Engineered for flexibility and durability, the Keyway Tie offers the strength of concrete with the elasticity of wood tie track, simplifying replacement and maintenance.

- Intersperse Keyway Ties between wood ties using standard MOW equipment

- Strengthen gauge and adjust gauge up to +/-0.4 inches

- Match wood tie track modulus, lower ballast pressure compared to standard concrete tie track, and extend the life of adjacent wood ties

- Guard rail and transition ties available

We offer 100% Buy America compliant integrated railway solutions from specialty trackwork, concrete ties, and fixation to signaling systems and monitoring solutions.

Join us at the IHHA Conference to hear more about our Keyway Tie. Stop by to learn how we are innovating to help railroads improve track performance and availability.

Keep all type and logos 1/2 inch from trim

Vol. 121, No. 10 Print ISSN # 0033-9016, Digital ISSN # 2160-2514

EDITORIAL OFFICES 1025 Rose Creek Drive Suite 620-121 Woodstock, GA 30189 Telephone (470) 865-0933 Website www.rtands.com

DAVID C. LESTER Editor-in-Chief dlester@sbpub.com

JENNIFER M c LAWHORN Managing Editor jmclawhorn@sbpub.com

EDITORIAL BOARD

Brad Kerchof, formerly Norfolk Southern Robert Tuzik, Talus Associates

Gary Wolf, Wolf Railway Consulting David Clark, CSX

CORPORATE OFFICES

1809 Capitol Avenue Omaha, NE 68102

Telephone (212) 620-7200 Fax (212) 633-1165

ARTHUR J. MCGINNIS, JR. President and Chairman

JONATHAN CHALON Publisher

MARY CONYERS Production Director

NICOLE D’ANTONA Art Director

HILLARY COLEMAN Graphic Designer

JO ANN BINZ Circulation Director

MICHELLE ZOLKOS Conference Director

CUSTOMER SERVICE: 847-559-7372

Reprints: PARS International Corp. 253 West 35th Street 7th Floor

New York, NY 10001 212-221-9595; fax 212-221-9195 curt.ciesinski@parsintl.com

By David C. Lester, Editor-in-Chief

It doesn’t take much looking around to appreciate the amounts of creativity and ingenuity that go into our nation’s transportation infrastructure. Massive bridges like the Brooklyn in New York and the Golden Gate in San Francisco, complex interstate highway interchanges, and airports with miles-long runways are all impressive accomplishments. While the railroads sometimes receive grants for infrastructure projects through CRISI grants (Consolidated Rail Infrastructure and Safety Improvements) and other funding sources, the cost and expertise needed for maintaining a line is monumental and is the railroads’ responsibility. That’s why the Class Is have huge capital budgets every year. By and large, the expertise to maintain and repair comes from railroad personnel. Third parties perform some functions, such as rail grinding, but the carriers must internally sign off on projects before they begin.

The capability of and demands placed on railroad engineering teams requires folks who like to be outside, are smart, and willing to work hard. Some of the stories I’ve seen over the years about line restorations after major storm damage are impressive. For example, we recently reported on the reopening of CSX’s Blue Ridge Subdivision, which is the line that used to be the Clinchfield

Railroad. About this time last year, Hurricane Helene blasted the southeastern United States and took out approximately 60 miles of this line, which serves North Carolina and Tennessee and handles about 14 million gross tons of freight every year. RT&S’ Managing Editor, Jennifer McLawhorn, filed reports on our news website beginning just after the hurricane hit and continued through much of 2025 as CSX repaired the line in mountainous territory. (Please check our website, www. rtands.com, to read Jennifer’s reports and watch videos of the progress made by CSX). The Blue Ridge Subdivision was reopened in late September, and folks couldn’t ask for a better opening –– a revenue train with CSX’s Clinchfield Heritage Unit on the point. (Note image above, courtesy CSX).

It was essentially the same story at Norfolk Southern, where Helene destroyed lines east and west of Asheville, N.C. Those lines were restored between late 2024 and April 2025, and the loops at Old Fort, N.C. are currently under restoration with completion expected within the next several months.

DAVID C. LESTER Editor-in-Chief

Duane Otter, Scientist, PhD, PE

Ekrem Koç, Senior Engineer I

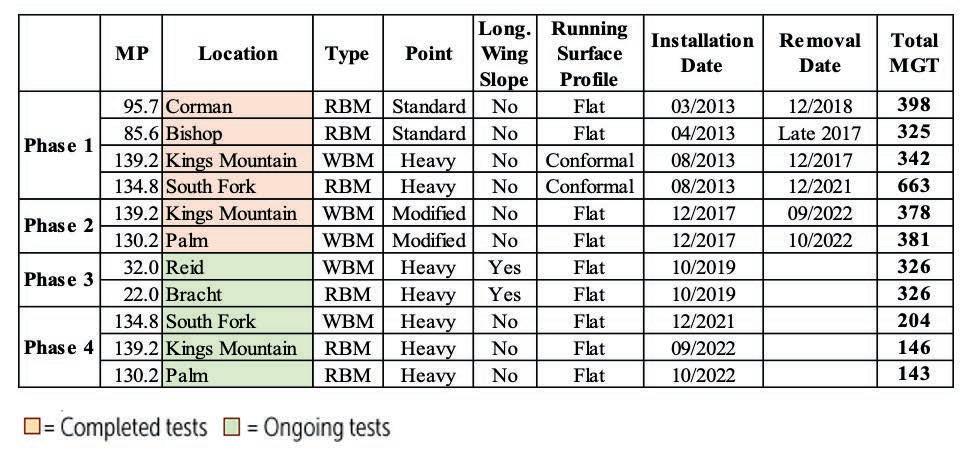

In 2013, MxV Rail engineers began testing the performance of several No. 20 frog designs on a busy main line of the Norfolk Southern Railway (NS).1 The first phase of testing began with two NS standard frogs and two premium frog systems. The premium test frogs had heavy points, conformal running surface profiles, low-impact or welded heel designs, and elevated guard bars. The outcomes of this initial trial were documented,2 and the tested frogs have since been removed from service.

In the next phase of frog testing, two

additional frogs were introduced to the same line in 2017, featuring a modified heavy point design.3,⁴ Achieved by widening the flangeways, this modification was crafted to fulfill pre-2020 Federal Railroad Administration (FRA) track safety standards for Class 5 track without necessitating a waiver. In late 2022, after nearly five years of service and the accumulation of approximately 380 million gross tons (MGT), the two modified heavy point frogs were removed from service.

The third and ongoing phase of testing features designs incorporating longitudinal wing slopes. The elevation relationship between the point and the wings was re-evaluated, leading to the development of a longitudinal profile better suited to accommodating hollow worn wheels at the wheel transition zone.⁵,⁶ For this phase, two frogs with longitudinal wing slopes were installed on the same NS line. These frogs remain in service and have accumulated over 325 MGT each.

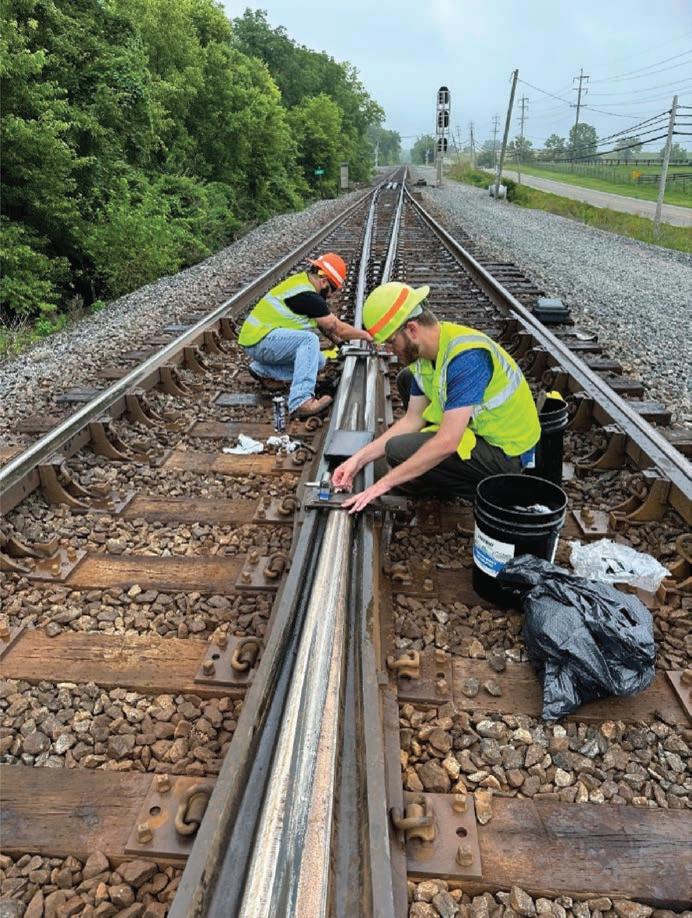

Following the removal of the modified heavy point frogs in 2022, two new heavy point frogs with flat running surface profiles were installed at those locations as part of the fourth phase of testing. Table 1 summarizes the test frogs and their design attributes. In addition to rail-bound manganese (RBM) frogs, some are of the welded boltless manganese (WBM®) design. During Phase 4, MxV Rail engineers will continue to conduct regular measurement visits to the test site (Figure 1), with at least one annual inspection.

