The results are in and we couldn’t be happier. Scania has been voted the number one* truck brand in the country by the people whose opinion we value the mostNew Zealand truckies.

We’re chuffed to have rated highest on all measures, including most preferred, comfort, safety, sustainability, performance, efficiency, service and parts. Thanks New Zealand. It means a lot.

A PGF Transport Iveco X-Way heads north on SH1 near Hihitahi, between Taihape and Waiōuru. Photo: Faye Lougher.

A PGF Transport Iveco X-Way heads north on SH1 near Hihitahi, between Taihape and Waiōuru. Photo: Faye Lougher.

Hammar is the world leading manufacturer of Sideloaders, self-loading vehicles for containers and more. A competetive quality solution for container logistics, special transports and terminal handling.

+ Made in Sweden since 1974, delivered to more than 122 countries world-wide

+ Lift, transport and transfer up to 50 tonnes

+ Increase safety and efficiency with grounded containers

+ One vehicle, one driver, anywhere, anytime

EDITORIAL DIRECTOR

Dave McCoid

Ph: 027 492 5601

Email: dave@nztrucking.com

EDITOR

Gavin Myers

Ph: 027 660 6608

Email: gavin@nztrucking.com

For all advertising enquiries:

ADVERTISING MANAGER

Pav Warren

Ph: 027 201 4001

Email: pav@nztrucking.co.nz

Mike Devon

Ph: 027 332 4127

Email: mike.devon@nztrucking.co.nz

Maddy McCoid

Ph: 027 336 6811

Email: maddy@nztrucking.co.nz

SUB

Tracey

EDITORIAL

Faye Lougher

Further details and online complaints at www.presscouncil.org.nz

6 months

One

1 Year Australia (11 issues) $250

As I was sitting down to find a topic for this issue’s editorial, the latest International Transport Forum publication, Transport System Resilience , popped into my inbox. How timely, I thought, considering the extent to which ‘infrastructure’ and ‘resilience’ have dominated New Zealand’s headlines, conferences and general conversation recently. [On that point, you’ll want to turn to page 102 and read what Peter Brown from NZTA Waka Kotahi had to say at the Teletrac Navman TMS Conference.]

While we, and the ITF report, focus on the areas of infrastructure that relate to or impact the road transport industry, the country’s infrastructure problem has leached far and wide. Our old mate Nick Leggett, in his latest capacity as chief executive of Infrastructure New Zealand, is quoted as estimating New Zealand’s infrastructure deficit at just over $200 billion –including costs to build the projects we need and carry out the required maintenance on what we already have. That’s just under half of the country’s

2022 GDP. Words such as ‘substantial’ and ‘frightening’ are mere understatement. As far as transport systems are concerned, though, at least New Zealand isn’t alone. The ITF report discusses the results of an ITF roundtable on the subject, which brings together international experts from the Forum’s 66 member countries. So, as New Zealand grapples with its own challenges regarding transport infrastructure and resilience, what might we learn from our international counterparts?

It might seem obvious, but the key messages of ‘Transport networks are vulnerable’, ‘Disruptions have spill over effects’, and ‘Be systematic about resilience’ ring true. On that last point, the ITF says: “The concept of transport resilience must be built into national-level policies, long-term plans, appraisal procedures, competition policies and transport indicators.” On the face of it, the current coalition government seems to be on point with that recommendation, if a little impulsive in some of its recent decisions – Interislander,

anyone? Still, it’s early days yet…

The report notes that huge uncertainty exists on where disruptions might occur in future. Of course, we witnessed exactly that with the likes of Covid-19 and Cyclone Gabrielle. More worryingly, though, it also states that “despite progress in risk assessment, few governments currently use existing tools to identify potential risks”.

The ITF suggests an important distinction is between a system’s robustness, or mitigation – “the extent to which disruption reduces the functioning of the system” –and its capacity to recover or adapt – “the time needed to return to business as usual”. Improving robustness can be considered a form of mitigation, whereas recovery capacity can be obtained through adaptation measures … But how do we actually implement ‘resilience’?

It’s advised that resilience should be a core objective and an integral part of transport policy. We should develop analytical tools that help reduce uncertainty about future disruptions, and

develop guidance for policymakers on how to prepare for transport system disruptions. That involves estimating the costs of disruption, mitigation and adaptation, and embedding concepts such as redundancy. And finally, the report suggests learning how to deal with disruptions from other nations.

In fairness, I suspect little of this would be a revelation for the likes of the New Zealand Transport Agency, which seems to be aware of its role and responsibilities in keeping the nation moving, if traditionally a little hamstrung.

As Diane Edwards, the New Zealand president of CILT, said at the TMS Conference: “The real problem is the fact we have a three-year government cycle.” Yes, it’s the politicians for whom this may well make good bedtime reading.

Wouldn’t that be a sweet dream?

Gavin Myers Editor

Fruehauf is excited to announce the acquisition of Adams & Currie Limited, a cornerstone in Christchurch's transport engineering sector for nearly 50 years. This strategic move enhances our market leadership and expands our manufacturing and service capabilities across the South Island. Adams & Currie’s reputation for excellence and a skilled team complements our commitment to quality and customer service. The Lunn Road site will continue operations, joined by Fruehauf's robust network to better serve our loyal customers. We celebrate this milestone, ensuring it's business as usual with promising growth and integrated service solutions ahead. Welcome to a strengthened future together!

Trailer manufacturer Fruehauf has announced the acquisition of Christchurch transport engineering company Adams & Currie.

Adams & Currie has manufactured trucks and truck bodies for nearly 50 years. Fruehauf owner and managing director Jeff Mear said the acquisition continued Fruehauf’s growth by achieving one of its strategic objectives.

“Adams & Currie has several key strengths that were attractive to Fruehauf. Its people are highly capable, skilled and experienced trailer and body manufacturers who have successfully delivered a range of products since 1976,” he said.

The manufacturing site at Lunn Road will continue to serve Adams & Currie’s needs while also providing a service centre site for South Island customers of Adams & Currie products as well as Fruehauf and Schmitz Cargobull.

Former executive directors Peter Laurenson and Keith Robinson will remain with Adams & Currie while Pat Lagan has chosen to retire.

Mear said it would be business as usual for all staff at Adams & Currie. “We will, over time, explore areas where Fruehauf’s capability can assist Adams & Currie and vice versa. There are several areas where there are distinct synergies but not concerning people numbers,” he said.

“We forecast to be growing staff numbers over future months to help attend to our growing South Island service offering.”

The Adams & Currie manufacturing site in Christchurch will complement Fruehauf’s existing manufacturing and service centre sites at Feilding and Auckland.

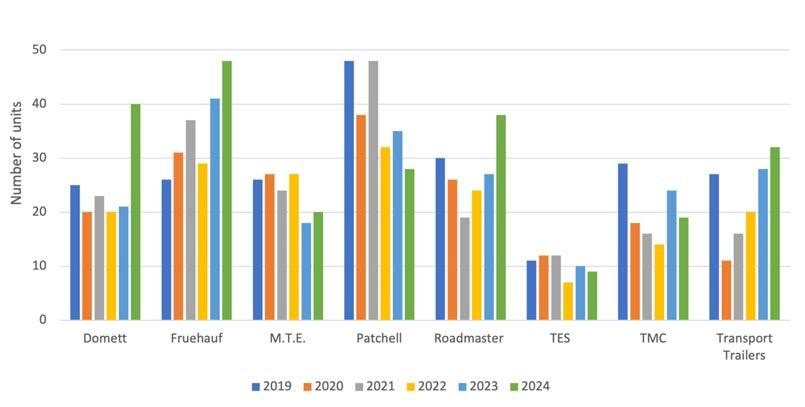

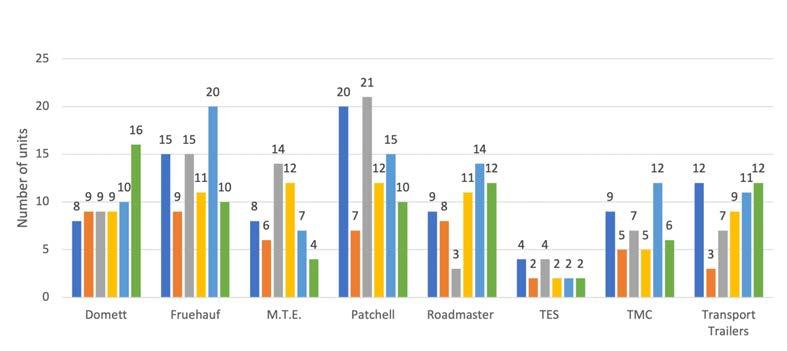

“Fruehauf had already secured the No.1 market position for trailer builds in 2023 and this acquisition will continue to strengthen this,” Mear said.

“The industry has many existing competitors; however, we remain focused on what we do and where we are heading, and Adams & Currie was a key part of our strategic plans to spread our reach to our many loyal South Island customers and to build resilience in our product and stronger service offerings.”

