*U.S. and Canada only

*U.S. and Canada only

Reinke continues to forge ahead with solutions to exceed expectations for growers worldwide. Dedication and perseverance pushes Reinke beyond what is expected.

The Electrogator® was introduced in 1968 as the first reversible, electric drive center pivot with an under-truss design. The use of high-strength steel was introduced, creating a stronger system while weighing less.

The Electrogator 2 features an enhanced tower and span design. With its exclusive single-leg tower, the E2 is sleek and unobtrusive, reducing crop loss as it moves through the field. It has a wider tower base for increased stability. Growers can expand coverage of their irrigated acres with the Swing Arm Corner system. Together with the Touch Screen control panel and variable rate irrigation, precise amounts of water can be applied.

The Electrogator 3 (E3™) is changing the expectations of irrigation. It is ideal for growers seeking to maximize efficiency and yield. Uniform Coupler Spacing provides a consistent application rate from the first coupler to the last. With the ReinLock™ Trussing System, the patented technology increases strength and rigidity. There is no comparison with Reinke’s hook and receiver joint. It is a multi-directional pivot flex joint, which creates greater precision movement between the spans.

Growers are able to get the most out of their irrigation systems. Precision, efficiency and cost effectiveness are key to achieving peak performance. Unlock new possibilities! Discover Beyond the Possible with Reinke.

The industry’s exclusive maintenance-free bearing.

*Patented design

Providing superior span support with strength and rigidity.

*Patented design

A multi-directional pivot flex joint which is an industry exclusive.

The unique and Reinke exclusive tower design reduces crop loss, as it moves through the field.

The seal is a Reinke exclusive with an industryleading warranty.

*Patented design

Ensuring consistent application rate from the first coupler to the last.

*Patent pending design

The world's first precision series of center pivot irrigation systems, and the ultimate game-changer for growers who demand the very best.

The E3 is a revolutionary system presenting groundbreaking advancements in water management technology. It is the optimal solution for growers looking to enhance efficiency and maximize yield.

The open-frame design allows for easy access to the main control panel, and is easily retrofitted to all irrigation systems.

\ MAINTENANCE-FREE BEARING is a patented industry exclusive, transforming the way rotational machine movement operates. It also provides superior holding strength and long-lasting performance.

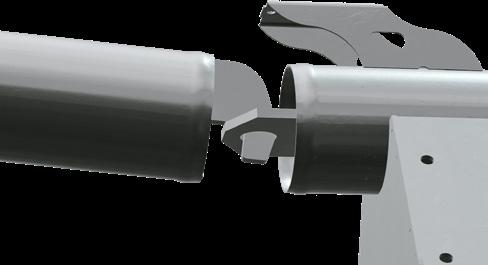

\ HOOK & RECEIVER JOINT is a high-performing flex joint for any terrain, providing greater freedom across 3 axes. There is no comparison with Reinke's hook and receiver joint.

Experience a revolution in irrigation with the all new, redesigned E3 spans, with precision-spaced couplers in mind.

\ UNIFORM COUPLER SPACING allows for precise coupler spacingregardless of span lengths or combinations. It allows for more efficient and uniform water usage.

\ V-RING SEAL is a patented and time-honored industry exclusive with a warranty of 25-years. It eliminates seal failures due to UV exposure.

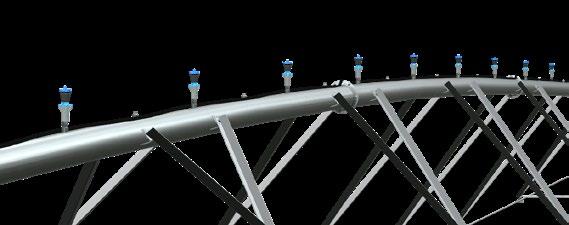

\ REINLOCK™ TRUSSING SYSTEM offers a new and improved way of spanning the field. It provides tighter tolerance with the patented, anti-racking 5-point hub with single bolt.

Reinke stands apart with its exclusive and unique single-leg tower design, while the tower stiffeners work seamlessly with the ReinLock Trussing System. The tower tops are improved by not having a separate first and last pipe, and the tower bases are the widest available on the market.

