MANUFACTURE

TECHNOLOGY

DESIGN

CONSTRUCTION

• Steady growth in timber decking market

• Timber redefining public infrastructure

• Keeping injured workers connected to work

MANUFACTURE

TECHNOLOGY

DESIGN

CONSTRUCTION

• Steady growth in timber decking market

• Timber redefining public infrastructure

• Keeping injured workers connected to work

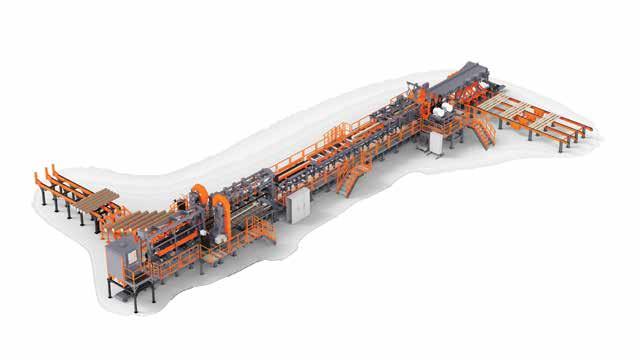

State-of-the-art technologies for prefabrication enable efficient production of the highest quality. Together with the experts from WEINMANN, System TM and Kallesoe, HOMAG Australia offers you the appropriate plant technology for both the joinery and the element construction and develop together with you the production concept that suits you best In this way, you are flexibly positioned - today and tomorrow - with your individual solution.

Volume 35 – Issue 5

Incorporating Australian and New Zealand

Established 1977

Front Cover:

The global timber decking market size is valued at $US 9.7 billion in 2024, demonstrating steady growth driven by robust demand across residential and commercial construction sectors, according to US/India market research company Research Intelo.

Story page 15

Publisher and Chief Executive: Hartley Higgins

General Manager: Robyn Haworth

Editor: Bruce Mitchell b.mitchell@ryanmediapl.com.au

Advertising: Jamie Richardson j.richardson@winetitles.com.au

Adelaide Office +61 (08) 8369 9514

Production & Creative Services: Robyn Haworth

Timber classifieds: j.richardson@winetitles.com.au

Adelaide Office +61 (08) 8369 9514

Subscriptions: subs@forestsandtimber.com.au

Adelaide Office +61 (08) 8369 9500

Subcription rates

Accounts:

Adelaide Office +61 (08) 8369 9500

Postal Address: 630 Regency Road, Broadview South Australia 5083 Phone: +61 (08) 8369 9500

Melbourne Office: Suite 2262, 442 Auburn Rd, Hawthorn VIC 3122 Phone: +61 (03) 9810 3262

Find us on Facebook @AustralasianTimber Website www.timberbiz.com.au

Conditions

The opinions expressed in Australasian Timber Magazine are not necessarily the opinions of or endorsed by the editor or publisher unless otherwise stated. All articles submitted for publication become the property of the publisher. All material in Australasian Timber Magazine copyright 2022 © Ryan Media. All rights reserved. No part may be reproduced or copied in any form or by any means (graphic, electronic, or mechanical including information and retrieval systems) without written permission of the publisher. While every effort has been made to ensure the accuracy of information, the publisher will not accept responsibility for errors or omissions, or for any consequences arising from reliance on information published. 18

6 8 20

The use of timber in public infrastructure is transforming how communities engage with shared spaces by promoting sustainability, aesthetic appeal, and social connection. As concerns about climate change and environmental responsibility grow, timber stands out as a renewable, low-carbon alternative to traditional building materials like concrete and steel. Its use reflects a community’s commitment to environmental stewardship, fostering a stronger sense of collective identity and responsibility.

Architecturally, timber introduces warmth and natural beauty to public spaces such as libraries, transit hubs, community centers, and schools. This organic aesthetic creates inviting environments that encourage people to spend more time in these spaces, enhancing community interaction. Unlike colder, industrial materials, timber structures often evoke a sense of calm and comfort, making public buildings feel more like extensions of home rather than impersonal facilities.

Moreover, timber allows for flexible, modular design, which can respond to community needs more dynamically. Structures can be built more quickly and with less disruption, making infrastructure projects more accessible and transparent to the public.

This fosters greater community involvement and support during the planning and construction phases.

The visibility of local timber also contributes to a stronger connection between people and place. When sourced responsibly from nearby forests, timber projects can support local economies and reduce transportation emissions, while reinforcing cultural heritage and craftsmanship.

Opal is taking legal action against the Victorian Government over the 2023 axing of a wood supply contract which was supposed to run to 2030.

In filings lodged in the Supreme Court of Victoria, Paper Australia Pty Ltd (trading as ‘Opal’) commenced proceedings against the State Government of Victoria for $402 million in damages following the Government’s breach of the Wood Pulp Agreement (Agreement) to provide a stable supply of wood to Opal, the operator of the Maryvale Paper Mill in the Latrobe Valley, Victoria.

Opal (part of Nippon Paper Group) is a paper and packaging group with sites across Australia (including a number in Victoria) and New Zealand. The Maryvale Mill is a major employer in the Latrobe Valley, employing more than 500 team members on the site directly, with additional jobs created externally in the wider community and supply chain.

The Mill has been a cornerstone of the Latrobe Valley for more than 85 years, deeply woven into the social and economic fabric of the region. The Mill’s direct economic output generates an estimated contribution to the Latrobe Local Government Area of more than $622 million annually.

In May 1996 the Victorian Government entered into the Agreement with Amcor Limited, the then operator of the Maryvale Mill, to supply pulpwood, with the Agreement expiring in June 2030. In 1998, Amcor assigned its rights under the agreement to Paper Australia Pty Ltd (now trading as Opal). Under the Agreement, the Victorian Government’s stateowned enterprise VicForests was providing Opal with eucalypt

Opal’s Maryvale Mill is a major employer in the Latrobe Valley, employing more than 500 people.

wood, a critical raw material for white paper production.

In November 2022, the Government advised Opal it would be unable to fulfill its contractual obligations to supply wood.

For the 2022/23 Financial Year, a reduced supply of wood was supplied to Opal by VicForests and subsequently, the Victorian Government made it clear that it did not intend to supply any wood to Opal in the future, forcing Opal to terminate the Agreement in May 2023. Opal says that with no viable alternatives available to replace the discontinued wood supply, it was forced to close its white pulp and paper production at the Maryvale Mill in early 2023, resulting in the loss of more than 400 jobs across Australia.

The closure, together with the reduction in production volumes, consequential redundancies, and the severe commercial impacts on the entire Opal Group arising from the loss of its white pulp and paper business, has caused—and continues to cause—Opal to suffer substantial loss and damage.

Opal says it has sought to reach a negotiated outcome with the Victorian Government. However, after almost three years of

discussions without resolution, Opal says it has been left with no choice but to proceed with a court-determined outcome for the damages owed to it by the Victorian Government. Opal hopes that, with the case now before the Supreme Court of Victoria, the matter will be determined fairly and in a timely manner, providing resolution not only for Opal and the Victorian Government, but also for the Maryvale Mill, the Latrobe Valley, and the wider Victorian community.

As the matter is now before the court, Opal will not be making further comment.

Nationals Member for Eastern Victoria Region and Shadow Minister for Public Lands Melina Bath told the ABC Opal was a huge employer in the Latrobe Valley.

She said the government closing the timber industry seven years early had created “significant harm” to the local community.

“It cut off a supply chain for Opal which resulted in … loss of jobs and loss of production,” she said.

“This legal action confirms the very serious economic damage, not just to Australian paper, but to the broader Gippsland community,” she said.

Anew 27-metre mass timber Sprint Canopy — Southeast Asia’s tallest single-span timber structure — now stands proudly over Singapore’s new $1.4 billion Geneo development, the city state’s new ‘work, live, and play’ hub.

