Sustainability Powered by Swiss Steel

Part Two: Women in Mold Building

Automation in Tooling

Key Talent Takeaways

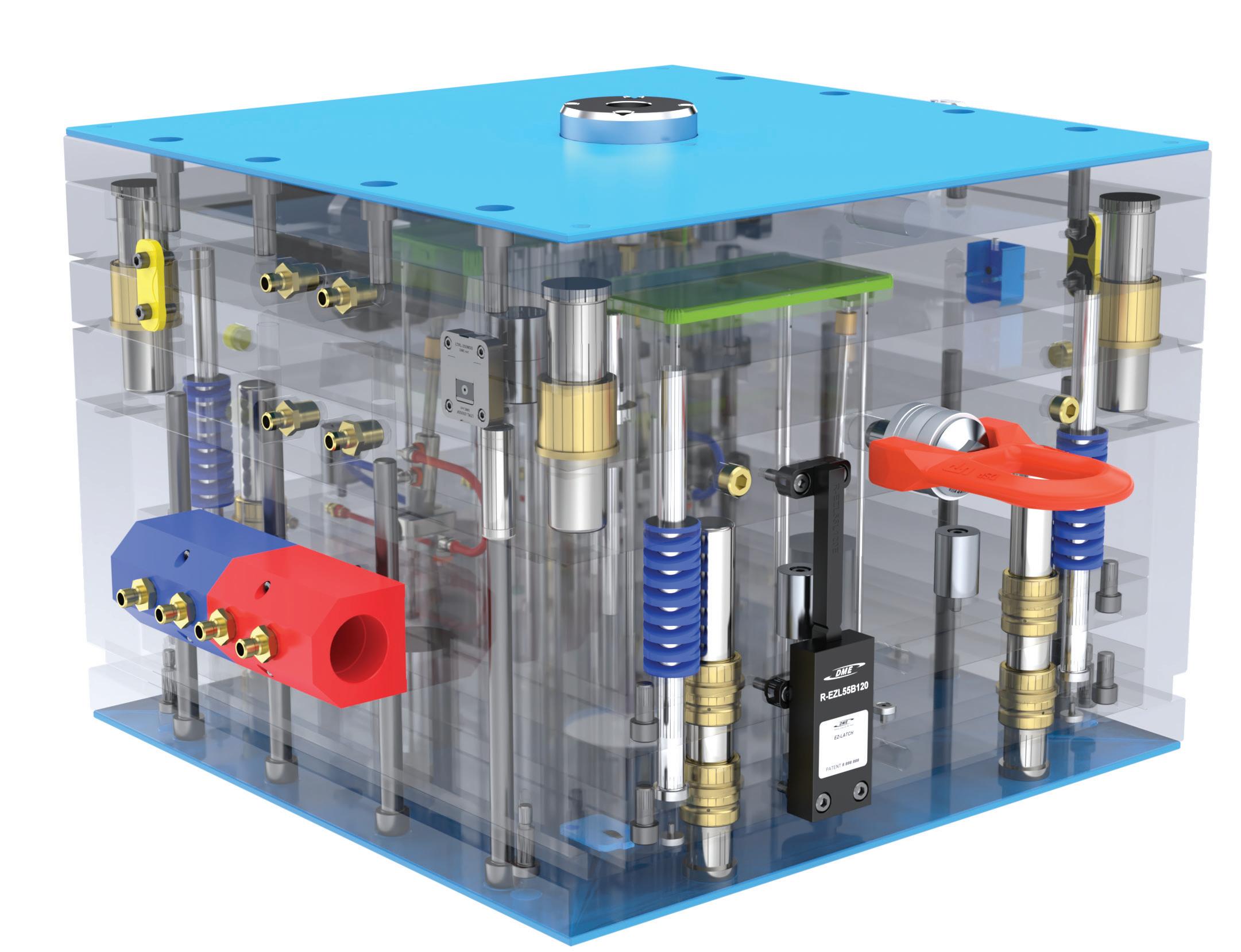

“ For molds that will run for decades, Progressive is the only choice. ”

Corey Fox, Accede Mold & Tool Co.

Sustainability Powered by Swiss Steel

Part Two: Women in Mold Building

Automation in Tooling

Key Talent Takeaways

“ For molds that will run for decades, Progressive is the only choice. ”

Corey Fox, Accede Mold & Tool Co.

As a third-generation moldmaker, Accede’s Corey Fox has a unique perspective on long-term tooling performance:

“Our customers require warranties for as many as ten million cycles. That begins with the precision fit provided by Pro’s pins, the lifetime warranty for Bar Locks, and CVe Monitors as part of the service plan we provide.”

With a view of the long-term, we’re innovating today. Contact us for the new v17 Catalog from Progressive, the team that’s looking as far into the future as you are.

A look at software solutions in mold manufacturing to streamline the processes of design, simulation and production by integrating tools, such as CAD/CAM, mold flow analysis or CNC programming, to reduce lead times, improve efficiency and enhance precision.

AMBA TEAM

Troy Nix, Executive Director

Kym Conis, Managing Director

Susan Denzio, Business Manager

Rachael Pfenninger, Director of Strategic Execution

Olivia Shotts, Public Relations Development Coordinator

Advising Editor: Kym Conis

Advertising/Sales: Susan Denzio

PUBLISHED BY:

P: 785.271.5801

Vice President, Editorial: Dianna Brodine

Editor: Lindsey Munson

Vice President, Design: Becky Arensdorf

Graphic Designer: Hailey Mann

Opinions expressed in this publication may or may not reflect the views of the Association and do not necessarily represent official positions or policies of the Association or its members.

TYLER VANREE AMBA President, LEGACY PRECISION MOLDS, INC.

It was a typical Friday night – we ordered pizza and watched a movie as a family. We tried a new pizza place and arrived 45 minutes later to pick up our food. At the counter, I found out they had forgotten to make our order – it’d be a 15-minute wait. “Well, that stinks,” I thought to myself. But 10 minutes later, a teenage supervisor, no older than 18, came out with our pizza, a smile, an apology and a coupon for a free pizza next time. As I drove away, I was struck by what had just happened. The entire place was staffed by teenagers with no adult manager telling them what to do. There was no rulebook for that moment. They simply did the right thing: expedited the order, acknowledged the mistake and took it a step further to make it right.

Even life’s small disappointments can offer valuable insights – both in the workplace and in our personal lives. I could’ve left frustrated and gone somewhere else. Instead, I got to witness someone turning a mistake into a memorable customer experience. It challenged me to ask myself, “How can I bring more of that culture into my work environment?” I’d challenge you to join me in being more intentional about looking for life’s small moments because they often show up in the most unexpected circumstances.

Tariffs remain a hot topic and a source of ongoing uncertainty in the global marketplace. AMBA continues to advocate and ensure that the voices of member companies are well represented on Capitol Hill. Omar Nashashibi, founder of Inside the Beltway Solutions, continues to actively lobby for trade policies that protect against unfair practices and help level the playing field for American mold builders. AMBA may request information from members; please take the time to respond and drive meaningful change. It’s easy to feel like your voice doesn’t matter – after all, you’re just one shop. But that couldn’t be further from the truth. When we come together and speak with one voice, we make a powerful impact in Washington.

AMBA has several new board members joining the ranks this fall. Jeff Ford with BICO Steel and Scott Kraemer with Xact Metal are joining as partner members. Steve Michon from Zero Tolerance and Todd Steging with Prestige Mold are joining as mold building members. On behalf of the AMBA Board of Directors, I want to publicly welcome them and look forward to having them around the table to drive positive change and momentum for the industry.

AMBA offers a variety of ways to stay engaged and continue learning – don’t miss out! I hope to see you at one of the upcoming events, including the Shop Floor Series Webinars, starting September 4, Tessy Tooling Plant Tour Workshop on September 11, the Third-Quarter Advocacy Update on September 25, MD&M Midwest on October 21-22 and the Emerging Leaders Plant Tour at Dynamic Group on October 23. If interested in these events or other opportunities, visit www.amba. org/events. There’s something for everyone – make plans to get involved!

As summer comes to a close and we look forward to this fall’s activities and the opportunities to connect, don’t forget: You are the AMBA. We are the AMBA. Together, we are stronger.

OFFICERS

National President

Tyler VanRee, Legacy Precision Molds

Vice President

Andy Peterson, Industrial Molds

Secretary and Legal Counsel

Alan Rothenbuecher, Benesch, Fiedlander, Coplan & Aronoff LLP

Treasurer

Hillary Thomas, Westminster Tool

Jeff Ford, BICO Steel

Justin Gregg, Dramco Tool Co., Inc.

Mike Hetherington, Franchino Mold & Engineering

Kyle Klouda, MSI Mold Builders

Scott Kraemer, Xact Metal

Steve Michon, Zero Tolerance

Troy Roberts, Tolerance Tool

Camille Sackett, Accede Mold & Tool

Scott Smith, Tessy Tooling

Todd Steging, Prestige Mold

By Lindsey Munson, editor, The American Mold Builder

“Progress through sustainable steel” is boldly positioned on Swiss Steel Group’s home webpage, highlighting its focus on reducing environmental impacts, supporting social responsibility and ensuring long-term economic profitability. In mold manufacturing, among other general areas, sustainable steel is significant in meeting customer demands for greener products, regulatory pressures and global climate goals.

Swiss Steel Group is headquartered in Emmenbrücke, Switzerland, with a business structure based on three divisions: engineering steel, stainless steel and tool steel. It is known for its broad product range extending from 0.013 mm drawn wire to 1,100 mm forged bar diameter. Additionally, Swiss Steel has a US presence with six distribution and service centers, and a steel production site known as Finkl Steel in Chicago, Illinois.

