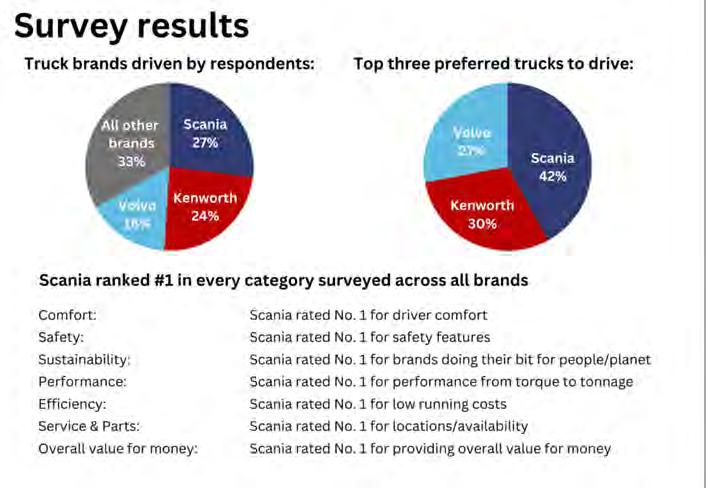

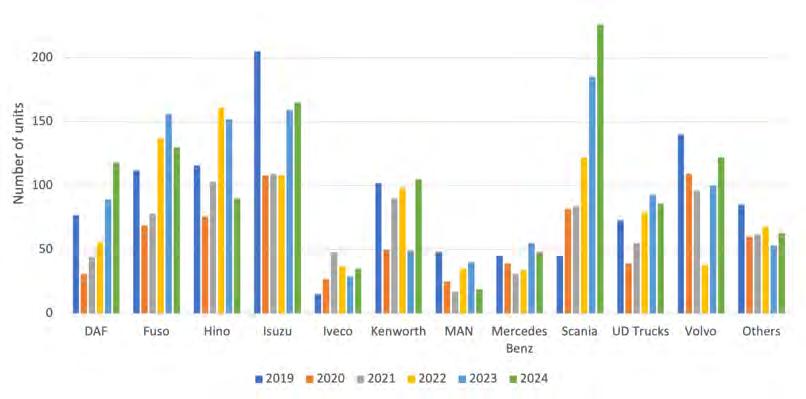

For the second year running the results are in and we couldn’t be happier. Scania has once again been voted the number one* truck brand in the country by the people whose opinion we value the most - New Zealand truckies.

We’re chuffed to have rated highest on all measures, including most preferred, comfort, safety, sustainability, performance, efficiency, service and parts. Thanks again New Zealand. It means a lot.

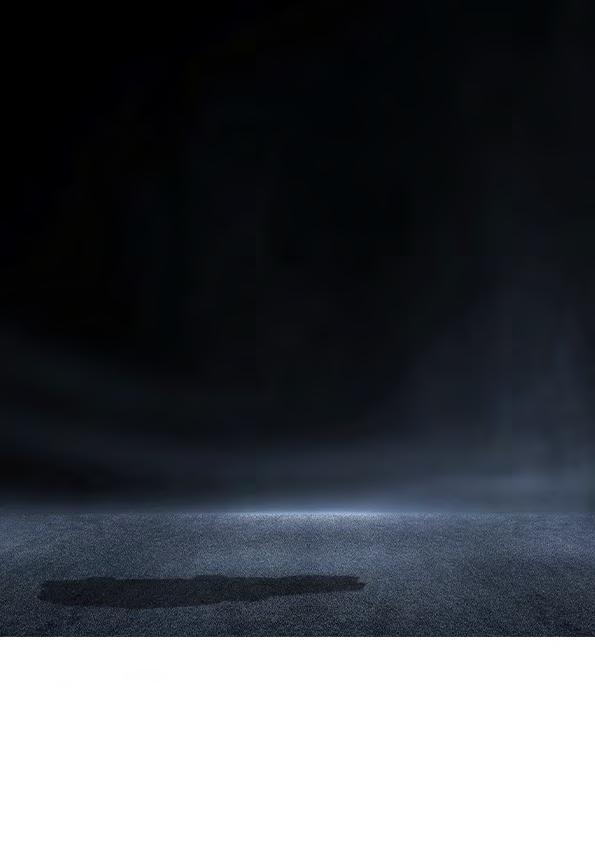

A Waimea Contract Carriers Western Star 4884, with a load of long-pole wood, climbs to the summit of the Spooners Saddle just south of Wakefield in the Tasman region. Photo: Dave McCoid.

