SEPTEMBER 29 - OCTOBER 1, 2025

A PRE-SHOW PLANNER

Quick Facts about PACK EXPO Las Vegas Exhibitor Guide and Floor Plan

An In-Depth Show Preview to Maximize Your Experience

New Product Highlights at the Show

Facilities + Infrastructure Directory

Unifying technologies

Unlocking possibilities

Coperion unites the leading technology brands in food manufacturing to deliver innovative system solutions for your operation.

Technology for:

• Systems & Ingredient Automation

• Pre-Dough, Mixing, Forming & Dividing

• Depositing, Decorating & Cutting Scan the QR code to find out

PMMI membership represents more than 1,000 manufacturers and suppliers of equipment, components, and materials as well as providers of related equipment and services to the packaging and processing industry. We work to advance a variety of industries by connecting consumer goods companies with manufacturing solutions through the world-class PACK EXPO portfolio of trade shows, leading trade media, and a wide range of resources to empower our members. The PACK EXPO trade shows unite the world of packaging and processing to advance the industries they serve: PACK EXPO International, PACK EXPO Las Vegas, PACK EXPO East, PACK EXPO Southeast, EXPO PACK México and EXPO PACK Guadalajara. PMMI Media Group connects manufacturers to the latest solutions, trends and innovations in packaging and processing year-round through brands including Packaging World, Healthcare Packaging, Contract Manufacturing + Packaging, ProFood World, Mundo EXPO PACK, and OEM. PMMI Business Drivers assist members in pursuing operational excellence through workforce development initiatives; deliver actionable business intelligence on economic, market, and industry trends to support members’ growth strategies; and actively connect the supply chain throughout the year.

Learn more at pmmi.org, packexpo.com, and pmmimediagroup.com

2 A Food Producer’s Guide to PACK EXPO Las Vegas

ProFood World Editor in Chief Derrick Teal welcomes you to the milestone 30 th year of PACK EXPO Las Vegas and shares the must-know information to maximize your time at the show as a food and beverage professional.

4 PACK EXPO Las Vegas Quick Facts

This quick-start guide includes essential show features to get started at PACK EXPO Las Vegas 2025.

8 PACK EXPO Las Vegas Show Preview

This detailed rundown of all the highlights at PACK EXPO Las Vegas will help you navigate the show with ease. Find information on show staples like networking events, student activities, and useful resources.

9 PACK EXPO Las Vegas Exhibitor List

Scan the Exhibitor List QR Code for an alphabetical list of exhibitors with booth numbers included.

17 2025 Exhibitor Locator

Advertisers in this issue have new technologies and innovations to show you at PACK EXPO Las Vegas. Find out where they’ll be on the show floor.

18 Advertiser Profiles

This unique advertising section profiles PACK EXPO exhibitors. Get a sneak preview of the leading firms you’ll see at the show.

50 Processing Zone Exhibitors

These pages include a rundown of exhibitors located in the Processing Zone.

52 New Product Solutions

Here, you’ll find summaries of new equipment solutions featured at PACK EXPO Las Vegas, along with booth numbers to easily find them on the show floor.

57 Facilities + Infrastructure Directory

Find companies that offer services for design-build, building infrastructure, and plant utilities.

A FOOD PRODUCER’S GUIDE TO PACK EXPO LAS VEGAS

PACK EXPO Las Vegas is celebrating its 30th year of driving innovation, and it’s shaping up to be an especially dynamic show for food and beverage processors.

The food and beverage industry continues to face evolving challenges: shifting consumer expectations, labor constraints, sustainability goals, and food safety, to name a few. This year’s show is designed to help you face those challenges with confidence.

To help producers make the most of their time, the Processing Zone is back and bigger than ever before for this show. Located in the North Hall, this pavilion features the latest and greatest in food and beverage processing technologies. Whether you’re looking for mixing, blending, heat treatment, or hygienic design, you’ll find solutions here to enhance product quality, increase efficiency, and ensure food safety. While you’re in the North Hall, be sure to attend sessions at the Processing Innovation Stage (Booth N-9100), to learn the latest trends and hot topics in food safety, sustainability, AI, and more. Overall, the Processing Zone is your onestop-shop for staying ahead of the curve in food and beverage manufacturing.

Also returning is the Confectionary Pavilion, sponsored by the National Confectioners Association and located in the South Upper Hall. Head there to find technologies including aeration, batch refining, cluster forming, and more. It offers a concentrated look at what’s next in sweet goods manufacturing.

Make sure to explore this year’s Technology Excellence Awards finalists (and particularly the Food & Beverage finalists) and vote for your favorites across each category. These technologies are new and never-before displayed at a PACK EXPO trade show, so it’s a great way to learn about the most cutting-edge innovations on the show floor.

To help navigate this huge show, download the free PACK EXPO Las Vegas Mobile App, sponsored by ProMach, Inc. It lets you explore the show floor, bookmark mustsee booths, and access the My Show Planner feature to create a personal agenda. For even more personalized support, check out the Attendee Resource Center online at pfwgo.to/8853. There, you’ll find an Attendee ROI Guide, a justification letter template, information on the free-for-attendees PACK Match 1:1 consultation service, and more.

I look forward to seeing you there!

Derrick Teal Editor-in-Chief

CONTENT

EDITOR-IN-CHIEF DERRICK TEAL dteal@pmmimediagroup.com

ASSOCIATE EDITOR CASEY FLANAGAN cflanagan@pmmimediagroup.com

EDITORIAL OPERATIONS

COORDINATOR TRACEY LABOVITZ tlabovitz@pmmimediagroup.com

DIRECTOR OF CONTENT KIM OVERSTREET

ART DIRECTOR KATHY TRAVIS

CREATIVE DIRECTOR DAVID BACHO

ADVERTISING

sales@pmmimediagroup.com

PUBLISHER PATRICK YOUNG pyoung@pmmimediagroup.com 610/251-2579

DIRECTOR, CLIENT SUCCESS & DEVELOPMENT COURTNEY NICHOLS cnichols@pmmimediagroup.com

ACCOUNT EXECUTIVE BRIAN J. GRONOWSKI bgronowski@pmmimediagroup.com 440/564-5920

SENIOR MANAGER, PRINT OPERATIONS LARA KRIEGER lkrieger@pmmimediagroup.com

FINANCIAL SERVICES MANAGER JANET FABIANO jfabiano@pmmimediagroup.com

PMMI MEDIA GROUP

PRESIDENT DAVID NEWCORN

VICE PRESIDENT, DIGITAL ELIZABETH KACHORIS

SENIOR DIRECTOR, EVENTS TREY SMITH

SENIOR DIRECTOR, DIGITAL MEDIA JEN KREPELKA

DIRECTOR OF MARKETING AMBER MILLER

DIRECTOR, AD TECH AND SEARCH JOAN JACINTO

FOUNDING PARTNER AND EXECUTIVE VICE PRESIDENT, INDUSTRY OUTREACH, PMMI JOSEPH ANGEL

PMMI Media Group

500 W. Madison, Suite 1000, Chicago, IL 60661 Web: www.pmmimediagroup.com

PMMI, The Association for Packaging andProcessing Technologies 12930 Worldgate Drive, Suite 200 Herndon, VA 20170

Phone: 571/612-3200 • Fax: 703/243-8556 Web: www.pmmi.org

CONNECT WITH US

@ProFoodWorld

www.linkedin.com/ showcase/profoodworld

@ProFoodWorld

PACK EXPO LAS VEGAS 2025 QUICK FACTS

Looking to discover what’s new in packaging and processing?

This at-a-glance guide gives you the essential details of what’s happening at PACK EXPO Las Vegas 2025, the ultimate packaging and processing event this year.

SHOW HOURS

9:00 A.M. – 5:00 P.M. MONDAY, TUESDAY

9:00 A.M. – 3:00 P.M. WEDNESDAY

MUST-SEE PAVILIONS

PACK EXPO Las Vegas is a massive showcase of cutting-edge technology and solutions. Targeted industry pavilions help attendees easily zero in on the innovations that matter most. For more pavilion information and to find exhibitors within every pavilion at PACK EXPO Las Vegas, visit pwgo.to/8803

The Containers and Materials Pavilion

Get hands-on with groundbreaking innovations in paperboard, glass, metal, flexible, and resealable solutions designed to captivate consumers and boost sustainability. This pavilion is a onestop-shop for attendees looking for new packaging to refresh, enhance, or differentiate their brand, add functionality, or improve sustainability. Find it in the South Lower Hall

The Healthcare Packaging Pavilion

Explore state-of-the-art packaging innovations for pharmaceuticals, biologics, nutraceuticals, and medical devices. Precision, safety, and innovation converge at this top destination for life sciences companies. Located in the North Hall

PLAN AHEAD WITH THE PACK EXPO LAS VEGAS MOBILE APP

Navigate the show like a pro with the free PACK EXPO Las Vegas Mobile App, sponsored by ProMach, Inc.

The Logistics Pavilion

Dive into the latest in warehousing, fulfillment, distribution, logistics, and transportation services — everything needed to move products faster, smarter, and more efficiently. With the current boom in e-commerce, the Logistics Pavilion will be the place to meet the moment. Find it in the North Hall.

The Processing Zone

Discover the latest food and beverage processing innovations, see the latest equipment in action, and explore advancements shaping the industry’s future at the Processing Zone. Find frontof-the-line solutions including homogenizing, heat treating, forming and sizing, and coating. Discover solutions to help increase efficiency, achieve total system integration, and ensure employee safety. Visit the Processing Zone in the North Hall

The Confectionery Pavilion

Head to the Confectionery Pavilion, sponsored by the National Confectioners Association, to see the latest confectionery technology in action, from high-tech aeration and batch refining to innovative shaping and cluster production. Explore the sweet science behind the latest candy-making trends. Located in the South Upper Hall

• Search exhibitors, products and educational sessions

• Access your My Show Planner

• Navigate the show with new GPS-style directions

• Locate concessions and view transportation options

• Join the Scavenger Hunt

• Vote in the 2025 Technology Excellence Awards

Take time to network, recharge, and gain valuable insights at the Candy Bar Lounge, hosted by the National Confectioners Association and sponsored by Syntegon. Find it within the Confectionery Pavilion at booth SU-26000.

