WORTH THE HYPE

Bold visuals, organic hues and fresh patterns transforming tiled floors

Creating Comfort

A collection designed to help families build a cozy sanctuary where they can play and relax.

FRESCO | MONUMENTAL

MARGUERITE | CRYSTAL COVE

AVALON | TRADITION

Photo courtesy Yianni Tong Photography

TAKING TILE TO THE NEXT LEVEL

TILE IS A VERSATILE, durable, water-resistant, easy to clean and stylish option for many areas in the home, from kitchens and bathrooms to laundry rooms and entryways. Its characteristics make it ideal for commercial applications, too, like public washrooms, lobbies and other high-traffic areas. Given this, much of this issue is devoted to the flooring option, with a particular focus on overarching trends and those specific to one of the most used rooms in the home. Other topics covered include mortar bed installations and how tile aligns with well-being standards.

First, Chris Maskell, CEO of the National Floor Covering Association (NFCA) of Canada, returns with his Contractor’s Corner column. The subject is timely: Humber River Health’s lawsuit claiming shoddy construction like uneven floors at the 2015-completed Humber River Hospital, putting patient safety at risk. Maskell delves into how the NFCA’s quality assurance program could have prevented the Toronto hospital’s flooring crisis.

Next is our regular Installation Matters column. Guest writer James Woelfel, a third-generation tile contractor and now industry consultant, uncovers the three main culprits of tile installation failures.

At the other end of this issue, licensed architect and sustainability expert Webly Bowles delves into how every segment of the flooring supply chain talks, what else, sustainability. Then, interior designer Katherine Stone highlights key flooring components of a condominium penthouse in midtown Toronto.

If you’d like to see a particular project featured in our Then & Now column, contact me at claret@mediaedge.ca.

PUBLISHER

Dan Gnocato dang@mediaedge.ca

EDITOR Clare Tattersall claret@mediaedge.ca

PRESIDENT Kevin Brown kevinb@mediaedge.ca

CIRCULATION circulation@mediaedge.ca

Published by

ART DIRECTOR

Annette Carlucci annettec@mediaedge.ca

GRAPHIC DESIGNER Thuy Huynh-Guinane roxyh@mediaedge.ca

PRODUCTION COORDINATOR Ines Louis Inesl@mediaedge.ca

Coverings is published four times annually — Spring, Summer, Fall and Winter — for Canada’s floor covering industry. Subscriptions are free to qualified participants in Canada’s floor covering industry. Subscribe at www.coveringscanada.ca. Readers from outside Canada may purchase subscriptions for $55 Cdn. For subscription inquiries, e-mail circulation@mediaedge.ca. Return undeliverable Canadian addresses to: Coverings 251 Consumers Road, Suite 1020, Toronto, Ontario M2J 4R3

MediaEdge Communications and Coverings disclaim any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect to the results of any action taken or not taken in reliance upon information in this publication. The opinions of the columnists and writers are their own and are in no way influenced by or representative of the opinions of Coverings or MediaEdge Communications.

Copyright 2025

Canada Post Canadian Publications Mail

Sales Product Agreement No. 40063056

ISSN 0834-3357

251 Consumers Road, Suite 1020, Toronto, Ontario M2J 4R3 © 2025 by MediaEdge Communications. All rights reserved.

Clare Tattersall

Cuisine et salle de bains Chervin : 30 ans dʼexistence

Cʼest en 1991 que Kevin Bauman a transformé sa passion pour le travail du bois en une entreprise dʼébénisterie personnalisée à Waterloo, en Ontario. Des décennies plus tard, Chervin Kitchen & Bath a étendu ses racines pour ...

Bonne fête du Canada La semaine dernière, nous avons publié notre numéro dʼété, et cette

Plus de 110 millions de vues en une semaine : Transformer Table

Une simple vidéo montrant lʼensemble innovant table à manger extensible et banc de Transformer Table prend le monde dʼassaut après avoir amassé 250M de vues sur ... Lire la suite

Job Vacancies Across Canada

Les employeurs de tous les secteurs au Canada ont cherché à combler près dʼun million de postes vacants au deuxième trimestre, soit le nombre trimestriel le plus élevé jamais enregistré. Les postes vacants ont augmenté ... Lire la suite Over Half of SMEs Still Making Less Than Normal Revenues

Avec la rentrée parlementaire, les deux tiers (66 %) des petites entreprises souhaitent que le gouvernement fédéral se concentre sur la réduction du fardeau fiscal ... Lire la suite

Office Furniture Market – Growth, Trends, Forecasts

Le marché canadien du mobilier de bureau devrait connaître une croissance de 4,2 % au cours de la période de prévision entre 2016 et 2026. Après une baisse graduelle ... Lire la suite

Une ballerine devenue ébéniste soutient les femmes de métier

Depuis son premier cours de danse à lʼâge de huit ans, Brandy Kawulka dit quʼelle était destinée à devenir une danseuse de ballet. Grâce à son engagement et à son ... Lire la suite

A $100-MILLION

LAWSUIT LESSON

How

NFCA’s quality assurance program could have prevented Humber River Hospital’s flooring crisis

By Chris Maskell

For the smooth operation of any facility, especially hospitals, you need flat, level, functional floors.

A lawsuit filed in Ontario’s Superior Court of Justice in April, by Humber River Health, alleges that flat, level floors were not delivered in the case of Humber River Hospital.

“Non-level floors make it difficult for staff to move equipment, supplies, food and patients on wheeled transportation devices,” says Humber River Health in the claim. “Often, wheeled carts have to be placed behind rubber stoppers to prevent the carts from sliding out of position.”

According to a CTV article, Humber River Health’s statement of claim also pointed out there is “bubbling and tearing of the rubber flooring in nearly every area of the hospital, including the emergency department, birthing unit and patient recovery rooms.”

Uneven, bubbling and deteriorating floors is not a good start for a brandnew facility. Unfortunately, the flooring issues described in this lawsuit are too common and repeat across the country.