Ang Chow Hwee, Director of Architecture at Woh Hup (Private) Limited, and Chethiya Ratnakara — former lead for design implementation and coordination at Venturer Timberwork and now Managing Director of Versobuild Pte Ltd - will present lessons from this project at Timber Construct 2025 in October.

“Because timber construction in Singapore is still rare, there are very few people who know how to do this,” Ang explained. “So when we started, we explored some value engineering… but the client was firm on using timber.”

Thanks to off-site prefabrication and an efficient design strategy, the canopy went up in just five months.

“For logistical efficiency and to manage costs, we shipped the components flat-packed,” Ratnakara said. “They were preassembled in a warehouse about

20 km from the site before being installed seamlessly on location.”

In total, more than 780 custom components of GL30c and GL24c Spruce glulam—totalling more than 1,150 m³—were fabricated by Finland’s Versowood Oy.

Some beams measured up to 19 m long and made the six-week journey on specialised Ma-Fi trailers.

“We had to assure everyone that the timber was sustainably sourced and responsibly procured,” Ang added.

Inspired by Gothic cathedrals, the canopy’s triangular geometry keeps elements slim while efficiently draining Singapore’s heavy rains.

“Timber design engineers scrutinised every joint, piece by piece,” Ang said.

A glass roof installed above the timber structure ensures the plaza stays dry, even during monsoonlevel downpours.

Meeting Singapore’s 120-minute fire-resistance standard posed one of the biggest hurdles.

Ratnakara and her team adopted a sacrificial charring method, combining performancebased fire engineering, advanced

structural modelling and additional testing to satisfy local authorities without hiding the timber’s natural beauty.

Leading design platform for mass timber company CLT Toolbox has rebranded itself as SPEC Toolbox.

The platform originally focused on Cross-Laminated Timber (CLT) and has grown to include eight product categories and the new brand reflects its expanded mission.

The product expansion now provides tooling for Glulam, LVL, light-frame construction, screws, hangers, and brackets, with an acoustics module to be released soon. This approach of eliminating technical barriers for specifiers is resonating within the industry, with the platform boasting over 5,000 user signups globally and partnerships with 30 major product suppliers.

The company says the evolution to SPEC Toolbox is a key step forward for users and partners, broadening the scope of technical problems the platform is engineered to solve to provide digital tooling to the industry that makes it easier to specify modern, innovative products.

“Our mission is simple: to make innovation easy to specify,” said Adam Jones, CEO of SPEC Tool-

box. Product manufacturers drive innovation for industry and passionate engineers every day are seeking solutions for their projects that challenge the norm.

“CLT and the mass timber industry is an embodiment of this innovation, and I experienced this myself both as a supplier at XLam and a specifier at WSP,” he said.

“Now, with SPEC Toolbox, we are giving designers the confidence to specify the materials of the future and enabling a much-needed shift towards more sustainable and cost-efficient construction and putting incredible manufacturer solutions right into the hands of engineers”

For engineers, the platform eliminates the need to build significant spreadsheets that can take hundreds of hours or to rummage through disparate supply chain data found in PDFs. SPEC Toolbox removes the technical barriers to product specification, scaling engineering capacity and giving designers the confidence to specify the materials of the future.

This directly addresses the challenge that innovation is often hard to specify, fulfilling the company’s mission to make it easy.

The platform’s success has been driven by its diverse and talented founding team, including:

• Adam Jones (CEO), who previously felt the specification problems as a supplier at XLam and a specifier at WSP.

• Ringo Thomas Co-founder & CCO, who has poured his career full of experience in B2B sales to help drive the

growth of a global customer footprint in a very short time

• Lelissie Bedada Co-founder & Head of Engineering, leads the engineering effort of 17 structural engineers in Addis Ababa, Ethiopia.

• Ikhsan Agustian Co-founder & CTO, who invented key technology the team leverages to build the worldclass software.

The Hyne Group, through its national Hyne Pallets network, is pleased to announce the acquisition of Seapal Pallets & Crates located in Kilcoy, South-East Queensland.

It marks the sixth pallet manufacturing acquisition in less than two years and the second in Queensland.

Hyne Group CEO, Jim Bindon, acknowledged the proud history of Seapal which has been in operation since 1998under the current ownership of Trevor Carter.

“As we continue to grow our na-

tional pallet network, we welcome Seapal, which, like the Hyne Group, has along history across Queensland and Northern NSW.

In addition to standard pallet manufacturing, the business delivers custom solutions to service the unique freighting requirements such as those of large manufacturing businesses”.

“We see some strong, future synergies with our Express Pallets & Crates business located close by in Narangba. This includes fibre supply, freight, staffing & management, production planning

and raw material scale efficiencies.” Mr Bindon said.

Seapal has an extensive network of customers across the mining, agriculture, logistics and food sectors, with Peter Hyne recently addressing staff on site and welcoming them to the Hyne Pallets structure. Timber Supply for the Seapal business will continue from the co-located sawmill, ownership of which will be retained by Trevor Carter. But this will be complemented by Hyne’s leading Queensland sawmill business at Tuan, one of the largest sawmills

in Australia. This supply capability and flexibility, ensures certainty and consistency for all existing and future customers. The Seapal trading name will remain the same and the team will transition across to Hyne Pallets at completion.

The Hyne Pallets network now consists of Seapal Pallets & Crates, Kilcoy, QLD; Express Pallets &Crates, Narangba, QLD; Newcastle Pallets, Newcastle, NSW; Rodpak, Melbourne, VIC; Pallet & Bin, Shepparton, VIC and Pinetec, Perth, WA.

New Zealand’s largest Glulam timber manufacturer Techlam has been awarded the structural timber package for the Tonga Parliament redevelopment project by Westland Construction.

The contract includes the supply and fabrication of glulam timber components for the new NZ$60 million Fale Alea that will replace the original building destroyed by the 2022 tsunami.

For Techlam, this represents an opportunity to once again showcase New Zealand-made engineered timber on the international stage, particularly in a building that will serve as the democratic heart of the Kingdom of Tonga.

“It is not every day you get to contribute timber solutions to a building that will serve as the centre of a nation’s democracy,” Brett Hamilton, Techlam’s managing director, said.

The project, which had been delayed after the Hunga Tonga-Hunga Ha’apai eruption, has been collaborative from day

one. Techlam was part of the design conversation from early on, working alongside Westland Construction, Holmes Consulting and Warren and Mahoney.

This early contractor involvement is core to how Techlam operates on every project. By engaging during the design phase, the team can influence the layout, structural approach and detailing decisions, all of which significantly impact both cost and buildability.

“The value engineering sessions were incredibly collaborative,” Brett said. “We brought our manufacturing expertise to the table early, suggesting approaches that would work better from a fabrication perspective, while the architects and engineers pushed us toward solutions that served the building’s cultural and functional requirements.”

For the Tonga Parliament project, this meant Techlam could optimise the timber design from their Levin facility’s capabilities in a controlled environment, while

ensuring components would integrate easily on the construction site in Nuku’alofa.

The architectural requirements include curved and complex glulam structures. This is exactly the type of challenging work that gets the Techlam team excited.

“Our Levin facility is set up perfectly for this kind of work,” Brett said.

“With over 7,500m² of production space, we can handle the scale and complexity. More importantly, our team has the experience with curved glulam that makes these challenging shapes possible.”

The fabrication process will soon be underway to meet both the structural demands and the architectural vision that will define Tonga’s new parliamentary home.

For a New Zealand company, working on projects across the Pacific is about strengthening regional connections and demonstrating what Kiwi manufacturing can achieve.

“The parliamentary building

isn’t just infrastructure; it’s where important decisions about the country’s future will be made. We are proud that New Zealand engineered timber will be part of that story,” Brett said.

