LEVERAGING 60 YEARS OF BUILDING FAÇADE KNOWLEDGE

Building with Stone Wool

Insulated Sandwich Panels

Building with Stone Wool

Insulated Sandwich Panels

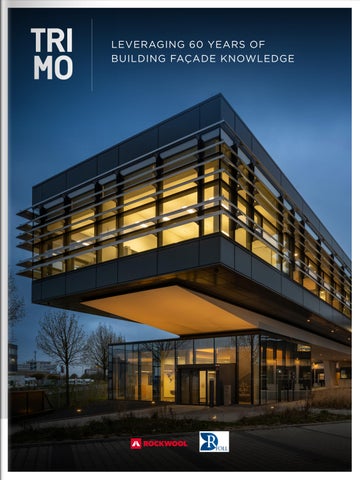

Equipped with unmatched knowledge of building façades garnered from over 60 years in business, Trimo takes building envelope solutions to a new level. We speak to Nay Tawile, CEO, and Janez Kunič, CCO, about the company’s next-generation product line, undeniable commitment to customers, and drive for sustainable architecture

Writer: Lucy Pilgrim | Project Manager: Cameron Lawrence

The European façade sector is one of the most demanding in modern-day construction.

Industry players are contending with inflation and rising interest rates that are putting pressure on investment decisions.

Nevertheless, increasing emphasis on energy and sustainability regulations, together with higher requirements for safety, are creating a highly dynamic sector.

“Customers now expect more reliable, energy-efficient solutions, delivered with speed, transparency, and predictable quality over the full lifecycle of a project,” opens Nay Tawile, CEO of Trimo, leaders in high-performance building envelope solutions.

This raises the bar for performance and opens up many opportunities for companies that are willing to adapt, differentiate, and respond quickly to customer needs.

“Every project, market, and customer brings new challenges, but there is also a chance to create meaningful, future-focused solutions. It’s a space where innovation and customer-centric thinking can truly make a difference,” adds Janez Kunič, CCO.

These conditions provide the perfect environment for companies to differentiate, build long-term

partnerships, and shape how buildings will perform over the next 30 to 40 years.

“For Trimo, this context reinforces our focus on high-performance façade and building envelope solutions, reliable execution across many countries with different norms and regulations, and the capability to serve fast-growing segments, such as data centres and global industrial players, which operate across multiple markets,” Tawile expands.

Having experienced an upward trajectory since its inception in 1961, Trimo today is recognised as a global leader in premium stone wool core sandwich panels for façades and roofs, having delivered more than 60 million square metres of façades to over 25,000 clients globally.

With more than 450 employees, production facilities in Slovenia

• 450+ employees

• Sells to over 120 countries

• Operates a commercial network across 30 markets

• Two production sites

and Serbia, and a strong sales network across nearly 30 countries, the company works closely with architects, investors, and contractors worldwide.

Moreover, Trimo’s project portfolio includes collaborations with highly reputable organisations such as Airbus, Heathrow Airport, Nestlé, Philips, DHL, Porsche, IKEA, Prologis, Mercedes-Benz, and Coca-Cola.

This demonstrates the trust placed in Trimo’s products and the value it brings to complex architectural and industrial projects.

“Our solutions are mainly used in high-tech industries, data centres, and logistics, where customers need reliable fire performance, strong energy efficiency, and architectural quality in often complex, multicountry operations,” insights Tawile.

Together with REX Panels & Profiles (REX), Trimo is proud to represent the Insulated Panels division within Recticel Group (Recticel) – a Belgian organisation focused on advanced thermal and acoustic insulation solutions and supporting the energy transition.

Indeed, being part of Recticel greatly expands Trimo’s network, granting access to new customers and partnerships and strengthening its credibility in key markets.

“We combine our façade expertise

“WE STAY ENGAGED FROM THE EARLY PLANNING STAGES ALL THE WAY TO INSTALLATION, OFFERING TECHNICAL GUIDANCE AND RESPONSIVE COOPERATION. THIS COMBINATION OF ADVANCED TECHNOLOGY, RELIABILITY, AND CLOSE PARTNERSHIP IS WHY TRIMO REMAINS A PREFERRED CHOICE ACROSS EUROPE”

– JANEZ KUNIČ, CCO, TRIMO

with Recticel’s strong background in materials and innovation, creating solutions that are more competitive and aligned with future market needs. This connection helps us offer greater value to our customers and strengthens Trimo’s position across all our regions,” Kunič expands.

Being part of the group also greatly advances the company’s investment capabilities.

“Within the Insulated Panels division, Trimo, together with REX, benefits from the financial strength and insulation know-how to fund new capacity, technologies, and product development.

“A clear example is the new

insulated panels factory being built in the US under the Recticel umbrella. It’s a major investment that will anchor the group’s presence in the country and support our growth ambitions in the wider North American market,” Tawile reveals.

Trimo strives to go above and beyond with its vast range of products, most acutely emphasised by its flagship fire-resistant panel range, Trimoterm –known for its top-notch performance.

Qbiss One, meanwhile, offers architects a clean, precise, and highly flexible façade solution.