FAR FROM THE EXCEPTION

Every day, Canadian projects face similar challenges to deliver acceptable dry and flat concrete surfaces that meet the floor covering trades’ requirements.

Connecting the work results of the trades involved does not ‘just happen.’

The National Floor Covering Association (NFCA) of Canada’s quality assurance program (QAP) helps close this divide.

For example, the concrete (forming, placing and finishing) trade is directly related to the flooring trade, but are at opposite ends of the construction schedule — months, sometimes years apart. Subsequently, they rarely meet to discuss aligning work results.

Minimum industry standards published in NFCA’s Floor Covering Reference Manual — a standard specification that should be in all Canadian projects — state, “All substrate surfaces to receive resilient flooring shall be flat to a tolerance of three-sixteenth inch within a 10-foot radius (4.8 millimetres within a three-metre radius), or in accordance with the flooring manufacturer’s installation requirements. All concrete surfaces scheduled for flooring shall be tested and confirmed ‘thoroughly dry’ per adhesive and flooring manufacturer’s requirements.”

While many architectural specifications already state this, we continue to have problems.

So, what’s so different about NFCA’s specification?

NFCA’s specification states who will be responsible to perform what work — a key requirement when aligning the trades and having the right people carry the right budget to pay the right people to produce the right results. No arguing. No delays. No cost overruns. No lawsuits.

Take moisture testing as a typical example. With no clear assignment of who willtakethetests,shortcutsareoftenthedefaultorworse,notestingatall.

The result: Adhesive bond failure and bubbles in the finished flooring. Not an easy fix.

National Floor Covering Association of Canada inspector checks that concrete flatness meets floor industry standards.

CORRECT ARCHITECTURAL SPECIFICATIONS

Architectural specifications with ambiguous language on the subjects of testing and flat concrete surfaces have in many cases been rubber stamped from project to project across the country. These should be replaced with up-to-date, accurate flooring specifications placed in the correct architectural divisions.

NFCA offers a specification guide for resilient flooring on its website that can be downloaded free of charge by consultant/specification writers.

The next challenge is getting it read, as the best specification in the world is useless if not read, understood, believed and followed.

This is where NFCA’s QAP makes a big difference. A NFCA assigned, independent inspector gives a voice to the architectural specifications, represents everyone involved equally with timely facts, the truth and the right way to proceed, so the result is a win-win all round.

WHAT’S RIGHT, NOT WHO’S RIGHT

The erosion of trust between construction parties is a common occurrence that causes a new build to head off the rails. Once control is lost, it’s very hard to re-establish because trades are now colliding, workers become frustrated, workmanship suffers, costs increase, invoices go unpaid, relationships break down and delays become reality.

In such cases, a third-party, independent expert is a valuable resource to proactively avoid problems from developing and help bring progress back online should control be lost.

QUALITY DOES NOT JUST HAPPEN

There are three critical pieces to the QAP: early detection to substrate issues; monitoringinstallerexpertise;andcontinuous,independentoversight.

It is alleged that uneven concrete slabs were a prime cause of the floor failures at Humber River Hospital. QAP’s pre-installation inspections include reviewing slab flatness and levelness requirements, how to survey, measure and deliver acceptable results, and who is responsible for what task.

The lawsuit cites “faulty work by contractors and subcontractors,” according to the GTA Chronicle. Under QAP, installers have to meet NFCA’s trade qualification standards and there is real-time monitoring of workmanship.

In public-private partnership (P3) projects like Humber River Hospital, private consortiums juggle complex situations. The consistent presence of a third-party inspector — neutral, aligned with defined installation standards and present to help all involved equally — would have hindered shortcuts, provided authoritative feedback at each stage and facilitated immediate responsive actions.

A WAY FORWARD

Ontario should learn from Humber River Health’s litigation with urgency. For future hospitals designed to meet 21st century expectations, we must build tomorrow’s infrastructure with the assurance that quality will be delivered. IncludingNFCA’sQAPinnewhospitalconstructioncandramaticallyreduce theriskoffailedflooring,protectpatientsandcaregiversfromrepairworkand facility downtime, and safeguard the bottom line, saving public dollars.

Chris Maskell is CEO of the National Floor Covering Association (NFCA) of Canada. Chris has worked in the floor covering industry for more than 30 years. During this time, he has been a flooring contractor, manufacturer’s representative and business owner. As CEO of NFCA, he works with the board of directors to promote NFCA standards and updated specifications for commercial floor covering installations. He also operates NFCA’s quality assurance program, a specifiable third-party inspection review service for commercial projects, and is a certified floor covering inspector.

DELIVERING QUALITY IN CONSTRUCTION

Here are five reasons why provincial ministries and their health authorities should embed the National Floor Covering Association’s quality assurance program (QAP) into new hospital builds.

Safeguards patient and worker safety. Uneven floors pose tripping hazards, prevent smooth operation of rolling loads, such as IV carts, hospital beds, instruments and catering trollies, and cause uneven wear and tear from janitorial machines skimming the high spots and missing the low ones. The QAP’s structured oversight avoids these faults before they arise.

Reduces life cycle costs. The fee for the QAP is less than 1.5 per cent of the flooring contract price (on larger projects) — a small amount compared to the staggering costs of legal claims, repeated repairs and facility downtime. In the long-run, prevention and providing higher quality results are demonstrably cheaper.

Enhances accountability within public-private partnership (P3) models. P3s often diffuse responsibility. Embedding a neutral quality assurance arm ensures accountability operates independently of the financial incentives of builders or operators.

Provides insurance via maintenance bonds. When contractors back their work with a two-year, 100 per cent maintenance bond, hospital operators have that extra comfort. They can depend on contractors to remedy floor issues, rather than resorting to litigation or ad hoc piecemeal fixes.

Aligns with building standards and education. Ontario’s healthcare infrastructure is aging and failing in many places. The QAP fosters broader education for all involved — project managers (builder and owner), consultants/architects and installers. The resulting action will quickly sync with provincial efforts to provide updated, modern facilities, delivered on time and on budget with warranties intact, as they should be.