The American Mold Builder magazine had the opportunity to interview Daniel Frie, vice president of Deutsche Edelstahlwerke Services GmbH Sales Europe and Americas Tool Steel Division. He provided an inside look at the center of Swiss Steel’s commitment to sustainability, the framework for building a green steel platform and how actions by key players have an integral part in its strategy, operations and decision-making processes.

Dating back to the late 1970s, Swiss Steel has held a space in the US market distributing specialty steel long products.

Then, in 2004, the former ThyssenKrupp Specialty Steels was acquired by Schmolz and Bickenbach. In 2008, a merger of the former Ugitech USA and Swiss Steel USA was completed – creating one entity that remains today. As mentioned, the company has six distribution and service centers for various steel products located throughout the Midwest, East Coast and West Coast.

Alongside Swiss Steel’s US distribution market, Finkl Steel, a steel production site for the Swiss Steel Group located in Chicago, Illinois, is a global supplier of forging die steels, plastic mold steels, die casting tool steels and custom open-die forgings, processing over 200,000 tons of steel each year. Its products are manufactured at four production facilities in Chicago, Detroit, Houston and Quebec. Falling under one entity with two melt shops, three forging facilities and four production locations, Finkl Steel has built “a tradition of progress and quality.” It was the first steel manufacturer in the US to receive ISO 9001 certification.

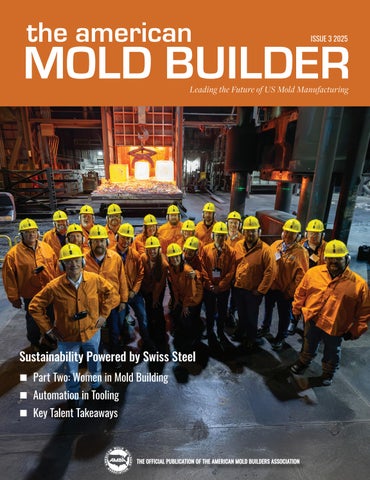

In early June, Finkl Steel unlocked the door, fired up the machines and made space for the moldmakers, welcoming members of the American Mold Builders Association for a plant tour workshop. During this event, attendees gained insights into Finkl Steel’s advanced manufacturing processes, quality control systems and innovative approaches to steel production; it also held a mold steel workshop. In an extremely intense industrial environment, members were mesmerized by the molten steel, massive machinery and extreme heat, as well as by those speaking

on behalf of Finkl Steel about operational awareness and best practices.

Finkl Steel and its parent company, Swiss Steel Group, enjoy strength in numbers, both in steel production and in history. Their commitments to sustainable practices are ramping up and warranted, now more than ever.

“For Swiss Steel Group, focusing on sustainability represents a clear competitive advantage. More and more customers, particularly large global companies, are placing increasing emphasis on sustainable production processes and CO2 reduction across the entire supply chain. Sustainability is thus seen not only as an ethical responsibility but also as a key to market differentiation,” said Frie.

Swiss Steel Group is implementing a range of innovative measures to reduce emissions. Frie said, “For example, the use of hydrogen and green electricity is being promoted actively wherever possible, such as in the heating furnaces used in production. Another central element is the recycling of scrap and chips from customers, which are brought back to the plant and processed in electric arc furnaces (EAFs) that can be operated 100% with green electricity. This closed-loop system plays a significant role in lowering the CO2 footprint of production.” Through Swiss Steel Group’s diligent efforts in the use of energy from renewable sources, its total emissions are up to 83% lower than the industry average.

Familiar to customers across sectors in automotive, construction, aerospace and toolmaking, among many others, the demand for low-emission materials is reshaping supply chains – particularly steel. This industry shift is driving a rising market demand for green steel, which is imperative to the environment but also a competitive necessity.

Frie said, “For decades, we have been using EAFs to produce steel with significantly lower CO2 emissions compared to conventional methods. This technology enables us to produce only about 20% of the average CO2 emissions of global steel production.”

In North America, the company already operates electric heat treatment furnaces that are fully powered by green electricity, representing an important step toward even more eco-friendly production. “In addition, the Finkl Sorel plant will soon commission its first electric forging furnace, which will allow for zero CO2 emissions in a portion of the production. These efforts are just the beginning of an extensive journey toward even more sustainable steel production that meets the growing customer demand for green steel,” said Frie.

Additionally, Swiss Steel Group actively pursues the integration of advanced technologies to further improve efficiency and sustainability. This includes the use of Artificial Intelligence and automation in various areas of production to optimize processes, reduce energy consumption and enhance quality. Frie said, “Especially in logistics, digital solutions are employed to provide precise control and monitoring of supply chains, reducing waste. Furthermore, we are working intensively on the introduction of green hydrogen to replace fossil fuels in production and reduce emissions in the long term. These innovations contribute to the continuous improvement of production processes, lowering the ecological footprint while enhancing competitiveness.” Steel is one of the most circular materials in the world, and often is underestimated – after repeated use, it retains its high quality and performance.

In June 2025, Finkl Steel hosted an AMBA plant tour and workshop for its membership. Photos courtesy of Jimmy Renallo, Creative Technology, www.creat.com . Renallo has over 10 years of experience in capturing American manufacturing – grit, innovation and enduring strength brought vividly to life in every frame.

•

•

•

•

•

•

•

•

•

40

•

•

•

When asked how the company adapts to supply chain disruptions, energy price fluctuations and changes in regulations, Swiss Steel Group stated it greatly benefits from its global presence – with production sites in North America and Europe. This geographic diversification allows for products to be manufactured in the most suitable plants depending on demand, mitigating the impact of disruptions in one region.

Frie said, “In addition, we rely on agile logistics processes and modern planning systems that enable quick responses to unforeseen challenges. This ensures that product quality remains high and delivery times are met.”

“The machine tool industry is expected to evolve significantly in the coming years,” said Frie, “with a strong shift toward automation, digitization and sustainability. These changes are driven not only by technological advances but also by the increasing need to manufacture more environmentally friendly products and reduce CO2 emissions. We actively are working on the development of products and solutions that meet these requirements by combining highly precise, sustainable steel products with innovative manufacturing technologies. Our focus is on long-term partnerships with our customers to help them adapt to upcoming market and environmental changes.”

Swiss Steel Group has joined the Science Based Targets initiative (SBTi), a corporate climate action organization that enables companies and financial institutions worldwide to play their part in combating the climate crisis. 1 In collaboration with the SBTi, Swiss Steel has set meaningful goals and targets – committing to achieving net-zero emissions by 2050. The initiative is through a partnership between the CDP, the United Nations Global Compact, the World Resources Institute and the World Wide Fund for Nature, which encourages climate action by enabling organizations to set science-based targets for reducing emissions.

More information: www.swisssteel-group.com or info-USCA@swisssteelgroup.com (Patrick Gerkin, CEO / country manager)

Sources 1. Science Based Targets. www.sciencebasedtargets.org/about-us.

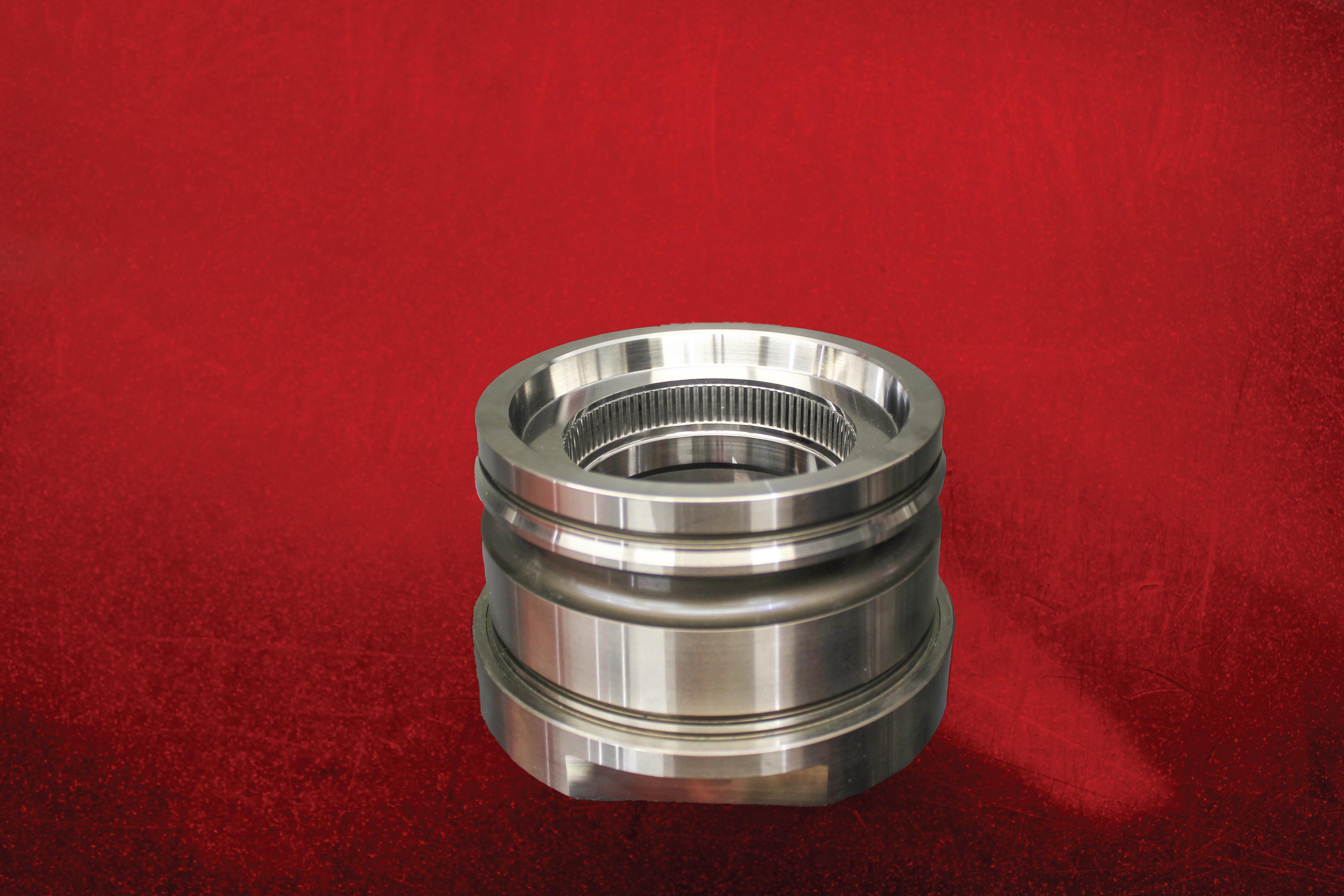

With over 160 years of steel production experience backing their brands, Swiss Steel Group is not only a pioneer, but also a market leader in specialty steels. Their comprehensive range of Formadur®, Thermodur®, Cryodur®, and Mold Die® grades, produced by Deutsche Edelstahlwerke / Germany and Finkl Steel USA / Canada, allows you to choose the ideally suited mold material for your application. In addition, an extensive range of value added services provides you with more alternatives from one source, Swiss Steel USA / Canada.

