CENTER LIFT TECHNIQUE

DavRail offers a comprehensive range of services designed around the Center Lift Technique to engineer safety, deliver speed, and optimize budgets across a variety of Maintenance of Way projects.

DavRail’s Center Lift Technique uses unique equipment to remove and replace turnouts, panels up to 330 ft, and up to 1 /4 -mile sticks of rail, without the need for cranes, heavy rigging, or sectional cutting. This innovative approach allows teams to access and ef ficiently repair subgrade, getting tracks back into service far quicker than traditional MOW methods. The Center Lift machine fl eet includes:

• TRACS - Alpha

• XO Beam - Switch & Panel Crossing System

• Panel Lifter

• TRT TM - Track Rail Transposer

Our expertise spans turnout installation, mud spot remediation, crossings, tunnels, sub-grade work, public transit, ballasted bridges with narrow shoulders, and more. We tackle challenging Maintenance of Way projects with technical precision and extreme mobility. Likewise, our fully remote-controlled machines dramatically increase worksite safety while driving down headcount and operational costs.

Clients who have already introduced the Center Lift Technique into their MOW arsenal have realized the following benefits:

• At least 50% more ef ficient than traditional methods

• Adjacent rail lines stay open

• Requires 75% fewer delivery vehicles and laydown space

• Delivers cost savings and faster project completion

• Effective in confined and complex MOW environments

With DavRail, railroad operators and contractors gain industry-leading expertise, advanced technology, and scalable solutions; ensuring every project is completed safely, ef ficiently, and precisely.

SALES, LEASE AND CONTRACTING

Your Center Lift Options

DavRail offers fl exible ways to put our Center Lift Technique to work for your railroad projects:

I. Purchase a Machine

You can own the equipment outright and gain full access to our specialty products. Every machine in our fl eet is versatile and can handle a wide variety of projects under the Center Lift Technique umbrella.

II. Lease a Machine

Favorable lease terms, with a lease-to-own option, provide access to DavRail equipment without full purchase. This is perfect for seasonal projects or temporary needs, especially those with critical timelines.

III. Sub-Contracted DavRail Operators

Let our trained team of skilled operators take on the project for you. For one fl at rate (no extra fees based on project type), you can have full access to our expertise without the longer-term commitment of a sale or lease.

The Center Lift Technique delivers more than just machines, it provides solutions for complex MOW challenges, backed by full service, support, and skilled operators. Our specially engineered equipment is designed to maximize ef ficiency, increase safety and reduce costs, and with fl exible options to buy, lease, or contract, you gain THE BEST solution to tackle your most critical Maintenance of Way obstacles every time.

WHERE WE OPERATE

Vancouver, Canada

Fort Worth, Texas

Monterrey, Mexico

São Paulo, Brazil

DavRail’s reach extends across North and South America, delivering our Center Lift machines and services wherever they’re needed. With strategically located partners and service hubs, we provide seamless logistics, local technical support, and expert guidance for every machine. This approach streamlines operations, reduces complexity, and maximizes profit margins while ensuring reliable, ef ficient, and worry-free project execution for our customers.

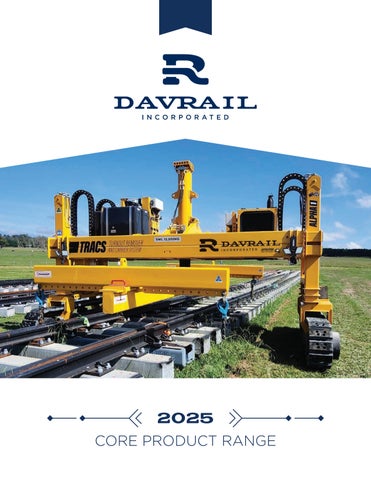

TRACS ALPHA

TURNOUT REMOVER & CARRIER SYSTEM

Advanced Movement

Capabilities - Side Shift

Any Size Turnout, Anywhere

Self Loading for Transport

TRACS Alpha is an innovative new solution for turnout/panel movement, installation, and track construction.

