For the second year running the results are in and we couldn’t be happier. Scania has once again been voted the number one* truck brand in the country by the people whose opinion we value the most - New Zealand truckies.

We’re chuffed to have rated highest on all measures, including most preferred, comfort, safety, sustainability, performance, efficiency, service and parts. Thanks again New Zealand. It means a lot.

EDITORIAL DIRECTOR

Dave McCoid

Ph: 027 492 5601

Email: dave@nztrucking.com

EDITOR

Gavin Myers

Ph: 027 660 6608

Email: gavin@nztrucking.com

For all advertising enquiries:

ADVERTISING MANAGER

Pav Warren

Ph: 027 201 4001

Email: pav@nztrucking.co.nz

Mike Devon

Ph: 027 332 4127

Email: mike.devon@nztrucking.co.nz

Maddy McCoid

Ph: 027 336 6811

Email: maddy@nztrucking.co.nz

SUB EDITORS

Tracey Strange, Faye Lougher

EDITORIAL

Carl Kirkbeck, Craig McCauley, Shannon Williams, Russell Walsh

LITTLE TRUCKER

Shannon Williams

Ph: 021 182 4803

shannon@nztrucking.co.nz

CONTRIBUTORS

Craig

Faye Lougher

Alison Verran

Mike Verran

Andrew Geddes

Niels Jansen (Europe)

Paul O’Callaghan (UK, Europe, Australia)

Mike Williams (Australia) Will Shiers (UK)

(USA)

New Zealand Trucking magazine is published by Long Haul Publications Ltd. The contents are copyright and may not be reproduced without the consent of the editor. Unsolicited editorial material may be submitted, but should include a stamped, self-addressed envelope. While every care is taken, no responsibility is accepted for material submitted. Opinions expressed by contributors are not necessarily those of New Zealand Trucking or Long Haul Publishing Ltd. All rights reserved. This magazine is subject to the New Zealand Press Council. Complaints are to be first directed to: editor@nztrucking.co.nz with “Press Council Complaint” in the subject line. If unsatisfied, the complaint may be referred to the Press Council, PO Box 10 879, The Terrace, Wellington 6143 or by email at info@presscouncil.org.nz

Further details and online complaints at www.presscouncil.org.nz

6 months (6 issues)

One year (11 issues)

Two

1 Year Australia (11 issues) $250

Ilive in the suburbs directly across the road from a prominent state-integrated primary school – and by ‘directly’, I mean I can walk in a straight line down my driveway, across the street and through the office building door. As you’d expect, just about the entire length of the block is a school zone with four substantial speed humps. One of these is a pedestrian crossing, installed last year when the council added a second footpath to our side of the road.

Each day, I watch motorists navigate these humps. I watch parents take over the surrounding streets, dropping off and fetching their kids, and I watch pedestrians walk up and down. Each day, numerous drivers will hit the speed humps so hard and fast that they bottom out their cars or give serious airtime to whatever flotsam is in the back of their ute, and more parents and kids will just cross the road at will than walk along the path to the new crossing.

As with any other city, Tauranga has a plethora of cycle paths and lanes. Having cost many millions to install over

the years, they serve a good purpose. I use them myself when I fancy a pedal, and I know one person personally who rides his bike 5km to work and back every day. Sadly, I doubt the same can be said for other residents, some of whom clearly feel they shouldn’t be restricted to their special lanes while most others seemingly have no desire for that mode of transport – such is the overwhelmingly barren state of those paths and lanes.

I share these observations in the wake of last month’s 2024 National Land Transport Programme release. As expected, the coalition government has done what it promised it would and prioritised investment in roading infrastructure. Of the $32.9 billion total, basic calculations reveal about $18.4 billion relate directly to road maintenance and improvements, $6.4 billion has been allocated to public transport, $460 million to footpath and cycleway improvements and $1 billion to rail. The rest consists of road policing and safety ($1.7 billion), weather event recovery, resilience and climate response, debt repayments and so on.

You can find the full details

on page 15 and, as you’ll read elsewhere in this issue, our own industry has praised the plan. But, as expected, the opposition, academics and interest groups have bemoaned the priority being placed on road infrastructure while the likes of cycleways and rail have had their allocations slashed. This will drastically, negatively, impact on things like vehicle emissions and pedestrian safety, they say.

While everyone’s entitled to share their opinions, I feel it necessary to counter that for the better part of a decade, the shoe has been on the other foot. As my opening anecdotes illustrated, it’s seemingly made little difference, while the rest of our roading infrastructure has suffered for it.

From my own humble, everyman point of view, yes, it’s about time investment went back to roading infrastructure. We’ve said before it is as much about safety and efficiency as anything else. It means all road users, from commercial and public transport vehicles to private motorists in gas-guzzling V8s to EVs or motorcycles, can complete their journeys more quickly, easily and safely with

reduced fatigue and wear and tear to their vehicles. And, in the case of commercial vehicles, that means avoiding unnecessary costs being passed on to consumers brought about by premature repairs and increased diesel consumption.

Further, yes, investment in public transport systems is good (and we have $6.4 billion worth of it here), but we certainly don’t need a further proliferation of cycleways and speed humps right now. If anything, we need increased spending and effort on education and enforcement, encouraging and incentivising people to use these facilities properly and obey the road rules, and penalising them when they don’t. And that all starts every morning when we take our kids to school and lead by example by doing something as simple as crossing the street.

Gavin Myers Editor

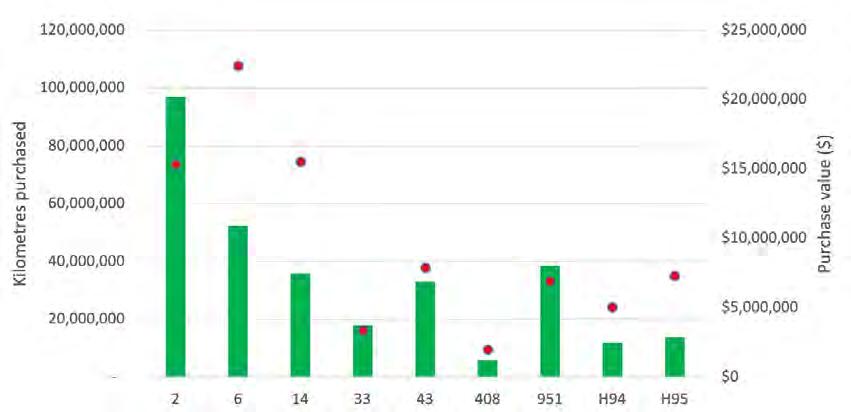

The Scania R540 No Bad Days, owned by Kane and Tamara Scott’s family business Scott Carrying Company, has won the 2023-2024 John Murphy Memorial Top Truck of the Year competition.

After a month of public voting on the New Zealand Trucking website, the Scania emerged victorious in a closely fought competition, with the top three voted separated by just a couple of hundred votes out of the

4800 total.

“That’s very humbling, we’re very, very happy with that. It’s definitely a credit to the guys who drive it every day; they keep it in pretty shipshape form,” says Kane Scott.

No Bad Days operates out of Kaiapoi moving refrigerated product between Christchurch and Auckland, so is often seen throughout the country. “Thank you to everyone who put a vote our way and all the sponsors in the competition,” Kane adds.

As ever, the Top Truck of the Year competition is supported by Power Retreads, which will award Kane a set of premium Vipal retread tyres. Rochelle Thomas of Auto Art by Rochelle will also produce a bespoke painting of the winning truck based on the Top Truck poster that appeared in the December 2023/January 2024 issue.

These prizes, along with the 2023-2024 John Murphy Memorial Top Truck of the Year plaque – awarded in memory

of the former editor of New Zealand Trucking magazine –will be presented to Kane and Tamara in the coming weeks. Look out for that report in an upcoming issue.

Congrats to the Scotts and No Bad Days, and well done to all the other trucks that were in this year’s competition. And thank you to everyone who voted this year for supporting the competition.

We specialise in the design, manufacture, and maintenance of all classes of tankers and trailers for fuel and dry bulk goods.

Tickford Racing trusts Castrol fluids in its supercars and transporters. When performance matters, trust Castrol in your trucks.

The eActros 600 from Mercedes-Benz Trucks has been voted International Truck of the Year 2025 by a jury of 24 editors and senior journalists from the commercial vehicle press, representing 24 of Europe’s most important truck magazines.

The prestigious award was presented to Karin Rådström, CEO of Mercedes-Benz Trucks, during the IAA Transportation press day in Hanover, Germany, in September.

With 88 votes, the German truck manufacturer’s heavy-duty battery electric vehicle (BEV) beat stiff competition from Volvo Trucks’ Aero range with electric or conventional powertrains and the Iveco S-eWay electric tractor.