www.swisssteel-group.com Info-USCA@swisssteelgroup.com +1 800 323 1233

By Liz Stevens, writer, The American Mold Builder

The number of women in the executive ranks in mold building is on the rise. Why do women choose an executive career in mold building, and what kind of background is good preparation for this type of professional role? AMBA’s members include many successful, respected women in mold building C-suites, and The American Mold Builder magazine talked with three of them about their careers.

Julie LaVanway is president of Hanson International, St. Joseph, Missouri. Donna Pursell is CEO of Prestige Mold, Inc., Rancho Cucamonga, California. Carol Ebel is president/CEO of Janler Corp., Chicago, Illinois. The women shared their backgrounds and industry experience, along with their insights into the prevalence of women in mold building.

This trio of accomplished mold building executives has something in common: Each of them started her higher education studying accounting. Hanson’s Julie LaVanway earned a Bachelor of Science in Accounting degree from Andrews University in Berrien Springs, Michigan. Prestige Mold’s Donna Pursell began her education at a junior college and then attended California Polytechnic State University, Pomona, California, where she majored in accounting. Janler’s Carol Ebel earned an undergraduate degree in accounting and economics at Loyola University, Chicago, Illinois. Ebel then became a certified public accountant. She went on to graduate school at Northwestern University, Evanston, Illinois, and earned a master’s degree in business management.

Pursell landed a role in mold building early on and has stayed for the long term. “My education gave me the fundamentals,” Pursell explained, “but it has been hands-on experience within the industry where I have learned the most.” She has been at Prestige Mold for 42 years, solving real-world challenges under pressure. “There aren’t books that can prepare you for what you’ll come up against,” she said, “or that describe the sense of accomplishment you gain on a regular basis.”

LaVanway got her start at a logistics company and then made the move to an affiliated mold building company. “I came from a sister company –Hanson Logistics – seven years ago to be Hanson International’s controller,” she said. “Two years into that role, I was promoted to vice president, chief financial officer.” LaVanway thought she had reached the height of her career when company leadership approached, asking her to interview to be the next president of Hanson International to succeed the retiring president.

“I earned the promotion to president three years ago against the odds,” she explained. “I was in competition with two male candidates who had over 25 years of experience in the industry and with Hanson.” Company ownership and the internal team selected LaVanway because they wanted a fresh set of eyes on the business.

Ebel was born into a mold building family, but she did not expect to have a career in the family business. “My father started a mold building company in 1952,” she said. “Some of his brothers worked in the company and so did my older brothers, so I heard a lot about it.”

After receiving her undergraduate degree, Ebel moved to Phoenix, Arizona, and lived there for eight years. “I took a controller position with a large family-run/owned contracting company involved in land development, sand and gravel, road building and mid-rise buildings,” she explained. “That role included lots of budgeting, project development/management and corporate strategy.” She moved on to banking and more land development and building/financing before returning to Illinois for graduate school at Northwestern.

“At that time, I was living with my parents, and I got involved in the business with my dad,” Ebel said. “During graduate school, I did consulting for the company, which then had grown to nearly $30 million in sales, and which also had a component manufacturing side.” When Ebel’s father wanted to retire, she joined the company as president – 35 years ago.

Ebel described what drew her to a career in mold building. “I loved business, in general, because of our family business and the company issues that always were being discussed by my family,” she said. “That background made me eager to understand tax and business and accounting, but I really never aspired to be in charge or to run the family company.” Ebel returned from Arizona, however, with general knowledge about running a business. “When the family company needed some financial expertise and leadership, I had more business knowledge to offer than my brothers in engineering, sales and operations. And so, I stepped in. I love the business.”

LaVanway has fallen in love with mold building, too. “Over the past seven years,” she said, “moldmaking has won my heart, and I have become passionate about it. One of the drivers is the talent needed to run a company like this. We have a very highly skilled workforce that is critical to what we do.” For the most part, Hanson grows its talent straight out of high school and enrolls graduates into a Department of Labor-registered apprentice program. “We have a

workforce of 90,” LaVanway explained, “and 19 of the teammates are apprentices, which is amazing.”

Another driving factor for LaVanway is the technology emerging in the industry. “It always is changing and advancing,” she said, “and that is exciting to me. And finally, I love this business because I am improving people’s lives. I have the responsibility to ensure that Hanson’s teammates have a clean, safe and engaging place to work in, with a good income and benefits.”

Pursell echoed the commitment to lift up employees in a supportive workplace. “I take pride in being accountable, making decisions and creating an environment where people can thrive and do their best work,” said Pursell. “I lead this company because I am driven to build something meaningful and leave a legacy. Leadership allows me to turn my vision toward long-term success for the business.”

Mold building, in particular, appeals to Pursell. “From a financial and operational standpoint,” she said, “this industry presents unique challenges – tight margins, capital-intensive equipment and the need for efficiency at every step. Being part of an industry that produces tangible, high-demand products is both rewarding and intellectually engaging.”

The women commented on the growing number of women in mold building and its supply chain, yet lamented that finding a woman in a mold building corporate setting still is an unusual sight. “From what I have seen,” said LaVanway, “there are not very many of us, but the situation is improving!”

According to Pursell, women have made stronger inroads into businesses that are adjacent to mold building. “I do see more women in upper executive roles with our customers and throughout our supply chain,” said Pursell. “Just speaking from my experience, within the moldmaking and molding community, women in these roles are few and far between, leaving room for growth.”

“Thirty-five years ago,” said Ebel, “I would have said I was almost a loner in the industry. Today, there are more of us, but the executive ranks still are predominantly male.” Ebel noted that there is a group of women who are running companies, but in many cases, they are doing this after having taken over a company that was started by their father or husband. “I haven’t met a woman who has started her own mold building business,” she said, “but I have seen some who have taken over the lead role and developed their companies into something larger.”

At Plastic Engineering & Technical Services, we are.

We define performance. For nearly 30 years, we’ve helped our customers to produce more e ciently, with lower cycle times and lower per unit costs.

Our new compact stainless steel, modular unitized system features exible heaters that can be utilized o n multiple designs, so you don’t have to stock custom bent heaters Our new drop heaters provide more uniform heating and feature smaller pockets and no clamps They have in-line ow restrictors

for better process repeatability, and no over-pressurizing the cylinders. It all adds up to a reduced sized hot runner system, shorter heating times and better tool performance.

We deliver value. We complement our hardware with leading-edge analytical tools, including Mold ow® and MOLDEX3D so ware. We’ll work with you on design issues and optional gating solutions before the mold or hot runner manifold system is ever built. Use us for the mold ow analysis and the manifold build, and we’ll do whatever it takes to make your hot runner/manifold system work to your complete satisfaction.

We’re committed to your success. Find out more. Call us today at 248.373.0800 or visit us at www.petsinc.net.

tEbel is one of the women who has guided her company toward modernization and growth. “After 35 years, I feel like I have made a big mark on Janler,” she said. “Forty years ago, when I started, there wasn’t the kind of equipment like we have today, and our approach to training was very different from what it is now.” Ebel stressed that the relationships she has cultivated with employees have spurred her to champion causes for better health benefit options and for training and education to build a better workforce but also to improve the lives of Janler’s employees.

The trio of executives has found that the gains that have been made in attracting and keeping more women in mold building, in the C-suite and in general are modest and are due to a handful of identifiable reasons.

LaVanway cited the value of role models and companies that understand the realities of the work-life balance.

“Having other women to look up to has helped, for sure,” she said, “and so has making work hours less rigid and more flexible to accommodate those who have a career and a family… I have five kids!”

Ebel shared her experience. “Over the years,” she said, “I’ve made a lot of efforts to attract and hire women, but I have not been very successful in finding women who want to do the work of a mold builder or a machinist, or in the quality area.”

She noted that in the suburbs of her Chicago-area company, there are good high school shop machining programs, but most of the shop students are male. “In colleges or junior colleges,” Ebel said, “there are some good technology and machining engineering programs. So women do get into engineering, but in the high school shop classes, females are hard to find.” High school counselors, she said, say that females are just not attracted to mold building and manufacturing in general, perhaps due to old misconceptions of industry workplaces. “‘Dirty, dark and dumb’ was how I used to sum up those misconceptions,” she said, “when, in fact, our workplaces are bright, clean and organized. We must work on changing that perception because people in our industry earn excellent wages and have very good lifestyles.”