As procurement and fabrication continue through 2025, the Techlam team is focused on delivering components that meet the exacting standards this project demands.

“Every project teaches us something new,” he said.

“Building on our experience across the Pacific, from Cassidy International Airport in Kiribati to the EFKS Saleaula in Samoa and Lomani Island Resort in Fiji, this project brings its own unique challenges around precision and cultural significance. It’s exactly the kind of work that keeps us passionate about what we do.”

The project is expected to be completed by 2027, with the parliamentary complex opening to serve Tonga’s legislature processes for generations to come.

In an industry where physically demanding roles and tight production schedules are the norm, injuries can disrupt operations and put pressure on teams.

But one South Island timber business has found a better way — keeping injured workers connected to work and reaping the benefits.

Westco Lumber, a timber sawmill and distributor employing over 100 staff across Ruatapu and Christchurch, wanted to improve how it supported injured employees.

“When people injured themselves, they’d be put off work and we wouldn’t see or hear from them for several weeks,” says Ebony Hillman, Westco Lumber’s health and safety team leader.

“We could hear the stress this was causing. People were saying they felt isolated and anxious about their job. We knew we could do better.”

Keeping injured workers connected to their workplace — through modified duties or regular communication — can make a big difference. It helps people feel supported, maintain their sense of purpose, and stay engaged with their team. For businesses, it means retaining skilled staff and reducing disruption.

Westco Lumber joined an ACC recovery at work trial to see what difference a workplace could make. The trial involved team leaders, senior management, and employees working together to review processes, develop resources, and track progress.

One of the most practical changes was introducing checklists for team leaders.

“Every injury and every situation are different,” says Ebony.

“Having a basic step-by-step list means you always get the information you need. Regardless of whether someone was injured at work or at home, the same steps apply”.

Improved communication was another key learning.

“Sometimes people feel anxious because they think they’re letting everyone down,” Ebony explains.

“Regular check-ins help them feel included and valued. Continuous reassurance is hugely important.”

Westco Lumber also strengthened relationships with local health providers, including doctors, physiotherapists, and occupational therapists.

“Better communication with health providers means that if recovery isn’t going to plan, we can act early and find alternative strategies,” says Ebony. “They understand what we do, and we’re on the same page about modified duties.”

Identifying suitable duties for injured workers was a challenge at first. Over time, Westco Lumber expanded its list of modified duties from four to eighteen options, all approved by an occupational therapist.

“It’s not one size fits all,” says Ebony. “You have to think creatively. Look beyond the person’s main role and see what other strengths they have. Break tasks down so others can share the load. That’s what worked for us.”

The results speak for themselves: Westco Lumber is seeing fewer injury claims, faster returns to work, and happier, more engaged employees, which is better for their bottom line.

“When you’ve got happy people, production is amazing too,” says Ebony.

The company’s efforts have been recognised — they were a finalist for the West Coast Leading Light Business Excellence Awards 2024 ‘ACC Employer of the Year’, and Ebony won the Canterbury

West Coast Forestry Awards 2024 ‘Outstanding Health and Safety Management Award.’

Mark Ross, Chief Executive of the Wood Processors and Manufacturers Association, says Westco Lumber’s approach is a great example for the industry.

“If you don’t have a key person in a role, productivity slows down. Recovery at work is about retaining expertise and help getting people back to work safely and sooner. Start small, keep it simple, keep it specific.”

For Ebony, the biggest takeaway is the positive impact on people.

“We’re seeing better relationships, more questions, and happier people. Improving work life flows into home life and the community. That’s a big driver for us.”

Want to make recovery at work easier in your business?

Learn more about the supports available. Explore ACC’s practical tools and templates: www.acc. co.nz/recovery-at-work

Comact, a leader in OEM high-caliber wood processing equipment, has signed a new strategic partnership with Lakeland Steel, based in Rotorua, New Zealand.

This partnership marks an important step in Comact’s global growth strategy and reinforces its commitment to better serving customers across New Zealand, Australia, and the South Pacific.

As part of this new strategic partnership, Lakeland Steel will represent Comact in New Zealand, Australia, and the South Pacific, strengthening its local presence and ability to serve customers in the region.

Beyond sales representation, Lakeland will also support Comact projects by providing localized services, including engineering, drafting, manufacturing, fabrica-

tion, installation, maintenance, and repair, ensuring responsive, high-quality execution aligned with Comact’s standards.

“This partnership brings together two organizations with deep expertise and a shared focus on customer success,” said Simon Potvin, CEO of Comact. “Lakeland Steel’s strong regional presence and technical capabilities make them an ideal partner as we expand our footprint in Australasia.”

Founded in 1976, Lakeland Steel (also operating as Lakeland Engineered Projects) is recognized as a trusted partner for innovative sawmill solutions in the region.

Their team offers end-to-end engineering services from their headquarters in Rotorua, supported by a state-of-the-art 3,200 m2 workshop, CNC equipment, heavy lifting gear, and a specialized 500

m2 paint and blasting facility. Together, Comact and Lakeland Steel are already delivering results. The teams are currently working on a major project for Red Stag Timber in Rotorua, involving the sale and installation of a Comact double fork stacker, a MoCo stacker, and all associated equipment and automation required to rebuild the outfeed line at the planer mill. The project is scheduled for delivery during the upcoming Christmas holiday period.

The partnership reflects Comact’s long-term vision of supporting sawmills worldwide with cutting-edge solutions and local expertise. With this alliance, customers in New Zealand and Australia can expect faster access to Comact’s technologies, more localized service, and a strong

foundation for future projects. For over 100 years, Comact has been a leading OEM in high-caliber wood processing equipment, digital technologies, cutting solutions, project services, and aftermarket support. Driven by innovation and excellence, we are dedicated to helping our customers address their most pressing operational and business challenges in today’s industry.

Whether for brownfield or greenfield projects, Comact’s expertise provides wood processing facilities with the confidence that their investments will yield superior performance, throughput, and ROI. This ensures they remain competitive and achieve sustained growth in an ever-evolving market. For more information, visit www. comact.com

Sterling Structural, a leading manufacturer of cost-effective, pre-fabricated mass timber and hybrid structural systems in North America, has launched its CLTimber Bay System, a comprehensive building solution specifically designed for industrial and commercial projects including warehouses, data centers, and large-scale retail facilities.

The CLTimber Bay System combines the environmental benefits of mass timber with the speed and efficiency of a pre-engineered solution. Building on Sterling’s expertise in delivering large-scale industrial projects, the system addresses the growing demand for sustainable industrial and commercial buildings as corporate real estate priorities shift toward smarter building systems that support both people and the planet.

“As the industrial and commercial sectors evolve, developers are prioritizing building systems that deliver both environmental performance and construction efficiency,” said Michaela Harms, Vice President of Mass Timber at Sterling Structural.

“Our CLTimber Bay System responds to this shift by providing a sustainable and turnkey mass timber solution that’s optimized for performance, flexibility, and con-

structability—delivering on site, on time, and on budget.”

Unlike traditional mass timber suppliers, Sterling Structural provides a complete, fully engineered building solution that includes structural design, CLT supply, structural steel, connection hardware, and installation through its trusted network of partners. This integrated approach streamlines procurement, reduces job site coordination, and keeps projects on track with domestically sourced and manufactured materials that are reliably delivered to the project site.

Key features of the CLTimber Bay System include:

• Accelerated Construction: Prefabricated panels can be installed with factory-applied Weather Resistant Barrier (WRB) to fast-track envelope completion;

• Simplified Installation: CLT provides a continuous structural surface, making attachment of racking, mechanical systems, or tenant improvements straightforward without additional blocking or costly field coordination;

• Environmental Performance: Dramatically reduced embodied carbon compared to traditional tilt-wall construction using

100% domestically grown, regenerative timber.