It is the second time an electric

truck has won the International Truck of the Year Award, which dates back to 1977. In addition, five of the seven vehicles on this year’s IToY shortlist are batteryelectric models with zero tailpipe emissions.

“This is another sign that the energy transition is gaining momentum among truck manufacturers and is attracting the interest of European transport operators,” says the International Truck of the Year (IToY) jury.

According to the IToY rules, the annual award goes to the truck launched in the previous 12 months that makes the most significant contribution to road transport efficiency. The judging is based on a number of critical criteria, including technological

innovation, comfort, safety, driveability, energy efficiency, environmental footprint and total cost of ownership (TCO).

The numerous IToY journalists who participated in the more than 15,000km eActros 600 European Testing Tour 2024, organised by Mercedes-Benz Trucks, praised the new ProCabin’s advanced aerodynamics. With its protruding front section and smooth, curved surfaces, the ProCabin is designed to improve airflow by 9% compared with the current model.

The IToY journalists appreciated the powertrain’s performance, based on twin 400kW electric motors on the electric axle and three LFP battery packs of 20 kWh each. This powertrain provides

smooth acceleration with three different driving programmes in a quiet, vibration-free working environment.

As the IToY judges witnessed, with more than 600kWh of installed capacity, a standard 40-tonne tractor-semitrailer combination can achieve a range of more than 500km without intermediate recharging.

Summing up the jury’s vote, International Truck of the Year chairman Gianenrico Griffini said, “Mercedes-Benz Trucks designed the eActros 600 as an electric truck right from the start. This decision has put a state-of-theart BEV on the road capable of fulfilling a wide range of longhaul missions.”

The MAN hTGX – a heavy-duty truck with a hydrogen combustion engine – has won the 2025 Truck Innovation Award. The International Truck of the Year journalists presented Alexander Vlaskamp, CEO of MAN Truck & Bus, with the prestigious award during the IAA Transportation press day in Hanover.

Following the inaugural Truck Innovation Award in 2019 in recognition of the aFAS Level 4 automated driverless safety truck and the ATLAS-L4 and ANITA autonomous driving projects in logistics operations in 2023, this is the third time MAN Truck & Bus has won this trophy.

The Truck Innovation Award, created by the International Truck of the Year (IToY) jury, recognises excellence in advanced transport solutions. The IToY group comprises 25 commercial vehicle editors and senior journalists, representing major trucking magazines from Europe and South Africa.

With 84 votes, MAN’s hTGX beat off competition

from Renault Trucks’ Oxygen – a prototype distribution truck – and Iveco’s S-eWay Fuel Cell (FCEV), a zero-emission electric long-distance vehicle.

During a road test in Saalfelden, Austria, IToY journalists praised the hTGX’s diesel-like performance and driveability, delivered by MAN’s 16.8L H4576 in-line, six-cylinder, spark-ignition hydrogen engine.

The International Truck of the Year judges also praised the heavy-duty truck’s near-zero carbon footprint, the range of around 600km provided by the 56kg, 700-bar hydrogen tanks and the simplified after-treatment system.

Summing up the jury’s decision, Gianenrico Griffini, chairman of the International Truck of the Year, said, “MAN’s hTGX opens a new chapter in decarbonising road transport. It can be the vehicle of choice for heavy-duty applications, such as in the construction sector, in challenging climatic conditions.”

Keith Andrews has begun trading in new dealerships in Christchurch, Tīmaru and Dunedin, becoming the nationwide sales dealer for Daimler Truck’s MercedesBenz, Freightliner and FUSO commercial vehicle brands.

Prior to 12 September, Keith Andrews represented MercedesBenz Trucks, Freightliner and FUSO in the North Island, and CablePrice represented the three brands in the South Island.

To deliver all New Zealand customers the full benefit of the general distributor appointment, Keith Andrews Holdings and CablePrice have now reached agreement on the sale and acquisition of selected South Island Daimler Truck dealerships.

Keith Andrews Trucks will now

begin trading at CablePrice’s 29 Waterloo Road, Christchurch, truck dealership together with sites in Tīmaru and Dunedin. CablePrice’s dealerships in Nelson, Greymouth and Invercargill will maintain their Daimler Truck service and parts status.

The Keith Andrews truck sales team will be located across the South Island, making Keith Andrews the nationwide sales dealer for Daimler Truck’s Mercedes-Benz, Freightliner and FUSO commercial vehicle brands.

The established South Island sales team have all joined Keith Andrews, including Andrew Buschl based in Nelson, Wayne Byrnes and Theo Ferreira in Christchurch, Hamish Stonehouse in Tīmaru, and

Tristan Duffell in Dunedin and Invercargill.

“The CablePrice team has achieved great success with FUSO in particular and been an integral part of market-leading truck and bus sales efforts in the past three years,” said Keith Andrews Holdings executive director Kurtis Andrews.

“It has been a very busy time, and without doubt, it has been a pleasure to meet the teams in Christchurch, Tīmaru and Dunedin over the past months. Despite the distractions of the purchase process, it’s heartening that everyone has remained highly committed and focused on the job of keeping Daimler Truck customers moving,” he said.

“While we welcome the truck teams in Christchurch, Tīmaru

Our 100 year history proves that when you do everything with heart, nothing is too heavy. Mitsubishi from Centra, moving New Zealand forward.

You can hire a Mitsubishi Forklift on a fixed term hire contract, maintenance included on terms from day to day right up-to 7 years

• New or Used, ex fleet forklifts available

• Huge range to choose from

• Delivery within 24hours

Auckland - 32 Hastie Avenue, Māngere Bridge, Ph: 09 634 8500 Hamilton - 38a Maui Street, Ph: 07 849 5128

Tauranga - 12/45 Kaweroa Drive, Tauriko, Ph: (07) 282 9910 Palmerston North - 25 Bisley Street, Ph: 06 355 9033 Christchurch - 38a Parkhouse Road, Ph: 03 343 6814

and Dunedin, we are thrilled by the prospect that CablePrice will continue to provide fantastic customer support in the mainland in Nelson, Greymouth and Invercargill.”

CablePrice NZ managing director Aidan Mahony added, “I am extremely proud of what our team has achieved since becoming the South Island dealer for Mercedes-Benz, Freightliner and FUSO trucks, and I believe all customers will benefit from having a New Zealand-based and focused general distributor.”

Andrews and Mahony said Keith Andrews Holdings and CablePrice aim to maintain all existing operations to ensure a smooth transition and a high level of customer support.

Here’s proof that getting to where you want to be is always better with an understanding of what the destination looks like, a map, and the right vehicle. In the wake of the industryled HARMfree Transport and Logistics workplace safety and wellbeing initiative achieving 300 sign-ons representing 80,000 workers, programme manager John Sansom has taken it on the road.

“HARMfree is now a significant community linked via a common and effective application, all at different stages along their journey, and all communicating and collaborating. It’s time to get those people together and network, continue to build relationships, share ideas, and

experiences. They are making a difference.”

Following on from the initial meeting in Christchurch, 36 participants from the Auckland region met in Manukau on 28 August for a review, coaching, and networking event.

Kelly McLuckie, senior consultant in New Zealand and Australia for programme partner Success Formula, was present and spoke about good work design, perspective and cultural change in the transport and logistics industry when looking at harm prevention.

HARMfree Connect webinars and additional in-person events will round out the rest of 2024, with plans to continue the series early in the new year. To stay updated, sign up for HARMfree or follow them on Facebook or

HARMfree is a collaborative industry-led application aimed at improving workplace safety, and worker wellbeing in transport and logistics. The initiative is led by the New Zealand Trucking Association, in collaboration with National Road Carriers, Success Formula, Fit For Duty, and AutoSense.

The recipient of funding assistance via an ACC Workplace Injury Prevention grant, HARMfree provides an online step-by-step pathway for small and medium sized businesses looking to make meaningful positive change in the area of harm prevention and cultural change.

Scania has sold 50 heavy trucks to Hall’s Group in one year – a record volume of sales to a single customer in Scania NZ’s five-year history.

The 20 Scania G560 Super 8x4 tractor units, delivered last month to Hall’s, come within 12 months of Hall’s also buying 30 V8s from Scania.

Hall’s transport operations GM, Damon Bryant, said as a fleet operator in New Zealand, Hall’s Group understands its role to help reduce emissions within the sector.

“With these Scania G560 Supers, the business will continue its relentless focus on road safety and fuel efficiency in order to make a difference,” he said.

Scania’s national key account

and sustainable solutions manager Craig Pepperell said the G560 Supers represent the latest in fuel efficiency as well as the usual full suite of Scania safety features.

“The Super’s six-cylinder platform is fully Euro-6 compliant and designed for optimum fuel efficiency and CO2 reduction,” he said.

“They are a stepping stone in the transition towards greater sustainable transport solutions, and it’s very satisfying to see a major industry player like Hall’s Group see the merit in this fantastic Scania product.”