Pursell agreed that presenting the industry’s opportunities and giving girls and women more access to STEM education early will help attract more talent. “I believe that education and manufacturing career awareness have helped drive women into the molding world,” said Pursell. “We have seen more female engineers coming out of college. Early STEM program exposure for young women

Ebel stressed that the relationships she has cultivated with employees have spurred her to champion causes for better health benefit options and for training and education to build a better workforce but also to improve the lives of Janler’s employees.

introduces them to manufacturing careers that I never had even considered, nor even knew existed when I was younger.”

Women bring knowledge, talent, work ethic and fresh perspectives to manufacturing and mold building. The more women are hired at every level in a company, the more that company expands its horizons.

More information: www.hansoninternational.com, wwww.janler.com and www.prestigemold.com

CGTech, Irvine, California, offers Vericut simulation, optimization and composite software for manufacturing, combined with Icam Posts, to revolutionize the production process. The company has released Vericut 9.6, an update that introduces advanced artificial intelligence capabilities and a range of productivity-focused enhancements that simplify machining workflows, improve collaboration and deliver real-world usability across the shop floor. Vericut 9.6 adds two transformative AI-driven tools that redefine how users interact with the software, including Vericut Assistant (VA) and Vericut Intelligence (VI). For more information, visit www.vericut.com

EMUGE-FRANKEN USA, West Boylston, Massachusetts, a manufacturer of high-performance end mills, taps, thread mills, drills and other rotary tools, now produces the EMUGE TiNoxCut High Performance End Mills Line in its US facility. These US-made end mills, named TiNox-Cut VAR, are application-specific for the machining of tough materials and guaranteed to deliver unmatched metal removal rates and tool life. The “VAR” acronym indicates the end mills are versatile, Americanmade and offer reliable performance. The TiNox-Cut VAR End Mills Line is offered in four end mill types for semiroughing and finishing applications, including TiNox-Cut VAR-NF, TiNox-Cut VAR-N, TiNox-Cut VAR Base and TiNox-Cut VAR Trochoidal. For more information, visit www.emuge-franken-group.com

PCS Company, Fraser, Michigan, a mold equipment supplier, now distributes a no-dye version of the Defender rust-prevention solution for applications that use corrosive materials, such as PVC. Defender™ No Dye by NanoPlas is a semi-dry aerosol spray that provides longer-lasting protection of molds without causing bleed-through. Its acid vapor neutralizer additive protects tooling when molding PVC and other corrosive materials and also prevents damage from fingerprints. For more information, visit www.pcs-company.com

Seco Tools LLC, Troy, Michigan, a supplier of comprehensive metal cutting solutions, has launched a new generation of Round 20 copy mills and inserts for a wide range of applications, including face, side, slot, plunge and ramp milling. Round 20 inserts are compatible with cutter bodies from previous generations and provide additional performance in challenging materials. The cutters and inserts are suited for productive medium-to-rough milling in steel, stainless steels and heatresistant superalloys and also can be applied productively to cast iron and hardened steels. Round 20 features 16 available cutter bodies with four shim options and three cassette options, as well as 30 indexable cutting inserts. For more information, visit www.secotools.com

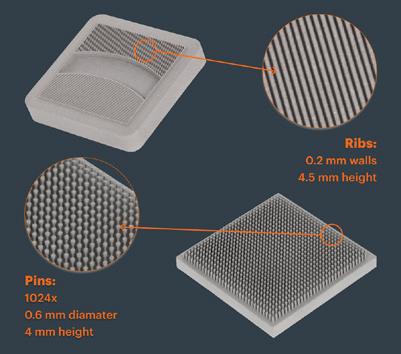

Mantle, San Francisco, California, a company that develops automated toolmaking systems, has announced its new Top Definition capabilities. This software update further extends Mantle’s best-in-class fine feature capabilities, which commonly are used by its customers to eliminate the costly and timeconsuming sinker EDM operations traditionally required to produce these features. With Top Definition, features as thin as 0.008" (0.2 mm) are printed directly – an 80% reduction from previous limits – while dramatically improving the as-printed strength of small features that previously were too fragile to print. Mantle has made the update available to all customers through an over-the-air software release. For more information, visit www.mantle3d.com

Progressive Components, Wauconda, Illinois, a company that develops and distributes components for the production tooling industry, has expanded its UniLifters® offering with a Cooled UniLifter Assembly. The Cooled UniLifter Assembly features a precision-machined core blade (sizes include 3/4" and 1 1/4") that accommodates a high-flow cascade tube, seated with a Buna O-Ring and options for spherical bushings and lifter head keys. In addition, Progressive introduced the CVe Access Monitor (CVe AC) to its range of mold monitoring devices and software solutions. The CVe AC provides essential mold performance data through Bluetooth® pairing with smartphones, eliminating the need for wires or additional hardware. For more information, visit www.procomps.com

• MOLD FINISHING

• LASER WELDING

• LASER ENGRAVING

• HOT RUNNER REPAIR

• MOLD MAINTENANCE

• LASER MACHINE SALES

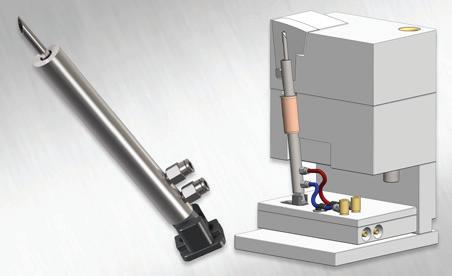

er mold finishing, laser welding, laser graving, mold maintenance, and hot runner manifold repair all under one roof. We also manufacture and sell the only fully American made laser welding and laser engraving systems, custom built specifically for your toolroom

Let Alliance make a di erence for you.

EVERY PART OF THIS MACHINE IS EASILY ADJUSTABLE TO ALLOW YOU THE VERSATILITY AND FLEXIBILITY YOU NEED TO MEET ALL OF YOUR DEMANDS

CONTACT US TODAY ABOUT AN IN-HOUSE DEMO, TO SEE THE ALLIANCE DIFFERENCE.

By Rachael Pfenninger, director of strategic execution, AMBA

US mold builders have faced turbulent business conditions over the last several months, from late 2024 into the first and second quarters of 2025. Despite this shifting political landscape, however, US mold builders are feeling largely optimistic as they see advocacy efforts, like those executed by the AMBA alongside partner Inside the Beltway Solutions, shift policy and generate favorable market conditions.

This sentiment was drawn from AMBA’s most recent benchmarking effort, in which it surveyed its membership on how recent advocacy efforts have impacted business operations and their overall outlook. When asked to compare their current business outlooks (in June 2025) to their outlooks six months prior, over half of this survey’s respondents reported an improved outlook. This partially is due to a dramatic increase in quoting; only 7% of respondents reported no recent increase in quoting, while 79% (over three-quarters) have seen quoting rise by 20% or more.

Although the industry is feeling some initial positive impact from ongoing international trade negotiations and the enactment of specific policies, mold builders are not without their challenges. For instance, while many respondents reported welcoming an increase in quoting, others are waiting on the materialization of new purchase orders and reshored work. If and/or when these purchase orders come to fruition, labor constraints and a lack of access to skilled labor could continue to restrict capacity utilization, which was hovering around an average of 60% at the time of this survey’s publication.

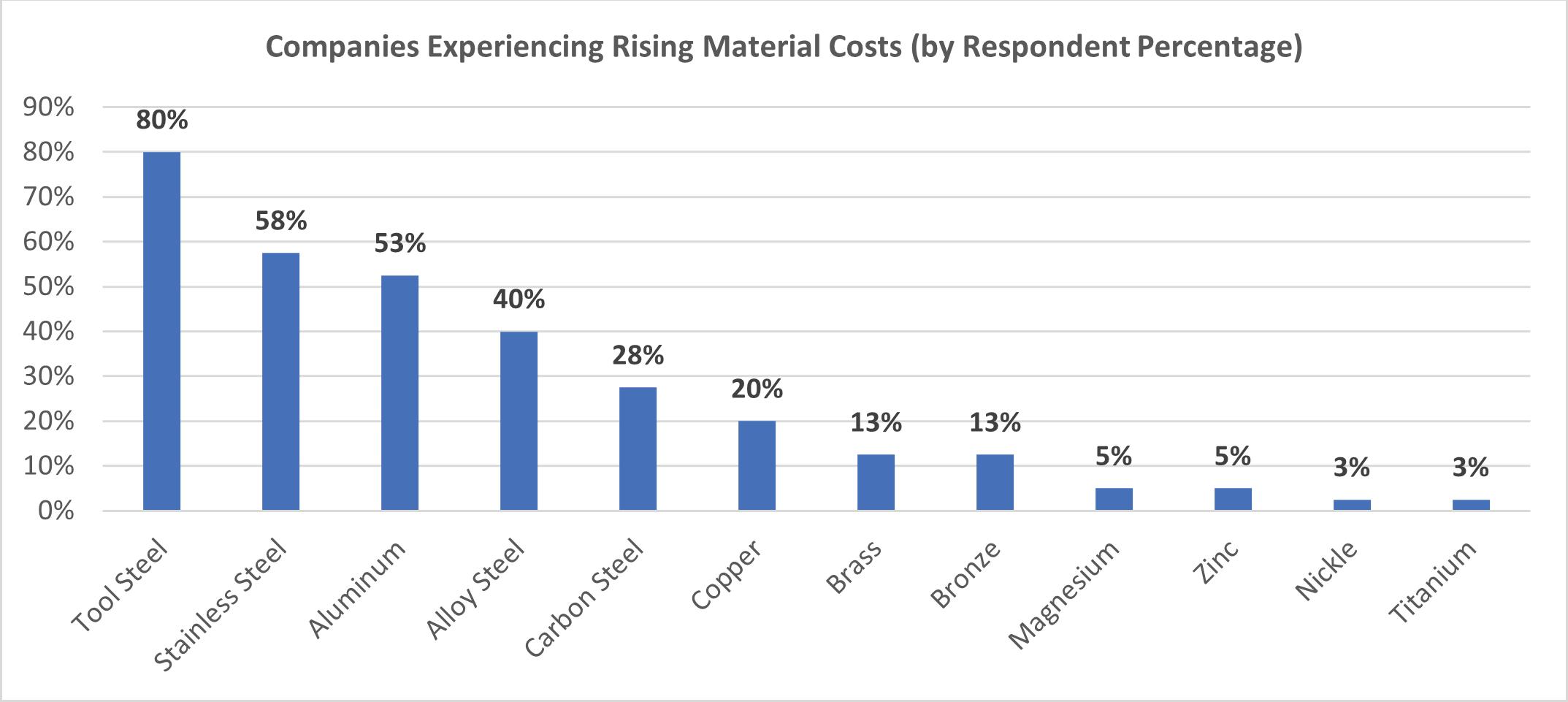

The challenge doesn’t end there for US mold builders and their suppliers. Nearly every respondent who participated in this particular survey reported experiencing a rising cost for one, if not multiple, materials. Tool steel, stainless steel and aluminum all have risen in cost, according to over half of the survey’s responses; alloy steel, carbon steel, copper, brass and others all have risen in cost as well. (Chart 1)