After three successful biennial events in 2019, 2021 and 2023, the fourth iteration of Wheels at Wānaka in 2025 will be the event’s finale.

“Anyone who loves machines, cars, tractors –anything and everything with wheels or tracks really – would be mad to miss Wheels at Wānaka 2025,” said event general manager Allan Dippie.

Dippie said the event had grown into more than just a vintage vehicle show, becoming a “biennial migration for vehicle owners and enthusiasts, a gathering of passionate individuals sharing their love for classic, vintage, modern and unique machines”.

“From roaring engines to gleaming chrome, the event has been a celebration of New Zealand’s automotive, agricultural and construction history and the craftsmanship that goes into creating and maintaining the mechanical masterpieces.”

The 2023 Wheels at Wānaka event was a huge success, with patron numbers reaching 40,700 over three days, compared with 25,000 in 2021.

The 2023 event generated $19.2 million in total direct spending. During the threeday event, 2500 to 3000 wheels and machines were on show, of which 350 were trucks and 106 earthmovers.

Dippie expressed gratitude for the unwavering support from partners, participants, exhibitors and the community, acknowledging the event’s financial contributions to many local and national charitable causes.

The 2025 show will celebrate 100 years of Caterpillar, with new interactive attractions and further additions to announced in the coming months.

Dippie said Wheels at Wānaka 2025 promised to

be a grand finale – “a fitting occasion to fondly farewell an event that has captivated vehicle enthusiasts from across the country and around the world”.

“The 2025 event will be buzzing with energy, with rare and exceptional vehicles, plus all number of machines, including hundreds of tractors, steam engines, cars and trucks, along with dirt bike races, interactive ATV, 4WD and rally demos, a huge earthmoving extravaganza, tractor and truck pull competitions and a non-stop parade-ground programme,” Dippie said.

“There’ll be a host of activities to engage attendees of all ages. Past participants and enthusiasts are encouraged to join in making this farewell edition a memorable one.”

Tickets for the 2025 event, at Easter Weekend 18-20 April at Three Parks, Wānaka, are on sale now.

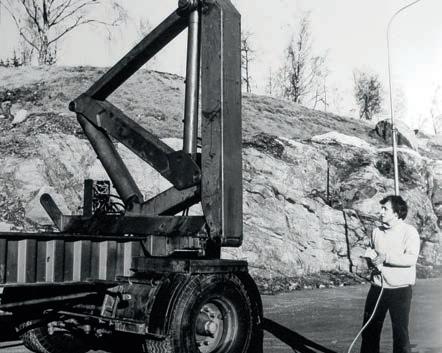

This year marks 50 years since Bengt-Olof Hammar developed the first Hammar sideloader and founded Hammar Maskin AB in Sweden. The first Hammarlift was built in the same year, later nicknamed The Shark due to its registration number HAJ 789. Haj translates as shark in Swedish.

The Shark is now something of a legend, having travelled around Sweden and Norway. In 2008, it returned home to Hammar in Olsfors where, 50 years after its manufacture, it still can be operated and lift heavy containers. The original

owner of The Shark remains a loyal Hammar customer and took delivery of its most recent Hammar sideloader in December 2023.

“Performing the first lifts with the first sideloader I built is one of my strongest memories during my 50-year journey with the company,” said Bengt-Olof Hammar, CEO and owner.

Hammar sideloaders have been sold into more than 122 countries; the company has an estimated 65-70% share of the global sideloader market, with five subsidiaries and more than 50 service stations worldwide.

Since 1974, the tare weight

for the lightest 30-plustonne capacity Hammars has decreased from about 10 tonnes to less than seven. The model programme has grown from two to seven different models, and the safe working load has increased from 30 to 45 tonnes.

In 2024, during its 50th anniversary, Hammar will take another big step in sideloader development, adding two new models – Hammar 550, the world’s first sideloader with a 50-tonne safe working load, and the new flagship model, Hammar 500.

“The Hammar 550 is a big step forward in broadening

the sideloader market and expanding what sideloaders are used for.

It has been developed for loads that are heavier and larger than any other sideloader has previously been able to handle,” said Bengt-Olof.

The Hammar 500 has a 36- or 45-tonne safe working load. It features a 6m crane reach and support legs that provide significantly increased stability.

These features allow a large handling area that, for example, enables stacking of two containers two rows deep. Its capacity is approximately equivalent to 100 metre tonnes.

CHRISTCHURCH BRANCH

9 Waterloo Road, Sockburn Phone: 03 344 5733

ASHBURTON BRANCH

189 McMurdo Street, Tinwald Phone: 03 344 5733

Scania NZ has appointed Fernando Bustamante as its new service director to help lead an eight-person team.

He previously worked as a services director with Scania Iberica (Spain and Portugal) in Madrid.

“I am very motivated about my leadership role in an area of the business that Scania NZ has committed significant, ongoing investment in,” said Bustamante.

“From the development of new service centres and workshops in Invercargill and Hastings this year to investing more than $40 million in spare-parts stock and the recruitment and upskilling of more technicians, it is all about ensuring that we have the best capacity to service our customer base.

“I am proud to lead a team that includes more than 400 technicians across our wider Scania network.”

Scania NZ managing director Victor Carvalho said improving customer experience was always top of mind.

“Every services-related investment we make is done with achieving better outcomes for our customers.

“The more expansive our service centre network is, the more highly trained technicians we have, and the more right parts that are available at their fingertips, all adds up to faster servicing of customer vehicles and less downtime off the road,” Carvalho said.

“Every dollar we invest in this area has a direct benefit to our clients’ bottom lines in their businesses.”

Bustamante hails from Argentina and has held service-related managerial roles with Scania for the past 19 years in Argentina and Spain.

It is with heavy hearts that we say goodbye to Aaron Thompson a cherished member of the Hino NZ family. Aaron was not just a colleague; he was a beacon of light, a pillar of strength, and a true friend to all who knew him.

Aaron was a man of many admirable qualities. His dedication and hard work was an inspiration. He was someone you could always rely on, someone who never wavered in his loyalty, and someone who cared deeply for those around him.

Aaron’s passion for work and commitment to excellence set him apart, making him a role model for us all.

His presence in Auckland’s Hino team for seven years was a testament to his dedication and love for his work. Aaron found joy in connecting with people and his genuine interest in others endeared him to all who had the privilege of knowing him.

Beyond his professional life, Aaron was a proud dad, an amazing brother, and a loving son. Family meant everything to him and he cherished every moment spent with his loved ones. He went out of his way to help others, whether they were customers, colleagues, friends or family.

It’s difficult to capture the essence of Aaron’s personality in words. He was a man of few words but his actions spoke volumes. Those who knew him were touched by his kindness, his generosity and his unwavering support. He had a heart of gold and a spirit that lifted others up.

As we mourn the loss of Aaron, the Hino NZ team wants to pay tribute to a man who brought so much joy and love into the world. Our thoughts and prayers are with his family during this difficult time.

Rest in peace, Aaron. You will always hold a special place in our hearts.

Daimler Truck has opened a new truck-dedicated parts warehouse in the logistics hub of Truganina in Melbourne’s west to serve its customers across Australia and New Zealand.

Situated on a 30,000m2 site, the facility will handle parts for the Mercedes-Benz Trucks, Freightliner and Fuso brands, and Alliance Truck Parts.

The new 20,000m2 facility features a solar array that can produce 125,000kW/h of energy each year, as well as a 45,000L rainwater tank, motionsensing energy-efficient LED lights, double-glazed windows and electric-vehicle charging stations.

Until now, Daimler Truck parts were kept at a warehouse shared with Mercedes-Benz passenger cars.

Daimler Truck Australia president and CEO, Daniel Whitehead, said introducing the new warehouse was a big step forward.

“This dedicated truck and bus parts warehouse is at the centre of our commitment to our truck and bus customers across

Australia and New Zealand,” he said.

“It will allow us to better meet their specific needs, which are very different to those of passenger car customers.”

Whitehead said the warehouse development fitted with the sustainability goals of

Daimler Trucks.

“Daimler Truck is a sustainability leader with our pioneering fully electric Fuso eCanter and Mercedes-Benz eActros and eEconic trucks, so it is only fitting that our parts warehouse is designed accordingly.”

UD Trucks’ most popular model, the Quon, turns 20 years old in May 2024 and UD Truck Distributors (NZ) (UD Trucks NZ) is celebrating 20 years of continuous innovation.

Since its launch in 2004, the popularity of this model has continued to grow in New

Zealand and around the world.

Marvin Fynn, UD Trucks NZ sales manager confirms, “This is a huge milestone for any truck model, showing its true versatility in applications around the globe, and New Zealand is no exception.”