Scania NZ managing director, Victor Carvalho, said the scale of these successful consignments to Hall’s Group is testament to the customer-first mindset and

• Truck & Trailer Wheel Alignments

• Long wheel base vans / heavy vans and motorhome wheel alignments

• Tyre sales and fitting

• Induction heating and straightening of bent trailer axles and diff housings

• On & off truck wheel balancing

• Axle Camber Corrections

Group; Victor Carvalho, managing director Scania New Zealand, and Steve Koekemoer, chairman of the board for Hall’s Group.

strategy that Scania NZ has focused on in recent years.

“Growing our network of service centres and branches around New Zealand to a total now of 23, as well as an unrelenting prioritisation on after-sales parts and servicing, gives confidence to operators of large nationwide fleets like Hall’s Group,” Carvalho said.

“They need to know their vehicles can be serviced effectively and efficiently wherever they are around the

country. They have that surety with Scania.”

Scania NZ still has another service centre to come online this year in Hastings, with a further three or four more planned in the next three years, along with refurbishment plans for existing sites.

“We also hope to announce a strategic property acquisition soon, with an eye to futureproofing our service centre network even more,” he said.

The Government has unveiled the next three years of transport projects, worth $32.9 billion.

Of that, $23.6 billion will come from the National Land Transport Fund, $5.8 billion from councils’ rates, and additional Crown investment.

The plan was developed by the NZ Transport Agency Waka Kotahi in line with the Government Policy Statement on Land Transport finalised in June.

Transport Minister Simeon Brown said the National Land Transport Programme will create a more reliable and efficient transport network that boosts economic growth and productivity.

The programme has four key priorities:

• Delivers on the coalition

agreements to reintroduce the successful Roads of National Significance (RoNS) programme, with a pipeline of 17 RoNS across the country

• Gets back to basics, focusing on maintenance and pothole prevention to reduce the number of potholes on our roads

• Supports reliable public transport services and delivers four new major public transport projects to increase travel choices in our main cities

• Ensures councils are doing the basics brilliantly, with increased pothole prevention, reduced funds for cycleways, and no funds for speed bumps.

Walking and cycling

improvements, which goes towards helping councils build new cycleways, has been almost halved from $910 million in the 2021-2024 programme to $460 million – a large cut when factoring in inflation that has occurred in that time. Rail has also been cut from $1.3 billion in the last plan to $1 billion in this one.

Auckland is a big winner, getting about a quarter of the funding at $8.4 billion. The plan will see $7 billion going towards building additions to the state highway network, including the 17 new Roads of National Significance (RoNS) promised by the National Party during its election campaign.

Roadrunner Manufacturing is marking its 50th anniversary this year.

Founded in late 1974 in Bulls, Roadrunner Manufacturing has come a long way from its humble beginnings. Today, it has expanded its offerings from standard diesel tanks and aluminium toolboxes to a comprehensive range of products and services, including air tanks, hydraulic oil tanks, and highly specialised custom projects.

The company’s success is attributed to its commitment to quality, a broad base of valued customers, and an exceptional team of skilled professionals.

General manager Nick Webster credits the dedication of Roadrunner’s team of 25 staff, including welder fabricators, water jet technicians, and sales personnel, for the company’s sustained success.

“They have definitely helped us through all the peaks and troughs of the last wee while,” Webster stated.

While the company prides itself on its historical achievements, it is also looking towards the future. A testament to Roadrunner’s commitment to innovation is the recent acquisition of a robotic welding system and the establishment of Precision Machine Technology

(PMT), a sister company born from Roadrunner’s distributorship of OMAX abrasive water jet systems.

“They thought we would saturate the market with about eight to 12 water jet systems,” Nick says. “But with New Zealand’s No.8 Wire tradition of ingenuity, we have just cracked over 100 machines that are now being operated by manufacturers, makers, designers, innovators, and thinkers across the country. It has been a massive success.”

This expansion signifies

Roadrunner’s push towards technological advancement to meet the evolving needs of the market.

As it celebrates its 50th anniversary, Roadrunner Manufacturing acknowledges the significant contributions of its former owners, shareholders, and the strong community around them. The company looks forward to continuing its legacy and ensuring Roadrunner remains a symbol of quality and reliability in New Zealand’s manufacturing landscape for years to come.

Our Low Rider chassis has been refined over many years with safety and stability in mind. With your load lower to the road, you can be assured your drivers are safer and loading is easier. Mills-Tui’s industry-leading, 5 years/1,000,000 km chassis warranty finishes the job off nicely. If you want a trailer that is innovative and built to last, call 0800 MILLS-TUI

Heavy Vehicle & Machinery Services (HVMS) has partnered with Canadian company Diesel Tech Industries to establish installation facilities for the Guardian Hydrogen Diesel System.

The initiative marks a significant step towards advancing sustainable solutions within New Zealand’s heavy transportation sector.

The Guardian Hydrogen Diesel System, developed by Diesel Tech Industries, is internationally recognised, and represents a cutting-edge dualfuel technology designed to lower emissions and enhance operational efficiency in dieselpowered vehicles.

HVMS will leverage its expertise in procurement, installation, and compliance to support New Zealand companies in transitioning to cleaner transport solutions through vehicle conversions and educational initiatives.

“Having the industry-leading Guardian Hydrogen Diesel System commercially available to our New Zealand and Australian customers is a game-changer, allowing fleet owners to continue to utilise their existing

diesel-powered assets whilst making solid steps towards decarbonisation,” said Mark Irving, business development manager at HVMS.

“Hundred per cent hydrogen OEM vehicles are still some years away with respect to suitable supply and affordability, making the Guardian Hydrogen Diesel System a viable and prudent dual-fuel product for today, helping cut diesel use and reduce emissions,” he said.

Scotty Hale, HVMS director, said the concept of dual fuel appears to be resonating the best with heavy fleet owners.

“With hydrogen now commercially available since May 2024, the timely emergence of the DTI hybrid solution throughout New Zealand will be a game-changer, offering affordable solutions for companies as they continue their important decarbonisation journey,” he said.

HVMS is poised to accelerate the adoption of the Guardian Hydrogen Diesel System through its comprehensive service offerings, encompassing installation, integration and training.

Trust Ixom and SCR for dependable AdBlue supply in NZ. Contact us at sales@scrsolutions. co.nz or 0800 145676 for all your bulk, packaged, and dispensing equipment needs. Reliable, secure solutions when you need them 24/7.

UD Trucks has appointed Zane Erwee as its new retail sales manager.

Joining the team in mid-2024, Erwee’s role focuses on the growth of the UD Trucks retail business and leading the UD Truck sales team operating in the North Island.

Starting his career in 2007 in South Africa, he has sold trucks and managed sales teams over the past 17 years. He has been a sales manager for both Fuso Trucks and Freightliner, and then moved to the South African UD Trucks dealership, under the Imperial group.

Zane relocated to New Zealand with his wife and two daughters in 2019 and worked

for NZ Trucks. Most recently, he has been working for a leasing company, managing truck and equipment maintenance and aftersales.

“We are very pleased to welcome Zane to the UD Trucks team. His extensive experience and knowledge of the product will add immense value to our loyal customers and to the rest of the team,” said Colin Muir, UD Trucks general manager.

“I chose this role,” says Zane, “not only because of my experience with UD Trucks, but also because the product is fantastic. I can easily stand behind its capability and performance. UD is a brand that I am passionate about.”

Taupō-based dairy processing company

Miraka has launched New Zealand’s first green hydrogen dual-fuel milk collection tanker.

The initiative is part of the company’s kaitiakitanga objectives and is expected to achieve a significant reduction in milk collection transport CO2 emissions – a key goal for the dairy company. The Miraka dairy plant already has one of the world’s lowest manufacturing carbon emissions footprints, emitting 92% less CO2 than traditional coal-fired dairy factories.

The FH16 700 Volvo green hydrogen-diesel dual-fuel milk collection tanker is the first of its kind for milk collection here. It will cover approximately 165,000km annually and has the capacity to haul 58 metric tonnes and requires two hydrogen refills daily.

Chair of Miraka, Bruce Scott, said the truck’s introduction marked another significant milestone for the company.

“This new vehicle aligns with our founders’ kaitiakitanga vision and values and our commitment to environmental care, supporting Aotearoa New Zealand’s transition to a

ENTER NOW TO BE IN TO WIN A PAIR OF PETERSON’S SUN GLASSES

low-carbon future,” he said.

Miraka CEO, Karl Gradon said although hydrogen-powered vehicles were still an emerging technology, Miraka believed green hydrogen represented the most environmentally appropriate energy source for heavy freight.

“Our green hydrogen dualfuel tanker is designed to reduce milk collection CO2 emissions by approximately 35% per vehicle, benefitting te taiao, the environment and our community,” he said.