During the initial phase of testing, the heavy point frogs monitored at Kings Mountain and South Fork exhibited notably reduced deformation compared to the standard point frogs.2 The heavy point WBM frog located at Kings Mountain was removed from service after over four years of service and the accumulation of approximately 340 MGT. At South Fork, the RBM frog with a heavy point remained in service for more than 660 MGT and over eight years.

The original heavy point design did not comply with pre-2020 FRA track safety requirements for Class 5 track guard check gage. In 2003, the FRA granted railroads a waiver that permitted Class 5 speed operations despite guard check gage conforming to Class 4 track frog standards. Ultimately, the FRA incorporated the waiver into the regulations in 2020, acknowledging the proven

safety of heavy point frogs.⁷

To satisfy pre-2020 FRA track safety requirements, the modified heavy point design was developed by widening the flangeway within the heavy point area.3,⁴ This widening was accomplished by removing some metal from the wings over approximately a 60-inch transition zone.3 Two modified heavy point WBM frogs with welded heels and flat running surface profiles were manufactured and installed at Kings Mountain and Palm. Both frogs remained operational for about 380 MGT and nearly five years.

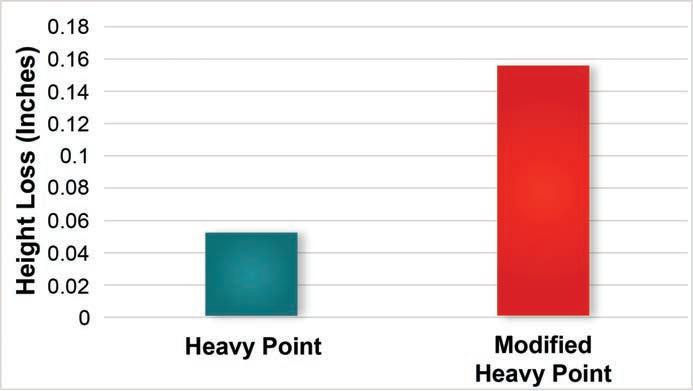

The heavy point frog design features a thicker point that contributes to better durability and reduced metal flow and deformation.1 The cross-sectional profiles measured during periodic inspections revealed that the frogs featuring the modified heavy point design were not performing as well as those equipped with the original heavy point design.⁸ The modified heavy point frogs exhibited greater deformation, particularly on the point. Two distinct design differences between these frog systems could potentially account for this outcome. The modified heavy point frogs have flangeways that are wider within the heavy point area, resulting in a shorter wheel transfer zone in the longitudinal direction. A previous analytical study predicted higher impact forces in these frogs with the wider flangeway.⁴ Additionally, in contrast to the original heavy point frogs that incorporated conformal running surface profiles, the modified heavy point frogs featured flat running surface profiles. Figure 2 provides a comparison of the average frog point height loss measurements over the wheel transfer zone for both the original heavy point frogs and the modified heavy point frogs at about 150 MGT.

Another challenge for frog performance is accommodating a wide spectrum of wheel profiles. The relationship between wheel profiles and the elevation differential between the wings and the point determines how the wheel transitions between the wings and the point. The use of point risers has become common practice to mitigate impacts at the transition zone and facilitate smooth wheel traversal over the frog without abrupt collisions against the frog point. Nevertheless, point risers alone do not prevent hollow worn wheels from striking the wings during trailing point movements, giving rise to the need for longitudinal wing slopes in frogs. For the third phase of the ongoing test, two

Table 1. Test frogs and their design features

frogs featuring longitudinal wing slopes were installed and monitored in revenue service at Reid and Bracht, along the same NS line. The Reid test frog, a WBM frog with a heavy point and flat-top running surface, was equipped with asymmetrical wing slopes. These slopes begin at the frog’s point, with the top surface elevation of the wings decreasing by 1/8 inch

in a 24-inch slope for the main route wing and 1/8 inch in a 12-inch slope for the diverging route wing, moving from the point to the heel.

The other test frog featuring a longitudinal

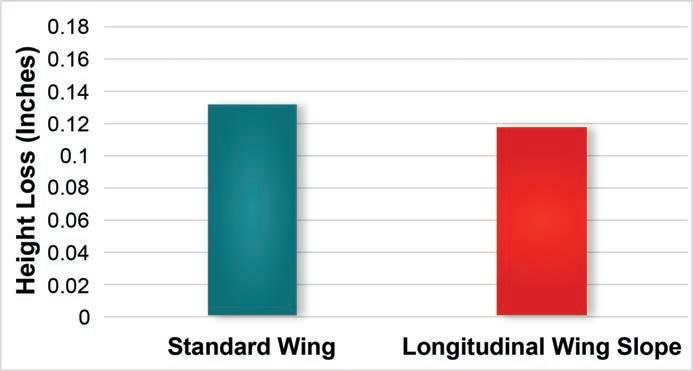

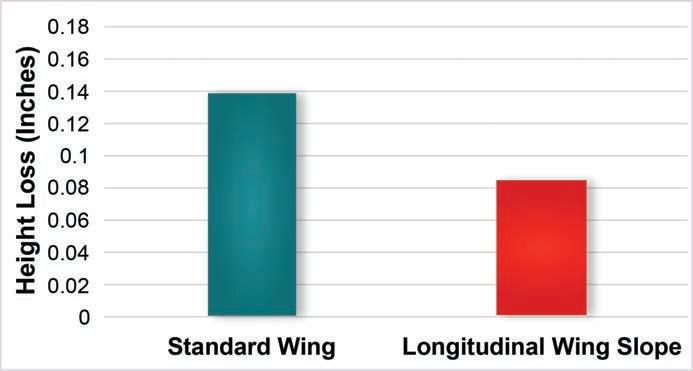

wing slope is installed at Bracht. The Bracht frog is an RBM type with a heavy point and flat-top running surface. This frog has a symmetrical longitudinal profile design, with a 1/8 inch in 24-inch slope on both wings. Similar to the Reid frog, the longitudinal wing slope initiates at the frog’s point.⁵,⁶ Figure 3 shows the mainline wing height loss at about 200 MGT. Figure 4 shows the height loss experienced by the diverging wings for the same tonnage.

Drawing upon the maintenance insights gathered from the local personnel of NS, of the four frogs assessed, neither of the wings on the Bracht frog and only the diverging wing on the Reid frog underwent any weld repair. Both the mainline wings and the diverging wings seemed to benefit in terms of average height loss within the wheel transfer zone. The height loss difference is more apparent on the diverging route wings.

The Technology Digest this article is based on can be found in the MxV Rail eLibrary along with more than 1,000 other publications describing the railway research, testing, and analysis available from the Association of American Railroads (AAR) Strategic Research Initiative (SRI) program. While this article covers testing in revenue service, MxV Rail’s software, laboratory facilities, and test tracks are also used consistently to meet the railway industry’s needs for both publicly accessible research efforts and contractual tests for individual customers. Explore the full scope of MxV Rail’s innovation and access the complete research library at www.mxvrail.com.

Acknowledgements

MxV Rail extends sincere gratitude to Brandon K. Smith, former Sr. Metallurgical Engineer, and to the local NS track crews for their support during these test activities.

Initially this study was jointly funded by the AAR and the FRA. Beginning in October 2022, these tests have continued solely under AAR’s SRI program.

References

1. Otter, D. & Koc, E. 2024. “Update on Revenue Service Frog Testing.” Technology Digest TD24-009. AAR/MxV Rail. Pueblo, CO.