The Reusable Packaging Pavilion

Sponsored by the Reusable Packaging Association, discover reusable packaging solutions that reduce waste, drive down costs, and supercharge supply chain efficiency, all while supporting the planet. Located in the South Upper Hall

The Association Partner Pavilion

This pavilion houses associations from the PACK EXPO Partner Program, which connects attendees to leading associations from all segments of packaging and processing. Find them in the West Hall For a full list of participating associations, visit pwgo.to/8804

The Education and Workforce Development Pavilion

Explore PMMI U’s array of offerings, including sought-after training workshops. Colleges and universities from across the country will showcase their mechatronics and packaging and processing programs, while companies will have the opportunity to engage with students interested in pursuing careers in the industry. Located in the North Hall Lobby.

PMMI U Workforce Development

PMMI U is offering its popular training workshops in Las Vegas to coincide with PACK EXPO Las Vegas.

Risk Assessment Workshop: September 27-28, 2025. Learn more at pwgo.to/8805

Certified Trainer Workshop: September 29-30, 2025. Learn more at pwgo.to/8806

Field Service Essentials: September 29-30, 2025.

Learn more at pwgo.to/8807

Educational Opportunities Abound

Beyond the exhibits, PACK EXPO Las Vegas offers more than 100 free educational sessions right on the show floor. These sessions deliver expert insights on a wide range of topics, from automation, AI, and sustainability to navigating tariffs, reusable packaging, food safety, and more.

Multiple stages throughout the show floor serve specific learning interests, including the Innovation Stages, Processing Innovation Stage, Sustainability Central, Industry Speaks, and the Reusable Packaging Learning Center. Whether you’re looking to explore emerging technologies or gain practical strategies for your operation, there’s something for everyone.

Attendee Resource Center

The Attendee Resource Center on the PACK EXPO Las Vegas website is an online gateway with information and resources to help you maximize your time at the show. Use it to access the My Show Planner tool to mark your “must-see” interests and schedule meetings in advance, learn about the PACK Match 1:1 free consultation service, download the Attendee ROI Guide, use the justification letter template, and much more. Find it at pwgo.to/8826

Technology Excellence Award Finalists: Your Vote Counts!

The Technology Excellence Awards are back at PACK EXPO Las Vegas 2025, and it’s up to you to vote for the winner. The awards recognize exhibitor’s brandnew innovations never-before displayed at a PACK EXPO trade show. All registered attendees are eligible to vote for favorites among the finalists across four categories: Food & Beverage, General Packaging & Processing, Personal Care & Pharma, and Sustainability.

Voting will begin on September 22 and continue onsite until Tuesday, September 30 at noon. There are three ways to vote: onsite, on the official show mobile app, and online. The winner of each category will be announced via social media and press release Tuesday afternoon. While you’re at the show, be sure to check out the finalists and winners at their booths! For a complete description of the finalists’ technologies, visit the Technology Excellence Awards page at pwgo.to/8808

Packaging & Processing Women’s Leadership Network Breakfast

The Packaging & Processing Women’s Leadership Network (PPWLN) fosters growth, knowledge sharing, and networking opportunities for women in packaging and processing. Each year at PACK EXPO Las Vegas, PPWLN hosts a networking breakfast to share experiences, build meaningful connections, and hear from influential voices in leadership and workforce development.

This year’s featured speaker, Alison Fragale, an organizational psychologist and professor at the University of North Carolina-Chapel Hill, is a nationally recognized negotiation, communication, and workplace dynamics expert. Her keynote at the PPWLN Breakfast will offer attendees new perspectives and tools to grow personally and professionally.

The PPWLN Breakfast is open to all PACK EXPO Las Vegas attendees, regardless of gender, and is designed to welcome everyone who supports the development of a diverse and inclusive industry.

The Networking Breakfast takes place September 30, from 7:30 a.m. to 9:00 a.m., in Room N-247 at the Las Vegas Convention Center. Register to attend at pwgo.to/8818. Admission is free but an RSVP is recommended, as space is limited, and interest remains high.

The PPWLN breakfast is proudly sponsored by PPWLN Gold Sponsors: Morrison Container Handling Solutions and ProMach, Inc.; PPWLN Breakfast Sponsors: BW Packaging, Emerson Discrete Automation Group, Plexpack Corp., Septimatech Group Inc., SMC Corporation of America, and Smurfit Westrock

PACK EXPO LAS VEGAS 2025 SOLUTIONS START HERE

Discover thousands of innovations and unmatched learning opportunities at the most comprehensive packaging and processing event of 2025, now celebrating 30 years of industry impact.

Unlock your next breakthrough at PACK EXPO Las Vegas 2025 (Sept. 29-Oct. 1; Las Vegas Convention Center), the ultimate packaging and processing event this year. An estimated 35,000 attendees will gather in Las Vegas to explore 2,300 exhibitors and thousands of cutting-edge solutions. Produced by PMMI, this biennial event reliably showcases the most cutting-edge technologies and facilitates invaluable networking opportunities, making it essential to stay informed on the industry’s latest developments. Explore game-changing advancements across over 40 vertical markets, from food and beverage to pharmaceuticals, e-commerce, and more. You can discover crossover solutions you won’t see at vertically targeted events, expanding what’s possible for your business.

Three Decades of Driving Innovation

In 2025, PACK EXPO Las Vegas marks 30 years as one of North America’s most influential packaging and processing events. From its 1995 launch as a regional event to its current form as an international powerhouse, the show has expanded dramatically in size, scope, and impact. The show reaches another new milestone this year, surpassing 1 million net sq ft of exhibit space for the first time, making even more room for new solutions and innovations.

The packaging and processing industry never stands still, and neither does PACK EXPO Las Vegas. Whether it’s Sustainability Central and the Logistics Pavilion added in 2023 to address these vital topics, or the Industry Speaks learning stage where thought leaders from the PACK EXPO Las Vegas Partner Program share valuable insights, this show remains a step ahead of the biggest trends and technologies shaping the future.

To commemorate this milestone year, PMMI proudly honors its PMMI Member Companies that were part of the inaugural show and continue to exhibit today with a 30-Year Legacy Exhibitor logo. Find the list of Legacy Exhibitors at pfwgo.to/8829.

EXHIBIT LOCATION/HOURS

SEPTEMBER 29 – OCTOBER 1, 2025

Las Vegas Convention Center Las Vegas, Nev.

9:00 a.m. – 5:00 p.m. Monday, Tuesday 9:00 a.m. – 3:00 p.m. Wednesday

Registration pricing: Don’t miss the largest gathering of packaging and processing professionals of the year at PACK EXPO Las Vegas. Attendee registration is open for packexpolasvegas.com. Registration is $130.

Why Register? PACK EXPO Las Vegas registration brings exceptional value, especially if you plan early to achieve maximum ROI. Your badge gives you access to:

• All three days of the largest packaging and processing event of the year, with 2,300 exhibitors across over 1 million net sq ft of space.

• Over 100 educational sessions taking place directly on the show floor, covering the latest industry trends, technological advancements, and best practices.

• The PACK Match program for end-users: A one-on-one virtual consultation with a non-biased industry expert to find the right suppliers and solutions ahead of the show.

• New Show Floor Tours: Attend the PACK EXPO Discovery Tours, sponsored by Formic, or the PACK EXPO Sustainability Tour, sponsored by Anchor Packaging, for an expert led tour of the show. Participation is free, but space is limited. Apply at pwgo.to/8828

• Networking on the show floor and at select events, including the Young Professionals Networking Reception sponsored by Beckhoff Automation LLC at The Cove Bar & Arcade, a private performance of Mystère by Cirque du Soleil® at PACK gives BACK™ sponsored by Rockwell Automation, and more.

Please note: No one under the age of 14 is permitted on the show floor.

In 2025, the focus of PACK EXPO Las Vegas remains firmly on what’s next: AI, automation, workforce development, digital transformation, and sustainability. The show continues to actively engage members, partners, and emerging leaders to shape the next decades of innovation, collaboration, and industry impact.

MUST-SEE SPECIALTY PAVILIONS

To enhance the PACK EXPO Las Vegas experience for attendees, the show floor features several specialty pavilions, all of which have expanded from 2023. For more pavilion information and to find exhibitors within every pavilion at PACK EXPO Las Vegas, visit pfwgo.to/8830

The Logistics Pavilion

Dive into the latest in warehousing, fulfillment, distribution, logistics, and transportation services — everything needed to move products faster, smarter, and more efficiently. With the current boom in ecommerce, the Logistics Pavilion will be the place to meet the moment. Find targeted solutions related to the supply chain, including warehousing, fulfillment, distribution logistics services, and transportation providers. Find it in the North Hall

The Healthcare Packaging Pavilion

Explore state-of-the-art packaging innovations for pharmaceuticals, biologics, nutraceuticals, and medical devices. Precision, safety, and innovation converge at this top destination for life sciences companies. Located in the North Hall.

The

Processing Zone

Discover the latest food and beverage processing innovations, see the latest equipment in action, and explore advancements shaping the industry’s future at the Processing Zone. This pavilion supports the integration of processing and packaging, a key function in the manufacturing environment. Find front-of-the-line solutions including homogenizing, heat treating, forming and sizing, and coating. Discover solutions to help increase efficiency, achieve total system integration, and ensure employee safety. Visit the Processing Zone in the North Hall

EXHIBITOR LIST

Searching for a specific company or solution?

Visit the online exhibitor list to easily discover exhibitors and locate them on the show floor.

Find detailed descriptions of each exhibitor and filter by product category, vertical market, and more to find the right solution for your company.