Miraka, Central Transport and Halcyon Power entered into a partnership a year ago, establishing a rural hydrogen hub, which Gradon said one day could be expanded nationwide.

Tūaropaki Trust, a cornerstone shareholder in Miraka, provides geothermal energy and steam for the Miraka dairy plant through its Mokai Power Station. Under a joint venture partnership with Japan’s Obayashi Corporation, Tūaropaki established Halcyon Power, Aotearoa’s first commercial-scale green hydrogen plant. Halcyon will supply the green hydrogen for the new tanker from its facility, adjacent to the Miraka dairy plant.

Our winning photo this month is from Josh Piggott who snapped this beaut 2023 Scania 770 on the desert road at a chilling -1 degree night for Douch Transport Ltd, based in Rotorua. It carts bulk groceries from Auckland to Palmerston North for Progressive, then loads milk from Longburn to Tauranga 6 days a week. Nice shot Josh.

Send your best night bling photo as well as contact details into nightmoves@nztrucking.co.nz to enter

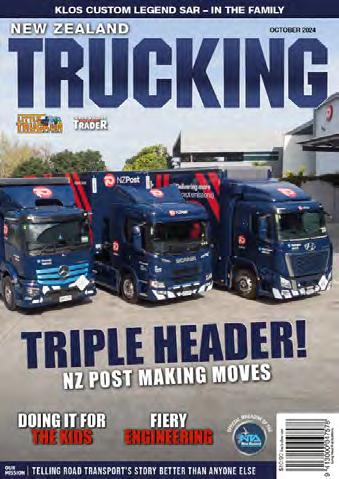

NZ Post is among the country’s leading companies when it comes to operating alternativepower vehicles. From motorcycles to vans, it has long focused on electrifying its vehicle fleet. It was among the first locally to start operating electric trucks and the first to operate a hydrogen fuel-cell electric vehicle.

With the NZ Post programme running for a few years, and with five heavy EVs and one heavy FCEV in operation, we were welcomed to document the journey so far. The result is a New Zealand Trucking cover feature unlike any before, comprising three different trucks from three different OEMs – not to compare them, but to see how each is being put to work moving the nation’s post and parcels with zero tailpipe emissions.

Story by Gavin Myers

by Dave McCoid, Earl Edwards and Gavin Myers

Save for a few who have thrown themselves headfirst into the future of alternative propulsion, it would probably be a fair bet many of us don’t realise how much activity is going on in the background among New Zealand’s transport operators. As they go about their daily business, many are acutely aware that times are changing, and that they need to – at the very least – start thinking about the future makeup of their fleet.

Featuring Reliance Transport’s Scania 25P electric trucks on the cover of the February 2023 issue was a milestone for New Zealand Trucking. We decided years ago we wouldn’t feature an alternatively fuelled truck on

card – just like any other in the fleet – much has happened in the heavy-truck space in the 21 months since they went on the road. Each year, industry conferences and events place a greater focus on alternative propulsion, with increased discussion on the topic and more of a showcase by OEMs, distributors and associated suppliers. New models are becoming available at a faster rate. Once, words like ‘electric’ and ‘hydrogen’ might have been either uttered in a hushed tone with a glance over the shoulder or accompanied by an eyeroll or two. Today, the industry is noticeably sitting up with interest. The amount of space our own publication dedicates to the topic increases consistently. PART I

the cover of the magazine unless it were in operation on par with its ICE peers – doing the daily grind for an operator who had taken the plunge and put its money where its mouth is. That’s to say, not merely ‘on trial’. In the early stages of the EV story, expectations of return on investment would come second to the upfront cost of getting going – and the knowledge and experience gained in this ‘brave new world’. With its two Scania 25Ps and company-wide Project Switch programme, Reliance Transport had set itself up as a Kiwi frontrunner in the operation of heavy electric vehicles.

While those two trucks continue to operate with a no-news-is-good-news report

But rewind another year to February 2022, and we reported on Hyundai New Zealand’s launch of its Xcient FCEV, which took place towards the end of the previous year. Billed as New Zealand’s first hydrogen-powered truck, it was the first of five the company planned to introduce to New Zealand. As a hydrogen fuel-cell electric vehicle, it utilises compressed hydrogen gas to produce electricity by way of a chemical reaction in an onboard hydrogen fuel cell that powers its electric drivetrain.

By July 2022, an Xcient FCEV had entered service with NZ Post, the first of its kind to be put into commercial operation in New Zealand. In July this year, that truck clocked over 100,000km. The milestone coincided with NZ Post adding a Mercedes-Benz eActros 300 and three Scania 25P tractor units to the fleet. Now is perfect timing, then, to find out about the company’s alternative propulsion journey and see the trucks in operation.

At this point in history, companies setting and committing to achieving climate

targets are nothing new. From the biggest corporates to the smallest sole operators, whether government-mandated, customer-initiated or done just because it’s the right thing to do, the drive to be environmentally conscious in as many areas of business as possible has experienced an increasing groundswell year on year.

For a corporate the size of NZ Post, all the above applies. The government has set its targets over the years, customers are becoming more attuned to how their parcels are delivered, and the company knows it’s the right thing to do.

“Our sustainability division set science-based targets for our emissions, and with the road fleet being the biggest emitter in the business, I had a bit of responsibility around that,” explains Ryan Beale, national road operations manager, as we sit down to discuss the journey so far.

Conor Keane, sustainability programme manager, elaborates: “In 2018, NZ Post committed to reducing its scope 1, 2 and 3 greenhouse gas (GHG)

emissions by 32% by 2030 from the 2018 base, and committed to being carbon neutral by 2030. That was best practice at the time, but we updated our science-based commitment in 2023 to be a net-zero emissions operation by 2050 and reduce our GHGs by 42% by 2030 and 90% by 2050. It’s a more ambitious target, due to the changing science and increasing urgency.”

Conor says that the company is currently recognised as committed to net zero by science-based targets, but to become verified, it is exploring the individual transport mode pathways within the business, and what technology and investment will be required to meet that 42% reduction.

“A number of assumptions underpin these pathways, so from heavy freight, that means exploring the technology of trucks, charging, dual fuel and things we haven’t even considered yet.”

As Ryan alluded, transport is the biggest emitter in the business – accounting for 97% of emissions. International air freight is the highest emitter,

followed by road freight and domestic air freight. “A sizeable portion is from heavy road freight,” says Conor. “To date, we’ve prioritised the decarbonisation of our vans, cars, forklifts and motorbikes, and then we have electric Paxters alongside the last-mile delivery contractor fleet.

“In tandem, we’ve been trialling a number of heavy freight options with the intention of reducing the emissions that come from our heavy freight by around 15% of the 42% reduction we require by 2030 – a sizeable amount.”

Currently, the company has set out to understand the TCO (Total Cost of Ownership) of the different technologies and – here’s a term most readers probably wouldn’t have encountered yet – the margin abatement cost (the cost to remove one tonne of CO2 over a vehicle’s lifetime).

“We then start to get a picture of viability, combined with their operational suitability, and what the infrastructure we’d need to install is to facilitate different routes for these trucks. The more and varied environments

we can put the trucks in, the more confidence we can have in them,” Conor explains.

The race to meet ambitious targets can be daunting for any organisation, even one the size of NZ Post. However, size does have its advantages, creating options and flexibility with how to best ‘feel out the waters’, and repeatability and direct comparisons when it comes time to crunch the numbers. It also means that somewhere in the mix are loyal and dedicated operators who get the big picture and are willing to accept any challenges in putting the trucks to work early on.

“Around 28 years ago, NZ Post shifted to a contract model. Several existing employees shifted to that model, including Neil Dennett, Ramesh Lal and Greg Carley. They’ve all been with us for quite a while,” says Ryan.

Each is the custodian of a different vehicle in different use cases – Neil’s Shea Transport operates the Xcient, Ramesh’s Lal’s Transport the eActros (and

The Xcient FCEV leaves the APC, in the reality of midwinter operation – looking like the real-world, double-shifted working truck it is.

earlier, a Fuso eCanter) and Greg’s Greg Carley Transport the Scanias. “The benefit we have is the fact we design our network to fit our requirements from a customer perspective. The luxury there is we have enough routes to pick from to put the vehicles somewhere they could work. The trucks are doing the Ks, and we’re enjoying it,” Ryan says.

But let’s not get ahead of ourselves … Once group sustainability manager Dawn Baggaley had set the targets, work had to be done to actually get the vehicles on the road.

The team looked at the options available with insight from consultancy firm DETA.

“Early on, we looked at the eCanter when Keith Andrews’ demonstrator came in,” says Ryan. (We drove it for our May 2020 issue – Ed.) “It was cool, but our typical truck would start at about 18 tonne, and the eCanter was a lot smaller, so we were a bit apprehensive.” The roller cages NZ Post uses are designed to maximise the dimensions of truck bodies in New Zealand and accommodate as many as possible in each vehicle.