UD Trucks launched the Quon

in response to increasing driver shortages and environmental challenges. The Quon represented a paradigm shift in the Japanese truck industry at the time, being the first to commercialise Selective Catalytic Reduction systems, or SCR, operating on AdBlue. This is now standard across the industry, and a legacy of the Quon.

The Quon was developed on a platform of innovation, and this continued with the launch of the “All New Quon” in 2017. This iteration focussed on the needs of the driver and the customer, but also in the consideration of the environment, which exceeded the Euro-6 emission level requirements.

The Quon continued to evolve and by 2023, UD Trucks had launched the “Advanced Quon” improving power of the GH11 engine and enhancing the driver experience even

further, inside and outside of the cab. These improvements in technology also saw even more gains in fuel efficiency and significant advancements in safety systems.

Fynn adds, “UD Trucks technology development programmes have ensured that the Quon stays ahead of the competition and the latest upgrades. The driver safety and cab comfort are no exception.

“We are grateful to the increasing number of loyal customers in New Zealand that are choosing to add the Quon to their fleets. As well, we continue to receive very positive feedback about performance and the driver experience, proving to be a valuable addition to fleets across many industries, with a wide variety of applications.

“We look forward to celebrating this important milestone with customers in the coming months.”

Truck-trailer manufacturer and service and repair provider TMC Trailers has relocated its Auckland service centre from its workshop in Wiri to a new, purpose-built facility in Drury. TMC said the move marked a significant milestone in the company’s growth and its commitment to enhancing its services offering.

“The new workshop in Drury represents a leap forward in our ability to serve our customers more effectively and efficiently,” said Richard Currie, managing director at TMC Trailers.

“Designed with the needs of our clients and the demands of the industry in mind, the new facility allows us to expand our capabilities in structural and mechanical repairs on trucks and trailers, ensuring we continue to deliver the highquality service TMC is known for.

“The decision to move to

Drury is driven by our desire to accommodate our growing operations and better serve our clients with a modern drivethrough facility with plenty of on-site truck and trailer parking.

“The new location will enable us to increase staffing levels, improve turnaround times, and

continue providing exceptional service quality.”

Auckland service centre manager Stephen (Mille) Millichamp, along with all existing team members, will be making the transition to Drury.

The new workshop will see the addition of a COF vehicle

inspection lane in late 2024.

“We’re committed to providing comprehensive solutions under one roof, making it easier for our clients to receive thorough and efficient service for their vehicles,” Currie said.

systems and components for the global transportation industry. Hendrickson’s ZMD™ ZERO MAINTENANCE DAMPING™ eliminates conventional shock absorbers by integrating the damping function into the air springs.

the most innovative, durable, lightweight and costeffective suspension systems and components for the global transportation industry. Hendrickson’s ZMD™ ZERO MAINTENANCE DAMPING™ eliminates conventional shock absorbers by integrating the damping function into the air springs.

Our Innovation Built In™ philosophy yields some of the most innovative, durable, lightweight and costeffective suspension systems and components for the global transportation industry. Hendrickson’s ZMD™ ZERO MAINTENANCE DAMPING™ eliminates conventional shock absorbers by integrating the damping function into the air springs.

Tel: +64 9 570 4721 www.hendrickson.com.au

Tel: +64 9 570 4721 www.hendrickson.com.au

Tel: +64 9 570 4721

www.hendrickson.com.au

MAN Truck & Bus has demonstrated megawatt charging on an electric truck for the first time, charging a MAN eTruck with more than 700kW and 1000A at one of the first MCS charging station from ABB E-mobility.

The Megawatt Charging System (MCS) is a new charging standard that enables superfast charging for heavy-duty electric vehicles (up to 3.75MW, compared with a maximum of 400kW with CCS).

MCS chargers are intended to provide a fast charge during the driver’s legally prescribed driving break. The new technology complements existing depot charging solutions, providing a slower overnight charge.

“With MCS, sustainable longdistance transport with trucks and buses will be possible.

Even if we are still showing a prototype here; with the new MCS standard, we have not only doubled the amperage but also the charging capacity within just a few years,” said Michael Halbherr, CEO of ABB E-mobility.

The international standardisation process for the megawatt charging system is expected to be completed this year. Alexander Vlaskamp, CEO of MAN Truck & Bus, said the goal was for 30,000 MCS charging points in Europe by 2030, about 4000 of them in Germany.

“The electric trucks are available, megawatt charging is working. We now need clear signals from politicians, not least to build trust among our customers in favour of electrification. We now need to build and scale up the infrastructure quickly.”

Trucks waiting for ferries may have an alternative to parking on Picton streets if a facility in Waitohi Domain is built.

Money has been set aside in Marlborough District Council’s long-term plan to terminate Port Marlborough’s lease of the domain and use it for parking, complete with a new ablutions block.

After the Kaikōura earthquake, when SH1 was closed, the council obtained partial government funding to build a temporary truck park on Waitohi Domain, which could accommodate up to 26 truck and trailer units. Once the highway reopened, the land was leased to Port Marlborough.

Since then, there have been

increasing issues with trucks parking on Picton streets, with the council receiving complaints from residents regarding noise at night from refrigerated trucks, and safety concerns. Council surveys have found more than 50 trucks and trailer units parked in Picton streets when ferries are delayed.

While the Riverlands Truck Stop near Blenheim provided toilets, showers, a laundry and a place to have a meal, a similar facility is needed closer to the ferry terminal.

An ablutions block with a swipe card system, similar to that used at Riverlands, could be installed with an estimated cost of $400,000. The cost of terminating the lease with Port Marlborough is $209,500.

Mason Murphy of Ranfurly Transport is this month’s winner of the Peterson Night Moves photo competition. This shot was grabbed early morning at Clarence with a sympathetic sunrise lighting up the morning sky. As Mason put it - ‘even Mother Nature supports the colour scheme at Ranfurly Transport’. Congratulations Mason! Now get your entries in for June...

ENTER NOW TO BE IN TO WIN A PAIR OF PETERSON’S SUN GLASSES

Send your best night bling photo as well as contact details into nightmoves@nztrucking.co.nz to enter

‘You can take the man out of the machine, but you can never take the machine out of the man.’ If you were going to sum up Steve Martin in one sentence, that might be it. Vocational trucker to the core, this year, the Dunedinite celebrates 20 years in business, and 45 years in an industry that’s wound into his DNA. The latest addition to his boutique fleet is typical Steve Martin – a reflection of its owner’s passion and purpose.

Story Dave McCoid Photos and by Carl Kirkbeck, Dave McCoid

Vegan, plant-based (they’re not the same evidently), carnivore, paleo, magnesium, CoQ-10, ginseng, cross-fit, Bikram yoga, cupping, blah, blah, blah! Every day, we’re bombarded by ‘experts’ telling us how to enhance our health and wellbeing through diet, supplements, introspective journeys, bizarre treatments, or some variation of an ageold exercise. But no one seems to be researching the health

benefits of the only thing that really matters. The one thing usurping all other contenders in the title race for life’s ultimate elixir … happiness. The truth is, you can eat whatever you like, pop a million pills and potions, sit chanting cross-legged on a hilltop with only a loincloth covering your whatsits, smear yourself in a Himalayan salt sludge, or exercise to the point of collapse: it all counts for shit if you’re not happy. Without happiness, you’ll be ill, grumpy,

video Crossing the Boyle River bridge on SH7.and drink for all the wrong reasons.

Both Mick Jagger and I know this to be true. I don’t know Mick at all – sadly – but I do know at 80 years young, the buzz he gets from standing in front of an adoring crowd while delivering what only he can more than compensates for an offstage life outrageously lived.

Me? Well, I’m in New Zealand’s garden city, Christchurch, in front of Steve Martin’s brand new 8x4 T610 Kenworth tractor

with 860mm integral Aero roof sleeper. The truck is hooked to his four-axle Convair bulkpowder semi-tanker, and as I stand, staring in bewilderment, I know exactly why Mick is still prancing around the stage at four score years. Something is coursing through my veins, purging every bad thing I’ve imbibed over the past month, leaving me completely refreshed, revitalised, and believing I can run a mile in bare feet over broken glass. I have no doubt

that ‘thing’ is happiness.

At that moment Rod Stewart himself appears. No, not the fake singing one, New Zealand’s own trucking one. The real one: Steve Martin, the man whose name is on the sleeper of this fine motor carriage. He’s picked up his industry nickname due to a more than uncanny resemblance to the sandpapery-voiced bard – who, incidentally, turns 80 himself next year.

Steve’s got 17 years up his sleeve on the two octogenarian

rockers, but he does share something in common with both – an absolute love and devotion to what he’s spent his working life doing, and it’s instantly apparent the moment he arrives at the scene with shades and swept-back hair. At 63 – going on 23 – a big grin appears and he says, “Cowabunga dude! Is that cool or what?” Only he could get away with a Teenage Mutant Ninja Turtle greeting at 63.

“Yeah mate. That’s cool all right.”