CRIME STOPPER

Unravelling the mystery of tile installation failures

By James Woelfel

As someone who spends the majority of my waking hours investigating why a tile and/or stone project is not performing as designed and expected, I’ve come to think of each failure as a crime. Put simply, a tile or stone crime is an action or activity that, although not illegal, is shameful and wrong, violating both industry standards and best practices.

Crimes I see most often are the installer does not know how to properly install all components in the tile installation system, including the tile; the design professional fails to properly specify the correct installation system and tiles for the intended use of the application; the manufacturer or distributor does not understand or know the capabilities of the tiles being sold for specific installations.

While no one is going to jail, these crimes are not without victims because someone is always injured by the causative irresponsible actions. And while I don’t call the perpetrators criminals, they’re in need of corrective action.

THE QUESTIONABLE INSTALLER

The most common reason for tile failures is installation errors. I liken this problem to pre-meditation in a crime. The installer knew going into the installation that they had no idea what they were doing.

When investigating a failure, I ask the installer if they know the proper industry standards for the installation or if the installers followed the tile or tile installation system manufacturer’s instructions. Most of the time the installer says they did not read the manufacturer’s instructions or they did not know the installation standards.

Case in point: I recently finished an inspection for a project in Phoenix, where the architect stopped the installation because it did not look right. When I arrived on-site, two-thirds of the floor tiles were installed. It was a disaster. Grout joints varied in width from one-eighth inch to one inch. Tile mortar was used to flatten the installation. The waterproofing membrane, per the manufacturer, is not allowed to be installed in an exterior condition. This was a true tile crime.

THE DUBIOUS DESIGN PROFESSIONAL

I also recently completed a cement terrazzo inspection due to broken corners and deforming tiles. I observed multiple cracking grout joints in the installation. When tiles were removed for inspection, water was standing below the crack isolation membrane. The water was also dissolving the primer used to install the membrane. The cement tiles were deforming. When reviewing the plans and specifications for the project, the design professional failed to call out movement joints as required by the Tile Council of North America’s (TCNA) method EJ171. I asked the installers if they brought this to the attention of the design professional. They told me they had and that the design professional said movement joints were not needed. It was my determination that the cracking grout joints allowed water from the ride-on cleaning machine to penetrate the tile installation system all the way down under the crack isolation system. This enabled the membrane to fail and allowed water to be absorbed into the cement tiles, deforming them. When removing tiles not exhibiting cracked grout joints, multiple chisels were bent due to the tenacious bond of the tile to the mortar. This was a crime characterized as commission by omission.

THE MANUFACTURER OR DISTRIBUTOR AS SUSPECT

As a commercial tile contractor, there have been countless times I have reviewed the specification for the tile product and said, “That tile is a bad idea for that application.”

One project involved the installation of glass mosaic tiles in stainless steel pools. The glass mosaics specified were mesh-backed. We wrote several requests for information to the general contractor and architect, but we were turned down every time. A year after the completion of the installation, the tiles started to de-bond from the pools. All tiles were installed with the highest performing epoxy mortar and grouted with epoxy grout. However, the adhesive used to hold the glass mosaics to the mesh failed. The tiles were removed and all the mesh was properly embedded into the epoxy adhesive. When tested by a certified International Organization for Standardization laboratory, the adhesive, per the testing results, was similar in composition to Elmer’s glue. The design professional had read the product data of the material that stated the tiles were recommended for submerged applications. The manufacturer of the tile did not know or understand the capabilities of the mesh-backed mosaic tiles they were manufacturing and selling. This tile crime is likened to fraud.

When tested by a certified International Organization for Standardization laboratory, the adhesive, per the testing results, was similar in composition to Elmer’s glue.

REDUCING RECIDIVISM

All three of these tile failures should not have occurred. Installers must know the tile installation standards and follow the tile manufacturer and tile installation system manufacturer’s instructions. These instructions are recognized as more important than American National Standards Institute standards and TCNA methods. Ignoring manufacturer instructions, which often cite standards, can and will cause failure, and the brunt of the cost to repair or replace the installation will fall on the installation contractor.

Design professionals must also follow tile installation industry standards, especially in designing movement joint placement. From experience, most installation failures are caused by a lack of required movement joint placement. Countless times I have heard the architect say, “Movement joints are ugly” and “I don’t want the pattern interrupted.” Movement joints are required and necessary in tile work. Design professionals must do a better job in designing movement joint placement.

I fully understand manufacturers and distributors sell tiles. However, both the manufacturer and distributor must know their products need to perform, especially in the applications they recommend.

If you look at the consumption of tile in the North American market, the total is falling, especially in the last two years. Granted, there are other competing products, which explains some of the concern, but too many times I have heard an owner, after a ceramic tile installation failure, proclaim, “I am never using tile again.”

That is a tile crime for which the entire industry pays the price.

James Woelfel is principal at J.G. Woelfel & Associates, a tile and stone consulting firm in Mesa, Ariz. An experienced tile consultant and expert witness, James performs tile inspections, installation oversight, and preconstruction consultation and review throughout North America after nearly four decades in the tile installation business. He is chair of the National Tile Contractors Association’s (TCNA) technical committee, a voting member of the TCNA handbook committee, and a voting member of the American National Standards Institute’s 108, 118, 136 committee. James can be reached at tileconsultant@jgwoelfel.com.

Eight tile trends reshaping spaces IDEAS TO INSPIRE

By Clare Tattersall

Tile trends are always a hot topic, regardless of time of year. Knowing the colours, shapes and designs that will dominate for the foreseeable future is ideal to helping consumers who are looking to remodel or revamp various rooms in their home.

This year’s selection by tile industry experts, displayed at Coverings 2025, presents a dynamic blend of timeless craftsmanship and groundbreaking innovation, highlighting the enduring appeal and sustainability of tile in a wide range of applications.