Eager to see how an electric truck would fare, by the end of 2022, an eCanter had nonetheless been fitted with as large a body as possible and was put into service with Lal’s Transport, running between the North Shore depot and Hibiscus Coast Operations Centre in Silverdale. Having completed 100,000km, that unit has now been shifted to a Wellington-based operator who was able to put a smaller vehicle to work and keen to see how an EV would do. This will yield valuable insight, too, as in his care, the truck will cover more distance each day but move less volume.

Ryan says the eCanter has been very dependable. “It did go to Keith Andrews for a bit of work at one stage, which they addressed. But for the run, the only limitation was the capacity of the unit. Once we knew what the parameters were and worked within it, there were no concerns.”

Naturally, putting a heavy EV to work requires supporting infrastructure, and there were early lessons regarding charging. Ryan explains that NZ

Post does not want its vehicles to contest with public charging and has worked with Aucklandbased commercial electrical services company Trilect to install YHI chargers. “We learnt quickly that the charging has to fit for it to work,” he says.

Needing to keep pace with volume growth in the North Shore region, and specifically the Hibiscus area this vehicle supports, the eCanter was replaced by the eActros in July. It was a natural progression and immediately doubled vehicle capacity and more than doubled on range.

As we said earlier, the Xcient was, in fact, the first alternatively propelled heavy EV to go to work for NZ Post in mid-2022.

“That was a long path,” says Ryan. “Two years earlier, we were approached by Hyundai and told about the vehicles that had been pitched to Europe; they wanted to bring some to New Zealand. With the targets set for us to understand how to fulfil our requirement, we needed to start dabbling. We got in behind

it to make it work with Neil. He operates 15 contracted runs for our business, so we found a similarly matched vehicle on similar work that he was comfortable to replace with the Xcient.

“By 2021, we had concrete direction; we were going to go there. Neil understands technology is changing and we approached him because we thought his run was the best fit. We chatted about different options and how it would work. He and another contractor were involved in some of the design aspects. The path was troublesome for Hyundai, which had to bring the vehicle in and change it to right-hand drive, and Grant [Doull, national manager, hydrogen and eco commercial vehicles] spent a lot of time working around

accommodating a European configuration within VDAM and applying for permits to get it on the road in 2022.”

“But,” says Ryan, “it was all of a sudden on the road and at work.” And, with little battery weight impacting the load, it could also tow a trailer and haul a load over the Bombays to Hamilton without much concern.

“Clocking 100,000km shows it’s just been there to turn up and work. There hasn’t been much issue with the gear, the tech works,” Ryan says. “Neil knew to the decimal what diesel he was using on the same route.

The TCO is what we’re really interested in, and knowing what goes wrong over 1,000,000km with those trucks. With diesel, we’ve become accustomed to replacing certain parts

eventually, but this truck is a bit different. During our lease time, we hope there will be a supporting network so that we can look at expansion. It’s as simple to operate as a diesel equivalent, and that’s what Neil was looking for. But, in six years, batteries could change significantly as well…” Ryan says.

Until recently, the only sticking point has been refuelling with hydrogen. However, determined to keep the truck working, Hyundai stood up an interim refuelling solution while Hiringa was getting its network online with Waitomo. “It was a chicken and egg situation,” says Ryan.

“It’s been interesting. One of the first things you’d hear was, ‘Do you want to drive around with a big gas tank on your back?’ But now the guys are

used to it. Having Neil operate it, he can talk to other contractors, take them for a drive, show them the platform is workable.

“I can’t complain about it at all, and from a refuel perspective, 10 minutes is what the drivers are used to. Initially, hydrogen is a bit different, but once they know how it works the concern goes away.”

Earlier this year, NZ Post moved into its new Auckland Processing Centre (APC) in Wiri. The new 30,000m2 hub can process more than 30,000 parcels per hour at peak capacity. Significantly, it brings together NZ Post, Customs and MPI for national and international processing on one site. This meant Customs’ air cans (the vessel in which airmail

is stored for transport) would need to be transported to and from the site and the airport –and that meant more scope for new vehicles.

The timing being as great as it was, our initial visit coincided with the handover of three new electric Scania 25P 4x2 tractor units and their specialised 10m hard-side Fruehauf trailers with automated roller decks for loading and unloading of customs cans. Unlike the Xcient and eActros, both on six-year lease arrangements with TR Group, the Scanias have been taken on by NZ Post directly.

“We had a couple of 4x2s with 10m trailers in the fleet already and knew the configuration would be viable,” Ryan says.

“Greg previously operated diesel trucks in a different configuration for our domestic

air cans. When we said the new operation to transport international cans from the airport would be a great fit for electric trucks, he was comfortable with relinquishing some gear to take these on board.”

The Scanias’ operation will be of low mileage but high utilisation. Their docks at the APC have been equipped with two dual-gun chargers, so that they can top up every time they offload.

Conor says: “We’re confident the Scanias will be quite replicative of a lot of the trucks in our fleet. We’re comfy with the range; it’s more the operation, charging, loading and unloading where we need the assurance. Strategically, it could make sense to build out the network from one hub

to leverage the infrastructure between the different Post hubs and lower the ratio of capital investment costs for charging. That’s the next step. Once we’ve decided on technology, we can decide how to leverage existing routes and sites to build that network as best as possible.

“We envisage these trucks would run longer than a typical ICE equivalent due to lower maintenance. Residual cost is still a variable due to the likes of battery degradation, but residual costs for a diesel will be, too, as we begin to transition. So, there’s uncertainty all round. It’s an industry challenge, but these trials will give us an understanding.”

Ryan echoes Conor’s sentiments: “The Scanias will be a great

• Approximately 140 contracted heavy vehicles move the country’s post –these range from three-axle 18-tonne units up to full longhaul B-trains. Euro-5 is the current mandated emissions standard for new vehicles, with a move to Euro6 set for March 2025.

• A concerted effort to move to electric and plug-in hybrid light vehicles has been made, with 585 such vans and cars in the fleet. Mercedes-Benz eVitos were allocated to depots requiring a van, and the company has recently kicked off a new cascade deal to reduce the cost for operators to get into an eVito.

• The company aims for 100% of its owned vehicle fleet to be electric by the end of 2025, with motorbikes and forklifts the last two vehicle types to be fully converted.

• A project to put a US-made Beta Alia e-cargo plane in operation between Wellington and Blenheim has just kicked off with Air New Zealand. “Air New Zealand feels the Cook Strait would be the ideal place to test it. Using it for cargo increases the strength and resilience that may be needed. We’re in the early phase of understanding the operational constraints before going operational in 2026. It will be the first battery electric domestic flight,” says Conor Keane, sustainability programme manager.

• Regarding domestic air cargo, the company has procured three new planes that offer greater fuel efficiency and reduced carbon emissions.

validation, allowing many contractors to see how it works and allowing us to understand where we’ll require the charging infrastructure. The trucks are all tangible; people can come drive them and see the benefits.

“In Auckland, we run a huband-spoke model. The Wiri APC and Highbrook AOC (Auckland Operations Centre) are our two main hubs sending freight out to the extremities of the greater Auckland region. So, this will allow us to determine where we can say, ‘The next vehicles with these contractors may need to be something similar.’ I feel, especially within Auckland, BEV will be holistically beneficial – for example, a truck sitting on Puhinui Road for half an hour idling is burning diesel for nothing.

“For the further-out sites, where we don’t need full truck-and-trailer spec yet, we’ll be range-testing and understanding that viability, getting that TCO and making the operators aware of what they’d be in for, and what we’d require around charging. Longer distance linehaul … we’re waiting to see what comes from the OEMs. Our Auckland-Wellington run leaves here at 8.30pm to be at the depot at 5am to present to the couriers before 9am. We can’t lose half an hour charging. But increased charging rates could be a gamechanger … Look how we’ve gone from 50kW to 200-plus in the last few years. Refuelling or charging stations in the National Park would be ideal,” Ryan says.

None of that’s to say contractors are limited to the existing options. Dual-fuel conversions, such as those the likes of HW Richardson is

pursuing, could also be a mid-term option for some contractors.

“Every time we’re presented with a new truck, we are starting to question what the best fit is. Because we own the network, we can specify the requirement and ensure we’re making the right decisions. The contractors so far have been involved and dedicated to making it work. I reckon 90% of our contracting fleet would be onboard with change if it were ready. Of course, we can’t charge our customers an extra 50% because we’ve gone zero emissions,” he says.

“We’ll continue to progress, and my belief is the market will continue to change. At the moment, these are quite earlygeneration trucks. The truck has to fit – and if we select a run, will it still fit in three to five years? We have to be open-minded, too. If we have to change the way we move the freight, then we may need to do that.”