\ SINGLE-LEG TOWER is a robust design which provides enormous strength.

\ DOUBLE-WALLED TOWER BOX is available on all Reinke irrigation systems. It provides a moisture-free environment for electrical components because it is made of a high-quality, UV-resistant material.

\ REINKE WHEEL GEARBOX leads the industry with a 10-year or 16,000-hour warranty, making it a valuable upgrade as it does not come standard on the E3 system.

The dedication to deliver the best irrigation system in the industry, extends right to the end booms. They are an industry exclusive, with an inverted truss design.

\ END BOOMS provide more flexibility in coverage lengths, and the bolted rod ends allow for customizable clearance.

Reinke uses high-quality materials and innovative engineering in all their center pivot irrigation systems. Each system is unique with custom features to match the grower's exact needs.

A pioneer for center pivot systems, the Electrogator was the first reversible, electric drive center pivot with under-truss design. The single-leg tower remains a key feature of the Electrogator 2, known for its sleek and unobtrusive design.

\ High-strength steel is used resulting in a structure weighing less

\ Single-leg tower has a wider tower base for increased stability

\ V-Ring Seal eliminates seal failures due to UV exposure and strengthens the connection with steel-to-steel connection

\ Maintenance-Free Bearing is made of durable, nonmetallic material, with superior holding strength and long-lasting performance

\ Double-Walled Tower Box provides a moisture-free environment for electrical components

Standing out as the industry's ONLY aluminum center pivot is the Alumigator. It is 40% lighter than all-steel systems.

\ High corrosion resistance pipe, preferred for highly corrosive water

\ Favored strongly for difficult soil types

\ Due to lighter weight, wheel tracks are practically non-existent

As a compact irrigation system, the Minigator is ideal for smaller and irregularly shaped fields, field corners and low-gallonage wells. It is the cost-effective solution and a proven workhorse.

\ Compact and durable with a 3-leg pivot center

\ Transport easily with pickup or tractor

\ Can be configured with a Kwik Tow option

Maxigator™ systems are built to irrigate square or rectangular fields while conserving water. There are a number of custom features available to match the grower's needs. The grower can be ensured of thorough coverage.

\ Offers great versatility

\ Forward and reverse tow options, internal check valves

\ Double inlet hose systems, quick coupler connections on both ends

\ Double-end feed option is also available

\ Best option for larger fields

\ All four tires stay on the ground due to floating axles, which allow the unit to pull large hoses used by high-flow systems

\ Ability to use either power cord pull or onboard power supply

\ Gives the grower the benefits of both pivot and lateral move irrigation

\ Uses only one cart path and no towing is necessary

\ Multiple paths can be planned for one rectangular or L-shaped field, with numerous irregular configurations

\ Compact and carries its own pumping equipment and generator

\ Using the center-feed option in larger fields will result in decreased system pressure loss, resulting in energy savings

\ Navigator GPS provides extreme accuracy in timing and application

\ Furrow uses specially designed wheels that track a V-furrow parallel to the travel path

\ Buried Wire requires less maintenance and creates no obstacles

\ Cable assures accurate lateral movement and uniform water distribution over the entire field

\ Fence requires minimum maintenance and creates no additional obstacles in the field

Reinke has you covered with a specialty system to meet every need. No matter if the farm is oddly shaped, has unirrigated corners or demands light applications regularly - crops are covered with Reinke!

A patented design to irrigate the field corners with efficiency and uniform water application. Growers can get the most crop per drop!

\ Path is enhanced based on GPS positioning to ensure proper water application

\ Significantly reduces the occurrence of under and over watering

\ Growers can choose from three control packages to suit their needs

\ ESAC 6.0 comes standard and includes six sprinkler zones

\ ESAC 12.0 for greater performance comes with additional sprinklers and up to twelve zones

\ ESAC 12.5 uses custom travel path of the system, to design the sprinkler package for ultimate performance

\ The ESAC is an option for growers who want the efficient and uniform water application an electronic zone control provides

With the Wrap Span, acres previously off-limits to center pivot irrigation, can now be irrigated.