Like the Knowles’ Kenworth K220 or the James’ Scania 770S, there’s a lot to unpack here. If we’re being brutally honest, Kenworth’s T610 8x4 tractor in non-SAR posture sporting an integral sleeper is a machine you could get horribly wrong in the looks stakes unless you’re a true aficionado. Like its forebears from another era, the T600A, 602 and 604, you’re not starting with a classic block of clay from which to sculpt your beauty like you are with say, a bluff K-model cab, or bonneted T9/C5. Curved bonnets, set-back curvy guards, a low stance, integral sleeper cab, a heavily raked A-pillar – and adding even more cosmetic complexity over cousins of the past, a second-steer axle!

Lucky then the label ‘aficionado’ is perfect for Steve, truck-mad since he first opened his eyes and looked at the world. Nor is he alone. Nephew Reece has the diesel

chromosome somewhere in his DNA double helix and plays a vital role in day-to-day operations and the presentation of the gear. Together, he and his uncle are a great duo.

Nor is this their first T610 rodeo. Regular readers will recall Steve’s first Kenworth T610, a stunning 6x4 tractor with 600mm integral sleeper, winning the Top Truck spot in March 2021. That unit tows a B-train bulk-powder unit Steve built new a year or so before, towed by his Freightliner Argosy prior to the first 610 arriving. In the hands of Reece and Craig Hayward, the first T610 has just clocked over 850,000km and the trailers 1,400,000km – not that you’d know looking at them.

Of course, one of the greatest cosmetic enhancements you can give to a truck is to put a tanker behind it. Tubes, barrels, or bulk powder, there are few trucks that don’t look cool towing a tanker, and if you’re going to ‘top of the pops’ of the

tanker genre itself, then bulk powder takes some heading off. The new truck tows a 14.1m Convair five-hopper quad-steer and the beauty of that is the balance the quad brings to the 8x4 tractor. There are four axles and a natural rake front and back, making the whole thing look like something akin to the bullet train.

But, of course, balance and symmetry are only the start and Steve is quick to extol the virtues of the lower South Island truck customising scene – a pool of talent he says is the equal of anywhere and one he reckons is largely an undiscovered jewel.

“Ferg at McCormick Motor Bodies in Dunedin is a magician,” he says. “They set this whole thing up and it’s just faultless; they’re craftsmen. Look at the boltless guards and that fabrication behind the sleeper to tidy up gaps and make it all look seamless ... the vents made to look like light

surrounds, the deck plating – I just think it’s next level.

“Likewise, sparky Tony Mansfield at Harrex Downing and Little, who wired up the 130-plus Peterson marker lights. “The workmanship is absolutely on point.

“Then there’s the paint. Elite in Tīmaru. I think they’re without peer to be honest, and Andrew [Geddes] at Timaru Signs and Graphix has always done my signwriting. I don’t even tell him what I want. He asks but I just say, ‘It’s your canvas. Go for it!’ And look what comes back. I seriously believe we have the best craftspeople down south. I really do.”

There you have it, then! With two great family minds and a bunch of artisan craftspeople in action, the 8x4 tractor was always destined for spectacular – so much so that it earned one of the coveted spots inside the big gala event at the recent 100 Years of Kenworth celebrations at Mystery Creek.

Paused

for a coffee break at BP Raeward. It’s hard to fault.

Make no mistake, as happy a place as it is, Steve Martin

Contracting is another truckers’ trucking company, and if you’re not a full-immersion type, Darwin’s theory might well play out. That’s not saying anything about some adherence to archaic work practices to prove your worthiness, far from it. Like so many of recent, Steve says running the way we did back in the day is long gone, and keeping it tidy removes noise from the business and makes it more enjoyable to boot. No, the Darwin thing is more about who you are as a person … you know … working – trucks, eating – trucks, sleeping – trucks, TV – trucks, holidays – trucks … yeah, you get it. Testament to that is the nature of the operation versus the effort that goes into the machines. As you’ll read below, downtime is an ugly word at SMC, and some of the fleet family amass absurd mileages in no time at all. You would forgive Steve all day long if he were to take a sausage factory approach to his mechanical charges, yet every one is a showpiece, tastefully customised to within an inch of its life. Euro trucks are presented Euro-cool, and US gear US/Antipodean-cool … and never the styles shall meet. In short, presenting a plain white ‘sausage’ of freight utility to effect the daily transport requirement in this operation would be akin to hacking

your head off with a teaspoon handle. Cool on the outside is just as essential as inside the fridge van his Scania tows, and vital in the happiness culture, mood and productivity of the business.

It’s interesting when you think how many of the South Island’s devoted and slick operators come out of the Goodman Fielder camp. There is no better marketing – or assurance of product care – than passion, presentation and personal standards, and someone in the big show knows that implicitly.

Still one of the coolest trucking catchphrases ever, although in

all honesty, the days of trucks consistently clocking up big annual distances in the North Island – and even the top of the South, for that matter – are largely a thing of the past. There are simply too many people, poor and inadequate roads, few bypasses, and ever more delays at the points of load and unload.

Below mid-Canterbury, however, a couple of those factors begin to abate – there are fewer people, and as a result, better roads. Steve’s whole career has been around big mileage trucks – doubleshifting and familiarity with big annual distances are his normal. However, there are big

distances, and then … there are big distances. The 6x4 T610 in front of the B-train is hovering around 850,000km as it passes its third birthday, yet even that will induce a yawn from its owner. The triple-shifted Scania S620 on the Dunedin/ Christchurch, Dunedin/Central Otago milk and produce run has just pipped 1,100,000km at just two years and three months old. Yes, folks, you read that right. Suffice to say, horsepower in this yard always begins with a ‘6’.

“I run a Guardian Seeing Machine in that truck also and really rate it as a safety device.

“Yeah, it keeps you on your toes. The run is pretty much

On display at the 100 Years of Kenworth gala

The trucker’s trucker and he wouldn’t have it any other way. Right: The artisan work by McCormick Motor Bodies is everywhere – take this lower sleeper panel filler with vents made to look like light surrounds. event.

non-stop; the truck only switches off for its weekly service. The previous truck on the run was a Mercedes-Benz Actros 2663, and that was a bloody good machine. It was simply the support that let it down.”

A new S620 Scania was in the throes of being commissioned as we went to press. “Given the lead times on gear in recent years, the rule of thumb on that run is: on the day a new truck goes to work, you pretty much order its replacement.

“We’ll need to start thinking about the 6x4 610 soon, also. The trailers can have a spruceup sometime next year. They’re on 1,400,000km and in need of a bit of cosmetic here and there.

Stones, grit, CMA, [ice road treatment] and even flour, they all give them arseholes.”

Time for action. We are off to Nelson to deliver 27,500kg of flour into the Molenbergbranded silo at Goodman Fielder’s Nelson bakery. That payload puts us at about 47.7 tonne gross out of a potential 48. Light and airy bread might well be fantastic, but the flour tanker arriving at at the bakery arriving in a similar state?

Definitely not fantastic. The units are therefore fitted out with SI-Lodec scales in order to ensure the available compliance envelope is optimised. “Wouldn’t be without them,” says Steve.

“We can see on the tablet when loading without being in the truck, and when we’re unloading, it’s just another tool to help us know we’re all empty. Also, peace of mind when passing the check stations.”

The big Cummins fired up, Steve engages gear in the handstirred transmission and rolls out of the depot on Washbournes Road in Hornby. He winds his way to Main South Road before turning right at The Hub corner onto SH1 north. A quick stop at BP Raeward for the obligatory caffeination, and we all stand back for another moment to take the rig in.

Sitting plumb level, it’s pretty difficult to fault. The Kentweld bumper, grille bars, the stacks

are just the right size and length, the Armoury chrome rims contribute to just the right amount of chrome and colour code, and there’s little chance you’ll miss the whole thing with 131 additional Peterson lights on the tractor, another 51 on the semi, plus spots in the grille and green strip lighting. “According to Peter Swan at Convair, I’m the first to put the running lights along the top rail.”

Time’s up, the 610 rolled out and on through Woodend and Amberly before making the west turn at Waipara, just north of the CVST site at Glasnevin. Lucky, it was a lovely autumnal day and the rig made effortless progress up the Balmorals towards Culverden. By the time

Photo: Craig Hayward.

Photo: Craig Hayward.

we reached the wee hamlet an hour and 20 minutes north of Hornby, the caffeine had done its job and bladder relief was required.

Steve operates between 1350 and 1800rpm as rule – tapping into the power bank on lift-off during early shifts to help get the show rolling, and as the ground speed increases, you hear the shifts shorten up, using torque to preserve the impetus gained.

It’s not the big steady climbs or long descents that test your metal in a manual truck. Finding the right sprocket before settling in for the big pull or descent should not present an inordinate challenge. The skill resides on stretches of road like

SH7 on the run from Hanmer through the Lewis Pass, and then SH65 and 6 down the Shenandoah on to Murchison and beyond. The rise and fall is relentless in varying grades and therefore road speed, with no consistency in lane width, and of course, constant directional change.

