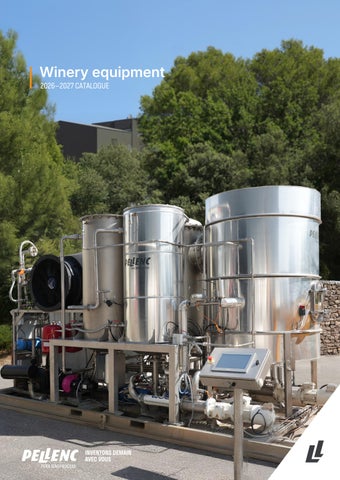

Winery equipment

2026–2027 CATALOGUE

2026–2027 CATALOGUE

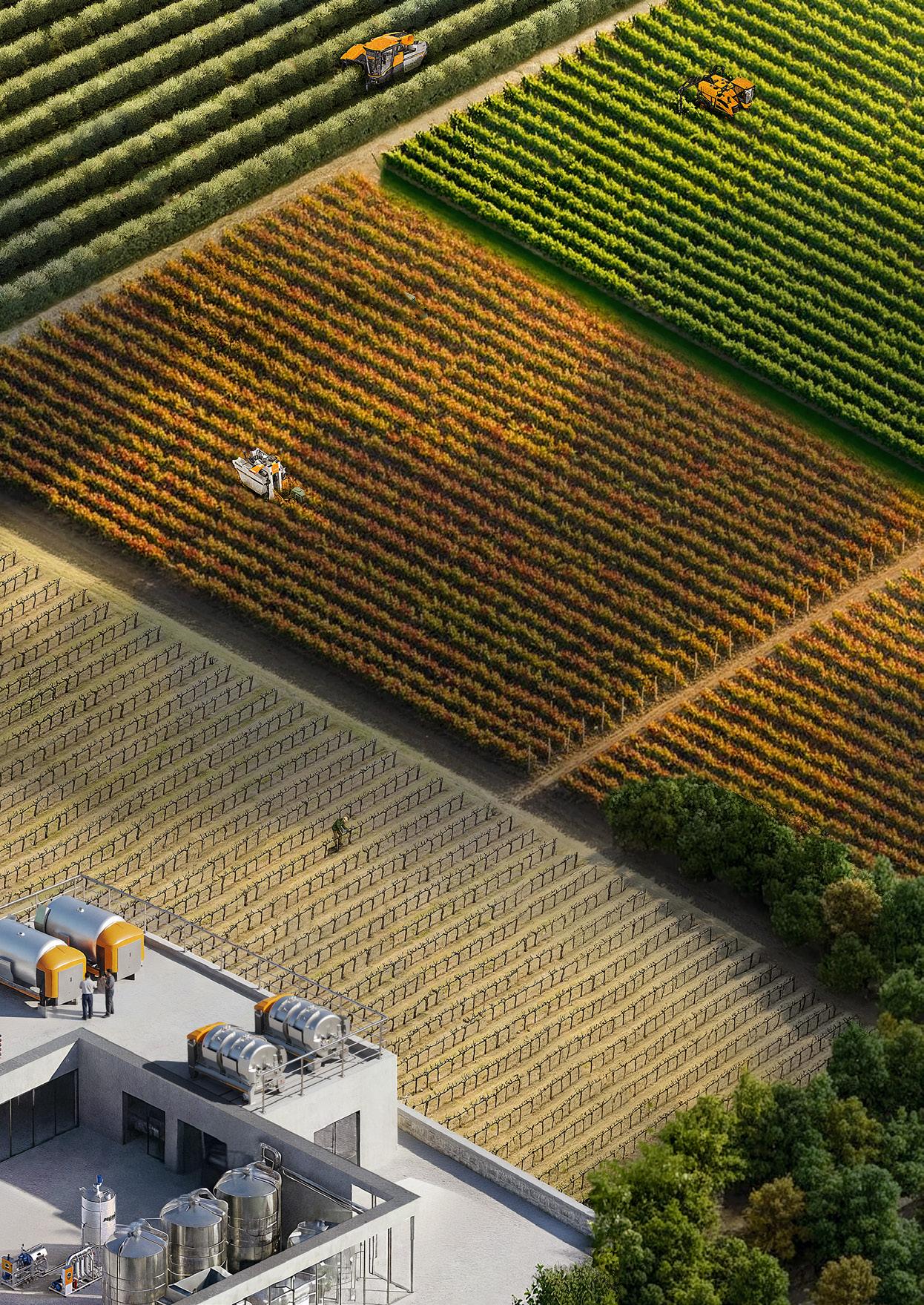

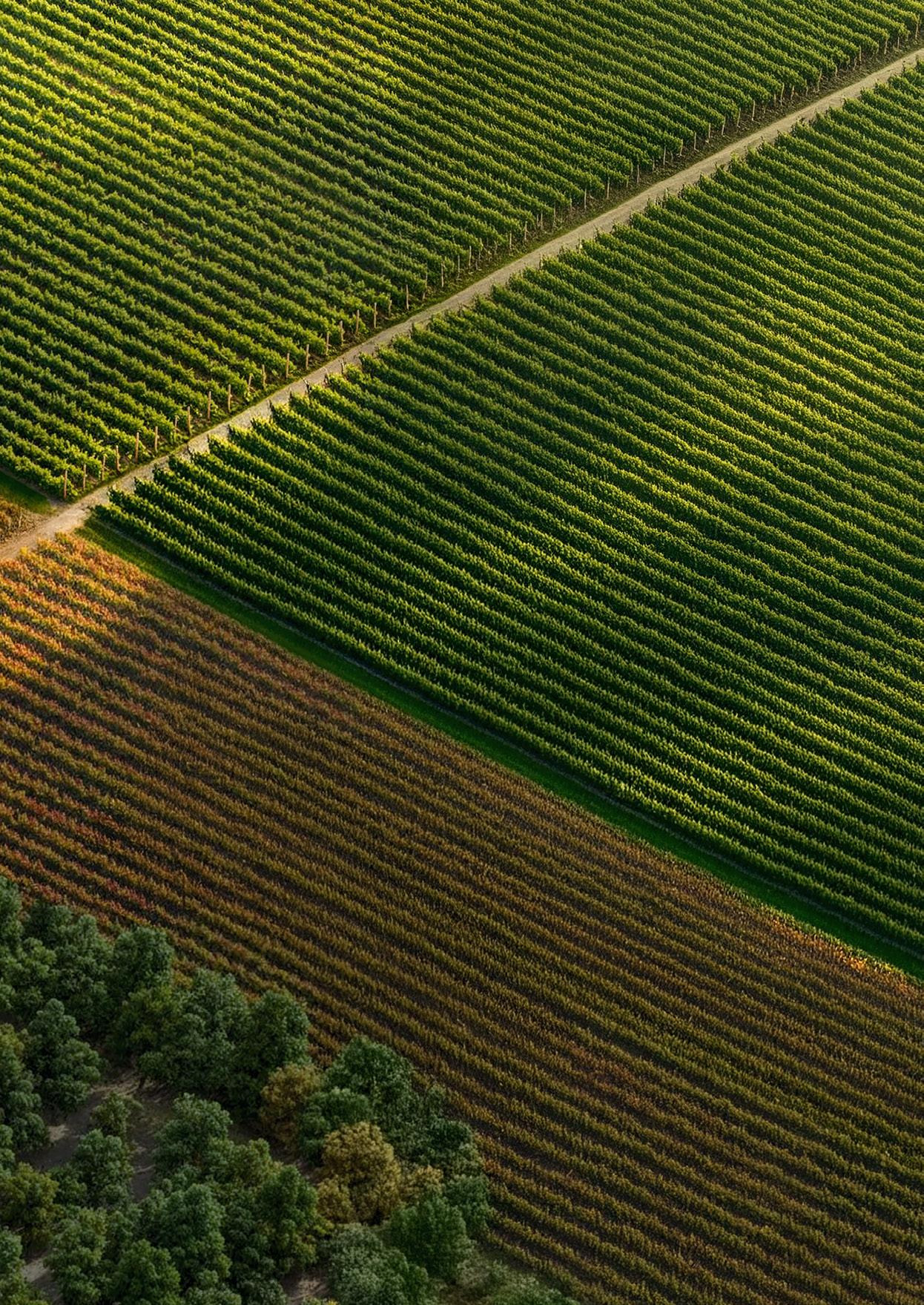

From the vineyard to the winery, every decision matters. At PELLENC, we know the importance of making the right choices to shape the quality of your wines. That’s why we offer you our technology and expertise, to support you every step of the way. Our comprehensive range offers products, services and advice, guaranteeing reliable, high-performance solutions tailored to your needs. Designed for maximum control, durability and ease of use, our equipment preserves the integrity of the fruit and reveals all the richness of your terroir.

From the design stage to the monitoring of your installations, we remain by your side – because innovation, above all, means understanding your business in order to make every harvest a success.

HEAD OFFICE

COUNTRIES COVERED BY OUR DISTRIBUTORS

ALGERIA / ARGENTINA / AUSTRALIA / AUSTRIA / BELGIUM / BOLIVIA / BRAZIL / BULGARIA / CANADA / CHILE

CHINA / CROATIA / CYPRUS / CZECH REPUBLIC / DENMARK / FINLAND / FRANCE / GEORGIA / GERMANY / GREECE

GUADELOUPE / HUNGARY / ICELAND / INDIA / IRELAND / ISRAEL / ITALY / JAPAN / JORDAN / KOREA / LEBANON

LUXEMBOURG / MACEDONIA / MAURITIUS / MOLDOVA / MOROCCO / NETHERLANDS / NEW CALEDONIA

NEW ZEALAND / NORWAY / PERU / POLAND / PORTUGAL / RÉUNION / ROMANIA / SAUDI ARABIA / SERBIA

SLOVAKIA / SLOVENIA / SOUTH AFRICA / SPAIN / SWEDEN / SWITZERLAND / TASMANIA / TUNISIA / TURKEY

UNITED ARAB EMIRATES / UNITED KINGDOM / UNITED STATES.

Head office

Pertuis, FRANCE

Distribution subsidiaries

Production subsidiaries

FRANCE – SPAIN – CHINA – SLOVAKIA –PORTUGAL

Mixed subsidiaries (distribution and production)

SPAIN – FRANCE – ITALY

We have over 2,000 approved distributors around the world. PELLENC expands its network further every year to offer its technologies and products to as many people as possible.

Industrial mastery serving every aspect of the sector

As a recognised industrial player, PELLENC designs all its equipment in France, deploying an integrated process that guarantees quality, reliability and innovation. Operating in a number of sectors – winegrowing, winemaking, arboriculture, olive growing, parks and urban spaces – the Group offers a full range of tools and machinery. This global approach makes PELLENC a benchmark player from the vineyard to the winery, able to support professionals at every stage of their production.

• Integrated industrial expertise

• Global solutions for every operation

• Sustainable, user-focused innovation

INDUSTRIAL INNOVATION

Technological innovation for premium products

• €21.1 million of revenue invested in R&D

• Over 1,340 patents filed

High-tech skills development

• 200 R&D employees

+8% average growth since 2014

7 industrial sites in France, Europe and China

63% of activity devoted to exports

Nearly 2,000 employees

PERA, a family business founded in 1896, joined the PELLENC Group in 2014.

PELLENC PERA OENOPROCESS sets the standard in terms of support and innovation for wine creators and producers.

Season after season, our teams of experts help to build and commission efficient installations and keep them in perfect working order.

We devise solutions in consultation with our customers and partners to design the innovative installations of the future.

RESPONSIVENESS

Support and hotline, harvesting service

AVAILABILITY

6 days a week during harvest

ECONOMICAL

Optimised costs and solutions

International presence 100% French production

Dedicated experts in our customers’ business sectors

Personalised support

Custom solutions Process optimisation

Undisputed quality

Recognised satisfaction

1

PELLENC PERA OENOPROCESS optimises your winemaking processes, providing innovative global solutions adapted to your needs. From understanding your needs to the end use of the processes, our experts support you from A to Z in making your installations plans a reality.