COLOURS OF SAND

The world is known for rich colours and calming hues of sand on and near beaches, dunes, deserts, ocean floors and other places. With a warm and often calming palette, the colours of

sand are earnest and neutral, portraying the essence of a natural, earthy and eco-friendly environment. So, too, does tile in the colours of sand give rise to peaceful, relaxing and eye-catching atmospheres. Sand-inspired tile stem from the colour wheel’s warmer and lighter side of the brown spectrum, extending from off-white and cream to golden beige, tawny, fulvous and tan.

LINES, LINES, LINES

Thanks to impressive innovations in 3-D technologies, lines — whether it be striped, ribbed or fluted looks — create dynamic volumes and plays of light and shadow with contrasting materials and colours, adding depth and character into a space, while geometric patterns and bold stripes bring moments of movement and intrigue.

MINERAL DRENCHNG

Colour drenching takes a bold turn with the use of gauged porcelain panels. Enveloping entire spaces in the rich tones and textures seen in marble, onyx or travertine creates a seamless and dramatic effect. From floors and walls to countertops and even furniture, the natural beauty and texture of marble-look tile — be it a bold black, grounding green or luminous white — become the dominant visual elements, transforming the space into an immersiveworkofart,asluxuriousasitisgrounding.

MOSAIC ARTISTRY

Mosaic tiles have long combined beauty and functionality, allowing designers to create personalized patterns and artistic statements. Today, mosaics are having a big (or rather, large-format) resurgence. Porcelain panels

Ivory-toned porcelain tile from Landmark Ceramics’ Trail collection mimics the look of travertine.

with stone-looks artfully cut together, either in geometric layouts or flowing organic designs, merge traditional mosaic artistry with modern durability and low maintenance. Whether handcrafted or large-format, mosaic styles continue to transform surfaces large and small into captivating focal points.

RE-HUMAN

In an age dominated by AI and algorithms, there is a revived longing for the tactile, human experience. As such, tile surfaces are increasingly drawing inspiration from materials like corrugated paper, torn fabric, textile design and handcrafted wooden textures, while showcasing delicate floral engravings and 3-D extruded volumes, working to powerfully bridge the gap between high-tech and handmade artistry.

SENSORIAL DESIGN

Interior designers are going beyond the visual spectrum to curate spaces that engage all five senses. Thanks to advancements in digital decorative technology, ceramic manufacturers are now able to perfectly replicate natural textures and patterns, creating tiles with enhanced tactile and visual experiences. Furthermore, many designers are paying closer attention to the sense of smell. As ceramic tiles are naturally free of volatile organic compounds, they do not retain odours; rather, they assist with establishing an aromatically-pleasing and clean environment.

VEINS OF GOLD

The opulence of marble-look tile is elevated

to brilliant new heights with a touch of gold. Creamy stone looks, accentuated by rich golden veining, radiate warmth and grandeur, bringing a touch of luxury to any setting. Innovative glaze applications allow for metallic variations that reflect just enough light to strike the balance between dazzling and demure.

WATER WORLD

Water spurs major inspiration across contemporary ceramic design, flooding the scene with colour palettes of soft aqua and pastels to deep sea, ethereal hues. Patterns, textures and fluid, smooth forms reminiscent of sea waves are brought to life through 3-D reliefs, traditional brushstrokes, masterful glazing techniques and distinct shading effects.

\\ TOP: Anthology’s Calypso collection in Bali pairs warm beige hues with cool teal accents (left). Etherea by Ceramiche Refin (right). Light haloing and subtle fossil traces lie on the dense background, maintaining the homogeneous appearance without colour contrasts, conveying a sense of purity. BOTTOM: Appiani’s Eden collection of ceramic mosaic tiles of hexagonal geometry (left). Sculpture Gold by Wonder Porcelain (right). Inspired by natural marble, the tile series features a rich golden hue with bold and intricate veining.

PREMIUM MORTAR SYSTEMS

POLYMER-MODIFIED MORTARS

LARGE-FORMAT TILE MORTARS

Innovation Meets Installation.

We understand that offering quality products is not nearly enough. You need a partner who will stand by you, before, during, and after the sale to help you achieve success. A partner with an experienced technical support team that helps every project go smoothly, and who helps protect your good reputation by offering the quality, personal service and support you need.

THE RIGHT PRODUCTS

Every installation has unique needs, which is why PROMA offers one of the widest selections of quality setting materials available. Installing in a high-traffic or exterior environment under a tight deadline? PROMA provides the high-strength, rapid-curing PRO QUICK PLUS SYSTEM. Do you need an easy-to-use, one-step setting material that combines the extreme performance and superior strength of a two-part system? PRO HPX does exactly that and is truly revolutionizing the industry. Are you installing moisture-sensitive stone, such as green marble? PROMA offers compatible setting materials for this –PRO GROUT XTREME and PRO SEAL & SET 100 NS.

INNOVATIVE SOLUTIONS

Always proactive, always listening, always moving forward. PROMA’s research and development team works closely with our customers and with the world’s top raw materials suppliers. This synergy allows PROMA to develop new and innovative products that excel beyond current industry standards and enables us to bring tomorrow’s technology to today’s products.

SUPERIOR QUALITY

PROMA offers one of the broadest array of products available so you can choose the right solution for any given job. Our products have been engineered to provide user-friendly, time-saving jobsite characteristics and exceptional, long-lasting performance through strength, flexibility and durability.

ECOLOGICAL AND RESPONSIBLE

Many of PROMA’s products have been formulated to have minimal impact on the environment, are safe to apply, and do not contribute to unfavorable jobsite conditions or adversely affect indoor air quality. Some also help contribute toward attaining credit requirements within the LEED® (Leadership in Environmental and Energy Design) USGBC and CAGBC Rating Systems, and WELL® (International WELL Building Institute) certification program. Products have achieved independent validation by the renowned environmental auditor Vertima.

TILE STYLE

Bathroom products to bet on for 2025 and beyond

By Isabel Fernandez

Bathrooms are among the most important rooms in a home, serving as both functional spaces and personal sanctuaries. The use of tile is a great way to set the mood and tone in this frequently used room, so staying on top of what’s ‘in’ is paramount. This year brings an array of exciting options that promise to elevate any lavatory.

