21 - 23 October 2025 | ICC Sydney, Australia

21 - 23 October 2025 | ICC Sydney, Australia

The International Mining and Resources Conference + Expo (IMARC) is Australia's largest and most influential mining event, serving as the country's leading platform for the global mining industry to come together, deliver ideas, and ignite discussions. With a high-calibre conference, an extensive showcase of leading suppliers, and a variety of networking opportunities, IMARC highlights the latest trends and technologies driving the entire mining value chain forward. The 2025 conference theme, "Strengthening Supply Chains, Optimising Costs, and Driving Productivity," will delve into pressing topics such as business resilience, technological innovations, and operational efficiency.

10,500+ Registrants

1,000+ Mining Company Attendees

550+ Speakers

120+ Countries

500+ Exhibitors

20,000m2 Exhibition Floor

Head of Editorial: Jack Salter jack.salter@outpb.com

Deputy Head of Editorial: Lucy Pilgrim lucy.pilgrim@outpb.com

Senior Editor: Lily Sawyer lily.sawyer@outpb.com

Editor: Ed Budds ed.budds@outpb.com

Editor: Rachel Carr rachel.carr@outpb.com

Copy Editor: Lauren Kania lauren.kania@outpb.com

Art Director: Stephen Giles steve.giles@outpb.com

Senior Designer: Devon Collins devon.collins@outpb.com

Designer: Louisa Martin louisa.martin@outpb.com

Production Manager: Alex James alex.james@outpb.com

Digital Marketing Director: Fox Tucker fox.tucker@outpb.com

Web Content Manager: Oliver Shrouder oliver.shrouder@outpb.com

Social Media Executive: Jake Crickmore jake.crickmore@outpb.com

CEO: Ben Weaver ben.weaver@outpb.com

Managing Director: James Mitchell james.mitchell@outpb.com

Chief Technology Officer: Nick Norris nick.norris@outpb.com

Finance Director: Suzanne Welsh suzanne.welsh@outpb.com

Finance Assistant: Victoria McAllister victoria.mcallister@outpb.com

CONTACT

Mining Outlook

Norvic House, 29-33 Chapelfield Road Norwich, NR2 1RP, United Kingdom. Sales: +44 (0) 1603 804 445

Editorial: +44 (0) 1603 804 431

SUBSCRIPTIONS

Tel: +44 (0) 1603 804 431 jack.salter@outpb.com www.mining-outlook.com

Follow us on Linkedin: @miningoutlook

Follow us on X: outlookpublish

Welcome to our 11th edition of Mining Outlook.

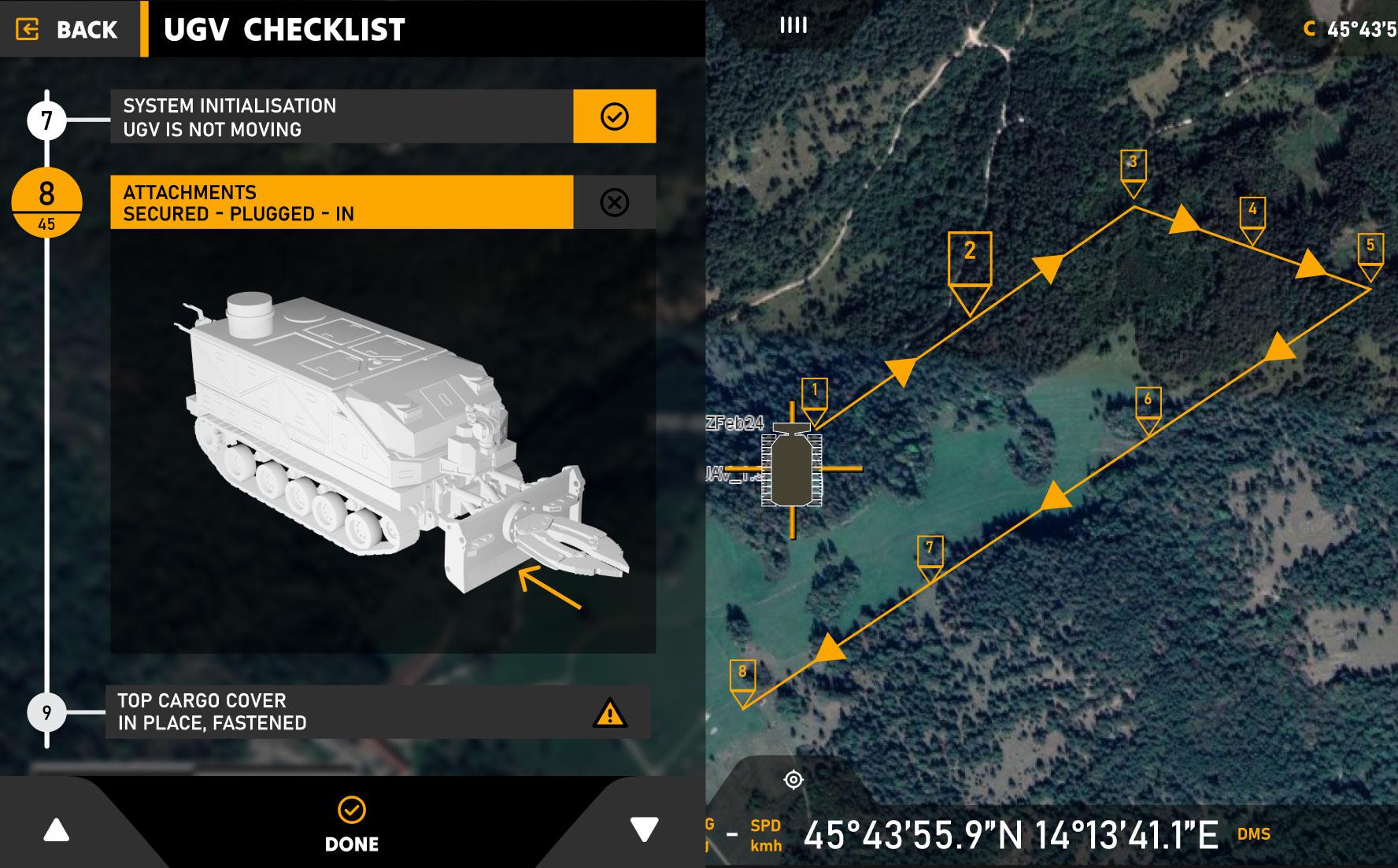

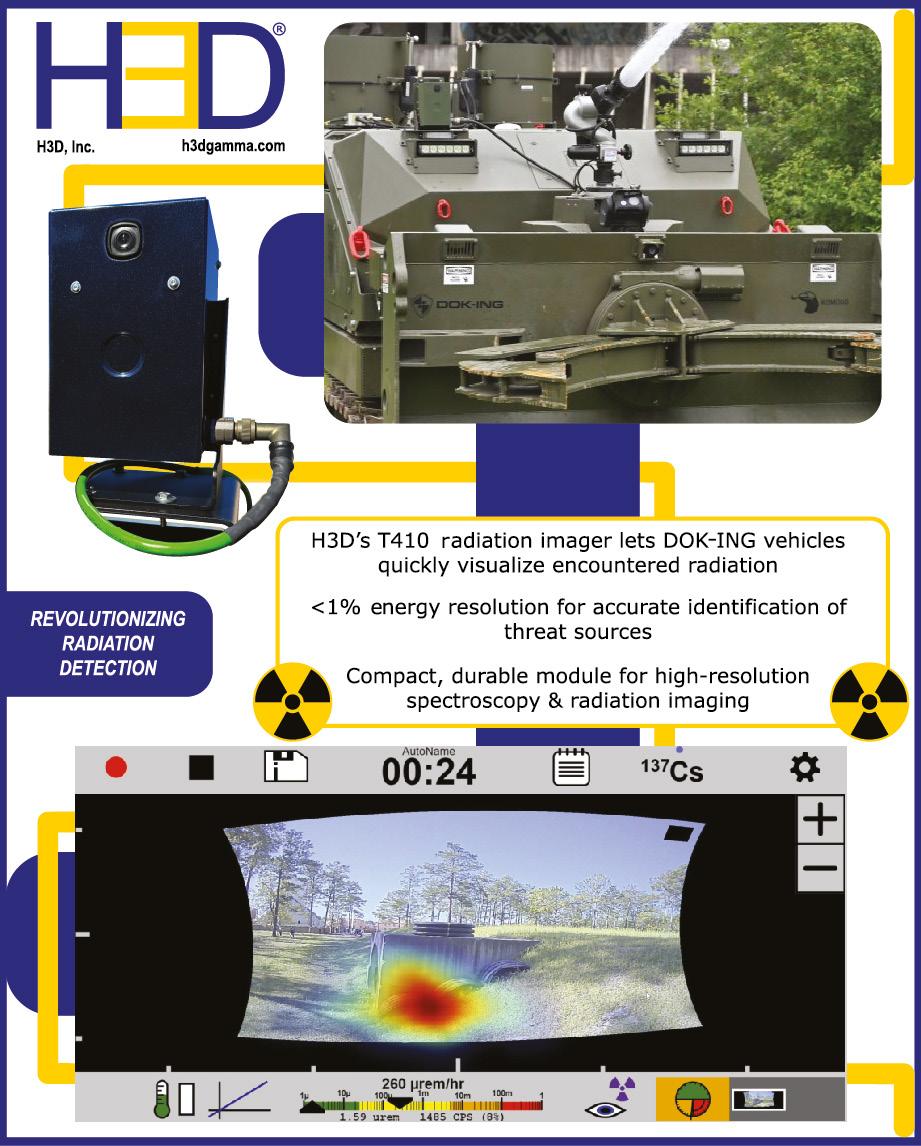

Leading this issue’s front cover, along with the charge in heavy-duty robotics and autonomous systems, is DOK-ING.

The Croatian manufacturing powerhouse is globally renowned for producing world-class unmanned vehicles that protect human lives in otherwise hazardous and harmful environments.

DOK-ING Mining is recognised as a leader in innovative ultra-low and extra-low profile mining solutions and building a future where mining is no longer seen as dangerous or outdated, but as a space of innovation, safety, and high efficiency.

It has pioneered a state-of-the-art fleet of narrow reef equipment (NRE), which is poised to become the global benchmark in mechanised mining.

“What began as a bold idea is now setting the standard for what’s possible in some of the world’s most challenging underground environments,” insights Luka Petro, COO of DOK-ING Mining.