EXAMINING THE CUSTOMER’S NEEDS AND SITE LAYOUT

• Analysis of the customer’s needs and expectations

• Definition of the most appropriate winemaking process

DESIGN AND LAYOUT

2

• Preliminary study with layout plans

• Technical verification of the layout

• Optimisation of process flow and operation

Validation of the offer and the layout

EQUIPMENT PRODUCTION

3

4

• Manufacture of specific equipment and solutions

• Development of custom automation

• Custom design and manufacture of electrical cabinets

ON-SITE INSTALLATION AND CHECKS

• Assembly and installation

• Testing the installation

• Checks on correct operation before harvest

COMMISSIONING AND PROCESS OPTIMISATION

5

6

• Optimising settings to achieve the best performance

• Winemaking support

MAINTENANCE AND TROUBLESHOOTING

• Preventive maintenance

• Maintenance contracts

• Repairs

PROJECT MANAGER (project coordination, compliance with deadlines and quality requirements)

Technical sales staff Winemaking engineers

Design office engineers: automation, electrical, electronic and mechanical engineering, thermal processes (CAD)

Industrial teams: welding, sheet metal works, machining, surface treatment, electricity, automation, modern equipment (welding robots, precision digital lathes...)

After-sales service at the factory

After-sales service at the factory Winemaking engineers

After-sales service from the factory Winemaking engineers

AFTER-SALES TECHNICIANS (80 mobile technicians during the harvest - France and Europe)

• Harvest reception three screw loading bays + H1000 destemmers + pump hoppers

• Pressing

SPC 240 and two SPC 320

• Thermovinification

• Pressing

SPC 320, PN480, PN240

• Thermovinification

• Pressing site 2 SPC 240

“A reliable, robust hopper for high-quality work”

The PELLENC PERA OENOPROCESS range of reception hoppers adapts to all types of installation and provides a regular feed for destemming and sorting equipment.

“We have a PERA PELLENC reception system with a vibrating reception hopper. We chose this equipment to provide a regular feed for our H600 destemmer and do a good job of separating the green parts of the plant. The very good manufacturing quality of this hopper gives it excellent robustness and reliability. We process flows of about 25 t/h, enabling us to absorb the estate’s harvest easily.”

Patrick Galliano

Operations Director & Oenologist, Château Saint Maur

Provence-Alpes-Côtes-d’Azur (Var) – FRANCE

Hoppers with vibrating bottoms can be used to feed destemming and selective sorting systems for processing the harvest. The grapes are preserved thanks to the vibrating unloading system.

The hoppers are equipped with:

• Vibrating bottoms mounted on silent blocks

• AISI 304 stainless steel structure

• Pneumatically-operated sealed door

Options: juice drainage grids, intermediate opening, washing, manual opening, juice tank with pump control, weighing.

Vibrating hopper

Pneumatically-operated sealed door

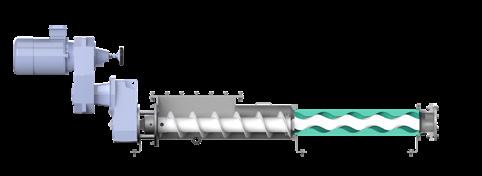

These hoppers are equipped with a screw fed gradually with grapes by the tipping of the hopper itself. They feed the destemmer directly.

Screw hoppers feed the destemmer directly with a constant optimised flow rate. The large-diameter screw moves the volume and preserves the grapes. Screw hoppers can be horizontal or inclined depending on the needs of your installation.

They are equipped with:

• 3 mm thick AISI 304 stainless steel hopper

• 5 mm thick stainless steel screw, Ø 400 mm

• Metal inert gas welding

Options: weighing, coupling, drainage grids, juice tank with pump control.

Direct feed to the destemmer

These hoppers enable significant collection of high-quality juices (less oxidation) from the harvest thanks to a very large drainage area. They optimise the filling of the press for mechanical harvests. ONLY AVAILABLE AS CUSTOM SOLUTIONS

“ Effective sorting while protecting the rest of the process”

These robust, reliable destemmers are designed for manual or mechanical harvesting, with easy cleaning and maintenance.

‘‘The winery has been using PERA PELLENC destemmers for many years. They are reliable and robust, and they allow us to separate stems, leaf stalks, leaves and foreign bodies from the harvest, preventing breakages in the rest of the process. Our destemmer is fitted with a system for separating ‘to be cleaned’ grapes from ‘clean’ grapes, enabling us to bypass the destemmer and thus limit the squashing of grapes that have already been destemmed. Adjusting the speed of the destemmer shaft gives us high-quality results at a flow rate of about 50 t/h.”

Alain Pierre Technical Director, Vignerons de Buxy Burgundy (Saône-et-Loire) – FRANCE

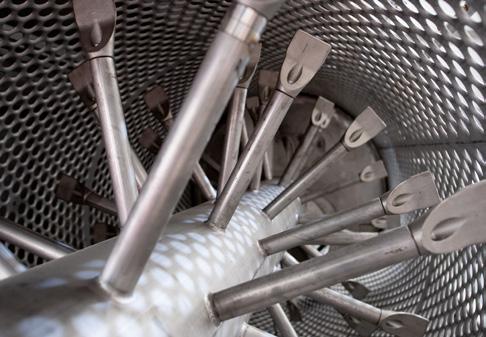

• Large-diameter cage rotating independently of the destemmer shaft

• The destemmer shaft consists of fingers ending in adjustable spatulas

• These optimise the quality of your harvest

• Easy access to all components

• Simple and quick to adjust

• Easy cleaning: built-in spray arms

• H400 is a mobile destemmer on wheels

• The rotation speed of the destemmer shaft can be adjusted by remote control

• Reliability: tried and tested robust construction

“A system with remarkable sorting quality”

The KLINER roller sorting tables range is the high-quality answer to the needs of large vinification units and private cellars. Their innovative systems for automatically and manually adjusting the settings greatly improves the quality of sorting. KLINER automatically adapts to all harvest types.

“The solution offered by PELLENC PERA OENOPROCESS fulfils all our criteria: the roller system enables remarkable sorting quality by removing a large proportion of the plant debris (stem fragments, leaf stalks etc.) left behind after destemming.

Its automatic adjustment in real time adapts to the different qualities of the harvest. The system is compatible with our reception rates, between 50 and 60 t/h. Finally, cleaning the sorting table is quick and easy. Today, 100% of the grapes from our cooperative are sorted by this powerful system.”

Alain Pierre Technical Director, Vignerons de Buxy Burgundy (Saône-et-Loire) – FRANCE

• Green waste removal: stems, leaves, leaf stalks

• Removal of foreign bodies

• Improvement of wine quality

• Automatic and manual sorting adapted to the harvest

• Flow rates suited to the reception systems of large vinification units

• Integrates into a PERA PELLENC reception line

• Reliable and robust technology tried and tested by the PELLENC group

• Works on any type of harvest

• Fully retractable for easy cleaning

• Continuous operation coupled to the destemmer

• Compact and robust

• Operates continuously

• Adaptable to high flow rate*

• Automatic adjustment for all types of harvest, ensuring safety, saving effort and optimising efficiency

*according to the machine's specifications for use

KLINER R : the roller sorting table can be adjusted manually to fit beneath a small rotary destemmer.

KLINER : suitable for automated cellar processes.

The conveyor belt sorting table is ideal for sorting whole clusters before destemming. Its advantages are:

• Robust: stainless steel fabrication.

• Smooth food-grade PVC belt.

• Juice collection tank.

• Mobile assembly on castors.

• Adjustable belt scrapers.

• Electrical cabinet with start/stop control.

Ideal for manually sorting whole clusters or destemmed grapes, the TVT vibrating sorting table has two drainage areas with two grids (for removing juices, pips, small insects and plant matter), two drainage baskets on slide rails for waste recovery and two tanks for liquid collection on slide rails with a male connector.

• 2 draining grids

• Stainless steel fabrication

• 2 side waste channels

• Mobile assembly on castors

• Adjustable pads for levelling

• 2 vibration motors

• Variable frequency drive to adjust the speed

• Electrical cabinet with motor circuit breaker and switch, start/stop control

The hopper drains and regulates manual or mechanical harvest processes. It consists of a dual sorting table with drainage grids with oblong holes of different dimensions, a drainage basket on slide rails and a juice tank.

• 2 draining grids

• Stainless steel fabrication

• Mobile assembly on castors

• Electrical cabinet with start/stop control

• Adjustable pads for levelling

• 2 vibration motors

• Variable frequency drive to adjust the speed

• Anti-splash risers on three sides

• TBox hopper capacity/dimensions

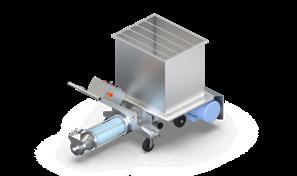

ECCENTRIC SCREW PUMPS

Ideal for pumping whole clusters or destemmed fruits, before or after fermentation.

• Robust: stainless steel hopper and rotor

• Double-pitch elastomer stator

Options: hopper extension, SO2 tapping, bridge breaker, dry running sensor.

Eccentric screw pump

MOBILE PUMPS ON WHEELS FIXED POSITION

fixed eccentric screw pump with hopper

UNDER TANK

rectangular-hopper pump for use under a tank

“

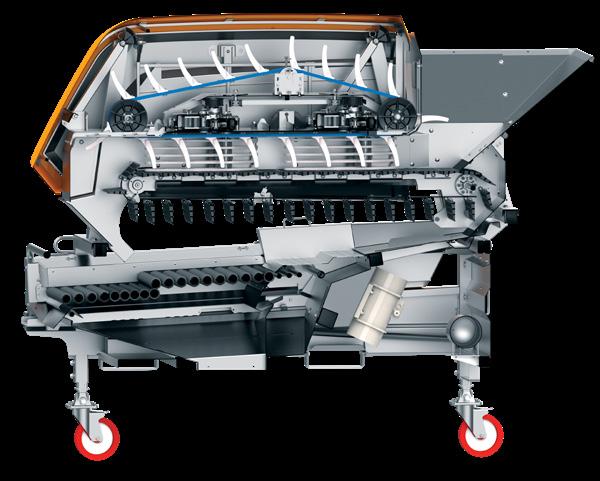

Designed to offer impeccable harvest quality, INTEGRAL’ WINERY combines high-frequency linear destemming with a dual sorting system: a vibrating drainage and distribution table, and a two-level roller sorting table. This exclusive technology guarantees up to 99.8% cleanliness* while preserving the integrity of the grapes. Green plant waste is efficiently separated, making it easier to manage and optimising the quality of the winemaking process.

Gold medal

INTERVITIS – 2013 Commendation

SITEVI – 2011

VINITECH – 2010

“Having used the new INTEGRAL’ WINERY on the estate from the outset, I have noticed significant improvement in waste washing and centralisation, which saves time and simplifies waste management.”

Thierry Usseglio

Domaine Pierre Usseglio Provence-Alpes-Côtes-d’Azur (Vaucluse) – France

• 99.8% cleanliness*

• 95% of leaf stalks > 35 mm removed

• Whole grapes preserved

• Gentle handling of grapes and stems

• High throughputs with no loss of performance

• Tried and tested by more than 2,000 winery users

• High-quality work with manual or mechanical harvesting

• Simple, instant adjustments

• Quick cleaning (15 to 30 minutes)

• Easy installation and handling

• Adaptable to size of berries and type of harvest

• Several models available to suit the size of your winery

• Full range of sorting technologies in a single machine

• 2-in-1 process: destemming combined with mechanical sorting

• Reduced labour requirements

• Up to 25% savings on overall process costs

* Based on IFV tests in 2008 and 2011, with a manual harvest of Merlot grapes.

High-frequency linear destemming modules

Feed fingers

Harvest receiving hopper

Sorting: vibrating drainage and distribution hopper

Sorting: feed rollers

Sorting: variablescreen rollers

All elements open wide for quick access and optimized cleaning, reducing maintenance time and water consumption.