Naturally, few operators have the benefits at hand that NZ Post is lucky to have, such as its size or ability to select from a pool of fixed routes. But what that does afford the rest of the industry is insight into how the vehicles can be expected to operate, what infrastructure is required and how it fits into the picture, and what needs to be done now to meet future expectations.

On that note, Ryan concludes: “If we want to advance this, the industry has to work together. New Zealand is remote, and it’s not easy to compete with scale. VDAM is also an issue. As a country, we all need to jump into it.”

You might be forgiven for not even noticing the eActros, Xcient FCEV or the Scania 25Ps in their smart blue and red NZ Post livery next to their peers. Only when you get up close do you notice their respective ‘Electric Vehicle’ and ‘Hydrogen Vehicle’ decals and the script ‘Delivering more (except emissions)’ on their curtains.

However, the keen-eyed bloke who pulled up his Honda Accord next to the eActros while we were waiting at the lights on Auckland’s Greville Road offramp certainly did. Maybe it was the branding or the lack of diesel-engine clatter that got his attention – either way, he made

full use of his time stopped, craning his neck out the window to have a good look.

“People actually do look at it in traffic and on the motorway. Someone even took a picture of it!” says driver Ajay Kumar. “Other drivers have asked about it too, taken it for a drive. They also like it,” he adds as we pull away smoothly and silently.

We’re on our way back to the North Shore depot from the Hibiscus Coast operations centre in Silverdale. Ajay completes five of these 46km cycles Monday to Friday and ends with an evening run to the APC and back. In the mornings, another driver kicks off the day with an early run between Ellerslie and the North

Shore, and pops the truck back on its charger to top up for Ajay. That’s approximately 390km altogether, and Ajay is able to complete his shift on one charge before the eActros is parked at its charger at the North Shore depot and left to rejuvenate until work starts again at 3am the following morning.

This range capacity from the truck’s three 336kWh lithium-ion battery packs has been a gamechanger compared with the eCanter Ajay was on previously, which had to be plugged in and topped up at each stop. Average economy over truck’s life so far is 93.9kWh/100km.

“This run has grown a lot and become busy with everything

moving north,” says 51-year-old Ajay, who has been with NZ Post for 17 years and driven for Lal’s Transport for 14 years.

Being a much larger vehicle, it’s also doubled the carrying capacity to 12 NZ Post roller cages. This being our heaviest load of the day so far, we’re carrying 11 cages, which equate to about 4.4 tonnes. The weight is barely noticeable compared with when Ajay is returning empty cages to Silverdale. Whether we’re threading through traffic or keeping pace on the motorway, the eActros acquits itself with minimal fuss, accelerating smoothly and easily, with the two-speed transmission shifting at 30km/h, and its

electric torque carrying us on from there.

Ajay has five stages of regenerative braking at his disposal, operating as any conventional retarder would, with the added benefit of adding a bit of charge back to the batteries.

“It is soft, easy, very smooth, quiet … Very different, but very good,” says Ajay about working an electric truck. The sound meter returns a perfectly acceptable 70dB at 90km/h, marginally quieter than a diesel Arocs in numbers but noticeably so in the cab.

An ideal day cab, the M Cab ClassicSpace offers the driver a good amount of space and comfort and easily accessible storage. Ajay enjoys the full benefits of Mercedes-Benz Actros tech, with the brand’s MultiMedia Cockpit and MirrorCam options we’re now quite familiar with.

“The MirrorCams are good. They work well, fine with reversing and at night, and great in the rain,” Ajay reckons. Of course, the full suite of active safety systems is present and correct, too.

“I think they’re good trucks for the future, and I’m grateful NZ Post gave me the opportunity to

try it out as a brand-new truck,” says Ajay.

The owner of Lal’s Transport is Ramesh Lal, who has a 30-year history with NZ Post and currently runs 14 Post trucks on the North Shore and one in Hamilton.

He says other than an issue with the power steering pump, which was solved quickly by Keith Andrews Trucks, the eActros hasn’t put a foot wrong in 11,000km so far. “Keith Andrews has been great, and so far, the truck has been good. It’s great for the new generation and I fully recommend other

Tare: 10,450kg (load cert)

GVM: 19,000kg (load cert)

GCM: 19,000kg (load cert)

Wheelbase: 5500mm

Electric motor: eAxle with two integrated liquid-cooled motors

Power: Max - 400kW (536hp), continuous330kW (443hp)

Torque: Undisclosed

Emissions: BEV

Transmission: Two-speed internal

Clutch: N/A

Front axle: Offset

Front-axle rating: 8000kg (load cert)

Front suspension: Air suspension

Rear axle: Mercedes-Benz e-axle

Rear-axle rating: 11,500kg (load cert)

Rear suspension: Air suspension

Brakes: Disk. EBS with ABS and ASR

Auxiliary braking: Five-stage regenerative braking

Additional safety: Acoustic vehicle alert system. Secondgen MirrorCam. Active Brake Assist 6 with pedestrian detection and radar/ camera-activated advanced emergency braking system. Active side guard assist 2. Stability control assist, lane keeping assist, proximity control assist, attention assist, roll control assist. Electric park brake. Tyre pressure monitoring. Light and rain sensors. Driver airbag

Additional productivity: FMS fleet management system. Truck Data Center 8

Batteries: Three lithium-ion battery packs

Battery capacity: 336kWh

Charging: CCS Type-2

Estimated charge time: 75 minutes (20% to 80% at 150kW)

Maximum quoted range: 300km

Wheels: Alcoa Alloys

Tyres: 315/70 R22.5

Electrical: 24V

contractors to look into it. Fully loaded, it does the same job at the same speed as any other truck.”

The eActros is one of two eActros 300 4x2 rigid units and two 4x2 tractor units Keith Andrews Trucks initially brought into the country. Matt Gillatt, product planning and alternative fuels transition manager, says the company is monitoring the truck to gain meaningful data on its operation. “It’s fitted with the Mercedes-Benz telematics

platform, so we’re keeping an eye on it month by month. All is going well at this early stage, though. Our stated range is a conservative number and NZ Post is able to achieve good range due to weight and the driver’s ability to create range with the regenerative braking.

“NZ Post has done an amazing job taking on the eCanter and now the eActros. They are really setting up their contractors to succeed.”

Xcient FCEV cruises by emitting just water.

It’s quite amazing to see the number of trucks streaming down Langley Road, Wiri, and into the APC in the early evening. We’d been following the Xcient’s day-shift driver, Dev Narayan, for the past few hours, and now, at about 6pm, we are in the cab with him, sitting in a queue of truck and trailer units coming to collect their evening transfers. As the trucks file in and out and more continually join the queue, the team of forklift drivers shuttle their Maxi bins to the docks and into their respective trucks. It’s one of those scenes that look outwardly chaotic but is, in fact, amazingly slick.

Dev typically runs two loads between the Onehunga Courier Depot (OCD) and APC and two between the South Hub depot and the APC each day before loading up and refuelling for night driver Gurdit Dhillon.

Thirty-five-year-old Dev has been driving for Shea Transport since 2020 and came off a Volvo FH truck and trailer to take over the day shift on the Xcient in May. “It was a different feeling at first; I was so used to driving a diesel. On a diesel, you can feel the revs, the clutch engagement, that something’s happening … In this, you just hit the accelerator. But I’m used to it now; it’s smoother, quieter,” he says with a laugh.

As Dev’s been slightly delayed today, Gurdit is waiting to take over outside the APC. His first stop is the Hiringa

hydrogen refueler at Waitomo on Roscommon Road. He pulls in and turns around to align the left-hand refuelling nozzle with the bowser. Interestingly, the first thing that strikes us is how manoeuvrable the 6x2 Xcient is with its steering tag axle (which locks at 40km/h) and two-axle trailer. Gurdit makes a typically wide turn, but the unit’s about-turn in the space of a forecourt is impressive. (Later, we’re told that reversing is slightly trickier, as the two-axle trailer is very quick to respond to steering inputs.)

The fuel level reads 47% at the end of Dev’s day shift. The drivers need to power down the truck completely to unlock its refuelling nozzle. It’s the moment we’ve been waiting for – to see the Xcient FCEV refuelling with hydrogen! He jumps out and connects the dispensing nozzle to the truck, swipes the truck’s RFID tag, hits the green button … and that’s it. The pumps start to fill the tanks, as anyone who’s ever refuelled a vehicle would be used to, and in about eight minutes, 15.92kg of hydrogen is dispensed. The dispenser shuts off, Gurdit disconnects the nozzle, jumps back in the cab, and sets off to collect the rest of his load from the Highbrook AMC for his nightly run to the Te Rapa Waikato depot north of Hamilton. As novel as it is, it’s all a bit anti-climactic. It’s just like refuelling as we know it – simpler, even.