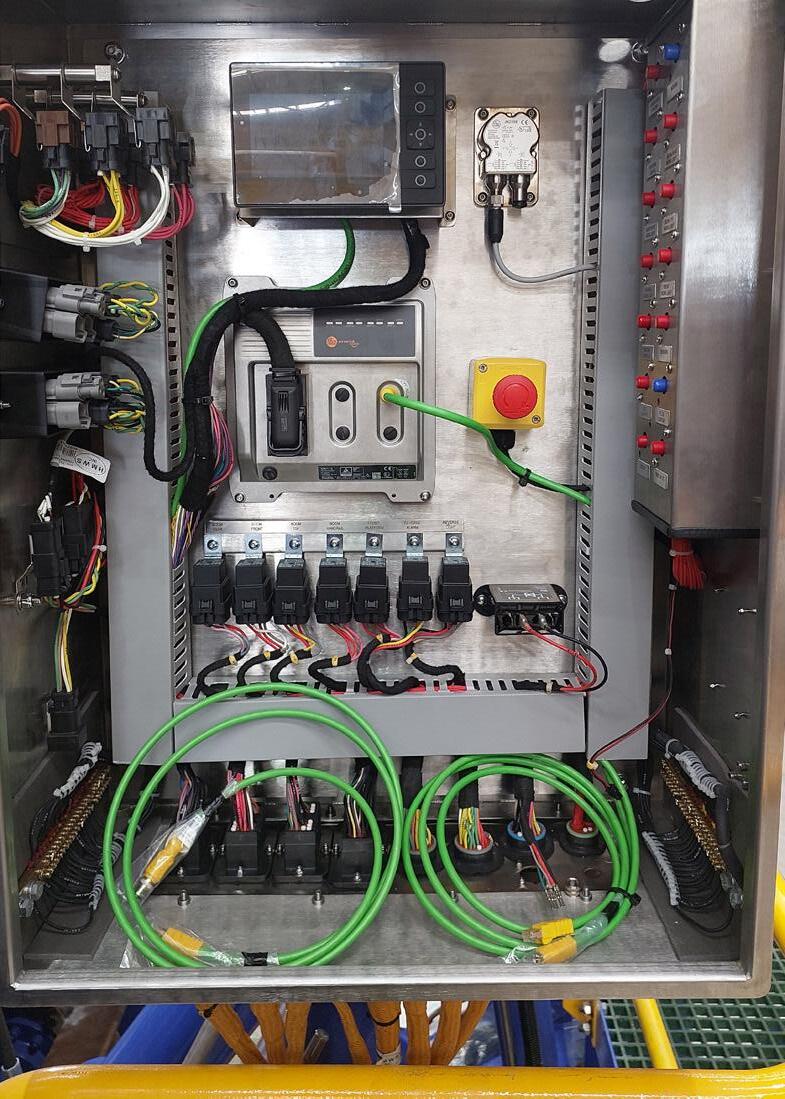

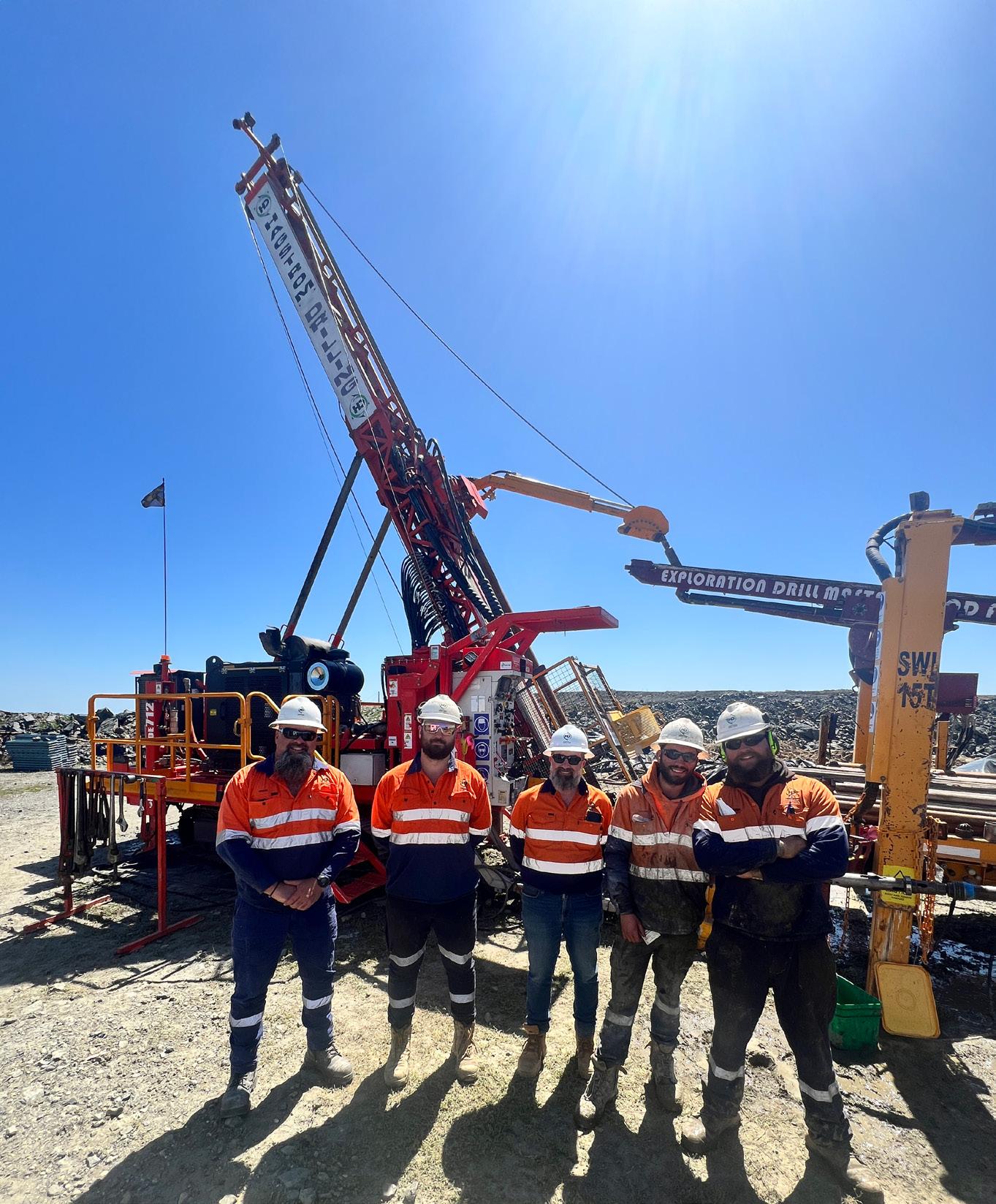

Wallis Drilling, a leading drilling services provider with extensive experience throughout Australia, also offers a comprehensive array of modern drilling methods.

One key project the company remains particularly proud of is the development and successful deployment of its Mantis 200 air core rig.

“This represents the latest evolution of our in-house engineering capability – a fully self-contained, high-capacity air core rig with advanced safety and automation features,” acclaims Grant Wallis, CEO and Managing Director.

Elsewhere, Caravan Resources Group is redefining the industry landscape in Central Asia, positioning Kazakhstan as a leader in next-generation metallurgy and mining.

What sets the company apart is its specialisation, flexibility, and deep understanding of technology.

“Our expertise lies in leaching, combining local specialists experienced in handling poor, complex compositions and harmful impurities like arsenic, bismuth, and antimony. By collaborating with an international team, we leverage local knowledge and global experience, providing us with a technological edge,” outlines CEO, Rustam Dussipov.

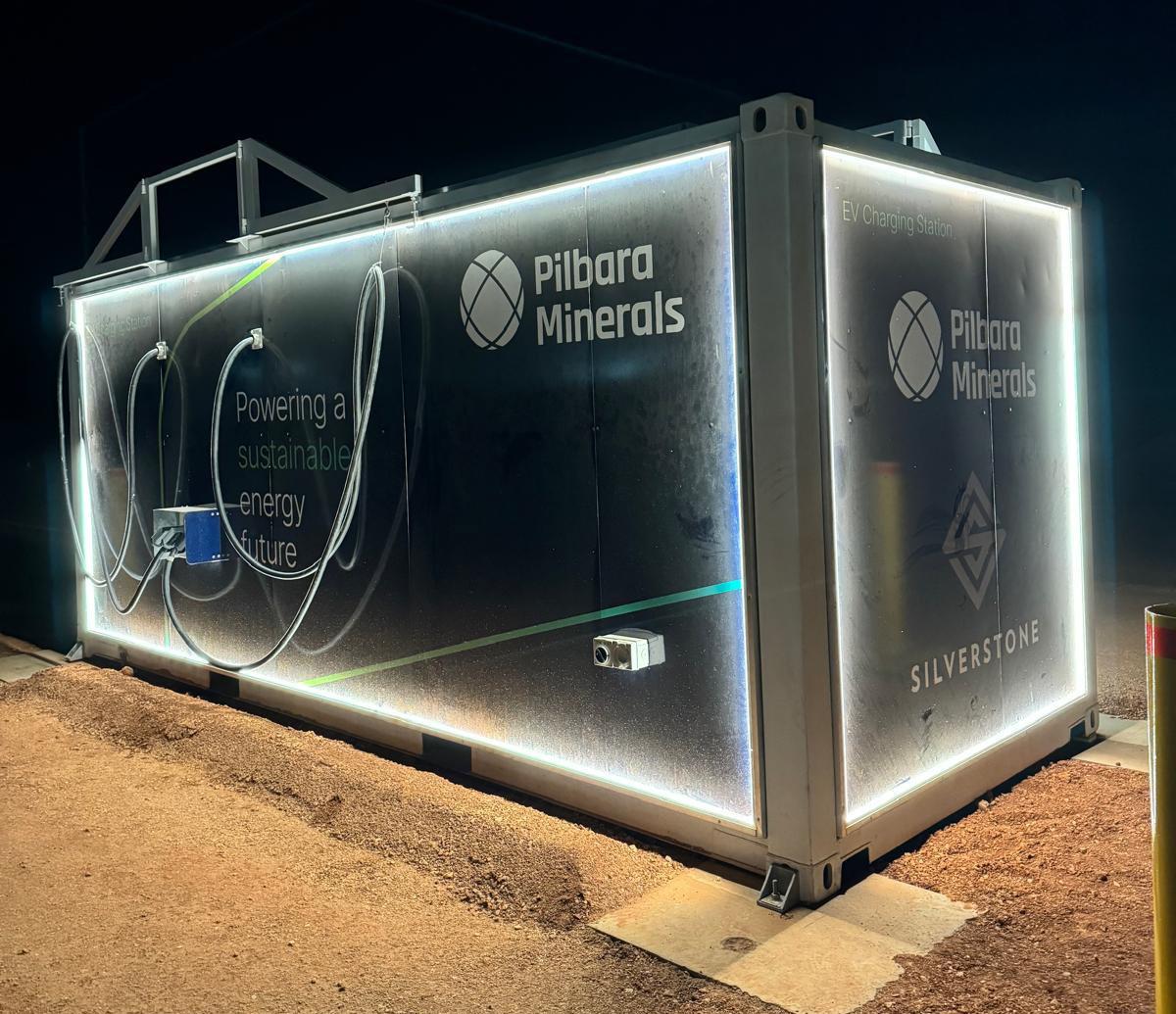

In this bumper issue, we also delve into the latest mining innovations and technologies being utilised by Master Drilling, Silverstone, National EWP, Titeline Drilling, and many more.

We hope that you enjoy your read.

Jack Salter Head of Editorial, Outlook Publishing

POSTING ON SOCIAL media to millions of followers, US President Donald Trump declared that imports on gold will not face US tariffs following a federal ruling that sent global bullion markets into a frenzy.

A White House official recently indicated the administration would issue a policy that would clarify

ACLARA RESOURCES (ACLARA), a leading Canadianowned mineral developer, has entered into a strategic partnership with the Virginia Polytechnic

whether gold bars would face import taxes after US Customs and Border Protection announced imports of bullion would be subject to duties, causing chaos in global gold markets.

Despite Trump’s recent announcement, however, a formal updated policy is yet to be issued by government agencies.

WHAT WAS ONCE one of the UK’s largest surface mines is to be converted into a nature hub, marking the region’s first biodiversity site.

The conversion of Portland Burn in Northumberland has been highlighted as a new ‘habitat bank’ open to potential investors.

This follows previously fallenthrough plans to convert the land into housing, which the Northumberland County Council approved a £7.5 million loan for to property investors Advance Northumberland in 2017.

However, it was revealed earlier this month that the plans for this had never come to fruition and there is currently no chance of the loan being repaid, making way for this exciting green development.