Today, AMBA continues to work alongside founder and Washington, D.C.-insider Omar Nashashibi of Inside the Beltway Solutions so that it can continue to build on the success experienced in Washington, D.C., as the tariffs on tooling, molds and dies imported from China remain due to the efforts of the industry.

Additionally, AMBA keeps its members “in-the-know” on all of the day-to-day legislative action that impacts AMBA members, from tariffs and taxes to regulations, job training and resources related to workforce development.

To learn more about AMBA’s advocacy efforts, visit www.amba.org. To download the no-cost, members-only whitepaper referenced here, AMBA Advocacy Efforts for the US Mold Manufacturing Industry, visit the AMBA Publications page. To register for AMBA’s next membersonly quarterly update, which is provided by Omar Nashashibi, Inside the Beltway Solutions, visit www.amba.org/events

AMBA PROVIDES MEMBERS-ONLY ADVOCACY RESOURCES

Capitol Beat: Delivered monthly from Inside the Beltway Solutions, AMBA’s advocacy partner, this e-newsletter provides information on the latest policy shifts, tax updates and legislative actions happening in Washington, D.C., along with their potential impact on US mold manfacturing.

Quarterly Updates: Each quarter, Omar Nashashibi of Inside the Beltway Solutions provides AMBA members with a virtual update on the latest activities supporting the industry, the most recent developments from policymakers and how those actions may impact US mold manufacturers.

Public Policy Slide Deck: Monthly, Inside the Beltway Solutions provides AMBA and its membership with a Manufacturing Public Policy Slide Deck, highlighting key points worth noting for US mold manufacturers regarding legislative policy and current actions.

Grants Matrix: In addition to its other grant and scholarship opportunities, AMBA publishes a monthly Grants Matrix that outlines state, regional and national grants available to US businesses and manufacturers. These grants, tax incentives and other sources of financial support address a variety of areas, from job readiness training and economic growth to apprenticeship programs and public infrastructure.

Our Roughing Stones are designed to remove material quickly and efficiently, making them the perfect choice for tackling tough machining marks, EDM scale, and other challenging surfaces.

AMBA is introducing the Shop Floor Series, a new fourpart virtual program focused on key operational challenges in US mold manufacturing. Sponsored by the Emerging Leaders Network, this member-exclusive series encourages peer learning and real-time problem solving.

Each session includes a short, supplier-led presentation on topics such as automation and lights-out machining, continuous improvement and technology, and AI agents in manufacturing – concepts and practical use. Each session will include interactive polls, activities and discussions. Members will explore roadblocks and share best practices that drive improvement.

Sessions will take place on September 4, September 18, October 16 and October 30. AMBA members may attend one or all at no cost. For more information and to register, visit www.amba.org/events

Limited Spots Remain for Tessy Tooling Plant Tour

Only a few spots remain for AMBA’s Plant Tour Workshop at Tessy Tooling in Erie, Pennsylvania, on September 11, 2025. Attendees will explore how Tessy applies automation, job scheduling and continuous improvement to support complex, high-precision tooling programs. Topics include NC validation, 5-axis work holding, spindle monitoring and more.

The experience begins with a supplier trade fair and welcome reception on September 10 from 3 p.m. to 6:30 p.m. The trade fair is open to US mold manufacturers at no cost. To attend the trade fair, RSVP to info@amba.org. Registration for the Tessy Plant Tour is $229 for members, $329 for non-members. For more information and to register, visit www.amba.org/events.

Save the date for the AMBA Emerging Leaders (EL) Network Plant Tour Workshop at Dynamic Group. During this event, AMBA members will have the opportunity to network with like-minded peers who are new to the industry and in emerging leadership roles. Special pricing will be available to first-time plant tour attendees. This event will be hosted in

conjunction with MD&M Midwest (October 21-22, 2025) and includes a day pass to the tradeshow. For more information and to register, visit www.amba.org/events

NEW WHITEPAPERS HIGHLIGHT INDUSTRY TRENDS

Two new members-only whitepapers now are available through AMBA’s benchmarking efforts.

The Recruitment and Retention: Takeaways for US Mold Manufacturers

Whitepaper shares insights gathered by the AMBA Emerging Leaders Network on what attracts emerging talent to the mold manufacturing industry. The whitepaper includes key takeaways and individual responses from AMBA members across the country.

The 2025 AMBA Advocacy Impact

Whitepaper summarizes results from a May 2025 survey focused on how tariffs and advocacy efforts are affecting sales, quoting, labor and overall business outlook in US mold manufacturing facilities.

Both resources are available to AMBA members at no cost. For more information and to download these whitepapers, visit www.amba.org/publications.

UPCOMING VIRTUAL EVENT OPPORTUNITIES

Third Quarter Advocacy Update September 25 | noon-1 p.m. (EST)

Led by Omar S. Nashashibi of Inside the Beltway Solutions, LLC, this quarterly webinar will cover the latest developments in Washington that impact US mold manufacturers. Topics will include tariffs, Chinese subsidies, tax policy, regulatory rollbacks and more.

AI Tools for Improved Process and Marketing Efficiency October 29 | noon-1 p.m. (EST)

Shelly Otenbaker of WayPoint Marketing Communications will share highlights from her AMBA Conference 2025 presentation on using AI in marketing. She’ll explore tools for content, SEO and video, and discuss how to evaluate them based on cost, value and alignment with business goals.

These events are available to AMBA members at no cost. For more information and to register, visit www.amba.org/events.

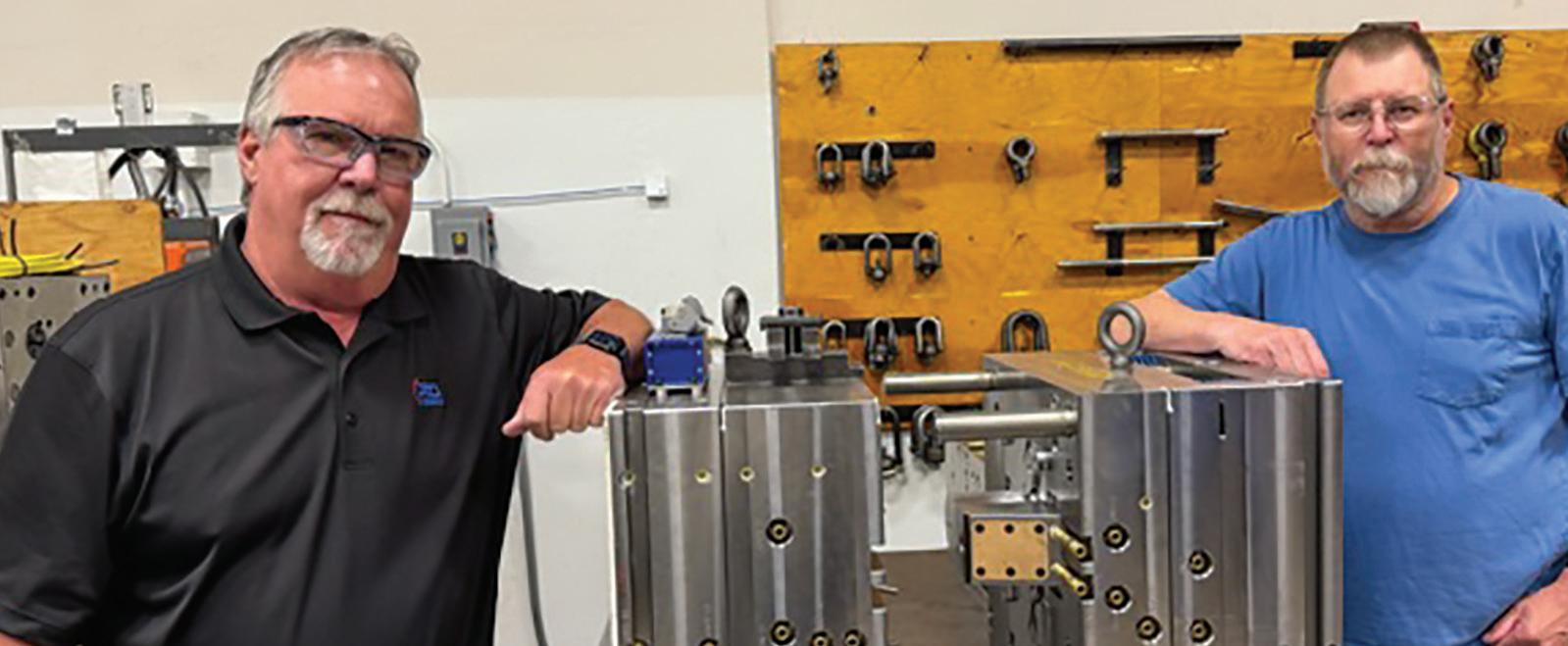

This fall, AMBA members once again will hit the course in support of iWarriors through two upcoming charity golf events: the iWarriors Alliance Charity Golf Outing on September 19 in Mundelein, Illinois, and the iWarriors United Tool and Mold Golf Outing on October 24 in Fountain Inn, South Carolina.