A Waimea Contract Carriers Western Star 4884, with a load of long-pole wood, climbs to the summit of the Spooners Saddle just south of Wakefield in the Tasman region. Photo: Dave McCoid.

EDITORIAL DIRECTOR

Dave McCoid

Ph: 027 492 5601

Email: dave@nztrucking.com

EDITOR

Gavin Myers

Ph: 027 660 6608

Email: gavin@nztrucking.com

For all advertising enquiries:

ADVERTISING MANAGER

Pav Warren

Ph: 027 201 4001

Email: pav@nztrucking.co.nz

Mike Devon

Ph: 027 332 4127

Email: mike.devon@nztrucking.co.nz

Maddy McCoid

Ph: 027 336 6811

Email: maddy@nztrucking.co.nz

SUB EDITORS

Tracey Strange, Faye Lougher EDITORIAL

Craig

Council Complaint” in the subject line. If unsatisfied, the complaint may be referred to the Press Council, PO Box 10 879, The Terrace, Wellington 6143 or by email at info@ presscouncil.org.nz

Further details and online complaints at www.presscouncil.org.nz

6 months

(6 issues) $59.50

One year (11 issues) $109

Two years (22 issues) $218

1 Year Australia (11 issues) $250

Crowd amasses pre-opening.

The Fairfield Freight Hub (FFH), just north of Ashburton, opened by Transport Minister Simeon Brown on Friday 19 April, is a hands-down winner for the town, the region and the local companies behind it.

Wholly owned by the Wareing Group, the hub demonstrates what can be achieved when public and private collaborations are focused on an end goal.

“In 2019, picture a freight train rolling past half empty, while myself and Murray Young [today NZ Express, then GM KiwiRail] are watching in dismay, knowing there was room for substantial improvement,” said Wareing Group CEO Mark Wareing to

guests at the opening.

Wareing emphasised the team effort in getting the hub from idea to reality, acknowledging the assistance of the Ashburton District Council, local MPs, Talley’s, KiwiRail and MSC Line, among others.

Centred in the midCanterbury food bowl, the FFH transforms the region’s daily flow of inputs and outputs. Central to that is the hub’s role as an empty container release point for MSC Line, and discussions are also underway with other shippers.

“Our exporters don’t have a very long time to get their product to port, and by having empty containers here, we can take out one leg of that journey

for them,” said Mark.

FFH also moves rail transfer operations from an old site in the middle of Ashburton to the Fairfield industrial park.

The efficiency gains for road transport are significant. Congestion currently plagues container traffic moving to the Port at Lyttelton, and hubbing at Fairfield will reduce that by up to 40,000 truck movements per year. There are also significant environmental gains as the facility draws on solar energy for a part of its operations.

Put to the real test early, the hub has been operational since the Rangitata rail bridge outage, and site manager Mat Bruce and operations manager Heath Little

said it had come through with flying colours.

Fairfield Freight Hub – fast facts

• 40,000m2 facility

• Dr y store 2000m2

• 800 TEU

• 120 reefer plugs

• Bulk commodity silos

• 60 containers railed a day from two rail placements

• 200kW power consumption offset.

Wareing Group CEO Mark Wareing addresses guests at the opening.

Two key men ensure smooth daily operations –Heath Little (left), onsite operations manager, and Mat Bruce, site manager.

The facility will handle two rail placements per day.

Multi-modal, multi-product with room for expansion.

Heavy container handling.

Wareing Group CEO Mark Wareing addresses guests at the opening.

Two key men ensure smooth daily operations –Heath Little (left), onsite operations manager, and Mat Bruce, site manager.

The facility will handle two rail placements per day.

Multi-modal, multi-product with room for expansion.

Heavy container handling.

Three lucky transport engineers are off to the United States to participate in a dedicated transport course after receiving scholarships from the Institute of Road Transport Engineers of New Zealand.

The institute’s scholarship fund provides financial assistance to members to help further their knowledge and technical expertise in road transport.

This year, IRTENZ offered scholarships to attend a threeday course at the University of Michigan on the dynamics of heavy-duty trucks.

IRTENZ president Chris Carr said the high calibre of applicants for this year’s prize saw the organisation award three scholarships for the course.

“We were pleasantly pleased with the quality of the applicants and we found it was difficult to choose a winner,” Carr said.

The full 2024 scholarship award was given to Rory O’Sullivan, who has been involved in the heavy vehicle industry since 2011 in multiple roles and is currently the general manager, manufacturing, for Fruehauf NZ.

