Fabdec is a company renowned for its innovative stainless steel vessels and heat transfer products. With over 60 years’ experience and a growing presence in a diverse range of sectors, the Shropshire-based company proudly maintains a strong market-leading position. Sales Manager for BRITANX, Mark Madeley, told Inside Food & Drink about the latest company developments. Report by Imogen Ward.

With a hand in several sectors, Fabdec is determined to explore these more, starting with the growing food and drink side of the business.

“We are really focused on growing the business and introducing new products to the market,” Sales Manager for BRITANX Mark Madeley said. “As a very diverse company, we manufacture numerous products and solutions for a variety of markets across the globe. Over the past five years our food and drink segment, BRITANX, has witnessed an impressive sales increase of 50 per cent. This is definitely a growing market for us, and we are excited to see what else we can do.”

Initially established in 1960 within the dairy industry, Fabdec has worked tirelessly to offer the most innovative stainless steel solutions via its brands (DARI-KOOL, EXCELSIOR, KINGSTON and BRITANX).

“Fabdec currently exports its products to more than 40 countries,” said Mr Madele. “A large chunk of this comes from our dairy business DARI-KOOL, which is very popular within Japan, Canada and the US. However, as the head of BRITANX, which covers Food, Beverage & Processing, I’m especially focused on exploring the potential of the BRITANX brand.”

Uncovering a legacy in BRITANX

Fabdec’s entrance into the food and beverage sector is quite a recent milestone within its 63-year history, which occurred by chance after receiving an interesting phone call.

“We really began exploring our capabilities within food and drink around 15 years ago after a business contacted our factory in relation to some old vessels that they wanted to replace,” Mr Madeley explained. “The equipment was adorned with a Fabdec name plate; the only problem was, we had no idea what these v essels were. Initially manufactured years ago, these products had somehow been lost, so we had to search back through our archives to locate the long-forgotten concept drawings.

“The vessel is essentially a vertical milk tank, but it really kick-started our presence within the brewery segment. Since then, we have manufactured equipment for whisky and rum distilleries; we have also made wine tanks and now we are producing more complex machinery dedicated to mixing processes.”

This undeterred dedication is mirrored within Fabdec’s goal of becoming a household name in the food and drink industry. To achieve this, the company has recently made several key investments.