BLACK AND WHITE

Black and white tiles have remained a classic and timeless choice in the interior world. From checkerboard flooring to geometric designs, the monochromatic palette creates a sense of balance and suits various styles, from retro to vintage to modern.

HERRINGBONE BRICK

Herringbone brick tile is ideal for recreating the perfect rustic country look. The slim brick tile helps give the illusion of space and adds a decorative feel whilst keeping with neutral shades. The herringbone style is a popular laying pattern that can be achieved with most tiles, so long as the width is half or less than the length.

KIT KAT

Kit kat is a style of tile that, as the name suggests, resembles the popular chocolate bar, featuring small, rectangular tiles arranged in a grid pattern. These mosaic finger tiles are admired for their streamlined linear appearance, working with contemporary bathrooms.

MOCHA MOUSSE

For consumers looking to incorporate colour into their bathroom, earth tone tiles reminiscent of Pantone’s colour of the year are the way to go. Mocha Mousse is a warming, brown hue imbued with richness. It nurtures with its suggestion of the delectable qualities of chocolate and coffee, answering consumers’ desire for comfort.

\\ LEFT TO RIGHT: Alba patterned ceramic tile in monochrome black and white, with flecking details and subtle marking to the base tone for a slightly imperfect look. Tuscany tumbled herringbone brick tile features subtle tonal variation as well as rich fossilization. OPPOSITE PAGE: Pamplona Blanco patterned porcelain tile takes inspiration from the famous Italian ‘Majolica’ tiles, traditionally designed and hand-painted by artisanal craftsmen. All photos courtesy Quorn Stone.

PATTERN AND TEXTURE

Patterned tile comes in a range of styles, from vintage-inspired floral motifs and bold geometric shapes to classic Moroccan. Beyond its aesthetic appeal, porcelain and ceramic patterned tile is a practical choice for a high-moisture environment like the bathroom.

Textured tile is having a heyday with the move in interiors toward tactile surfaces and finishes. The range of finishes, 3-D technology and unique surfaces offers an array of textures.

REAL AND FAUX MARBLE

Marble has been used for centuries and is once again having a moment. Known for being a dense and a hard-wearing material, the natural stone is

available in a variety of colours with unique patterning and details. Whether a classic white marble like Bianco Carrara, or Riviera Emerald, a rich green with intricate white and grey veining, marble tile elevates any scheme, adding a timeless elegance.

Marble-look porcelain tile has been a popular alternative to real marble for a number of years, with the realistic print, wide array of available designs, ease of maintenance and lower price point. With advancements in technology, it has become increasingly more difficult to distin-

guish between faux marble and the real thing.

ZELLIGE

Zellige is artisanal, enamel-coated tile crafted in Morocco, with a rich glaze, unique texture and beautiful variation of pigments. Reminiscent of original Moroccan tile, many Zellige-style tiles are now made from porcelain and ceramic, resulting in a very strong tile that is easier to install and maintain. The diversity in tone, glaze, depth and shades has seen the popularity and widespread appeal of Zellige grow in recent years.

Isabel Fernandez is the marketing director at Quorn Stone, a leading expert in the import and retail of natural stone and porcelain tiles. Established in 1995, the now second-generation family business has built its reputation on its high-quality stone flooring and exceptional customer service.

TRIED AND TRUE

Installing ceramic tile with old-fashioned mortar bed method

By Scott Conwell

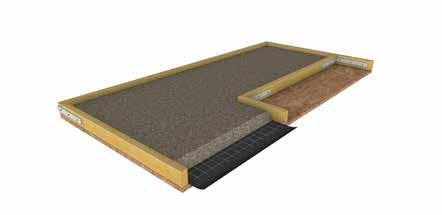

The classic method of laying tile in setting beds built up of sand, cement and sometimes wire reinforcement over the floor structure is a work technique that has declined in recent years as thinset mortars and installation methods have improved and become more prevalent. However, mortar bed techniques for installing tile will never disappear completely as they remain appropriate for certain types of applications, such as heavy-duty areas of use, cases where the variable thickness of the mortar (mud) bed is needed to correct an irregular substrate, and other instances where the design professional or building owner has a preference for this classic installation method. Design professionals and specification writers should therefore have a basic understanding of mud floors and require that the installing contractor meet minimum qualifications for this specialized type of work.

MUD WORK COMPONENTS

A cleavage membrane is a component often specified in mud work to provide a bond break in floor assemblies if differential movement is expected between the tile assembly and substrate. Cleavage membrane materials vary but they are often paper-based, delicate and easily damaged. A qualified tile installer will take care not to tear, puncture or otherwise damage the cleavage membrane during the installation process. If damage does occur, the installer should replace and reinstall the material.

Floors require minimum overlaps in the cleavage membrane, generally four inches or 100 millimetres. Failure to install the cleavage membrane to this criteria may result in ineffective bond break or moisture intrusion into the floor structure.

Reinforcement is a component that is gen-

erally required within mortar bed floors to impart flexural strength, control shrinkage of the mortar and prevent cracking. Proper installation of galvanized wire mesh reinforcement in mud floors is a critical skill that is within the work scope of tile installers.

In order to function properly, the reinforcement must be continuous, properly lapped by two inches minimum. The positioning of the reinforcement in mud floors is critical to the performance of the floor. If the reinforcement is too high or too low from the centre of the mortar bed, its ability to add flexural strength and adequately reinforce the system may be compromised. Skilled tile setters are expected to maintain the vertical position of the reinforcement in the centre one-third of the mortar bed.

While installation of the cleavage membrane and reinforcement are important, the primary task faced by installers of mud floors is to properly float the mortar beds flat, level and plumb, and to the specified thickness. A good tile installer is trained to float the mortar to the proper thickness at key benchmarks, and to vary the thickness as necessary to cor-

rect substrates that are not flat. Mud floors must be flat and level upon completion and ready to receive a tile finish.

