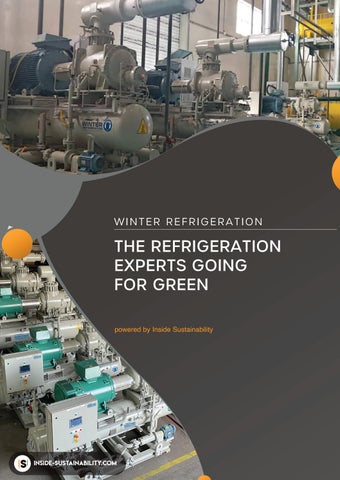

With almost 40 years’ experience in the design and manufacture of refrigeration packages, WINTER REFRIGERATION was created to revolutionise the global refrigeration industry. Even today, that innovative flair remains. Sales Manager Pegah Emami-Kalb discussed the company’s journey to green in an exclusive interview with Inside Sustainability. Report written by Imogen Ward.

Founding WINTER REFRIGERATION in 1984, Managing Director Reza Emami is an expert when it comes to natural refrigeration.

“Anyone that works with Mr Emami knows that he breathes, works and lives with ammonia,” Sales Manager Pegah Emami-Kalb said, with a smile. “Aligning with this dedication, our refrigeration products and packages are designed to work with natural refrigerants, including ammonia, CO2 and hydrocarbons.”

Setting up WINTER in the United Arab Emirates, Mr Emami was inspired by the location and quick to pioneer the

refrigeration industry with more sustainable options.

“Being located in the Arabian desert, where we have very limited access to resources, really helped us understand the true essence of sustainability,” Ms Emami-Kalb said. “Our location also comes with additional advantages: our energy costs are lower in comparison to our contenders – allowing us to be very price competitive with our products.”

On offer at WINTER is a vast range of products, which includes oil and gas refrigeration packages, heat pumps and condensing units. With these products,

WINTER saves its customers expenses: As an industrial company within the UAE, WINTER is also able to offer extremely reduced customs rates to customers in countries that have signed agreements with the UAE Government.

the company targets two main industries: oil and gas, and industrial refrigeration/agrofood. According to Ms Emami-Kalb, the oil and gas sector is already focused on the progression of natural refrigerants. The industrial refrigeration/agrofood sector, on the other hand, has a way to go.

“Although we cater for both industries, industrial refrigeration/agrofood is definitely an area where we see the biggest gap for sustainable solutions,” Ms Emami- Kalb explained.

