Product Overview

Our offer

- More than just a product

Expertise

Standard product range

Customized

Warehouse solutions

Packaging solutions

Sourcing

About Internordic

In addition to offering one of Sweden’s broadest ranges of bearings, seals, locking elements, linear products, and bronze materials, Internordic provides extensive opportunities for product development, refinement, and logistics solutions close to your operations. Over the years, we have built a strong network and collaborations with carefully selected manufacturers. Combined with our broad knowledge and expertise, we consistently find the right product and solution for every unique need and application. Our ability to develop customized and unique products together with our customers creates strength and flexibility.

Internordic is headquartered in Nässjö, Småland, where the company was founded in 1987. Since 2025, we have also operated an office and warehouse in Örebro.

Internordic is part of the OEM International group, one of Europe’s leading technology trading companies, operating in 15 countries through 37 businesses.

A strong product range that never stops evolving

Internordic’s extensive product portfolio is one of our key strengths, providing great flexibility in development projects with our customers. For many years, we have collaborated with carefully selected manufacturers, building both depth and variety in our product range. Today, our products are used across most industries, including the automotive sector, material handling, and machinery manufacturing. Our customers range from large international corporations to small niche companies.

Solutions close to the customer

Close collaboration with our customer is a key factor in our operations. Internordic is far more than just a supplier, and we are always available to discuss product selection, application ideas, or commercial matters. We offer training in product selection as well as practical training, such as warehouse assembly, either at the customer’s site or in our facilities.

Product development

In addition to our extensive stocked standard product range, we develop customer specific solutions in close collaboration with our clients. This can include minor modifications to a standard product or the creation of an entirely new product composed of multiple components, allowing us to replace assembly steps in your operations with a ready-to-install solution.

We manage safety stock and varoius logistics setups on a daily basis to ensure availability and proximity to our customers’ operations.

Simply create a company account and log in here:

On internordic.com (in addition to placing web orders) you can always:

• Check stock availability

• View list prices or your own agreed prices and discounts

• Create your own order templates, and more

• View your order history

iBec – Our own quality center in China

iBec has been Internordic’s own operation in China since 2001, focusing on customer specific bearing solutions and value-added standard products.

- Founded in 2001

- 13 employees

- Extensive network of around 100 factories, with about 10 in regular use

- Factory quality assurance

- Product quality control

- Technically well equipped quality center, certified according to ISO 9001 and operating in compliance with TS 16949

- Logistics hub for efficient deliveries

Bearings

Seals Fasteners

Our manufacturers

Customized solutions

Sometimes the best solution is a customized product. In many cases, these replace assembled products that the customer previously handled themselves. By using specialized components, the customer’s production becomes more efficient while logistics are streamlined.

Many of our customer’s products are developed through close collaboration between us and the customer. That’s why it’s important for us to be involved early in the process, so we together can provide the right solution for each unique application. Through our value-added services, including pre-assembly of multiple products for your application, customers benefit from reduced handling and assembly costs, resulting in increased production efficiency.

7components5manufacturers 1supplier

You benefit from:

• Order process made easier, by involvning less suppliers

• Optimized production planning and logistics

• Easier and more efficient assembly

• A lower total cost

Customized products

Examples

• Modified installation dimensions, preload and design

• Extended inner ring on bearings

• Plastic coated bearings

• Coated seals

Kitting & Processing

Simplified logistics

• Consolidated supply chain

• Simplified assembly

• Custom packaging, e.g. seal kits

• Tailored labels

Assembled products

Several components - one product

• Efficient and sustainable production

• Cost efficient

• Streamlined procurement

• Quality assurance for individual components

• Quality assurance overall

Deep groove ball bearings

Deep groove ball bearings are robust, versatile and quiet. They can operate at high speeds and, in addition to radial loads, they can also cope with a degree of axial load, as well as being easy to fit.

Single row bearings are also available with effective seals, these are pre lubricated with grease in production, and under normal conditions they are totally maintenance free. Two row bearings withstand higher radial loads.

• Wide range of uses

• Suitable for high speeds

• Open and sealed

• Robust and quiet

• Self-contained

Deep groove ball bearing, sealed

• Wide range of uses

• Suitable for high speeds

• LLU-LLB-ZZ

• Robust and quiet

Deep groove ball bearing, open

• Wide range of uses

• Suitable for high speeds

• Robust and quiet

Topline HT200

• Optimised bearing for extreme temperatures of up to +200°C

• Chemical resistant viton seal

• Available with shield HT200ZZ

Topline LT

• Optimised bearing for temperatures

• down to 60°C

• Available with lubrication adapted

• to cold and humid environments

• NBR rubber seal

• Available with shield LTZZ

• C3 internal clearance

Topline HVZZ

• Bearing for higher speeds

• Manufactured with P6 tolerance and P5 operational precision tolerance

• Reduced energy consumption

• C3 internal clearance

Topline FT150

• For temperatures up to 150°C

• Suitable for high speeds

• Viton sealed

• Available with shield FT150ZZ

• C3 internal clearance

Topline F600

• Bearing for extreme temperatures

• of up to +350°C

• Optimised bearing solution for furnaces

• C5 internal clearance

• Unsealed

Topline F604

• Bearing for extreme temperatures

• of up to +350°C

• Optimised bearing solution for furnaces

• Sheet metal sealed

• C5 internal clearance

Spherical roller bearings & Self-Aligning ball bearings

Through NTN SNR, Internordic offers the ULTAGE range of spherical roller bearings. The bearings, manufactured in Europe, represent a further development with improved properties such as speed, service life, lower friction and working temperature. They feature up to 18% more bearing capacity and an up to 75% longer service life, giving customers a better option.