In Steve, I’m instantly reminded of Ray Feki in Tutu and Raewyn Manuel’s Western Star 4884 Ruaumoko (New Zealand Trucking magazine, September 2021). Steve lives up to every expectation you have of him when it comes to the execution of the trucking art form. His pedigree and decades in the industry manifest themselves in abundance. He

is completely at ease in his machine; it may as well be a Toyota Corolla. The shifter simply slides from one gear to another mid-conversation with no apparent signs he’s even listening to the truck –and yet we all know to what degree that isn’t the case. What the Steve Martins, Ray Fekis and Guy Knowles of the world tell us is how much the so-called boffins who bleat on about changing gears being a dangerous, inefficient, fatigueinducing distraction are, in fact, speaking through a hole in their hindmost quarters. What they are telling us is just how appallingly we’re doing at training the new generation when it comes to

understanding their machines at the seat-of-the-pants level.

“The Scania is a lovely truck and ideal for the work it’s on with multiple drivers. You wouldn’t find a quieter and smoother truck to drive, and I’ve never taken the AMT out of auto; it’s that good. But as trucks go, it’s just not me, you know? There’s nothing to do. It’s a me thing.”

The X-15 provides the perfect backdrop to events in the cab. Its guttural rumble is more than clearly evident and it certainly gets the sound meter working a little higher than we’ve been used to of recent – well into the second half of the 70 and even early 80dB range in times of action. This is truckin’.

What also exercised its presence was the large white thing full of flour hooked to the back. Running along past the Boyle River and climbing the Lewis toward the Goings section the semi was always ‘there’, and Steve says you need to be more cautious than in the B-train.

He’s a huge fan of the Convair product – “It’s the Rolls-Royce of powder tankers” were his exact words. However, neither does he take longevity for granted, making one purchasing decision he says pays handsomely when it comes to relieving stress in the units he owns – oscillating fifth-wheels. “This one runs a Holland, and the whole fleet is on oscillators. It’s just a thing I have. There’s so much twisting

and raking in the course of a day’s work and that stress has to go somewhere. I’ve got two on the B-train and Convair were a bit cautious of that originally, saying we wouldn’t feel what the back trailer was up to, but that’s all about the people you have working for you, I reckon. The Scania on the milk – that’s got one. Where we unload in Queenstown, the truck is on a severe angle while the trailer is level. Normally, a fridge trailer will let go first in the rear door frames, but that one’s mint. I’m convinced it’s the fifth wheel.”

The in-cab ride is certainly influenced by the big trailer and there’s the occasional nudge from the second steer, but nothing to write home about.

In all respects, it’s a Kenworth doing exactly what they do best, telling you how they’re coping. The 610 is barely off the mark with only 15,000km on the clock, but she scaled the steepest part of the Lewis in sixth high-split (12th) at 1350rpm and 45km/h. As the note lowers, the cab goes quiet for a moment, and two truckheads enjoy the sound of 2779Nm (2050lb/ft) of torque taking responsibility for progress away from the 459kW (615hp) of power at around 1400rpm.

In terms of spec, it’s a standard affair with a 22 series 18-speed manual Eaton Roadranger behind the 15L Cummins X-15, and to the rear of that, Meritor MT21-165 GPs

on Kenworth AG460 suspension.

Descending the other side the Jake happily holds the show at 1750rpm and 40km/h in fifth high-split (10th). Without prompting, Steve expressed his opinion on how essential it is to be able to stop dead on loaded descents in the event something is waiting around the next blind corner.

We round up the Shenandoah section north of Springs Junction and roll out through Maruia, Murchison and along the Buller River at Kawatiri toward the Hope Saddle. The surefootedness of the chassis in this country explains in part why this truck brand has earned the place it has in trucking folklore.

Lewis Pass single lane bridge, outside and inside. Photo: Dustin Wright.

At the foot of the Shenandoah.

Lewis Pass single lane bridge, outside and inside. Photo: Dustin Wright.

At the foot of the Shenandoah.

Chris Gray is Steve’s man at Southpac, and Steve speaks highly of the relationship. “He rings you back! It’s that simple. If he doesn’t know the answer, he says, ‘I don’t know the answer Steve. But I’ll ring you back’, and he does. Every time. He’s an ex-Southern Viking man originally, and started in parts, so good habits were entrenched early. And he’s bloody easy to talk to.

“I have to mention Dean Cooper, also. He’s awesome. Anything you want, Dean can get it for you. I wanted train horns, I told Dean … I got train horns.”

The makers of Dr Who certainly

had a hand in Kenworth’s integrated sleeper range. Inside, the 860mm jobbie is a tardis, I kid you not. Outside, it looks low, sleek, and snug – inside it’s a big space. Steve’s north of six-foot and he has no issues at all standing up straight from the driver’s seat under a roof line that arcs up and away to the rear.

Grey Graphite is the official moniker for the buttoned vinyl trim.

Storage-wise, there are lockers above the driver and passenger, front and overhead, and under the bunk, which are also accessible from the outside – as is the bunk itself, #howcoolaresleeperdoors! There’s also shelving up high

either side of the sleeper, one accommodating the telly in this case. Between the steers on the right is a toolbox, and there’s a battery box on the left.

Hard plastics accommodate the high traffic areas and there’s woodgrain on the door-pulls and dash.

The 2.1m cab is a fantastic place to live and work. There’s nothing to say about the dash that’s not already been said – a clear binnacle, big, easy-to-getto buttons, great heating and air conditioning, and superb driving position. At some point, that binnacle will go full-digi and catch the K220 – who’d have thought we’d ever be heard saying that!

Steve opted not to have

the infotainment system by choice, saying in his opinion, the traditional set-ups give better sound and longer, more stable range.

There’s plenty of glass and superb mirrors. Visibility out front is fab with the bonnet raking steeply. Those car-like A pillars and bar-setting mirrors mean left/right clearance in the cab is as good as it gets in a fixed-mirror world.

The interior hasn’t escaped the Steve Martin vocational truck-nut treatment. Silver bezels adorn the binnacle gauge cluster and our friends at PearlCraft have provided the steering wheel and shifter head. Interestingly, it’s a PearlCraft-ed Kenworth SmartWheel, which

runs on an exchange basis by all accounts, meaning you send them yours, and they supply one that’s already done.

What I did really like … a lot … was the vinyl boot around the shifter. Often the custom heads look a little weird with a thin shaft under them – 10/10 for that.

Finishing it off is red strip lighting, which gives the whole thing a cool burgundy glow. To quote a ‘Martinism’ on that…”It’s a me thing.”

“The only place they’re [both Kenworths] in low-range is climbing the lookout point in Dunedin,” said Steve as we crested the Spooner’s hill north

of Nelson in seventh high-split (16th) at 38km/h and 1750rpm. At the foot of the range on the northern side, we pass through the string of hamlets between Hope and Richmond before arriving at Stoke and the bakery on Bolt Road.

“I was a bit worried about the big semi when I first got it. We can’t get the B-train into the Dunedin bakery without splitting it and using a wee shunter we have for the back half. Although the math said we could get the quad in there hooked to this one, theory versus reality … you know? I took it down for a first run-through, and it does fit, but man, it’s tight. There is no margin for error.”

Nelson is the complete opposite, it could not be easier

– drive in the gate and a straight back alongside the silo. We park for the night, awaiting the morning unload.

As with the first Kenworth, Steve’s gone for a PTO-driven blower mounted under the deck plate on the left. It’s a superb installation by Skookum, the local agent for the Convair product.

Powder tankers – I’ve always thought them to be a scary thing. There are horror stories about implosions when pressure differentials get out of whack, and explosions … funnily enough, when pressure differentials get out of whack – yikes! I was determined to understand the fine art of powder delivery from a gun!

Loading is easy – open the

hatches on the top and the flour just drops in via a sock from some magical place above. But then comes the getting-it-out bit, which normally means discharging into a hopper high in the sky. For that, you need a gravity-defying transport medium – enter, fast-moving compressed air.

First though, Steve hooks up the earth wires – yes, like most powders, flour can get all charged up during the unload process, and when you combine that with the considerable heat the discharge air generates zooming along the pipe, it’s best that electrical energy is given somewhere to go. Not doing so can be another reason things don’t go as planned.

Steve connects one end of

1) T610 cockpit with a bit of ‘oomph!’. Silver bezels, PearlCraft and full vinyl boot on the shifter. 2 & 3) The outside presentation disguises the voluminous cavity within.