\ Configurations can accommodate up to two joints by positioning the Wrap Span system in one or more spans

\ Using a standard joint, the span can wrap up to 10°

\ When using a span joint that reroutes the water through a flexible coupler, the span can wrap up to 90°

Easily disconnect one or more pivot spans, and proceed past an obstacle in order to irrigate previously unreachable acres.

\ If a field widens on the opposite side of an obstacle, an additional span or spans of a different length can be reached

\ For ease in connecting, the auto-stop function self-aligns the parent system to the dropped span

Flexibility without sacrificing strength and efficiency.

Unique in its ability to quickly adapt to movement in multiple directions. Wheel hubs are mounted on base beams and can quickly swivel 90°. Plus, the quick hitch can be moved to any side for easy towing.

Sets the standard for short field towable pivot systems. Available with a hydraulic lift option as well as a motorized Kwik Tow Kit that allows you to move the system laterally for short distances. Can be towed from the end of the system.

The Reinke Engine-Driven Mini-Pivot is a single-span system ideal for small fields and areas where power access is limited. It comes with a variety of gearbox, span length and end boom options and has a maximum system length of 318'.

EVERY INCH. EVERY ACRE.

Whether your farm has unirrigated corners, is oddly shaped, demands frequent light applications or has an obstacle or two, we have a specialty system that meets every one of your needs – and covers every inch of your field.

Simplifies the collection of essential irrigation and crop data, allowing growers to efficiently oversee numerous machines from any smart device. Seamlessly integrating with most pivot irrigation brands, ReinCloud 3 ensures optimal water management.

\ User Friendly Interface: Intuitive design for quick access to critical insights

\ Advanced View Layers: Weather, soil, yield, chemigation, fertigation, and seeding maps

\ Customizable Control: Machine groupings, commands, and sector programming

\ Unique Text Notification Generator for custom notifications that make sense to you

Growers will save time and resources by not having to go out and check the irrigation system physically. ReinCloud 3 is fully integrated with Reinke's latest remote management hardware, RC3.

The range of hardware provides solutions for connecting all electric pivots through RC3 telemetry. The RC3 devices can be installed within minutes.

\ Easily monitor and control irrigation systems from anywhere

\ Compatibility: Works seamlessly with most pivot brands

MCP-ULTIMATE

\ Industry-leading 3-year warranty

\ Designed to give complete remote control of machines equipped with Reinke's RPM Advanced Plus™ or Touch Screen panels

Two global leaders in agriculture technology are collaborating to provide precise management solutions for growers around the world. By integrating Reinke precision irrigation with CropX technologies, farm management has been simplified while saving money and resources for the grower.

The latest iteration has been developed with growers' most pressing ag data, water management and operational challenges in mind. Working together with CropX, growers stay informed and connected, so decisions can be made on the go.

CropX and ReinCloud 3 tools are integrated to provide data on soil moisture, disease and fertility management - in addition to field water movement. Growers are aware of what is happening from the roots to the shoots!

Reinke precision irrigation and CropX® farm management tools are simplifying decision-making for the grower.

The grower can leverage information above and below the ground to maximize the performance of their Reinke irrigation system.

\ Stay informed with any smart device

\ Irrigation management saves money and resources by making the data work for you

\ Added agronomic value for disease awareness and fertility management

Trusted by growers, Reinke and CropX are leading the way for technology in the field. The shared endeavor enables the grower to maximize the performance of the irrigation system and minimize waste.

CropX soil monitoring sensor is far more than a tool. It's an easy-to-install power move that puts next-level crop control in the palm of your hands.

\ Self-calibration and easy installation gets the grower up and running in minutes to deliver irrigation insights in record time.

\ Only affordable all-in-one solution for all crop types, no setup costs and no other needed equipment.

\ Cutting-edge wireless connectivity is accessible even in remote areas offering cellular and satellite connectivity.

\ Innovative spiral design offers unparalleled accuracy on soil moisture readings with a true read of undisturbed soil in the field.

Growers using the Reinke Direct ET™ by CropX, have access to technology that directly measures the Actual Evapotranspiration (ETa) of a crop.