The Containers and Materials Pavilion

Get hands-on with groundbreaking innovations in paperboard, glass, metal, flexible, and resealable solutions designed to captivate consumers and boost sustainability. This pavilion is a one-stop-shop for attendees looking for new packaging to refresh, enhance, or differentiate their brand, add functionality, or improve sustainability. Find it in the South Lower Hall

The Confectionery Pavilion

Head to the Confectionery Pavilion, sponsored by the National Confectioners Association, to see the latest confectionery technology in action, from high-tech aeration and batch refining to innovative shaping and cluster production. Explore the sweet science behind the latest candy-making trends. Located in the South Upper Hall Take time to network, recharge, and gain valuable insights at the Candy Bar Lounge, hosted by the National Confectioners Association and sponsored by Syntegon. Find it within the Confectionery Pavilion at booth SU-26000

The Reusable Packaging Pavilion

Sponsored by the Reusable Packaging Association, discover reusable packaging solutions that reduce waste, drive down costs, and supercharge supply chain efficiency, all while supporting the planet. Located in the South Upper Hall

The Association Partner Pavilion

This pavilion houses associations from the PACK EXPO Partner Program, which connects attendees to leading

PMMI U is offering its popular training workshops in Las Vegas to coincide with PACK EXPO Las Vegas, including:

n Risk Assessment: September 27-28, 2025

• This workshop provides engineers, safety officers, and operations managers valuable insights into industry standards, the machine risk assessment process, identification of health and safety hazards, and effective mitigation of risks. Learn more at pfwgo.to/8832

n Certified Trainer: September 29-30, 2025

• The Certified Trainer workshop will give attendees strategies and tactics to train across all employee skill levels, including service technicians, service and training managers, maintenance technicians, internal trainers, line supervisors, and any employee tasked with training fellow employees or customers. Learn more at pfwgo.to/8833

n Field Service Essentials: September 29-30, 2025

• This two-day workshop explores the non-technical knowledge and skills needed to be a great technician. Through demonstrations and role-play exercises, attendees will learn about customer service, troubleshooting, environmental issues, safety, training, and service call follow-up. A PMMI Member Exclusive. Learn more at pfwgo.to/8834.

PACK EXPO SUSTAINABILITY TOUR

Sponsored by Anchor Packaging, this industry expertled tour will provide a curated experience designed for first-time attendees and senior decisionmakers who are actively seeking sustainable solutions. Find more information and apply at pfwgo.to/8837

PACK EXPO DISCOVERY TOURS

Sponsored by Lantech on Monday; Formic on Tuesday, the PACK EXPO Discovery Tours are a curated experience that simplifies the show for busy professionals. They are designed for senior-level decision-makers and first-time buyers of packaging and processing automation. Led by seasoned industry experts, each tour delivers valuable insights and context, helping attendees make the most of their time on the floor. Find more information and apply at pfwgo.to/8838

associations from all segments of packaging and processing. Find them in the West Hall. For a full list of participating associations, visit pfwgo.to/8831.

Showcase of Packaging Innovations®

Sponsored by Smurfit Westrock

This attendee favorite will display award-nominated packaging solutions. Find it on the bridge between the North and West Buildings

The Education and Workforce Development Pavilion

PACK EXPO Las Vegas serves as the ultimate resource hub

for strengthening the existing workforce and nurturing the future workforce. Explore PMMI U’s array of offerings, including sought-after training workshops. Colleges and universities from across the country will showcase their mechatronics and packaging and processing programs, while companies will have the opportunity to engage with students interested in pursuing careers in the industry. Located in the North Hall Lobby

EDUCATIONAL OPPORTUNITIES ABOUND

Beyond the exhibits, PACK EXPO Las Vegas offers over 100 free educational sessions right on the show oor. These sessions cover various topics, including the latest industry trends, technological advancements, and best practices. Attendees gain valuable knowledge that can be directly applied to their operations, fostering innovation and ef ciency. Visit the links after each description for full session lists.

TECHNOLOGY EXCELLENCE AWARD FINALISTS DON’T FORGET TO

The Technology Excellence Awards are back at PACK EXPO Las Vegas 2025, recognizing exhibitors’ brand-new innovations never-before displayed at a PACK EXPO trade show. All registered attendees are eligible to vote for favorites among the finalists across four categories: Food & Beverage, General Packaging & Processing, Personal Care & Pharma, and Sustainability.

Voting will begin on September 22 and continue onsite until Tuesday, September 30 at noon. There are three ways to vote: onsite, on the official show mobile app, and online. Your vote counts!

The winner of each category will be announced via a press release Tuesday afternoon. While you’re at the show, be sure to check out the finalists and winners at their booths! To learn more, visit pfwgo.to/8835

The Technology Excellence Awards 2025 Finalists are as follows:

Food & Beverage Finalists

HyperBarrier® Paper. Replaces multilayer plastics with a single-layer nanocomposite barrier coating on paper, for recyclable high-barrier food packaging. COPAR SMART PACKAGING, Booth SU-30098A.

Senzani U-Seal. Cold-sealing technology that enables the creation of fully recyclable cardboard packs in a variety of shapes from flat blanks. Senzani Brevetti SPA, Booth SU-26041

Efficient Agitation (EA) Retort. This technology allows for more versatile packaging options in retort processing, using a patented trapezoidal motion for greater mix energy and shorter stroke length during sterilization. JBT Corporation, Booth N-8612

General Packaging & Processing Finalists

HaiPick Climb. Hai Robotics says this is the first robot of its kind, capable of climbing warehouse racks and operating in lowprecision environments. Hai Robotics USA, Booth SU-25090

Volta All-Electric Adhesive Jetting Head. This adhesive applicator uses an all-electric design and features integrated pattern control for direct programming on the head itself. Robatech USA, Inc., Booth N-8447

MAG-B Horizontal Form Fill and Seal. This HFFS machine features magnetic track motion, pitch-less operation, and rapid changeover capabilities. Bartelt Packaging, Booth W-1130

Personal Care & Pharma Finalists

PR-12 and PR-24 Syringe Plunger Rod Insertion and Labeling Machine. High-speed, high-control plunger rod insertion and syringe labeling in one compact unit. WLS, Booth W-1152

MLD Advanced. This syringe filling system features 100% inprocess control and gentle, no-glass-to-glass-contact handling. Syntegon, Booth N-5244

BK-4 Precision Belt Capper with EM-980 Torque Tester. A capper with a four-belt clutched cap tightening system for gentle, consistent torque across cap styles, and an inline torque monitor. Kaps-All Packaging Systems, Inc., Booth W-820

Sustainability Finalists

ZeCycle Recycling Program. This closed-loop program allows for recycling of VCI film and LDPE poly films, processing them into PCR resin for use in new VCI film, and creating a measurable environmental impact. ZERUST Corrosion & Cleaning Solutions, Booth SU-25054

Machine Stretch Film with 30% PCR Content. Thin, strong films with 30% PCR content and a baled film collection program to support circularity. Trioworld, Booth SU-34018

Comprex North America, LLC. This chemical-free CIP system uses compressed air and minimal water to clean piping systems. Floco Process, Booth N-6760

Sustainability Central

Presented by Packaging World and sponsored by Dow, Sustainability Central is your first stop to stay on top of what is arguably the biggest, most multifaceted challenge the packaging industry is currently facing. Expert-led sessions will help you navigate the complexities of sustainability and what it means for your brand. Session topics will include sustainable packaging solutions, Extended Producer Responsibility and other legislation, circularity, and much more. This is a vital destination for anyone looking to understand and implement sustainable practices in packaging and processing. Find it in the South Upper Hall, Booth SU-35000. For a complete session list, visit pfwgo.to/8836.

Innovation Stage

Catch free, 30-minute seminars on breakthrough technologies and best practices, presented across three stages each day by suppliers and subject matter experts. Session topics include cobots, automation, AI, navigating tariffs, thermal inkjet (TIJ) technology, and more. Located in the West Hall, Booths W-4300, W-4310, W-4318. Find the complete session list at pfwgo.to/8839.

PACKAGING & PROCESSING WOMEN’S LEADERSHIP NETWORK BREAKFAST

The Packaging & Processing Women’s Leadership Network (PPWLN) fosters growth, knowledge sharing, and networking opportunities for women in packaging and processing. Each year at PACK EXPO Las Vegas, PPWLN hosts a networking breakfast to share experiences, build meaningful connections, and hear from influential voices in leadership and workforce development.

This year’s featured speaker, Alison Fragale (left), an organizational psychologist and professor at the University of North Carolina-Chapel Hill, is a nationally recognized negotiation, communication, and workplace dynamics expert. As a speaker, author, and educator, Fragale is known for blending research with relatable stories that help professionals better understand power, confidence, and leadership. Her keynote at the PPWLN Breakfast will offer new perspectives and tools to grow personally and professionally.

The PPWLN Breakfast is open to all PACK EXPO Las Vegas attendees, regardless of gender, and is designed to welcome everyone who supports the development of a diverse and inclusive industry.

The Networking Breakfast takes place September 30, from 7:30 a.m. to 9:00 a.m., in Room N-247 at the Las Vegas Convention Center. Register to attend at pfwgo.to/8845. Admission is free but an RSVP is recommended, as space is limited, and interest remains high.

The PPWLN breakfast is proudly sponsored by PPWLN Gold Sponsors: Morrison Container Handling Solutions and ProMach, Inc.; PPWLN Breakfast Sponsors: BW Packaging, Emerson Discrete Automation Group, Plexpack Corp., Septimatech Group Inc., SMC Corporation of America, and Smurfit Westrock.

Processing Innovation Stage

This stage focuses on advancements in processing technologies, offering insights into improving efficiency and product quality. Session topics include food safety, sustainability, food processing, AI, and more. Find it in the North Hall, Booth N-9100. For a complete session list, visit pfwgo.to/8840.

