves positioning the structural connection, consisting of X- ONE and X-PLATE, on the wall axis. This allows the perfectly pre-shaped components of the X-SEAL system to adhere to the metal components of the connection, thereby ensuring hermetic and thermal-acoustic insulation. In order to understand the fire performance of this system and to verify the degree of fire protection offered by the X-SEAL components to the X-RAD system, a research programme is underway at the Università Tecnica di Monaco (TUM)

A mid-floor MI node was studied at this stage, complete with X- ONE, X-PLATE and X-SEAL and its acrylic belt sealing, assembled inside a 5-layer CLT panel. Two different types of specimens were tested:

structural wall with X-RAD system without any coating on the fire side (A)

structural wall with X-RAD system covered with type A coated gypsum plasterboard according to DIN EN520 assembled as backing (B)

To monitor evolution of the temperatures during the test, thermocouples were installed on: outer surface of MI central plate side and upper surface of X- ONE head of VGS screws on X- ONE connector outer head of the bolts on X- ONE connector LVL insert head surface of X- ONE connector

The test was conducted in compliance with the European standard EN 1363-1, which specifies the main principles for determining the fire resistance of various elements of construction when subjected to standard fire exposure conditions.

In this regard it may be useful to recall the decline of the mechanical properties of steel as the temperature increases, as described by Eurocode EN 1993:1-2. Note the significant reduction in yield stress, in elastic modulus and in the proportionality limit, when above 400°C. When 500°C have been reached, the yield stress is reduced by 20% and the elastic modulus by 40%. This temperature value is considered as the reference value during the test.

Layout of the thermocouples on the surfaces of the samples

Assembly of the X-SEAL components

Layout of the thermocouples on X-ONE and X-PLATE

Evolution of the average temperatures recorded in the sample (B) coated (side exposed to fre)

X-PLATE F (3/5)

X-ONE BASESCREW FA (8/10)

X-PLATE FA (2/4/6) X-ONE X PLATE (11/12/13/14)

X-ONE BASESCREW F (7/9)

X-ONE CRACK (17/18)

Evolution of the average temperatures recorded in the sample (A) not coated (side exposed to fre)

The analysis of the results highlights how all of the components in the X-RAD system maintain a T° lower than 500°C for more than 60 min, thus showing excellent fire performance, thanks to the protection offered by the X-SEAL system and by the coated gypsum plasterboard

X-PLATE F (1/3/5) X-ONE BASESCREW FA (8/10)

X-PLATE FA (2/4/6)

X-ONE X PLATE (11/12/13/14)

Evolution of the average temperatures recorded in the sample (A) not coated (side not exposed to fre)

X-ONE BASESCREW F (7/9)

X-ONE CRACK (17/18)

The analysis of the results highlights how most of the components in the X-RAD system (except for the most outer parts of X- ONE) maintain a T° lower than 500°C for at least 30 min, nevertheless showing good fire performance, thanks to the protection offered by the X-SEAL system

Fire performance of the X-RAD system in the test chamber (sample A not coated)

Note the significant difference in T° recorded at t = 60 min between the side exposed to fire (T° ≈ 600°C) and the side not exposed (T° ≈ 80°C)

Packaged quantities may vary. No liability is assumed for printing, technical data and translation errors.

Pictures partially completed with accessories not included. Images for illustration purposes only.

This catalogue is the exclusive property of Rotho Blaas srl and may not be copied, reproduced or published, in full or in part, without prior written consent. Any violation will be prosecuted according to law.

The values provided must be verified by the designer in charge.

All rights reserved.

Copyright © 2017 by rothoblaas