INSTALLER QUALIFICATIONS

Installation of tile in a mortar bed may be considered a specialty skill today, but the ability to work with mud is a skill still taught at the pre-apprentice level by the International Masonry Institute (IMI). Proficiency in mud work is a hallmark of a tile contractor signatory with the International Union of Bricklayers and Allied Craftworkers (IUBAC). One way design professionals can be assured mud work meets industry standards and best practices is to include a requirement in the quality assurance paragraph in Sec. 1 of the tiling specification that states tile installers be certified via the Advanced Certifications for Tile Installers (ACT) program, developed by the Tile Council of North America and manufacturer members, Tile Contractors Association of America, IMI, IUBAC, National Tile Contractors Association and Ceramic Tile Education Foundation.

Scott Conwell is director of industry development and technical services at the International Masonry Institute(IMI). Scott leads IMI’s tile, marble and terrazzo industry development program and is the creator of its masonry detailing series, an online collection of construction details and technical information that sets the industry standard for architectural details on masonry, tile, stone and terrazzo. He is a registered architect and fellow of the American Institute of Architects and Construction Specifications Institute.

Wire reinforcement properly overlapped and suspended in mortar bed

Mortar bed flat and level, and thickness as specified

Cleavage membrane intact and properly overlapped

DESIGNING FOR WELL-BEING

Natural tile and stone help create healthier spaces, support wellness certification requirements

By Megan Mazzocco

The built environment profoundly shapes human health in ways the design industry is only beginning to fully understand. Recent research reveals that environmental factors, collectively known as exposome, account for 85 per cent of disease risk factors, while genetics contribute just 15 per cent. This striking disparity is driving a fundamental shift in how architects, designers and specifiers approach material selection, with natural tile and stone emerging as key components in creating wellness-focused spaces.

Spending the majority of time indoors — despite the fact that people are part of nature, not apart from it — leaves occupants at-risk of exposure to substances associated with the HVAC systems, plumbing/water, building materials and artificial lighting specified and installed in

the built environment. Specifying natural tile and stone can help mitigate some of that risk in several applications.

SCIENCE BEHIND WELLNESS DESIGN

Exposome was coined in 2005, to describe all environmental exposures throughout a person’s lifetime, including chemical exposures and external stressors that directly impact health outcomes. For the design community, this concept has profound implications for material specification and space planning.

“I’m beginning to see more and more connections between the environmental side and health side of things,” says environmentalist Holley Henderson, who is also founder and principal of sustainability collaborative H2 Ecodesign.

THE AIR BREATHED INDOORS

Perhaps no factor influences occupant health more directly than indoor air quality (IAQ). The average person breathes 11,000 to 15,000 litres of air daily. This staggering volume makes material emissions a critical consideration for designers.

“We actually ingest four times more air per day than food or water, and we spend 90 per cent of our time indoors, which typically has two to three times morepollutantsthanoutdoors,”saysHenderson.

Natural tile and stone offer significant advantages in this regard. Unlike synthetic materials produced through chemical processes, these materials typically emit fewer volatile organic compounds. Their low-emitting properties contribute to better IAQ, while their durability means they won’t break down and release particles over time.

TRANSPARENCY AND CONTROL

The American Society of Interior Designers’ (ASID) 2025 trends report highlights growing toxic awareness among design professionals and clients, with younger people demanding greater transparency about material composition and environmental impact. This shift aligns perfectly with tile and stone’s natural properties.

“Consumers and clients are much more aware of plastics and chemicals that we’re being exposed to, making tile and stone a healthier choice,” says Henderson.

Effective source control — the practice of selecting materials with minimal harmful emissions — represents the first line of defence in creating healthy interiors. Natural stone requires no chemical processing to achieve its final form, while ceramic tile undergoes controlled firing processes that eliminate most organic compounds.

THE CONNECTION TO NATURE

Research consistently demonstrates that exposure to nature reduces stress, improves mood and enhances cognitive function. The biophilic design movement leverages these findings by incorporating natural materials, patterns and forms into interior spaces.

“I use neuroaesthetics to motivate homeowners to use their home gyms; it is so important that natural light and light reflectance values support daylighting and circadian health alongside the natural patterns and sacred geometry of natural tile and stone that evoke biophilia in recovery spaces,” says Jana Donohoe, founder of Jana Donohoe Designs, about the new health-minded branch of her business that combines personal training, health coaching and design for well-being.

Tile and stone excel in this application, offering authentic connections to nature that synthetic alternatives cannot replicate. Each piece contains unique natural variations that engage the senses and create visual interest. As a flooring surface choice, natural tile and stone transitions seamlessly from outdoor to indoor settings, creating visual continuity and beckoning building occupants to engage more regularly with biophilic elements and the outdoors.

The economic benefits of biophilic design are equally compelling. Studies show incorporating natural elements can reduce stress-related healthcare costs, improve productivity and increase property values, making the business case for specifying natural materials.

SUSTAINABILITY MEETS WELLNESS

The intersection of sustainability and wellness represents a growing priority for design professionals. ASID’s trends report emphasizes that these concerns are “interrelated issues” requiring “complex variables” to meet sustainability needs while mitigating health risks.

“Designers are innovating to focus on the wellness of the occupants,” says Henderson. “There’s a Terrapin Bright Green study showing evidence that offices with tile and stone experience less absenteeism and higher graduation rates in K-12 education.”

Tile and stone address both priorities simultaneously. Natural stone is generally biodegradable and requires minimal processing, reducing its environmental footprint. Ceramic tile can incorporate recycled content and is increasingly manufactured using renewable energy sources. Both materials’ exceptional durability means longer service lives and reduced replacement cycles.

MATERIAL LONGEVITY

As the industry embraces circular economy principles,tileandstone’slongevitybecomesasignificant advantage. While synthetic materials may degrade and require replacement within decades, properly installednaturalstonecanlastcenturies.

“The marble ages with the family is a common saying in Italian,” says intrapersonal neuroscience and mindfulness expert Gianna Vallefuoco of Vallefuoco Contractors.

This longevity supports waste reduction goals while maintaining consistent performance characteristics. Unlike materials that may off-gas or deteriorate over time, tile and stone maintain their low-emission properties throughout their service life.