The control panel, close to the work area, allows the operator to see the results immediately and adjust the settings.

HIGH-FREQUENCY LINEAR DESTEMMER

Gentle separation of the grapes from the stem through vibration: intact grapes, stems kept whole.

Feeding the sorting table: the freed grapes travel along the mesh conveyor, avoiding any squashing.

Vibrating drainage and spreading hopper:

• Prepares the harvest for sorting and the removal of juice, seeds, aborted berries and small debris.

The PELLENC two-level roller sorting table:

• Notched solid feed rollers: orienting and extracting leaf stalks.

• Studded screening rollers: removing stems, leaves, extra corps and foreign objects.

• Quick adjustment of the screen size depending on the harvest.

Direction of movement of the harvest

Feed fingers

High-frequency linear destemmers Meshed conveyor

Feed rollers and screen rollers on two levels

Distribution area Drainage area

Destemming frequency

Vibrating drainage and distribution table

Height-adjustable legs with castors 500–1050 mm

Legs with castors 1050–1300 mm

Chassis for mounting above Intregral’Vision

Seed/juice separation

“ Incredible technology that sorts according to our needs”

Visionic sorting, grape by grape, instantly detects and removes any unwanted material: green waste, foreign bodies, immature or damaged berries. The INTEGRAL’ VISION guarantees a perfectly healthy, uniform harvest that meets the most demanding quality standards.

Silver medal

VINITECH – 2008

INTERVITIS

INTERFRUCTA – 2010

“This is an incredible technology. Sorting removes leaf particles, stems and even microscopic splinters, which you can hardly see with the naked eye and couldn’t remove by hand. The quality is incredible, and so is the precision of the settings. You can adjust the machine to sort by grape size, maturity or colour – all the criteria you want to work on or refine.”

Château Lassègue, Saint-Emilion

Bordeaux (Gironde) – France

• 100% custom, personalised sorting

• Real-time choice of sorting level

• Regular, rectilinear sorting

• Total protection for berry integrity

• Uniform final product

• Sorting suitable for both mechanical and manual harvesting

• Immediate start-up with no initial calibration

• 2,000 items sorted per second, up to 12 tonnes/hour

• User-friendly touchscreen interface with the selection displayed instantly

• Quick, precise adjustments to achieve the desired quality

• Built-in pre-cleaning system and complete wash cycle in 20–25 minutes

• Easy access to all areas thanks to the optimised design

• Reduced water consumption and downtime

• Significant reduction in labour costs with completely automated sorting

• Full mobility thanks to adjustable castors and centralised control

• Best value for money on the market

• Optimises the quality of your wines

User-friendly interface

Results of high-quality optical sorting

Camera

Buffer tank + air handling system

LED lighting

Nozzle array

Sorted grape outlet

Visionic sorting waste recovery bin

Vision unit Touchscreen control panel

The belt cleaning system and easy access to all areas of the machine reduce cleaning times and water consumption.

This perfect sorting has a direct positive impact on wine quality.

IMPROVEMENT

REDUCTION

Complexity and aromatic intensity

Volume in the mouth

Tannin suppleness

More direct wines

Herbaceous character

Bitterness

Astringency

Dryness

Grooved blue conveyor

Reception of the harvest from the vibrating table

Pneumatic, hydraulic and electrical connections

Adjustable wheeled legs (option)

The user-friendly touchsensitive interface provides five different settings for red grapes and three for white grapes, each with its own specific criteria.

1 – Preparation of the harvest

Drainage, uniform distribution over the whole width, removal of small waste – optimised sorting (vibrating table).

The camera continuously films the harvest on the conveyor. The PELLENC sorting software analyses the images according to the selected sort level (sorting by shape and colour).

Stabilisation of the harvest and alignment opposite the compressed air nozzles to improve sorting accuracy (grooved blue conveyor).

Nozzles eject unwanted elements using compressed air: green waste, dry berries, damaged or immature grapes.

Flow rate (depending on grape variety, maturity, health status, water stress and sorting quality required)

outlet height (min–max in mm)

Pneumatic tank (2 x 24 L) + air

Pre-cleaning in place

Vision unit waste recovery bin with disposal screw

Height-adjustable legs with castors

Control of peripheral systems (EXTRACTIV’, INTEGRAL’ WINERY, etc.)

“ Very easy adjustment for uniformly crushed grapes”

The EXTRACTIV’2 crusher opens the grapes in a controlled, uniform way depending on their maturity, promoting optimum extraction of juices, polyphenols and aromatic compounds. It integrates perfectly into the reception line and reaches flow rates of up to 25 tonnes/hour.

“We tried the new PELLENC crusher on several varieties for our rosé, white and red wines. We were won over by several aspects of this truly innovative device: it’s very easy to adjust, the system bursts the grape more favourably for on-skin maceration, and the berries are crushed very uniformly. Cleaning is extremely easy: just a jet of water is enough.”

Domaine de Valdition Provence-Alpes-Côtes-d’Azur (Bouches-du-Rhône) – France

• Better extraction (juice, phenolic compounds, flavour precursors)

• Stabilised colour: tannin-anthocyanin combinations

• Open berries: increased area of contact between juice and skin

• Reduction in herbaceous flavours and bitterness

• Pips and green berries are not crushed

• Reduction in maceration time

• Faster rotation of the fermentation tanks

• Quick cleaning

• Easy installation and maintenance

• Simple, instant adjustments

• Compatible with different chassis

• High throughput of up to 25 t/h

Crushing intensity adjustment: adjustment of the wheel rotation speed to achieve the crushing intensity required

and phenolic compounds

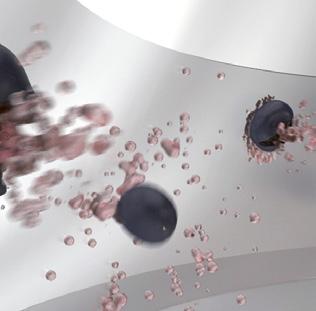

Crushing wheel: the berries are thrown against the conical frame of the crusher

Opening of the berries: juice release and larger surface area of contact between juice and skin.

Better extraction of skin compounds: polyphenols, aromatic compounds etc. Simple real-time adjustments depending on the crushing intensity required.

Résultats après 5 mois de mise en bouteille Indice des polyphénols totaux

Tests carried out from 2010 to 2012 with INRAE showed better colour stabilisation and a higher Total Polyphenol Index (TPI) several months after bottling.

EXTRACTIV’ 2

Crushed grape outlet (mm)

(with no options) (kg)

Power supply 16 A 3P + 400–480 V three-phase

Rated power (kW)

Hopper adaptable to the output of the Selectiv’ Process Vision 2

Chassis for use beneath Selectiv'Process Winery S

• Available as an option

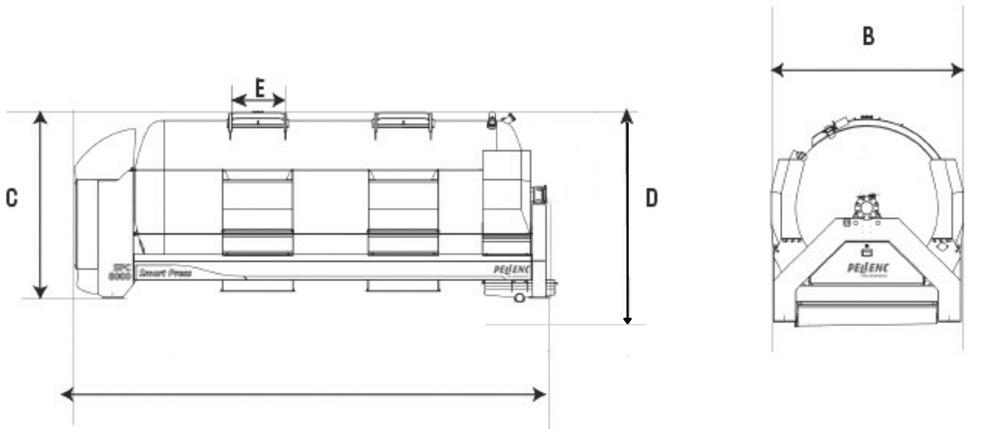

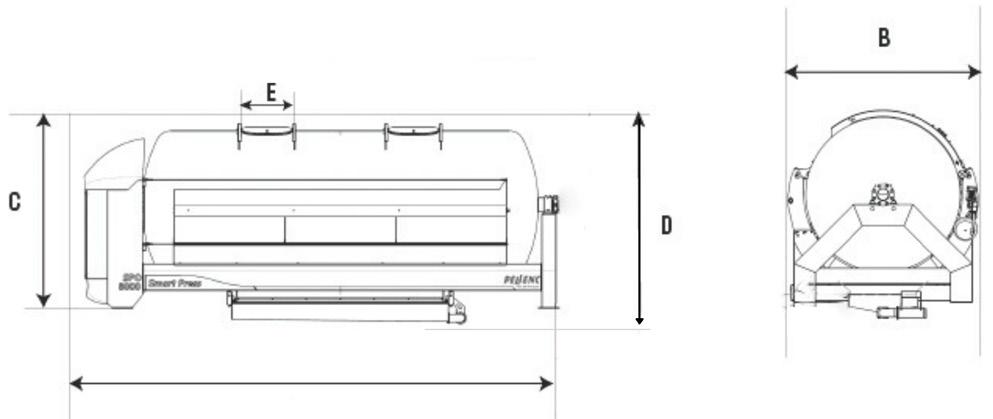

“An accessible, simple, reliable press”

This new range of closed-cage pneumatic presses is designed for winemakers looking for simplicity, reliability and efficiency. Compact, functional and economical, these models benefit from a robust design combined with intuitive control thanks to the 10” touch screen. It is the ideal solution for producers that want both extraction quality and control over costs.

• High-strength food-grade PVC membrane

• Gradual pressing to preserve grape integrity

• Gentle extraction to limit crushing and solids generation

• Clear, high-quality juices

• Juice channels can be removed quickly for easy washing

• Wide doors (500 x 600 mm) for quick door filling

• Stainless steel juice tank (360 L) on swivel castors

• Quick cleaning and reduced water consumption

• 10” touch screen with smooth real-time cycle control

• Visualisation of all parameters and curves

• Customisable pressing programs

• Swivel castors with brake for easy movement in the winery

Pre-configuration axial feed

• Manual axial input Ø 100

• Axial pressure audible alarm

• Standard stainless steel legs

Double manual door Touchscreen control panel

PRESS'ENTIEL 20 closed-cage press

• Automatic pumping of musts

• Stainless steel filling hopper on frame

Pre-configuration axial feed

Automatic pumping of musts

Door feed 1 manual double door

Note: The specifications are provided as a guide only, and are subject to change without prior notice from the manufacturer. * Estimated capacities depending on grape variety, year, maturity, type of harvest and filling conditions.