In the dynamic and demanding world of railway maintenance, safety and ef ficiency are paramount. The Affective Rail & Plant TRACS (Turnout Remover & Carrier System) Alpha is a revolutionary solution designed to redefine how turnout panels are managed. Engineered for maximum performance, The Alpha offers an unparalleled combination of safety, ef ficiency, and versatility, transforming the way rail infrastructure is maintained.

Features and Benefits

• Fully Remote-Control Operation:

The TRACS Alpha system is operated entirely via remote control, allowing for precise maneuverability and operation from a safe distance. This innovation signi fi cantly enhances safety by reducing the need for personnel to be in close proximity to active lines.

• Compatible With All Track Gauges:

The TRACS Alpha is engineered to handle turnout panels of any size gauge and con fi guration. Its adaptability ensures that the system can be used across various railway networks without requiring modifications.

• Ef ficient Self-Loading Capability:

The TRACS Alpha system can load itself onto road transport vehicles, streamlining the logistics of moving the machine between job sites. This selfloading feature reduces downtime and transportation costs, making The TRACS Alpha an even more attractive solution.

• Side Shift Capabilities:

The TRACS Alpha is designed for superior maneuverability on all types of track. It can move both along the track, as well as navigate sideways to facilitate precise installation of turnout panels - Side Shift. This fl exibility allows for dramatically more ef ficient and infinitely more accurate adjustments, minimizing the time required for track or geometry changes.

Scan here to view The TRACS Alpha Specifications Sheet

• Adjustable track width allowing use in Extra Wide environments.

• 27,557.75 lbs/12500 kg lifting capacity.

• Suitable for single line & multiple track layouts

• The TRACS Alpha machines are designed to work in multiples to handle any gauge of track/panel.

• Compact size and maneuverability allows for easy transportation, rapid deployment, and demobilisation.

• Travels safely at gradients of 11°

• In the event of an main engine power failure, The TRACS Alpha machine can be moved off the rail infrastructure utilising its own built-in recovery system

• EMC Certi fied to ISO11452 (Automotive EMC)

• Noise level at operators’ ear: 76dB (A), engine idle / 84dB (A) engine full at 3.28 ft radius

• EU Stage vs US, Tier 4 Final compliant engine limits emissions exposure

XO BEAM

SWITCH & CROSSING PANEL SYSTEM

Lifts up to 19,840lbs per Panel System

Remote Controlled Single Line & Multiple Track Adjustable Width

Revolutionizing the method of removing and replacing rail switches, crossings, & panels.

The XO Beams are fully remote-controlled, instantly establishing an exclusion zone and eliminating any safety concerns traditionally associated with manual handling. The speed of panel removal and installation is crucial during limited track and time shuts, allowing for the necessary rework of the track foundation before replacing the switch or crossing panel.

Affective Rail & Plant has designed and developed the XO Beam to provide a safe and highly ef ficient solution for removing, transporting, and installing all types of switches and crossing panels, regardless of track gauge. Used with our transport system, the XO Beam can ef ficiently move large panels from the build area to the work site, ready for quick installation.

Features and Benefits

• 19,840lbs/9000 kg lifting capability per machine.

• A fully loaded Lifting System can turn in any direction while in motion.

• Variable track width allows access and use in narrow environments like bridges, tunnels, and below grade.

• Ideal for removing and installing turnouts and panels on both single line and multiple line systems.

• Can easily cross multiple tracks.

• Compact size and maneuverability enables easy transportation, and rapid deployment to and from site.

• Fully adjustable lifting beam setup.

• Designed to work in multiples to handle any gauge, or composition of track panel.

• Can safely perform work at gradients of up to 11°

• Self recovery in the event of engine failure.

• 12,566lbs base weight per machine.

• 26 Gallons Typical for 2 typical 10 hour shifts.

• Lift Plan provided.

Scan here to view the Switch & Crossing Panel & XO Beam Specifications Sheet

PANEL LIFTER SYSTEM

Lifts up to 20,000lb per Panel Lifter

Works Under OLE & Catenary

Compact and Maneuverable

Revolutionizing the method of removing and replacing rail panels.