\ Actual water use of a specific field is ETa, which is measured directly and in real-time

\ ETa is measured over a broad area of the field

\ Easy-to-understand insights into the water needs of the crop

\ Irrigation recommendations can also be made

\ Critical crop information is received in real-time

Integrating Reinke precision irrigation with CropX farm management tools, saves time and expense, giving the grower peace of mind.

Optimize water distribution. Maximize yield potential.

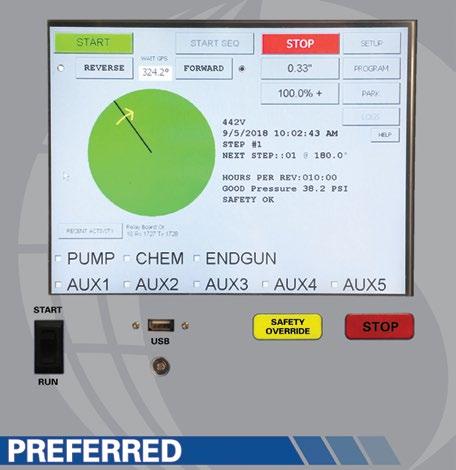

Variable rate irrigation (VRI) applies precise amounts of water to match numerous variables within each field. Multiple prescriptions can be created based on soil variables and topography. From the RPM Preferred Touch Screen, you’ll be able to immediately verify that everything is running properly.

Sector VRI segments the coverage area into multiple pie-like slices (sectors) up to ¹⁄₁₀th of a degree by controlling the speed of the pivot, which increases or decreases the water application rate. The base application depth can be easily adjusted higher or lower without changing the prescription. Works with existing sprinkler packages.

In addition to the Sector VRI, the coverage area can further be divided into as many as 84 rings. By combining the sectors and rings, more than 300,000 independently controlled zones are created for precision water application. Additional hardware is required.

As efficient as the parent system, the patent pending Reinke SAC VRI provides precision irrigation throughout the swing arm corner. This user-friendly technology includes a predictive prescription that can be optimized easily over time. The Reinke SAC VRI is available with the RPM Preferred Touch Screen or AnnexPF panel. Additional hardware is required.

We believe in developing precision management technologies that stay two, three, ten steps ahead of tomorrow’s challenges. And that starts in the field by continuously testing and researching what works and where we can improve our systems. It’s not about irrigation today, but how we can more efficiently irrigate in the future.

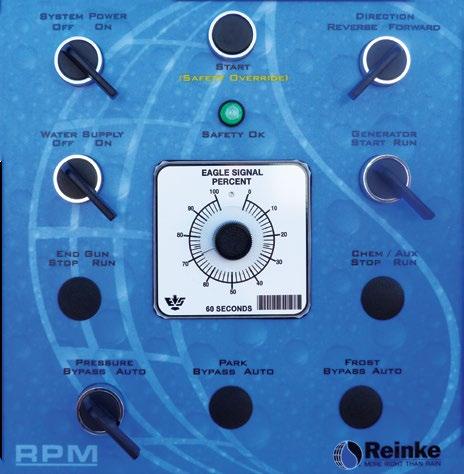

Reinke Precision Management (RPM) control panels are custom built for reliability and trouble-free use. Plus, they’re easy to upgrade and customize.

0.1 RPM BASIC

\ Value priced

\ High-quality, powder-coated steel enclosure

\ Features include: commercial or generator power, end gun control, speed control, directional operations, auto reverse and start/stop

\ Easily upgradeable

\ High-quality, powder-coated aluminum enclosure

\ Includes RPM Basic panel features, plus: higher corrosion-resistant enclosure with many additional options such as digital speed control, end gun override, low-voltage safety and frost control

\ Improved user experience

\ Full-color 4.3" customizable touch screen display

\ Includes RPM Standard panel features, plus: digital end gun and auxiliary control, sector programming and GPS for improved accuracy, digital pump control, selectable auxiliary options and pressure monitoring with transducer

0.4 RPM CONNECT™

\ Screenless, remote-operated panel using ReinCloud 3

\ Limited controls on the panel including start, direction and stop

\ Same features as RPM Advanced Plus through ReinCloud 3

\ All-inclusive panel

\ Larger full-color 10.1" touch screen display

\ Includes RPM Advanced Plus panel features, plus: VRI, start sequence, multilingual display, USB port, downloadable logs and much more