Both outings raise funds to support the iWarriors mission, providing personalized tablets to severely injured service members to aid in their recovery and reintegration.

For more information and to register, visit www.amba.org/events.

Our best solution for all your applications.

We design and manufacture hot runner systems for automotive, thin wall packaging, beverage & home, beauty & personal care, medical & healthcare, technical & electronics industries.

Fast color change, short cycle times, processing of PCR compounds and Biopolymers, maximum design flexibility, fast start-up production, high process and product repeatability: we offer the technology that Best matches your needs.

Xact Metal

200 Innovation Blvd., Suite #257 State College, Pennsylvania 16803

Main POC: Scott Kraemer, application engineer

Email: scott@xactmetal.com

Phone: 814.205.1505

Xact Metal, a US-based designer and manufacturer of metal 3D printers, aims to establish a new level of price and performance while ensuring ease of use for quick shop integration. The company’s metal 3D printing technology enables conformal cooling and venting in existing printable tooling steels, leading to reduced cycle times, fewer gas traps, less part warp and higher quality parts.

amba members saved an average of $6K in mro spend in 2024$4,800 more than average member dues.

Get involved to start saving today.

Dynamic Group Inc. (DGI), Ramsey, Minnesota, a manufacturer of precision injection molding and tooling solutions, has announced the launch of a new brand identity. The rebranding effort includes a refreshed visual identity, a new logo and a modernized digital presence, all designed to better communicate DGI’s value proposition and align with its strategic vision for the future. For more information, visit www.dynamicgroup.com.

Slide Products, Wheeling, Illinois, a manufacturer of injection mold release agents and maintenance solutions, has completed a comprehensive revamp of its headquarters. The renovation kicked off with the installation of a 10,000-gallon raw material storage tank. Phase two followed shortly after, with a 45% expansion in warehouse space, as well as an investment in high-efficiency lighting, upgraded furnaces and improved shelving/organizational systems. In the final phase, Slide shifted focus to the interior creating a modern, collaborative and ergonomic work environment. For more information, visit www.slideproducts.com.

Mold-Masters®, Georgetown, Ontario, a developer and supplier of hot runners, controllers, auxiliary injection and co-injection systems, has announced the opening of a fullservice customer support center in Phoenix, Arizona. This strategic expansion strengthens Mold-Masters’ aftermarket capabilities across the Southwestern US and Northern Mexico. The Phoenix facility is equipped to provide comprehensive aftermarket services. For more information, visit www.moldmasters.com

M.R. Mold & Engineering, Brea, California, which designs and manufactures liquid silicone rubber, gum stock silicone and plastics injection molds, is celebrating 40 years. From humble beginnings in 1985 with 1,500 sq. ft. of space and a couple of used machines, M.R. Mold has taken pride in building quality silicone and plastic injection molds for the past 40 years. Continually expanding capabilities, M.R. Mold now operates in a 25,000 sq. ft. facility in Brea, California, alongside its 4,000 sq. ft. Technology Center, which is home to six company-owned molding machines. For more information, visit www.mrmold.com

By Edward Bassous, management consultant, R.E.R. Software, Inc.

For the past decade, the buzzwords in the tooling industry have revolved around automation and Industry 4.0. Professionals have heard countless speakers emphasize that the future of the industry hinges on adopting automation. When a person thinks of automation, often the picture is of a facility filled with robotic arms, high-tech CNC machines and pallet feeders.

At this point, companies tend to react in one of the following ways:

1. Dismissal: This won’t work for the company; it’s a job shop. The company manufactures custom parts with high-variability.

2. Skepticism: Some shops are thriving with automation, but when the company tried, it didn’t have much luck.

3. Hesitation: Sure, automation sounds great, but why take the risk? The company’s profit margins are fine as they are.

4. Commitment: The company recognizes that automation is a long-term process requiring careful planning, execution and continuous improvement.

No matter where a company falls on this spectrum, it shares one truth – it operates in an extremely competitive market. In the die and mold industry, the key to survival and growth lies in improving operations continuously and increasing throughput. Automation is an essential component of that strategy.

Automation is much more than robotic loaders and advanced machinery. Many aspects of a business can benefit from automation, and implementing it should be a gradual and well-thought-out process. It requires people, research and persistent trial and error. The journey, once begun, quickly becomes embedded in a company’s operational DNA. One of the most profound statements heard from an executive was, “If we are not striving every day to find change and improvements, then change will force itself upon us.” Automation is not about reaching a final destination; it’s an ongoing cycle of continuous improvement. It’s not about making a one-time investment in high-end machines like DMGs, Makinos or Hermles. It’s about fostering a culture of innovation and adaptability. Rushing into automation without preparation is a mistake. A business must lay the groundwork through a structured, iterative cycle – the automation cycle that leads to success follows these key steps.

Success in automation begins and ends with people. The best technology and software are meaningless without the right team in place. Leaders must foster an environment where employees feel empowered to share ideas and innovate. The most successful managers:

Photo courtesy of R.E.R. Software.

• Encourage open dialogue and constructive debate.

• Listen to their teams and provide thoughtful feedback.

• Implement employee-driven suggestions, even when uncertain about the outcome.

Innovation originates from people. While financial compensation is important, a positive and engaging work culture is what retains talent. Many businesses struggle with attracting skilled labor. However, the industry currently lives in the information age, where young people are more tech-savvy than ever. Schools are incorporating computer science and engineering into their curricula, but manufacturers are not doing enough to tap into this talent pool. Manufacturers should ask:

• How many high school students have done facility tours?

• How many co-op students have been brought in?

• How often does the company engage with colleges and universities?

• Has the company interviewed computer science graduates?

R&D often is overlooked due to cost concerns, but failing to innovate can be far more expensive in the long run. Technology, software and tooling are evolving rapidly, and here are key R&D initiatives to follow:

• Regularly engage with vendors to explore the latest technology.

• Test new software solutions to improve efficiency.

• Investigate industry trends and adopt best practices.

Now that manufacturers understand the importance of having the right people and continued R&D, the next logical step in preparation is to clearly define processes. There is nothing worse in a complex manufacturing environment than having each person or team perform work as they see fit. This adds to the variables affecting each department’s performance. While variations in skill levels are expected, they should not define how work is completed. Instead, standardized processes should be in place to ensure consistency, efficiency and quality. No one is born with the skill to design a mold, machine a mold or spot a mold –those skills are learned from someone. The key questions are: How many internal team training sessions have been conducted in the past 12 months? How many process documents have been created?

A company knows who its Grade A designers, machinists and moldmakers are, but is the company leveraging its expertise to pass knowledge along to others? Are teams reviewing design issues, machining errors or programming

flaws and discussing why they occurred? Are top employees across all departments meeting monthly to discuss challenges? Do designers understand the difference between a 0.5" lock radius vs. a 0.6" radius when highspeed machining with a 1" ball tool? Do machinists understand how different stepovers and deflection affect the spotter’s time? If these discussions are not happening, there is room for improvement. Establishing uniformity in processes across all departments is critical. Every team member should be able to take over a task seamlessly from another without disruptions. If this is not the case, process standardization is needed.

There are countless ways to rough, semi-finish and finish a mold, but some methods significantly are more efficient. Predictability and repeatability are fundamental for automation success, especially in mold machining. The only way to measure success or failure is through consistency. For example, define what tooling should be used for roughing a mold, from the largest to the smallest diameter. These decisions should be documented, with minimal exceptions. The goal is to eliminate unnecessary fluctuations in hours spent on similar mold types. Continuous improvement only is possible when a standardized baseline is established. Remember, it all starts and ends with people. Empower the team to document and follow standardized processes, and make sure these processes are enforced.

Once processes are defined, the next step is to establish standards. Standards ensure uniformity and prevent unexpected outcomes. While not achieved overnight, they evolve and improve over time. Growing pains are inevitable. Remember, “repeatability” and “predictability” are essential for automation success.

At the 2023 AMBA conference, briefly mentioned in my presentation was the importance of defining standards. A simple example is defining stepovers or step downs for each tool. Why should these vary between operators when working with the same material? After the presentation, a gentleman approached, excited about the concept but unsure if he had someone capable of developing these standards. After some thought, he identified his machining manager as the right person but was concerned about adding to his workload. The response was simple, “Does the manager take a vacation?” The answer, of course, was yes.

Change is never easy, and there will be hurdles. However, change is necessary to achieve long-term goals. If it means pulling top talent out of production for a few weeks or months to establish standards, then so be it. Investing in automation extends beyond hardware and software – it requires investing in people. Automation is

timpossible without clearly defined processes and standards. Predictability only can be achieved through data gathered from repeatable, standardized methods. By creating and enforcing these standards, the organization will be well on its way to sustainable automation success.

Now that companies have empowered their workforce, conducted research and development to define processes and established standards, it is time to begin the execution and testing phase. Remember, this process is cyclical – it must be repeated continuously to drive innovation and improvement. During this phase, collecting data is essential. While an automated system to capture this data is ideal, in its absence a reliable manager or designated personnel should be responsible for maintaining detailed records.

The execution phase in the machining department does not always require brand-new equipment or pallet loaders. Before making significant investments, it is crucial to first prove the ability to run lights-out operations efficiently and safely. The key to success in this phase is ensuring that predictability and repeatability firmly are established through the defined processes and standards.