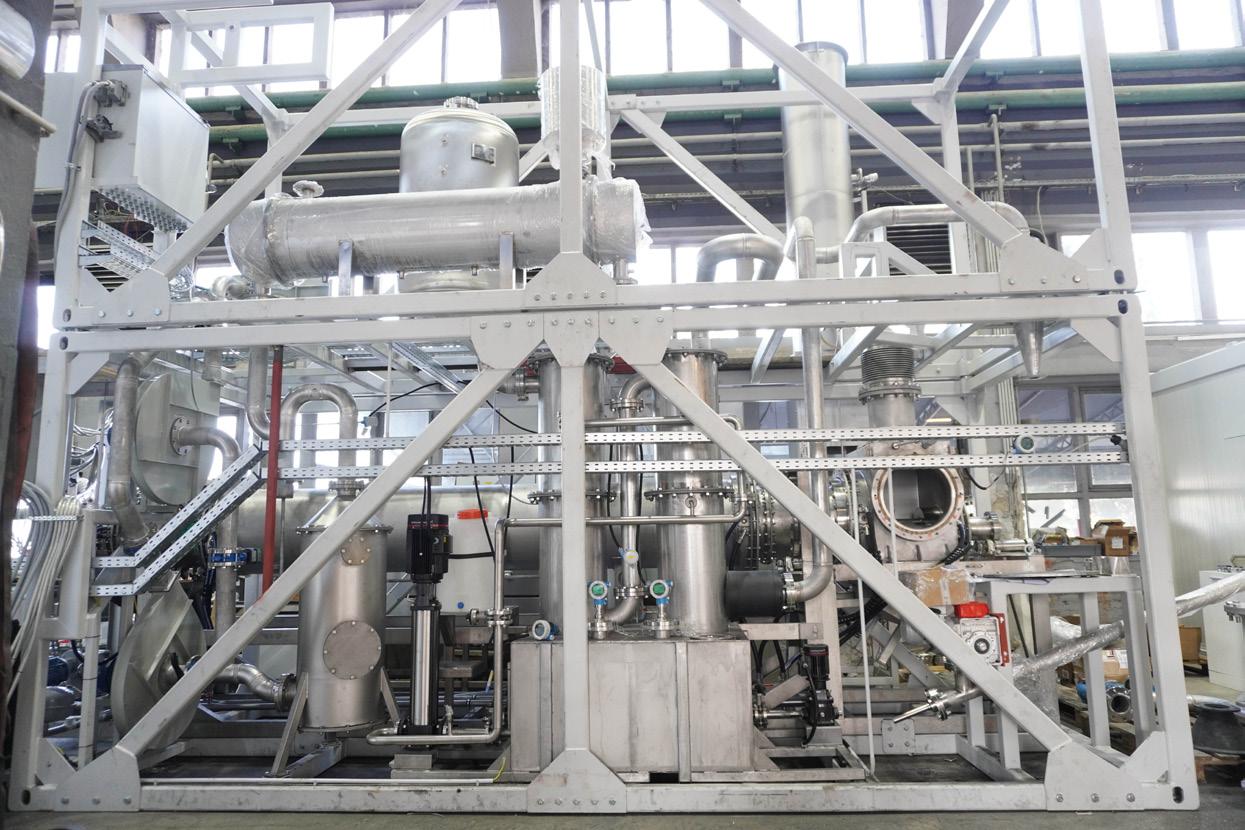

Institute and State University for the development and operation of its state-of-the-art separation pilot plant.

Currently being implemented at the Virginia Tech Corporate Research Center in Blacksburg, Virginia, the plant will highlight the advancements of Aclara’s solvent extraction technology to produce individual,

high-purity light and heavy rare earth elements.

Once operational, the separation facility is projected to produce over 99.5 percent pure neodymiumpraseodymium, terbium, and dysprosium, thus creating a supply chain for critical rare earth elements outside of China.

CATL – THE world’s leading battery producer – has announced the suspension of operations at its lithium mine in China, causing shares of other producers to skyrocket, amid speculation Beijing is making moves to overcome industrial overproduction. It is believed that the mine’s closure

A RECENT REPORT from BloombergNEF (BNEF) suggests the current surge in artificial intelligence (AI) data centres could have serious ramifications for the global copper market, leading to a supply shortfall of six million tonnes (t) by 2035.

BNEF analysts state that copper supply will average approximately 400,000t per annum in the next decade, peaking at 528,000 in 2028. The rapid rise in data centres, meanwhile, could require up to 4.3 million t by 2035, alongside

in the Jiangxi province could signify the country’s wider plans to tackle overcapacity in a range of its biggest industries, including lithium, a vital resource used in electric vehicle (EV) batteries.

However, the mine’s suspension is only temporary after one of its licences expired. CATL is currently going through the application process for permit renewal, with the mine’s closure having a negligible impact on the company’s overall operations.

increasing demand from other sectors, including power transmission and wind energy, where copper usage is forecasted to double in the next decade.

As such, global copper demand is expected to reach 35 million t in 10 years’ time, a far cry from the 29 million t of projected copper supply.

WEST CUMBRIA MINING (WCM), a metallurgical coal producer, was granted permission to build a brand-new coal mine in Whitehaven, Cumbria. However, the plans were later scrapped by a High Court judgement over environmental concerns.

As a result, both WCM and its Singaporean investor, Woodhouse Investment, are suing the UK government for compensation in an investor-state dispute settlement taking place through an international trade court.

The current Labour government set a deadline for WCM to decide whether they wanted to continue with the mine development process, but the company later dropped the plans.

ASIA PACIFIC

EVOLUTION MINING (EVOLUTION), Australia’s secondbiggest gold mining organisation, has more than doubled its full-year profits, setting a new record thanks to a sharp increase in the price of the precious metal.

According to a statement released this week, the company’s net income rose by 119 percent to AUD$926 million in the previous 12-month period, whilst its revenue generated from customer contracts also increased by 35 percent to AUD$4.35 million.

Evolution’s shareholders will reap the rewards of this growth as the company is set to pay a dividend of 13 cents per share, an increase from the five cents paid a year ago.

Ben Ting, Chief Commercial Officer at Echion Technologies, delves into the abundance of benefits afforded by the use of hybrid technology in the mining sector, paving the way for increased decarbonisation

Writer: Ben Ting, Chief Commercial Officer, Echion Technologies

The mining industry plays a crucial role in achieving mass electrification. The rapid rise in demand for the rare earth minerals that most battery technologies require has placed greater pressure on the industry to improve its productivity and efficiencies, but mining is also facing significant pressure to decarbonise its operations to meet global emissions targets.

Haul truck operations, for instance, currently contribute significantly to global carbon emissions at around 68 million tonnes of carbon dioxide (CO2) per year, the equivalent greenhouse gas (GHG) footprint of Finland or New Zealand, according to Rocky Mountain Institute. Therefore, choosing the right solutions to enable mines to run as cleanly and cost-effectively as possible is a major challenge for mine operators. However, emerging, innovative battery technologies are unlocking the possibility for hybrid-electric haulage trucks that offer a practical solution for industry decision-makers as they seek to transition towards full electrification.

The majority of mining sites are located in remote areas, which often presents challenges of limited grid capacity and a lack of charging infrastructure.

Although fully electric vehicles (EVs) could offer substantial reductions in emissions and the high cost of vehicles, significant upfront investment would have to be made in the supporting infrastructure to enable full integration in operations.

For many operators, the capital required to invest in both new vehicles and charging networks is not practical, but by combining advanced battery chemistry with conventional diesel systems, a potential move to hybrid technology can become a more viable nearterm solution.

The recent advancements in battery technology, such as Echion Technologies’ (Echion) niobiumbased anode material XNO® – which was specifically designed with industrial applications in mind – mean that hybrid haulage trucks are now a true possibility.

Standard lithium-ion batteries used in most passenger vehicles require a long time to fully charge but, when used in lithium-ion cells, XNO® offers outstanding performance characteristics that far outperform current mainstay batteries when applied in heavy-duty applications. These include rapid charging, an extended cycle life of more than 10,000 cycles, and market-leading safety attributes. These benefits are critical in mining operations where reducing downtime and improving operational reliability are paramount. In the demanding, hot, and humid underground conditions where mining trucks operate continuously, current ‘off-the-shelf’ batteries cannot provide the significant volumes of sustained power required for performance or safety, making efficient and safe hybrid mining vehicles a previously unviable option.

This changed in 2024 when we demonstrated the benefits of utilising our niobium-based anode technology through a collaboration with Switch Technologies. This saw the retrofitting of a mining workhorse vehicle, a Toyota Land Cruiser 79 Series, into a hybrid vehicle.

Although testing and refining are still ongoing, through our joint approach to collaboration and development, we have produced a working prototype hybrid vehicle that we believe will be able to complete around 90 percent of a standard shift for a vehicle of its kind on battery power.

This has illustrated the power of XNO® when utilised in a hybrid vehicle and demonstrates its ability to provide rapid charging and reliable performance, even in remote mining conditions.

A hybrid option also offers operators greater assurance and levels of comfort in terms of range anxiety. The design of our hybrid Land Cruiser prototype allows for easy mode switching at the discretion of the operator.

This flexibility is key for mining trucks, which are required to perform continuously across multiple settings. An operator can choose battery mode when the conditions support rapid, or even regenerative charging, and diesel mode when longer range is needed.

As a result, mining fleets experience increased uptime and efficiency whilst still contributing to a significant reduction in operational emissions.

Crucially, the project presents a commercially scalable model for decarbonisation in mining. By enabling operators to retrofit existing vehicles rather than committing to full fleet replacement, hybrid technology is able to provide a more capital-efficient route to emissions reduction.

It also enables the flexibility for mining companies to extend the operational life of their assets, manage costs, and begin their electrification journey at a pace that aligns with the current infrastructure and operational priorities.

Whilst the long-term benefits of fully electric mining vehicles are clear, waiting for supporting infrastructure to catch up will delay progress in the move to decarbonise operations and mining sites.

The hybrid approach provides a strategic stepping stone for operators to take advantage of today. It will

enable the industry to modernise its fleet and reduce its carbon footprint immediately, whilst the methodology, planning, and resources can only be considered for longer-term adoption of fully electric technologies.

The future of mining will be defined by innovation and collaboration. By utilising hybrid battery technology, industry decision-makers are able to move towards an essential milestone on the journey to fully electric, sustainable, high-performance operations.

Ben Ting is the Chief Commercial Officer at Echion with experience across the defence, high-value manufacturing, and transportation industries and expertise in systems engineering, technology commercialisation, and innovation.

At Echion, Ting is responsible for the company’s marketing, business development, sales, product management, and commercial management. This includes engagement with original equipment manufacturers (OEMs), end users, and cell and battery system manufacturers to accelerate the commercial adoption of Echion’s XNO® battery anode technology.

Blackrock Mining Solutions is a comprehensive resource for geotechnical challenges, emphasising tailored solutions based on client-specific needs and an unwavering commitment to problem-solving. General Manager, Andrew Seccombe, provides strategic insights on the company’s role in the industry

Writer: Rachel Carr

As a nation founded on abundant natural resources,

Australia’s mining industry is a powerhouse that has long been a cornerstone of its economy.

This dynamic sector makes a significant contribution to the country’s GDP and exports. Therefore, it is not surprising that a large number of mining companies, both small and multinational, are listed on the Australian Securities Exchange (ASX). With over 7,400 businesses operating throughout the Australian mining industry, services to provide ongoing support, guidance, and exploration strategies are essential. Primed to deliver these, and much more, is Blackrock Mining Solutions (BMS).

Initially established as a geotechnical consulting company, BMS has since expanded its capabilities and services within the construction and mining industry, which include geotechnical design and consultancy in underground and

surface mining, civil and tunnelling projects, as well as asset remediation projects.