“In recent years, we’ve taken this even further by developing Qbiss Notch in collaboration with Pininfarina, bringing a new level of architectural refinement and design sophistication to the market,” Kunič informs.

The company’s customers value the fact its systems are fully engineered, meaning they address several critical requirements simultaneously, including fire safety, thermal efficiency, airtightness, and design.

“I often say we ‘produce unicorns’; we don’t just make panels – we deliver complete building envelopes with design and engineering support throughout the project.

“Building with stone wool insulated sandwich panels”, authored by Professor Marco Imperadori, is the first comprehensive guide dedicated to stone wool insulated sandwich panels. It combines concise industry insights with practical, real-world applications.

One standout example is the Isarphilharmonie at the Gasteig HP cultural quarter in Munich. Here, stone wool insulated sandwich panels help deliver concert-hall acoustics, robust fire safety and a highly sustainable envelope in a temporary yet architecturally striking structure. The project shows how sandwich panels can meet demanding performance requirements while enabling fast, flexible construction. Access your own version here

The BIM Studio by ROCKWOOL Core Solutions is here!

Discover a faster, more intuitive way to access high-quality data for your projects. From BIM models to building data!

Try it now and experience the difference

“Our partnership with Trimo is built on mutual trust and a long-standing relationship. I’m proud to see them recognised in the market for the high quality of their solutions, which fully leverage the benefits of stone wool.”

Bernard Plancade Managing Director ROCKWOOL Core Solutions

Our Spanrock® stone wool has passed the Cradle to Cradle Material Health assessment. As core material in sandwich panels, it combines strong mechanical properties with high-quality thermal performance. As a non-combustible material, Spanrock® helps contain fire, limits its spread and does not contribute fuel. It also prevents mould growth, making it a safe and durable choice.

Learn more here

“Our collaboration with Trimo shows how integrating sustainability into architectural practice can create both environmental and commercial value. By supplying Cradle to Cradle Certified® Material Health stone wool, we help project teams deliver safer, more sustainable buildings and strengthen their position in the marketplace.”

André Coelho Nunes Business Unit Director Sandwich Panels

At the Gweithdy workshop building at St Fagans National Museum of History in Cardiff, stone wool insulated sandwich panels help deliver a BREEAM-certified, high-performance space that combines energy efficiency, durability and comfort. Partner with ROCKWOOL Core Solutions to bring certified, sustainable envelopes to your next project. Scan the QR code for more

“Customers rely on us to solve details, interfaces, and compliance questions, not just supply materials,” Tawile tells us.

Indeed, Trimo is renowned for the support it provides to customers throughout their project lifecycles.

“We stay engaged from the early planning stages all the way to installation, offering technical guidance and responsive cooperation. This combination of advanced technology, reliability, and close partnership is why Trimo remains a preferred choice across Europe,” Kunič attests.

The company’s expanding presence across four regions is an additional strategic advantage as it allows Trimo to remain in close proximity to customers and truly understand what drives each market, whether it’s premium design, energy efficiency,

delivery speed, or overall project value.

“Each market operates at a different pace and with different expectations – from highly sustainability-driven Northern Europe to fast-moving, design-focused Western and Southern Europe markets and more cost-sensitive but rapidly growing regions in Central and Eastern Europe,” Tawile explains.

This diversity keeps Trimo highly adaptive and challenges the company to innovate with intention, ensuring its solutions meet a wide spectrum of technical, regulatory, and aesthetic needs.

“Our presence provides a clear competitive advantage as we can identify trends early, address regional requirements, and transfer best practices across our markets,” Kunič adds.

At the pinnacle of its leading building envelope solutions, data centres remain one of the strongest representations of Trimo’s technical expertise and delivery performance.

“Our work with global clients such as Google and Microsoft, as well as hyperscale projects like the Stargate UAE programme, confirms we can meet demanding specifications, coordinate large teams, and ensure reliable execution,” Kunič shares.

Trimo has several other recent projects that demonstrate the diversity of its portfolio. For instance, the company’s involvement with LEGO in the US and the Natural History Museum in the UK highlights its ability to support cultural and complex projects whilst also being compliant with the latest environmental guidelines.

“IN SHORT, SUSTAINABILITY IS NOT A SEPARATE PROGRAMMEIT IS PART OF OUR DAY-TO-DAY OPERATIONAL DECISIONS”

– NAY TAWILE, CEO, TRIMO

The company’s story began in 1961 as a small metalworking business in what was then Yugoslavia and is now Slovenia.

Over time, Trimo evolved to become a specialist in prefabricated steel construction elements, and in the 1970s and 1980s started developing its own façade and roof solutions. This work laid the foundations for what later became the Trimoterm fire-resistant panel range – a landmark product for the business.

The 1990s marked a period of strong international expansion with the establishment of new subsidiaries across Europe and the company’s first major projects outside the continent. A further step-change came in 2009 with the launch of the Qbiss One façade system, which strengthened Trimo’s position amongst design-oriented building envelope manufacturers.