Higher speeds allow access to more applications. The bearings permit 0.5 misalignment without any reduction in bearing capacity, and lower loads permit even greater misalignment. With metal cages the bearing can operate from 60°C to 200°C, although suitable lubrication should be used. Stabilised heat treatment allows this wide temperature range.

For tough applications such as high speed, shock loads and pollution a brass cage should be chosen. It reduces friction, and thanks to its design it reduces resonance whilst simultaneously improving load distribution through the bearing.

Spherical roller bearings are available with tapered bores, which are mounted with a suitable adapter sleeve. As standard, spherical roller bearings are manufactured with lubrication holes in the outer ring.

Various suffixes for NTN SNR spherical roller bearings:

• M – brass cage

• W33 – lubrication slot and hole in outer ring

• K – tapered bores for mounting with adapter sleeve

• C3/C4 – increased internal clearance

Spherical roller bearings - cylindrical bores

• Robust and insensitive to misalignment

• Suitable for heavy loads

• For tough applications there are bearings with brass cages

Spherical roller bearings - tapered bores

• Sleeve allows easy mounting and dismounting

• Suitable for heavy loads

• For tough applications there are bearings with brass cages

Spherical roller bearings ROX®

- metal shielded, cylindrical or tapered bore

• Sealed spherical roller bearing with the same properties as an open bearing

• Extended service life in demanding environments, reducing maintenance costs

• ISO dimensions make it easy to upgrade an existing design with an optimised bearing

Spherical roller bearings

- sealed

• For demanding applications in a contaminated environment

• Extended service life with effective seals

• Rubber-sealed EE bearings are wider than standard

• Metal-sealed bearings are available with the same width as standard

• Lower maintenance costs, longer service intervals

EF800

Spherical roller bearings - tapered bores

• Easy mounting and dismounting with adapter sleeve

• Robust bearing for tough applications with vibrations

• For vibrating applications

• C4 clearance as standard

Self-aligning ball bearing - cylindrical or tapered bores

• Align itself

• Low friction, allowing for a low temperature even at high speeds

EF800

Spherical roller bearings - cylindrical bores

• Robust bearing that is insensitive to misalignment

• For vibrating applications

• C4 clearance as standard

Self-aligning ball bearing

- sealed

• Align itself

• Pre lubricated and maintenance free

Angular contact & Thrust ball bearings

Single row and two row angular contact ball bearings. Axially displaced raceways between inner and outer rings means suitability for transfer of combined loads, creating rigid bearings. Axial force is generated from radial load, and this has to be counterbalanced by a corresponding force.

Another bearing is generally used to counteract this force. Single row angular contact ball bearings are available in two standard versions. Without suffix G, where only one bearing per bearing point is used, and with G as a suffix, showing that the bearing is flush ground and adapted for direct mounting against another flush ground bearing. The design of the two row angular contact ball bearing is comparable to two single row angular contact ball bearings, mounted in an O arrangement. This bearing has narrower installed dimensions than two single row bearings. The bearing is designed to transfer both radial and axial loads in both directions. Relatively high speeds are permissible, though there is a very limited misalignment capacity.

Thrust ball bearings are intended to transfer axial loads in one direction, but they will not withstand any radial load.

Single-row angular contact ball bearing

• Good for combined loads

• Very limited capacity for misalignment

• A flush ground version is available for mounting of two or more bearings

Two-row angular contact ball bearing 52/53, sealed

• Permits both radial and axial forces

• Both open and sealed versions are available as stock items

Two-row angular contact ball bearing 52/53, open

• Permits both radial and axial forces

• Both open and sealed versions are available as stock items

Thrust ball bearing

• Only for axial load

• Easy and affordable solution

• Does not permit misalignment

• Low speeds

Tapered & Cylindrical roller bearings

Cylindrical roller bearings: can transmit heavy radial loads, even at high speeds. The ‘E’ version has optimised internal geometry, thereby increased the radial bearing capacity whilst retaining the external main dimensions. Because of their design, involving cylindrical rollers, they are only able to cope with extremely small axial loads, and the misalignment capacity is very limited. There are many different versions of cylindrical roller bearings, with a floating inner ring or outer ring, allowing a degree of axial displacement as a result of heat expansion.

Tapered roller bearings using imperial dimensions: designed like their metric counterparts. They are highly suitable for transfer of high radial and axial loads, though only in one direction axially. NTN uses the designation 4T standard for these bearings. 4T means case hardened steel, creating an up to 40% longer service life.

Tapered roller bearings metric: The inner and outer rings as well as the rollers in a tapered roller bearing are conical. They are highly suitable for transferring big radial and axial loads. Single row tapered roller bearings can only be loaded axially in one direction and must be counterbalanced by a counteracting force. The bearings are usually dismantlable outer ring and inner ring with roller set. We only include single row tapered roller bearings in this catalogue. Please contact Internordic for further information on two and four row conical roller bearings.