Sterling Structural and its complementary product, engineering and installation partners provide comprehensive environmental product data, material weight analyses, logistics benefits, and

schedule advantages over traditional tilt-wall construction.

The system supports developers seeking U.S.-based supply and measurable sustainability outcomes while maintaining construction efficiency and cost-effectiveness.

Latest Housing Industry Association forecasts show that recent policy announcements will see more than one million new homes commencing construction over the next five years.

The HIA recently released its quarterly Housing and Economic Outlook Report, covering forecasts for residential building activity across Australia.

This HIA Outlook has revised the forecast for the number of new homes to commence construction in the five years to June 2029 from 986,000 to 1.01 million considering recent policy decisions.

“Higher than previously anticipated population growth, and changes to government policy, have resulted in an upgrade to our forecasts for the number of

homes that will commence construction over the next five years,”

HIA Chief Economist Tim Reardon said.“Despite the upgrade in the Outlook, policy settings remain too restrictive to achieve the goal of 1.2 million new homes over the next five years.

“The decline in the cash rate has seen home building activity pick up, but this improvement is not evenly spread across regions or building types as government policies remain the main determinant of the volume of home building,” he said.

“Indications are that Australia’s population growth will remain elevated and exceed 30 million before the end of 2030. This will force up the price of established homes and increasingly see new home construction as a cheap-

er alternative to purchasing an established home.”

Mr Reardon said that changes to government policies were starting to focus on reducing the costs and barriers to new home building and would add further to the supply of new homes.

“In this Outlook there is an upgrade to the forecast number of homes to commence construction in New South Wales due to recent changes announced in this year’s state Budget,” he said.

“A plan for the government to underwrite apartment sales, the pattern book and fast-tracking approvals will have a tangible uplift in commencements in New South Wales over the next few years.

“The announcement by the Australian Government to lower the cost of Lenders Mortgage

Insurance (5 per cent deposit) will also see an ongoing increase in first home buyers building a new home. This policy could add as much as 10,000 new homes, per year, to supply. Further reform of macro-prudential restrictions introduced since the GFC also warrant review and could add further to the supply of new homes.”

Mr Reardon said that home building activity would flow to those regions with the lower cost of delivering new homes to market.

“For this reason, home building activity increased first in Western Australia, South Australia and Queensland. New South Wales and Victoria remain laggards given the significantly higher cost of land and home supply in those states,” he said.

Across Australia, a quiet design revival is transforming the way communities engage with public infrastructure.

Timber, once confined to traditional applications is now at the heart of contemporary sport and recreation design. Its warmth, sustainability, and engineering adaptability are making it a material of choice for civic projects focused on connection, movement, and long-term performance.

Long valued for its warmth, sensory appeal, and versatility, timber is increasingly being chosen for public environments where design must meet durability. Whether in the structure beneath a basketball court or the flowing formwork of a skate park, or in curved skate ramps and nature-integrated pathways, timber offers a combination of performance, sustainability, and visual presence that few materials can match. It is enabling spaces that feel both functional and inviting, bringing communities together in uniquely local ways.

“Timber offers a unique combination of performance and atmosphere,” says Big River Group’s Francis Cox, Regional Manager WA & SA. “In high-use public spaces, it brings structural strength, but also a kind of character that helps shape how people feel and move within the space.”

Recreational infrastructure demands materials that can withstand constant use while still contributing positively to the surrounding environment. Timber meets this challenge head-on. Its strength, adaptability and tactile qualities offer a rare combination that few other building materials can match.

One striking example is the recently completed Kalgoorlie Boulder Basketball Stadium in Western Australia, where timber

played a foundational role both literally and visually, in transforming the space. Supplied by Big River Group and installed by WA Hardwood Floors, more than 2,400 sheets of engineered structural plywood were used to form the subfloor foundation. The plywood met AS/NZS 2269 structural

standards, with stress grading up to F14, and was manufactured from plantation-grown Radiata Pine, ensuring both performance and environmental responsibility. The finished surface, a polished maple court, delivers the performance required for elite sport, while offering a sense of warmth

and refinement that elevates the venue beyond functionality. The redevelopment added two new indoor courts to complement the existing three, including a show court with grandstand seating for approximately 1,200 spectators. As the home of the Goldfields Giants in WA’s top-tier

NBL1 competition, and a base for local senior and junior leagues, the stadium now serves as a regional anchor for both sport and community.

The venue’s airy interior, accented with natural timber, enhances the experience for both players and spectators. It’s a reminder that materials contribute not only to how a space performs, but also to how it feels. Cox describes how this balance of form and function is exactly why timber continues to be chosen for civic centres.

“For high-use environments like Kalgoorlie, timber not only delivers on durability and ease of construction, but it also creates a space people want to be in. That matters, because these venues aren’t just about sport, they’re about community,” he says.

The idea that timber connects people to place is also evident at Stirk Park Skate Park in Kalamundra in Western Australia.

The reimagined and beloved community space with a design that draws inspiration from the area’s iconic Zig Zag trail. Nestled among mature trees and natural bushland, the park’s expansive concrete layout features deep bowls, sculpted transitions, and tiered platforms, brought to life through the precision of engineered timber formwork. Products including Laminated Veneer Lumber (LVL) E-Form, DeckPly F17, and supporting framing solutions allowed the park to follow the contours of the landscape, reinforcing a strong connection to place while ensuring structural integrity and long-term durability. DeckPly F17 formwork is engineered to AS 6669 and AS/NZS 2269 standards, with a durable marine-grade phenolic ‘A’ bond overlay that ensures a smooth concrete finish and longevity. The result is a space that balances performance with local identity, making timber not just a construction material, but a tool for storytelling and

community pride.

“What we love seeing is how timber helps ground these spaces in their environment,” Cox explains.

“It’s a material that feels natural, works with curves, and performs long-term which is exactly what these outdoor spaces need.”

In Mt Druitt, New South Wales, the recently completed Rathmines Skate & Youth Park showcases how timber, specifically Armourform Bending Ply 2400x1200x9mm enabled the creation of fluid curves, vertical features, and layered transitions essential to modern skate park design. The adaptability of timber formwork brought sculptural complexity and precision to the build, shaping a space designed for movement, progression and play. Timber’s role was critical in delivering a design that invites young people to engage with their environment in active, expressive

ways.

Meanwhile at Perth Zoo, timber formwork played a vital role in delivering a network of curved retaining walls, flowing pathways, and naturalistic interactive spaces. Set within lush greenery, the completed play and leisure precinct integrates concrete and timber-based infrastructure seamlessly into the surroundings. The use of LVL, DeckPly, and ArmourForm supported the creation of elegant, curved forms that enhance the visitor experience while standing up to the demands of high daily foot traffic. The project is a clear example of how timber can enable playful, durable, and environmentally conscious design outcomes.

As governments and developers increasingly seek out sustainable, low-carbon materials that align with long-term infrastructure goals, timber is fast becoming the

material of choice. Its renewability, low embodied energy, and growing range of high-performance formats make it ideal for public spaces that need to last both physically and socially.

“Recreational spaces are more than just built environments, they’re places where identity and community are forged,” explains Cox. “Timber brings those places to life beyond function - in a way that’s human, warm, and enduring.”

From inner-city youth parks to regional sports facilities, the renewed embrace of timber is helping to shape inclusive, functional, and future-focused spaces across Australia, proving that wood has a powerful role to play in our public lives, serving to ground the projects in their landscape and community, reflecting local identity and materials.”

The global plastics industry is set to benefit from world-leading wood fibre dice that will help position New Zealand as a leader in sustainable materials.

Developed by the Bioeconomy Science Institute and licensed exclusively to ConiForme, the fibre dice technology of the same name means wood fibres can be used to make sustainable, lighter plastics for the automotive, furniture, consumer products, appliances and packaging industries.