2. Jimenez, R., D. Davis, X. Shu, and I. Aragona. 2016. “Performance of No. 20 Frogs of Various Designs in Revenue Service.” Technology Digest TD16-028. Transportation Technology Center, Inc. (TTCI)/ AAR. Pueblo, CO.

3. Rakoczy, A., X. Shu, and D. Davis. 2015. “Evaluation of Heavy Point Frog Performance and Potential Design Changes for High Speed Service and Heavy Axle Load Service.” Technology Digest TD15-039. TTCI/AAR. Pueblo, CO.

4. Sciandra, E., S. Gurule, D. Otter, and D. Davis. 2018. “Evaluation of the Performance of a Prototype Heavy Point Frog.” Technology Digest TD18-013. TTCI/AAR. Pueblo, CO.

5. Bakkum, B., D. Davis, and S. Wilk. 2021. “Modified Frog Wing Slope Profile Test.” Technology Digest TD21-003. TTCI/AAR. Pueblo, CO.

6. Davis, D., B. Bakkum, S. Wilk, and D. Otter. 2019. “Review of Turnout Frog Running Surface Design.” Technology Digest TD19002. TTCI/AAR. Pueblo, CO.

7. Federal Railroad Administration. 2020. “Rail Integrity and Track Safety Standards” Federal Register Vol. 85, no. 195, Page 63362. https://www.federalregister.gov/d/2020-18339/p-amd-9. U.S. Department of Transportation. Washington, D.C.

8. Federal Railroad Administration, 2022. “Performance of Prototype No. 20 Frogs in Revenue Service” Research Results RR 22-17. U.S. Department of Transportation. Washington, D.C. CONTACT Global

mjbalve@globaltradeshow.com

By David C. Lester

Carl Walker of CSX Receives 2025 RT&S Engineer of the Year Award at AREMA Conference

Carl Walker, Vice President of Engineering at CSX, was presented with the RT&S Engineer of the Year Award at the opening session of the 2025 AREMA Conference, held in Indianapolis Sept. 14-17. For the complete story on Carl’s career and his selection as the RT&S Engineer of the Year,

please refer to the Sept. 2025 issue of RT&S. Jon Chalon, Publisher of Railway Age, Railway Track and Structures, and International Railway Journal, presented the award. Carl said “My time at CSX has been a rewarding growth experience, and I thank RT&S for this recognition.”

AREMA 2025 Conference Wrap Up

The AREMA 2025 Annual Conference & Expo was held in Indianapolis, from September 14–17. The event welcomed over 3,100 rail industry professionals for three impactful days of learning, networking, and innovation. It opened with a Golf Tournament supporting the AREMA Educational Foundation, followed by a lively Welcome Reception at the Indianapolis Motor Speedway Museum. Attendees participated in more than 60 technical presentations covering topics such as emergency response, automation, inspections, and artificial intelligence. The conference offered up to 12 Professional Development Hours,

with additional On Demand content available post-event. The Expo floor buzzed with activity, featuring nearly 300 exhibiting companies showcasing cutting-edge rail technologies and services. Key highlights included a high-energy keynote from Jeremy Gutsche, CEO of Trend Hunter; a thought-provoking Emerging Technology Panel; and a closing session on Wednesday with industry analyst Tony Hatch, Founder of ABH Consulting, offering strategic insights into the future of rail. The event reaffirmed AREMA’s role as the premier gathering for railway engineering professionals, where leadership, innovation, and opportunity converge.

Brightline Florida & HNTB Honored with William W. Hay Award for Excellence at AREMA Conference

Each year at the AREMA Conference, the organization bestows the Dr. William W. Hay Award for Excellence to an outstanding rail engineering project. The Hay Award was established by the Directors of AREMA to recognize outstanding achievement in Railway Engineering and to honor the memory and accomplishments of one of their members and leaders: William Walter Hay. Dr. Hay was a professional railroader in both the military transportation service and the private railway industry. He was a consultant on design, construction and operations of railroads and, for over 25 years, he was a Professor of Railway Civil Engineering at the University of Illinois, Urbana-Champaign. He was also a teacher, motivator, and mentor for dozens of men and women who chose to enter the transportation industry. Criteria for winning the award are:

• Innovation – The development and/or application of new concepts, products or practices including state-of-the-art physical and information-oriented technology.

• Safety – The enhancement of safety in either the application itself or as a process or procedure which contributes to the overall safety of railroad personnel or railway operations.

• Service Performance and Reliability – An undertaking which contributes to more efficient, effective and reliable railway performance, especially as viewed by the railroad’s customers.

At The 2025 AREMA Conference, held in September, the Hay Award was presented to both Brightline Florida and HNTB Corporation for the construction of a 38-mile east-west corridor, which is the final section of Brightlne Florida’s route from Miami to Orlando. This project involved approximately 700 workers and had 20 grade separations.

January 7-10, 2026 | The Diplomat Beach Resort, Hollywood, FL

■ 2026 engineering & capital spending plans (commuter rail/transit, Class I and short line)

■ Noteworthy national rail project overviews

■ Railroad Signals & Communications update

■ FRA safety updates & best practices

■ Sustainability and Industrial Development panels

■ Infrastructure outlook and legislation

■ Awards

It’s time to make plans to attend the premier rail industry event of 2026.

Join us in Hollywood, Florida, for an unparalleled opportunity to connect with key decision-makers in the transit, commuter rail and freight railway industries. Register now to lock in your spot at The Diplomat Beach Resort in Hollywood, Florida. Find all the details here:

by Jeff Tuzik

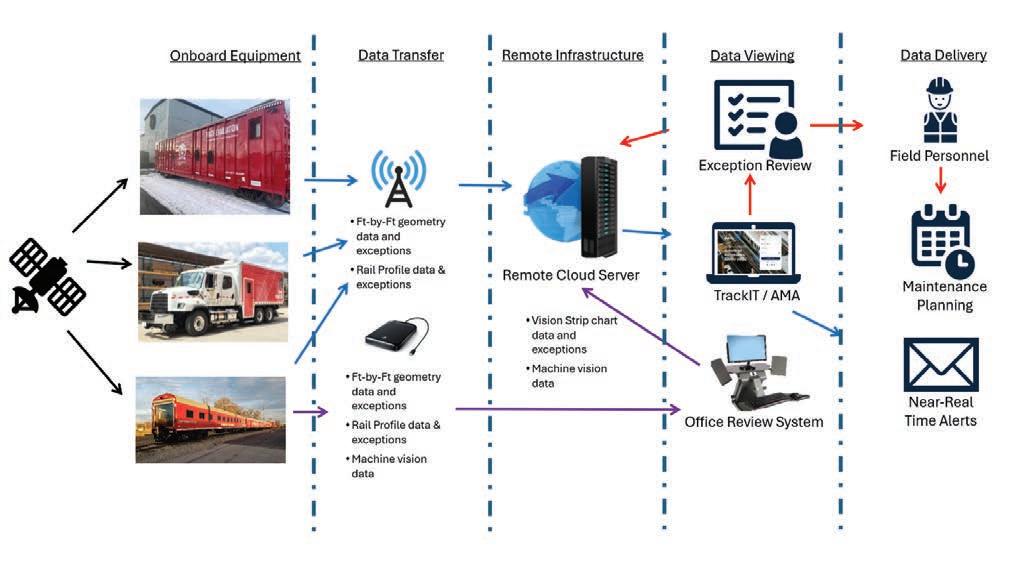

Track geometry inspection has always been an intrinsic part of railroading. That hasn’t changed and never will. But the way inspections are performed and the data they yield is changing rapidly. Automation is one of the biggest factors in the change, but the sophistication of inspection technologies and data management techniques are also contributors. This combination of factors allows railroads like Canadian Pacific Kansas City (CPKC) to collect more data in more locations with greater accuracy and objectivity than ever before.

CPKC has a well-developed but

ever-evolving track geometry inspection program. It includes traditional visual inspection by track inspectors, as well as manned and autonomous track inspection vehicles. “Prior to the CP/KCS merger, CP did all of its track geometry testing in-house,” Tyler Kerr, Manager of Track Evaluation at CPKC, told attendees of the 2025 Heavy Haul Wheel/Rail Interaction Conference. “KCS, on the other hand, contracted out most of their geometry testing.” Since the merger, CPKC has expanded their in-house geometry inspection program to cover the majority of the network, which now spans ≈20,000 miles

of track from Mexico to Canada, British Columbia to New Brunswick.