Cylindrical roller bearing

• Cylindrical roller bearings can withstand high radial loads and high speeds

• Optimised design for long service life

• Manufactured in different versions, depending on the application

Tapered roller bearing, metric

• Designed for high combined loads

• Constructed for axial load in one direction

Tapered roller bearing, imperial

• Designed for high combined loads

• Imperial shaft dimensions and external dimensions.

Needle bearings

Needle roller bearings, cam followers, track rollers and support rollers are all rolling bearings, and are usually used for big loads, and if space is limited.

HK needle bearing

• Needle bearing without inner ring, with thin pressed outer ring

• Space saving and costeffective bearing

NK needle bearing

• Needle bearing without inner ring for higher speeds andbigger loads

• Solid outer ring for greater rigidity and greater precision

NATR/NATV

- Roller followers

• Support roller with axial guide

• NATV suitable for higher loads than NATR, but not with suchhigh speeds

• Available as an LL sealed version

• Spherical or cylindrical outer ring

NKI

needle bearing

• For applications requiring greater operational precision

• Used when a shaft cannot be used as a raceway

KRV - Cam

followers

• Comb roller for high loads

• Threaded shaft spindle for easy assembly

NA/RNA needle bearing

• Needle bearing for high loads

• High speeds

• Great operational precision

• Available with seals

AXK

- Thrust roller bearings

• Axial needle roller bearings can be used with or without washers

• Space saving bearing

NKX needle bearing and axial ball bearing

• Needle bearing for combined loads

• Without inner ring

AS axial bearing washer

• AS axial bearing washer

• Used when moderate precision is necessary

Bearing units

Bearing units comprise bearing housings with spherical bearing position and a deep groove ball bearing with a corresponding spherical outer diameter. The bearing thus has a self-aligning capacity and can compensate for any shaft alignment errors.

The housings are made of cast iron, sheet steel, zinc alloy, composite or stainless steel. The insert bearings are normally made of chrome steel and are available in stainless steel. Available in accordance with the European standard E.

Bearing unit, cast iron

• Easy to fit, using a small number of attachment bolts

• Easy to fit on shaft, thanks to a plus tolerance in the bearing’s inner diameter

• Self-aligning capacity

Bearing units, pressed steel housing

• Easy to fit, using a small number of attachment bolts

• Easy to fit on shaft, thanks to plus tolerance in the bearing’s inner diameter

• Self-aligning capacity

• Affordable alternative to cast iron bearing unit

Thermoplastic units

• Steel bearing housings adapted for foods, pharmaceuticals and the chemicals industry

• Smooth housing that prevents mould and bacteria from forming

• Affordable alternative to stainless steel unit

Bearing unit, stainless-steel

• Stainless steel bearing unit

• Stainless steel bearing inserts and grease fitting

• Food approved lubrication

Bearing units SENTINEL, solid lubricant

• Food-grade lubricant (NSF-H1 approved)

• Available as composite bearing units or stainless steel bearing units

• Silicone seals and flinger washers combined with solid lubricant protect against high-pressure washing

Bearing insert UC/US - grub screw

• Two grub screws on inner ring

• Straightforward fitting

• L3 3-lip seal for contaminated environments

• G2 double lubrication holes (SNR)

EX/ES eccentric retaining ring bearing inserts

• Locking with eccentric retaining ring

• One rotational direction

• Easy mounting

• L3 3-lip seal for contaminated environments

• G2 double lubrication holes (SNR)

• Lubricated for life, maintenance free, as the bearings cannot be relubricated

Split plummer blocks

SNC type split plummer blocks differ from bearing units, as the housings are divisible using a lid and a lower part, allowing quick mounting and dismounting. A spherical ball or roller bearing is also fitted in the housing, providing a very high bearing capacity, especially with roller bearings.

The housings can also be provided with various seals and condition monitoring, are ready for relubrication and have an excellent heat dispersion capacity. They are available as standard with 20 to 160 mm shafts. If you need larger dimensions please contact us at Internordic, and we will help you.

SNC - split plummer blocks

• Modular design – Combine different options such as housings, bearings and seals, to suit your application

• Reinforced housing and lid, to withstand high stress levels

• Good heat dispersion

• Withstands high radial loads due to larger bolts securing the lid

• Markings in the housing for multiple relubrication options, outlets for condition monitoring, and mounting points

• These housings are often used in heavy industry

Cover plates

• Wide range

• Adapted for many different applications

• Temperature range -40 to +100 degrees

Seal for SNC split plummer blocks

• Wide range

• Adapted for many different applications

Location rings

• Wide range

• Adapted for many different applications

722500 - Series

• Wide range

• End cover or through shaft

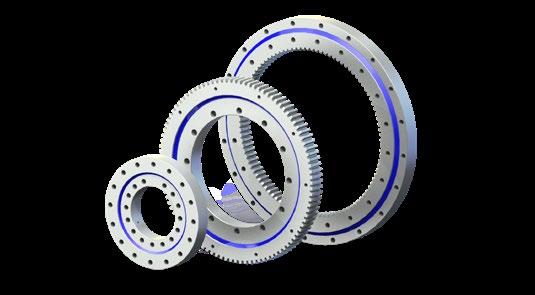

Slewing rings & Slew drives

We offer the market’s best slewing ring bearings and slew drives. These products are designed to withstand demanding industries and harsh conditions, enabling the handling of heavy loads, rotational forces, and precise motion. Examples of industries include forestry and agriculture, mining, energy and wind power, material handling, and automation.