The company also offers solutions for the provision of labour for ground support installation, ventilation device

installation and maintenance, ground consolidation and stabilisation, and waterproofing services.

Additionally, BMS supplies specialised underground mining and construction products, including grouts, cements, resins, and consumables, as well as a wide range of drilling equipment and concrete and shotcrete pumps for hire or sale.

Evidently, BMS is a vital resource for mining projects whose position as a leader in the industry can be attributed to its eagerness for problem-solving.

“Our people love the mining and construction industry; we are passionate about solving problems and delivering solutions – it is what we live and breathe every single day,” introduces Andrew Seccombe, General Manager.

“Our extensive range of products and services, combined with the expertise of our team, ensures our clients receive the best service possible.”

As the Australian mining industry continues to grow, it has revealed a significant gap in the workforce, primarily due to a critical shortage of skilled professionals.

This booming sector urgently needs qualified individuals to fill essential roles, underscoring the importance of attracting talent to sustain its growth and operations.

Additionally, there is increasing demand for expertise in specialised areas such as automation and digital technologies. Demand is exceeding supply as certain occupations within the mining industry are witnessing a decline in engineering and geology graduates.

Attracting and retaining talent therefore poses a challenge as many companies face high labour costs and experience competition for skilled workers from other sectors.

“Like many industries, the skills and labour shortage is a challenge and the market is highly competitive, making labour costs a significant portion of business’ expenses. We address this by offering attractive and competitive remuneration packages, training opportunities, and flexible working arrangements,” Seccombe assures.

Other urgent challenges include

“OUR EXTENSIVE RANGE OF PRODUCTS AND SERVICES, COMBINED WITH THE EXPERTISE OF OUR TEAM, ENSURES OUR CLIENTS RECEIVE THE BEST SERVICE POSSIBLE”

– ANDREW SECCOMBE, GENERAL MANAGER, BLACKROCK MINING SOLUTIONS

incorporating sustainability into mining solutions to enhance efficiency whilst minimising environmental impact.

“BMS is accredited with ISO 14001 for environmental management, which means sustainability is at the forefront of everything we do,” he informs.

Mining processes generate toxic waste materials that contaminate the surrounding air and water, thereby harming the communities and wildlife that depend on these resources.

“In recent years, BMS has collaborated closely with its joint venture (JV) partners to create better materials that lessen environmental and health impacts. This effort includes the development of non-toxic and non-hazardous consolidation resins, as well as lowcarbon grouts and cements, filling a gap where there were previously no viable alternatives,” explains

Seccombe.

These innovative materials offer a sustainable solution for the mining industry, significantly reducing the carbon footprint of mining operations and contributing to a greener future.

BMS has effectively customised its services to address the specific needs of various clients and projects, establishing itself as a comprehensive solutions provider for geotechnical challenges.

“The business structure enables us to first conduct geotechnical design, then tailor and supply appropriate materials, and finally execute the project,” Seccombe outlines.

For a project to achieve success, BMS places significant importance on the engagement stage, which involves collaborating closely with the client to tailor a solution that specifically addresses the project’s unique needs.

“We understand what is effective and what isn’t, so we are transparent and honest about what can be accomplished,” he acknowledges.

BMS is proud to highlight its recent accomplishment in executing an extensive grouting project at an underground coal mine in Queensland, demonstrating dedication to precision and cutting-edge solutions.

UNDERGROUND

• Grosvenor Mine

• Eagle Downs Mine

• Broadmeadow Mine

• Moranbah North Mine

• Kestrel Mine

• Carborough Downs Mine

• Ironbark No. 1 Mine

• Aquila Mine

OPEN CUT

• St Ives Mine

• Coppabella Coal Mine

• Moatize Mine

• Vulcan Mine Complex

• Runruno Mine

“The client encountered a faulted zone in the middle of the longwall block and considered relocating it around the fault, which would incur significant additional costs and render part of their resource unusable.

“Our geotechnical engineers designed the drilling and grouting pattern, whilst our cement scientists created the appropriate microfine grout and our operations team successfully completed the pumping and consolidation. As a result, the longwall was able to mine through this zone safely, with minimal stratarelated delays,” prides Seccombe.

The year ahead is poised to be productive for BMS as it plans to incorporate new technologies and innovations into geological and geotechnical assessments and solutions.

“We invest in R&D to improve our range of services and provide the best for our clients. In collaboration with one of our JV partners, we developed StrataLock – a non-toxic, non-hazardous, and low-temperature ground consolidation resin,” Seccombe details.

The success of this product led

to the JV company StrataLock Pty Ltd being named 2024 Queensland Mining Contractor of the Year at the Queensland Mining Awards.

“In addition, through our JV partner TerraSolve, we are delivering a stateof-the-art, integrated FLAC3D plug-in for stoping mines, which reduces reliance on consultants to undertake geotechnical numerical modelling, empowering site-based engineers and management to take control of operations.”

Clients can look forward to an array of exciting developments from BMS in the coming year, as the company has clearly outlined its strategic priorities.

“We have some significant plans for further business acquisitions and JVs on the horizon, which will broaden the range of products and services we offer to our clients. The product line-up will include cements, grouts, dust suppression products, and industrial chemicals,” Seccombe concludes.

As BMS embarks on future initiatives, the company remains steadfastly committed to delivering exceptional quality and innovative solutions to clients.

Barbex Group is a leading Ghanaian multi-business operator with roots in mining, agriculture, and technology. David Tabi, Head of Operations and Business Development, outlines how the company has been building its business on the foundations of integrity and excellence

Writer: Ed Budds

Founded in 1990 by Henry Tabi to serve the growing needs of Ghana’s mining sector, Barbex Group (Barbex) has been proudly enhancing the nation ever since.

“As one of the first Ghanaian-owned companies to start consignment stocks of critical reagents in the industry, we managed inventory and

allowed mines to focus on their core operations,” introduces David Tabi, Head of Operations and Business Development.

The company quickly became, and still is, a trusted partner offering a wide range of solutions such as overseeing logistics and port services, exporting samples for lab analyses, and liaising with regulators and companies on interesting assignments such as visa assistance, amongst others.

“Many of these services have grown over the years to make us a leading supplier of mining reagents, industrial chemicals, and equipment. To date, we have represented reputable companies such as DuPont, Orica,

Evonik, CyPlus GmbH, Solvay, Dunlop, and many others,” he prides.

Barbex’s facility and warehouses in Tarkwa – complete with the stateof-the-art Jubilee Terminal, which houses stock control and inventory management systems – allow it to deliver just-in-time supply services for clients across Ghana and beyond.

This includes effectively storing, supplying, and managing various quantities of reagents such as quicklime, cyanide, activated carbon, and hydrogen peroxide.

“We pride ourselves on being the first Ghanaian service support company to earn the International Cyanide Management Code (ICMC)

certification, which reinforces our commitment to global safety and environmental standards.”

The global mining sector is evolving rapidly, with technology and sustainability shaping its future.

As such, digital tracking systems, automation, and environmentally responsible practices are now considered industry benchmarks.

“We have embraced these trends by deploying cutting-edge technology to improve service speed, accuracy, and safety. This ties in perfectly with our just-in-time delivery philosophy,” Tabi affirms.

Furthermore, to remain ahead of the curve, Barbex partners with renowned laboratories and technology innovators.

“These collaborations allow us to introduce advanced solutions that minimise environmental impact whilst increasing efficiency for our customers,” he adds.

For Barbex, the goal is simple – to deliver exceptional value without compromising the environment.

At present, Barbex is particularly excited about a strategic partnership with a technologydriven company that focuses on sustainable materials processing.

David Tabi, Head of Operations and Business Development: “Reaching 35 years as a fully Ghanaian-owned, family-run company in a sector dominated by global players is a remarkable milestone.

“The smooth transition of leadership from our founder Henry Tabi to Mary Asante-Asamoah is a proud achievement and a significant highlight in our 35-year history. Running the business with a female Executive Director is a masterstroke that has allowed Barbex to also flourish under her leadership whilst staying ahead of the curve.

“Our success and growth are built on integrity, safety, diligence, and excellence – values that have carried us through every challenge.

“Seeing Barbex expand from a local operation to a trusted name in West Africa’s mining industry is something we take immense pride in.

“For example, over the last 10 years, we have been supplying quicklime to the mining industry in Ghana – a feat we are particularly proud of, given the monopoly that had been placed on the chemical for more than 25

“We hope to continue our success in this area by serving other countries in the sub-region as well.

“Prior to this achievement, in the early years, our ability to become one of the few to handle consignment stock for a mining giant was, and still is, one of our proudest moments.”

This initiative is designed to reduce environmental degradation through sustainable metal processing with traditional mining methods.

“In the modern age of environmental awareness and consciousness, Barbex is seeking to help in this regard. We are also looking into viable ways of ensuring sustainable production and manufacturing whilst safeguarding profit and longevity,” Tabi explains.

“It’s a bold step towards integrating secular economy principles into our operations and represents the future of mining support services in Ghana and beyond.”

The COVID-19 pandemic was one of the toughest periods for the company as it exposed vulnerabilities within global and local supply chains, forcing Barbex to rethink and redesign its operational model.

“We implemented a more flexible but resilient logistics framework, diversified our supplier base, and strengthened our digital capabilities to manage inventory and track shipments more efficiently,” he tells us.

This period of disruption became a turning point, enabling the company to identify bottlenecks, close gaps, and innovate in ways that continue to benefit its clients today.

“WE AIM TO BECOME NOT ONLY A TRUSTED SUPPLY CHAIN PARTNER FOR ALL IN THE VALUE CHAIN BUT ALSO A REGIONAL LEADER IN INTEGRATED MINING SOLUTIONS”

– DAVID TABI, HEAD OF OPERATIONS AND BUSINESS DEVELOPMENT, BARBEX GROUP

Moving forwards, Barbex’s vision is to evolve further up the mining value chain.

“This means expanding and upscaling our operations beyond Ghana and scaling into sub-Saharan Africa whilst adding manufacturing and processing capabilities to our portfolio,” Tabi sets out.

“We aim to become not only a trusted supply chain partner for all in the value chain but also a regional leader in integrated mining solutions.”

The coming year will be one of innovation and expansion for the company.

As such, Barbex is exploring new lines of business within Ghana and the West African subregion, strengthening its logistics infrastructure, and forming new alliances and partnerships through the Ghana Chamber of Mines as well as other recognised institutions, all whilst leveraging advanced technologies to better serve its clients.

“Our focus is on creating a robust, diverse, dynamic, future-ready company that can compete on both regional and international stages,” he finishes with pride.