Natural promotion

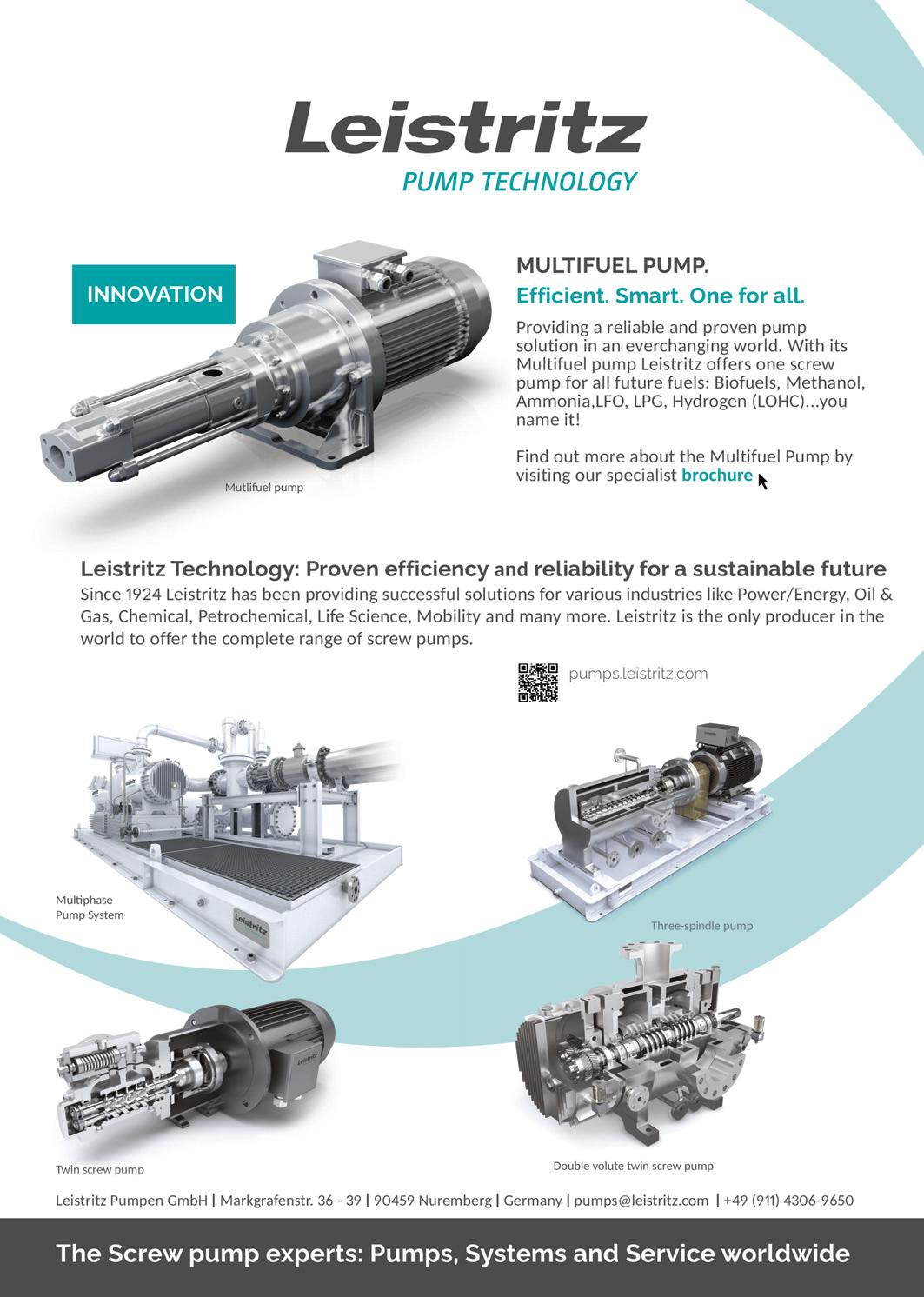

With this knowledge in mind – and a clearcut understanding of natural refrigerants –the company endeavoured to become the perfect choice for those looking to invest in greener refrigeration plants. Currently experts in ammonia and CO2, WINTER offers these options (alongside hydrocarbons) with plants that are exceptional in design and can be tailor-made for each customer.

“Our standard screw compressor and chiller packages are widely used within the food processing industry and any other sector that requires low temperatures to operate,” said Ms Emami-Kalb. “These products are designed to be plug-andplay solutions that are reliable and longlasting. We also developed them to be

easy to install and convenient to handle during transportation. Providing a complete plant room on one skid, where possible, allows it to be transported and placed in its destination in one piece.”

One stand-out product currently on offer at WINTER is the ammonia industrial chiller. Designed to work with ultra-low ammonia charge, the product is incredibly efficient and sustainable. Thanks to ammonia’s properties (particularly its lack of ozone depletion and neutral global warming potential), the chiller can help reduce a customer’s carbon footprint by replacing older, less efficient and less reliable systems.

“We truly believe that natural refrigerants are the future: that’s why we encourage our clients to pursue that path as much as

possible,” Ms Emami-Kalb added. “These refrigerants all have lower GWP and ODP compared to traditional refrigerants.”

Always eager to improve upon its customers’ experience, WINTER is quick to research and develop new products. Last year at Chillventa 2022, the company released the brand-new Heat Pump Package, which was developed to work alongside refrigeration plants.

“WINTER’s R&D team understood the importance of the waste heat that was being expelled into the environment from refrigeration plants,” Ms Emami-Kalb said. “From this, the team developed the Heat Pump Package, which utilises waste heat by reducing it to more useful temperatures, rather than exhausting it into the atmosphere. At a time where global energy prices are sky-high, everyone is looking

for ways to improve their energy efficiency: we have the solution for that.”

Since launching the product last October, WINTER has received a lot of interest from customers, and the company foresees a very promising future for the heat pump.

Harmonising with Howden

Winter Refrigeration’s consistent reliability and quality-excellence has led to several exciting opportunities. In 2010, the company became the official packagers within the Middle East for Howden –a global leader in compressor engineering.

“Howden is the Rolls Royce of screw compressors, so our partnership with them was a major breakthrough for us,” said Ms Emami-Kalb. “This disrupted the region’s market and really established us as a key player in the industry.

“Our refrigeration packages set new, widely accepted standards. Today, our products are running efficiently all across the globe. Although we are Howden’s official packagers for the Middle East, we are not limited in our exports. In fact, this revelation actually encouraged us to expand our reach. We opened a sales company in Germany, and our official packaging status came with us.”

As part of its partnership with Howden, WINTER retrofits screw compressors; replacing customers’ worn-out systems with brand-new Howden models. The company even modifies the skid to ensure the new compressor is a perfect fit, and it offers the service as a more sustainable and cost-effective alternative to purchasing a new skid.

The company also supplies all the spare parts needed for Howden compressors, saving customers valuable time and money

Supporting local

All of WINTER’s production processes rely on 20 highly efficient machines (from CNC to automatic welding), and the consistency and reliability of its hard-working suppliers. With an entire role dedicated to maintaining supplier relationships, these companies are incredibly important to WINTER.

“Personally, I believe that building long-term relationships with suppliers and partners is a crucial element of any company’s success,” Ms Emami-Kalb said. “At WINTER, we have a dedicated p erson to manage these relationships.

We foster a collaborative environment that helps strengthen our business and encourages mutual benefits and growth.”

Creating relationships locally is also strongly encouraged at WINTER. In line with its commitments to reducing its carbon footprint, as well as supporting local, WINTER is an avid supporter of the Make it in the Emirates campaign. As an open invitation to investors, innovators and entrepreneurs, this campaign encourages businesses to improve the National In-Country Value of the Emirates. WINTER’s own NIV has reached 60%.

Looking forward, Ms Emami-Kalb felt positive regarding the company’s future: “We take great pride in ensuring our industrial refrigeration products and solutions consistently meet the requirements of the marketplace.

We have a deep understanding of the ever-changing needs of our customers and are confident in planning for future trends.

“Mr Emami is continually looking for new solutions, products and markets. The aim with that is to awaken the market for natural refrigerants. Especially here in the Middle East, there is a lot of potential to increase sustainability – particularly in the district cooling plants.

“This is an area that is quite resistant to the implementation of natural gases, but we are working hard to change that. We are approaching a lot of companies to show them exactly why we are passionate about this topic,” she concluded. “We already have the solution; we just need the first company to jump onboard and I’m confident the rest will follow.”