With over 20 years of experience in rotating modules, gears, and power transmission, TGB Group has become a world leader in developing slewing ring bearings and slew drives, as well as in producing motion solutions for industrial markets and renewable energy.

What a drive consists of and 3 steps to choose the right one

See all products here

Slewing rings

• Available with internal or external gear, also without gear

• Made to handle high axial and tilting loads, also radial loads

• Very well sealed, to cope with tough environments

• Available as standard range and customised

Slew drives

• Integrated drive, installed directly on the customer’s application

• Made to handle high axial, radial and tilting loads

• Great holding torque thanks to the self locking design

• Very well sealed off, to cope with tough environments

• Available as standard range and customised.

Freewheels

With its compact and space-saving design, the freewheel is a complete solution that works both as a bearing and as a freewheel. The design with its reversing protection device function has a wide range of uses, typical applications being when you are seeking a reversing protection device, a freewheel function or an indexing freewheel. With a nominal torque value of up to 325 Nm, freewheels can cope with tough applications imposing stringent demands as regards locking effect.

Freewheels are available with an 8 to 40 mm shaft dimension, both with dust seals and with a rubber seal for a contaminated environment. Fitting is performed using an interference fit or with a keyway, either in the inner ring or both inner ring and outer ring. To achieve a maximum and precise locking effect, an interference fit is preferable. The torque is transmitted via the rings in the freewheel, and on to the housing and shaft, leading to safe and efficient use of the freewheel, with endless areas of use.

Freewheels are used in many different applications, e.g. machine tools, the packaging industry and materials management.

Freewheel ZZ / FZ

• Precise and strong locking effect by means of an interference fit

• Both reversing protection device and bearing function

Freewheel ZZ..2RS / FZ..2RS

• Pre-lubricated freewheel with effective seals for contaminated environments

• Precise and strong locking effect by means of an interference fit

• Both reversing protection device and bearing function

Freewheel ZZ..PP / FZ..PP

• Keyway for straightforward fitting

• Both reversing protection device and bearing function

• Keyway in accordance with DIN 6885 tolerance on keyway JS10

Freewheel ZZ..P2RS / FZ..P2RS

• Pre-lubricated freewheel with effective seals for contaminated environments

• Keyway for straightforward fitting

• Both reversing protection device and bearing function

• Keyway in accordance with DIN 6885 tolerance on keyway JZ10

Freewheel ZZ..P / FZ..P

• Keyway for straightforward fitting

• Both reversing protection device and bearing function

• Keyway in accordance with DIN 6885 tolerance on keyway JS10

Locking nuts

SFERO lock nuts are a unique and patented series of locking and regulating nuts. SFERO’s unique lock nuts, which are characterised by the simplicity of fitting, dismantling and refitting hundreds of times, whilst retaining a very high degree of precision, as well as reliability without any special tools. Together, these features make for a time benefit, and thus a cost saving. A much better locking effect, compared with conventional lock nuts, is attained without risking damage to threads in nuts or on shafts, whilst minimising the risk of clearance as a result of wear, both radially and axially.

Locking is by means of a sprung slit that has been cut out on three sides from the nut’s thread. One or two grub screws press the slit’s thread profile down into the receiving thread profile on the shaft, attaining a precise and strong lock that is distributed evenly over the whole contact surface. The system means that neither the slit nor the receiving thread are at risk of damage, creating significant benefits compared with use of a separate insert made of metal or artificial fibre.

Piscetta’s shaft nuts or ‘ball bearing nuts’ are used to stress fixed bearings and other components on shafts, and for fitting and dismantling shaft spindles or on sleeves. The nuts have four or eight uniformly positioned recesses on the outside for pulling hook spanners or impact hook spanners. Bearings on conical.

KM-nut

• Locking of bearings and components on shafts

• Easy to use together with MB secure locking

LR locking nut with radial locking

• Radial locking

• Does not damage the threads can be refitted without detriment to the locking effect

• Mounting of ball screws

• Rotating high-speed spindles

MB-washer

• Used to strengthen the KM locking nut’s locking onto the shaft

• Together with the KM locking nut, this makes for stable and straightforward locking

LF locking nut with front locking

• Radial locking

• Does not damage the threads can be refitted without detriment to the locking effect

• Mounting of ball screws

• Rotating high-speed spindles

KM GI

• Built in elastic nylon ring that locks against the shaft thread

• Quick and straightforward locking for normal use

Plain bearings

Thanks to their excellent properties, plain bearings are used in nearly all sectors of industry where maintenance-free bearings are required, e.g. in the food and chemical industries, and where shortages of lubrication are possible and where the bearing requires very limited space.

Additional advantages of plain bearings include their ability to withstand much higher loads, shocks, and vibrations. Some form of lubrication must always be used, either as supplementary lubrication or in a self-lubricating design. When properly designed, there is no contact between the material surfaces, resulting in minimal friction at normal operating speeds.