Investing where it matters

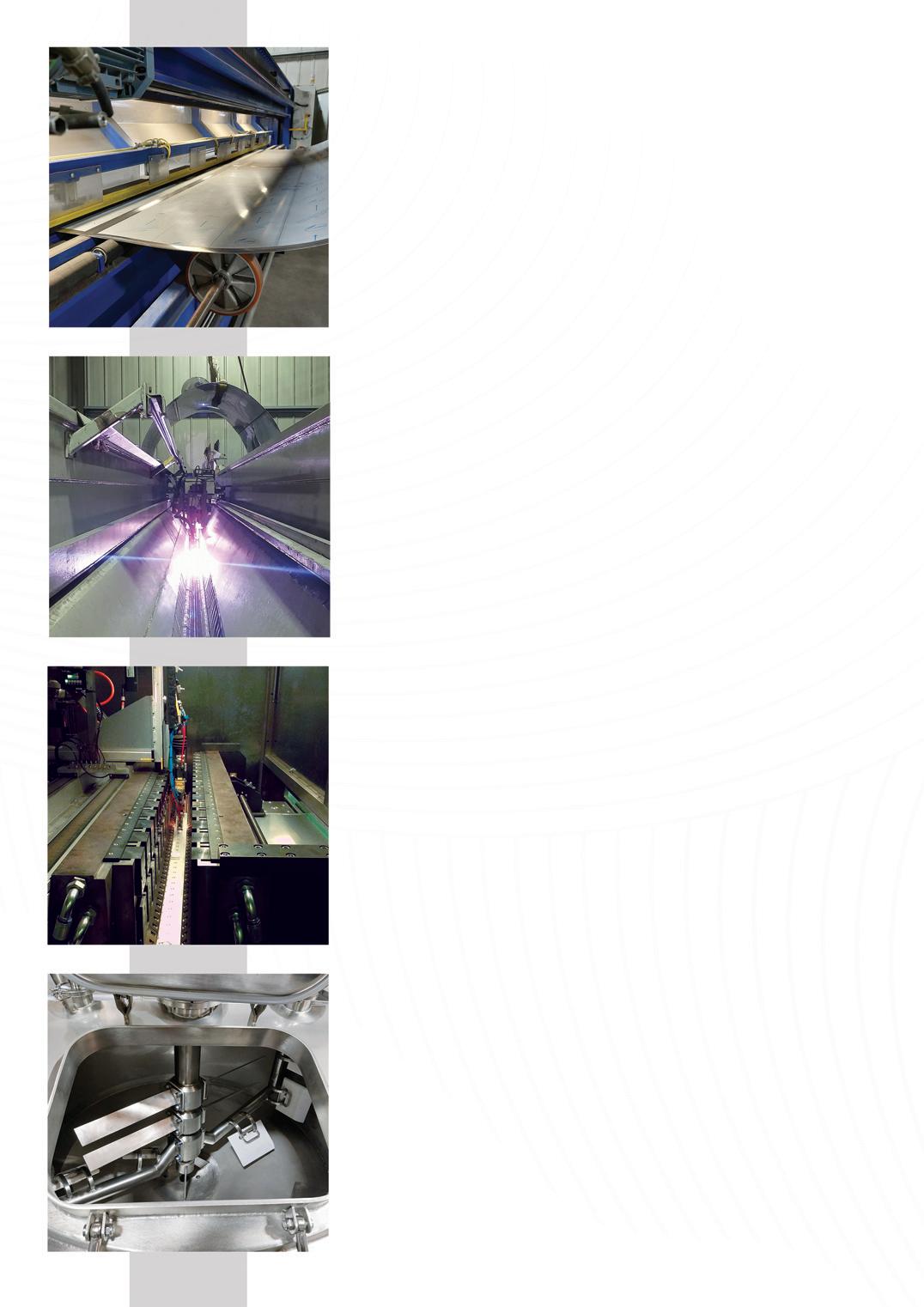

Two years ago, Fabdec invested in a new pillow plate laser welder, which has resulted in some significant savings.

“This is currently the only one available in the UK,” Mr Madeley said. “If our competitors manufacture vessels that need a pillow plate sheet, they would either need to import it from Holland or Germany, or they can buy the part direct from us. This has provided us with a huge competitive advantage.

“90 per cent of our vessels utilise pillow plate sheets, so this has also made our own processes more cost and time efficient. Previously, we used a very outdated machine that added three extra steps to the manufacturing process. As a result, we can now also weld together sheets of steel up to seven by two metres in size.”

Investing where it matters:

The company is also committed to investing in people. Fully appreciating the value of a dedicated and content workforce, Fabdec provides consistent training and support. Career progression is also greatly encouraged. 16 years ago, Mr Madeley himself started within the company’s design office and now heads an entire division.

A new CNC press break machine was also purchased to allow for manufacturing with more acute angles. Before the introduction of this machine, the company had to produce several of its dairy products in parts. However, thanks to its four-metre capacity, this additional step has been eradicated.

Moving toward household status

The company has completed several great projects in recent months, including one for a major fast-food chain. Following the implementation of Brexit, this fastfood chain decided to make some changes on where they sourced a specific ingredient. Having previously imported from Holland, the chain was l ooking to set up five new sites dedicated to the production of this ingredient.

“We indirectly supplied the equipment for the first of these sites via Beswick Refrigeration Services,” said Mr Madeley: “This included two 12,000 litre sponge dough mixing tanks, a CIP tank and two water treatment tanks.

“BRS are very good at specifying technical designs for tanks, so in total, this project took around 12 weeks to complete, from design to completion. Following the success of this, we are also in contention for supplying the tanks for the second site, which requires two 3,000 litre sponge dough mixing tanks.”

Another successful project saw Fabdec working with a nationally favoured dessert brand. This project included the manufacture

of five mixing tanks: three that have heating capabilities, dedicated to caramel, and two gel mixing tanks.

“Also going through the factory at the moment are some sourdough mixing vessels, which are being manufactured for a local bakery,” said Mr Madeley. “We have an ongoing relationship with this company. It already had equipment at its site, so the company was looking for machinery that was similar in design, but larger, to meet the demands of the growing sourdough trend.

“The project consists of two vessels, a left-handed and right-handed one, and once these machines are installed and up-and-running, the company intends to duplicate this order annually for the next five years.”

Last year also marked a momentous milestone for Fabdec, after it successfully manufactured its largest conical dualpurpose vessel to date. This project was delivered to Butcombe Brewery for fermenting purposes and had an impressive capacity of 30,000 litres. Following the completion of this, the brewery has placed a repeat order which is well underway.

With an abundance of experience in vessel manufacturing, Fabdec can deliver a complete service from design to delivery, all within a time frame of 10 to 16 weeks. And with expertise in the weird and wonderful, the company is also incredibly flexible when it comes to the needs of customers. One such example saw Fabdec manufacture a stainless steel rain harvesting tank, which was used to feed the irrigation system of a three-storey tropical greenhouse in Hackney, London. Having built a dazzling reputation with its customers, Fabdec’s future sparkles as brightly as its stainless steel products. “Not only do we manufacture a standard range of products, but we also utilise our expertise

and skill to offer bespoke builds,” Mr Madeley concluded. “Our continued investments in our machinery, facilities and people help make that possible, and we receive regular feedback about the helpful and approachable nature of everyone that works here.

“Our plan going forward is to continue developing these areas to ensure we can support as many markets and industries as possible. That’s the only way we are going to achieve our goal of becoming the household name for high quality, hygienic, stainless steel vessels.” n