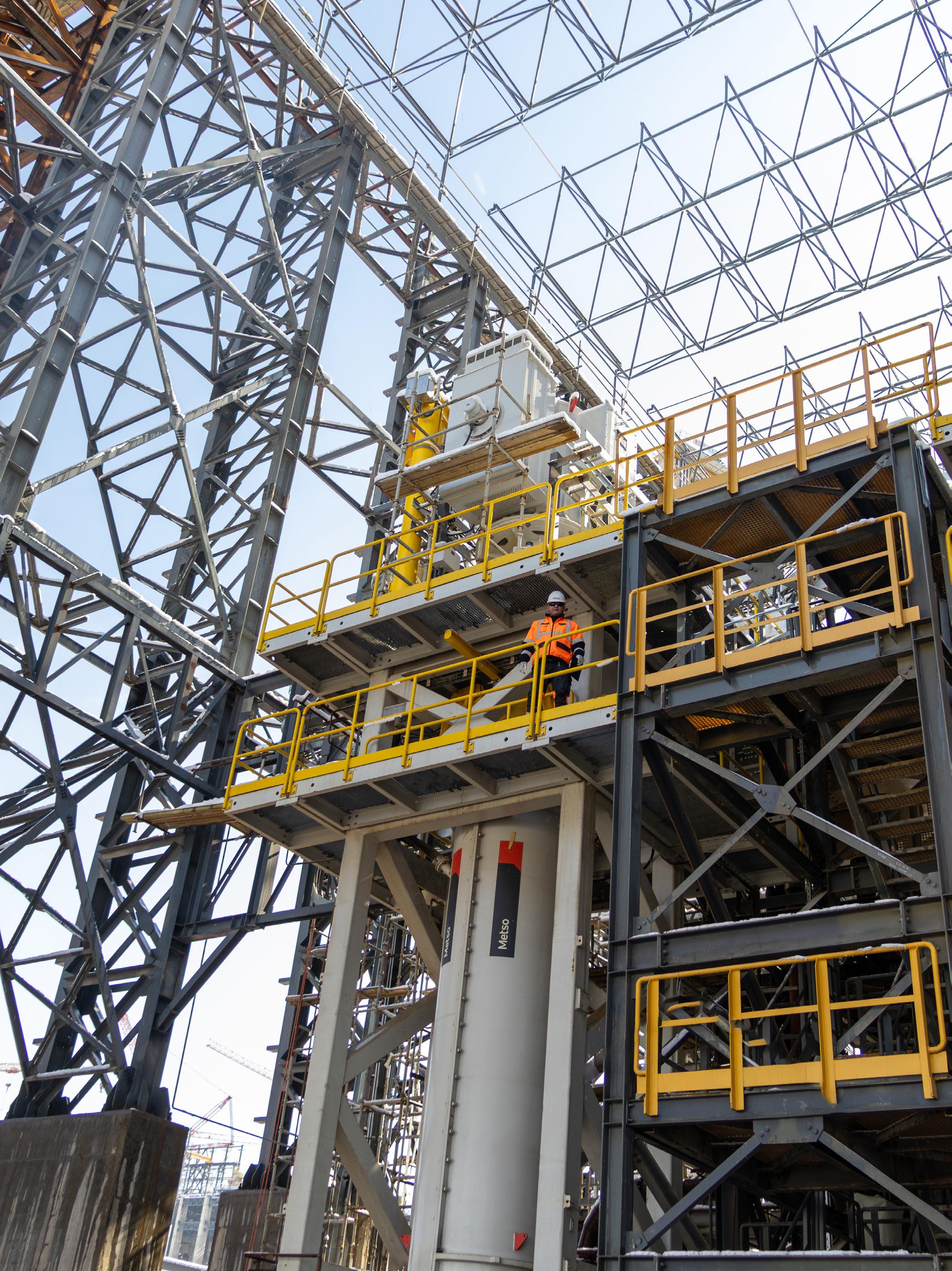

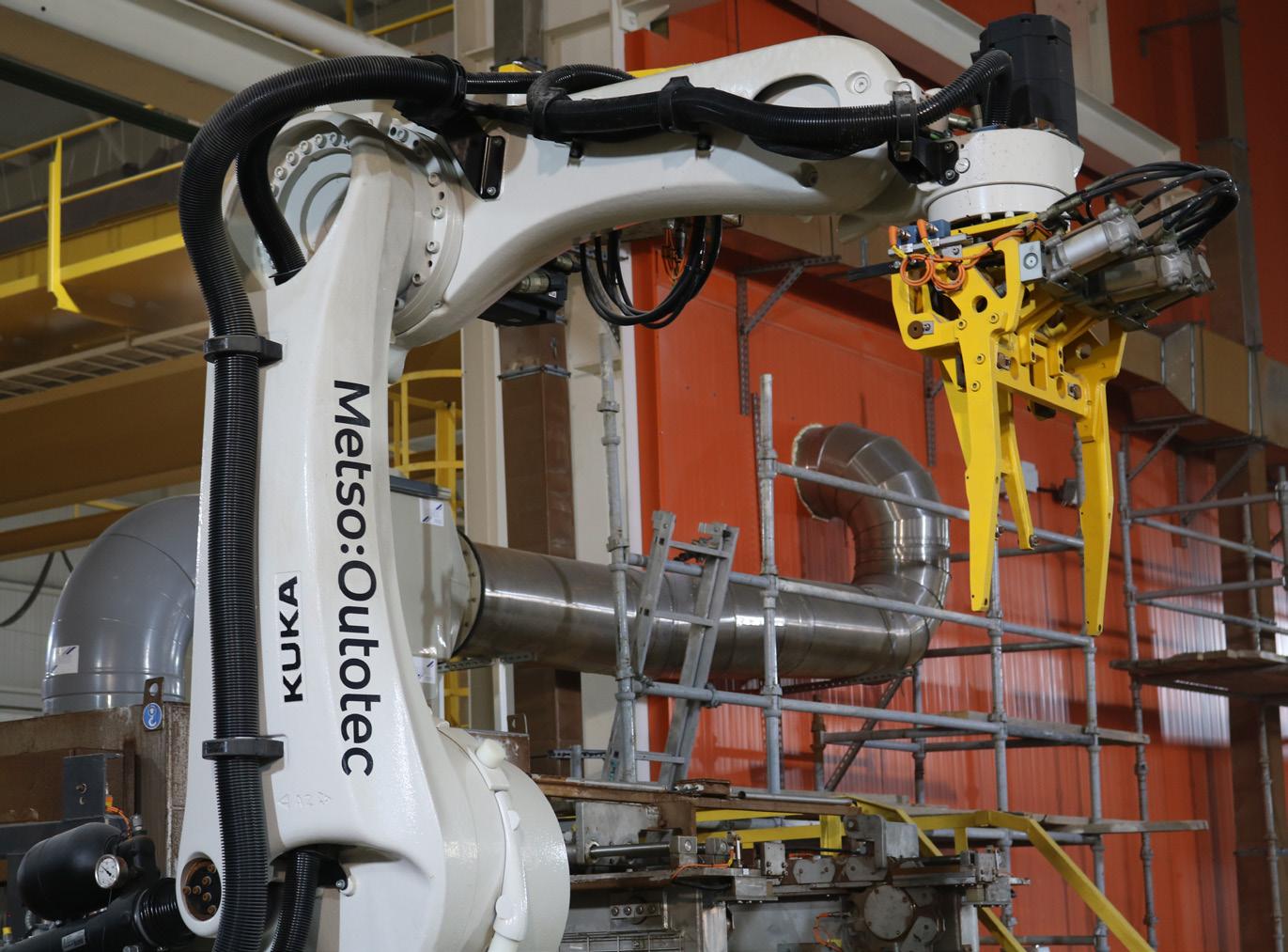

As

Metso celebrates 30 years of

successful

partnerships across

Central Asia, the company continues to innovate towards a greener future for the mining and minerals sectors. Mikhail Balychev, Vice President of Sales and Services – CEA Region, tells us more

Writer: Lily Sawyer

In recent years, countries in the Central Asia (CEA) region - namely Kazakhstan, Uzbekistan, Kyrgyzstan, and Mongolia - have increasingly begun to capitalise on their rich reserves of copper and other critical raw materials. We’re seeing a growing wave of international interest in the region’s mining potential,” begins Mikhail Balychev, Vice President of Sales and Services – CEA Region at Metso.

As such, environmental, social, and governance (ESG) factors have become an increasing priority for such companies due to the competitive advantages afforded by safer, greener, and more efficient mining techniques.

The rising prevalence of automation and digitalisation, meanwhile, has resulted in an uptick in autonomous mining and data collection techniques, whilst artificial intelligence (AI) is being increasingly utilised in analytics to identify gaps and patterns and advance operations – all of which has led to a burgeoning

mining scene.

However, a shortage of skilled labour persists, particularly in more remote areas, alongside concern surrounding workers’ safety and well-being.

A sustainable technology and service partner to the mining, aggregates, and metals refining industries, Metso has emerged as a significant player.

On a mission to limit global warming to 1.5 degrees Celsius (°C) with science-based targets, the company is ideally positioned for continued success as it strives to innovate towards a greener future for the mining and minerals sectors.

Proudly part of several recent and ongoing flagship mining projects across CEA, Metso has been able to demonstrate its strong presence and long-term commitment to the region.

In Kazakhstan, the company’s

aftermarket business supports almost every benefaction plant in the country, supplying critical spare parts and performance upgrades to major players such as KAZ Minerals, Kazakhmys, Eurasian Resources Group (ERG), JSC AK Altynalmas, and RG Gold.

In terms of its greenfield operations, Metso has delivered complete crushing and hydrometallurgy lines for Caravan Resources, Ashyk-Tas, and Almaly Mining, along with a concentrator plant at the ShatyrkulZhaysan cluster for Kazakhmys.

In addition to these active projects, it is collaborating with both government and private stakeholders on several large open-pit deposits currently moving through the geotechnical assessment and permitting stages.

“These are five to 10-year development prospects, and our early involvement helps to ensure optimal flowsheet design and future performance,” Balychev emphasises.

“INNOVATION IS AT THE HEART OF OUR METSO PLUS APPROACH, ENABLING US TO SUPPORT THE DECARBONISATION OF THE ENTIRE MINERALS PROCESSING VALUE CHAIN”

– MIKHAIL BALYCHEV, VICE PRESIDENT OF SALES AND SERVICES – CEA REGION, METSO

In Uzbekistan, Metso is supporting Almalyk Mining and Metallurgical Complex (AMMC) with a series of large-scale technology deliveries that are central to the country’s mining and metallurgical growth.

These include a comprehensive equipment package for the Copper Concentrator Plant-3 (CCP-3), one of the largest in CEA, a frame agreement for the delivery of a major new copper smelter, and two advanced sulphuric acid plants designed to meet both production and environmental requirements.

Elsewhere, in Mongolia, Metso is working with Erdenet Mining Corporation – one of the country’s leading producers of copper and molybdenum.

“Here, we are also supporting the Oyu Tolgoi project, one of the world’s largest known copper and gold deposits, by delivering highperformance solutions for mineral processing,” Balychev says.

Whilst each of these projects is

important in its own right, together they demonstrate how Metso’s technologies and expertise are helping shape the future of sustainable mineral processing across CEA.

The AMMC CCP-3 is one of the largest and perhaps most important mining projects currently underway in CEA – and Metso is proud to play a central role in its development.

“Our scope of delivery for this project is extensive, including basic engineering, manufacturing, and supply of a wide range of advanced technologies,” Balychev tells us.

The company’s contributions range from HIGmill® regrinding mills, TankCell® and Concorde Cell™ flotation technologies, and high-rate thickeners to FrothSense+™ cameras, Larox® pressure filters, slurry pumps, and MHC™ Series hydrocyclones.

Metso is also supplying samplers, Courier® 6X SL elemental online analysers, PSI 500i particle size analysers, and a state-of-the-art

process control system, along with installation and commissioning advisory services and critical spare parts.

Given the scale and complexity of this project – particularly the simultaneous installation of such a large volume of equipment – tight coordination and quality execution has been essential.

“Our professional team has been present on-site from day one of installation, supervising assembly and ensuring full technical compliance,” he explains.

A large team of Metso engineers and supervisors are currently working on-site, with additional automation experts and metallurgists set to join them to support commissioning.

Notably, Metso’s portfolio includes the Select™ range of horizontal grinding mills – a strategic addition designed to help customers balance performance, sustainability, and cost-efficiency.

Mikhail Balychev, Vice President of Sales and Services – CEA Region:

“Our Mineral Processing and Hydrometallurgy Conference in Kazakhstan is an annual event that we organise to bring together customers, partners, and industry stakeholders.