You can also order products entirely according to your own drawings and specifications.

Calculate load and speeds

• Suitable for lighter applications

• PTFE sliding surface on tin-plated steel backing.

• Particularly suitable when external lubrication is not desired or not possible, as well for as high loads at a low speed and a high speed for low loads

• Also viable in oil or water, and display good corrosion resistance

• Allow very high and low temperatures, and are low-friction

Steel

• For extremely heavy loads, abrasion (heavy, grinding movements) or impact stress

• Available as solid steel or wrapped spring bushing

• Special designs on request

Bronze

Graphite

• Requires initial lubrication, after which minimal maintenance is needed.

• Handles dirty environments, shock and impact loads, as well as misalignments to a certain degree

• Available as partly self-lubricating for longer service life

Plastic

• Versatile material, endless possibilities thanks to injection moulded production method

• Great variety of application possibilities, from lighter to heavier and more demanding applications

• Self-lubricating as a basic feature, with the capacity to deal with or benefit from oil and water

A classic in many variations Suitable for dirty environments, shock loads, high loads, vibrations and corrosive environments

• Hardness between 90 and 150 HB for optimum service life

• Typical applications include construction, forestry, and agricultural machinery

• Available as a self lubricating option with sintered bronze or filled lubrication pockets

Composite

• Excessive load, abrasion (heavy grinding movements) or impact stress

• Self-lubricating as a basic feature, with the capacity to deal with or benefit from grease, oil and water

• Available in standard sizes for DIN ISO 4379, to replace traditional bronze bearings

• Self-lubricating bearings with built-in graphite plugs for extra wear-resistant bronze

• Cylindrical bearings, flanged bearings, or sliding plates

• Maintenance-free plain bearing

• Suitable for high loads

• Capable of withstanding extreme temperatures

• Long service life

Turned bronze bearings

• Suitable for high loads

• Wide range of applications

• Long service life

• Wide temperature range

EX3M Nickel Bronze

• Extreme load capacity

• High wear resistance

• Suitable for dirty and corrosive environments

Dynaweave

• Fiber-reinforced PTFE

• Self-lubricating

• Capable of withstanding high loads

• Good performance under vibrations

Spherical plain bearings & Rod ends

Spherical plain bearings and rod ends are standardized bearings that are particularly suitable in applications involving pendulum motion and heeling motion at relatively low speeds. Thanks to the self-adjusting capacity, permitting adjustment movements in different directions, they are suitable where a skew setting option is required.

The inner ring has an outer spherical convex envelope surface corresponding to the outer ring’s spherical but concave inner envelope surface. This bearing type can cope with oscillating and alternating loads as well as static loads.

Spherical plain bearing

• Steel/steel requires maintenance

• Steel hard chrome/bronze requires maintenance

• Steel hard chrome/PTFE fabric maintenance free, should not be lubricated

• Steel hard chrome/PTFE composite maintenance free, should not be lubricated

• Available in stainless steel

Rod end - weldable

• Steel/steel

• Forged

• Circular transverse surface

Rod end

• Steel/steel requires maintenance

• Steel hard chrome/bronze requires maintenance

• Steel hard chrome/PTFE fabric maintenance free, should not be lubricated

• Steel hard chrome/PTFE composite maintenance free, should not be lubricated

• Available with external and internal thread

• Available with right hand or left hand thread

• Available in stainless steel

Thrust spherical plain bearing

• Steel/steel

• Steel/PTFE fabric (maintenance-free)

• Best option for axial loads

Rod end - clampable

• Steel/steel

• Also available with left hand thread

Angular contact spherical plain bearing

• Steel/steel

• Steel/PTFE fabric (maintenance-free)

• Best option for combined loads

• Withstand big radial loads

Clevises & Angle joints

Typical applications for clevises are pneumatic cylinders, gas cylinders and linkage systems. Typical applications for angle joints are gas springs, gas cylinders, wire controls vehicle control cables, hydraulic cylinders, construction machinery and agricultural machinery.

Angle joints

• Din 71802

• Available in various materials

• Customisable

Axial joints

• Din 71802

• Available in various materials

• Customisable

Clevis

• Din 71752

• Available in various materials and with various threads

• Customisable

Bolt

• We offer various types of bolts for the clevises

Ball studs

• Din 71803

• Complement to housing see Axial link

• Available in various materials

Bolt/washer/pin

• We offer various types of bolts for the clevises

Ball units

Ball units are an important component in the handling industry. They are used to load and feed machines, or as an alternative to wheels or sliding plates. Ball units can be used with the ball uppermost, which is most common, or downwards, thereby reducing the load capacity. A number of different attachment methods are available, and there is an appropriate type of ball transfer unit for each method.

Most types of ball units are equipped with seals to prevent the ingress of dirt into the balls. Furthermore, several types are equipped with one or more drainage holes in the bottom, so dirt that has penetrated will also find its way out.

The basic materials are carbon steel balls with a galvanised housing, but ball units made entirely of stainless steel are also included in the range. There are also balls made of other materials, such as nylon. A series of miniature ball units for very small and compact bearings is included in the range, as well as ball transfer units that can cope with very big loads.