This will establish New Zealand as a global leader, as demand for sustainable plastics and the need for continued innovation across global markets increase.

The fibre dice – so-called because of their square shape that enables easier cutting – are produced in a small size that can be easily handled by existing plastics processing machinery.

They can reduce tooling abrasion and shorten processing cycles while enhancing mechanical properties, dimensional stability and scratch resistance for high-performance results.

The dice hold wood fibres together until they are released and evenly dispersed into the plastic resin. This technology addresses the odour, quality and consistency challenges that come with other natural fibre solutions.

The Bioeconomy Science Institute began working with ConiForme in 2021 to commercialise the dice technology. ConiForme general manager Jeremy Warnes says ensuring technologies are developed to meet market needs takes time, and it’s an exciting step to now be able to take the fibre dice to market.

“This technology delivers environmental benefits, fantastic properties and production efficiency improvements. It’s a win for

everyone.

“Composites made using wood fibre dice are produced from renewable resources and are more sustainable than glass fibre equivalents. They are also easily recyclable and help manufacturers meet legislative end-of-life requirements,” he says.

ConiForme is working with the Daiken Corporation, a leading MDF manufacturer, and its subsidiary Daiken New Zealand to produce the dice. Daiken MDF business operating officer Takahisa Honda says manufacturing ConiForme wood fibre dice is an exciting evolution of MDF business in New Zealand.

“It opens doors to new markets in construction materials as well as in auto parts, food packaging and beyond – all while driving innovation and advancing sustainability.”

According to Research and Markets, the global natural fibre composites market is projected to reach $18.65 billion by 2030, with an expected 12 percent

compound annual growth rate from 2025. “We see the market growing, driven by increasing consumer demand for sustainable plastics, evolving legislative requirements and the need for improved performance, particularly in automotive applications,” Jeremy says. “As industry trends

continue to accelerate, this will create exciting opportunities for our partners.”

ConiForme has aligned with ITOCHU Plastics Inc. to distribute the wood fibre dice in Asia and is currently in testing with plastics processors and manufacturers in Japan, the EU and the US.

The global timber decking market size is valued at $US 9.7 billion in 2024, demonstrating steady growth driven by robust demand across residential and commercial construction sectors, according to US/ India market research company Research Intelo.

Research Intelo says the market is expected to expand at a Compound Annual Growth Rate of 5.4% from 2025 to 2033, reaching a projected value of $US 15.5 billion by 2033. This growth is primarily fuelled by increasing investments in housing infrastructure, a rising trend towards outdoor living spaces, and the ongoing shift towards sustainable and eco-friendly building materials.

Research Intelo says the market is poised for substantial expansion as consumers and builders increasingly favour timber decking for its aesthetic appeal, versatility, and environmental benefits.

Outdoor living has become an integral part of modern home design. Homeowners are increasingly seeking ways to create functional, stylish, and sustainable spaces where they can relax and entertain. Among the many options available, timber decking stands out as a timeless choice. Known for its natural beauty, durability, and versatility, timber decking has become a preferred solution for transforming patios, gardens, and pool areas into inviting retreats.

WHY CHOOSE TIMBER DECKING?

Timber decking offers a unique combination of aesthetic appeal and practicality. Unlike concrete or synthetic alternatives, timber creates a warm and organic feel that blends seamlessly with nature. Its rich textures and natural grain patterns bring character to outdoor spaces while providing a

comfortable surface for walking barefoot.

Beyond its visual charm, timber is highly versatile. It can be customized in various finishes, stains, and designs, making it easy to complement both traditional and contemporary architecture.

Key Benefits of Timber Decking:

1. Natural Beauty

Timber exudes a sense of authenticity and elegance. Every plank is unique, adding individuality and charm to your outdoor area.

2. Durability

When properly maintained, hardwood decking such as teak, cedar, or ipe can withstand harsh weather, resist pests, and last for decades.

3. Eco-Friendly Option

Timber is a renewable resource. Choosing certified sustainable wood ensures minimal environmental impact while promoting responsible forestry.

4. Comfort and Safety

Timber decking remains cooler underfoot than many synthetic alternatives, making it ideal for hot climates. Additionally, it provides natural slip resistance when treated correctly.

5. Adds Property Value

A well-designed timber deck not only enhances outdoor living but also increases the resale value of your property.

Types of Timber for Decking

• Softwood Decking: Affordable and easy to work with, softwood options like pine are treated to resist rot and insects, making them suitable for budget-friendly projects.

• Hardwood Decking: Premium choices like teak, ipe, and merbau offer superior durability, rich colors, and long-lasting performance.

• Composite Timber Alternatives: A blend of wood fibers and recycled plastics, composites mimic natural timber while requiring less maintenance.

Timber decking is more than

just a flooring choice—it is an investment in lifestyle, beauty, and sustainability. Whether used for a garden, balcony, or poolside, timber creates inviting spaces where families and friends can gather, relax, and connect with nature.

Once a traditional timber framing operation run by Elanore and Peter for over 30 years, NSW-based Dark Red Frame and Truss has undergone a complete transformation under new ownership.

In 2023, Zac Naumcevski, a builder by trade, purchased the business with a clear goal: to modernise an industry that has long resisted change.

“I have worked on countless sites where natural timber twisted, bowed, or became unusable within weeks,” said Zac. “It is economical, but it is so difficult to work with— especially when exposed to the elements.”

Like many builders, Zac began requesting Laminated Veneer Lumber (LVL) framing about five years ago to improve job site consistency.

But the cost of LVL was a major barrier.

“The prices were unrealistic. It just was not accessible,” he said. This all changed when Zac took over Dark Red Frame and Truss. He approached LVL suppliers with a bold idea: manufacture LVL frames and trusses in-house, at a more realistic price point. Two suppliers came on board, and the business hasn’t looked back since. In less than two years, Dark Red Frame and Truss has become

Australia’s only full LVL frame and truss manufacturer. The company now operates two plants — one in Oberon and another in Bathurst, NSW — and has fully exited the softwood framing market.

“We are now running our own race, especially in the LVL truss space,” Zac said. “There is no competition because the rest of the industry has been too slow to move.”

For too long Zac believes the timber framing sector has been held back by outdated mindsets. Most business owners in the space are in their 70s and resistant to innovation, he says, preferring to do things the way they have always been done.

“But builders today need better,” he said. “Framing is faster and straighter with LVL. There is less waste, less time spent straightening frames, and far fewer callbacks.”

While LVL framing may add $1,000–$1,500 to the upfront cost of a home build, Zac argues the long-term savings are greater.

“When you factor in three or four guys on site trying to fix twisted frames, you are already behind,” he said. “We help customers understand the real cost of softwood.”

LVL, an engineered timber product, is manufactured under controlled conditions, which

means perfectly straight, knot-free material that performs better under load and over time. For high-end builders using techniques like shadow lining, and having true and square frames is critical.

“Once people see how much easier their build is with LVL, they don’t go back,” he said.

While Zac does expect competitors to eventually move into the space, he welcomes the challenge.

“Competition is healthy. It pushes us all forward,” he said. “But the industry has not responded yet, even with the success we’re seeing.

We have got state-of-the-art equipment, streamlined production, and top-tier supplier support.”

In Bathurst, the company has invested in fully automated machinery, keeping Dark Red ahead

of the curve.

Zac is also focused on building the next generation of talent. His 17-year-old son Tristan is already managing one of the plants while studying a Certificate III in Frame and Truss Manufacture with NTHA , along with a traineeship in estimating and detailing.

“We have thrown him in the deep end, but he is thriving,” Zac said. “It has been amazing to watch.”

Looking ahead, Zac is confident the market will shift in favour of engineered products.

“Softwood is becoming less viable,” he said. “Trees are being cut too early, and the timber’s just not the same quality anymore. It’s twisting sooner, bowing more, and builders are starting to notice.”