The Fleet

CPKC’s track geometry measurement fleet is comprised of five autonomous track geometry measurement system (ATGMS) cars (with a sixth going into service shortly), six hi-rail vehicles (two heavy trucks and four light trucks), and one manned track evaluation train (TEC92), Kerr said.

Of the manned inspection vehicles, the TEC92 consist is equipped with the widest range of inspection technologies. Its

Tyler Kerr, Manager of Track Evaluation at CPKC.

Deputy Division Manager at ENSCO

capabilities include: geometry and profile measurement, gage-restraint measurement, rail surface imaging, joint bar imaging, and track component imaging.

“The deployable gage-restraint measurement system is one of the most important parts of the system,” Kerr said. This deployable 5th axle applies 40,000 lbs of downward force and 14,000 lbs of outward or gage-spreading force. This measures the track’s gage restraint and also provides the opportunity to measure differences in track geometry between a loaded and unloaded state, he said.

The “heavy” hi-rail vehicles measure

track geometry and rail profile, and the four “light” hi-rail vehicles measure only track geometry. “The hi-rail trucks have been instrumental in the way we do things; they offer flexibility, since they can get to specific locations that need attention much faster than a train.”

The autonomous inspection fleet is made up of four “conventional” boxcars, three of which measure track geometry, and one of which measures geometry and rail profile. There are also two so-called “Total Track Assessment” boxcars, which are equipped with track geometry measurement systems as well as machine

vision and lidar imaging systems.

CPKC’s geometry measurement fleet measured a total of 311,554 miles of track in 2024. In 2023, that number was only 118,000 miles; “We’ve changed our strategy and approach to testing, particularly with regard to the ATGMS program,” Kerr said. “We used to be very selective about where these cars went.” But in 2024, CPKC decided to attach three ATGMS cars to intermodal service trains which cover most of the network in a single week. This vastly expanded their coverage and data intake.

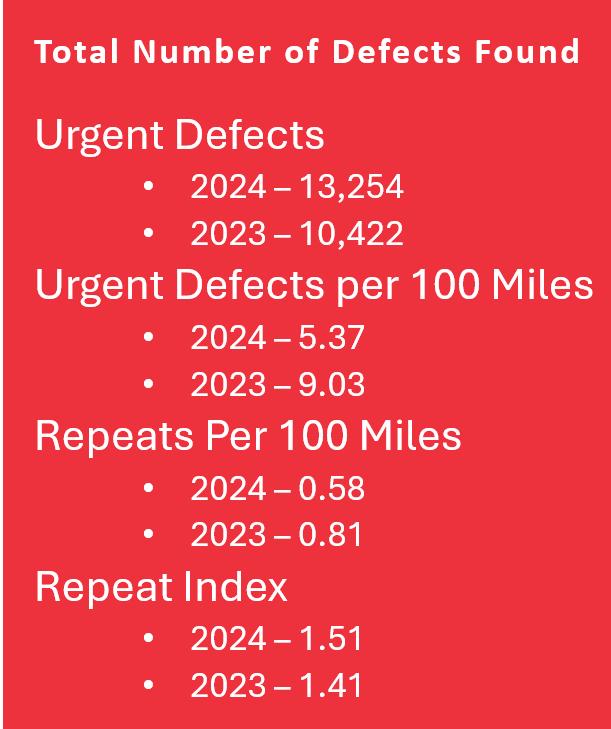

Figure 2 shows select geometry defect

In 2024, CPKC decided to attach three ATGMS cars to intermodal service trains which cover most of the network in a single week. This vastly expanded their coverage and data intake.

statistics for 2023 and 2024. “Our urgent defects went up in 2024 [from 10,422 to 13,254], but we’re testing a lot more track, so it’s expected,” Kerr said. However, both urgent defects per 100 miles and repeat defects per 100 miles both fell (from 9.03 to 5.37 and 0.81 to 0.58, respectively), indicating an overall improvement in track geometry condition.

In addition to data from the track inspection fleet, CPKC also collects data from 12 vehicle/track interaction (VTI) monitors in operation throughout the system. These systems, which measure parameters like carbody accelerations, truck lateral accelerations, axle impacts, and 10-foot midcord offsets, provide an additional layer of data on track condition that can be helpful in prioritizing maintenance or issuing slow orders, said Rafael Maldonado, Deputy Division Manager at ENSCO Rail.

CPKC is working with ENSCO to further leverage their VTI data by focusing on patterns in the data. “A VTI monitor might send out one critical alert a week but record 30,000 exceptions. Obviously, those exceptions aren’t manageable, but there’s value in the data,” Maldonado said. Certain patterns and combinations of lowlevel VTI exceptions that may presage a more serious or catastrophic event can be identified by a so-called combo cluster algorithm, he said. Identifying these locations can help guide inspectors and future maintenance efforts even if there isn’t a defect present that exceeds an FRA or Transport Canada threshold.

On another front, CPKC is currently in the pilot stage of programs aimed at automating both tie and joint bar inspection. Both of these systems are machine vision-based. In addition to the real-time flaw detection they provide, the data they collect will be used to build an inventory and classification system for these components, CPKC’s Kerr said.

CPKC is also exploring rail surface imaging. This system images the rail from the top down and assigns numerical values based on surface damage type, location, and severity. This enables analyses, trending, and most importantly objectivity that traditional visual inspection cannot provide, Kerr said. The significant commonality between these machine vision systems (tie inspection, joint bar inspection, rail surface imaging) is the goal of turning subjective visual data into quantifiable metrics.

Inspection vehicles and systems that cover a lot of ground generate a lot of data. With over 300,000 miles of tested track and multiple data streams, it’s easy to see how ATGMS data would be overwhelming without the right data management and software tools in place to turn the data into understandable, actionable information.

CPKC uses many applications, some developed in-house, some vendorsourced, to manage its ATIP data. Among these, there are three primary applications they use to manage, access, and visualize data: Track Asset Management (TAM), which CPKC developed in-house, is used to schedule and record visual inspections, defects, maintenance actions and repairs.

ENSCO’s Digital Track Notebook® (DTN) is primarily used by track inspectors to log and track defects and maintenance. ENSCO’s TrackIT® is a platform that stores and displays inspection data from multiple systems, (and thus of multiple types) aligned to a unified location. “Just as you don’t want your teams to operate

either,” ENSCO’s Rafael Maldonado said. “So, it’s critical to have a centralized location, like TrackIT, to ensure that your datasets are in sync.”

One of the challenges with collecting so much data at such a high rate, is knowing what to act on and when to act on it. The last thing any railroad wants is for critical defect data to get lost in a sea of less critical data. “On CPKC, when a defect rises to an urgent level, typically based on FRA or Transport Canada thresholds, an alert is automatically sent out to the field so someone can review it and take whatever action is needed,” Maldonado said.

But human review of the data is still an important component of autonomous programs; trained analysts who understand the data can weed out false positives, bad data, errors and malfunctions, and in doing so improve the alert algorithm’s future accuracy, he said.

As CPKC moves forward with its many ATIP initiatives, numerous challenges remain, despite the successes. At present, regulatory bodies like the FRA and TC do not allow these technologies

to be used in lieu of traditional track geometry inspection, except in cases where special waivers have been issued. So, despite the wealth of data CPKC’s autonomous vehicles collect, they must still satisfy regulatory requirements. There is also the fact that many autonomous technologies, particularly those based on machine vision, are still proving themselves—it will likely be some time before such systems are as trusted and as ubiquitous as WILD systems, for example. Nonetheless, CPKC’s ATIP projects demonstrate that autonomous inspection systems are already transforming track inspection, and therefore changing the ways in which the railroad industry goes about its business.

Jeff Tuzik is Managing Editor of Interface Journal . https://interfacejournal.com

This article is based on a presentation made at the 2025 Wheel/Rail Interaction Heavy Haul conference. https://wheelrail-seminars.com/

All images are courtesy of CPKC except where otherwise noted.

Racine Railroad Products’ cutting edge operator control interface and computerized automation not only increases production, it also improves safety while making our machines easier to operate and maintain the equipment. We offer a wide-range of innovative powered portable hand tools.

October 30 & 31, 2025

Hyatt Regency Jersey City

Jersey City, NJ

Railway Age’s Next-Gen Train Control has been the industry’s single-most important communications and signaling event since 1995. For our 30th anniversary, we are expanding our program to encompass the entire system. Expert-led sessions will examine the complex integrations incorporating signaling, train control, telematics, artificial intelligence, deep data analysis, cybersecurity measures and more.