To bear in mind:

• Load, static/dynamic/shock

• Size of goods to be moved

• Noice requirements

• The hardness of the receiving surface

Flange fixing unit

• For general use

• Low profile

• With drainage hole as standard

Thread fixing unit

• Ball transfer unit for screw fitting with adjustable height

• Different thread lengths

• Different thread types

Spring loaded unit

• Sprung ball transfer unit for impact loads

• Ideal for casting machines

Base fixing unit

• Ball transfer unit for fitting above

• High profile

• Attachment hole for screw in the substrate

• Big attachment plate for stable fixation

• Self-adjusting, thanks to the built in spring

• Warning: do not dismantle the ball transfer unit it is pre stressed

Heavy duty unit

• High load capacity

• Low profile

• Black galvanized for better rust

• resistance

• Ball transfer unit for submersion in substrate

• Available with drainage hole

Mini ball transfer unit

• Compact design

• Down to 4.8 mm ball

Euro unit

• Ball transfer unit for submersion insubstrate

• Low profile

• Attachment with rivet or screw, orsolely with a light fit

• With drainage hole as standard

• There are two types for very big loads

Float-on

• Float on castors for transporting and handling disc material

• Suitable for especially fragile and treated materials, in particular glass

• Available in black rubber and red polyurethane

• 35 mm and 50 mm in diameter

• PUR is recommended for heavier loads and demanding work conditions

Fixeringsklämmor

• Available in several variants, for various attachment methods

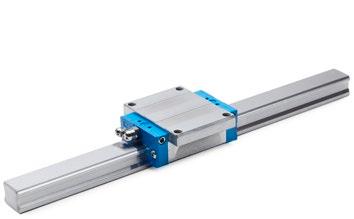

Linear guides

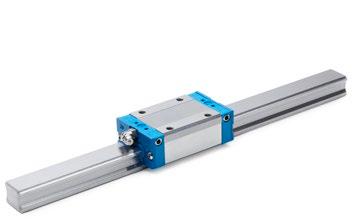

Rail guides from NTN SNR are stocked in Nässjö for rapid delivery. We have a wide range of carriages with different preload and seal options. Rails are stocked at the full length of 4000 mm, which is cut in accordance with the customer’s specification to suit their exact requirements.

Linear guides are used in a number of different applications, such as tools, packaging and printing machines, automation and special machinery, the wood industry, electronics and medical technology. The internal properties of NTN SNR linear guides allow a good level of self adjustment, make for lower manufacturing costs for mounting surfaces and compensate for mounting errors.

LGBC linear guide with ball chain

• High capability for acceleration and high speed

• Less noise generation

• Smoother operation

• Higher dynamic load capacity

• Reduced maintenance requirements

LGBX linear guide without ball chain

• Stable operation

• In line with DIN 645

• Good self-adjusting properties

• Many preload and precision options

LGMC miniature linear guide

• Lightweight

• Compact design

• Available with different preload and seal options

• Sizes 7, 9, 12, 15 mm

LGBR/LGMR rail guide

• Various surface treatments are available

• One type for all applications

• J-type for rail joint

Linear guides accessories

• Wide range of different seal options,scrapers

• Lubrication system LU1 container for less frequent lubrication

• Rail caps for rail holes different materials and cover strips

Clamping and braking elements

• Manual locking

• Pneumatic locking, two versions

• Also available with electric or hydraulic control

Linear products

The aim of linear products is to reduce friction and increase precision in linear movements. Internordic is the Linear Centre for NTN SNR, and markets our supplier’s full range of linear guides, ball bushings, linear axis units, ball splines and ball screws. We also have a wide range of accessories.

We stock our most common products in Nässjö , and ongoing deliveries from NTN SNR’s central warehouse ensure we have good availability. We make minor adjustments at our logistics centre, so our customers receive rapid and quality service.

Linear axis units

• Several alternative guide and drive systems

• Service friendly

• Compact design

• Telescopic units for space-saving

• High loads and high precision

Shafts

• Tolerance class h6

• Diameter from 4 to 60 mm

• Material Cf53 (1.1213) standard

• Our shafts are available in alternative materials on request

• Also available as a hollow shaft

Ball screw

• Rolled ball screws in tolerance classes T7 and T5

• Ground ball screws in tolerance classes T5, T3, and T1

• Standard diameters 6–80 mm, special diameters 6–125 mm

• Leads from 1–50 mm

• Various nuts and accessories

Ball bushings

• Wide range of different types

• Choice of material by application

• Seal for guaranteed service life

• Ball bushing unit with aluminium housing and integrated lubrication system

Ball splines

• Standard diameters from 4 to 100 mm

• Various torque bushing options

• Several tolerance classes

• Customisable

Ball bushing accessories

• Shaft support

• Support bars for long stroke length

• Clamping elements

Radial & Axial seals

The primary function of the radial rotary shaft seals is to separate two different media in rotating applications with relatively low pressures, where the seal lips are flush with the shaft. Shaft seals are available in various designs.

‘V’ rings (front seals) are tried-and-tested variants for sealing an application off. Their primary effect is as a dirt seal, and there are various profiles for the various applications, including in the heavy duty version, where the seal is affixed to the shaft using a clamp.