“We are just giving the industry a better option. It is available now, we just need people to be willing to change,” Zac said.

After 17 years of dedicated service to the construction industry and Snowy Monaro community, the team at High Country Truss and Frames has made the difficult decision to close its doors.

The move comes as the economic downturn gripping the building and construction sector worsens, along with the increased use of steel in the ACT building sector.

The decision to close the factory marks the end of an era for a company highly regarded for its craftsmanship, local employment and community support.

High Country Truss and Frames was started nearly two decades ago. It quickly became a cornerstone of the local building and supply landscape.

The factory specialised in the design and manufacturing of timber roof trusses, wall frames and floor

systems. This provided support for residential and commercial construction projects throughout the Snowy Monaro, South Coast and ACT.

Over the years, the company run by David, Elizabeth and Jannene Van der Plaat developed a reputation for its reliability, technical expertise and strong commitment to customer satisfaction.

For many local builders and tradespeople, High Country Truss

and Frames has been more than a supplier, it was a partner, and the builders would head into the office and work through the job together.

The company will still offer frames, trusses and floor systems to local builders through Cooma H Hardware, using a third party the owners have a strong relationship with.

- MONARO POST

Cross-laminated timber (CLT) manufactured from reclaimed wood is no longer just a sustainability ideal — thanks to Stora Enso and the EU Woodcircles project, circular CLT is real, and the next frontier is scaling it.

A milestone in the EU Woodcircles project marks a significant achievement for Stora Enso, as the company has successfully produced a CLT panel entirely from reclaimed wood within the EU-funded Woodcircles project. This achievement, realised at the Ybbs Mill in Austria, marks a major step forward in the transition to circular construction and demonstrates the potential of upscaled timber in high-performance applications.

Woodcircles is a four-year Horizon Europe initiative involving 20 partners across the continent. It explores how wood can be reused, re-engineered, and reintroduced into the built environment without compromising structural integrity or design flexibility.

FROM DEMOLITION TO DEMONSTRATION

The process began with a batch of reclaimed wood, collected by a project partner, Enemærke & Petersen A/S which was processed into standard boards in Ybbs, Austria. These panels were then sorted, planed, and turned into CLT lamellas—thin timber layers used in CLT production. In collaboration with the Danish Technological Institute (DTI), Stora Enso manufactured two full-size CLT master panels: one made entirely from reclaimed wood, and another hybrid panel combining reclaimed and virgin timber.

These panels will form the structural core of a modular demonstration building that will be assembled, dismantled, and reassembled in cities across Europe. They will showcase the viability of circular timber construction in real-world settings.

“The process looked straightfor-

ward on paper, but in practice it involved a steep learning curve,” says Michael Harm, Stora Enso’s project lead for Woodcircles. “There’s increasing pressure to move from linear to circular material use, and this project is helping us take meaningful steps in that direction.”

While the panels represent a technical success, scaling up production poses significant challenges. Reclaimed wood can vary widely in quality, may contain contaminants, and is not consistently available in the quantity or grade required. Sorting, cleaning and grading demand new industrial processes, as well as fresh supply chain actors capable of delivering uniform-quality reclaimed timber at scale to manufacturers like Stora Enso.

“This is just the beginning,” Harm notes. “We’ve proven it can be done but scaling it will require innovation across the entire value chain—from demolition practices to digital tracking of material provenance.”

The project also highlights the importance of cross-sector collaboration. Engineers, architects, researchers, and manufacturers must work

together to develop standards, tools, and systems that support circularity without compromising performance.

The next phase of Woodcircles focuses on Design for Manufacture, Assembly, and Disassembly (DFMAD)—a concept that enables buildings to be taken apart and reused with minimal waste. Stora Enso, collaborating with Waugh Thistleton Architects and other partners will develop a standardised component-based mass timber building that can be reused across multiple life cycles.

“From October 2025 to spring 2026, we will work with Stora Enso and other consortium partners, as well as the valuable input of the cities of Turin, Rotterdam and Tartu, to construct the first DFMAD demonstrator building using the reclaimed CLT panels. The demonstrator will showcase high-value recycled timber materials as well as demonstrate the benefits of adaptability and reuse of building systems. Once complete, the structure will tour partner cities, serving as a mobile showcase of circular timber design,” said Kirsten Haggart of Waugh Thistleton Archi-

tects.

The building will not only demonstrate material reuse but also incorporate smart monitoring systems to track performance, durability, and environmental impact over time.

“To prove the concept of upcycling wood waste, the journey began in Denmark, continued in Austria, and will extend through collaboration with our UK partners, culminating in a demonstrator across Torino, Tartu, and Rotterdam. This pilot paves the way for our transformative ‘Urban Sawmill’ initiative, positioning Woodcircles as a model of sustainable construction’s future” said María Teresa López Bertani, Communications Officer for Woodcircles.

Stora Enso’s achievement is a reminder that circularity in construction is not a distant ideal — it’s a practical challenge that can be met with the right mix of innovation, collaboration, and persistence.

“We’re proud to have taken this first step,” says Harm. “But the real work lies ahead—scaling the process, refining the technology, and building the ecosystem that makes circular timber construction the norm, not the exception.”

David McElvenny

Recognition of prior learning (RPL) sounds like it should be a simple concept to implement.

The principle is that if a person already holds some of the skills that are covered in a competency-based course, they can have them recognised once they’ve satisfied an RPL assessment procedure.

This allows them to skip over the topics they’re already ‘competent’ in, thereby shortening the time required to complete the course.

In cases where the student can show that they’re already competent in all elements of the course, they are eligible to receive the accreditation without needing to do any training at all.

Although the concept itself makes a lot of sense, its implementation over the years has become rife with abuse and fraud, to the extent that the federal regulator (ASQA – Australian Skills Quality Authority) for the vocational education and training (VET) system now ranks it in the top tier of risks threatening the integrity of VET.

As a result, ASQA has made RPL a major priority in its 2025-26 regulatory audits and is being very public about the action it takes against non-compliant training providers.

One of the industry sectors that has attracted much media attention recently is building and construction.

The industry has been plagued with problems relating to defective building practices, especially in apartment blocks, and some of the blame has been shunted back to shonky registered training providers (RTOs) and their RPL practices.

At the most serious end of the spectrum, ASQA has been track-

ing down and deregistering RTOs that were selling fraudulent trade qualifications to students.

When an RTO breaches the compliance standards this blatantly, it’s relatively easy for the regulator to uncover them and take action.

But it’s a much bigger battle to hold RTOs to account when they use more subtle techniques to exploit loopholes in the RPL process, such as going through the motions of conducting a proper RPL but burying the shortcuts in jargonised, bureaucratic assessment tools – in a sense, beating the regulator at its own game. For a smart operator this can be easier than it sounds, given the fact that the VET sector already uses a very formalised, overly-complicated language, especially among the government agencies involved in the sector, including ASQA. The problem of a ‘paper-qualified’ but under-skilled workforce is only compounded when workers who have received their accredi-

tation from an ‘RPL mill’ go on to become trainers and assessors themselves. This has a self-perpetuating effect on devolving skill levels and substandard training and assessment practices.

It’s probably fair to say that the timber industry is less prone to these sorts of problems than the high-profile industries already on ASQA’s radar, such as building and construction, childcare and aged care.

There are several reasons for this. One is that the timber industry is smaller and there are far fewer mandatory accreditations required to work in it, so there isn’t the same level of demand to provide fast-track qualifications. Another is that the industry doesn’t tend to attract business operators involved in immigration or visa applications, which opens up a whole other world of regulation and potential for exploitation. But this doesn’t make the timber industry immune to the problems of poor-quality training or ‘tick-

and-flick’ assessments.

There are some circumstances where RTOs and their clients both have a vested interest in doing as little as possible to satisfy the requirements of a course –particularly in government-funded training programs.