Register and connect with industry leaders, explore innovations, and stay ahead of rail project trends and regulations.

Sponsorships: Contact Jonathan Chalon, 212.620.7224, jchalon@sbpub.com

Kris Kolluri President & CEO NJ Transit

Clarelle DeGraffe General Manager PATH

Dustin K. Lange Sr. Dir. Engineering Norfolk Southern

Mario Péloquin President & CEO VIA Rail Canada

Jonathan Kirby Sr. Dir., NJT PTC NJ Transit

Brian Yeager Dir., Advanced Tech. & Train Reliability Norfolk Southern

Tom Prendergast CEO Gateway Development Commission

Matthew Kim AVP, IS Enterprise Strategy CPKC

Steven Vant Chief Engineer C&S Conrail

Designed to move water away from the track bed, ditching and drainage systems are essential points of track maintenance. Managing the flow of water ensures stability and prevents erosion of trackbed material. No matter the season, flooding and heavy snow can pose challenges for Maintenance of Way. Crews need proper equipment to address the issue of trackbed integrity. Several vendors have answered that call and have provided a snapshot of what they offer.

RCE Equipment Solutions , home of the Railavator Hi-Rail excavator, says it “offers a diverse model lineup of Hi-Rail excavators designed to excel in ditching and drainage applications. Each Railavator model can be equipped with an integrated tilt-rotator coupler, streamlining the process of cutting ditches, creating swales, and shaping embankments with exceptional precision. The compact models— including the 50, 85, and 135—feature RCE’s exclusive hydraulically expandable track undercarriage system, enabling the Railavator to straddle railway tracks for maximum stability and accuracy during

Brandt’s RTB100 is built for road and rail and can travel up to 24.9 miles per hour on both.

By Jennifer McLawhorn, Managing Editor

lateral operations. Meanwhile, the larger models from the 210 series upward come standard with modified track systems engineered to provide generous clearance for effortless track straddling capabilities. Among the available attachments, the Jawbone bucket has become a customer favorite, combining the functionality of a smooth-edge bucket, clamshell, and toothed bucket into a single versatile tool. Regardless of project complexity or scope, RCE Equipment Solutions remains committed to developing customized solutions that address each client’s specific operational requirements.”

For Plasser American , “clean ballast is essential for maintaining track geometry and proper drainage. Plasser American’s ballast cleaning machines cater to a variety of railroad maintenance needs. For routine projects on plain track and turnouts, the RM80 is a powerful choice. This efficient machine features a single excavating chain and screening unit, along with a 50-mph travel speed and rapid setup/breakdown times to maximize track availability. Plasser American’s commitment to comprehensive track maintenance extends beyond the rails

with the FRM85 and FRM802 shouldercleaning machines. Plasser Shoulder Ballast Cleaners are designed to cut the entire shoulder width and full depth in one single pass to provide a productive and efficient operation. Offered with a single shaker box or, for higher performance, a double shaker box configuration, these units maintain clean ballast shoulders, promoting proper drainage and reducing the frequency of maintenance cycles.”

Loram told RT&S it “offers a full suite of products to create and maintain ditches to keep water flowing away from the ballast section of the track. For smaller ditching tasks and work around near track obstructions, the Self-Powered Slot (SPS) is the ideal solution. For high performance out of face ditching, the Badger Ditcher is the product of choice. For projects requiring high speed excavation and work around obstacles, the Ditcher Max can meet all ditching needs. All Loram’s ditching solutions are selfpropelled and can travel at speeds up to 45 miles per hour. The SPS is capable of removing, and placing, almost any type of material within the reach of the excavator. The SPS can excavate to create/clean ditches

at up to 250 tons of material per hour and work around, or remove, any obstacles that may be present to create a clean ditch line. Up to 550 tons of excavated material can be stored on the consist for offload at an appropriate location. The Ditcher is the highest performance machine in the market for creating consistent ditches along track. The Ditcher can excavate up to 1,000 tons of material per hour and discharge excavated material up to 35 feet from track centerline or into the gondola cars in the consist. Up to 225 tons of excavated material can be stored on the consist for offload at an appropriate location. The Ditcher is ideal for cutting new ditches, terracing slopes, and cleaning eroded material out of existing ditches. The DC Max combines the excavating speed of the Ditcher with the flexibility of an SPS for a premium ditching solution. Utilizing a DC Max the excavator can remove obstructions from the planned work location for the Ditcher so consistent and smooth graded cuts can be made regardless of the starting condition of the work area.”

Herzog ’s “Multi-Purpose Machine (MPM) continues to redefine efficiency in maintaining the railroad right-of-way (ROW), particularly with its advanced ditching capabilities. Proper drainage is critical to track stability and safety, and the MPM delivers a streamlined solution for clearing and shaping ditches with precision and speed. Equipped with a highpowered boom and specialized buckets, the MPM removes mud, sediment, and vegetation that can clog ROW ditches and compromise ballast integrity. Its extendable reach allows operators to cut, clean, and reprofile ditches without the need for multiple machines or extensive manual labor. The result is a cleaner, more effective drainage system that protects track structure from water damage and reduces the likelihood of washouts. What sets Herzog’s MPM apart is its mobility and versatility. Designed to travel efficiently on track, the machine can quickly mobilize to different locations along the line, minimizing downtime and maximizing productivity. Crews can perform ditching alongside other essential maintenance tasks the MPM handles, such as material handling, making it a true multi-tasker. By combining innovation with practicality, Herzog’s MPM ditching capabilities help railroads extend track life, lower maintenance costs, and ensure a safer, more reliable network for freight and passenger operations.”

A rep from Brandt told RT&S , “In the

rail industry, every minute matters. Downtime from track damage and repairs isn’t just inconvenient, it’s costly. That’s why effective maintenance, from ditching to drainage, is essential for keeping operations on track and expenses under control.

The Brandt RTB100 Hi-Rail Backhoe is built for that challenge, delivering fast, reliable performance with a versatile design that shifts seamlessly from road to rail. The RTB100 is built for road and rail and can travel up to 24.9 mph on both, helping

you reach remote ditching and draining sites faster and more efficiently. The front rail gear lifts the front wheels clear of track switches and crossing planks while providing great stability and bumper suspension. Plus, an accumulator suspension on the rear rail gear delivers adjustable traction and constant rail engagement for optimal safety. High-capacity hydraulics ensure maximum power flow to the attachments while delivering impressive lift capacity and reach.”

By Jennifer McLawhorn, Managing Editor

Whether they are made of wood, concrete, composite materials, or steel, railroad ties are necessary for holding rails in place and distributing loads of passing trains. Over time, these passing loads and environmental factors wear down rails and ties. Railroads must complete regular inspection programs of these ties to ensure they are performing as expected. RT&S spoke to several suppliers that offer ties and tie maintenance services for this article.

Stella-Jones manufactures pressuretreated wood railway ties and told RT&S it “supplies the railway industry with up to 10 million pressure-treated wood ties

per year. The company’s railway ties and other timber products support Class I, regional, and short line customers and industrial projects outside of the rail industry. Stella-Jones produces mixed hardwood and oakwood treated ties with creosote, borate and copper naphthenate for railway bridges and grade crossings, maritime and foundation pilings, and construction timbers. The company also offers customized wood treatment services tailored to customer needs.

Stella-Jones operates over 40 wood treatment facilities in the United States and Canada with 11 focused on the railway industry and has a network of several hundred sawmill suppliers. Its expansive North American network allows it to offer broad, economical coverage using rail, truck and maritime transport for its products. Combining large wood tie production capacity and long-term relationships with numerous wood suppliers ensures Stella-Jones has a constant supply

of raw material to support customer repair and maintenance demand, as well as unforeseen emergencies.”

For TiEnergy, renewable energy is the name of the game. A rep for TiEnergy says, “Railroads are investing heavily in sustainability, and railroad ties are a critical part of the story. When ties reach end of life, TiEnergy ensures they don’t become a disposal problem but instead a renewable opportunity. For decades, TiEnergy has partnered with Class I, short-line, and private railroads to recycle up to two million retired ties per year—turning waste into value for both railroads and landfills. The company’s innovation is TIEROC, a high-performance Alternative Daily Cover (ADC) engineered from clean, recycled wood ties. Approved under state landfill regulations, TIEROC preserves airspace, applies cleanly in all conditions, and acts as a secondary producer of biogas, supporting the rapid growth of Renewable Natural Gas (RNG) projects across the U.S. Each recycled tie saves 3.06 pounds of carbon from entering the atmosphere, advancing the decarbonization goals of both railroads and landfills.”