1) T610 cockpit with a bit of ‘oomph!’. Silver bezels, PearlCraft and full vinyl boot on the shifter. 2 & 3) The outside presentation disguises the voluminous cavity within.

the main discharge line to the blower behind the cab and the other to the input pipe running up the silo from the base. He fires up the X-15 and sits her on about 900rpm, and we are all go. That gets air moving along the main discharge line. One or two at a time, he then starts the aerators located in the bottom of each of the five trailer hoppers. They disturb and fluff up the flour, encouraging it out of the discharge tubes and into the main discharge line where it’s swished up and away into the silo and on to Molenberg heaven. The third member of the discharge trio is the top line, which essentially puts a compressed air hat on the flour in the hoppers so it does, in fact, continue to leave the show as

the load disappears. You can imagine not having the ‘air hat’ when there’s bugger all left in the hopper. It would all billow around inside and be hard to get in the exit line.

Steve can control any of those functions individually, so as simple as it sounds in principle, playing the bulk-powder discharge symphony is a learned art. The reason I say symphony is he can’t actually see anything; it’s all pressure gauges, watching the discharge hose out the back – if it’s wobbling steadily, that’s a good thing, and also the groans the hoppers make as the air does its thing. Good gauges, good sounds, and a wobbly hose mean good things; bad gauges, bad sounds, and a stiff or flaccid hose mean bad things – like

blockages. Having witnessed it all, the trailer does really sound alive, ‘telling’ you when its tummies are empty or unhappy. Interestingly, the whole thing happens at about 20psi. When you consider a truck tyre can be anything from 80 to 110psi, it shows just how complacent we’ve all become around highpressure vessels keeping our trucks and trailers rolling. There are also pneumatic hammers that ‘tap-tap’ the hoppers to loosen any residual. Done well, it’s a cinch, and just over an hour after arriving, the discharge hose is being packed away in its immaculate chrome carrier.

One thing we all learn as we get older is we don’t get many days, and every one wasted will never

be refunded. Not all are blessed to the extent Mick Jagger, Rod Stewart and Steve Martin are, where true happiness resides in their vocation of choice, and the mere act of working is a buzz.

Steve Martin has proved that in the world of trucking, outrageous uptime and presentation are not antagonistic bedmates as long as your passion matches what achieving both demands. The quid pro quo of that is when it’s your passion, you don’t realise the demand.

When you are that person, however, what truck do you choose? Well, that’s always individual, but it is the Steve Martins of the world that Kenworth builds its product for: vocational operators where the truck is far more than a tool of transport utility – trucks that can be individualised and not only tell the world what it is you do,

but who you are.

There was a lot of chat around the T610 pre-launch, in the same way there was pre the T600A back in the day. They were both very different-looking Kenworths, in the case of the 610, sleek with car-like A pillars. Would they encompass everything a Kenworth needed to be? Would they satisfy the Steve Martins of the world?

Not all change is bad. It’s often a case of moving with the times, finding your place in them without compromising who you are. In its products, Kenworth gives people the opportunity to do just that.

In conclusion, then, I give you the Kenworth T610 and Steve Martin. A product that can teach you a lot about values-based evolution, and a man who can teach us a lot about life and where its value truly resides.

Tare: 10,820kg (load certificate)

GVM: 32,000kg

GCM: 97,000kg

Wheelbase: 5400mm

Engine: Cummins X-15

Capacity: 15L

Power: 448 – 459kW (600 – 615hp)

Torque: 2779Nm (2050lb/ft)

Emissions: Euro-5

Transmission: Eaton Roadranger RTLO22918B 18-speed manual

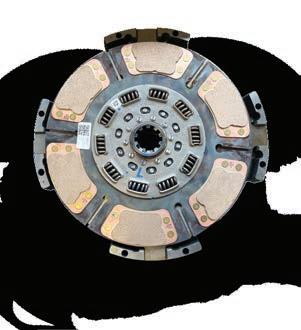

Clutch: Eaton 2050lb/ft East Pedal Advantage 3 – VCT Plus clutch (manual adjust) with hydraulic clutch assembly

Front axle: Meritor dual MFS66-122 13.2T

Front-axle rating: 12,000kg

Front suspension: 12T taper leaf springs – load share

Rear axles: Meritor MT21-165 GP rear axles with dual diff locks

Rear-axle rating: 20,900kg

Rear suspension: Kenworth Airglide 460

Brakes: Drum

Auxiliary braking: Jacobs engine brake

Additional safety: EBSS (ABS, Drag Torque Control (DTC), Auto Traction Control (ATC)), FUP, additional productivity

Fuel: 695L

DEF tank: 160L

Wheels: Armoury chrome rims

Tyres: Front: 305/70 R22.5 (offset) Rear: 275/70 R22.5

Electrical: 12V

Cab exterior: Stamped aluminium, riveted and bonded 2.1m 860mm integral sleeper. Single-piece curved windscreen. Aerodynamic mirrors remote and heated mirrors. Cab skirts and roof spoiler.

Can interior: ISRI 6860/870 pro black air suspension driver’s seat. Woodgrain fascia. FM/AM radio and CB with four speakers and tweeters. Grey Graphite upholstery.

Extras/custom: Outside: Kentweld bumper, stainless-steel headlight surrounds, stainless bug guard with backlit bug and swan. Colour-coded stainlesssteel visor, chromed mirrors, twin stacks with 7in pipes, stencilled Kenworth shrouds on the stacks, stainless sleeper monogramed highlights, trim, and sleeper cab side skirts with marker lights. Alloy tank and cab steps with stainless-steel facia. Stainless-steel guard flair on front guard, stainless-steel second steer guard and hole-less stainless-steel rear guards with infills. Colour-coded deck plates and fabricated rear sleeper infills. Stainless-steel fifth-wheel rail covers. Custom rear stainless-steel-wrapped light bar with Peterson round lights. 131 additional Peterson marker lights. Slimline LED spotlights behind the grille. Six grille bars, painted fuel, DEF tanks, battery and toolbox (between steers).

PTO-driven blower fitted inside chassis. Inside: PearlCraft smart wheel and shifter head. Vinyl shifter boot. TV.

If you were looking for a time and a place to mark the beginning of the Steve Martin story, it’s Dunedin in the mid-1950s and two young fellas on the side of the road with a broken-down car. One of the two was Steve’s father, John Martin. From Motueka, he had finished his building apprenticeship and decided a roadie with a mate was just the ticket for a break away.

Anyone could have happened along at that moment, but it wasn’t just anyone who did. Wib Maxwell of Maxwell Brothers fame idled up alongside.

“Are you fellas alright?”

“Yep, yep, we’ll be right.”

“Right-oh, then. Oh well, if you need a job to sort yourself out, come and see me.”

And at that point, we could go straight to the T610 on the cover and say The End … not really.

John decided to take Wib up on his offer and soon found himself driving an Albion and tipulator on the Bluff Harbour project.

A lot of John’s work came via the company’s commercial association with Fulton Hogan,

and it was while on a roading job in Mossburn that he decided to pop into a local diner where working behind the counter was Aileen. He was looking at his sweetheart and future wife.

Eventually, they set up camp in Dunedin, and John moved on to work for local carrier R A Little on a meat run to Queenstown. They had two sons, Stephen in 1961 and Lindsay in 1962.

Fun fact time! As we know, Steve has pursued a wonderful career in trucking and Lindsay is a builder in Christchurch – now there’s a perfect paternal DNA

occupational split!

“Dick Little bought Dad a brand new Mercedes-Benz 1923 4x2 tractor and he carted containers on an A-train, or logs via a dolly setup. A six-speed/ two-speed, it was an amazing truck, and he loved it. It had the two spare tyres mounted up behind the cab, side by side, and Dick reckoned that was all you needed for a log guard. He used to turn up at skids and the other log truck drivers would laugh at the single drive. Once in Tapanui, the crane driver said he’d give him a hand to get going, and then to everyone’s amazement, Dad and the Benz pulled up and away – half sideways climbing the hill leaving the site, and gone. When he got back for the second load, the crane operator said he’d been about the only one not towed that day.”

As Steve grew up, it was clear he was ‘diesel-powered’, and as soon as he was able, he was hanging around and eventually

helping at the yard with whatever was happening – all the good wholesome activities: learning from the older men, riding in anything that moved, and helping with characterbuilding stuff like furniture shifts. Obviously, he would eventually join the fold, and his first real truck was a V8 petrolpowered C1800 International that was stretched and repowered with a 175hp Scania motor by company mechanic Russell Turner. “It had a sixspeed Gardner transmission and a three-speed auxiliary and was good for 85mph. I carted meat to the PPCS [Primary Producers’ Co-operative Society] cutting plant in the Kaikorai Valley.”

A change in the log fortunes saw Dick scupper that activity, and the Mercedes-Benz left the fold, much to John’s disappointment. His next steed was a new Leyland Crusader with a 290hp Detroit 8V71 – a truck he absolutely didn’t bond with, according to Steve.

“Dick eventually bought Dad a new Fuso and I was lucky enough to get the Crusader. I was about 20 years old by then and loved it – rain, hail or snow, the roof hatch was open and the windows down.”