Industry Speaks

Experts from the PACK EXPO Partner Program, covering multiple industry verticals, will address the latest hot topics and industry trends such as sustainability, remote access, supply chain solutions, augmented reality, and operational efficiency. Located in the West Hall, Booth W-4324. For a complete session list, visit pfwgo.to/8841

Reusable Packaging Learning Center

Sponsored by the Reusable Packaging Association, hear from experts on strategies to implement a reusable packaging system that can improve material-handling performance, reduce operating costs, create new economic values, and lower the environmental impacts of a brand’s supply chain. Located within the Reusable Packaging Pavilion in the South Upper Hall, Booth SU-34000. Find the complete session list at pfwgo.to/8842.

NETWORKING AND SPECIAL EVENTS

Take advantage of the numerous networking events designed to connect professionals across various sectors at PACK EXPO Las Vegas. These events provide opportunities to exchange ideas, discuss challenges, and build relationships leading to future collaborations and business growth. For an online rundown of all networking and special events, visit pfwgo.to/8843.

A Dazzling Night at PACK gives BACK™

Sponsored by Rockwell Automation, step out on the town with an exclusive, private performance of Mystère by Cirque du Soleil® — a special event just for PACK EXPO Las Vegas attendees! From gravity-defying feats to whimsical comedy and stunning visuals, this unforgettable experience promises thrills at every turn. Best of all, proceeds from this annual event will support the PMMI Foundation, providing financial support for packaging and processing education throughout the U.S. and Canada.

See the performance on Sunday, September 28, at Treasure Island Las Vegas. Doors open at 6:15 p.m., with the performance at 7:00 p.m. Tickets are $95 each, or buy nine and get the 10th free. Take advantage of the 10-tickets-for-the-price-ofnine deal to treat customers or business partners to the show.

Don’t miss this extraordinary night of entertainment for a great cause! To buy tickets and find more information, visit pfwgo.to/8844.

Young Professionals Networking Event

SPONSORED BY:

Sponsored by Beckhoff Automation LLC, the Young Professionals Networking Reception at PACK EXPO Las Vegas offers up-and-coming leaders an opportunity to socialize with their peers in a fun and relaxed environment, perfect for making new connections in the industry. Attend the event at The Cove Bar & Arcade September 29 at 7:00 p.m. to 9:00 p.m. Free with registration; RSVP required. Learn more and register at pfwgo.to/8846

First-Time Attendee Lounge

In this exclusive lounge, first-time attendees can access product locators, talk to experienced show staff, get access to a special networking breakfast September 30 at 8:00 a.m., or simply relax and recharge to help maximize your time at the show. Don’t miss the special sessions on How to Navigate the Show Floor taking place Monday and Tuesday at 8:30 a.m., and Simplify Supplier Sourcing with ProSource, MondayWednesday at 12:30 p.m. The lounge and breakfast are both sponsored by ProMach, Inc. Located in the South Hall, Room S-220. Learn more at pfwgo.to/8882

Vision 2030

Explore the future of packaging and processing in these immersive forums designed to facilitate conversation and build

business strategy. Industry visionaries will discuss emerging trends, sustainability, and technological advancements shaping the industry for the next decade. Designed exclusively for CPGs and PMMI members in operations, plant managers, and engineers, these sessions promise actionable strategies to elevate your business. Learn about topics and session scheduling and register in advance at pfwgo.to/8883

STUDENT ACTIVITIES

Today’s students are tomorrow’s industry leaders. That’s why PACK EXPO Las Vegas offers programs and activities aimed at getting students excited about careers in packaging and processing. For information on all student opportunities, visit pfwgo.to/8847

Future Innovators Robotics Showcase

Robotics teams from Las Vegas area high schools will bring the robots they’ve designed and built to showcase them in action. Each team’s high school receives a $500 grant from the PMMI Foundation to support their participation. Come watch these fun demonstrations and feel free to ask questions. Find it in the North Hall Lobby

The Amazing Packaging Race

Sponsored by Emerson Discrete Automation Group, teams of engineering students from colleges, trade schools, and universities across the U.S. will race around the PACK EXPO

Las Vegas show floor, completing tasks and solving problems at the booths of participating exhibitors. Students can explore the cuttingedge world of packaging and processing and compete for cash prizes, while companies can connect with the future workforce by participating as a race destination. The race takes place Wednesday, October 1, beginning at 9:00 a.m. Learn more at pfwgo.to/8848

The PACK Challenge

This exciting, real-world, end-to-end competition challenges teams of students to design and build working packaging machinery and compete against other schools at PACK EXPO International in Chicago. The winning team from 2024, Spruce Packaging, will showcase their winning design at the show in Las Vegas. Be sure to check it out in the North Hall, N-6100

Student Lounge

Sponsored by Visionary Benefactor Schneider Electric, the student lounge will be open for students to come and meet with HR professionals to discuss career opportunities, receive resume

PMMI FOUNDATION INITIATIVES

The PMMI Foundation provides financial support for packaging and processing education throughout the U.S. and Canada. Since its inception, the PMMI Foundation has given more than $5.4 million to strengthen the industry’s workforce. Enjoy the following events, with proceeds benefiting the Foundation.

n The PMMI Foundation Golf Tournament: Held the day before PACK EXPO Las Vegas (Sunday, September 28), this annual charity event brings packaging and processing professionals together for a morning of golf, networking, and giving back. The 2025 event takes place at Bali Hai Golf Club and welcomes players of all skill levels. More than just a fun outing, proceeds support scholarships, student travel, and workforce development programs through the PMMI Foundation. In 2023 alone, the tournament raised over $40,000 to help close the industry’s talent gap. Learn more and register to play at pfwgo.to/8850.

n Silent Auction: Featuring entertainment, sports, and historical memorabilia, this Silent Auction will take place Sunday through Wednesday of the show. All bidding will occur virtually, and items will be displayed in the West Hall Lobby. Proceeds will go to benefit the PMMI Foundation.

Student Tour Opportunities

Students attending PACK EXPO Las Vegas are invited to attend the PPWLN Breakfast, followed by a tour given by members of the PPWLN Executive Council. To find more information on the breakfast and register to attend, visit pfwgo.to/8849

Student tours are also available beyond the PPWLN tour. PMMI staff will conduct tours of the show floor daily at 10:00 a.m. and 2:00 p.m. Contact Kate Torrence at kate@pmmi.org for more information.

PLAN AHEAD WITH THE PACK EXPO LAS VEGAS MOBILE APP

Navigate the show like a pro with the free PACK EXPO Las Vegas Mobile App, sponsored by ProMach, Inc

n Search exhibitors, products, and educational sessions.

n Access your My Show Planner and add to your personal agenda.

n NEW! Turn-by-Turn Navigation helps you find anything with improved GPS-style directions.

n Get in the know on transportation & dining options, meeting rooms, FAQ’s and more

n Join the Scavenger Hunt.

n Vote in the 2025 Technology Excellence Awards.

RESOURCES FOR THE SHOW

Attendees have access to a host of tools and resources to help them make the most of their time at PACK EXPO Las Vegas.

My Show Planner

My Show Planner allows you to create a personalized collection of “must-sees,” and your key means of tracking your interests before, during, and after the show. Add exhibitors and sessions of interest and even schedule meetings in advance, maximizing your time at the show. To get started, visit pfwgo.to/8851

PACK Match Program

This complimentary program offers registered end-user attendees a one-on-one virtual consultation with a non-biased industry expert, helping to find the right suppliers and solutions to address their needs before they arrive at PACK EXPO Las Vegas. Upon completing the consultation, the attendee will receive a list of exhibitors they can visit during the show, curated to provide solutions to their challenges. This service is only available to end-user buyers of packaging, processing, or related solutions who have registered to attend PACK EXPO Las Vegas. The deadline to register and schedule an appointment is September 16. Consultations with PACK Match Advisors take place September 8-25. To learn more and register, visit pfwgo.to/8852

Ask the Experts

The Ask the Experts program is an additional attendee resource offered onsite at PACK EXPO Las Vegas, serving as an extension of the PACK Match program. Ask the Experts will be staffed by experienced packaging or processing industry executives. Get expert guidance on finding the right packaging or processing solutions to address your specific challenges. Find them in the South Building and West Building Lobbies.

Attendee Solutions Center

This is your onsite destination for industry advice and show planning tools. Get one-on-one guidance, map your route, and print your itinerary using product locators. Find them in the West Building Lobby

Attendee Resource Center

This is an online gateway with information and resources to help attendees maximize their time and get more ROI from attending the show. Download the Attendee ROI Guide, use the justification letter template, explore additional search tools to find the best solutions at the show, and much more. To access it, visit pfwgo.to/8853.

The PMMI Booth

The PMMI Booth showcases all that the organization offers to its members and the packaging and processing industry. Learn about PMMI business drivers including Business Intelligence, Workforce Development, Industry Services, and more. Get acquainted with the PMMI Media Group and the PACK EXPO brand of trade shows. Stop by to discover how PMMI can make a difference in your business, career, and community. Find it in the West Hall Lobby

Insider Advantage

The Insider Advantage Program at PACK EXPO Las Vegas 2025 is designed exclusively for leading national and multinational CPG buying groups seeking a more strategic and productive show experience. This upgraded experience offers an unmatched combination of convenience, comfort, and connectivity offering a lounge with Wi-Fi, product locators, refreshments, and semi-private meeting space access available on a first-come, first-served basis. For groups bringing 10+ employees, private meeting space is available to hold executive-level discussions, host strategic partners, or regroup with your team. Space is limited and reserved on a first-come, first-served basis. To join, fill out the interest form at pfwgo.to/8854 or contact Claire Morrell at cmorrell@pmmi.org.