0.6 RPM ANNEX™

\ Upgrade an existing panel to the latest pivot control technology

\ Utilizes backend components of the host panel

\ Works on Reinke or competitive panels

\ Available configurations: Advanced Plus (AnnexAP™), Connect (AnnexCT™) and Preferred Touch Screen (AnnexPF™)

Reinke has always offered only the best sprinkler products to provide a multitude of droplet sizes and pattern widths using advanced rotary, offset axis rotary and fixed spray sprinkler technologies best suited for the specific crop or application. Whether it is for the Electrogator 2, using 40” and 57” outlet spacing – or the E3 with 30” and 60” outlet spacing, we have a product available that’s capable of generating the desired application rate. By utilizing a variety of plates, operating pressures, mounting heights and sprinkler spacing, we can custom design a sprinkler package to fit virtually every field.

Offset Axis, Multi-Trajectory,

i-Wob2 10 to 15

Xi-Wob 10 to 15 Offset Axis, Multi-Trajectory,

All Sprays 6 to 20

Pressure regulators are also useful for reducing higher pressures near the pivot point where the sprinkler nozzles are the smallest, thus minimizing plugging, wind drift and evaporation. They are required for use with many of the sprinkler options that have been engineered for operating pressures within a specific range, for optimum water application, extended life of the product and ultimately increased yield.

Pressure regulators eliminate the pressure variation at the sprinkler nozzle caused by:

\ Variations in available water supply

\ Elevation changes within the field

\ Fluctuations in demand such as end guns and swing arm corners

As always, Reinke also offers a wide variety of sprinkler mounting components to customize your system to your specific needs. Contact your Reinke dealer for more information.

End guns are an economical way to add profitable acres to your farm operation. The optimum operating pressure for an end gun can range between 40 and 70 psi and is based largely on the nozzle size of the end gun which is determined by the system length, total system flow (gpm), operating pressure and the distance of throw or effective coverage of the end gun.

Reinke understands the importance of efficiency. We place the booster pump at the end of the system near the end gun to provide maximum power and minimize friction loss.

Every Reinke irrigation system is engineered and designed for season after season of reliable service. The system is enhanced when it is galvanized, offering a number of advantages:

\ Corrosion resistance by acting as a barrier against rust and external factors

\ Long-term durability leads to reduced maintenance expenses, saving time and resources

\ Includes cleaning and pre-treatment of the system components in a selfenclosed pre-treatment room

\ Components are prepared for dipping into the molten zinc bath

\ Galvanized coating adds longevity to Reinke irrigation systems

\ Adds additional strength and prepares the system to withstand the elements

Sporting its signature blue look, this high-performance gearbox will outwork and outlive any competitive gearbox in the field.

\ New high-torque gears enable greater load capacity

\ Extra long carriage bolts allow use with reinforced rims

\ The 13-bolt mounting pattern is compatible with most center pivot brands

\ Provides years of reliable service

\ Minimizes gear wear allowing for a longer lifespan

\ Reduces running temperatures, extending the gear’s life

\ Backed by the best warranty in the industry

Possessing high-quality components, this gearbox can easily switch from towable to non-towable and carries a 10-year or 10,000-hour warranty.

Made of ³⁄₄ x ³⁄₄ fine-grain high-strength steel shaft.

\ UMC® Standard Coupler is designed to connect the center drive gear motor to the final drive gearboxes

\ The patented UMC® CX™ Coupler is a universal, shock-reducing connection between the center drive gear motor and the final drive gearbox that uses a single wrench to replace

A high-efficiency gear motor delivers exceptional torque to propel your system over the roughest terrain and through difficult soil conditions. Specifically designed and built for the demands of mechanized irrigation.

\ Helical gear design – 95% efficiency

\ High-strength steel shafting provides long life and dependability

\ Top fill plug positioned to set correct oil level

\ All critical electrical connections are encapsulated to resist

moisture penetration

\ C.S.A. and UL approved

\ 3 output RPMs (low 60:1 ratio or 29 RPM; standard 40:1 ratio or 43 RPM; high 25:1 ratio or 70 RPM)

\ 8-year, 8,000-hour warranty

With a higher load rating than standard 6-ply tires, radial tires reduce compaction and provide greater floatation and traction. They are ideal for using on ESAC systems or other longer and/or heavier spans.

