TRACS Alpha

Turnout Remover and Carrier System

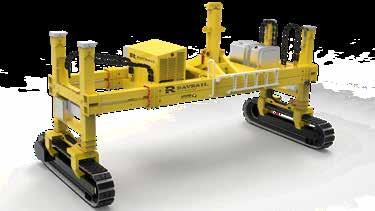

The TRACS Alpha

Turnout Remover and Carrier System is an innovative new solution for turnout/panel movement, installation, and track construction.

In the dynamic and demanding world of railway maintenance, safety and efficiency are paramount. The Affective Rail & Plant TRACS (Turnout Remover & Carrier System) Alpha is a revolutionary solution designed to redefine how turnout panels are managed. Engineered for maximum performance, The Alpha offers an unparalleled combination of safety, efficiency, and versatility, transforming the way rail infrastructure is maintained.

Key Features of TRACS Alpha

• Fully Remote-Control Operation: The TRACS Alpha system is operated entirely via remote control, allowing for precise maneuverability and operation from a safe distance. This innovation significantly enhances safety by reducing the need for personnel to be in close proximity to active lines.

• Compatible With All Track Gauges: The TRACS Alpha is engineered to handle turnout panels of any size gauge and configuration. Its adaptability ensures that the system can be used across various railway networks without requiring modifications.

• Efficient Self-Loading Capability: The TRACS Alpha system can load itself onto road transport vehicles, streamlining the logistics of moving the machine between job sites. This selfloading feature reduces downtime and transportation costs, making The TRACS Alpha an even more attractive solution.

• Side Shift Capabilities: The TRACS Alpha is designed for superior maneuverability on all types of track. It can move both along the track, as well as navigate sideways to facilitate precise installation of turnout panels - Side Shift This flexibility allows for dramatically more efficient and infinitely more accurate adjustments, minimizing the time required for track or geometry changes.

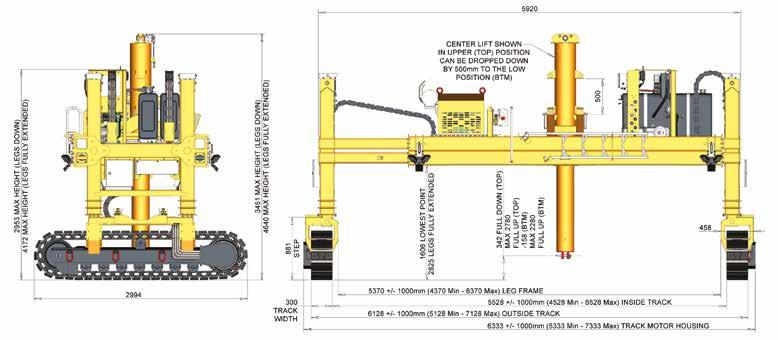

Performance Specification

A diesel powered, hydraulically driven, remotely operated, tracked vehicle with a range of attachments for handling all lengths of turnout panels

• Height Center-Top Position: 11.33 ft (retracted), 15.25 ft (ext)

• Height Center-Bottom Position: 9.67 ft (retracted), 13.58 ft (ext)

• Height Frame: 9.67 ft (retracted), 13.67 ft (ext)

• Base Weight: 16,534.65 lbs per machine

• Lifting Capacity: 27,557.75 lbs per machine

• Lifting Beam - 4 Point Quadlift “H” Beam: Available to suit any gauge or form of rail

• Fuel Capacity: 29.06 US gallons typical for 2 x typical 10 hour shifts

Safety & Efficiency

The TRACS Alpha system is engineered with a strong emphasis on safety. By removing the need for manual handling in potentially dangerous environments, The TRACS Alpha minimizes the risk of accidents and injuries. Its remote control operation further ensures that operators can maintain a safe distance from the rail line, adhering to the most stringent safety protocols.

Likewise, The TRACS Alpha offers a transformative approach to turnout panel management. The ability to self-load onto road transport and its versatile movement capabilities streamline the entire process of removing, transporting, and installing turnouts and panels, reducing the overall project costs.

Conclusion

The TRACS Alpha Turnout Remover And Carrier System represents a significant advancement in MOW technology. By prioritizing safety through remote operation and enhancing efficiency with its self-loading and versatile movement features, TRACS Alpha sets a new standard for turnout handling. Embrace the future of railway maintenance with The TRACS Alpha, and experience unparalleled safety, efficiency, and innovation in every project.

Additional Features & Benefits

• Adjustable track width allowing use in Extra Wide environments.

• 27,557.75 lbs/12500 kg lifting capacity.

• Suitable for single line & multiple track layouts

• The TRACS Alpha machines are designed to work in multiples to handle any gauge of track/panel

• Compact size and maneuverability allows for easy transportation, rapid deployment, and demobilisation.

• Travels safely at gradients of 11 °

• In the event of an main engine power failure, the TRACS Alpha machine can be moved off the rail infrastructure utilising its own built-in recovery system

• EMC Certified to ISO11452 (Automotive EMC)

• Noise level at operators’ ear: 76dB (A), engine idle / 84dB (A) engine full at 3.28 ft radius

• EU Stage vs US, Tier 4 Final compliant engine limits emissions exposure