CLEANING FOR HEALTH

Effective cleaning protocols are essential for maintaining healthy indoor environments. The materials specified significantly impact cleaning effectiveness and occupant exposure to cleaning chemicals.

“Tile is great for high-touch surfaces,” says Henderson. “Routine cleaning keeps out the subtle dust that pollutants cling to.”

Tile and stone surfaces facilitate effective cleaning without requiring harsh chemicals. Their non-porous nature (when properly sealed) prevents moisture and contaminant absorption, while their smooth surfaces allow for thorough cleaning with minimal chemical intervention. This reduces occupant exposure to cleaning agents while maintaining hygienic conditions.

MECHANICAL SYSTEM INTEGRATION

While material selection plays a crucial role in indoor environmental quality, integration with mechanical systems amplifies these benefits. Proper ventilation and filtration work synergistically with low-emitting materials to create optimal indoor conditions.

“Working in conjunction with tile, look for a HEPA stand-alone indoor air purifier that has activated charcoal, which will clean at the rate of two-thirds of the room’s floor space in square feet per hour,” says Henderson.

The WELL Building Standard recommends specific ventilation rates and filtration requirements that complement careful material selection. When tile and stone are specified alongside high-performance HVAC systems, the combined effect significantly improves indoor environmental quality.

WELLNESS AS A STANDARD PRACTICE

The wellness design movement represents more than a passing trend — it reflects a fundamental understanding of how built environments impact human health. As certification programs like WELL, Fitwel and Living Building Challenge gain adoption, specifying materials that support wellness goals becomes essential for project success.

“Seventy-eight per cent of millennials see workplace quality as important, and 70 per cent of them would trade that well-being in their office design for salary,” says Henderson.

For tile and stone professionals, this shift presents significant opportunities. By understanding and communicating how natural materials support wellness objectives, industry professionals can position themselves as essential partners in creating healthier built environments.

Megan Mazzocco is a certified life and health coach, and certified in Yale University Science of Well-being, yoga and reiki. She is a Be Well Lead Well certified guide, and founder at Wellbeing X Design, a series of evidence-based frameworks to design life, work and sleep. As a high-performance coach for creatives, Megan leverages neuroscience, psychology and trauma-informed somatic coaching to help clients express their authentic selves unapologetically and thrive physically, emotionally, intellectually and spiritually.

TRACING THE THREAD

How every segment of the flooring supply chain talks sustainability

By Webly Bowles

Sustainability is not a trend in the flooring industry — it’s a business imperative with perennial momentum. From green building certification to local regulation to growing consumer demand for healthier and more responsible products, the flooring industry has been at the forefront of sustainability for decades. Yet despite shared goals, each segment of the supply chain speaks about sustainability differently. From retailers and wholesalers to installers, manufacturers, architects, interior designers and building owners, understanding each other’s sus-

tainability language is key to unlocking value across the entire ecosystem.

EDUCATORS AND INFLUENCERS

Retailers and wholesalers are on the front line of customer trust. Retailers bridge the gap between complex industry standards and everyday purchasing decisions while differentiating product offerings’ strengths directly to the customer. Manufacturer information and product labelling are their education, so sustainability must be easy to understand, clearly communicated and relevant to customer decision-making. Product

certifications like FloorScore and Greenguard, or third-party verified environmental product declarations (EPDs), are vital tools. But often, retailers and wholesalers’ discussions focus on health, durability and ease of maintenance.

To communicate with customers, clear product labelling and transparency, easily accessible health and safety data (low-volatile organic compound (VOC) products), and information about the value of eco-labels are important to retailers and wholesalers. Additionally, they appreciate manufacturer-supplied education and support to gain more insight into products.

When architects interact with wholesalers, they want to understand how the product was developed, not just the sustainable attributes.

“Lunch and learns are great but salespeople need to know the story of the product,” said Ashleigh Savage, an interior designer with SmithGroup, at this year’s Flooring Sustainability Summit. “There is a story that evolved to get to this bio-based flooring. The salesperson should tell the story, not just state that it’s biobased.”

Being on the front lines, answering consumer questions and reviewing procurement needs makes retailers an asset to manufacturers to dial in marketing and educational language.

INNOVATORS UNDER PRESSURE

For manufacturers, sustainability begins with sourcing and spans the entire product life cycle. Their conversations involve complex metrics like embodied carbon, recycled content, material health, end-of-life recyclability and circular economy strategies. They focus on life cycle assessment data, carbon and/or chemical disclosure, regulatory compliance standards and staying ahead of procurement trends.

The business case for developing sustainable products must be solid. Consistent standards across jurisdictions and rating systems like LEED and WELL ensure a predictable demand for sustainable products.

Manufacturers can lead by listening to the interests and needs of their largest purchasers and bring-

ingtheirsupplychainsalongthesustainabilityjourney to disclose all ingredients in a product. Designers appreciate that some product information is confidentialbutfulldisclosurebuildstrustwithdesigners.

“We understand (manufacturers) need an edge on proprietary ingredients, (but architects) want to understand what’s in the product,” said Joshua Rubin, technical design director at Perkins&Will, who was also a member of the summit’s architectural panel.

PERFORMANCE-FOCUSED

Flooring installers engage with sustainability through product performance, safety and waste. Their key concerns are how easy products are to install, whether adhesives and materials are safe to handle, and what happens to scraps and packaging. Installers may not talk about EPDs, but they are deeplyawareofdurability,wastediversionandcompliancewithjobsiteregulations.

When manufacturers offer installation training, installers join because it provides deeper insight into the product. Installers value low-VOC emission productsthatoff-gasfewerchemicalsduringinstallation, efficient installation methods (click-in-place systems and prefinished products), and take-back andrecyclingproductsthatreducewaste.Sincethe end-user interacts with their work, proper training from manufacturers limits call-backs and ensures clientsatisfaction.