Standard • Option

“Quick and precise for high-quality juices”

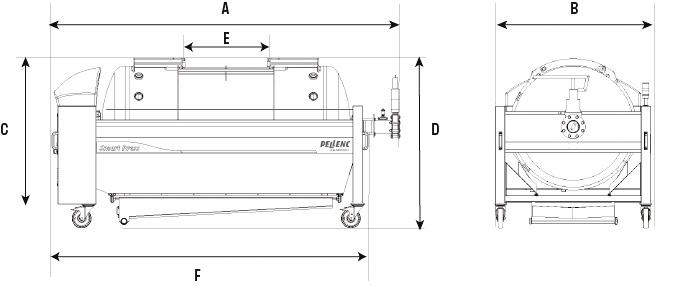

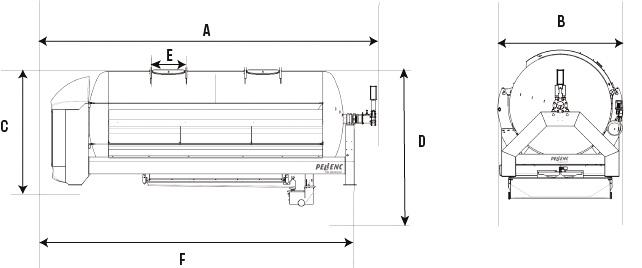

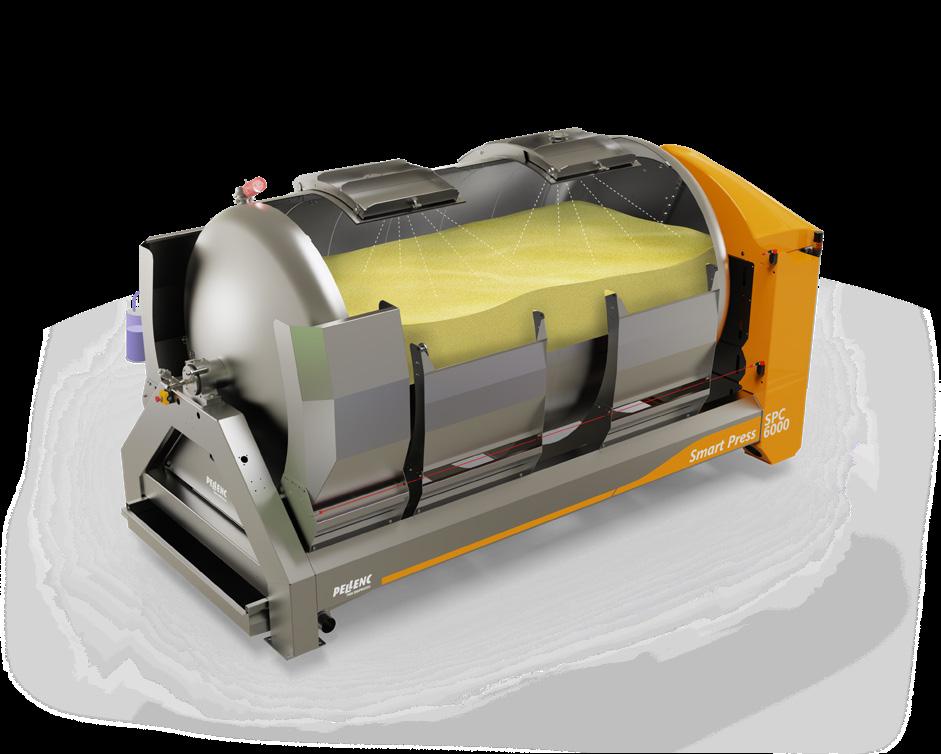

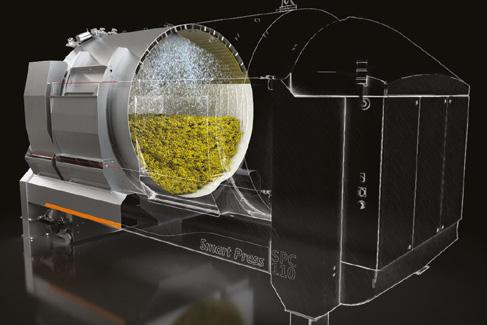

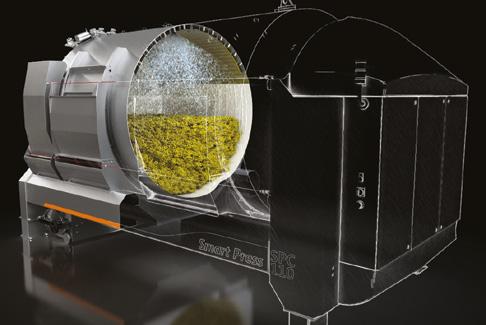

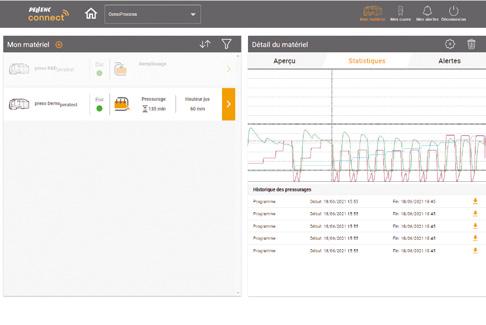

The new generation of SMART PRESS presses: Smart Power 2, to meet the needs of even the most demanding winemakers! This range of pneumatic closed-cage presses is intelligent, oenological and efficient.

The Fast Press drainage grids optimise juice flow, while the Touch Press control interface ensures simple, intuitive and efficient control.

“The highly effective Easy Fill and Easy Press 2 features save us time while optimising juice quality. We are very careful with cleaning, and the new Easy Clean technology works perfectly. We carry out 80 pressings per press each year on average, and the results with the SPC² are stunning. Particular attention has been paid to ergonomics, with a larger screen for easy viewing. The PELLENC CONNECT app gives us peace of mind even when we are out in the vines, with alerts that ensure the operation is running smoothly.”

Cédric Carcenac

Domaine Carcenac, 100 hectares Montans (Gaillac), Occitanie (Tarn), France

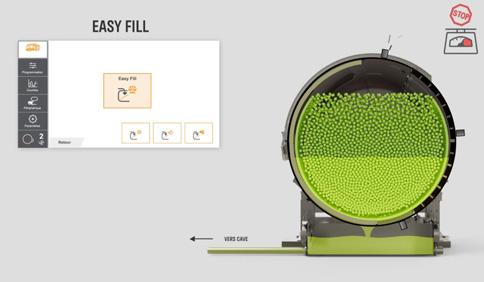

• Touch Press: intuitive 12” (30.5 cm) touch screen

• Easy Fill: optimised secure filling based on volume/weight/ duration data

• Easy Press: choice of automated programs or advanced custom control

• Control based on volumes extracted and real-time weighing (optional depending on model)

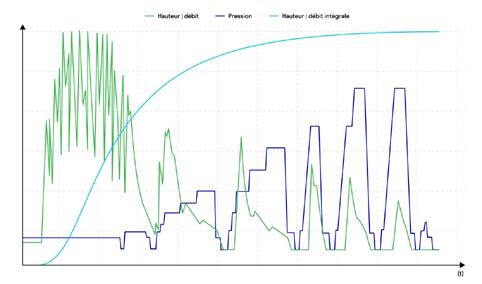

• Real-time display of pressing and juice yield curves

• Connected press: remote real-time tracking of the press with the PELLENC Connect app

• Optimised filling capacity with Easy Fill

• Choice of cycle based on the desired profile

• Real-time automated optimisation

• Fast changeover between the stages of the pressing cycle

• Energy saving

• Can be used for on-skin maceration

• Fed by harvest pump via axial inlet valve (manual or pneumatic) or by gravity through the door

• Clear juices with few solids thanks to self-filtration through the pomace and punched Fast Press drainage grids with vertical slots

• High-quality juice flowing directly into the sealed juice tank

• Aromas and colours are preserved

• Easy-to-program juice selection

• Better protection and recovery of end-of-press juices

• ENOXY+ (option): antioxidants injected into the tank

• INGAS (option): juice protection with neutral gas

• Quick and easy cleaning thanks to the Fast Press drainage grids

• Easy access to drainage areas (under the grids)

• Easy Clean² (optional): optimised water quantity

• Optimised cleaning time at the end of the day (20 to 45 min)

Pressing curves displayed in real time

UNRIVALLED SURFACE AREA FOR DRAINAGE

• Vertical punched slots

• Fast juice extraction

• Soft, non-abrasive surface

• Reduction in solids

• Low level of crushing

• Smooth surface with nowhere for pomace to build up

• Quick evacuation with little residue

• Easy, quick washing thanks to the hinged drainage grids

• Easy Fill coupled with flow and tank pressure measurement to control rotation

• High-performance partial rotation: the movement unclogs and breaks up juice pockets

• Natural juice drainage when pressure is stable

• Partial rotations triggered if the juice flow slows down

• Full revolution in up to 10 minutes: few rotations, low level of solids and up to 3% less solid matter in juices (compared to full rotation)

• Controlled pressure in the press without blocking the grids

• Stop position adjusted via three valves for natural air evacuation

• Polyurethane membrane suitable for food contact on both sides

• EC/FDA compliant and suitable for thermovinified grapes

• Air diffusion drain to balance pressure

• Quick emptying thanks to a coil that moves the pomace towards the door

• Servicing access hatch (manhole) on the air side available on models from 65 hl

Pneumatic juice flow valves Fast Press drainage grids

ENOXY+ INGAS

Axial inlet with valve

Easy Clean washing tapping

Enclosed, inerted juice tank with flow measurement and relative volume metering

SPC² 80 Smart Press closed-cage press – sectional view

Touch Press and Easy Press²: cycle automation and full traceability

• Custom pressing cycles for the winery’s needs (logistics, quality etc.)

• Real-time program changes

• Monitoring of pressure and yield curves

Advanced

• The operator programs the different pressing phases: pressure, holding pressing time, number of turns to break up the pomace

• 20 customisable programs (up to 99 lines) exportable via USB stick

Easy Press²

• Automatic control of pressing cycles based on juice flow and the degree of drying required. The operator adjusts two criteria: quality and dryness

• Optimised pressing time and pomace break-up

• Five predefined pressing profiles

• Real-time juice yield display: litres extracted/100 kg grapes

• Display of extracted volume as soon as the press is filled

• Juice selection optimised according to the volumes actually extracted

• Percentage display relative to the most recent peak/total volume already extracted

• Accurate monitoring of juice extraction: avoids juice loss and over-extraction

• Systems controlled via the Touch Press display

• ENOXY+ and INGAS

• Injection of neutral gas during rotation in the final pressing phase

• Manually programmable via the Touch Press screen

• Control based on changes in conductivity

• Separate juices automatically based on quality

• Automatic washing (CIP) with retractable rotary nozzle

• Washing through sealed door

• On rails or wheels

Axial feed with fill-end detector and Easy Fill

Power Pack² (flowmeter – weight sensor – Easy Fill²)

Drainage

Membrane

Advanced Pressing Cycle (20 options) or Easy Press²

Easy Clean automatic washing cycle

Easy Clean² washing with rotary nozzle

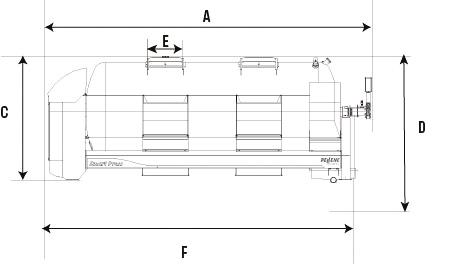

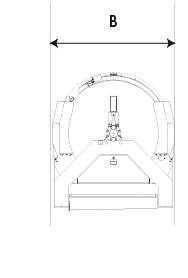

Ø

manual or pneumatic

Electropolished Fast Press draining grids

High-density polyester weave coated on both sides with polyurethane Food grade FDA/EEC 1227

Note: The specifications are provided as a guide only, and are subject to change without prior notice from the manufacturer. * Estimated capacities depending on grape variety, year, maturity, type of harvest and filling conditions.

“ Features that optimise pressing time and juice quality”

The SMART PRESS range of open-cage pneumatic presses combines simplicity of use, robustness and efficiency. Thanks to their careful design and the intuitive Touch Press interface, they offer precise, high-quality juice extraction.