“It serves as a valuable platform for knowledge exchange, allowing us to present both proven technologies and new innovations, share Metso’s successful case studies from around the world, and engage in open discussions about the challenges and opportunities facing the mining industry.

“This year’s conference was especially significant as it was held in celebration of the 30th anniversary of our successful partnerships in the region.

“This important milestone gave the event a sense of occasion and reinforced our long-standing commitment to supporting the development of the mining and metals sector in CEA.

“Overall, the event not only showcased Metso’s global expertise but also highlighted the strength of our local relationships and importance of collaboration in driving the industry forwards.”

The pre-engineered mills combine proven technology with optimised standardisation, significantly reducing delivery times and installation complexity, whilst their modular design minimises environmental impact during installation and maintenance.

With the first two mills in the Select™ series having already been installed and launched at the Shatyrkul-Zhaysan copper plant in Kazakhstan, which have been in operation for a year, Metso has already witnessed the market’s support for this product.

2025 marked 30 years of Metso’s presence in CEA – a major milestone reflecting the decades of trust, collaboration, and shared success the company has built with its customers and partners in the region.

In preparation for the anniversary, Metso explored its archives and discovered that its first delivery to the region — flotation machines for a processing plant in Kazakhstan — dates back to 1982.

However, the company officially marks the beginning of its presence in CEA from 1995, when its first representative office was established in Uzbekistan.

“This historical connection made the anniversary even more meaningful to us,” Balychev smiles.

Over the past three decades, the company’s presence has grown from a single local representative to a regional team of more than 200, including 35 field service engineers.

Now operating from offices across Almaty and Karaganda in Kazakhstan, Tashkent in Uzbekistan, and Ulaanbaatar in Mongolia, Metso’s expansion is tangible.

It also maintains three strategically located warehouses across the region to support its customers with faster deliveries and stronger aftermarket service.

As such, Metso has been able to supply over 1,500 units of equipment to its customers since it was established in CEA.

“Our anniversary was more than a celebration – it was an opportunity to reflect on how far we’ve come

and reaffirm our commitment to supporting the sustainable growth of mining and metals operations across the region,” he enthuses.

Another interesting fact is that the two largest Lokotrack® mobile crushers in the world, currently in operation

Mikhail Balychev, Vice President of Sales and Services – CEA Region:

“Metso has an extensive footprint in the Asia Pacific region spanning 27 locations, which helps our customers deal with labour shortage challenges as we can deliver local support.

“The company’s largest global service centre is in Pilbara, Western Australia, where our ongoing investment extends to the state’s capital.

“We recently announced the installation of a mega-class mill liner press in Perth, which is currently the only mill liner manufacturer in Australia.”

in CEA, also belong to Metso.

The Lokotrack® LT160 – one of the biggest track-mounted primary crushers globally – has been in operation for Navoi Mining and Metallurgical Combinat (NMMC) in Uzbekistan since 1995.

Metso’s LT200, meanwhile, is also running at Altay Polimetally’s open-pit operation in Kazakhstan.

“These machines are not only engineering landmarks but also symbols of the long-term trust placed in Metso’s technologies,” Balychev prides.

Looking ahead, Metso’s key priorities for the coming year include expanding its service network, deepening partnerships with customers, and accelerating local manufacturing capabilities.

Meanwhile, it is actively bringing in more field service engineers, signing new site performance contracts, and increasing the availability of critical components.

Initially, this will take place primarily in the company’s warehouse in Karaganda to enhance responsiveness and minimise downtime for customers.

At the same time, Metso is supporting the next wave of greenfield developments across the region – particularly as ore grades decline and deposits become more geologically complex.

“Our goal is to be involved early in the process, helping customers design optimised flowsheets and select the right technologies from the start,” Balychev surmises.

Another strategic focus for the company remains on localisation as it works closely with its Kazakh partners to localise more of its production and assembly activities.

“This will enable us to better support the domestic market whilst reaffirming our long-term commitment to the region’s mining industry – not only as a supplier, but as a trusted partner driving positive change across CEA.”

To minimise its environmental footprint, Metso has clear, measurable goals in place to reduce the impact of its operations, logistics, and procurement processes.

First, it seeks to accomplish net zero carbon emissions across its operations by 2030.

“As of 2024, we’ve already reached a 72 percent reduction compared to our baseline,” Balychev points out.

Metso also seeks to achieve a similar target across its logistics operations, aiming to reduce its carbon dioxide (CO2) emissions by 20 percent this year. As of 2024, the company was already on track to exceed this target with a 13 percent reduction.

The company additionally works closely with its direct suppliers to encourage science-based climate action.

As such, in 2024, more than 31 percent of the company’s direct

procurement spend was with suppliers who mirror its own targets.

Further to operational emissions reductions, Metso’s commitment to the environment is reflected in its R&D investments, namely through the Metso Plus offering.

“Metso Plus is a dedicated portfolio of advanced, sustainable solutions that help customers reduce their energy and water consumption, improve efficiency, and lower emissions,” he details.

“Innovation is at the heart of our Metso Plus approach, enabling us to support the decarbonisation of the entire minerals processing value chain,” Balychev passionately concludes.

We’re unveiling the mystique of the amethyst – nature’s healing gem –known for its velvety hues and rich history. From ancient Greece to modern jewellery designs, discover the timeless charm of these captivating cosmic cuts that have spellbound people throughout the ages

Writer: Rachel Carr

The historic love affair with amethysts is due to their enviable desirability as a highly sought-after, stunning variety of quartz, known for their striking spectrum of purple shades, from light lavender and deep violet to plum and mauve.

Amethysts can be found in several forms, including clusters and polished stones extracted from geodes and alluvial deposits worldwide.

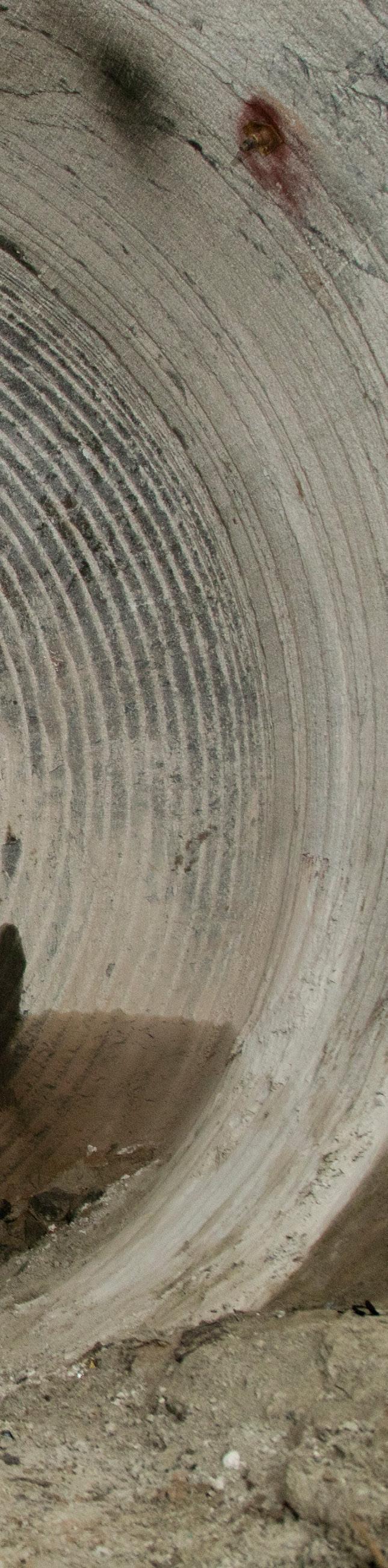

Often occurring as 12-sided crystals, open-pit mining is commonly used for shallow deposits, but deeper deposits may require underground methods, including the creation of tunnels or shafts.

Typically found in igneous and metamorphic rocks, with the greatest abundance in volcanic formations, amethysts are composed of silicon dioxide and owe their colour to the presence of iron impurities and natural radiation.

The purple stones have held significance in various cultures throughout history, having been believed to possess protective and healing properties, guarding

against intoxication, promoting clarity of thought, enhancing spiritual awareness, facilitating emotional stability, and helping to dispel anger and anxiety.

As such, many people wear them or keep them close for their calming properties of peace and balance. Historically, amethysts were also associated with royalty and luxury and used in ceremonial objects or worn by nobility to signify status. The iconic Princess Diana once wore an oversized, ornate amethyst cross, which has since only been sparkling on Kim Kardashian’s cleavage at the 2024 Met Gala.

Considered one of the most beautiful jewels by the Royals, Queen Camilla was also seen with a heartshaped amethyst and pearl necklace, whilst one of her predecessors, Queen Mary, gifted a tiara – part of a parure of regal jewellery – to her daughter-inlaw, Queen Elizabeth II’s mother.

Amethysts add a unique element to the royal collection, showcasing the beauty and significance of each treasure.

Amethysts are sourced diversely as they are widespread across the globe, making them an affordable choice for jewellery, yet their beauty is nothing short of extraordinary, with such rich diversity and unique characteristics. Madagascar is a notable contributor, alongside Afghanistan and Pakistan; however, Brazil and Uruguay are leading suppliers.

Brazilian amethysts truly shine thanks to their rich colour and remarkable clarity, with prime mining locations in Rio Grande do Sul, Minas Gerais, Bahia, and Maraba. Interestingly, heat-treated amethysts from Minas Gerais can take on a fascinating green hue, captivating jewellers who refer to them as “green amethysts”.

Uruguay, known for its deep purplish-blue amethysts, produces specimens that many consider to be the most beautiful in the world, despite their blemishes. The gems from the capital, Artigas, are particularly celebrated, boasting an unfathomable age of around 130 million years.

On the African continent, Zambia and Namibia emerge as two premier sources of amethysts, beloved for their outstanding clarity. In South Africa, they are also abundant, and artisans often carve these less distinct pieces into beautiful forms.

Whilst Thunder Bay, Ontario and Digby, Nova Scotia are vital stops for amethyst enthusiasts, as the former’s stones are known for their inclusions.

In Europe, the yield from the Zillertal Alps in Austria produces spectacular amethysts. Here, the gems tend to fade more quickly when exposed to sunlight compared to their counterparts found elsewhere. Yet, some unique stones from this region command higher prices than those from Uruguay, for example, due to their exquisite quality.

Meanwhile, the Murinska region of the Ural Mountains in Russia is also home to a noteworthy source of amethysts. These gems have a deep and captivating colour, but due to extensive mining, they have become increasingly rare.

In addition, Hungary’s Zemplén Mountains, with unique amethyst crystals, radiate a silk-like glow, showcasing their translucent beauty. Idar-Oberstein in Germany, famed for its agate, has also seen its amethyst

deposits dwindle, halting mining activities in the country.

Elsewhere, Italy produces gems that are evenly coloured and transparent. Found in Osilo, Sardinia, these larger stones shine with clarity, but they lack the deep hues often sought after.

Lastly, Kazakhstan, particularly near Lake Balkhash by Priozersk, is renowned for producing exquisite amethysts. Doubly refractive with striking near-white crystal prisms transitioning to deeper colours at the tips, these stones are a treat for collectors.

Amethysts have a deep and storied history dating back to prehistoric times, believed to have been first discovered in France around 25,000 years ago.

However, the cultural significance of amethysts is rooted in ancient Greece, where the gemstones were worn or carved into drinking vessels to prevent intoxication – its name translates as ‘not intoxicate’ from the Greek word ‘amethystos’.

Early Greek legends associate amethysts with Dionysus, the god of wine and pleasure, often depicted holding a goblet or bunch of grapes to symbolise festivity and revelry. Also known to the Romans as Bacchus, he embodies pleasure, ritual madness, and the cycle of life and death, linking wine to both celebration and mourning.