SPECIFIERS WITH VISION

Architects and designers have been early adopters of sustainability, signing on to climate pledges like the American Institute of Architects’ 2030 Challenge and Materials Pledge. Sustainability is a creative constraint and a client value proposition. Their vocabulary includes EPDs, health product declarations, carbon footprints, green building certifications (LEED, Living Future, WELL) and circularity. They seek materials that are aesthetically compelling and aligned with performance and environmental criteria.

Architects are not standing by until their clients request sustainable products.

“Transparency is fundamental to accountability,” said Anica Landreneau, global director of sustainable design at HOK and Flooring Sustainability Summit speaker. “We’re not waiting for clients to opt into healthy materials. Healthy materials are baked into all of our projects.”

Architects value product transparency, documentation of products that contribute to green building rating systems, digital tools, specifications and direct engagement with manufacturers. When manufacturers collaborate to install sample flooring in their clients’ buildings, they can show the actual product value.

Flooring manufacturers can win loyalty by engaging design teams early, offering sustainability narratives that fit their aesthetic vision and telling a compelling story that resonates with the building owner. Installing a sample of the product for a large project proves the value of the flooring by seeing it in place.

“Let’s work together to get clients comfortable with new products,” said Landreneau. “We can do a mock-up in an existing building before buying one million square feet.”

COST-CONSCIOUS DECISION-MAKERS

Building owners and developers are increasingly integrating sustainability to meet environmental, social and governance goals, comply with regulations and reduce long-term operating costs. Their focus is on the return on investment and tenant satisfaction. They want to know how flooring will perform in the long-term and reduce risk, especially in institutional and commercial sectors.

Durable and long life cycle products are desirable to owners and developers. They also seek documentation that can support green building

reporting and products with an interesting story to highlight on building tours.

Katie Doyle Mesia, Gensler’s firm-wide design resilience leader and sustainability director, saw this firsthand.

“We want to understand the story behind your products — where the ingredients come from, how they’re put together and the journey they take before we ever see them. We want to know about the people creating them,” she said at the summit. “When we understand the process and the people, we can connect with your product more deeply and see how it supports the overall design concept. We can find materials in the right colour or style, but what really sets something apart is its story. Our clients want to be able to share that moment of connection when they walk employees, guests or customers through their spaces.”

Manufacturers who can bring a story to life in terms of cost savings, carbon impact and operational performance will be most effective in influencing owner decisions for sustainable flooring products.

SUSTAINABILITY A SHARED STORY

Theflooringindustryhasbeenleadinginsustainability since the popularization of green building rating systems. But leading well requires all stakeholders, including retailers, manufacturers, installers, designers and building owners, to listen and learn from one another. When each party understands how the others define, pursue and measure sustainability, the result is not just greener floors but a stronger, morerobustindustry.

By speaking a shared language, trust is established, innovation fostered and a sustainable marketplace created.

Webly Bowles is a licensed architect and sustainability director at WAP Sustainability, a full-service sustainability firm that supports clients in measuring, managing and reducing the environmental impacts of their products and operations through life cycle assessment, environmental product declarations, greenhouse gas reports and sustainability strategy development. WAP provides technical expertise and industry guidance to support regulatory compliance, transparency and market leadership in sustainability.

REGALLY REFINED

Hardwood flooring grounds grandiose penthouse in luxury condo development

By Katherine Stone

In the context of a new-build project, flooring is the structural language of the home, a primary gesture that anchors space long before furniture or decor enter the frame. In a penthouse on Toronto’s Avenue Road corridor, the floor was treated as both foundation and narrative device.

What began as a single penthouse purchase before the pandemic transformed mid-construction when the client was offered the opportunity to combine two top-floor units. The resulting home spans half the building’s upper level, with fully customized finishes and a floor plan tailored around light, flow and adaptability.

As a new build, there was no existing flooring to remove. The project offered a clean slate — a rare designer’s gift to compose an environment from the ground up.

At the heart of the design is custom-crafted herringbone flooring, laid perpendicular to the corridor’s axis. This unexpected orientation subtly interrupts the flow of the hallway and provides a quiet spatial pause, providing an intentional shift from linear circulation to thoughtful progression. It is flooring as orchestration, not surface.

Warm white oak was specified in public and transitional zones, namely the central corridor that serves as a connective spine and living, dining and kitchenareas,allinasoftmattefinish.Itsreflectionofnaturallightpreserves the balance between brightness and restraint, reinforcing the home’sarchitectonic rhythm. A circular ombré rug in the living space dissolves from black to tan, echoing the gradient between furnishing and architecture.

In the master suite, the palette remains but the flooring shape shifts beyond the threshold to wide planks oriented widthwise to foreshorten the visual from the corridor.

Installation posed its own choreography. The herringbone segment required precise calibration. Close collaboration with the flooring joiner ensured pattern breaks met at designed thresholds, particularly leading into the master bedroom entry. Temporary guides and overhead sightlines guaranteed spatial perfection.

Transition details were resolved through bespoke solid oak thresholds, book-matched to the grain, sitting flush to eliminate tripping risk and visually tethering the spaces. Flush transition was equally functional and ideal for city living, high traffic zones and future flexibility.

In a project driven by rhythm, movement and intention, the floor is design — not decor. The way floors are composed, detailed and materialized speaks to how the home is meant to be occupied. Here, each step is both instruction and invitation.

Katherine Stone is an interior designer at Kingston, Ont.-based Stone & Associates, an award-winning interior design and architectural studio with more than four decades of experience delivering highly personalized residential design. Known for its ability to balance tradition with modernity, the firm is guided by curiosity, practicality and intuition. Katherine can be reached at info@stoneandassociates.ca.

Photos courtesy Yianni Tong Photography

Lavish 49 oz/sy pile weight that whispers quality & luxury with every step.

Built-in stain resistance for beauty that lasts, even in busy households.

Certifications & best-in-class warranty that speaks confidence.

Some choose floor coverings. Others choose lasting impressions. For those who know the difference, there’s Beaulieu… and the Tryesse Couture collection.

The revolutionary ColorPoint technology allows for extraordinary patterns and precision in a durable product.

Audace - J1801 Tartan - J1802

Artsy - J1803