Geopier® seeks smart solutions for

Stella-Jones supplies up to 10 million pressure-treated wood ties each year.

ties and tie maintenance. “Since pioneering Rammed Aggregate Pier® technology in 1989, Geopier has supported thousands of projects worldwide with proven systems for soil stabilization and foundation support. Our GeoSpike® system is the ultimate solution for railroad subgrade challenges. Designed to strengthen weak track foundations without removing rails, ties, or ballast, GeoSpike installs quickly and cost-effectively— often reducing expenses by up to 50% compared to traditional methods. Using durable HDPE shells driven between ties and filled with aggregate, GeoSpike creates rigid elements that transfer loads from the ballast through soft soils into competent layers. The result? Superior track stability, reduced deformation, and long-term performance under heavy Cooper E80 loads.” When asked why railroads should choose GeoSpike, Geopier responded that it has “rapid installation with minimal downtime, the elimination of costly track removal, and is proven to correct mud spots, dips, and surface defects.”

From Loram , “Aurora is a cuttingedge track inspection platform designed to revolutionize how railroads approach tie maintenance. Traditionally, evaluating wood or concrete ties required manual inspection, a process that was both labor-intensive and prone to inconsistency. Aurora changes this dynamic by using advanced imaging, 3D profiling, and optional X-ray technology to provide railroads with a precise, data-driven understanding of tie condition across entire territories.

The system collects vast amounts of track-bed data, which are then processed into detailed 3D models. From these models, algorithms identify and classify individual ties, assessing defects such as rot, cracking, plate cutting, or structural failure. Instead of subjective visual ratings, railroads gain quantifiable, repeatable results. This enables maintenance teams to know exactly which ties need replacement, how many are approaching failure, and where resources should be directed. Aurora’s output is more than inspection—it’s actionable intelligence. By integrating tie condition data into planning, railroads can schedule tie replacement programs with greater accuracy, reduce unnecessary work, and extend the life of usable ties. Over time, this approach lowers costs,

Aurora uses advanced imaging, 3D profiling, and optional X-ray tecnology to provide railroads with a precise, datadriven understanding of tie condition.

improves safety, and supports more efficient capital planning. In short, Aurora transforms tie maintenance from guesswork into a predictive, precision-driven process that strengthens the backbone of the rail network.”

The Willamette Valley Company Railroad Solutions “offers several products for wood, composite and concrete tie repairs. SpikeFast® ES-50 is specifically designed to remediate wood and composite railroad ties, anchoring spikes with comparable strength to un-spiked hardwood ties. It is a patented, dual-component, non-foam 100% solid polyurethane product engineered to anchor cut-spikes or screw-spikes. SpikeFast® ES-50 is dispensed from hand-held canisters, or 200-gallon returnable steel totes through a uniquely designed, pressure/temperature-controlled meter and can be applied in a wide range of outdoor conditions. SpikeFast® ES-50 is easy to apply with minimal equipment maintenance and clean up. Its quick cure time allows for high production rate, or ties per minute, and delivers excellent gauge holding and dynamic rail roll over for existing crossties. SpikeFast® CTR-100 was developed by WVCO to answer the railroad industry’s need for an outstanding concrete tie repair product. SpikeFast® CTR-100 is time tested, meets railroad specifications, allows quick

repair of damaged ties, seals, and protects concrete from abrasion, increasing effective tie life and reducing costs. SpikeFast® CTR-100 restores original geometry for proper cant & gage and reduces head deflection. With a quick cure time, SpikeFast® CTR-100 gets trains back on track with as little downtime as possible.”

Nisus’ “QNAP® copper naphthenate is a non-restricted use preservative for pressure treating crossties and bridge ties and is widely available at quality treaters across the United States. It contains no toxic heavy metals and is not a listed carcinogen or sensitizer. Testing by the USDA Forest Product Laboratory demonstrated an estimated service life of over 30% longer than other available options. Additionally, QNAP ties are the easiest to QC, improving longevity and cost efficiency in track. The cleaner handling characteristics of QNAPtreated ties mean that crews have less risk of skin irritation and burns when handling treated ties, and bridge crews report that QNAP treated ties are less slippery when wet. QNAP has a superior environmental profile compared to other oil-borne preservatives, while also resulting in less drippage and bleeding in use, a particularly important aspect for bridges over pedestrian walkways, roads, and rivers. Plus, when ties have

reached the end of their service life, there are increased options for disposal, from boiler fuel to residential landscaping.”

Omaha Track says it “handles and processes more than 2 million ties, providing reliable and environmentally responsible solutions to railroads and utility partners across the country. Its tie disposal services are designed to maximize safety, efficiency, and sustainability. By investing in innovative processing methods, we ensure that every tie is responsibly managed — whether through recycling, repurposing, or clean energy conversion. In 2025, we proudly opened a new biomass facility in Attalla, Alabama, strengthening our ability to convert used ties into renewable energy resources. This facility represents a major step in our ongoing commitment to sustainability and adds to our growing network of operations nationwide. With demand increasing, Omaha Track is planning to bring at least one more biomass facility online by the end of the year. As our operations expand, so does our mission: to provide the rail industry with dependable tie disposal services while supporting a cleaner, greener future. Omaha Track remains dedicated to innovation, growth, and being the trusted partner for railroad tie recycling and disposal across North America.”

JIM VENA CEO Union Pacific

TOPICS INCLUDE:

• Redrawing the U.S. Class I Network

• Surface Transportation Board Perspectives

• Freight Rail Business Development Strategies

• Technological Breakthroughs

• Locomotives: Moving Beyond Diesel

MAR. 10, 2026

JERRY SPECHT, AREMA President 2025-2026

September was an extremely busy month! Everyone was getting back into the groove of sending kids off to school and ending all the vacations that could be afforded in the Summer. A successful attendance at the AREMA 2025 Conference & Expo, with over 3,200 attendees, an increase from last year’s attendance, provided a substantial showing that people enjoy getting together and catching up on what is happening within the industry. As Tony Hatch shared in his industry update, the times couldn’t be more exciting than they are now! For this month, I want to discuss the importance of networking and collaboration at AREMA – not only during the Conference & Expo, but during Technical Committee meetings.

Participation in industry organizations plays a crucial role in professional growth, offering invaluable opportunities for networking, collaboration, and continuous learning. We have the chance to learn from those who have been in the industry for a long time, as well as those who have recently joined the railroad profession.

Seasoned railroaders can pass along their knowledge of why things are done while new railroaders have fresh ideas to challenge the status quo that our industry needs to ensure that the path is still correct (or not). One of my calls to action during my Presidential acceptance speech was, “Challenge the Status Quo.” We must constantly ask the question, “Why?” It keeps the seasoned railroaders in a position to explain but also opens them up to question as some things have changed for the better, and other things don’t need to continue the way they have always been done.

This brings me to the “Story of the Meatloaf”: A little girl walks into the kitchen and sees her mom removing the meatloaf from the oven. Mom takes the meatloaf and chops the ends off, throwing them into the garbage. The daughter asks her mom why she just threw the perfectly good meatloaf into the garbage. Her mom responds by telling her that is what her mother used to do. The daughter asks her why. The mother says that she does not know why and that she should ask grandma.

The little girl proceeds to ask Grandma why she chops the ends of the meatloaf off and throws it in the garbage. Grandma responds that her mother used to do the same and she didn’t know why. Grandma proceeds to tell her granddaughter that she would need to ask her mom.

The little girl proceeds to ask her GreatGrandmother why she practiced the wasteful art of throwing good meatloaf in the garbage. Great-Grandmother responds – because the serving tray was only so big and she wanted it to fit perfectly in the serving tray for display.

The moral of the story is that if we do not know WHY we are doing things, we are doomed to repeat the mistakes of the past. Challenge the Status Quo!

Networking within industry organizations facilitates connections with professionals from diverse backgrounds and levels of expertise. This networking can lead to meaningful relationships, mentorship opportunities, and valuable insights that might otherwise remain inaccessible. By participating in conferences, workshops, or seminars hosted by industry groups, individuals can introduce themselves to collaborators, employers, or business partners, expanding their professional networks effectively and efficiently. One develops a contact list of people to reach out to for questions pertaining to a specific issue that may be new to their organization – but may have been solved somewhere else. As has been said, there is no sense in reinventing the wheel! This network provides a support structure for individuals to develop success but also prevent mistakes that could be significant.