When government incentives become the primary motivator for signing up an employee in an apprenticeship or traineeship, it’s possible for RTO and employer to have a sort of unspoken agreement to minimise the time and effort invested in the program, so that both parties maximise their financial return.

And if the students themselves are only interested in the paper qualification at the end, or not interested at all, then they will be willing participants in the collusion. Even if students are keen to make the most of the training opportunity and learn as much as they can, they’re often none the wiser about what they’re missing out on or the level of commitment

they should be receiving from their employer and RTO.

So what should the RPL process look like when it is conducted properly? Unfortunately, the RTO Standards are quite vague about the nuts and bolts of carrying out an RPL, since the same general directives are designed to apply to every industry and every competency – from sawmilling to hairdressing to business studies. Let’s start with what RPL is not, to clear up some common misconceptions.

RPL is not a credit transfer –sometimes abbreviated ‘CT’ on a qualification transcript. Credit transfers are used when a qualification contains a unit that the student has already completed. In these cases, no further training or assessment is required in that unit.

RPL is not a recognition of current competency (RCC). The term RCC is often used to refer to refresher courses that involve the re-assessment and re-issue of a competency that the student already holds. In the timber industry, this generally includes chainsaw units, first aid and other competencies that need to be periodically refreshed for safety or regulatory reasons. The mining and civil construction sectors use a similar process called verification of competency (VOC). In the last edition of Australian Forest and Timber News (July/ August 2025) I talked about RCC in relation to chainsaw refresher courses.

RPL is not a shortcut assessment process, where some

The purpose of an RPL assessment tool is to collect evidence of competence that the student has already accumulated over time in their work or other endeavours.

elements have been dropped out of the assessment tool because the student says they can already do those things. It is true that an RPL assessment tool will often be structured differently from a normal assessment tool used in a full training course, but this isn’t because any of the performance criteria are missing – it’s because the evidence of competence provided by the student is not limited to the assessment tasks that form part of the normal course.

An RPL assessment tool still needs to list all of the criteria specified in the unit of competency that’s being assessed. However, instead of relying solely on the training course’s own tests, assignments and practical demonstrations, it can accommodate other types of evidence that the student provides from their past experience or studies. These may include related qualifications, examples of work produced and

testimonials from employers or industry experts, along with anything else that’s deemed valid evidence.

The purpose of an RPL assessment tool is to collect evidence of competence that the student has already accumulated over time in their work or other endeavours, assess its merit, and identify any gaps in their skills or knowledge that may still need ‘gap training’. As such, its main benefit is to reduce training time, not assessment time. In fact, there are some competencies where the criteria are so complex or specific that it’s easier for the student to just undertake the normal course assessment process, rather than trying to assemble suitable RPL evidence to match the requirements.

RPL has its place in the VET sector, but it doesn’t help a student to learn new skills or improve existing skills. When the process

is abused, it can actually have the effect of reducing skill levels and expertise in the industry, as under-skilled but ‘qualified’ workers pass on their own poor practices to learners under their supervision. In the end, its only real value to the student (and their employer) is to speed up the process of achieving an accreditation. But even then, there may be times when there’s more value to be gained by completing a full course and seeing new ways of doing things or refining existing skills, rather than being given a tick-off for competency elements that they’re deemed to have already satisfied.

DAVID MCELVENNY IS THE CEO OF BUILDING LEARNING

(WWW.BUILDINGLEARNING.COM.AU) AND WORKSPACE TRAINING (WWW.WORKSPACETRAINING.COM.AU).

Despite industry concerns about dwindling supply, Australian Sustainable Hardwoods (ASH), Australia’s leading hardwood manufacturer and supplier, has been working hard to increase availability and ensure a secure and ongoing supply of Tasmanian Oak.

A renowned hardwood, Tasmanian Oak remains one of Australia’s most trusted and versatile building materials. Often referred to as Tassie Oak, ASH’s brand of Tasmanian Oak is called, Australian Oak. Through advanced processing methods and investment in innovation, ASH has significantly expanded capacity of Australian Oak. Timber previously destined for export or reduced to wood chips is

now being converted into beautiful, long-lasting and higher value Tasmanian Oak products.

This effort has been driven by significant investment, planning, and a clear commitment to supporting the long-term needs of architects, specifiers and those in the construction and design industries.

Builders, furniture makers, manufacturers and home renovators can feel confident sourcing and specifying Tasmanian Oak timber across a wide range of applications including timber cladding, lining boards, windows, doors, stair components, flooring and joinery, knowing it will be available in reliable volumes from a trusted local supplier.

This renewed capacity also means a return to stock of ASH’s sought-after F17 structural timber and the introduction of new products like Australian Oak Classic Grade cladding and lining. Classic Grade offers designers and specifiers an affordable way to bring natural warmth, character and sustainability to their clients’ projects, without compromising on quality.

By maximising timber resources and committing to innovative manufacturing, ASH is ensuring that builders, architects, specifiers, and manufacturers can access one of Australia’s most reliable and loved hardwoods, today and into the future.

A renowned hardwood, Tasmanian Oak remains one of Australia’s most trusted and versatile building materials.

Engineers in Australia have developed a new building material with about one quarter of concrete’s carbon footprint, while reducing waste going to landfill.

This innovative material, called cardboard-confined rammed earth, is composed entirely of cardboard, water and soil – making it reusable and recyclable.

In Australia alone, more than 2.2 million tons of cardboard and paper are sent to landfill each year. Meanwhile, cement and concrete production account for about 8% of annual global emissions.

Cardboard has previously been used in temporary structures and disaster shelters, such as Shigeru Ban’s iconic Cardboard Cathedral in Christchurch, New Zealand. Inspired by such designs, the RMIT University team has, for the first time, combined the durability of rammed earth with the versatility of cardboard.

Why it matters

Lead author Dr Jiaming Ma from RMIT said the development of

cardboard-confined rammed earth marked a significant advancement toward a more sustainable construction industry.

“Modern rammed earth construction compacts soil with added cement for strength. Cement use is excessive given the natural thickness of rammed earth walls,” he said.

But cardboard-confined rammed earth, developed at RMIT University, eliminates the need for cement and boasts one quarter of the carbon footprint at under one third of the cost, compared to concrete.

“By simply using cardboard, soil and water, we can make walls robust enough to support low-rise buildings,” Ma said.

“This innovation could revolutionise building design and construction, using locally sourced materials that are easier to recycle.

“It also reflects the global revival of earth-based construction fuelled by net zero goals and interest in local sustainable materials.”

The cardboard-confined rammed earth can be made on the construction site by compacting the soil and water mixture inside the cardboard formwork, either manually or with machines.

Study corresponding author and leading expert in the field of structural optimisation, Emeritus Professor Yi Min ‘Mike’ Xie, said this advancement can spearhead a leaner, greener approach to construction.

“Instead of hauling in tonnes of bricks, steel and concrete, builders would only need to bring lightweight cardboard, as nearly all material can be obtained on site,” Xie said.

“This would significantly cut transport costs, simplify logistics and reduce upfront material demands.”

Ma said cardboard-confined rammed earth could be an effective solution for construction in remote areas, such as regional Australia, where red soils – ideal

for rammed earth construction –are plentiful.

“Rammed earth buildings are ideal in hot climates because their high thermal mass naturally regulates indoor temperatures and humidity, reducing the need for mechanical cooling and cutting carbon emissions,” he said.

The mechanical strength of the novel material varies based on the thickness of the cardboard tubes.

Ma said the team has developed the formula for this strength design.

“We’ve created a way to figure out how the thickness of the cardboard affects the strength of the rammed earth, allowing us to measure strength based on cardboard thickness,” Ma said.

In a separate study lead by Ma, carbon fibre was combined with rammed earth, proving it had a comparable strength to high-performance concrete.