2025 EXHIBITOR LOCATOR

BUSINESS DRIVERS

AUTOMATION & DIGITAL TRANSFORMATION

GROTE COMPANY 26 N-6142

OXIPITAL AI 35 N-7650

SANI-MATIC, INC. 37 N-8450

FOOD SAFETY

EAGLE PRODUCT INSPECTION 22 N-7610

FPS FOOD PROCESS SOLUTIONS CORPORATION 24 N-7242

KEY TECHNOLOGY INC 30 W-1040

PROSPECTION SOLUTIONS 6, 7 N-7838

SANI-MATIC, INC. 37 N-8450

VAC-U-MAX 45 SU-26032

SUSTAINABILITY

WEBER INC 46 N-7656

VERTICAL MARKETS

BAKERY & SNACKS

ASHWORTH BROS., INC. 18 N-6950

PROBAT INC. 36 SU-26014

PROSPECTION SOLUTIONS 6, 7 N-7838

WEBER INC 46 N-7656

BEVERAGE

E.A. BONELLI + ASSOCIATES, INC 20 N-5972

MEMBRANE PROCESS & CONTROLS 31 N-7026

SANI-MATIC, INC. 37 N-8450

CONFECTION & CANDY

PROBAT INC. 36 SU-26014

VAC-U-MAX 45 SU-26032

DAIRY

E.A. BONELLI + ASSOCIATES, INC 20 N-5972

MEMBRANE PROCESS & CONTROLS 31 N-7026

PROSPECTION SOLUTIONS 6, 7 N-7838

SANI-MATIC, INC. 37 N-8450

WEBER INC 46 N-7656

FOOD INGREDIENTS

EAGLE PRODUCT INSPECTION 22 N-7610

VAC-U-MAX 45 SU-26032

FROZEN & REFRIGERATED FOODS

FPS FOOD PROCESS SOLUTIONS CORPORATION 24 N-7242

IDAHO STEEL PRODUCTS 28 N-6460 KEY TECHNOLOGY INC 30 W-1040

FRUITS & VEGTABLES

EAGLE PRODUCT INSPECTION 22 N-7610

IDAHO STEEL PRODUCTS 28 N-6460 KEY TECHNOLOGY INC 30 W-1040

SORMAC INC. 44 N- 7060

GRAINS, SEEDS, BEANS, FLOUR & NUTS

PROBAT INC. 36 SU-26014

MEAT, POULTRY & SEAFOOD

EAGLE PRODUCT INSPECTION 22 N-7610 FPS FOOD PROCESS SOLUTIONS CORPORATION 24 N-7242

PROSPECTION SOLUTIONS 6, 7 N-7838 WEBER INC 46 N-7656

PET FOOD

EAGLE PRODUCT INSPECTION 22 N-7610

PROSPECTION SOLUTIONS 6, 7 N-7838

PRODUCT CATEGORIES

CLEANING, SANITIZING & CIP

HRS HEAT EXCHANGERS 21 N-8040

SANI-MATIC, INC. 37 N-8450

CONVEYING & PRODUCT HANDLING

ASHWORTH BROS., INC. 18 N-6950

D&F EQUIPMENT SALES, INC. 19 N-7714

GROTE COMPANY 26 N-6142

IDAHO STEEL PRODUCTS 38 N-6460

KEY TECHNOLOGY INC 30 W-1040

WIRE BELT COMPANY OF AMERICA 48 N-7318

URSCHEL LABORATORIES, INC. 40 N-7410

VAC-U-MAX 45 SU-26032

VDG (VAN DER GRAAF) 42 N-8258

DRY PROCESSING & HANDLING EQUIPMENT

PROBAT INC. 36 SU-26014

URSCHEL LABORATORIES, INC. 40 N-7410

WIRE BELT COMPANY OF AMERICA 48 N-7318

VAC-U-MAX 45 SU-26032

VDG (VAN DER GRAAF) 42 N-8258

FACILITIES, DESIGN & INFRASTRUCTURE

E.A. BONELLI + ASSOCIATES, INC 20 N-5972

FOOD PROCESSING EQUIPMENT

D&F EQUIPMENT SALES, INC. 19 N-7714

Ashworth Bros., Inc.

450 Armour Dale, Winchester, VA 22601 USA

Phone: 540-662-3494

Email: ashworth@ashworth.com

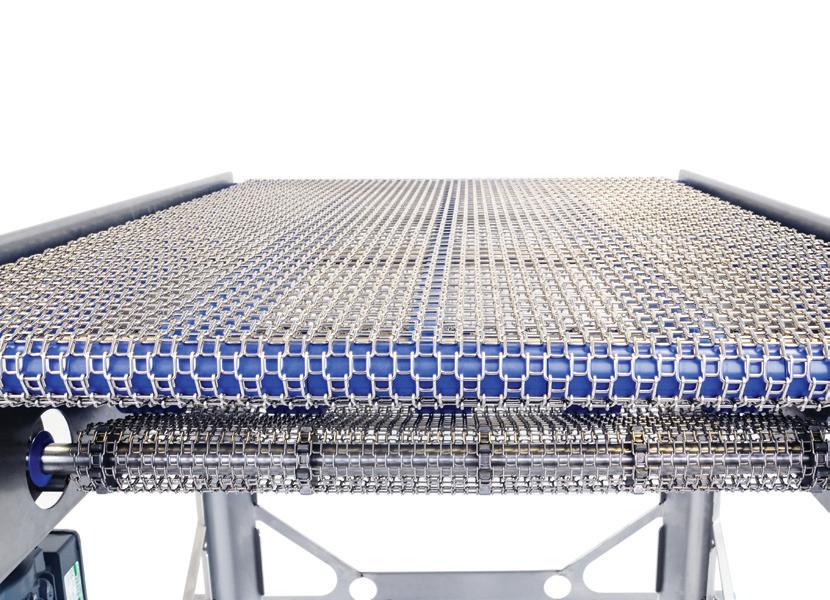

The Best of Both Worlds: Ashworth’s Custom Conveyor Belts

At Ashworth, when we say we offer “the Best of Both Worlds,” we mean it. Since 1946, manufacturers worldwide have trusted Ashworth for high-quality, customized conveyor belts. With both metal and plastic options, our belts are engineered for your specific needs. Whatever your challenge, Ashworth has the solution.

High-Quality, Customizable Metal Conveyor Belts - Ashworth has a metal belt for every application. The new Heavy-Duty Small Radius Omni-Grid® 360 Weld is small, but mighty with a tension rating of 400 pounds. Combined with its patented zero-tension, 360 buttonless weld it offers improved durability, additional strength, is easy to clean and can increase belt life

Plastic Conveyor Belts for Ease and Efficiency - While many metal belts excel in freezers and coolers, plastic conveyor belts may be the better choice when product release is key. Our SpiralSurf® belt is a freezer favorite, offering excellent product release, enhanced airflow, and improved drainage thanks to its flush grid design. Plastic belts are also easy to repair on-site, requiring no special tools—minimizing downtime and boosting efficiency.

Ashworth now offers EZ Splice® technology, making metal belt splicing faster, safer, and easier than ever—no welding required. Available on Omni-Grid® 360 and Omni-Pro® belts, EZ Splice offers the strength of metal with the simplicity of plastic belting.

Don’t settle for stock conveyor belts when a tailored solution can improve performance, reduce waste, and minimize downtime. With Ashworth’s metal and plastic conveyor belts, you truly get the Best of Both Worlds.

Celebrating over 75 years of innovation, Ashworth leads the market with the most conveyor belt patents in food processing, can making, and material handling. Companies around the world depend on Ashworth’s quality, customer service, and smart solutions to boost productivity. Ashworth Factory Service provides full engineering support—system refurbishment, troubleshooting, installation, and maintenance.

Request a quote today and speak with one of our experts to see how Ashworth can optimize your line and move your business forward. Learn more at www.ashworth.com. www.ashworth.com

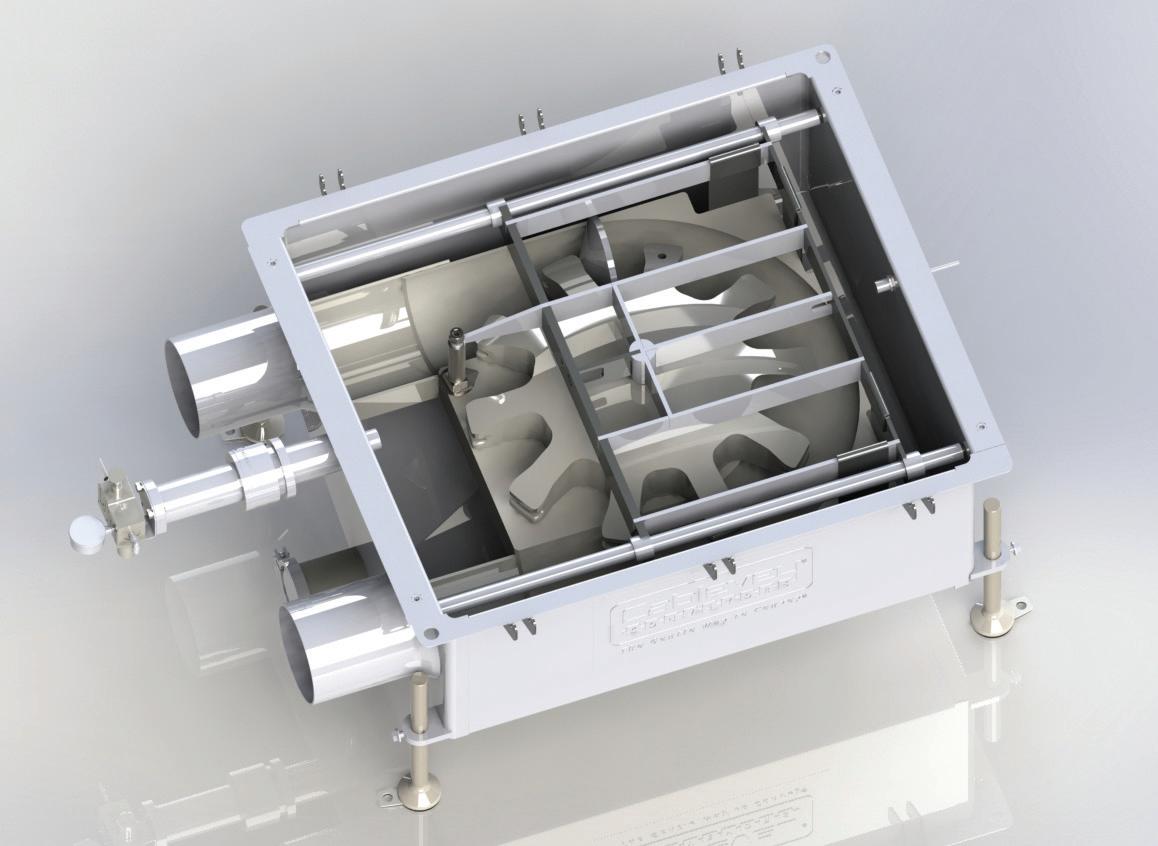

D&F Equipment Sales, Inc.