With this technology, worldwide rail track maintenance and construction projects are completed in less time and with reduced operational costs.

The Panel Lifter machines eliminate manual handling and improve the accuracy, as well as increase the productivity of installations.

Panel Lifters are completely remote controlled, creating an instant exclusion zone while also eliminating safe handling concerns.

The speed of removal is critical during limited possession timelines to enable rework of the track foundation ahead of replacement. The Panel Lifter system has been successfully and ef ficiently overcoming rail logistics challenges for more than 10 years.

The Panel Lifter revolutionizes the method of removing and installing rail panels up to 330 feet in length swiftly, safely, and with greater ef ficiency than traditional methods.

Features and Benefits

• 20,000 lb lifting capability per Panel Lifter, multiple units increase lifting capability; for example three units would lift approximately 60,000 lb.

• Fully certi fied to work across the rail network , including under live Overhead Line Equipment (OLE), Any Line Open working (ALO), and Catenary.

• A fully loaded Panel Lifter System can turn in any direction while in motion.

• Variable track width allows access and use in narrow environments like bridges, tunnels, and narrow right of way.

• Ideal for removing and installing panels on main line, repairs, and challenging new builds or crossings

• Can easily cross multiple tracks without damaging the rail.

• Can grab all gauges of track.

• Compact size and maneuverability enables easy transportation, rapid deployment, and demobilization.

• A panel lifter system of two machines can be used to move panel lengths up to 82ft long. More machines can be added to move longer panels.

Scan here to view the Panel Lifter Specifications Sheet

The Panel Lifter System adapts its footprint for hard to access areas

Works Under OLE & Catenary

Multi-Purpose

Rail Machine

Remote

Controlled

Rail movement and track construction made easier.

Our rail handling and movement equipment is streamlining track maintenance and construction projects around the globe – improving safety, creating ef ficiencies, and reducing costs.

DavRail, Inc.’s offering of the Trac Rail Transposer is a safe and ef ficient way to transport, remove, and install lengths of rail and associated iron work under live Overheard Line Equipment and Catenary.

The TRT removes and installs all profiles of rail and can work on all gauge of track. Multiple TRTs can be used to move long lengths of rail as well as transport, remove and install associated iron work like switches and crossings. The product is fully approved to operate in both North America and South America.

Features and Benefits

Scan here to view the TRT

• Suitable for plain rail, frogs, crossovers, and points.

• Approved to work under live Overhead Line Equipment (OLE), Any Line Open working (ALO), and Catenary.

• Removes, transposes, drags, and installs rail in a safe, controlled, manner by remote control.

• Ideal for use on both single line and multiple line layouts.

• Can easily cross multiple tracks, including areas with conductor rails, without fear of damaging the rail.

• Capable of threading rail past line side equipment and masts without fear of damage.

• Operates equally well in con fi ned spaces like tunnels and bridges, where right-of-way is at a premium

• Compact size and maneuverability allows rapid deployment and recovery.

• Its low gross weight means no Commercial Driver’s License is needed for transportation .

PTO POWERPACK

As an added bonus, all our Center Lift machines provide a critical secondary function as a mobile hydraulic power pack.

Standard track tools can run directly from the machines’ PTO, streamlining operations and reducing the need for additional equipment on site. Likewise, all your tools and gear can be loaded onto the machines for transport, further enhancing operator ef ficiency.

WHEEL TRUING

DavRail is excited to offer MOBILE, wheel lathing and WHEEL INSPECTION for the US market.

Keep your fl eet FRA-compliant and fully functional with precision mobile wheel truing, a critical requirement to keep your rolling stock wheels up to AAR profile specifications.

DavRail delivers this service directly to your locomotives or tamper machines, no matter the location. Our mobile wheel truing service eliminates the need for extra equipment, brick-and-mortar facilities, or taking units out of service. Our mobile approach reduces downtime, lowers operational costs, and ensures fast, reliable results.

Reprofile instead of replacing - Extend the life of your wheels and avoid unnecessary wheel-set purchases to maximize fl eet utilization and revenue.

Scan here to view our mobile truing in action

Andrew Davis - DavRail, President