“The Waitomo station is really convenient. Refuelling takes on average 10 minutes, up to about 16,” says Gurdit, adding an interesting observation:

“It’s nice not to have the greasy diesel. Diesel trucks always have a residue on the curtains and touchpoints, you don’t have that on this.” In a typical night shift running to the AMC, Te Rapa, back to the APC and over to Fliway Onehunga, the Xcient will cover approximately 300km and use most of its 31kg of hydrogen. Maximum range is quoted at 400km. The current average hydrogen consumption is 12.5km/kg.

We have a full load of 14 Maxis on the truck and 16 on the trailer bound for Te Rapa, and although he didn’t pass over the scales before leaving, Gurdit says it feels slightly heavier than usual, too. Not that you could tell from the passenger seat … The 2237Nm of torque (with a full 3000Nm available when climbing hills or overtaking, for example) driving through the Allison six-speed automatic transmission allows it to gain and maintain speed incredibly easily. That electric motor and Allison autobox combination is interesting –the shifts are there, but you really have to be paying attention to detect them.

Shea Transport asks the drivers to keep the Xcient to a maximum of 85km/h to maximise range and fuel economy. From the moment he enters the motorway, Gurdit sets the truck’s

adaptive cruise control. As we approach the Bombays, the truck applies nearly full power and maintains its speed easily. The adaptive cruise locks onto a truck ahead and slows to about 70km/h. “It’ll easily maintain 85 all the way,” says Gurdit.

Heading down the Bombays, he sets the Allison’s fourstage retarder to stage three, maintaining 85 and adding 4km to his range. Later, stage two is strong enough to hold the truck back down the Huntly Bypass.

“Because the fuel-cell system only needs 72kWh battery capacity for accumulating regen energy on descents and boosting power when needed climbing hills or overtaking, a transmission retarder acts as a safeguard against traditional battery electric regeneration, which loses effectiveness as the batteries replenish,” explains Grant Doull, national manager, hydrogen and eco vehicles at Hyundai NZ.

Thirty-six-year-old Gurdit began driving for NZ Post about three-and-a-half years ago, and transferred to Shea Transport earlier this year. “I drive it slightly differently to the diesels I was on before. You don’t push the torque in this. I’m easy on the truck compared to a diesel; the same load would feel heavy in one of the diesels. I can’t feel it pulling the load.”

The Xcient FCEV is impressively quiet, returning an average sound meter reading of 65dB at 80km/h, with just a bit of whistle around the nearside mirrors. At slower speed, one can detect the fuel-cell system emit a gentle whir now and then as it creates the energy to power the battery pack supplying the drive energy to the electric motor, which emits a higher-pitched whine than we’re generally used to with full BEVs. Cab space and quality are on par with similar European trucks.

Neil Dennett owns Shea Transport and has a 30-year relationship with NZ Post. Today, he operates about 30 units on Post duties. The Xcient entered the fleet as a replacement for a typical 540hp, eight-axle 18m

truck-and-trailer unit. Fitted with a 7m body and 10m trailer, it loses a metre on the truck. “It operates slightly under capacity because that was the only configuration Hyundai could bring in at the time,” Neil says. However, that’s been the only gripe to report as far as the machine is concerned. Neil says it’s been easy enough to understand running a FCEV and it’s impressed him. “I think it’s a great bit of kit, and it’ll be interesting to see how it continues to perform,” he says.

Neil adds some drivers were reluctant at first. “We were concerned at the beginning about getting drivers to buy in and drive it, but now it’s just another truck in the fleet, and we treat it that way. It was a princess when it arrived, but it’s really just another truck –we need that flexibility, and it’s what Hyundai NZ wanted from it, too. They’ve been great; helpful and enthusiastic. I take my hat off to them for getting behind this.”

In 2022, it was estimated that the Xcient FCEV would save about 50t CO2 over 80,000km. According to Grant, with calculations based off the 2.4km/L average consumption of the 540hp, eight-axle unit it’s replaced, the Xcient has saved 41,667L diesel and 111t CO2 over 100,000km.

“We’ve proven a lot and demonstrated what we needed to. The Xcient FCEV works and can be a good solution for a wide segment of the market. Another is planned to go on the road later this year,” Grant says.

“What’s made the programme a success is that NZ Post kept a flexible, open-minded approach to how we solve problems and go down the road. That has been extraordinarily important and is a huge credit to NZ Post.

“Hyundai has been monitoring it to see how we can better make it fit in New Zealand. What are the peculiarities? New Zealand is not in a position to dictate, though. We need to figure out how to adopt configurations from higher volume markets,” he concludes.

Tare: 13,500kg (load cert)

GVM: 28,500kg (load cert)

GCM: 42,000kg (load cert)

Wheelbase: 5420mm

Electric motor: Siemens

Fuel Cell: 90kW x2

Power: Max - 350kW (470hp/476ps equivalent)

Torque: 2237Nm

Emissions: H2O

Transmission: Six-speed Allison 4500 automatic

Clutch: N/A

Chassis: Undisclosed

Front axle: Undisclosed

Front-axle rating: 8000kg (load cert)

Front suspension: Two-bag air

Rear axle: Rear steering tax axle. 4,875:1

Rear-axle rating: 20,500kg (load cert)

Rear suspension: Four-bag air

Brakes: Disk

Auxiliary braking: Four-stage retarder plus regenerative braking

Additional safety: Vehicle dynamic control, forward collision-avoidance assist, lane departure warning, smart cruise control, easy hill-start system, rearfacing camera, driver airbag, vehicle-on warning

Additional productivity: Energy-saving utility mode

Batteries: Lithium-ion - Akasol

Battery capacity: 72kWh

Charging: Self-charging by hydrogen fuel cell

Fuel: 31kg hydrogen at 350 bar

Estimated refuel time: Eight to 20 minutes, depending on pump

Maximum quoted range: 400km

Wheels: Alcoa Alloy

Tyres: 315/70 R22.5

Electrical:

Low voltage - 12V and 24V High voltage - 630V

It’s highly unusual for a cover feature to showcase a truck that’s barely turned a wheel in operation. However, given the three Scania 25Ps arrived when we were meeting with NZ Post to construct this story, not including them wouldn’t have done justice to what the company is trying to achieve. Yes, it’s early days, and that means there’s still a lot of fine-tuning going on around processes, drivers and schedules, but the Scanias were straight to work, and so we thought we’d give them a week to settle in and come back to check them out.

Once everything is fully set up and ironed out, six drivers will double-shift the three

trucks. Greg Carley of Greg Carley Transport is contracted to manage the operation of the Scanias for NZ Post. He’s worked for NZ Post for 41 years and started operating Post trucks 26 years ago. “I’ve seen some changes along the way!” he quips as we walk around the 25P.

They are the first dedicated semi-trailer tractor BEVs Scania New Zealand has supplied, and the company claims the 25Ps offer up to 20 hours of operation on a single charge. Fully charged, the truck we sample shows a max range of 223km, and so far, it is averaging 169.6kWh/100km.

They run a dedicated route from the APC up Roscommon

Road, alongside the motorway and down Puhinui Road to the airport, a 16km round trip at a max speed of 60km/h. In a full shift, they’ll clock up to 160km –so range or power consumption is not a worry. Greg uses the example of one of the night driver’s runs. “He plugged in to charge at 1am during his break. That added 20% to the batteries. He was only down to around 55%, but it was more of a caution thing. At every decent opportunity the drivers get, they’ll put them on charge.”

Greg says charging has been very easy to adapt to and simple with the YHI chargers positioned at the APC’s customs docks.

While on the subject, this area of the APC is entirely

mechanised, with the air cans moving in and out of the facility on a roller floor system. With the trucks butted up to the loading docks, the cans are easily transferred to or from the 10m Fruehauf FBR trailers. These are fitted with the Joloda Hydraroll powered cargo roller floor system, designed for loading and unloading air cargo containers. A series of powered and free rollers pneumatically rise from the floor and the driver moves the cans along with the remote control. Flip-up stoppers safeguard against rollaways and there are cross bars to secure light loads if needed. The trailers hold six 4.4m3 AKE air containers at about a tonne each, or three bigger 11m3 AAY containers of

P-cab as comfortable as any other Scania.

between two and three tonnes.

“So far, I’m really impressed, they’re just a pleasure to drive,” Greg comments as we head along Roscommon Road for the airport. “I had a few hours of training with Alfons [Reitsma – Scania New Zealand senior product engineer, E-Mobility], which I passed on to my drivers. There’s not a lot on it that we need to touch. So far, so good, really.”

The Scania’s 230kW (310hp) of continuous power and 2200Nm torque is more than sufficient for the task. Get up and go is plentiful, with a smooth shift at about 30km/h by the twospeed internal transmission. The

two-axle truck, two-axle trailer semi combination is responsive to turn in, almost overly, says Greg.