In 2010, the high-tech ArtMe façade surface treatment received the Red Dot Design Award. The company subsequently refreshed its corporate identity six years later to reflect its global profile and focus on high-performance façades and roofs.

Another significant milestone in April 2022 saw Trimo become part of Recticel, strengthening its position within the broader European industrial network.

Today, more than six decades after its founding, the company continues to build on this heritage with a clear focus on innovation, architectural quality, and high-performance building envelope solutions, whilst actively reducing its environmental impact and supporting more sustainable construction.

Meanwhile, the company’s work with industrial clients worldwide showcases the durability, efficiency, and precision of its façade systems in demanding production environments.

“These projects highlight the breadth of our portfolio and trust customers place in Trimo,” details Kunič.

Alongside its industrial investments, the company is also working hard on improving operational excellence at its existing sites, with a number of product and process innovations in the pipeline.

Trimo lives and breathes its focus on sustainable architecture and design, with a strong commitment to reach net zero greenhouse gas (GHG) emissions by 2050.

This is supported by ambitious interim targets for 2030 which centre

around significant reductions in its direct (Scope 1 and 2) and indirect (Scope 3) emissions.

Such targets guide the company’s product development strategy and its decision-making around materials and design.

Qbiss One NEXT and Trimoterm NEXT – Trimo’s latest innovations in sustainable construction –are concrete evidence of its environmental approach.

Both achieve up to 69 percent lower carbon footprints compared to the standard Qbiss One and Trimoterm panels whilst maintaining the same performance expected of its façades and roofs.

More broadly, Trimo’s use of stone wool cores is an important part of its sustainability approach as it offers robust fire safety, strong thermal performance, and long service life, which help reduce customers’

environmental impact over the full lifecycle of their building envelopes.

This also means architects and developers don’t have to choose between design quality and green performance as Trimo’s façade systems support distinctive architecture and help move projects closer to their climate and sustainability objectives.

The company applies this same logic to its own internal processes.

“Sustainability starts with responsibility in our own operations. We want to be a company that leads by example not only through our products, but also in the way we work every day.

“That means continuously improving how we manage resources, reducing our environmental footprint, and making choices that reflect our long-term commitment to a greener future,” Kunič impassions.

For example, Trimo’s internal logistics fleet, comprising forklifts and on-site transport, is already fully electric, whilst more than half of the company’s cars and delivery vehicles run on electric or hybrid power, with the aim to eventually have a 100-percent electric fleet.

Trimo additionally generates its own electricity through an on-site solar power plant at its main

production site, directly reducing its operational emissions.

“Resource efficiency is another concrete focus – our production generates less than one percent residual waste. Therefore, topics like energy use, emissions, and waste are tracked with the same discipline as safety and quality in our regular management reviews.

“In short, sustainability is not a separate programme – it is part of our day-to-day operational decisions,” Tawile affirms.

Trimo’s success in the building façade space is built upon the professionalism and unwavering dedication of its people.

“Over the years, I’ve seen how their professionalism and commitment directly shape the trust our clients place in us. I empower them by removing obstacles, aligning teams around shared priorities, and ensuring they have the information and support they need to act confidently,” Kunič reflects.

Tawile echoes this belief in enabling staff to perform at their best by giving them clarity on priorities, cutting unnecessary bureaucracy, and pushing decisions as close as possible to the teams.

“I want people to feel they have the trust and space to act, not just follow procedures,” he elaborates.

Recognition is a cornerstone of this as each employee’s contributions are made visible across the company, whether it’s strong teamwork on a complex project, a smart improvement on the shop floor, or someone taking ownership in a difficult situation.

“The goal is a culture where colleagues feel empowered, accountable, and proud of the impact they have on our results and reputation,” Tawile prides.

Trimo likewise supports staff development through training and internal mobility, as well as providing direct feedback, clear expectations, and listening to people’s ideas.

Beyond upskilling and development, the company also pays close attention to the day-to-day wellbeing of its employees.

Case in point, Trimo regularly improves working conditions by installing extra air coolers and cooling stations for staff in the summer and providing healthy, well-balanced hot meals to all employees every day.

In 2026, Trimo’s utmost priority is to reinforce its leadership in core European markets, with a particular focus on the fast-growing data centre segment alongside high-tech industry and logistics projects.

“The dynamic expansion of data centres offers substantial potential for Trimo, and our solutions and services are already widely recognised and trusted by professionals in this field,” Tawile sets out.

So much so, the company is considered a reference point for premium stone wool core sandwich panels.

However, Trimo’s ambition is to further strengthen this position, stay ahead of competitors, and capture additional growth in overseas markets such as the Middle East and Southeast Asia.

The company’s other area of focus is growth in North America, achieved by building the right partnerships, aligning with local requirements, and advantageously positioning itself to support global customers consistently on both sides of the Atlantic Ocean.

“The third priority is operational excellence – improving productivity, reliability, lead times, and service across our sites whilst simplifying the way we work. This will empower our teams so that more decisions are taken closer to the customer and production line,” Tawile concludes.

Tel: +386 (0)7 34 60 200 trimo@trimo-group.com www.trimo-group.com