D&F Equipment Sales began as a small equipment and millwright services provider, and now, nearly 40 years later, it operates as a full-service equipment manufacturer and engineering supplier. Today, D&F encompasses over 200,000 square feet of manufacturing space, employing more than 300 skilled professionals. The company boasts a combined total of over 500 years of experience in the industry between sales and process engineers. www.dfequip.com

At D&F Equipment Sales, we specialize in Process Engineering, System Fabrication, and Service & Installation, offering custom-engineered solutions that optimize production, improve process flow, and meet the unique needs of our clients in the poultry, meat, and prepared foods industries. The D&F team turns problems into concepts, conveying solutions that optimize your operations. Let us guide you from concept to implementation and beyond, delivering results that ensure long-term efficiency and success.

EA Bonelli + Associates

Oakland, CA | Fresno, CA | Portland, OR | Denver, CO | Holland, MI

Phone: 510.740.0155

www.eabonelli.com

Email: eab@eabonelli.com

E.A. Bonelli is a leader in the master planning and design of processing plants, cold storage warehouses, and distribution facilities for the food and beverage industries.

Since our founding in 1960, E.A. Bonelli has focused exclusively on these sectors, combining a client-oriented approach with a wealth of experience to find proven solutions regarding space-planning, food safety requirements, and architectural and engineering design.

E.A. Bonelli has designed plants across North America, with a track record that ranges from small remodels to some of the largest expansions and newest plants in the United States. We have consistently been on the forefront of industrial architecture and engineering, meeting food and beverage trends by coupling practiced experience with design innovations. We understand processing environments and recognize the importance of zone separation for optimal hygienic and sanitary design.

E.A. Bonelli’s integrated design services provide architectual, structural, and MEP engineering. We recognize that our job is to design an environment that is both efficient and hygienic, in which safeguarding the client’s process is of paramount importance.

Over the course of more than six decades in business, E.A. Bonelli has grown considerably, from a San Francisco-based architectural office to a firm that now proudly provides support for our customers from offices across the United States. In addition to our Oakland, CA headquarters, EAB operates offices in Fresno, CA, Portland, OR, Denver, CO, and Holland, MI.

Even as E.A. Bonelli has continued to grow, our focus remains firmly rooted in the vision of our founder: client-focused, hygienic design for the food and beverage industries.

HRS Heat Exchangers

770 726 3540

info@us.hrs-he.com

www.hrs-heatexchangers.com/us

HRS Heat Exchangers will showcase its market-leading food processing solutions, helping manufacturers improve energy efficiency and reduce operating costs.

HRS equipment includes sanitary corrugated tube and scraped-surface heat exchangers, ideally suited to highly viscous products, which improve heat transfer and operational efficiency. Their heat regeneration options provide the highest levels of energy efficiency, cutting costs and reducing carbon. Standard features include remote monitoring and telemetry.

HRS’ offering comprises stand-alone solutions, complete packaged systems and bespoke options.

Eagle Product Inspection

1571 Northpointe Pkwy, Lutz, FL 33558

Phone: 1-877-379-1670

Email: eaglesales@eaglepi.com

www.eaglepi.com/technologies

Eagle Product Inspection is a trusted leader in x-ray inspection and fat analysis technologies, helping food processors worldwide protect their products, meet regulations, and improve operational performance. Whether inspecting raw or packaged goods, Eagle’s solutions detect contaminants like bone, metal, glass, and stone while also analyzing fat content, verifying mass, counting components, and checking package integrity—all in one streamlined system.

Powering Performance, Protecting Brands

Today’s processors face mounting pressure to deliver safer food, faster throughput, and stricter traceability. Eagle delivers—with rugged machines engineered for hygiene and efficiency, advanced imaging software, and industry-leading detector technology.

The

Dynamic Duo: PXT™ and SimulTask™ PRO

At the core of Eagle’s systems is the combination of PXT™, a photon-counting x-ray detector delivering unmatched resolution, and SimulTask™ PRO, advanced image analysis software processing up to 65,535 greyscale values and performing real-time analysis, within in one-tenth of a second. Together, this Dynamic Duo provides exceptional contaminant detection, faster decision-making, and reduced false rejects.

Engineered for what matters most:

• The industry’s most advanced contaminant detection

• Real-time analysis for faster reject decisions

• Unmatched image clarity and resolution

• Automated data capture for audit-ready traceability

• Hygienic designs that simplify sanitation

• Reduced false rejects and product waste

Discover why food processors rely on Eagle for superior safety, quality, and compliance— without compromise.

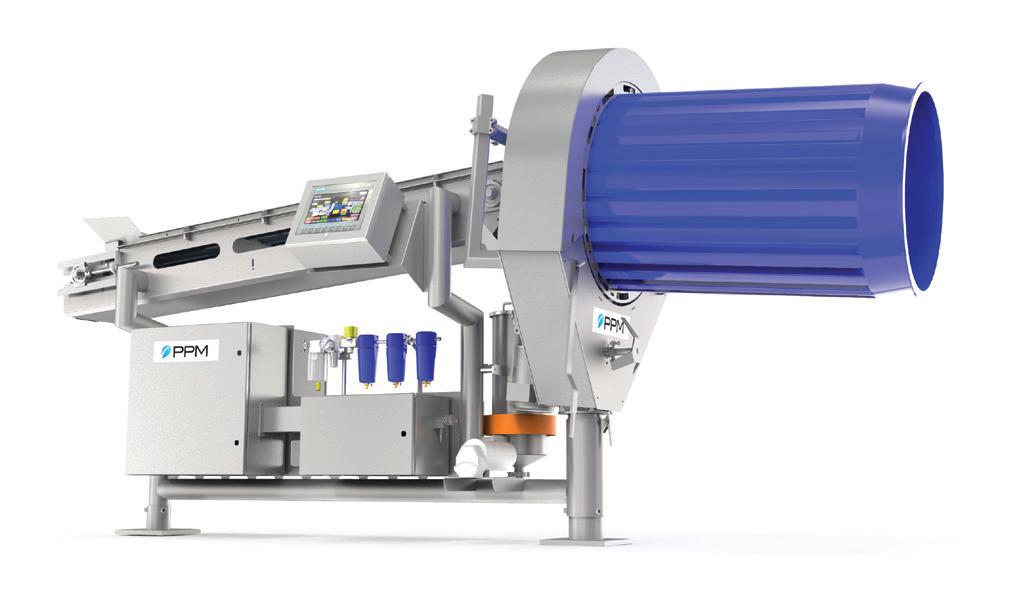

FPS Food Process Solutions

Suite 110, 13911 Wireless Way, Richmond, BC, Canada V6V 3B9

Phone: 604/232-4145

www.fpscorp.ca

Email: sales@fpscorp.ca

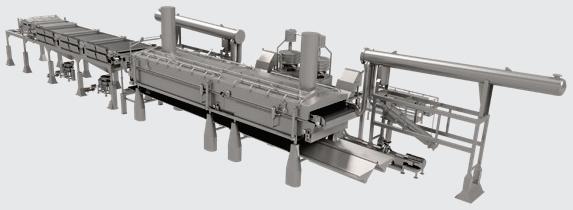

FPS Food Process Solutions is a global leader in turn-key food processing solutions. We provide innovative systems to ensure the highest efficiencies and to meet the most stringent sanitary demands. These factors transform into superior food quality, lowered total cost of ownership, and maximized profits.

We solve food processing’s toughest challenges. We ensure our customers’ products are managed through every step of the production process. Designed to seamlessly integrate, from raw receiving to frying to freezing to packaging, FPS is with you every step of the way.

In celebration of our 15th Anniversary (2010 – 2015), FPS is proud to mark its growth not only in global market expansion but also in industry-leading innovation – all to raise food processing industry standards. Originally established in 2010 in Richmond, BC, Canada, FPS now stands at 20 locations around the world covering six continents with manufacturing capabilities in Canada, US, Europe and China.

FPS thrives on building customer and partner relationships. Through strategic acquisitions and innovations in equipment design, FPS partnered with PEF-specialist OptiCept Technologies to design a patented dual conveyor belt chamber to handle efficient electroporation at high throughput capacities, bringing distinct advantages to both solid and liquid food manufacturers. Benefits include enhanced raw material extraction, less energy and water usage, less drying time, and improved product texture and quality.

FPS’s full suite of products include:

Freezers and Chillers

Conveyance and Product Handling

Fryers, Blanchers and Batter Solutions

Immersion, Thermal and Pasteurization Solutions

Pulsed Electric Field (PEF)

And more

The Grote Company Family of Brands

1160 Gahanna Parkway, Columbus, OH 43230, USA

Phone: 614-868-8414

The Grote Company Family of Brands has provided food processing equipment, parts, and services for decades. We work together to give food manufacturers a team of experts in their corner—with hundreds of employees in ten global locations dedicated to providing more complete solutions and unwavering support.

We ensure food plants run optimally with millwright and mechanical services, sanitary conveyance systems, best-in-class processing equipment, and a robust lifecycle program featuring aftermarket parts and technical services. We have skilled engineering, controls, robotics, project management, and field service teams ready at a moment’s notice. Over 400,000 square feet of domestic manufacturing capacity enables more OEM solutions and faster lead times.