“With the distance between the rear wheels of the tractor unit and the front of the trailer unit, it doesn’t take much of a spin on the wheel to turn the trailer. Especially reversing … it’s taken a bit of getting used to, and particularly, because the steering is so light. Nice and easy is the way!” he says.

“The trucks are going well and are in full swing with no issues to date – except that Greg struggles to get the drivers out of them!” says Alfons of their operation so far.

Wow! This must be one of the most ambitious, complicated, involved cover stories in New Zealand Trucking’s history, and we couldn’t have done it without the gracious input, time and effort of all involved.

From the side of NZ Post, a huge, warm thank you to Sarah Jarvis, Ryan Beale and Conor Keane for your time, sharing insight into your incredible organisation, and helping to coordinate some very busy trucks.

To Neil Dennett, Ramesh Lal and Greg Carley, thank you for making your respective trucks available, and providing critical info about their operation. And to drivers Dev Narayan, Gurdit Dhillon and Ajay Kumar, thank you for having us along for the ride.

Finally, thank you to Grant Doull of Hyundai New Zealand, Matt Gillatt from Keith Andrews Trucks and Alfons Reitsma from Scania New Zealand for sharing insight into these amazing machines and for your ongoing support of New Zealand Trucking Media.

Tare: 9000kg (load cert)

GVM: 19,500kg (load cert)

GCM: 29,000kg (load cert)

Wheelbase: 44350mm

Electric motor: Permanent magnet electric motor with oil spray cooling

Power: Max - 295kW (395hp), continuous230kW (310hp)

Torque: 2200Nm

Emissions: BEV

Transmission: Two-speed internal

Clutch: N/A

Chassis: Undisclosed

Front axle: Scania

Front-axle rating: 8000kg (load cert)

Front suspension: Scania air, fast level adjustment speed

Rear axle: Scania

Rear-axle rating: 11,500kg (load cert)

Rear suspension: Scania air, fast level adjustment speed

Brakes: Disk. ABS, EBS

Auxiliary braking: Five-stage regeneration

Additional safety: Scania ADAS package, ESP. Driver airbag

Batteries: Nine x 33kWh

Battery capacity: 297kWh (total installed)

Charging: CCS2 at 200A (130kW)

Estimated charge time: 100 min

Maximum quoted range: 250km

Wheels: Alloy

Tyres: 385/55 R22.5 (f) 275/70 R22.5 (r)

Electrical: 24V

From light to heavy-duty trucks and everything in between, there is a Hyundai Truck for your every business need.

MIGHTY

• 6-speed Allison Automatic

• Range of bodies built from the factory for your specific needs, or sold as cab chassis

• Short delivery lead time

• Licence type Class 1 or Class 2

MIGHTY EV

•Introducing our new zero-emissions truck(1)*

• NZ tested range of over 200km, while loaded to 5,995kg, on a single charge

• Fitted with the latest in-cab design, technology, and safety features

• Forward collision avoidance and lane departure warning

•Licence type Class 1 or Class 2

(1) Tailpipe emissions

PAVISE

• Full automatic transmission

• Range of chassis and wheelbase options

• Range of bodies built from the factory for your specific needs, or sold as cab chassis

• Forward collision avoidance and lane departure warning

XCIENT Hydrogen

• New Zealand’s first hydrogen powered truck

• 42,000 GCW, 400km range between refueling, emits only water(1)*

• 15 Min refuel through Hiringa’s high-capacity network

• Replacing one heavy diesel truck can eliminate 200 tonnes(2) CO2 P/A

(1) Tailpipe emissions (2) Based on 180,000km @ 2.4km/ltr diesel Call 0800 HYUNDAI (498 632) or visit hyundai.co.nz to find your local dealer today hyundai.co.nz/trucks

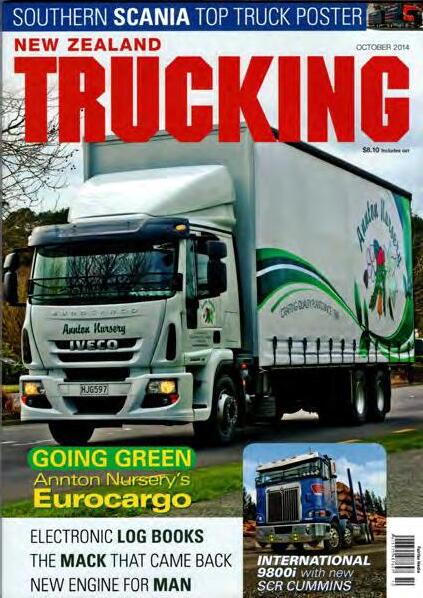

Taylor Marshall Transport has owned the Eurocargo for 13 months and put it to work on Auckland’s North Shore.

Currently owned by: Taylor Marshall Transport

Current odo reading: 372,016km

Mechanical work: New curtains and fixing wiring problems that caused fault codes

Current work profile: Palleted and general freight

Currently driven by: Anthony Bartlett

Basic original spec: Iveco Tector F4A E28 at 205kW (279hp), ZF 9S-110, Meritor MS-10164, 4.1:1

What we said in 2014: “The Iveco is full of European traditions, such as comfort and visual appeal. The outstanding feature is the truck’s quietness, the decibel meter indicates the cab noise matches that of a car.”

The Eurocargo was originally used for plant transport by Annton Nursery of Cambridge.

AN OUTSTANDING PRESENCE IN THE TOUGHEST OF JOBS. LEADING SF AXLE at 760mm LOWEST TARE Classic Style Truck.

R8-BT 8080kg (Tipper spec) C&C, less fuel, photo displays options

T8-LX+ 8450kg ! 56T GCM Rigged & Fuelled (as shown)

Story by Faye Lougher

Photos: Fraser Fire and Rescue

JZealand, and John Fraser taught me all about engineering. He taught me everything I know –but it was a small percentage of what he knew.”

ohn Fraser established J J Fraser Engineering as a production engineering company in the 1950s. Now known as Fraser Engineering Group (which comprises J J Fraser Engineering, Fraser Fire and Rescue, and Fraser Fire and Rescue Australia), it is one of the world’s leading providers of emergency firefighting vehicles. More than 1100 are currently in service in Australia, New

Zealand and the Pacific.

Following John’s death in 2022, the company continues to be run by director and general manager Martin Simpson and company director Raewyn Fraser, John’s daughter.

Martin was an underwater weapons specialist in the Australian Navy, with plans to start up an adventure tourism operation in North Queensland, when fate brought him to New Zealand in 1987. “I came to New Fire appliances are a common sight on our roads, but few people are aware that most of them are built by Fraser Fire and Rescue in Lower Hutt.

When Martin joined the company, it manufactured components for JF Hargreaves and New Zealand Railways, and undertook large jobs for Maud Kirk Couplings, Formway and Marine Air Systems.

“In 1987, we had the Stock Market Crash and then the government of the day, in all its wisdom, decided to outsource most of the manufacturing,” he says. “That was the start of where the government lost its way with the importance of manufacturing, and that continues to this day.”

In 2000, he heard that fire appliance manufacturer Lowe’s

A display of the amazing kit Fraser Engineering builds into its units.

Industries was in financial trouble and had been put into receivership.

“At that time we were manufacturing hose couplings and other components that went onto those fire appliances for Lowe’s, and also supplying the fire service with various components.

“I was just passing their doors one day when they were in receivership. The receivers were trying to trade out when they got into trouble. When I turned up, they had just virtually laid off all the staff and the company was going to completely disappear. I met the receiver, and then did a deal to try and turn it around. I went back to the engineering workshop and said to Raewyn that we should

buy them. And to my surprise, she said, ‘What a good idea’.”

Martin, Raewyn and John retained the remaining 10 staff to ensure their knowledge wasn’t lost.

“When I took them over, we had no work. I told the staff that if they were prepared to work in Frasers and do whatever we required, we would try and pull out work and see what we could come up with.”

He says it took a good six months before he secured that work.

“I think it was for police doghandling vehicles. That was one of the first jobs we got. Then we tried to get work with the New Zealand Fire Service but to our surprise, they were not cooperative. The first order I

managed to secure was for one type 3 heavy pumper for the Australian Capital Territories.”

Martin says they had to complete and deliver the vehicle before they were paid for it. The process was complicated further because the order was for a truck that was caught up in the receivership.

Once that order was completed, they convinced the South Australia Metropolitan Fire Service to allow them to get one of their chassis out of receivership too, and built a truck for them as well.

“Both authorities were so happy with the vehicles that South Australia then gave me the rest of the order for about another 10. And then eventually we won a contract with the New

Zealand Fire Service.”

After taking over Lowe’s Industries, they concentrated on doing as much of the manufacturing and fabrication as possible in-house.