Ma and the team are ready to partner with various industries to further develop this new material so it can be used widely. Companies looking to partner with RMIT researchers can contact research. partnerships@rmit.edu.au.

Every second year, the FTMA Australia State Seminars provide a vital opportunity for frame and truss manufacturers from across the country to gather, learn, and strengthen their connections.

The 2025 seminars, have again carried that tradition forwardbringing together a diverse mix of manufacturers, and industry leaders, to discuss the challenges and opportunities shaping our sector.

The program this year was deliberately crafted to offer both practical knowledge and big-picture thinking. Presenters included respected voices from the timber prefab industry, as well as experts across sustainability, workplace safety, research, and education. Each presentation reminded us of the unique position our industry holds - balancing the technical demands of engineering with the human responsibility of constructing safer, greener buildings, for the future. This year’s presenters gave attendees plenty to think about.

For the morning sessions, attendees were split into three groups and manufacturers had the benefit of connecting with the nailplate and software providers.

FTMA Principal Partners, MiTek, Multinail, and Pryda, showcased latest developments in their software, services, and machinery, to their associated manufacturers. The feedback we had from these sessions was that it provided an invaluable chance to liaise and scope out advancements.

For the afternoon sessions, all the attendees then came together. Among the seminar highlights was Tim Woods of IndustryEdge, who delivered impassioned and eye-opening (eye-watering!) data when it comes to Australia’s criti-

KERSTEN GENTLE Executive Officer

FTMA Australia

cal position in the housing crisis. Australia is not building enough dwellings - fact - and it hasn’t built enough, per annum, in 40 years. It’s the sombre truth. We need more affordable homes. We need more labour intake. And offsite prefab is a pivotal solution. It must be supported. For more details; Tim, along with Jim Houghton, have published findings; More Houses Sooner – Finding the Australian Dream, a report funded by Forest and Wood Products Australia.

Andrew Jones of Purple Infinity, gave updates on the Introduction to Timber Systems Design course, (nearing completion) and is asking for assistance from the sector for images and videos to help build the training’s volume and engagement. Please contact us if you are a frame and truss manufacturer, and can contribute.

Key researchers, Dr. Louise Wallis, Dr. Jon Shanks, and their university research colleagues from the AFWI funded projects, presented and led round-table discussions on a few key items, including removing noggings. There are over 11 projects specifically focused on the lightweight timber frame and truss sector, and FTMA is proud to be working with universities / researchers on these projects.

Attendees got to see a video, made by Timbertruss, that the FTMA National Safety Council

Paul Colless (Director at Calco Trusses & Timber), Robyn Perkin (National Sales Manager Pryda) and Christine Flanagan (FTMA Board Member, Director of Calco Trusses & Timber) at the State esminar in Brisbane.

has been supporting through development, and FTMA is now circulating to the sector. The video is crucial to assist in the safe delivery of trusses when it comes to forklifts, and overhead powerlines. The video can be viewed through www.ftmanews.com.

We also had an engineering collaboration from MiTek, Multinail, and Pryda, where a suite of their design engineer leaders came together to present on the important topic of breaking down warranties and what the obligations are for manufacturers.

We are very grateful to all the presenters - too many to mention here - that joined forces for these ‘Tech Talks’.

The State Seminars serve as a reminder that collaboration is our sector’s greatest strength. Demonstrating that by sharing knowledge and resources, we grow stronger.

As the 2025 seminar season wraps up, there is a palpable sense of optimism. While challenges undoubtedly lie ahead, the seminars demonstrate the resilience and creativity of our sector.

Each business has its own story, but we are united by a common purpose - to deliver high-quality, sustainable solutions that will help shape the homes and communities of tomorrow.

FTMA Australia is proud to facilitate these events, knowing that every conversation, presentation, and handshake contributes to strengthening the frame and truss industry as a whole.

They reaffirm something simple but profound: how wonderful it is to share our journeys, and build the future, together.

Most national system employees have a formal workplace right to disconnect under the Fair Work Act 2009. From 26 August 2025, the right to disconnect will also apply to employees of small businesses. Outside their working hours, employees can refuse to monitor, read or respond to contact or attempted contact from:

• their employer, or

• another person if the contact or attempted contact is workrelated (for example, workrelated contact from clients or members of the public) unless the employee’s refusal is unreasonable.

When will an employee’s refusal be unreasonable

An employee’s refusal to monitor, read or respond to contact or attempted contact will be unreasonable if the contact or attempted contact is required by law.

If the contact or attempted contact is not required by law, certain matters must be considered when deciding whether the employee’s

refusal is unreasonable. These include:

• the reason for the contact (or attempted contact)

• how the contact (or attempted contact) is made and how much disruption it causes the employee

• any compensation (monetary or non-monetary) the employee receives o to be available to work when the contact (or attempted contact) is made, or o to work outside their ordinary hours

• the employee’s role and their level of responsibility, and

• the employee’s personal circumstances, including family or caring responsibilities.

Other matters can also be considered. Who does the right to disconnect apply to?

The right to disconnect applies to national system employees.

If an employer was a small business employer on 26 August 2024, the right to disconnect will not apply to its employees until 26 August 2025. A right to disconnect term has been added to all 155 modern awards.

Enterprise agreements may contain a different right to disconnect term. Enterprise agreement terms that are more favourable to employees than the right in the Fair Work Act will continue to apply. TTIA will deal with these issues in upcoming IR Briefings which will be held in various states in October/November. Dates and

venues can be accessed by contacting the Association on (02) 9264 0011 or by email: ttia@ttia. asn.au

Employers are reminded that updated Fair Work Information Statements (FWIS) are available for full time and casual employment.

The FWIS document for permanent employees must be given to new employees when they first start work.

The Casual Employee Information Statement (CEIS) needs to be given to new casual employees before they start employment, or as soon as possible after. The CEIS also needs to be provided to all casual employees again after:

• 12 months of employment for casual employees of small businesses • 6 months of employment, 12 months of employment, and every subsequent period of 12 months of employment for casual employees of non-small businesses.

The Timber Veneer Association recognises the importance of members working together and sharing their knowledge. This helps to ensure they continue to produce high quality, state-of-the-art products.

To further this aim the Association has instituted a program of visits to timber veneer production plants across Australia. Field trips are linked to TVAA Committee meetings in the various States which minimises travel.

The latest in the program of site visits saw a group of close to 30 Committee members and guests visit the Big River Group’s Grafton manufacturing plant. The visit took place on 24th July, following a

PETER

LLEWELLYN Technical representative, Timber Veneer Association of Australia

Committee meeting and networking dinner the previous day

The Big River Group is one of the country’s largest formply and structural plywood manufacturers.

The Grafton plant was upgraded after the 2019/20 Black Summer fires, so it could be close to a sustainable supply of hardwood and softwood logs.

The TVAA visitors were welcomed by Big River production staff who led the group through the process of converting logs into veneers. A recent addition to the Grafton facility was an improved veneer pressing line, giving Big River the ability to produce their popular ArmourCab panels.

ArmourCab panels have a 16mm moisture resistant MDF (MRMDF) core with a 1.0mm Australian timber face bonded to each side.

ArmourCab is available in three native species (spotted gum, blackbutt and hoop pine) each with their own unique colours and natural markings,

ArmourCab panels are suitable for appearance grade cabinetry

and joinery applications in residential and commercial projects. According to Big River their ArmourCab panels are particularly well suited to CNC (Computer Numerical Control).

CNC machines precisely control the movements of cutting tools, resulting in accurate cuts and shapes. This allows woodworkers to produce complex designs with ease while ensuring consistency throughout the manufacturing process.

Of particular interest to the visitors was seeing logs being sliced and processed in the same plant as the more familiar process of pressing veneers onto a substrate MDF panel.