Collaboration is another significant advantage offered by active involvement in industry organizations. These groups provide platforms for sharing knowledge, best practices, and innovative solutions to common industry challenges. Members can

collaborate on projects, contribute to industry standards, or engage in advocacy efforts, leveraging collective expertise to achieve shared goals.

Collaborative initiatives often lead to innovations and advancements that benefit the entire industry, highlighting the collective power of unified professional communities. There are so many advantages of not tackling industry-wide problems in a silo. The collective power of a unified professional community helps ensure that a problem is solved properly.

The ideas generated by group thinking are well thought out. An example of this was the Centralized Traffic Control (CTC)/ Interoperable Train Control Messaging (ITCM) developed in the industry as the new protocol for CTC. This was done as a collective effort within the industry by Communication and Signal professionals who were looking to create a new protocol that would be secure, agnostic, and efficient for transporting controls and indications for signal systems. This exercise and development is currently being deployed by most of the railroads in the United States with great success.

Moreover, industry organizations facilitate continuous professional development. They offer access to training programs, certifications, webinars, and updated industry research, enabling members to stay informed about emerging trends, technologies, and regulatory changes. The mission of AREMA is to satisfy these needs in the industry and grow the competency of our members and supporters. Continuous learning within these networks ensures that professionals maintain competitive skills and remain relevant in fast-paced and evolving industry landscapes.

Ultimately, active participation in industry organizations is more than an opportunity; it is an essential practice for any professional aspiring to thrive in their career. Through networking, collaboration, and ongoing education, professionals not only enhance their individual career trajectories but also contribute meaningfully to their industries’ collective growth and innovation. Getting involved was another of my calls to action this year. The true value of networking, participation, and collaboration can only be achieved by involving yourself and actively participating in AREMA. This is where it is happening!

Thank you for attending the AREMA 2025 Annual Conference & Expo in Indianapolis; we hope you had an excellent experience. If you registered as a full Conference Attendee, you will get access to the On Demand AREMA sessions recorded during the event. Stay tuned for details.

Discover how cutting-edge sustainability and resiliency practices are transforming railroad engineering, operations, and infrastructure. Hosted by AREMA and RailTEC, the Sustainability & Resiliency Day on November 13 brings together industry leaders to explore practical applications to drive innovation in your organization. Register now at rrec.railtec. illinois.edu.

Registration opens this October for the 2026 AREMA Communications, Signals & Information Technology Symposium

OCTOBER 2-3

— a two-day journey through the past, present, and future of railway technology. Join us March 3–5 in Jacksonville, FL, to explore how innovation is transforming the rail industry. Learn more at www.csit26. arema.org.

Download the AREMA 365 App for essential rail resources and networking opportunities. Easy access to news, events, and educational materials lets you stay informed and connected to the industry. Download it today by searching for AREMA in your phone’s app store.

Did you know we offer a wide variety of On Demand education for learning on your time? Browse our most popular webinars, seminars, and Annual Conferences to earn your PDH credits on the go. Visit www.arema.org to start your On Demand learning today.

If you’re looking for a podcast to binge, listen to AREMA’s Platform Chats . It features guests from every aspect of the railway industry. Catch up on all five seasons available on all your favorite listening services today.

Leverage the power of your trusted association’s Railway Careers Network to tap into a talent pool of job candidates with the training and education needed for long-term success. Visit www.arema. org/careers to post your job today.

Committee 8 – Concrete Structures and Foundations Newark, NJ

OCTOBER 6

Committee 2 - Track Measurement and Assessment Systems Pueblo, CO

OCTOBER 9

Committee 9 - Seismic Design for Railway Structures Virtual Meeting

NOVEMBER 12

Committee 28 - Clearances Virtual Meeting

JANUARY 27-28

Committee 15 - Steel Structures New Orleans, LA

MAY 19-20

Committee 15 - Steel Structures Lancaster, PA

SEPTEMBER 29-30

Committee 15 - Steel Structures Virtual Meeting

APRIL 12-13

Committee 15 - Steel Structures Denver, CO

Joining a technical committee is the starting point for involvement in the Association and an opportunity for lifelong growth in the industry. AREMA has 30 technical committees covering a broad spectrum of railway engineering specialties. Build your network of contacts, sharpen your leadership skills, learn from other members, and maximize your membership investment. If you’re interested in joining a technical committee or sitting in on a meeting as a guest, please contact Alayne Bell at abell@arema.org.

For a complete list of all committee meetings, visit www.arema.org.

By John G. Green, Ph.D., P.E., P.Eng., Lecturer

Researcher,

On April 4, 2025, forty AREMA Student Chapter Members and CE-156 “Railroad Engineering:

An Introduction” class students from California State University – Fresno, also known as “Fresno State”, took a field trip to several BNSF Railway sites. BNSF, which runs one of the largest freight railroad networks in North America, has several projects of interest to railway engineering students in the Fresno area. The students first visited Calwa Yard, located in the south end of Fresno, and then toured the Manning Avenue CAHSRA Grade Separation Project site. Fresno State established its Railway Program in the Fall of 2019, with a unique aspect of the university’s program being that taking a field trip to a railway facility is an integral part of each railway class. BNSF Railway has been a valuable partner in the engineering students’ education, having hosted field trips for several years.

At Calwa Yard, students received a safety briefing, learned engineering details about the

Manning Avenue project, and gained insights from Melissa Ibarra, BNSF Project Engineer, who discussed her professional experiences.

After the visit to Calwa Yard, the students traveled to the BNSF’s Manning Avenue grade separation project. As part of the California High-Speed Rail Project’s Central Region Phase 1 construction, and located about six miles south of Fresno, a 342-ft-long by 43-ft-wide bridge is being built to take Manning Avenue over the BNSF and the CHSR tracks. The students were able to view the bridge abutments and foundational work construction at the Manning Avenue Overpass up close. Significant work has been done, with more than 412 cubic yards of concrete placed to form the abutment on the west side of the grade separation.

The bridge separates high-speed rail from BNSF freight and prevents highway traffic from interfering with passenger trains. Built by the California High-speed Rail Authority, this bridge eliminates the risk of truck and freight train collisions, improving safety for all locals.

The students all expressed their appreciation for the BNSF tour. Fresno State AREMA Student Chapter member Anissah Saad had the following to say about the field trip, “The field trip to the BNSF was an eye-opening experience. I had no idea how much behindthe-scenes planning and teamwork it takes to keep the railroad infrastructure in good condition, and to keep the freight moving every day. It made me reflect on how important railroads are to our everyday lives and gave me a new level of respect for the people who work in the industry.”

Fresno State extends sincere appreciation to the employees of BNSF Railway, especially Melissa Ibarra, for making this memorable experience possible for the future railroaders of Fresno State. Partnerships like this not only help inspire students to pursue careers in the railway industry but also help shape the next generation of innovators. Together, we lay the groundwork for a more connected, safe, and dynamic future in rail transportation.

Get PDHs at your Own Pace with AREMA’s On Demand Education

Access to important professional development content is just a few clicks away with AREMA Education. Our On Demand content spans many disciplines of PDH accredited courses that allow you to get your PDHs by learning from experts online without leaving your office.

1. LEARN MORE

Studies show that participants learn more while taking On Demand courses as you can skim through the material you understand and take more time in the more challenging areas.

2. GET INSTANT ACCESS

With AREMA On Demand courses, you don’t have to wait to learn and get your PDHs as they’re available instantly after purchase.

3. CONVENIENT AND FLEXIBLE

Above all things, On Demand education is meant to take at your own pace and on your time. Study from anywhere in the world, whether from your office or the convenience of your sofa.

4. COURSE VARIETY

AREMA On Demand education offers a wide variety of topics for all studies of the railway engineering community.

Register and Start Learning today at www.arema.org.

BECOME A MEMBER AND SAVE

Not an AREMA member? Join today at www.arema.org and get discounts on all AREMA Educational Offerings, from Virtual Conferences to our Webinars.

2400 Enterprise Dr., Independence, KS 67301 Call 620-485-4277 or visit precisionrwy.com for more details

Let Precision remanufacture your non-functional, outdated 6700 into a fully functional 6700 with the latest technology. If you have an old, worn-out 6700 ta m per, we have your solution.