– 2019

highquality presses

– 2016 Technical novelty award

– 2017

• Juice clarity ensured by efficient auto-filtration and the tank design punched with non-abrasive vertical slots limiting solids generation

• ENOXY+ anti-oxidation system (option)

• Intelligent automatic cycle control with Easy Press 2

• Simple cleaning in less than 30 min with the controlled spray ramp

• Reduced water and energy consumption

• Touch Press screen: smooth navigation, cycle viewing, real-time alerts

• Flexible programming:

--> Advanced mode: 20 customisable programs of up to 99 lines (pressure, time, pomace break-up)

--> Easy Press 2: automatic control based on two criteria: quality and dryness

• Connected press: remote real-time press tracking with the PELLENC Connect app

• Punched tank, limiting the solids generation and making cleaning easier

• Re-centring coils for quick, complete emptying

• Servicing access hatch on the air side of the membrane

• Total drainage plug and sliding tray

• Axial feed, either manual or pneumatic from a harvest pump

• Gravity feed through motorised door (1 or 2 doors) or from a conveyor

• Optimised filling capacity with Easy Fill

Manual or pneumatic axial feed

PRESS SPO 80 open-cage press

• Motorised movement: press mounted on rails or wheels

• ENOXY+ system: protection for musts, addition of inputs

• Controlled sulphur doser: antioxidant injected into the juice tank

• Juice selector and conductivity sensor: automated fraction quality control

• Reinforced washing: second controlled spray arm and/or high pressure wash

Axial feed with fill-end detector

Juice collection

drainage plug and sliding tank Easy Clean automatic

Drainage

tank perforated by oblong holes

“ Presses suited to the needs of Champagne winemakers”

PELLENC PERA OENOPROCESS has been supporting Champagne winemakers since 1989 with a range of CIVC-approved pneumatic presses that meet the requirements of French decree no. 2010-1441 of 22 November 2010. Experts from Pellenc workshop (Épernay - Champagne) design and install pressing centres and certified programming consoles. PELLENC VIGNOBLES CHAMPENOIS technicians carry out annual maintenance and provide harvest servicing with 24-hour availability.

The SMART PRESS range is available for Champagne region with closed cages of 4,000 to 12,000 kg and open cages of 2,000 to 8,000 kg.

Meets the CIVC requirements in French decree no. 2010-1441

• Juice clarity ensured by efficient auto-filtration and the tank design punched with vertical slots limiting solids generation

• “Qualitive”-certified press

• Intelligent cycle and end-of-pressing control (Optimal and Evolution options)

• Simple, fast washing thanks to punched tanks

• Sulphur doser juice protection system (option)

• User-friendly, intuitive Touch Press screen

• Programmed for Champagne process (CICV agreed): automatic stepwise pressing

• Connected press: remote real-time tracking of the press with the PELLENC Connect app

• Two-door tank design, compact with large diameter to optimise filling

• Robust, reliable design

• Total drainage plug for complete cleaning of the press

• Gravity or conveyor feed through the doors

• Servicing access hatch on the air side of the membrane

Sulphur doser

Tapping for complete washing

Pneumatic juice flow valves

Fast Press drainage grids

Injection of antioxidant

Enclosed, inerted juice tank

SMART PRESS SPC 6000 closed-cage press – sectional view

• Automatic sulphur doser: continuous sulphiting of the must with choice of dosages depending on the pressing time or flow rate

• Automatic juice selection: via solenoid valves based on volume, using flowmeter or sensors positioned on the compartments

• Automatic washing: automatic washing system via the axial inlet for optimum cleaning

• Optimal program: the electromagnetic flowmeter measures juice flow and the SMART PRESS controller adapts the pressing program to the flow rate

• Evolution program: pressing is adjusted and regulated based on the volume measured in the tank

Two independent motorised doors

HP washing of the punched cage Juice tank SMART PRESS SPO 4000 open-cage press

• Automatic juice tray movement: pneumatic cylinder for moving the tray

• Automatic sulphur doser: continuous sulphiting of the must with choice of dosages depending on the pressing time or flow rate

• Automatic washing: automatic washing system via the axial inlet for optimum cleaning

• Optimal program: the electromagnetic flowmeter measures juice flow and the SMART PRESS controller adapts the pressing program to the flow rate

• Evolution program: pressing is adjusted and regulated based on the volume measured in the tank

• Automatic washing: automatic washing system via the axial inlet for optimum cleaning

Cage type Half cage perforated by oblong hole 2 x 20 mm

working pressure (mb)

Automatic washing cycle

Press washing

Automatic high-pressure washing

Membrane

Side sprinkler nozzle ramp – Working pressure: 3 to 5 bar

High-density polyester weave coated with polyurethane FDA/EEC 1227 food grade – pinch fixing Juice

steel and sliding tray

“A digital breakthrough that offers real benefits”

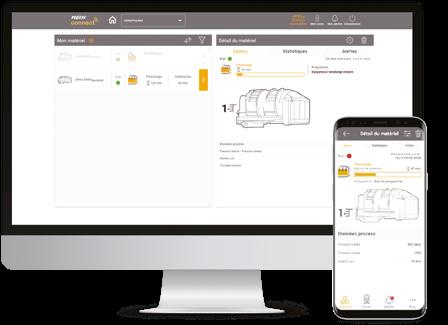

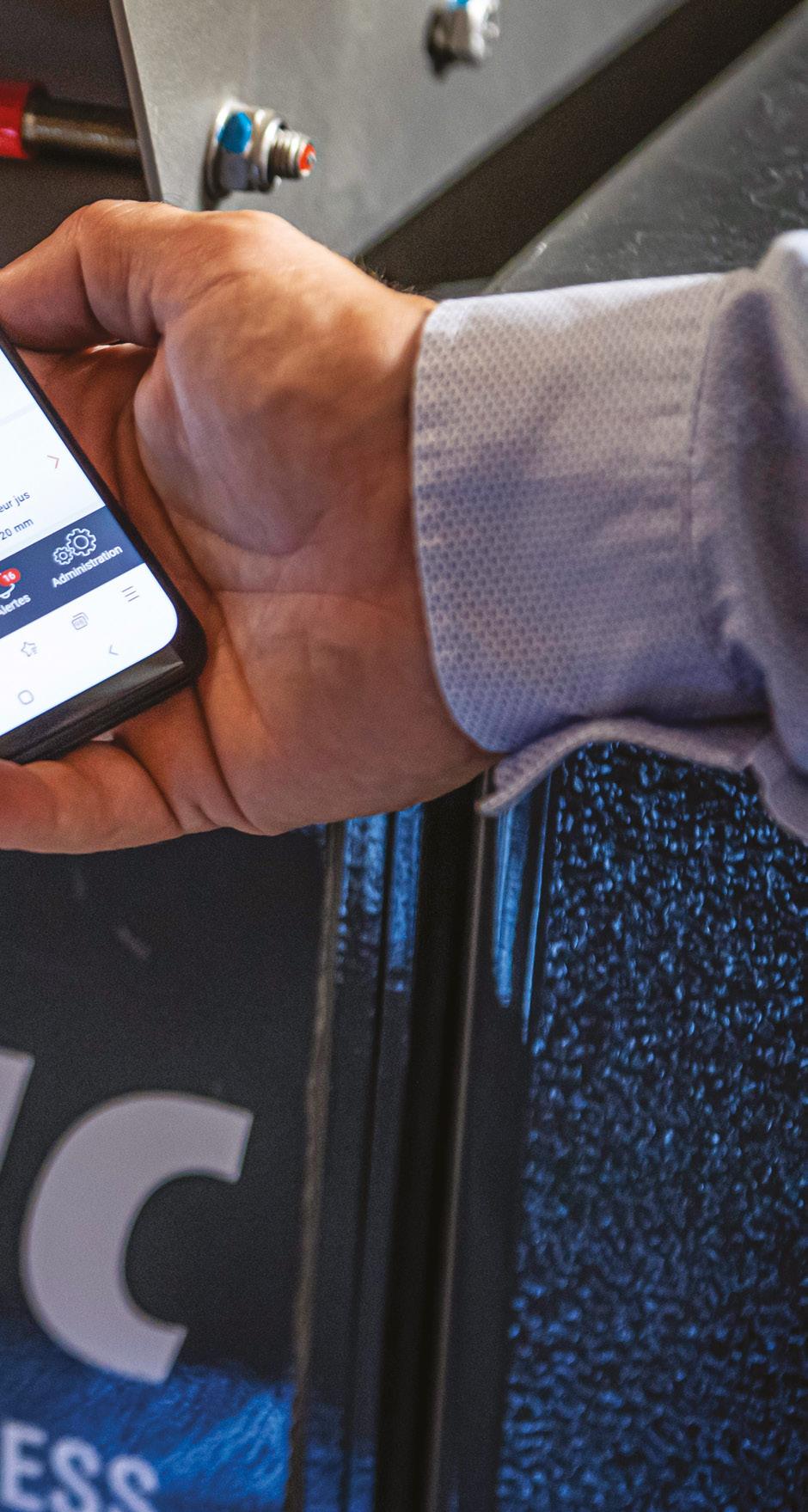

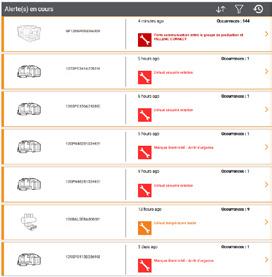

PELLENC PERA OENOPROCESS provides winegrowers, wine producers and oenologists with an advanced digital monitoring solution. With the PELLENC Connect app, you can control up to 10 presses at once and access a full range of data wherever you are. Communication takes place via the winery’s 4G or ethernet network, ensuring reliable, continuous transmission of information.

“With the Connected Press, PELLENC PERA OENOPROCESS gives demanding winemakers a digital breakthrough that offers real benefits: firstly, a special channel for communicating with the technical teams for a real-time diagnosis and potential rapid, controlled intervention, but also a remote source of information on the status and activity of the press, even when you’re out among the vines.”

Albéric Philipon Winemaker & owner of Château Carpe Diem Provence-Alpes-Côtes-d’Azur (Var) – France

• View of the status of each press

• Display of time remaining

• Identification of the current program and phase (up to 99 phases)

• Volume of juice extracted in real time with Easy Press 2

• Automatic archiving of pressing cycles

• Data export for complete traceability

• Curves and statistics for analysing and optimising processes

• Instant SMS notification of anomalies or cycles ending

• Remote troubleshooting for a fast, secure response from technical support and after-sales service

The PELLENC Connect platform centralises the management of all your PELLENC equipment: fermentation tanks, alcohol removal process, filtration, harvesting machinery, pruning shears, etc.

Press information displayed on the PELLENC Connect web platform

Real-time information on your smartphone

“ Reduce inputs while protecting the harvest and its aromas”

ENOXY+ is an automated system for injecting liquid oenological solutions into the heart of the harvest during the pomace break-up phases. This process reduces overall doses of SO2 by fractionation throughout the juice extraction process and increases efficiency. Repeated injection at very low doses blocks harmful enzyme activity (PPO, laccase etc.) and stabilizes the aromatic potential of the musts.

The SMART PRESS becomes a complete oenological tool, providing continuous protection for juices as soon as they are released.

“Trials of adding a fining agent directly to the presses for our Syrah and Grenache grape varieties have produced positive results. Chroma comparisons are similar in both tanks, even with fewer inputs. The aromatic potential and glutathione are mostly preserved, which is the main aim of this approach: reducing inputs and protecting the harvest and the aromas.”

Cave de Rousset

Provence-Alpes-Côtes d’Azur (Bouches-du-Rhône) – France

PROTECTION: BETTER AROMATIC INTENSITY

• Tailored gradual dosage

• Improved effectiveness of the SO2 or antioxidant

• Better concentration of glutathione and thiols

• Better-preserved final pressing and colour protection

• No impact on the versatility of the press

• No depreciation in the event of resale

• Compact system

• Control from the Touch Press interface

• The user chooses the duration and timing of the injection

– The dosing pump coupled to the buffer tank carries out the injection into the heart of the press via injection nozzles

1) Injecting vegetable proteins into the heart of the harvest as early as possible to guard against oxidation and reduce the doses of SO2 used.

2) Injecting antioxidant in liquid form (SO2, ascorbic acid etc.).

3) Injecting enzymes during on-skin maceration or following FLASH DÉTENTE maceration.

“A protection of musts to ensure quality and aromatic expression”

This simple, efficient process for juice drainage under a neutral gas flow is an essential PELLENC PERA OENOPROCESS solution for preserving the aromatic potential of the grapes. The juice leaves the press tank for the inerted juice tank (CO2 or nitrogen) via optimised impulse. The system protects juices against oxidation and can be supplemented by the ENOXY+ system to reduce the need for additional antioxidants.