The Crusader was eventually sold to Freightways OD Dave Bennet, replaced with a T81 Fuso, signalling the beginning of a happy association with the three-diamond marque for Steve. “I was heartbroken to lose the Crusader, but the Fuso was a good truck.”

R A Little was bought by Murray Samson in the early 1980s and Steve eventually found himself on a five-year-old International 3070, working one of the toughest physical gigs in the game – frozen meat deliveries from Dunedin through Central Otago. “That truck had done a genuine 86,000km, and I doubled the mileage in six months. The bloody heaters in them were diabolical. I used to tape butchers paper over

1) The Albion Steve’s father John drove for Maxwell Brothers. Where it all started. 2) The R A Little Leyland Crusader – his dad didn’t bond with it, but Steve couldn’t get enough. 3) The Mitsubishi FV315 Murray Samson bought to replace the T-Line. She had full bling for the day. All FV315s were cool, this one was extra so. 4) The Shadbolt Express! Tim even had a ride in this 400hp FV415. 5) The first Louisville. 6) A pinnacle truck for Steve in 1995, the Samson’s Ford LTLA. It delivered on every promise.

the front to try and raise the water temperature and make the heater work better. Murray was going to swap it out for an Eagle but I said, ‘Just get me a new Mitsubishi.’ He asked what I wanted on it, and I said, ‘A bullbar and chrome everything.’ And so, he did just that. It was an FV315 towing a 36ft (10.1m) fridge semi, and was a really cool truck. I won the Golden Guitars truck show with it.”

On linehaul now, as with Steve’s prior work, the trucks were double-shifted with the regular run commencing in Dunedin, carting general up to Christchurch, and then Invercargill produce south. Steve was required to be in Dunedin by 2am so the south leg driver could be at the Invercargill markets by 5am.

Next came consecutive Mitsubishi FV400 series trucks, and the second 400hp unit will always be remembered, not just for how well it went.

“I was having a break at the servo in Tīmaru about midnight and he just walked in and asked me where I was going and could he grab a lift!” The year was 1993, and ‘he’ was the one and only Tim Shadbolt – boisterous, 46 years old, and using the PR value of hitchhiking from Auckland to the deep south as the kick-start to a by-election campaign in Invercargill. Steve said though there was an element of truth, it wasn’t all PR. “It was the only way he had of getting down. He wasn’t that well-heeled at the time, apparently. He was genuine-as. I was heading right through that night and so he stayed with me. When we got to Invercargill, the telly was there, it was all go. He was great company, a really funny bloke. He was incredibly open and honest and probably told me more than he should have.” Steve laughs as he thinks back. “That truck is still around in the North Island, working as a mobile accommodation unit on movie sets.”

Then came two Ford Louisvilles, the first a Cummins N14-powered LNT, followed in 1995 by a truck he says was his

The Western Star is as cool a ‘sweeper’ as any fleet could wish for. There when needed, and when opportunity pops it’s little head up. Photo: Martin collection.

pride and joy – an LTLA or LTL Aeromax. “It was a fantastic truck and a big deal at the time. I went to the launch in Auckland, and it was on the stand at Mystery Creek that year.” The truck lived up to its promise, too: the 321kW (430hp) Detroit 60 Series was, in Steve’s words, “an incredible motor”, running out to well over 1,000,000km without being touched.

But, the only constant is change and things were certainly changing in the business. After 20 years in the R A Little and Samsons fold, all the way from enthusiastic kid to frontline driver, Steve accepted a job

offer from Alan Simms at Quality Bakers in the company’s bread distribution arm. “I started as a fleet driver for the first few years before the offer of an ownerdriver position in 2004. That was a big deal for me.” Steve Martin Contracting was rolling.

Steve’s first owner-driven truck was a Volvo FH460 daycab truck and trailer, carting bread between Dunedin and Invercargill. In unison with his previous driving history, where at least two of the same brand followed in succession, that truck was replaced by an FH520 sleeper cab. Following a restructuring of the runs, bread

gave way to milk, requiring the trusty Viking to be cut and tucked into a tractor unit so it could pull reefers. The new regular run was as familiar to him as the old – Dunedin/ Christchurch then home with stops in Ōamaru, and every second day a strop around Balclutha, Gore, Mossburn and Otautau, all in a six-days-a-week repeat cycle.

“Nothing wrong with the Volvos at all. They were bloody good trucks. But after the 520, they went to emissions fluid and I wasn’t ready for that.” [At that time, neither was the deep south network, to be fair – Ed.]

The two T610s make a spectacular duo. Photo: Andrew Geddes.

Then came the first headache. Unlike Guy and Helen Knowles, Steve didn’t escape the Cummins ISX EGR era unscathed, and the one in the Kenworth K108 Aerodyne that replaced FH520 was a troublesome child. “Five EGR coolers, three turbos, three radiators, and then a motor job all before 800,000km. Luckily it was on fleet management, so didn’t hurt me beyond inconvenience and having to cover it.” Then he rolls his eyes. “It’s been largely fine since the motor jobs so the owners after me have had a bloody good truck.”

In 2016, the first Freightliner Argosy arrived, a truck he still says today is without doubt the “cheapest truck to run I’ve ever owned. Both of them!” He glances across at ‘the old girl’, the original flour tanker tractor, now used as a backup to the two T610s and says, “950,000km and all it’s had is a clutch. That’s it.”

He’s also quick to extol the South Island’s legendary Freightliner salesman Trevor McCallum, saying, “Such a really nice guy and there’s nothing he didn’t know about a Freightliner. I sincerely wish Trevor all the very best.

for loading has moved in the intervening years to a facility on Blenheim Road in Christchurch, and although Steve still calls Dunedin home, the flour tankers operate ex-the Garden City. When it came time to replace the Argosy on flour in 2020, Steve did look at the big Cascadia, but the measurements didn’t quite fit, so Kenworth got the nod.

“The tractor’s been a good truck and attracts a lot of attention still. Last month, it slipped a liner and that’s been its first hiccup.”

Today, the fleet consists of five units – the two Kenworths on flour, the Scania, the Argosy as the spare flour tractor, and a devilishly handsome Western Star 4884 as a floating relief/ cover truck, or whatever else is needed.

The flour tankers run Christchurch/Dunedin, Christchurch/Nelson and Christchurch/Wellington. The hectic triple-shifted milk and produce run still largely follows the same pattern, except the interior run has moved from Southland to Central Otago. Day to day, Steve keeps the milk and bits and pieces rolling along, and filling in the gaps where needed – a great way to keep tabs on your business and understand what’s going on at the frontline. The reality is he loves trucks as much today as he’s ever done, and that’s where he likes to be most.

“I’d have definitely replaced the milk-run Argosy with another in 2018 had the Freightliner story here not begun to change, with increased pricing and then sadly the end of the truck.”

We’ve just mentioned the Freightliner Argosy on flour, so that’s a good segue. It always pays to answer the knock at the door because, sometimes, it is opportunity, and in late 2016, Steve took on the bulk flour deliveries ex-Tīmaru to the Goodman Fielder bakeries in Dunedin, Nelson and also up to the Hutt when product flow required. The source point

Steve confides, although he didn’t have any biological children, he has three awesome step children – Kane, Kate, and Dave Fitzgerald – along with two gorgeous grandsons, Lincoln and Lochie. Dave followed in Steve’s footsteps, with his love for trucking, and drives for RD petroleum.

Nephew Reece Martin runs the flour operation. We met Reece in the March 2021 Top Truck article. Being Steve’s nephew, and interested in the flour side of the business, he is the logical destination for succession. “He loves it, and he’s always on top of the game. He can pretty much tell you at any

moment how much flour is at the various destinations, and where the trucks are going.

No business runs without a pulse, and Steve does not hesitate to acknowledge family, mentors, bosses, peers, colleagues and staff throughout his career and takes great pride in the young people he’s helped into the industry.

He enjoys meeting and yarning with folk, although he’s certainly not a sufferer of fools in any way; you can’t be to stay in business, especially one as intense as his, with the uptime the trucks are expected to have. You could say Steve runs the old General MacArthur chestnut of beginning the relationship with 100% of his respect, and then it being up to you to maintain that. All that good stuff aside, he’ll admit in a heartbeat who the cornerstone of his approach

Following in the original Freightliner’s footsteps, the first flour tanker has had one clutch in 950,000km.

and attitude is – his wife Robyn.

“Robyn’s a registered nurse, working at the hospice as a community coordinator, helping people through end of life. She loves her job, and says it’s an absolute privilege to meet and

help people when they’re at that point in their journey. Robyn supported her own mother and both Mum and Dad through to the end of their lives. I can’t put into words the respect I have for her. She’s just bloody amazing.”

He chuckles, “When I’m a bit stressed, she just has this way of putting the whole thing into perspective, calming me down, and we’re good to go. She is one amazing lady and I love her to bits.”

is a chip off the old block and appears to have both diesel and flour in his veins! Now that’s a mix.