AREMA

Loram Maintenance of Way Inc

Messe Berlin GmbH

Next-Gen Freight Rail

Next-Gen Rail Systems

NRC

Racine Railroad Products, Inc.

Railway Educational Bureau

Stella-Jones Corp

voestalpine Nortrak Inc

WVCO Railroad Solutions PHONE #

301-459-3200

763-478-2627

212-629-7200

212-629-7200

262-637-9681

402-346-4300

800-272-8437

307-778-8700

541-484-9621

E-MAIL ADDRESS

marketing@arema.org alexis.b.nubbe@loram.com www.railwayage.com/ www.railwayage.com/ nrcma.org custserv@racinerailroad.com bbrundige@sb-reb.com kdulski@stella-jones.com gord.weatherly@voestalpine.com wvcorailroadsolutions@wilvaco.com

Reader Referral Service

This section has been created solely for the convenience of our readers to facilitate immediate contact with the RAILWAY TRACK & STRUCTURES advertisers in this issue. The Advertisers Index is an editorial feature maintained for the convenience of readers. It is not part of the advertiser contract and RTS assumes no responsibility for the correctness.

MAIN OFFICE

JONATHAN CHALON Publisher (212) 620-7224 jchalon@sbpub.com

AL, KY, TN, CHINA JONATHAN CHALON (212) 620-7224 jchalon@sbpub.com

CT, DE, DC, FL, GA, ME,MD, MA, NH, NJ, NY, NC, OH, PA,RI, SC, VT, VA, WV, CANADA: QUEBEC AND EAST, ONTARIO

JEROME MARULLO (212) 620-7260 jmarullo@sbpub.com

AR, AK, AZ, CA, CO, IA, ID, IL, IN, KS, LA, MI, MN, MO, MS, MT, NE, NM, ND, NV, OK, OR, SD, TX, UT, WA, WI, WY, CANADA: ALBERTA, BRITISH COLUMBIA, MANITOBA, SASKATCHEWAN HEATHER DISABATO (CHICAGO OFFICE) (312) 683-5026 hdisabato@sbpub.com

AMERICAS, EUROPE, ASIA, AFRICA, AUSTRAL ASIA NORTH AMERICA - CT, DE, DC, FL, GA, ME, MD, MA, NH, NJ, NY, NC, OH, PA, RI, SC, VT, VA, WV, AND EASTERN CANADA. EUROPE EXCEPT GERMANY, AUSTRIA, GERMAN SPEAKING SWITZERLAND, EASTERN EUROPE, ITALY, AND ITALIAN-SPEAKING SWITZERLAND. ASIA EXCEPT JAPAN AND CHINA. JEROME MARULLO (212) 620-7260 jmarullo@sbpub.com

GERMANY, AUSTRIA, GERMAN-SPEAKING SWITZERLAND, LATVIA, LITHUANIA, ESTONIA, POLAND, CZECH REPUBLIC, SLOVAKIA, HUNGARY, SLOVENIA, CROATIA AND SERBIA SIMONE AND SIMON FAHR

Breitenbergstr. 17 Füssen 87629

Germany Tel: +49 8362 5074996 sfahr@railjournal.com

ITALY, ITALIAN-SPEAKING SWITZERLAND DR. FABIO POTESTA Media Point & Communications SRL Corte Lambruschini

Corso Buenos Aires 8 V Piano, Genoa, Italy 16129

+39-10-570-4948

Fax: +39-10-553-0088 info@mediapointsrl.it

JAPAN

KATSUHIRO ISHII

Ace Media Service, Inc. 12-6 4-Chome, Nishiiko, Adachi-Ku Tokyo 121-0824

Japan

+81-3-5691-3335

Fax: +81-3-5691-3336 amkatsu@dream.com

IRJ PRO AND CLASSIFIED ADVERTISING SALES

JEROME MARULLO (212) 620-7260 jmarullo@sbpub.com

By David C. Lester, Editor-in-Chief

An interesting and fun possibility of moving into a new career later in life is to meet and work with people who you’ve followed and read for decades. Such was the case when, after 35 years of following railroading while in an information technology career, I entered the industry “professionally” as a railroad journalist in 2012. One of the individuals I had made a point of reading was Don Phillips. For many years, as readers may know, he was a columnist for Trains magazine under the name “Potomac Pundit,” later moving to simply “Don Phillips.” Those who are familiar with Don’s work know that he was a transportation reporter with the Washington Post for nearly twenty years and spent time afterward at the International Herald Tribune . Don began his career at UPI in the Atlanta bureau, later moving to its Washington, D.C. bureau.

The first of Don’s work that I came across was his piece in the October 1974 Trains , entitled “The Railroad That Stayed Out of Amtrak,” which profiled Southern Railway’s flagship passenger train, the Southern Crescent , which passed twice a day near my home in Atlanta, southbound in the morning and northbound in the evening.

As a young rail enthusiast still learning about the many fascinating aspects of the industry, I could not have asked for a more relevant or interesting article. Moreover, the man who penned it was an expert in the subject and a wonderful writer. For example, after lamenting the upcoming discontinuance of a couple of other SR passenger trains that were good but he referred to as “marginal,” he wrote the following.

“That’s the bad news. The good news is that every evening after 7:20 p.m. (depending on when a chronically late Amtrak connection arrives from New York), a stainless-steel streamliner pulled by three or four green-and-white E8s glides into another tunnel and emerges to roll past the U.S. Capitol, the Transportation Department Building, Amtrak headquarters, the Washington Monument, and the Jefferson Memorial

before the engineer notches out to accelerate across the Potomac River. Ahead is an overnight ride to Atlanta, a morning of twisting and turning over the grades of the Alabama Division to Birmingham, and (three days a week) a fast flat ride to New Orleans with a through sleeper to Los Angeles if you wish.”

Don continued the discussion with “Inside is a full dining car with tablecloths and fresh flowers; sleeping cars with private rooms, including a maste -

FROM MY PERSPECTIVE, DON NEVER MET A STRANGER AND WAS A GENUINE PERSON. HIS PASSING IS A TREMENDOUS LOSS TO THE RAIL AND TRANSPORTATION JOURNALISM COMMUNITIES.

room with shower; and reclining-seat coaches that still look like coaches (none of these psychedelic colors or wall carpeting). None of the cars — except perhaps some of the Amtrak runthrough cars — is more than three years from its last major overhaul.”

In addition to admiringly describing a fine passenger train, Don’s writing could also be entertaining. For example, in his November 1981 Trains column, Don wrote: “This is my second month in a row to eat crow. Last month, I had to admit underestimating Amtrak’s survival chances. This month, in one case, I was wrong about something and I want to admit my mistake. In another case, I feel as I have eaten crow literally ––on Amtrak dining cars––and I want to complain.” After a discussion of his “mistake,” which was to say that [then] Transportation Secretary Drew Lewis was going to “chop up Conrail like a

cow in a slaughterhouse,” Don got to his complaint. “Now about that other crow I had to eat. On the menu it was called steak, or fish, or chicken, but it was difficult to tell from the taste. Amtrak’s effort to cut dining-car losses by going to the fast-food concept is a disaster. I’m sure Amtrak will be able to improve the food over time, but that will be something like inventing a better Big Mac. Fast food is still fast food. And I simply can’t believe the use of plastic forks and trays was even considered. The last time I had plastic forks on a transportation conveyance was on Air Ghana in 1977.” [My, how times have changed! DCL]

In his June 1997 column, his writing style combined with his informed perspective as he commented on the division of Conrail between CSX and Norfolk Southern. “Never in railroad history has a merger involved breaking up a huge railroad like Conrail. This will truly be the unscrambling of an egg . . . The division of Conrail involves the undoing of the 1968 Penn Central merger, an abdominal combination of the Pennsylvania Railroad and the New York Central that should have never happened.”

I finally had the opportunity to meet Don at a meeting of the Lexington Group for Transportation History about 25 years ago and we always chatted at subsequent meetings. His company at dinner, social hour, or riding the rails was as lively as his writing. While we were acquainted, we were not close. Nevertheless, the opportunity to spend time talking with Don and getting some inside perspectives that would not see print was tremendous, and I sought his advice from time to time over the years.

From my perspective, Don never met a stranger and was a genuine person. Always in a good mood unless mad about something in railroading. His passing is a tremendous loss to the rail and transportation journalism communities, and, as I said in a note accompanying the obituary for Don on our news website, Don was one of the best, if not the best, transportation journalist(s) of our time. He will be missed.