The SMART PRESS becomes a complete oenological tool, providing continuous protection for juices as soon as they are released.

“We opened our new winery dedicated to high-end white wines in 2021. Our new presses equipped with INGAS are a natural part of this ambition, especially for maceration. Protecting the musts, during both filling and pressing, has proved its worth: we have seen a real leap forward in the quality of the musts and the aromatic expression of our wines.”

Claudiu Cretu

Averesti estate

Vaslui County – ROMANIA

• Inerted press

• Inerted drainage of juices during transfer from the press outlet

• Protection for colour and flavours

• No gas contamination (non-recycled neutral food-grade gas)

• Compact system

• The press retains its versatility

• No depreciation in the event of resale

• Reduced gas consumption (around 10% of the volume per pressing)

• Injection of neutral gas beneath the Fast Press grids during pressing

• Control from the Touch Press display

• Control over injection intensity and duration

• Direct connection to the axial inlet

INGAS: protection for colour and flavours

Injection of neutral gas beneath theFAST PRESS grids during pressing

“

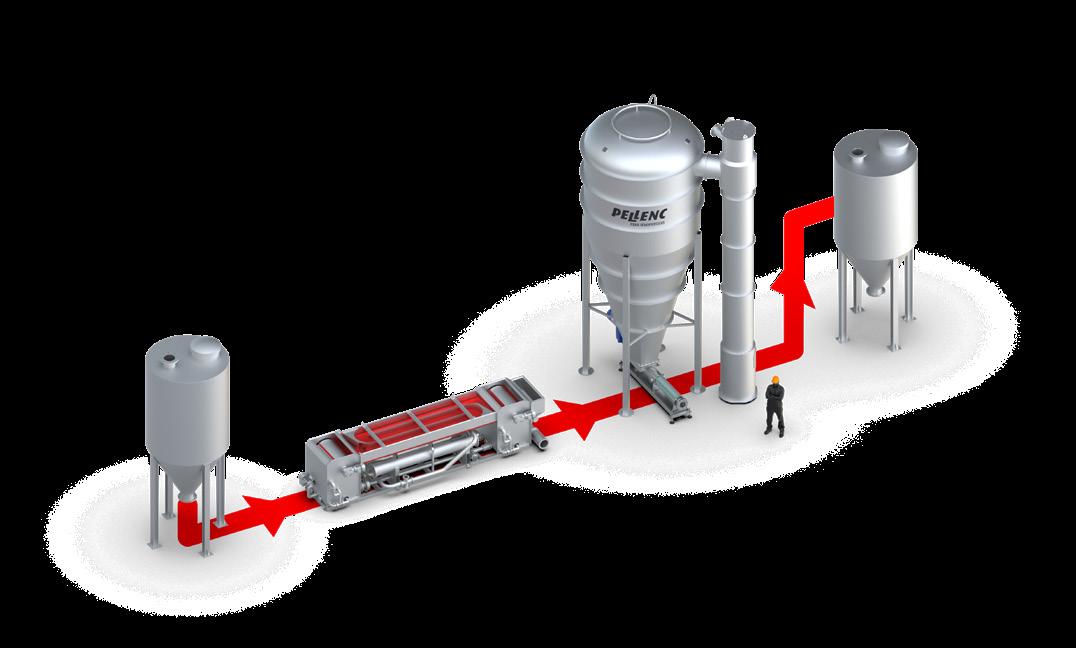

An innovation patented by PELLENC, working with INRAE, IFV and CRITT, SMART WINELYSE generates the targeted partial dealcoholisation of fermentation musts and finished wines. Integrated flexibly into the winemaking process, the winemakers adjust the alcohol content at different stages while preserving the character and quality of the wines. A major step forward in response to climate challenges and new consumer expectations.

“Using this dealcoholisation process, I was pleasantly surprised by its respect for the fruit when we were working on the musts. We produced a real wine, similar to the ones our buyers enjoy when they visit us. In the liquid phase, we find that the wines are well preserved. And what blew us away was the quality and aromas of the alcohol produced alongside. Yes, this is an innovative technology!”

Paul Oui Technical Director Tutiac – Bordeaux

PROTECTION FOR THE ORGANOLEPTIC PROFILE OF THE WINE

• Character, colours and aromas preserved

• No impact on the nature of the wine

• No preparation needed before dealcoholisation, or correction after

• No exogenous inputs specifically required

• High-quality correction of the alcohol level required with total peace of mind

• Increased release of polysaccharides and molecules responsible for the sensation of wine’s body and roundness

• Assurance of being able to complete alcoholic fermentation easily, especially at high levels:

• Nutrients from endogenous yeasts in place

• Detoxification of the medium during alcoholic fermentation

• Positive regeneration of aromatic compounds after dealcoholisation, during further alcoholic fermentation

• Very aromatic, full-bodied native alcohol (45–55°), linked to low temperature evaporation

• The alcohol can be reused as “wine alcohol”, as long as production complies with the legislation in the country of production

* production and storage of alcohol subject to national legislation in force and to mandatory declarations.

• 0 consumables, 0 wine preparation, smart control

• Simple automation: the operator enters the initial alcohol content, the target content and the volume to be processed

• Real-time display: volumes extracted, process in progress

• Fast automatic washing cycle

• Connected: monitoring via PELLENC CONNECT

• Compact, mobile module

The fermenting must is heated moderately and introduced continuously into the tank under high vacuum, where the water/ethanol mixture evaporates instantly. The condensate measuring between 45 and 55 vol% is extracted, and the alcohol content is lowered by 2 to 5 vol%. Depending on the goal, only a part of the tank is treated and then reintroduce into the initial tank to complete and let its fermentation end. With finished wine, the technology can reduce the alcohol content by up to 6 vol% in a single pass, without damaging the aromas or unbalancing the flavour.

The process is based on partial vacuum evaporation, a technique that significantly lowers the boiling point of volatile compounds. For example, a wine containing 10% ethanol boils at 20°C at an absolute pressure of 30 hPa. This low-temperature operation not only saves significant quantities of energy; it also preserves the organoleptic qualities of the product.

• The vacuum evaporation system is optimised to minimise energy consumption (COP = 5.0). The reversible heat pump simultaneously generates:

the hot water needed to heat the product to a high enough temperature for evaporation,

the cold water needed to feed the condenser, which liquefies the water/ethanol mixture and reduces the alcohol content of the processed product.

• Energy efficiency of the COP 5.0 heat pump: for power consumption of 18.5 kW, the unit generates up to 40 kW of refrigeration and 55 kW of heating.

• 3.0 kW screw vacuum pump

Pump cooled without waste water using cold water produced by the heat pump.

• The unit has enough capacity to process musts that are fermenting, cloudy or charged with CO2

Pure alcohol extraction rate

Fermenting must 25–35 L/h*

Pure alcohol extraction rate

wines

Trailer/container mobile skid

L/h*

• Included as standard * depending on alcohol content of the wine to be processed

“

The guarantee of efficient and controlled temperature for the harvest”

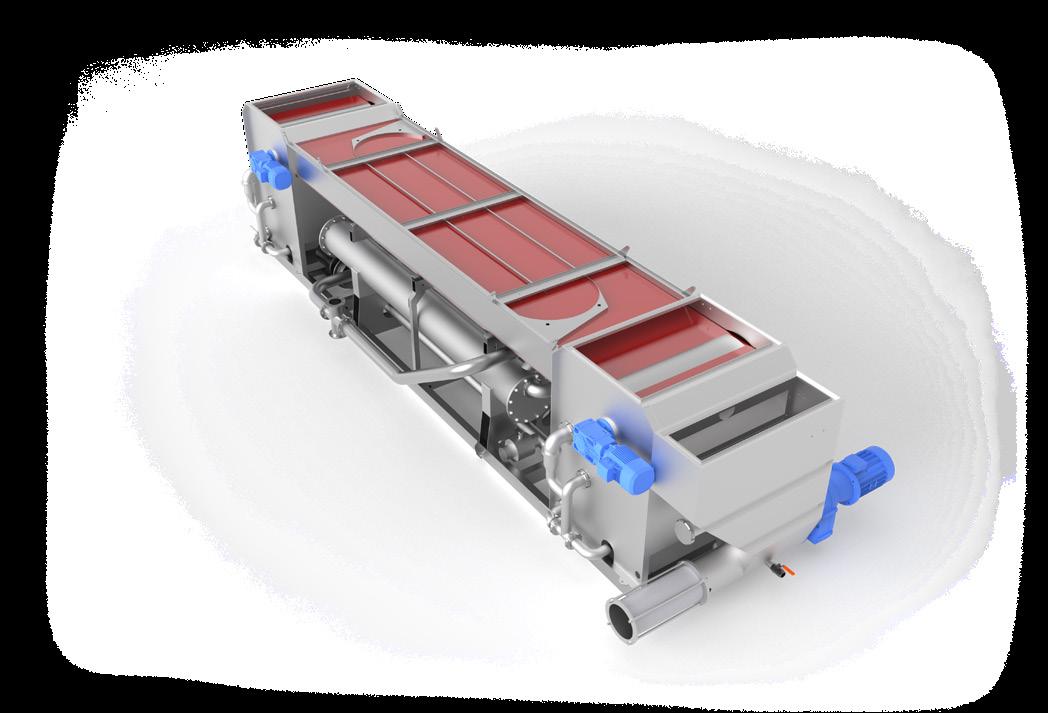

GULFSTREAM is a system for regulating the temperature of the harvest rapidly and uniformly thanks to a dynamic immersion process. It ensures precise control over thermal profiles, while preserving the physical and aromatic integrity of the harvest.

RESPECT AND QUALITY

• Preserves grape integrity

• Optimum extraction of phenolic compounds

• Reduction in pyrazine and geosmin, neutralisation of harmful enzymes (laccase, polyphenol oxidase etc.)

• Structured, supple, aromatic wines

PERFORMANCE AND SIMPLICITY

• Instant heating and cooling

• Intuitive touch screen and programmable controller

• Up to 35% energy savings

FLEXIBILITY AND VERSATILITY

• Suitable for whole or destemmed harvests

• 3 models with flow rates from 7 to 30 t/h

• Compatible with FLASH DÉTENTE

Freshly harvested feed

Heat exchanger for heating/ cooling the juice Juice bath for heating

The harvest is immersed in a temperature-controlled heat transfer bath and then drained dynamically by drums. The temperature is continuously regulated according to the type of winemaking selected (pre-fermentation hot maceration (MPC) or FLASH DÉTENTE).

“A process that significantly improves wine quality”

This innovative process involves a rapid, controlled heat treatment of the harvest, followed by cooling under an intense vacuum. This technology releases all the aromatic and colour potential of the grapes. Fine control of the temperatures and the vacuum ensures more stable, fruity wines, perfectly tailored to consumer expectations and international market standards.

“We see the ‘flash détente’ process as a very interesting invention. The technique has enabled us to modify the profiles of our wines, making them fruitier and rounder in line with the expectations of the global market. We are very satisfied with all the technical possibilities this technology offers us!”

Gonzalo CARCAMO Chief Winemaker

Viña La Rosa – Chile

• Rounder, fruitier, more full-bodied wines

• Stable colours and flavours

• Neutralisation of harmful enzymes (laccases, polyphenol oxidase etc.)

• Reduced sensitivity to oxidative phenomena

• Full potential of the grapes revealed

• Reduction in the number of pumpovers

• Better temperature control during fermentation

• 25% increase in fermented volume for the same energy input

• Easier tank emptying (with liquid-phase fermentation)

• Better cooling exchange during fermentation

• Continuous operation 24 hours a day

• Increased flexibility of harvest dates

• Ability to diversify the range of wines and juices produced

• Fewer manual operations

• Programmable controller

• Simple touch display

• Fast, intuitive configuration

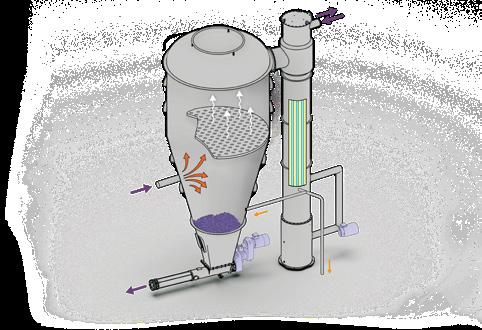

The FLASH DÉTENTE process consists of rapid heat treatment of the harvest at a high temperature, followed by instant cooling in a vacuum.