Amethysts have transcended geographical and cultural boundaries, being revered in many different cultures.

In Tibetan Buddhism, for example, the plum-coloured quartz is considered a sacred stone, used in prayer beads called mala to enhance meditation practices.

Elsewhere, amethyst scarabs in ancient Egypt, inscribed with intricate carvings, were used in funerary rituals and associated with royalty, spirituality, and protection.

Later, in medieval Europe, they were a symbol of royalty and religious piety, with their deep purple hue representing purity of spirit and divine favour.

Amethysts have been set in religious artefacts and royal crowns for centuries. Once considered equal in value to rubies, emeralds, and sapphires, and appearing in regalia and rings, the gem adorned the fingers of bishops, as well as symbolising the 12 apostles. In the Old Testament, an amethyst was one of the 12 stones representing the tribes of Israel.

The discovery of large deposits in Brazil in the 18th century transformed the availability and market value of amethysts, cementing their reputation as a beloved jewel.

• Amethysts are found on six out of seven of the world’s continents, including Oceania, where a legendary largest ever self-contained geode on Earth was discovered in Australia. Residing in an awe-inspiring creation of nature – the Enchanted Cave – it weighs an astonishing 20 tonnes (t).

• Elizabeth Taylor demonstrated her appreciation for historical craftsmanship with a Victorian gold and enamel amethyst bracelet.

• Cleopatra famously wore an amethyst ring throughout her relationships with Julius Caesar and Mark Antony.

• The Empress of Uruguay is a giant quartz crystal vein – the world’s biggest, it weighs 2.5t and is over seven foot (ft) thick, nearly 6ft wide, and more than 10ft tall. It is valued at USD$190,000, although it is not for sale.

• Amethysts rank at seven on the Mohs scale of hardness.

As with all gemstones, amethysts have their own unique significance and multiple meanings. The highly popular purple stones are used in meditations to heighten spiritual consciousness and are associated with peace and bravery.

Within chakra healing, they are linked to the crown and third eye chakras, thought to enhance spiritual awareness and intuition.

Moreover, they are believed to contain healing properties that speed up and increase the chances of recovery from various health issues and illnesses. In alternative medicine, amethysts are used to aid stress relief, support sobriety, and enhance intuition.

Their vivid colour and unique formations have also had an enduring influence on art and architecture, inspiring artisans and designers throughout history, leading to their use in decorative objects and mosaics. Today, amethysts have found their way into popular culture as a material in the video game Minecraft. Durable

enough for everyday wear, they are also used in jewellery, from rings and necklaces to earrings and bracelets. Their rich purple colour pairs well with both gold and silver, making them versatile in design.

The demand for the prized purple quartz has grown with more people seeking unique jewellery pieces. As a result, certain suppliers, particularly those offering high-quality, deepcoloured stones, can command premium prices.

Amongst these sought-after stones is ametrine, a naturally occurring blend of amethyst and citrine, which

showcases stunning gradients of purple and yellow, making each piece individual.

Additionally, cacoxenite amethyst contains inclusions that give it a distinctive appearance of golden threads against the purple backdrop, creating a mesmerising effect.

As amethysts continue to be valued not only for their aesthetic appeal but also for their rich history and cultural significance, they are one of the most beloved gemstones in today’s world, and their universal appeal is a testament to the stone’s unique and enduring charm.

As it seeks to establish itself as a first-choice investment destination, Indonesia’s mining sector is collaborating with foreign investors to leverage the nation’s vast reserves of nickel, gold, coal, and copper

Writer: Lily Sawyer | Project Manager: Joseph Perfitt

Benefitting from abundant natural reserves of critical minerals, Indonesia’s geological condition, coupled with a fast-growing economy, has seen it emerge as the ideal environment for mining investment in recent years.

As the world’s largest producer of nickel, the nation finds itself at the vanguard of the electric vehicle (EV)

revolution, with nickel-rich cathodes favoured for their ability to store more energy in EV batteries.

Indonesia is also amongst the top seven gold-producing nations and boasts the sixth-largest coal reserves in the world, presenting itself as a reliable and trustworthy mining investment destination – particularly in times of socioeconomic instability elsewhere across the globe.

In addition, as the home of the Grasberg mine –one of the largest reserves of copper in the world – the country is a major supplier of the metal. This has become particularly prevalent as demand for copper continues to rise due to its use in green energy infrastructure such as wind turbines and solar panels.

Beyond these staple critical minerals, Indonesia produces significant amounts of tin, bauxite, manganese, lithium, and cobalt, each of which creates diverse investment opportunities in mining and mineral processing.

To capitalise on the nation’s unique position, Indonesian President, Prabowo Subianto, is actively inviting foreign investors – particularly from the

Pacific region – to participate in Indonesia’s mining sector as it looks to raise over USD$600 billion for the mining and downstream industries by 2040.

To achieve this ambitious goal, the government invites investors to explore opportunities in directly supporting individual mining projects, alongside investing in technology and services, downstream processing and refining, and renewable energy.

Going forwards, having relaxed foreign ownership and divestment regulations in 2021 to encourage increased international participation in the sector, the Indonesian government hopes to establish strong local partnerships with foreign investors, navigating the market collaboratively to take advantage of long-term opportunities.

We hear from Hendra Sinadia, Executive Director of the Indonesian Mining Association, who discusses the organisation’s role in supporting government policy to advance the Indonesian mining industry whilst actively advocating for its members

Mining Outlook (MO): Firstly, could you talk us through the origins and primary goals of the Indonesian Mining Association?

Hendra Sinadia, Executive Director (HS): As the voice of the Indonesian mining industry and a key partner to

the Government of Indonesia, the primary goals of the Indonesian Mining Association (IMA) are to support sustainable mining in Indonesia and promote the nation as a stable investment destination.

IMA was founded 50 years ago on 29th May 1975. At the time, co-founders of the association included stateowned mining enterprises PT Bukit Asam Tbk (PTBA), which deals in coal; PT Aneka Tambang Tbk (ANTAM), which deals in nickel and gold; PT Timah Tbk, which deals in tin; and foreign investment enterprises like PT Freeport Indonesia, which deals in copper and gold, and PT International Nickel Indonesia (INCO), which deals in nickel.

The association then expanded its membership to include not only mining companies but those that

support the mining industry. The latter have since been categorised as associate members and include mining contractors, surveyors, traders, consultants, and suppliers.

Today, IMA has more than 90 members – 32 of which are primary members – and 60 associates.

MO: What is your take on Indonesia’s mining landscape, and how have you seen it evolve? Would you say it’s currently particularly exciting or challenging?

HS: Indeed, Indonesia’s mining industry is currently both exciting and challenging.

It’s exciting because Indonesia is a country blessed with rich mineral potential and huge renewable energy

VISION

• To support government policy to advance the Indonesian mining industry.

MISSION

• Address issues related to aspects of the mining industry and devise possible solutions.

• Learn and implement modern mining methods already adopted in other countries.

• Create mutual respect between both private and government members.

• Provide the mining industry with new and creative ideas.

• Cultivate an understanding of science, conducting research in collaboration with partner associations.

• Build the IMA network by partnering with similar professional organisations outside of Indonesia.

• Spread information and conduct objective analysis around industrial mining.

• Maintain high professional standards amongst its members.

• Promote infrastructure development needed to support the nation’s mining industry.

• Socialise with public and educational institutions around current developments and problems within the industry.

• Help boost the potential of university graduates by preparing them for a career in mining.

sources which means, in an era of energy transition, we have the advantage of being able to feed a growing demand for critical minerals both locally and globally.

Indonesia is amongst the primary producing and exporting countries for critical minerals such as nickel, copper, and tin. In addition, we have relatively large thermal coal reserves that can cater to strong demand from Asia.

On top of that, mining has been one of Indonesia’s primary revenue contributors and plays an important role in both regional and national development.

However, challenges have arisen, with mining becoming increasingly perceived in a negative light –despite the important contribution the industry makes to the nation’s economy.

“INDONESIA IS AMONGST THE PRIMARY PRODUCING AND EXPORTING COUNTRIES FOR CRITICAL MINERALS SUCH AS NICKEL, COPPER, AND TIN. IN ADDITION, WE HAVE RELATIVELY LARGE THERMAL COAL RESERVES THAT CAN CATER TO STRONG DEMAND FROM ASIA”

– HENDRA SINADIA, EXECUTIVE DIRECTOR, INDONESIAN MINING ASSOCIATION

Therefore, the role of IMA in particular is to challenge this perspective and navigate how best to advocate to government and large stakeholders for the benefits of mining.

MO: How do you support the collective interests of your members by organising lectures, seminars, and training activities?

HS: As an association, IMA is a key partner to the government. Our primary role is to represent individual members and, in some cases, the whole mining industry when it comes to dealing with policy and regulatory issues.

In addition, we organise activities that benefit our members and the association itself. For example, we oversee members-only meetings on areas of interest such as legalities, taxation, human capital, corporate social responsibility (CSR), the environment, forestry, marketing, downstreaming, and the energy transition, to name a few.

Across the organisation, we have established committees to deal with such issues, headed up by mining professionals proposed by our members and approved by the board.

MO: As an association that serves as a link between government and the mining industry, how extensively is IMA involved in contributing to policy and regulatory frameworks which may affect Indonesia’s mining landscape?

HS: As a partner to the government, we actively participate and provide constructive inputs in discussions surrounding policy and regulation.

As mining is intrinsically interconnected with other key sectors, we are often dealing with various government institutions – including institutions at local levels – at once.

The primary ministry we deal with is, of course, the Ministry of Energy and Mineral Resources. Then, there are other important ministries such as the Ministry of Finance, Ministry of Environment, Ministry of Forestry, Ministry of Trade, Ministry of Industry, and Ministry of Investment and Downstream Industry, amongst others.

In dealing with policy and regulatory issues, in some

cases, the government seeks our input at the initial stage of the policy and regulation drafting process. In this case, we internally consult our members and devise proposals before ultimately accepting regulations issued by government.

We are also actively voicing our perspective in public discussions, including media interviews and internal media, on policy and regulation.

Furthermore, IMA attends invitations from universities and educational institutions across the nation, advocating to students on the benefits afforded by the mining industry.

We also participate in discussions surrounding miningrelated issues organised by civil society organisations.

MO: How has the Indonesian mining industry demonstrated resilience in the face of adversity, such as the recent decline in exports caused by a governmentmandated coal reference price?

HS: Our government has proposed a coal reference price, known as Harga Batubara Acuan (HBA), for all coal export transactions. The government is aiming for more potential state revenue contribution on royalty payments from coal export transactions as the country is the world’s largest thermal coal exporter so far.

IMA has provided input to government on the issue of

An integrated coal mining company committed to continuously delivering value to all stakeholders

corsec@baramultigroup.co.id

www.bssr.co.id

HBA, having delivered an assessment on the potential impact of the policy if implemented. We informed the government that it is not easy to convince buyers to refer to HBA for transactions as most buyers prefer index-linked coal prices.

Of course, as a partner to the government, we ultimately accept all policies and regulations issued and encourage our members to comply. However, we expect the government to consider applying flexibilities given the market dynamics.

We are proud of the compliance demonstrated by our members, despite the challenges and impacts presented by some policies and regulations.

MO: Finally, what are IMA’s key priorities for the future, and how do you see Indonesia’s mining landscape evolving in coming years?

HS: Our main priority is to support government programmes.

In the new administration, under the leadership of President, Prabowo Subianto, the role of mining has become increasingly important.

For example, mining supports the government in ensuring national energy resilience and boosts domestic

bssr_official bssragmchannel669

industry through mineral downstreaming, particularly for members of the Association of Southeast Asian Nations (ASEAN). IMA provides constructive input to the government in this context.