The Shark Wheel is a one-of-a-kind airless segmented pivot tire, which minimizes rutting. It helps reduce soil compaction and has a 5-year limited warranty.

Agri-Trac is tough and long-lasting, allowing the pivot to keep moving while easily handling heavy soil, mud bogs and hillsides.

To ensure a pivot stops or reverses where you want it to, barricades are the safety measure to use if the pivot doesn’t move in a complete circle. They are made of long-lasting galvanized steel, with options to be permanent or movable.

With this innovative segmented airless pivot wheel never worry about flat tires again

Easily swap out segments for a smooth, uninterrupted

Conquer difficult soils with ease, designed for difficult terrain. The bi-directional tread pattern sufficient bite, enabling the wheel to perform effortlessly both directions

Enhanced durability with the modular paddles absorb load, increase surface area and minimize failures for improved performance

Since 1968, we have been dedicated to helping growers maximize yields with durable and innovative irrigation systems.

\ Reinke specializes in transforming irrigation methods

\ Products are created to work smarter, not harder

\ Systems combine precision and technology

\ Smart choice to enhance productivity

\ Reinke continues to be a trailblazer for center pivot irrigation systems

\ Using materials that are high-strength, nonmetallic, double-walled or securely sealed inside, assures the grower of a long-lasting system

\ Changes are made to address the many variables faced by the growers, whether it is the size of the field, terrain or water supply available

\ With a smart device, growers access information in real-time, aiding their decision making

\ Precision irrigation and agronomic planning tools are integrated

\ The tools ensure accurate water application for maximum efficiency

\ With advanced control systems to GPS-guided positioning and targeted water distribution, resources are conserved while optimizing yields

\ Adjustments can be made from anywhere, putting the grower in control

\ Systems are engineered and designed for season after season of reliable service

\ Long term durability leads to reduced maintenance expenses, saving time and resources

\ All systems and components are backed by industry-leading warranties

\ Reinke has you covered to meet every need

\ With uniform coupler spacing, the application rate is consistent from the first coupler to the last

\ Under and over watering is eliminated for every field with uniform water application

\ Irrigated acres expand the growers productivity

\ Stronger crops equals bigger yields

\ Committed to minimizing negative environmental impact while conserving energy and natural resources

\ Engineered for the future with unparalleled strength and durability

\ Committed to fostering a culture of ethical leadership, employee engagement and environment responsibility

\ Working together to forge strong relationships with growers, corporations and partners globally toward a sustainable future

Reinke dealerships are located across the United States, Canada and around the globe. No matter where growers are located, the Reinke dealership network is ready to assist.

Qualifying as a Reinke dealer is no simple task. An important part of the process is getting certified. All Reinke dealers are required to complete a series of technical classes and successfully pass each exam. By doing so, it lets the growers know the dealership is qualified to perform work on Reinke irrigation systems.

Reinke dealers work with the grower from custom design to installation to making sure the irrigation system performs as expected, year after year. They have the knowledge and skills to deliver the best in irrigation performance.

Agriculture is at the core of Reinke life, focusing on producing exceptional products. Employees, growers and dealers are essential. The Reinke team thrives due to the invaluable support and dedication of everyone around the world.

Chris Chambers has worked for Reinke since 2014. He enjoys the flexibility of his job and spending time with family. "With a good attitude, you'll be alright."

James Silva used to flood irrigate, which resulted in too much water to control. "With a Reinke center pivot, the amount of water is controlled better and easy to use."

In Botswana, rainfall is volatile and water is limited. Jac Johan van der Westhuizen needed to find a more reliable method of watering his crops. Jac stated, "with the Reinke system, I can save money and irrigate more sustainably."

Wade Walters loves technology! "ReinCloud® is great and allows me to be more efficient with my irrigation systems. No more wondering if a pivot is still running. I'm able to shut it off from anywhere and not waste water."

\

\

\

\

\