1. Heating of the harvest

• By coaxial dynamic heat exchanger or GULFSTREAM

• Temperature reached: 85°C

2. Cooling under high vacuum

• Thermotreated harvest input continuously

• Almost instantaneous cooling

• Vapours condense and are recovered

• Condensates and juices added back in

The process is fully controlled by a programmable controller that regulates the temperature at the outlet from the heating chamber depending on the type of winemaking chosen (pre-fermentation hot maceration (MPC): 70°C, flash détente: 85°C).

A simple, intuitive touchscreen interface allows the operator to control the various operating parameters (temperatures, maceration time) and informs the operator if any anomalies occur.

Compared to conventional vinification, FLASH DÉTENTE significantly increases the extraction of colorants, polyphenols and polysaccharides, guaranteeing more intense, fruity, full-bodied wines with no loss of tannic structure.

STANDARD PROCESS Traditional vinification

FLASH PROCESS Fermented harvest after flash

“A tool that makes flash détente technology accessible to everyone”

This module integrates the FLASH DÉTENTE technology into a compact mobile solution, specially designed for small producers. This patented process optimises wine quality by revealing all the aromas, colour and roundness of the wines produced, and enables you to create differentiated blends with strong market value. The multifunctional OENOSM’ART 8 adapts to all harvest profiles and quality targets.

“This is a great step forward for winemakers, making flash détente technology available to wineries with low‑volume harvests to process. Flash détente has proven its value over many years for the production of high-quality wines tailored to global consumer demand. Having all the elements integrated on a mobile skid means the system can easily be installed in private wineries, making it possible to provide it as a service. OEOSM’ART 8 is thus a new winemaking tool that makes flash détente technology accessible to everyone.”

Camille Vallat Vignobles Vallat Occitanie (Hérault) – France

• Rounder, fuller, fruitier wines

• Stabilised colour and flavours

• Neutralisation of harmful enzymes (laccases, polyphenol oxidase etc.)

• Reduction in defects from damaged harvests

• Better yeast incorporation: optimised fermentation kinetics

ENERGY EFFICIENCY AND PRODUCTIVITY

• Reduction in the number of pumpovers

• 25% increase in fermented volume for the same energy input

• Better temperature control during fermentation

• Multifunction: traditional thermovinification or flash détente

• Easier tank emptying (with liquid-phase fermentation)

• Continuous process until alcoholic fermentation

• Full value recovered from underripe or damaged grapes

• In-line enzyme injection at the outlet of the flash vacuum tank for optimised efficiency

• Programmable controller with intuitive touchscreen interface

• Skid-mounted module, ready to use

• Possibility of installation on a trailer for multisite use or for cooperatives

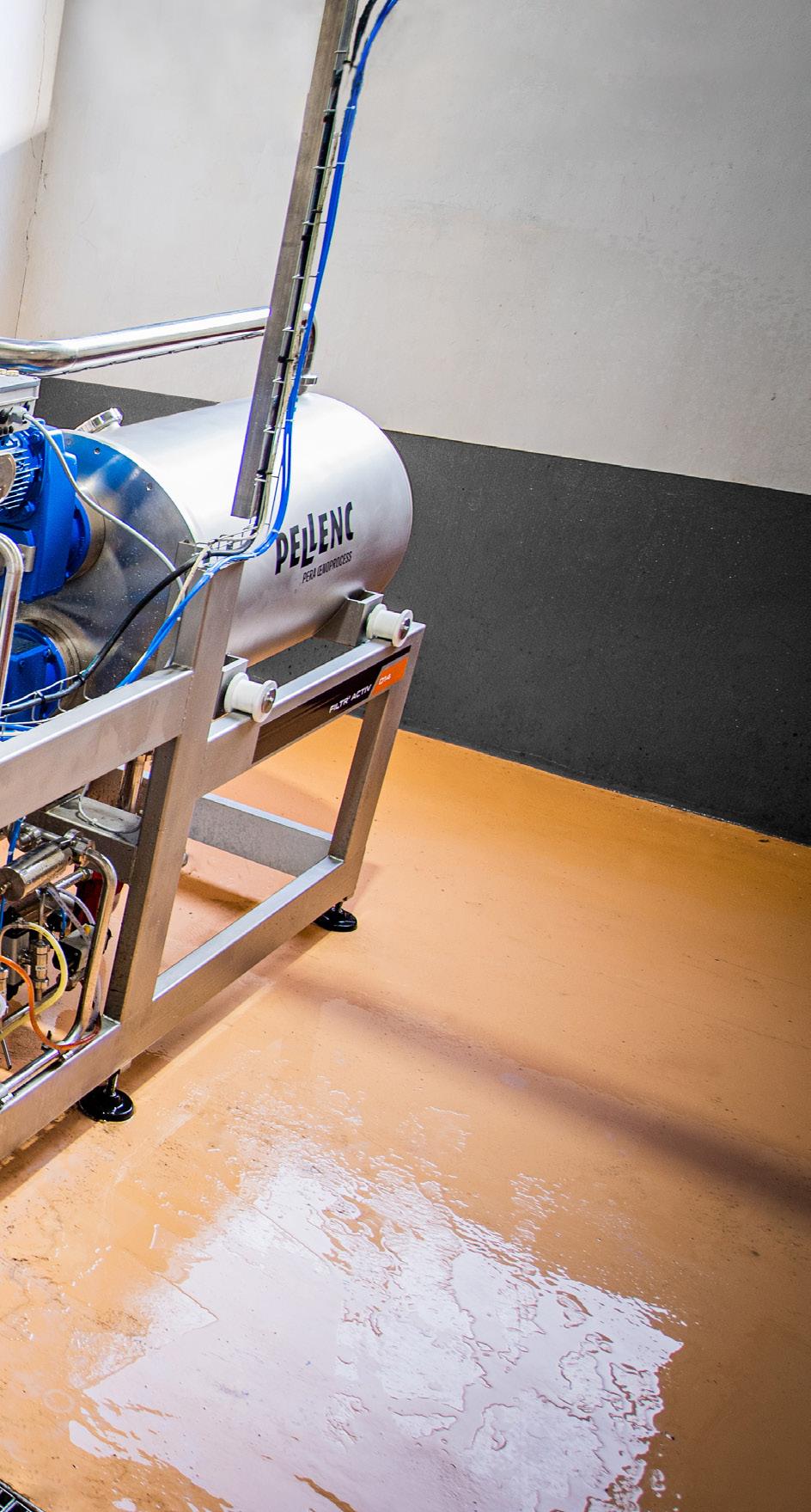

“A filter that adapts to wines of all types and wineries of all sizes”

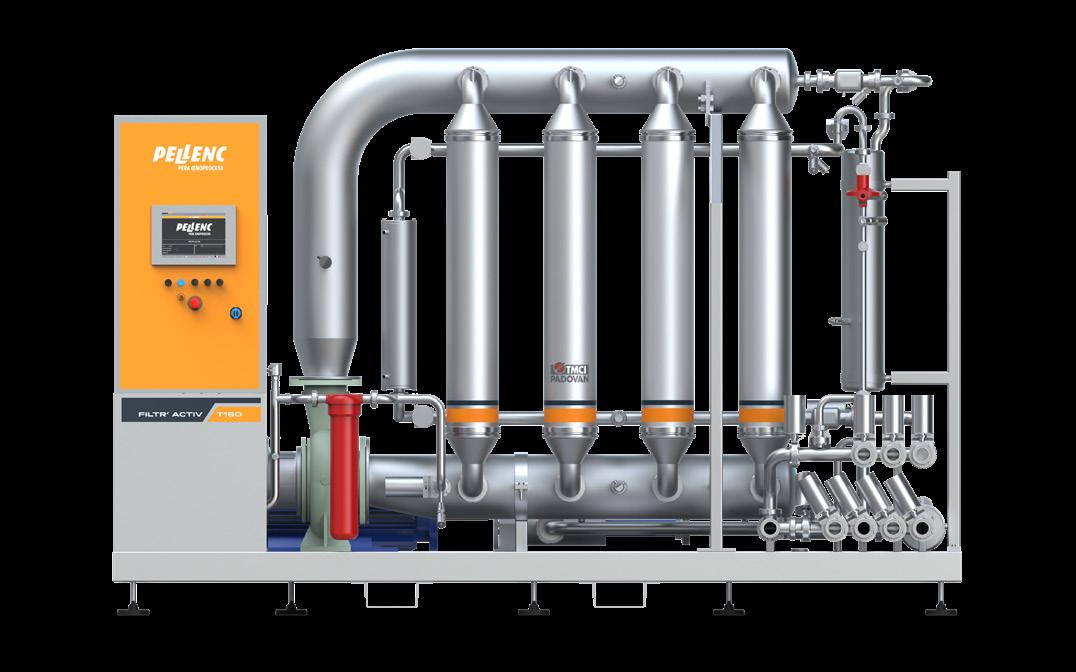

A precise, reliable cross-flow filtration solution, designed to adapt to all types of wines and optimise every stage of clarification. Available with ceramic or organic membranes, the FILTR’ACTIV T series guarantees high product compatibility and consistent performance in all configurations. Its automated touchscreen control simplifies operation, ensures complete cycle traceability and contributes to optimised, economical filtration, with reduced environmental impact.

• Filtration of juices, solids, wines and lees

• Quality of filtered products preserved

• High daily filtration capacities

• Residual filtration system to limit waste

• Six models available to suit your needs

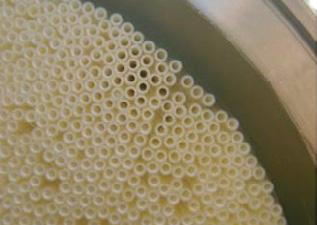

• Interchangeable membranes: organic (PES/PP) or ceramic

• Preset programs adapted to each type of wine

• Multiple inlets/outlets to automate your flows (option)

• 12” touchscreen interface with intuitive navigation

• Configurable automated operation

• Automatic unattended cleaning and storage

• The controller checks for filter cleanliness with a conductivity sensor

• Lower water and energy consumption

• Robust, durable stainless steel design

• Reduced operating costs

Circulation pump

Touchscreen interface

Back wash system

Filtration modules

The FILTR’ACTIV T range provides cross-flow filtration with a fixed membrane. Three types of membrane are available: organic PES, organic PP and ceramic.

The machine’s operation can be customised via the touchscreen interface to suit your winery’s needs.

• Production: volumes, valves and wine types chosen by the operator

• Cleaning: automatically programmed after the end of the first stage

• Storage: automatically programmed after cleaning

• Nitrogen saturation: limiting the product’s contact with oxygen in each filtration stage.

• Isobaric filtration: filtration of sparkling wines.

• Turbidimeter: continuously monitors the turbidity of the permeate, providing traceability and enabling production to be stopped in the event of deviation.

• Multiple inlets/outlets: the FILTR’ACTIV T can be equipped with three product inlet and outlet valves to automate the sequencing of filtration tanks or even blending.

• Residual filtration: reduces the amount of residual product at the end of the filtration cycle.

* Depending on the filterability of the product, the temperature and on a basis of 20h/d.