One of the biggest mistakes a facility can make is heavily investing in equipment before understanding and preparing for what automation truly requires. This can be particularly harmful to businesses that are trying to modernize but cannot afford years of trial and error. Machine salespeople often promise revolutionary solutions, but the reality is that no equipment alone guarantees success. True automation success always begins and ends with people and the processes and standards they establish.

At this stage, measuring success or failure is critical, as it directly impacts the next phase of improvement. In the first year at R.E.R., President Roger Bassous made a statement that initially felt extreme: He shared that every company eventually will become a technology company or cease to exist. He made this statement during a time of strong industry demand and profitability, which made it difficult to see his point.

Roger Bassous’ statement proved true – every company must rely on concrete data to make decisions. Gut feelings are no longer sufficient, especially when technology can provide full transparency. Making decisions without data is like playing Russian roulette – eventually, a misstep will have significant consequences.

Data eliminates uncertainty and provides clear answers to questions like:

One of the most profound statements heard from an executive was, “If we are not striving every day to find change and improvements, then change will force itself upon us.” Automation is not about reaching a final destination; it’s an ongoing cycle of continuous improvement.

y How many hours did a machine run unattended last night?

y What were the actual machining hours for each part?

y Who programmed the component that performed exceptionally well, or failed?

y Which tools failed most frequently during lights-out operations?

y Were failures due to flawed standards or an isolated material issue?

Without accurate data, these questions remain unanswered, and continuous improvement becomes impossible. North America’s competitive advantage lies in its people and its technological innovation. If decisions still are being made based on instinct rather than data, change is imperative. With global competition intensifying, every company must wake up each day asking how they can improve from the day before. The answers are in the data – it must be collected, analyzed and used to drive change.

Finally, the last phase of the cycle involves making necessary adjustments based on the data gathered. Whether the results indicate success or reveal weaknesses, the objective remains the same – continuous improvement.

Adjustments do not always involve cost increases. Many improvements come from better communication and refinement of processes. However, it is crucial to consider how changes in one department affect others. For example, a more aggressive machining stepover may reduce cycle times, but how does it impact the handwork or spotting departments? Every improvement should be evaluated from a holistic perspective to ensure company-wide efficiency.

The biggest takeaway from this phase is understanding that the business must function as a unified entity. Fragmentation between departments leads to inefficiencies. Success is not measured by an individual department’s performance but by the overall efficiency and profitability of the company. When a job is late or underperforms, no one wins. When

processes are optimized and the company thrives, everyone benefits.

Through first-hand experience, it has been taught that repeated issues will persist unless actively addressed. If design or surfacing flaws keep occurring, are they being properly communicated? Are adjustments being made? If information is not shared across departments, how can the team expect to improve? Clear communication, regular reviews and a commitment to refining processes will ensure continuous progress and long-term success.

Innovation and evolution have no finish line – they’re ongoing processes without end. The steps outlined here aren’t meant to reach a final goal but to foster continuous improvement. To stay ahead, manufacturers constantly must assess their current position by asking key questions:

y Does the company have the right team in place?

y Is the company investing enough in research and development?

y Are the company’s processes clear and well-defined?

y Does the company uphold strong standards?

y Is the company thoroughly analyzing its business and departments?

y And, most importantly, do employees come to work each day asking themselves how they can improve?

As an industry, we must adapt to change – or risk being left behind.

With over 20 years of experience in the manufacturing industry, Edward Bassous is a management consultant at R.E.R. Software and served as the lead developer for a system that integrated multiple DMG CNC machines with a Fastems robotic cell, achieving over 50% autonomous operation. Bassous also obtained a college diploma with honors in computer science during his early years working at Windsor Mold. R.E.R. Software provides state-of-the-art technology to improve manufacturing operation throughput and drive efficiency. Its software solutions enable innovation, efficiency and productivity, while improving overall business flexibility.

More information: www.RERSoftware.com

A look at software solutions in mold manufacturing to streamline the processes of design, simulation and production by integrating tools, such as CAD/CAM, mold flow analysis or CNC programming, to reduce lead times, improve efficiency and enhance precision.

CAM-TOOL / CGS North America, Inc.

440.522.8717

www.camtool.com

CAM-TOOL, based in Windsor, Ontario, is a CAD/ CAM software company specializing in high-accuracy 3D machining, primarily for mold and die applications.

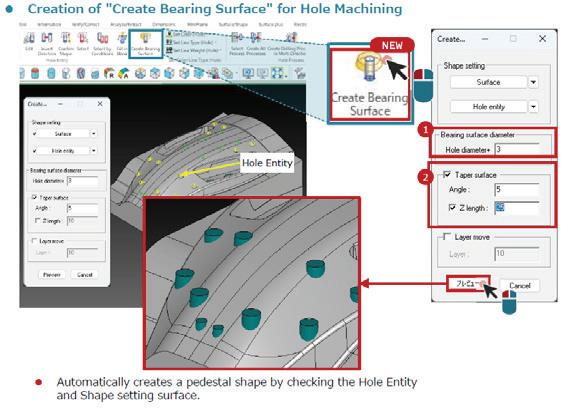

CAM-TOOL Version 21, scheduled for release soon, introduces cuttingedge advancements for mold builders. Its AIdriven cutting condition optimization now accounts for protruding tool length, enhancing efficiency. A new command automatically generates flat bearing surfaces for hole drilling on curved surfaces, significantly reducing manual modeling time. Enhanced 5-axis roughing features include “Delete Air-Cut” and “Auto Clearance” for efficient undercut handling. Notably, the machine simulation now performs interference checks between the tool change point and initial tool position – a feature typically requiring external software – using stock models and posture change verification to ensure seamless, built-in validation of machine movements.

Cimatron

877.596.9700

www.cimatron.com

Since 1982, Cimatron, located in Cincinnati, Ohio, has provided toolmakers with an end-to-end solution for designing and manufacturing tools – including molds, dies and electrodes – and programming any CNC and EDM machine for molds, dies, plates and

discrete manufacturing. Cimatron also provides standalone solutions for faster quoting, tool design, electrode creation and NC programming. Cimatron CAD-AI is a new CAD technology that accelerates mold design and production by using artificial intelligence (AI) to automatically detect part features within solid models. The software’s AIbased feature detection capabilities integrate seamlessly with Cimatron’s CAM automation tools to streamline the generation of safe and accurate CNC toolpaths.

EROWA Technology, Inc.

847.290.0295

www.erowa.com

EROWA Technology, Arlington Heights, Illinois, is a full-service supplier of palletization, automation and process control systems for the North American manufacturing market. EROWA’s JMS 4.0 process control system connects all data while controlling a company’s entire production process. With its automated data flow and real-time monitoring of production processes, JMS 4.0 provides the basis for a seamless workflow. Whether for die-sinking or cutting EDM, milling, drilling, turning, grinding, measuring or cleaning, the JMS 4.0 software solutions connect machines from a wide range of manufacturing technologies and manufacturers, enabling companies to continuously optimize their production.

HEIDENHAIN

847.490.7812

www.heidenhain.us

HEIDENHAIN, Schaumburg, Illinois, develops and manufactures linear encoders, angle encoders, rotary encoders, digital readouts and CNC controls for demanding positioning tasks.

HEIDENHAIN’s

StateMonitor is a machine data collection (MDC) software solution that brings full visibility into production processes, allowing users to monitor their machines from any location and ensure efficient machine utilization. A key feature known as energy monitoring delivers consumption data for electricity, compressed air and process water, enabling users to identify energy guzzlers, derive optimization measures and reduce energy costs. Data consistency across different systems is essential for efficient manufacturing. The StateMonitor software provides an interface for sharing job data with higher-level ERP and MES software. R.E.R. Software, Inc.