Gamma rings (front seals) are a tougher variant of the ‘V’ ring. They act as seals against dirt, but depending on the variant the sheet metal jacket also acts as a discharge ring and/or labyrinth seal outside the rubber seal. The latter requires a special groove at the sealing surface.

Radial seal

- metric and imperial

• Various materials

• Several different designs

• Easy to fit

Sealing lid

• Rubber clad jacket surface provides a good sealing effect

• Various materials

Axial

seals / V rings

• Various materials

• Several different designs

• Easy to fit

Shaft repair sleeve

• Perfect seal mode

• Simple to fit

• Economical solution

Gamma ring

• Various materials

• Good sealing effect

• Easy to fit

Mechanical face seals

• Used in extreme conditions and harsh environments where wear, dirt, and moisture are a challenge

• Robust construction consisting of two metal rings that seal against each other

• Long service life and minimal maintenance

Hydraulic & Pneumatic seals

Seals for pendulum motion in hydraulic and pnuematic applications. To optimise operational reliability and service life, choosing the right features for a cylinder is crucial.

Piston seals

• Wide range of profiles

• Wide range of dimensions

• Several different materials

Rod seals

• Wide range of profiles

• Wide range of dimensions

• Several different materials

Sealing sets

• Wide range

• Adapted to many different applications

• Temperature range 40 to +100 degrees

Back-up rings

• Wide range

• Adapted for many different applications

Wipers

• Wide range

• Adapted to many different applications

Guide rings/guide strips

• Guide tape on roll

• Easy to adapt

• Wide range

• Adapted for many different applications

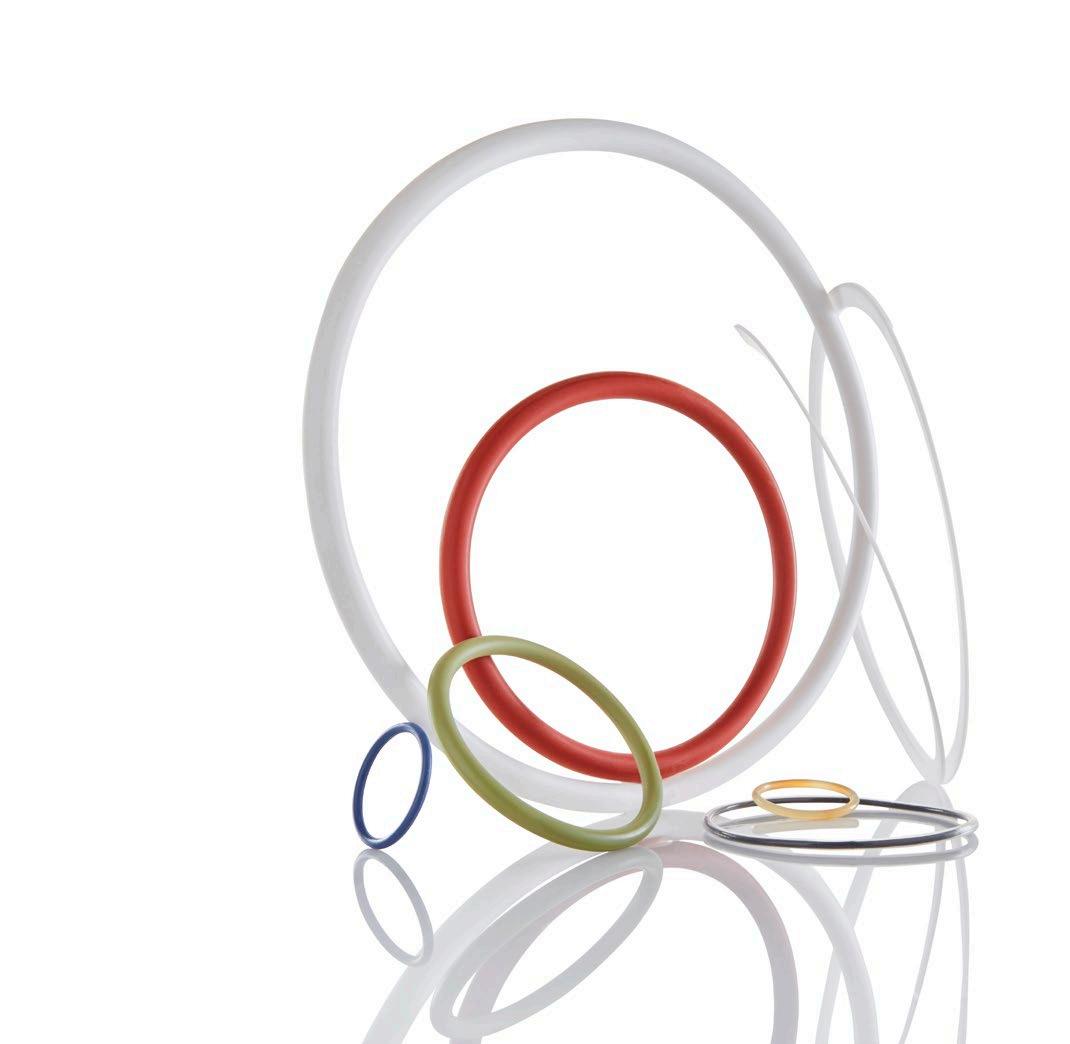

O-rings

The O-ring is shaped as a simple seal, primarily intended for static applications; in the correct ratio, O-rings can also function as a dynamic seal. Over the years, the O-ring has proven to be a reliable sealing solution in many applications, and the main challenge is selecting the correct material for the specific application.