“The most effective filter on the market for products with high solid contents”

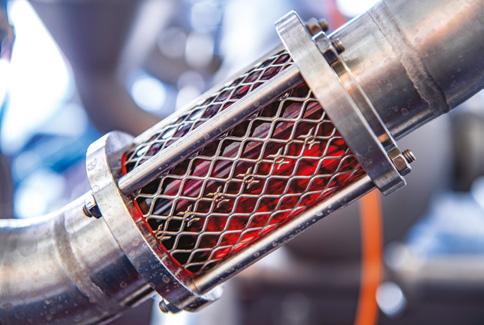

A cross-flow filtration system with rotating ceramic discs, designed for the optimum treatment of products with high solid contents. Thanks to the combination of slowly-rotating ceramic membranes and an innovative design limiting residual volumes, the FILTR’ACTIV D provides efficient clarification of solids, lees, retentates and tank bottom residues. It offers the best alternative to conventional rotary vacuum filtration technologies and systems using diatomaceous earths (kieselguhr, perlite etc.).

FILTRATION SUITABLE FOR PRODUCTS CONTAINING HIGH SUSPENDED SOLIDS

• Filtering of solids, lees, retentates and tank bottom residues

• Suitable for use with all types of oenological inputs

• Maintains temperature stability

• High clarification rate and consistent filtrate quality

• Pumped supply to the tank (stirred tank required)

• Long-life high-density ceramic discs

• Exceptional mechanical strength and chemical resistance

• Up to 92% by volume recovered*

• Processing capacity of up to 300 hl/day depending on model

*Depending on grape variety, temperature and filterability of the product

INTUITIVE INTERFACE

• 12” touchscreen with settings for each product

• Volume and filtration mode selection

• Automatic cycle start

CONTROLLED, SELF-PROGRAMMED MAINTENANCE

• Automated washing

• Reduced water and energy consumption

• Simplified, automated maintenance

Touchscreen interface

Ceramic disc rotation motors

Circulation pump

Built-in chemical suction pump

Dome containing filter discs

Filtered product inlet/outlet

FILTR’ACTIV D is a dynamic cross-flow filter with high-performance ceramic discs. The membranes, rotating slowly inside the filter tank, ensure homogeneous processing of the product.

This only technology of its kind on the market guarantees exceptional membrane durability.

The FILTR’ACTIV D is particularly suitable for filtering products containing suspended solids, such as solids, lees, retentates and tank bottom residues.

The FILTR’ACTIV’s operation can be customised via the touchscreen interface to suit your winery’s needs.

Programming modes:

• Production: volumes, valves and wine types chosen by the operator

• Cleaning: programming and automatic launch

• Storage: automatically programmed after cleaning

• Emptying: transfer from mixing tank to lee tank

Operating temperature conditions 0 – 50°C

Installed power

Power supply

4.9 kW, standard 380 V, 3-phase, 50 Hz, 60 Hz

* Depending on the filterability of the product, temperature etc.

8.9 kW, standard 380 V, 3-phase, 50 Hz, 60 Hz 15 kW, standard 380 V, 3-phase, 50 Hz, 60 Hz

3P + 400 V 16 or 32 A

480 V / 60 Hz power supply available for USA and Canada

Coaxial corrugated tube heat exchangers specifically designed for the heat treatment of:

• the harvest

• musts containing solids, pulpy juices

A spiral is created inside the internal tube using a process specific to PELLENC PERA OENOPROCESS: a continuous coil-shaped imprint is produced by deformation of the tube. This causes an increase in turbulence, and thus in the exchange coefficients. Modules are connected by easily-removable elbow fittings. The corrugated tubes and the elbows form a continuous section, with no narrowing or dead zones, so that no deposits can build up.

• Refrigeration

• Touchscreen fermentation control

• Thermostat with dual reading/setpoint display

• Stainless steel cabinet

• Pneumatic solenoid valve

BENEFITS

• Continuous control of refrigeration requirements tank by tank

• Reduced risk of excess heat

• Assurance of maintaining the required temperature

• Scalable computerised system

The winemaker measures and enters the density on the touchscreen to control the fermentation kinetics. The temperatures of all the tanks, their setpoints and the statuses of the heat exchangers are displayed continuously in real time. By selecting a tank, the winemaker can access temperature variations over the last 10 days or, with greater precision, the last 24 hours.

The graphical temperature control interface fulfils all the requirements of even the most demanding winemaker.

• Export all the control information to a computer (essential for correct batch traceability)

• View and control the operation from a computer or internet network

• Fermentation control interfaces with the PELLENC Connect application. See detailed page.

PELLENC CONNECT is a single portal for tracking the activity of all PELLENC connected equipment via a single account. Winegrowing (wide or narrow rows), winery equipment, arboriculture, battery tools: all these different worlds gathered together in one place!

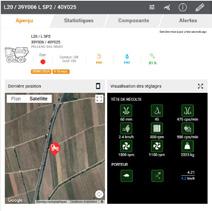

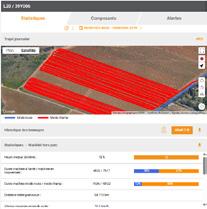

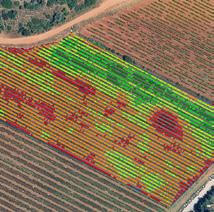

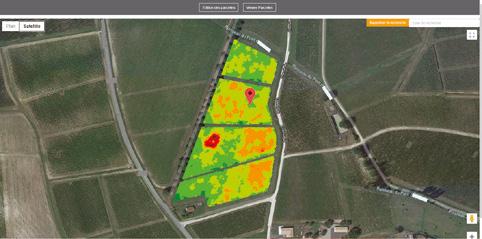

Fleet tracking, yield and vigour mapping

Multifunction harvester | Winegrowing tools for the harvester |

Self-propelled and tractor-drawn harvesting machine | Straddle tractor |

Self-propelled arboriculture harvesting machine

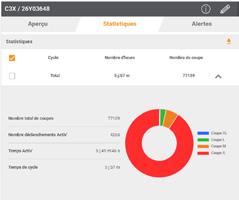

Settings, statistics

C3X pruning shears | F3X tying machines

Production monitoring

Press | Tank temperature control | Chiller unit

The PELLENC CONNECT platform connects all your equipment, from the vineyard to the winery, for real-time global control from a computer, tablet or smartphone.

• Instant view of machine statuses and settings

• Yield and vigour mapping and pressing and fermentation curves

• Usage history and complete traceability of operations

• Automatic alerts in the event of faults or anomalies

• Reminder of maintenance intervals

ANALYSIS AND TRACEABILITY

• Centralisation of all agricultural, oenological and technical data

• Technical and economic analysis of production cycles

• Monitoring of yields and input quality

• Optimisation of settings to increase accuracy and efficiency

• PELLENC’s experts are informed at the same time as the user if an alert occurs

• Real-time remote troubleshooting and direct transfer of operations to the after-sales service staff

• Optimised, accelerated technical support

• Personalised advice to optimise equipment use

• Remote technical support

• Coordination between winegrowers, oenologists and technicians

OPTIMUM multifunction harvesters

• Geolocation and screen sharing

• Configurable alerts

• Yield mapping (continuous weighing during harvest)

• Vigour mapping (via VISIO sensor on TLVP pre-pruner)

Presses, tanks, cooling process, and SMART WINELYSE dealcoholization units can be connected and monitored via PELLENC CONNECT:

• Remote control of pressing and setpoint temperatures for thermal regulation of tanks

• Monitoring information on refrigeration production and distribution

• Real-time monitoring of the press status and remaining time

• Exporting and analysing pressing curves to optimise programs

• Remote monitoring of customers’ and dealers’ equipment

• Access to diagnostic data and machine settings

• Analysis of pressing curves to optimise programs based on oenological results

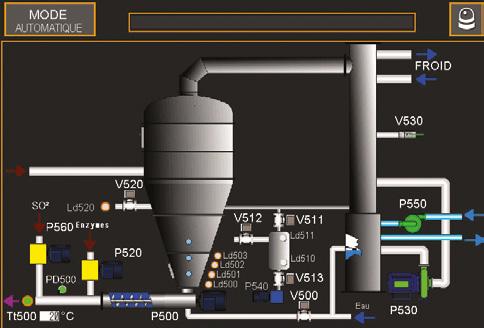

PELLENC PERA OENOPROCESS automation ensures centralised, secure control over all stages of the winemaking process. With user-friendly interfaces and high-performance monitoring solutions, these systems ensure accurate, responsive control over equipment, contributing to operational traceability, performance optimisation and management of critical parameters.

CRUSH PAD AUTOMATION

• Reception of the harvest

• Grapes in hoppers

• Whole clusters for crémant wines with press feed distribution system

• Control over selection valves between the crush pad and the presses and transfer circuits to the pomace screws

PUSHING THE GRAPES AND CLEANING THE PIPEWORK

• Pig pusher system: quick, complete pipe drainage

• Improved traceability of tank filling

• Reduction in the volume of water used for washing

• Centralised viewing of all presses on a single PC interface

• Real-time monitoring of cycles, defects and operational status

• Optimised cycle times and organisation of the presses

• Centralised control of transfers between heating systems, maceration and storage tanks, and FLASH DÉTENTE installations

• Automated cycle management

• Control over the system for evacuating pomace to the presses

• Automatic sequencing

• Touchscreen control over tank temperatures, with the option of remote control

• Connected regulation: email/SMS alerts sent automatically if there is a fault in the refrigeration unit or a temperature deviation

• Temperature history for each tank

2025 SMART WINELYSE

2021 FILTR'ACTIVE COUPLING

SMART PRESS

2019

SMART GLASS

KLINER

KLINER SORTING TABLE

2018

SMART PRESS

OENOSM'ART

2017 SMART PRESS

2016 SMART PRESS

2015 GREEN CRYOTM

2014 PRIX GRANDES ENTREPRISES

2013

2012

2011

2010

2008

SELECTIV’ PROCESS WINERY

EXTRACTIV’ 2

ENOXY+ PRESS

SELECTIV’ PROCESS WINERY

SELECTIV’ PROCESS WINERY

SELECTIV’ PROCESS VISION 2

ENOXY PRESS

1999 PRESS

CLUSTER PROVENCE ROSÉ: Wine innovation trophy

SITEVI: Bronze medal

SITEVI: Silver medal

SITEVI: Bronze medal: wine press

ENOMAQ: Outstanding technical innovation award

ENOMAQ: Technical innovation award

SIVAL: Innovation award – bronze trophy

VINARIA (International Fair Plovdiv): Innovation award in the machinery and technology for wine and spirits production category

VINITECH: Commendation – mobile thermovinification equipment using flash détente technology

ENOMAQ: Technical innovation award

SIVAL: Innovation award – machinery and automation

VINITECH: Range of intelligent, high-quality pneumatic presses

DYONISUD: Innovation award

SITEVI: Silver medal, multifunction refrigeration unit

FRENCH ENVIRONMENT MINISTRY: Business and environment awards 2014, eco-product for sustainable development category

INTERVITIS: Gold medal

VINITECH: Bronze medal

VINITECH: Bronze medal for “antioxidant injection during final pressing”

SITEVI: Commendation

VINITECH: Commendation

VINITECH: Silver medal

DYONISUD: First prize for innovation: “juice flow in an inert atmosphere”

SITEVI: Gold medal: “Conductivity/juice quality correlation in a pneumatic press” Excellence series, dual walls for cooling

1993 PRESS Automatic programmable pressing with a pneumatic press

1992 ELITE TANK On-skin maceration for white and rosé wine

1989 PRESS Automatic drain washing with pneumatic press

Patented equipment. The technical characteristics and photos are provided for information only, and are not binding in any way.

reserves the right to make any changes or improvement to its products that it deems necessary without notice.

on PEFC-certified paper.

PERA-PELLENC • Route d‘Agde • 34510 Florensac • France

Tel.: +33 (0) 4 67 77 01 21 • Fax: +33 (0) 4 67 77 00 44 • Email: pera@pera.fr

PELLENC S.A.S. • Quartier Notre-Dame • Route de Cavaillon • 84120 Pertuis • France

Tel.: +33 (0) 4 90 09 47 00 • Fax: +33 (0) 4 90 09 64 09 • Email: contact@pellenc.com

www.pellenc.com