Left: Steve and Robyn proud as punch and looking sharp outside the Kenworth 100 year function in February.

What an absolute blast for two days. It was really just a bunch of truckheads having the best time with a superb machine. Thanks to Steve for letting us do this on his 20th year in business, and making it happen so easily from his end. All the best to one of the industry’s true good guys.

Thanks to Chris Gray and Richard Smart for Southpac’s everwilling cooperation and support.

Steve’s nephew Reece Martin

Every cover truck holds a special place in the history of New Zealand Trucking magazine. We love to see where their road has taken them.

• Currently owned by: Hira Bhana & Co.

• Current odo reading: 500,000km

• Mechanical work: Gearbox repairs

• Current work profile: Fresh market produce from Pukekohe to Auckland twice daily

• Currently driven by: Gerald King

• Basic original spec: Isuzu 6WG1-TCC at 390kW (550hp), Isuzu MJX16 AMT, Isuzu RT210 rear axle on Isuzu four-bag air suspension, 4,1:1

• What we said in 2013: “This is a large roomy cockpit that is a lot quieter than the 460, and with quiet braking from the Giga-Tard and the benefits of the AMT combined, it’s a nice package to punt down the road.”

Unfortunately Hira Bhana was unable to supply a current photo of HBB973 before we went to print. However, we know it is still on its original run, with its original driver. “It’s due for replacement, but we’re still pretty happy with it,” says director Amrut Bhana. PROVIDES ASSISTANCE to the driver.

Blind spots are a major contributing factor in heavy vehicle vs pedestrian/cyclist interactions, particularly in left hand turns. MAX-SAFE have a range of solutions to help increase the driver’s awareness of vulnerable road users around their vehicle. Our solutions include optional visual and audible alerts for both the driver and the vulnerable road user i.e. inside and outside the cab. One such offering is MAX-SAFE Side View™: an affordable solution based on an AI camera that detects and protects pedestrians/cyclists – ultimately enhancing safety.

A big bold appearance meant HBB973 made a statement when it was new.

• SAFEGUARDS the side of the VEHICLE.

• PROTECTS PEDESTRIANS, cyclists and motorcyclists.

• HIGH ACCURACY – detects people (stationary and moving).

• MORE AFFORDABLE than sensor systems.

• SUITABLE for most ANZ CONDITIONS.

• Provides ALERTS and AUDIBLE WARNINGS.

• STATE-OF-THE-ART AI TECHNOLOGY.

• GREATER SAFETY and PEACE OF MIND –for Drivers & Fleet Managers.

• Part of the MAX-SAFE SAFETY ECO-SYSTEM.

Story by Ken Kirk

Story by Ken Kirk

He’s the ultimate ‘you won’t know until you give it a go’ type bloke who has never let the chance to write another chapter in his life book go by. Having hung up the keys – almost – on a fantastic career in trucks and other things, Ken Kirk has taken the time to share his time and tales.

Kiwi-born and raised

I was born in Picton in 1948.

Dad worked at the Tory Channel whaling station at the head of the Marlborough Sounds, and I went to the station school in my primary school years and then onto secondary in Christchurch.

In May 1962, I got expelled from college at the age of 14 and a half. Mum wanted me to try another school, but I wasn’t interested. I found myself a job with one of the vegetable markets in Christchurch working as an offsider on their case yard trucks. After I had been there a few weeks, the two drivers I was

working with took a shine to me because I was a willing worker and listened to what I was told. After a few weeks of me asking questions about driving the trucks, these two men, Don and Bill, who I will be forever grateful to, asked me if I wanted to learn to drive. Of course, I said ‘yes please!’

They laid out the rules and made it very clear that if I stopped listening, the lessons would stop. I listened and they spent the next five months teaching me how to load and drive a truck the right way, as they put it. I have carried that

teaching with me all through my driving life.

Mum finally talked me into going back to school and finishing the fourth form, which I did in December that same year, but I left once that was done. We moved from Christchurch back to Picton where I found a job working for a cable-laying contractor in Blenheim.

This was about February 1964 – I was just a kid labourer until the day the truck driver didn’t turn up for work. We had two trucks. The boss drove one and the truck driver drove the other. After a lot of ringing around

he came out and said to the other labourer and I that there wouldn’t be any work that day because we didn’t have a driver for the truck that carried the ditch-digger.

“I can drive it,” I said.

“What do you mean, you’re only 16,” he said.

“Yes. I can drive as well as Charlie can and probably even better – I don’t like the way he drives.”

“But you are too young to drive, you don’t even have your car licence yet, do you?”

“No, but I’m going for it in two weeks.”

The truck in question wasn’t flash, an old flathead petrol V8 Ford with a snub nose, a fourspeed crash box, and a beer crate with a wheat sack folded on it for a seat. On it’s back was a Fordson tractor with a tooth chain trench digger. The upshot was he got me to take it for a run around the yard and then back it into the shed again.

“Well, you can obviously drive, and we do need to get to work, so let’s go.”

Two weeks later, I got my car licence and the boss applied for a special heavy truck licence for me that got knocked back, so we just kept on doing what we were doing and never got caught. Charlie never did come back so I was the truck driver until the job ended. That carried on until the contract ran out and I went home to Picton where Dad got me a start with Todd’s Transport (later taken over by Kirby Carriers). The company did general freight in and around Picton and Blenheim. I was just shy of 18, so they took me on and booked me in to get my heavy trade licence.

The day I went for my truck licence in 1966, the cop who took me remarked I was extremely competent for someone who was just getting his licence, but didn’t ask any more questions.

I worked for Todd’s for about two years and obtained my heavy trailer licence in that time. I then spent a year driving for Nelson Fisheries in their relatively new Ford Thames

1) Port of Nelson in an Austin Loadmaster unloading mutton carcasses – note the sling-load in the top right. It was carted in a wooden bin and wrapped in muslin. 2) Ken’s first big linehaul rig was a Detroit-powered KM Bedford. Character-building stuff, but good adventures and memories. Seen here with a load of general on the Desert Road.

3) An FV315 and side loader working in and around greater Wellington as well as some linehaul. 4) A much-loved truck and job. The FV315 eight wheeler and four-axle trailer, taken here at the Makatote viaduct in the National Park in the early 1980s.

Trader (the long bonneted one), picking up catches off boats that sold to them from Port Underwood and French Pass, as well as stock loads to and from Nelson.

In 1969, I moved to Wellington and drove for BP doing tanker work delivering home heating oil and some bulk fuel to service stations. I did this for about 18 months and then moved into general freight with Container Freight for a couple of years.

A complete change of direction came in 1972 and I spent three and a half years as a relieving lighthouse keeper on lighthouses all over the country,

until my younger brother was killed in a tragic boating accident just off Tory Channel. I thought, ‘if he can die so young, I had better get moving and see some more of the world before it is my turn’, so I packed up and went to Australia for almost two years.

While there, I drove experimental Mack V8s, D8 Caterpillar dozers, graders, frontend loaders, Haulpak mining dump trucks, and anything else someone needed a driver for in the mines.

I then did a stint on a prawn boat as a deckhand fishing

for prawns across the Gulf of Carpentaria and the top end of Australia before getting into interstate driving work, including the Darwin milk truck out of Townsville; an Aussie-cab Atkinson with a 671 Detroit and nine-speed in her. It was a good job for a few months after which I flew back to New Zealand to marry the girl who had waited nearly two years for me to come home.

We got married in 1975 and settled in the Hutt Valley. I went working for Haldane’s Haulage for a couple of years in a little TK Bedford on around-town parcel work. Haldane’s then shut down, so I decided to lease a three-ton Isuzu truck to do around-town parcel deliveries for a company that gave me guaranteed work.

That lasted a bit over a year until the company I was carting for folded. A short stint with DJ McGregor’s on linehaul furniture removals taught me I didn’t fancy doing furniture removals for a living.

By now I was 30 and I spent two years at Wellington Dairy Farmers driving bottle trucks (Dodges, Commers and Isuzus) on the Upper Hutt run before moving onto artic and trailer tanker work. About this time, road transport was starting to kick off the restraints New Zealand Rail had on the movement of road freight over longer distances, through government deregulation. There was this little family outfit just up the road from the Dairy Farmers yard that was starting to get into

that sort of work, so I applied for a job there and got it.

That little family company was J D Lyons, working out of Pomare in the eastern Hutt Valley.

I started on a TS3 Commer with a 6V53 Detroit in it. I did mainly paper reels to The Evening Post newspaper from Miramar into Wellington central for six months, and then I started getting Palmerston North and Hastings runs. I then got moved onto the side loader doing container work, mainly in Wellington and the Hutt Valley, until I got my first linehaul truck, a KM Bedford with a 6V71 Detroit and a nine-speed box. I went all over the North Island in that truck and eventually moved up to a Fuso, which in those days was getting into the big