Our businesses operate on the principles of doing the right thing and treating others how they’d like to be treated. From the first inquiry to when our equipment needs to be replaced decades later, we are committed to supporting food operations and won’t stop until your machines and teams are running right. We call it our “enduring commitment.”

Our family of brands includes the following divisions:

Grote Company

ProFab

ONE FAMILY.

ENDLESS SOLUTIONS FOR FOOD PROCESSING.

PROCESSING

Idaho Steel Products

255 E Anderson Street • Idaho Falls, ID 83401 • USA

Phone: (208) 522-1275

www.idahosteel.com

Email: sales@idahosteel.com

Since 1918, Idaho Steel has been shaping the future of potato processing with innovative engineering and advanced manufacturing. For more than a century, we’ve partnered with processors worldwide to deliver high-performance equipment that improves efficiency, reduces waste, and ensures consistent product quality.

From raw receiving to finished products, Idaho Steel provides fully integrated solutions for every stage of production. Our technology covers washing, peeling, cutting, blanching, drying, frying, oil recovery, freezing, and packaging. With equipment like Drum Dryers, Strata Invicta Steam Peelers, Corda Invicta Fryers, and Nex-Gem Rotary Formers, we build systems that work seamlessly together for reliable, high-capacity performance.

Through our partnership with Kiremko and REYCO Systems, Idaho Steel offers turnkey solutions backed by decades of combined expertise. This tri-brand alliance has a global footprint, delivering complete fry lines to processors across North America, Europe, Asia, and beyond. Our combined engineering strength and worldwide installation network ensure you receive not only cutting-edge equipment but also the service and support needed to succeed in any market.

As a true one-stop shop, we design, manufacture, and install everything from raw potato handling through peeling, cutting, blanching, frying, freezing, and final packaging. Each line is custom-engineered to operate as one seamless system, eliminating the complexity of multiple suppliers while ensuring maximum throughput, consistent product quality, and faster ROI.

Every plant faces unique challenges, and we take the time to understand yours. Whether you need a single machine or a full-scale processing line, we engineer solutions that align with your goals and position your business for long-term success. Because experience matters—and true expertise is built, not bought.

Key Technology Inc.

Phone: 509-529-2161

www.key.net

Email: product.info@key.net

Key Technology offers food processors the single most complete source of high performance automated sorting, handling, and processing solutions.

A global leader in the design and manufacture of automation systems including optical sorters, conveyors and other processing equipment, Key provides complete solutions, supported for optimal performance and returns through their lifecycle.

Key services include line design and system integration, application testing, installation, start-up and training. Plus, customizable aftermarket support through our Duravant Lifecycle Services.

See u S at Booth #N-7026

Membrane Process & Controls

922 N. 3rd Ave, Edgar, WI 54426

Phone: 715-352-3206

Email: info@membranepc.com

www.membranepc.com

Membrane Process & Controls, Inc. (MP&C) is a premier provider of custom-engineered stainless steel liquid-phase process equipment. Located in central Wisconsin, MP&C operates a state-of-the-art manufacturing facility and specializes in the design, fabrication, and installation of membrane filtration systems, complete process skids, ASME pressure vessels, atmospheric tanks, automation systems, control panels, and full-scale facility equipment solutions. Established in 1992, MP&C remains a privately held, non-union company dedicated to delivering quality, innovation, and long-term customer success.

Linde

7000 High Grove Boulevard, Burr Ridge, IL 60527

Phone: 1-844-44LINDE

Email: contactus@lindeus.com

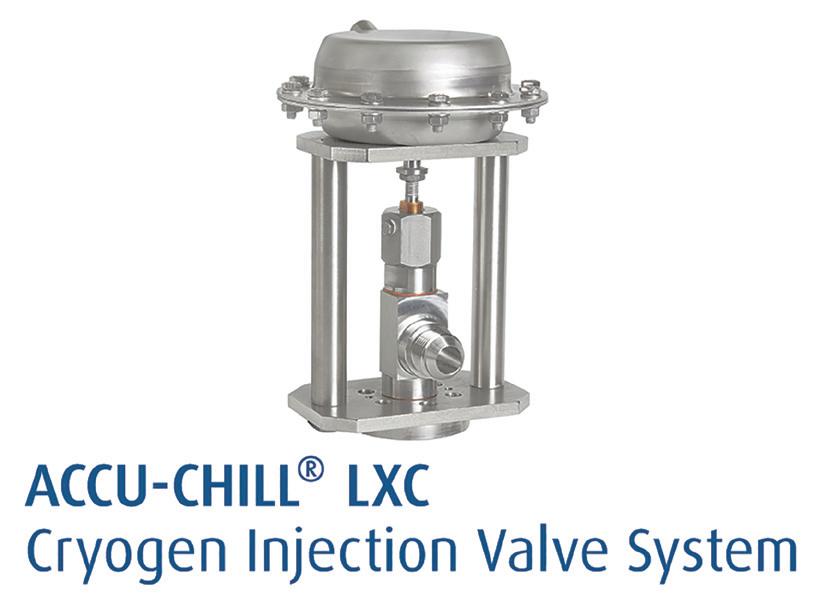

Rapid heat removal with cryogenic liquid nitrogen or liquid carbon dioxide offers processors a variety of options that meet their processing needs. Customers working with Linde’s industrial gas and equipment systems can boost productivity and maintain high product quality targets in freezing, chilling and cooling operations. Tunnel, spiral, flighted, snowing and in-line cooling systems provide cost saving benefits to our customers.

For Linde and the food processing market areas we serve, there are three unique competencies to address the needs of our customers. The focus on 1) product temperature through precise heat removing properties of cryogenic gases, 2) the scientific application knowledge of the gases and gas atmospheres acquired by servicing thousands of customers, and 3) the system support coupled with engineering experience that allow our customers to rely on Linde to help improve productivity.

Linde is a leading global industrial gases and engineering company. We live our mission of making our world more productive every day by providing high-quality gases, application technologies and services which are making our customers more successful and helping to sustain and protect our planet.

The company serves a variety of end markets including chemicals & refining, food & beverage, electronics, healthcare, manufacturing and primary metals. Linde’s industrial gases are used in countless applications, from life-saving oxygen for hospitals to high purity & specialty gases for electronics manufacturing, hydrogen for clean fuels and much more.

For more information about the company and its products and services for the food processing market, please visit www.lindeus.com/food

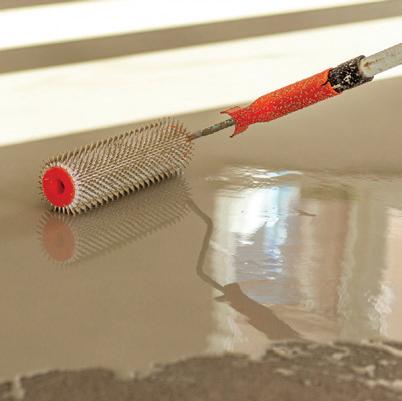

Cryogenic Freezing and Chilling Before Packaging

Miura’s on-demand steam system eliminates long warm-up times, ensuring uninterrupted productivity while using significantly less water than traditional boilers. The modular design lets you adjust steam output instantly to match demand, reducing energy waste and lowering operating costs.

Built with low-water content and advanced safety controls, Miura boilers minimize the risk of catastrophic failures by dramatically reducing stored water and pressure levels, keeping your laundry facility running efficiently and safely.

Email: info@oxipitalai.com

www.oxipitalai.com

Oxipital AI is a leader in AI-enabled machine vision technologies for robotic process automation and product inspection in critical industries such as food processing, agriculture, and consumer goods production. Our mission is to deliver customers actionable insights through deep object understanding and unlock previously unachievable levels of resiliency, efficiency, and sustainability in their manufacturing operations.

User-friendly, web-based setup tools and dashboards take the mystery out of AI, leaving your business with insights you can act on right now. With our Visual AI, businesses increase product quality, improve throughput and yield, reduce waste, and reduce overall dependence on labor. Visit us to see how our Visual AI solution is different from the rest.

PROBAT

6060 Primacy Parkway, Suite 251 | Memphis, TN 38119

Phone: 901/363-0921

www.probat.com

Email: info.hdm-usa@h-d-m.com

Since 1868, PROBAT has been a trusted name in coffee processing technology. Today, PROBAT delivers innovative food refining solutions tailored to your evolving needs – well beyond coffee. Following the establishment of Hamburg Dresdner Maschinenfabriken, encompassing the Bauermeister and MacIntyre brands in 2013, and the acquisition and integration of the esteemed food technology companies Royal Duyvis Wiener and AC Horn, the PROBAT Group is now strategically realigning its corporate brands under the globally recognized PROBAT name. This move aims to present a unified identity with clear, distinctive advantages.

With fully integrated solutions spanning coffee, cocoa, chocolate, nuts, popcorn, malt, and other specialty food segments – all delivered under one unified brand – PROBAT is setting a new benchmark for innovation and operational excellence in the food processing industry: From roasting, grinding, pressing and refining to flavor treatment, tempering, coating, and all-in-one solutions – PROBAT’s customizable processing systems cover every key step of production, ensuring precise control, seamless integration, and consistent product quality.

PROBAT delivers complete cocoa and chocolate processing solutions – from bean handling to liquor, powder, butter, chocolate, compounds, and coatings. With advanced, seamlessly integrated equipment and precise process control, they ensure food safety, consistent quality, and exceptional flavor, tailored to any production need.

Our high-performance nut and popcorn processing solutions range from precision roasters and nut butter mills to continuous popcorn systems for products like caramel corn and peanut brittle. We deliver consistent quality and efficiency, backed by decades of expertise, tailored solutions, and service focused on your needs.

Our dry grinding systems are trusted across food, pharmaceutical, cosmetic, and construction industries for their efficiency, reliability, and precision. Our solutions finely reduce materials to exact specifications – without the use of liquids or solvents. With a focus on customization and performance, we deliver tailored systems that meet the most demanding processing requirements.