Kruse Training 239.351.7428

www.krusetraining.com

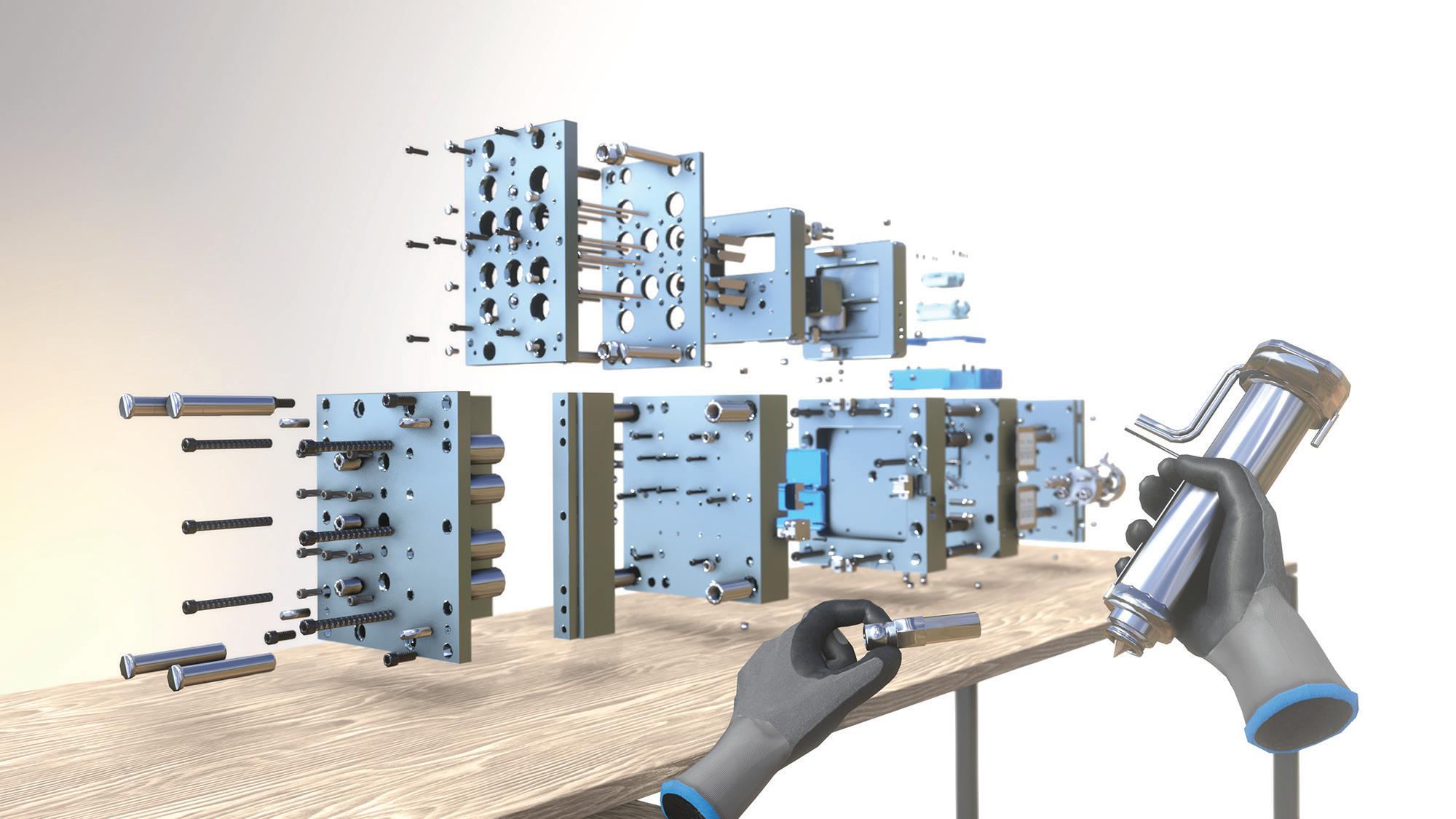

Kruse Training, Naples, Florida, a pioneer in cuttingedge educational methodologies, is making strides in this direction by launching its Molding Expert Injection Molding Virtual Reality (VR) application. In an industry where precision, speed and innovation are paramount, the mold design and manufacturing sector constantly seeks solutions to bridge the skills gap and empower a new generation of engineers. The VR tool is a cornerstone of Kruse Training’s eLearning platform, designed to recruit and develop a highly-skilled engineering workforce through immersive virtual reality training methods. By integrating VR into eLearning frameworks, companies can prepare their workforce for future technological shifts while driving immediate results in innovation and efficiency. This tool levels the playing field for small- and medium-sized enterprises by providing training resources that once were the domain of larger competitors.

R.E.R. Software, Inc., Rochester, Michigan, is a provider of advanced technological solutions specifically designed to optimize manufacturing operations. With an emphasis on innovation and efficiency, R.E.R. Software develops software tools that help manufacturers enhance throughput, streamline workflows and reduce operational bottlenecks. Its platforms are engineered to empower businesses with greater control and visibility over their production processes. R.E.R. Software is committed to driving operational excellence across the manufacturing sector. By integrating intelligent data analytics, real-time monitoring and automation capabilities, its solutions enable manufacturers to increase productivity, reduce waste and quickly adapt to changing market demands.

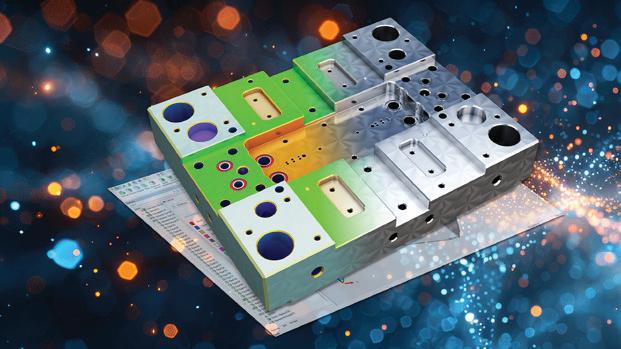

Tebis America

248.540.0430 www.tebis.com

Tebis, Troy, Michigan, a provider of CAD/CAM and MES software solutions, is helping shape the future of manufacturing with CAD/CAM automation, digitalization and collaboration. The company offers an integrated approach to machining that delivers unmatched reliability, precision and productivity, giving customers a competitive edge. Customers use Tebis solutions to efficiently and safely design, plan and manufacture high-quality models, molding dies and components. The company provides software, services and training to customers within a variety of industries, including automotive and aerospace.

By Rachael Pfenninger, director of strategic execution, AMBA

For US mold manufacturers, access to skilled labor continues to be both an impediment to profitability and a constraint on capacity, making it a major roadblock to long-term growth and operational sustainability.

To better understand how mold builders are tackling this particular challenge and provide best practices to other industry professionals, the American Mold Builders Association (AMBA) Emerging Leaders Network has led an effort to survey its membership on key questions related to employee recruitment and retention efforts. With the insights provided by its resulting whitepaper, Recruitment and Retention: Takeaways for US Mold Manufacturers, executives and management teams can better understand how others are achieving success and the ways in which they can improve their own efforts.

Those who identified themselves as emerging leaders were asked a series of questions, including how they discovered their current company/role and which inherent qualities and/or skills made them a good fit for their current role/ company. Below are a few of the summarized suggestions.

• Lean on Friends, Family and Referral Programs: Several responses cited the benefits of working for families or friends with whom they already had a relationship; employee referral programs also can help leverage positive employee experiences.

• Leverage External Relationships: Several member companies have attracted employees from external suppliers, customers and/or community organizations and educational institutions. Don’t overlook those who already have a relationship with the company.

• Develop Social Media Channels to Share Expertise and Culture: Culture played a big role in this survey’s open response data; in many cases, respondents indicated finding a company or expressing interest in employment after seeing positive cultural elements via organic social media efforts.

• Utilize Personality Assessments and Provide Continued Access to Training: Several employees referenced feeling they were a good fit for their current

role; personality assessments can help employers understand if a candidate will fit the role and company culture well. For employees seeking growth, providing continued emotional intelligence training can drive their continued growth and success.

• Evaluate Technical Skills and Provide a Clear Leadership Path: “Go-getting” candidates may not have needed technical skills, but that doesn’t mean they don’t have the aptitude. Provide a clear career path and evaluate interest in similar tasks or topics to determine if a candidate could be worthy of role-specific training.

Although executives did identify recruiting challenges, such as offering competitive wages and benefits, sourcing skilled employees and needing to educate future workforce members, others have found recruiting success.

Successful tactics included hiring an on-staff recruiter, building an apprenticeship program, generating career center and/or community-oriented relationships, use of online recruitment and social media platforms (particularly www.indeed.com and LinkedIn, respectively) and more.

Using the insights and topic preferences provided by respondents in its Recruitment and Retention Whitepaper, AMBA has designed its newest Emerging Leaderssponsored opportunity, the virtual Shop Floor Webinar Series. This series of one-hour, supplier-led sessions is designed to provide AMBA’s emerging leadership and operations staff with tips and trends related to topics impacting manufacturing, such as the use of AI on the shop floor, lights-out machining, automation and continuous improvement initiatives.

To learn more about upcoming virtual and in-person learning opportunities for AMBA Emerging Leaders, visit www.amba.org. For more information about the benchmarking efforts (including free, members-only whitepaper downloads), visit the AMBA Publications page.

MMT’s new column “SHOP TALK”, sponsored by Canon Virginia, wants to hear from YOU! Let’s celebrate the human side of our industry by sharing your unforgettable moments from the shop floor, whether it’s the mishap that taught you a valuable lesson or the crazy situation that still has co-workers talking. Share your tales from the trenches. After all, we’re in this together, one moldmaking adventure at a time!

by LET’S TALK

Sponsored

AMBA provides access to key legislative resources that help U.S. mold builders prepare for what’s to come.

A monthly e-newsletter that provides the latest on policy shifts, tax updates, legislative actions and more.

AMBA’s advocacy partner provides webinars on the latest industry initiatives, recent developments from policymakers and actions impacting U.S. mold builders.

Each month, AMBA's advocacy partner provides a slide deck that summarizes current legislative policy and tax reform.

Monthly, AMBA publishes a Grants Matrix on regional, state and national grants available to U.S. manufacturers. Interested in the resources above? Get involved! Scan the QR code or contact the AMBA offices at info@amba.org to learn more.

Shop Floor Series – Webinar: Automation and Lights Out Machining, September 4, www.amba.org/events

Mold Industry Supplier Trade Fair –Erie, Pennsylvania, September 10, RSVP to info@amba.org

Plant Tour Workshop – Tessy Tooling, Erie, Pennsylvania, September 11, www.amba.org/events

Shop Floor Series – Webinar: Continuous Improvement and Technology, September 18, www.amba.org/events

2025 iWarriors Alliance Charity Golf Outing, Mundelein, Illinois, September 19, www.iwarriors.org/golf

Third Quarter Advocacy Update, September 25, www.amba.org/events

Shop Floor Series – Webinar: AI Agents in Manufacturing (Part 1 – Defining Concepts), October 16, www.amba.org/events

MD&M Midwest, Minneapolis, Minnesota, October 21-22, www.mdmmidwest.com

Emerging Leaders Plant Tour Workshop – Dynamic Group, Ramsey, Minnesota, October 23, www.amba.org/events

2025 iWarriors United Tool and Mold Charity Golf Outing, Fountain Inn, South Carolina, October 24, www.iwarriors.org/golf

AI Tools for Improved Process and Marketing Efficiency, October 29, www.amba.org/events

Shop Floor Series – Webinar: AI Agents in Manufacturing (Part 2 – Practical Application), October 30, www.amba.org/events