In addition, from July 2024 to the end of December 2026, IMA will host and manage the Secretariat of the ASEAN Federation of Mining Associations (AFMA), whose members comprise national mining associations from Malaysia, Thailand, Philippines, Myanmar, Cambodia, and Laos.

As a founding member of AFMA, IMA is a partner to the ASEAN Secretariat, and our role is to support them in marketing the region as a sustainable mining investment destination. In this way, we support intra-trade and investment in the region.

Ph. 0851 5773 5195 / 0811 8519 79 info@ima-api.org ima-api.org

New Zealand is fortunate to have a mining industry that provides some of the vital minerals required for everyday modern life, contributing socioeconomic and environmental benefits to the country

Writer: Jack Salter | Project Manager: Deane Anderton

Given the global geopolitics around the ownership of critical minerals, and who they are being shared with, there is a growing understanding of and interest in them.

These minerals – including lithium, cobalt, rare earth elements, nickel, copper, and many more – are essential for the quality of life many are accustomed or aspire to.

Indeed, almost everything people depend on every day relies on minerals, from phones and computers to cars and refrigerators, and this will only increase in a green tech future.

Soaring gold prices, meanwhile, have also got people’s attention as a safe haven in times of political and economic turmoil.

In New Zealand, the government is enabling mining and committed to doubling exports from the industry in a number of ways.

This includes releasing A Minerals Strategy for New Zealand to 2040 and A Critical Minerals List for New Zealand in January 2025, supported by updated information from GNS Science mapping the mineral potential of New Zealand

Perhaps one of the biggest game-changers, however, has been the passing of the Fast-track Approvals Act (FTAA) in December 2024.

There has been international interest in this law as its purpose is to “facilitate the delivery of infrastructure and development projects with significant regional or national benefits”.

FTAA’s aim is to get important projects up and running without them being drowned in red tape and delayed for many years. The value of this new law is in the ‘one-stop shop’ approach to consenting projects, which saves time and money by allowing applications to be considered in

their entirety by a group of experts.

This is particularly important for the mining industry as to get a mine up and running in New Zealand, it requires applications to numerous different government departments that may treat them in different ways, with different timeframes, and sometimes with the desire to delay or block applications if they have prejudices or other priorities ahead of mining.

Mining and quarrying projects listed in the act include mineral sands, gold, coal, and seabed mining, whilst unlisted projects are also aiming to go through the fasttrack process.

Companies are currently making applications for consideration under FTAA, having opened in February 2025, as the New Zealand government’s support for mining being part of the country’s economic growth is increasingly noticed by global markets.

JOSIE VIDAL CEO, New Zealand Minerals Council

Following a recent rebrand, we speak to the New Zealand Minerals Council’s CEO, Josie Vidal, about the new name advocating for the country’s mining and minerals sectors

Mining Outlook (MO): Firstly, please introduce us to the New Zealand Minerals Council as the industry association representing the New Zealand mining sector.

Josie Vidal, Chief Executive (JV): The New Zealand Minerals Council replaced the name Straterra in April 2025. With the global interest in mined minerals, particularly critical minerals, we believed it was time to better align ourselves with a name that means something to both New Zealanders and those in the global supply chain.

I’m a great believer in keeping it simple and we want people to be able to link our name to what we do, connect with us easily, and understand that minerals are important to the New Zealand economy.

We’re a not-for-profit organisation and our membership

includes mining companies, explorers, researchers, and service providers that support the extractives industry.

The New Zealand Minerals Council’s member charter states that our purpose is to enable socially and environmentally responsible mining, providing minerals for a sustainable and resilient future and enduring value for all New Zealanders.

What that means on a daily basis is a small team based in Wellington, near the base of our central government, poring through proposed policy, rules, and law changes to ensure the extractives industry gets a say in change and is not victim to any unintended consequences that disrupt business.

We do this at a local government level as well, mostly in the parts of New Zealand where mining is impacted by policy and plan changes relevant to that region.

The primary role of the New Zealand Minerals Council is advocacy, and as part of that we need to talk to stakeholders and the general public to ensure they understand the vital role minerals play in all our lives and why New Zealand needs to be making the most of its mineral endowment with enabling and enduring policy and law.

Our Mining means progress page shows the work mining companies are doing and introduces the range of people who work in mining and are committed to good environmental outcomes.

MO: What critical role do mined minerals play in the modern world, and what benefits do they bring to the everyday lives of people in New Zealand?

JV: Like everywhere else in the world, we rely on minerals for energy, technology, medicine, food production, infrastructure, housing, communications, and pretty much everything you can think of. We often point out that when it comes to the origin of all the things we need, if it wasn’t farmed, it was mined – and farming relies on mined minerals.

Mining makes a significant contribution to the New Zealand economy, particularly in regional areas where mining takes place. About 7,470 people are employed in the extractives sector and the economic contribution is NZD$2.83 billion to GDP annually.

The products of New Zealand’s mines make a major contribution to the country and its economy, and there remains a lot of untapped potential to source the minerals the world can’t get enough of to fuel a low emissions future and sustain big data centres running artificial intelligence (AI).

Our mining industry is small compared to other mining jurisdictions, and we felt it was important in developing a minerals strategy that some of the existing mined minerals

should be part of the critical minerals list, including gold and coal. Our critical minerals list reflects our unique environment.

In addition to the minerals already mined, there is scope for some other minerals, including those in mineral sands, that are being mined or will be soon.

Whilst thermal coal is not on the critical minerals list –metallurgical coal is – that does not mean it is not critical to the New Zealand economy, and this is noted in the minerals strategy.

Renewable energy relies on the sun shining, the wind blowing, and the rain falling. When that doesn’t happen, coal is there as a back-up to ensure the lights stay on and businesses can keep running.

In New Zealand, there is a risk to energy security without coal, and this was realised in winter last year. Due to supply constraints, extremely high electricity prices saw manufacturing plants close temporarily –then permanently – and put pressure on ordinary New Zealanders who are already struggling with the cost of living.

Domestically, coal is also used in steel making; cement and lime manufacturing; food processing including milk powder and other dairy products; commercial hothouse heating; timber, wool, and leather processing; and commercial and public facility heating, including schools, universities, and hospitals.

Gold and metallurgical coal are our main exports from mining, so they are critical to the government’s goal of doubling the value of our mineral exports to NZD$3 billion by 2035.

An estimated 2.6 million tonnes of coal are mined annually for both domestic use and exporting, all from open cast mines. We export primarily to Japan, South Korea, China, and India, but also Canada, Saudi Arabia, and Australia, and export markets are strong.

Some New Zealand coal has highly sought-after properties, such as low sulphur and ash content, and superior “swelling” properties for use in blast furnaces. This coal is exported to steelmakers in Japan, India, South Korea, and Australia. At this stage, coal remains essential to steel production.

The reality is the world still needs and is still using coal. As long as there is an international market for New Zealand’s metallurgical coal, there remains potential for growth in the value of exports.

Whilst there is more support for mining, it is still a small industry and there won’t be a mine on every corner.

Mining has the advantage of being a highly productive industry capable of contributing to economic growth with well-paid jobs – the median mining income is 50 percent higher than the New Zealand average (NZD$92,790 vs NZD$59,030 in 2023 according to Stats New Zealand data) – and an increase in export revenue.

The mining and exploration sector is ranked number one in New Zealand for both labour and land use productivity. New Zealand’s productivity ranking is generally low compared to other developed countries, particularly within the Organisation for Economic Co-operation and Development (OECD).

“WITH THE GLOBAL INTEREST IN MINED MINERALS, PARTICULARLY CRITICAL MINERALS, WE BELIEVED IT WAS TIME

TO BETTER ALIGN OURSELVES WITH A NAME THAT MEANS SOMETHING TO BOTH NEW ZEALANDERS AND THOSE IN THE GLOBAL SUPPLY CHAIN”

– JOSIE VIDAL, CEO, NEW ZEALAND MINERALS COUNCIL

MO: Equally, how do you work to ensure decision-makers in government understand the value of responsible mining and its contribution to the well-being of New Zealanders?

JV: This is an important question. New Zealand has the advantage of a relatively stable government with both of the main political parties – National and Labour – being somewhat centrist.

RUA GOLD is an exploration company, strategically focused on New Zealand. With decades of expertise, our team has successfully taken major discoveries into producing worldclass mines across multiple continents. The team is now focused on maximising the asset potential of RUA GOLD’s two highly prospective highgrade gold projects.

The company controls the Reefton Gold District as the dominant landholder in the Reefton Goldfield on New Zealand’s South Island with over 120,000 hectares of tenements, in a district that historically produced over 2Moz of gold grading between 9 and 50g/t.

The company’s Glamorgan Project solidifies RUA GOLD’s position as a leading high-grade gold explorer on New Zealand’s North Island. This highly prospective project is located within the North Islands’ Hauraki district, a region that has produced an impressive 15Moz of gold and 60Moz of silver. Glamorgan is adjacent to OceanaGold Corporation’s biggest gold mining project, Wharekirauponga.

www.ruagold.com | info@ruagold.com |

We have Mixed Member Proportional representation in New Zealand, which means ruling governments can be made up of a number of parties supporting one of the two main parties. We currently have three parties making up the ruling government; our elections are every three years, and the next one is in 2026.

As our primary role is advocacy, our daily work includes meeting with decision-makers and those who support them in developing policy, rules, and laws to keep them apprised of the value of mining to the economy and well-being of New Zealanders. We are based in the capital city of Wellington so we can be quickly accessible to decision-makers.

MO: How important is a collaborative, reasonable, and responsible approach to engaging with government and the public on issues in the mining sector?

JV: Our approach to advocacy is to promote education, facts, science, evidence, and reasoned discussions.

Sadly, we are seeing the world over that some politically focused environmental organisations are swinging way wide of environmental issues and taking an approach that extends to aggression and violence.

This is filtering through to New Zealand and we have seen some unpleasant and illegal protest action against mining, which has resulted in arrests and court charges.

In speaking to activists, it seems they want to promote de-growth, de-population, de-industrialisation, and people living with less and going back to some kind of preindustrial lifestyle.

Some of their supporters are unaware of just how extreme the plans are, and it is hard to see generations for whom life has never been easier when it comes to access to food, shelter, healthcare, education, transport, technology, lifestyle, etc. accepting a world that would take that away.

The 2025 Edelman Trust Barometer, an internationally respected temperature test of what the public are thinking and reacting to globally, is grim reading. It shows that 40 percent of those surveyed see hostile activism as a viable means to drive change, which involves:

• Attacking people online

• Intentionally spreading disinformation

• Threatening or committing violence

• Damaging public or private property

We make submissions to the government, appear before select committees when they are considering law changes to explain the position of the mining industry, and engage through media to explain our position on what the government is doing.

Our organisation is apolitical, which means we engage with all politicians to ensure they understand the value of the mining industry. With a relatively short election cycle, it is important any potential new government knows what we do and why.

With a new government, we provide a Briefing to Ministers, which we share with any ministers likely to have an influence on the mining industry, and we meet with key ministers regularly to work through the opportunities and issues we raise for their term of government.

Drilling down on the demographics, 53 percent of those aged 18-34 support hostile activism.

We will continue to seek a collaborative, reasonable, and responsible approach to engagement on mining, and you have to hope that wins at the end of the day.

MO: How does the New Zealand Minerals Council enable socially and environmentally responsible mining in the country?

JV: It is worth noting that New Zealand’s contribution to the global supply chain of mined minerals comes from highly regulated mines governed by strict health and safety and employment laws as well as stringent environmental regulations.