O-ring cord allows you to keep the most common cross sections in stock and, when required, easily manufacture the exact O-ring dimension needed on site. Internordic offers both O-ring cord by the metre and flexible O-ring kits containing cord, a knife, fast-acting adhesive, and cutting and bonding templates.

The X-ring is a type of seal that can be used in dynamic applications and may serve as an alternative to an O-ring. The X-shaped profile provides a smaller contact surface than an O-ring, resulting in reduced friction and lower pre-stress. The X-ring is double-acting and requires minimal installation space.

O-rings

• Broad variety of compounds

• Easy to fit

• Cost-effective sealing solution

• Wide range of use

Technical

seals

• Designed for unique grooves

Customized seals

X-rings

• Broad variety of compounds

• Easy to fit

• Space efficient

O-ring cords

• No size limitations

• Easy to fit

• Cost-effective service solution

Back-up rings

• Easy to fit

• Wide range

Retaining rings & Shims

Retaining rings are a quick and simple yet effective form of locking. The product ranges from the standard DIN 471 and 472 to fully customised solutions tailored for specific applications.

The shims we stock is in accordance with DIN 988 and is primarily used for fitting bearings. We can also help you develop completely unique solutions for specific applications.

Circlips

• Wide range

• Wide range of dimensions

• Customised rings can be developed

E-clips

• Simple to fit

• Available stacked for automatic installation

Lock washers

• Simple to fit

• For both shafts and housings

Shims

• Customised solutions

• You avoid doing any groove-working

• DIN 988, types SS and PS, are easily accessible

Spring pins & Disc springs

Spring pins and coiled pins are fasteners that are available in a wide range of different applications. They can be used for everything from locking components in heavy machinery to hinges for the smallest plastic boxes.

Disc springs are used in applications where ordinary spiral/pressure springs are not sufficient, and they can withstand phenomenally big loads.

Vibration dampers are an effective way to reduce both vibrations and noise in applications. In addition, they significantly increase service life by preventing failures and damage that vibrations can cause.

Slotted spring pins

• Strong locking

• Wide range

• Also available in stainless steel

Disc springs

• Available in stainless steel

• Cope with strong forces

Coiled spring pins

• Wide range of uses

• Also available in stainless steel

• Even load against facing surface

Vibration dampers

• Effective noise and vibration reduction

• Reduced wear and longer service life

• Wide range for different mounting options and requirements

Clamps

We have top quality hose clamps that are in line with most of the different standards for most applications. Overall, this means you will find the clamp you need for your application, and you can also be sure you are getting one of the market’s best clips.

Hose clamps

• Wide product range

• Various materials

• High quality

Accumulator clamps

• Available in stainless steel and acid resistant

• Rubber clad also grips during vibration

Super clamps

• Very strong joins

• Wide dimension range

Rubber-clad clamps

• Both German and Swedish standards

• Perfect for attaching pipes or cables

Endless bands

• Also available in stainless steel

• 8 and 14 mm band width

• Perfect for service and maintenance

Cable ties

• High quality

• Delivered in sealed bags for increased service life

Grease fittings

The grease fitting is an important part of most moving applications. To ensure reliable relubrication and maintenance, we market world- class grease fittings of uncompromising quality. The standard insert has a hydraulic grip, but we also offer button head fittings, conical inserts, and the possibility of developing customised solutions.

Hydraulic grip

• High quality

• Good availability

Button head fitting

• Wide range

• Also available in stainless steel and acid resistant

Plastic inserts

We market various components for for plastic industry, ranging from threaded inserts to compression limiters, Press n Loks, and bushings for various types of plastic applications.

Thread inserts

• High quality

• Various materials

Compression limiters

• Available in both metric and imperial dimensions

Lock pins, Press-N-Lok™ BP100

• Strong permanent joining of two plastic components

• Inserted manually or through automated processes

• High level of corrosion resistance

• Easy and quick assembly

• Made of corrosion-resistant lightweight aluminum, completely lead-free

• Available in various lengths and with different numbers of knurls

Service & Maintenance

A prerequisite for components that are to last is proper maintenance. Lubrication is a very important factor, as is cleaning your hydraulic system for optimum seal performance.

At Internordic, we offer tools to ensure optimum material performance after fitting, a factor that largely determines a component’s service life.

Induction heaters and mounting equipment

Grease for various bearing applications

Shaft repair sleeve

Range box

Ball products

Installation tools for E-clips

O-ring tool kit

Circlip pliers

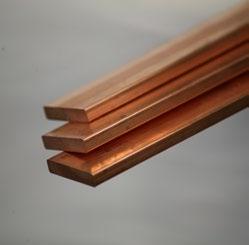

Bronze alloys

In addition to our stocked standard dimensions, we also offer special castings in a variety of bronze alloys. Our offerings range from individual centrifugally cast rings or tubes up to Ø 2500 mm in outer diameter to larger series of continuously cast products.

From raw material to finished, customer-specific product