PROBAT has grown into a leading one-stop partner for customers across coffee, cocoa, chocolate, snack, and emerging food segments worldwide. Everything we do is driven by a deep understanding of the market’s unique challenges and aspirations. We empower our customers to deliver top-quality products – day after day – with peak performance, resource efficiency, and maximum machine uptime.

Sani-Matic

2855 Innovation Way, Sun Prairie WI. 53590 - USA

Phone: 800/356-3300

www.sanimatic.com

Email: hello@sanimatic.com

Founded in 1943, Sani-Matic, Inc. offers a full line of automated cleaning systems and supporting Hygienic Component Solutions for the food, beverage, personal care, nutraceutical, and biopharmaceutical industries. These include clean-in-place (CIP) systems, clean-out-ofplace (COP) parts washers, cabinet washers, automated local and cloud reporting software, tunnel washers, boosted pressure systems, 3-A certified strainers, static spray balls, rotary and jet sprays.

Along with our Sani-Matic engineered solutions we now offer the CleanWorx® brand of sanitation equipment. These products feature standardized designs, a streamlined sales process, quick delivery, and easy operation & servicingall at a modest price point.

Silverson Machines, Inc.

355 Chestnut St., East Longmeadow, MA 01028

Phone: 413-525-4825

www.silverson.com

Email: sales@silverson.com

For more than 75 years Silverson has specialized in the manufacture of quality high shear mixers for the food and beverage industries.

Whether you’re concerned with reducing production times, sanitary processing, powder/ liquid mixing, producing stable emulsions, dissolving sugar, disintegrating solids,blending liquids of different viscosities, or dispersing and hydrating gums, thickeners, and stabilizers, Silverson has a mixing solution for you.

Time after time, companies specify Silverson mixers as the “standard” equipment for their manufacturing process, with a single Silverson high shear mixer able to perform a wide range of mixing applications with speed and consistency. With the exceptionally rapid mixing action of a Silverson high shear mixer, process times are substantially reduced compared to a conventional agitator.

Silverson Machines offer the largest capacity range from a single manufacturer, from our most popular L5M-A Laboratory mixer all the way up to in-tank mixers that can process batches of up to 8000 gallons.

JOIN US AT PACK EXPO LAS VEGAS – SU-30021

Experience Silverson’s cutting-edge mixing technology first-hand at PACK EXPO where we will be showcasing one of our latest innovations: the NEW FMX10 small-scale powder/ liquid mixer. This compact powerhouse offers a simple, effective, and hygienic solution for small batch processing, handling up to 50 liters (depending on viscosity). Featuring the same pumping rotor design as the HV model, the FMX10 processes higher viscosity mixes and offers an optional high-speed motor (9,000 rpm) and Flameproof specification for enhanced versatility.

Also on display will be a production scale Flashmix powder/liquid mixer, our popular L5M-A Laboratory mixer, In-tank Batch mixers, and a Bottom Entry unit. Our team will be available to discuss how our mixing solutions can revolutionize your production processes.

High Shear, High Impact

Slash mixing times up to 90% for increased

Slash mixing times by up to 90% for increased productivity

Effortlessly hydrate even the most challenging gums & thickeners

Maximize yields & achieve consistent results

Maximize & achieve results hydrate even the most gums & thickeners

to your food or process?

Ready to optimize your food or beverage production process?

xplore our pplication & how-to videos to nd the ideal solution for your mix >>

Explore our comprehensive mixing application guides & how-to videos to find the ideal solution for your mix >>

Urschel

1200 Cutting Edge Drive, Chesterton, Indiana, 46304 U.S.A.

Phone: 2194644811

www.urschel.com

Email: info@urschel.com

View Urschel machinery in-person including the DiversaCut 2110A® Dicer with builtin discharge conveyor. The conveyor facilitates batch processing into totes or onto conveying systems or platforms and eases routine servicing by maintaining the machine at floor level. Other Urschel machines on display include the E TranSlicer® Cutter, Sprint 2® Dicer, and the M VersaPro® (MVP) Dicer.

Urschel now offers even more food processing solutions through a recent acquisition. Stop by the Urschel booth to checkout KRONEN systems, available through your local Urschel salesperson in the U.S. and Mexico. KRONEN manufactures dryers, washers, peelers, conveyors, dicers, and slicers.

Learn more at www.urschel.com.

Urschel designs and manufactures high capacity, precision food cutting machinery designed for rugged production environments. Sanitary and dependable in design. Rely on Urschel cutting solutions to effectively process all types of products.

Expl re m re cutting s luti ns at urschel.c m.

VDG (Van der Graaf)

13771 Cavaliere Drive • Shelby Township, MI 48315 • USA

Phone: (888) 326-1476

www.vandergraaf.com

Email: info@vandergraaf.com

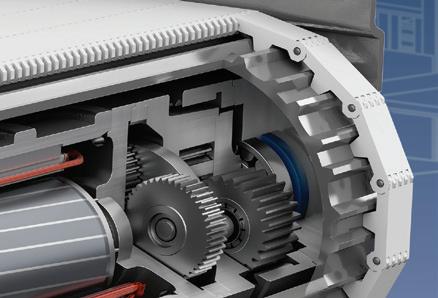

VDG is the leader in the design and manufacturing of drum motors for belt conveyors, with a strong focus on safety, reliability, and longevity. VDG adheres to a simple principle: provide reliable belt drive solutions to the material handling and food processing industries through innovation, continuous research and development, and precision manufacturing. Manufacturing in-house in the USA and Canada since 1985, using cutting-edge production technology and automation, VDG ensures product quality, short lead times, and after-sales service.

The VDG Drum Motor is a one-component conveyor drive that has all drive components, including the new premium-efficiency electric motor, gear reducer, and bearings, enclosed inside the drive drum, increasing mechanical and electrical efficiency, optimizing space, and promoting operator safety. Designed for 80,000 hours of continuous operation before maintenance, VDG Drum Motors reduce maintenance and operational costs and increase productivity. VDG Drum Motors are available in a range of diameter sizes, belt speeds, horsepower, and industry-specific options and features to suit various belt conveyor applications.

All-stainless steel SSV Series Drum Motors, designed specifically for food processing and handling belt conveyor applications, drive modular, wire mesh, and monolithic conveyor belts without using sprockets. The belt profile is either machined directly on the drive drum or on the exchangeable profiled sleeve (XP). The profiled sleeve on the SSV-XP Drum Motor can be easily removed and exchanged for another sleeve to match the belt required on the conveyor. Therefore, the same drum motor can be used when switching to another belt for a different type of processing.

All SSV Series Drum Motors feature an IP69K-rated sealing system, withstand up to 3,000 psi washdown pressure, and eliminate crevices that trap food by-products and bacterial harborage, reducing washdown time and water usage by 50%. Belt profiles are available for all major belt manufacturers.

The IntelliDrive™ Drum Motor features new synchronous permanent magnet motor technology, delivering 40% increased electrical efficiency, a wider range of belt speeds without loss of torque, and an increase in electric motor lifespan compared to a traditional external conveyor drive. It enables onsite diagnostics, full motor indexing speed control, and communications with other automated plant equipment.

Most Hygienic Conveyor Belt Drives

conveyor belts, SSV Drum Motors have the belt machined

conveyor belts, SSV Drum Motors have the belt profile machined directly

T belt profile is machined directly onto exchanged for another profiled sleeve to match q

Elimin e Rou ine M in en nce Reduce Energy Con ump ion Incre e Efficiency

L v ndergr f.com/produc (888) 326-1476

SORMAC INC.

6800 Wales Rd., Northwood, OH 43619, United States

Phone: 567 200 8420

www.sormac.com

Email: info@sormac-inc.com

Fresh produce processing technology at its best - Driven by reliability, quality, and expertise

Sormac is a leading manufacturer of advanced machinery for cutting, peeling, washing, and drying vegetables and selected fruits — serving the fresh-cut produce industry worldwide. Through close collaboration and customer-driven innovation, Sormac sets the standard in hygienic design, operational reliability, and product quality. With a dedicated team and global presence, Sormac manages the entire process in-house — from concept and design to manufacturing, installation, and long-term service. This integrated approach ensures consistent quality, faster response times, and solutions that fit your exact needs.

Our wide-ranging portfolio includes solutions for every scale and production setup:

• Flexible semi-automatic machines for easy operation and quick changeovers

• Fully automated lines for leafy greens, carrots, potatoes, onions, and more

• Custom-built systems, including seamless integration with third-party equipment

Live at our booth: Experience the difference!

See our latest technologies in action with live demonstrations of these standout machines:

Vegetable belt slicer BSM-150, Melon peeler MP-400, Basket centrifuge MC-44/Vario, Knife peeler UP-4000, and Slice and wedge cutter FS-3600 MultiSystem.

Whether you’re looking to streamline operations, improve product quality, or explore customized solutions, our team is ready to help you move forward.

Visit our booth to see the technology live and explore the possibilities — together with our experts.

VAC-U-MAX

69 William Street, Belleville, NJ 07109

Phone: 973 759-4600

www.vac-u-max.com Email: info@vac-u-max.com

VAC-U-MAX is a leading designer and manufacturer of bulk material handling systems for dry powder and bulk solids applications. Since 1954, the company has specialized in pneumatic conveying solutions that automate ingredient transfer for processing and packaging, improving efficiency, safety, and product consistency.

VAC-U-MAX systems handle a wide range of materials, from a handful to over 25,000 lbs/hr, using vacuum, aero-mechanical, and flexible screw technologies. Bulk material handling systems are tailored to move materials from sources like drums, bulk bags, and super sacks to destinations such as mixers, hoppers, auger fillers, feeders, blenders, and food extruders.

With decades of application expertise, VAC-U-MAX delivers reliable, efficient, and fully integrated solutions for processing and packaging.

Weber, Inc.

10701 North Ambassador Dr., Kansas City, MO 64153

Phone: 816/891-0072

us.weberweb.com

Email: solutions@weberweb.com