Financial assistance was also provided to Tim Stone from mechanical engineering consulting firm Randall & Associates, and Alan Kirk,

a heavy vehicle certifier at bodybuilder and trailer manufacturer Gary Douglas Engineers.

The University of Michigan course focuses on the special dynamic behaviour of truck systems, merging the fundamentals of vehicle dynamics with the details of truck components and properties.

“The University of Michigan is a long-standing transport research institute and is one of the leaders in the field,” Carr said.

“The course provides a solid background in vehicle dynamics and operations.”

Carr said New Zealand’s transport industry was unlike any other, and having people learn as much as possible would only benefit the sector.

“We’ve got a really strange country that we live in when it comes to our transport design. Our vehicles are not really like anyone else’s around us – we’re quite different to Australia, to Asia, to the US ... [and] very different to Europe except for some bits in Scandinavia.

“What we do is unique. And our topography is pretty unusual because everything’s sort of up and down and round and round. So we always need to be looking for the next thing that will improve our industry, and supporting the people who are going to come up with those things. We think that our

scholarship winners will be able to contribute greatly to industry knowledge with what they gain from this course.”

Carr said the scholarship represented a big step by IRTENZ to help the future transport industry.

“Like drivers, the engineers in our industry are getting

older, and we are losing IP as they retire.

“We need to do what we can to help provide education and training for the people that are in the industry, and hopefully provide some interest for people coming into it,” he said.

“This is IRTENZ investing in the future of heavy transport.”

Rory O’Sullivan, Tim Stone and Alan Kirk will all head over to the University of Michigan.The Commerce Commission has granted clearance for NZ Post to acquire PBT’s courier customer contracts.

PBT provides freight, courier and logistics services throughout Aotearoa, offering intercity courier services primarily to business customers in urban areas.

In reaching its decision, the commission focused on the potential impact of the proposed acquisition on competition in the supply of intercity economy courier services.

It had expressed initial concerns that the proposed acquisition would remove

a disruptive competitor for intercity economy courier services. However, after further investigation, chair Dr John Small said the commission was satisfied the acquisition was unlikely to lessen competition in any New Zealand market substantially.

Central to the commission’s decision was its assessment of the competitiveness of PBT absent the proposed acquisition.

“Our investigation indicated that absent the proposed acquisition, it is unlikely that PBT would likely provide a significant disruptive influence on the supply of intercity economy courier services,” Small said.

“Post-acquisition, customers

requiring intercity economy courier services would have options for courier providers such as Freightways, Aramex and Team Global Express, in

addition to NZ Post, and the loss of PBT is unlikely to have a material impact on the price and/or the quality of intercity economy courier services.”

Teletrac Navman has launched a new podcast

– Mobilising The Future of Fleets – as an educational

from the transport industry. The podcast covers the energy options for a mixedenergy fleet and the reasons

of behavioural change on the success of a mixed-energy future, and answers to questions submitted by fleet operators will

European sales manager at ANGI Energy Systems, a specialist in alternative energy solutions and also part of Vontier.

Alcohol detections in the workplace have risen significantly, according to new research from The Drug Detection Agency.

TDDA saw the detection rate nearly double during the 2022 and 2023 holiday periods. Traditionally, positive detections reduce after December and January, but initial testing results show the increase yet to subside, holding steady with a 13.8% increase over the past two years.

The data comes from Imperans, TDDA’s digital reporting system, the country’s largest private database of drug and alcohol testing information.

“TDDA has seen higher detection levels surpass the holiday season. There’s a longer tail on the issue, and it’s

becoming a regular trend. We’re flagging the increased alcohol use with our clients as well as the wider business community, so everyone is aware of the increased workplace risk,” said Glenn Dobson, CEO, TDD.

While data shows a marked increase in positive detections, anecdotal evidence indicates a range of issues causing the substance to extend from home to work. Stress at home, mental health issues and financial and inflationary pressures have been cited as triggers for use. Given the upward trend, companies are encouraged to review their current substance policies, also known as a drug and alcohol policies, to ensure it remains current, fit for purpose and legally robust.

“While it’s hard to draw

causal lines between workers’ behaviour and alcohol issues, anecdotally, TDDA is hearing that traditional dependence issues are being inflamed by factors like mental health issues as well as financial pressures,” said Dobson.

Understanding alcohol issues, establishing a cohesive drug and alcohol policy and training and education are essential for maintaining a safe and productive workforce as well as compliance with the Health and Safety at Work Act 2015 (HSWA). Employers are encouraged to regularly evaluate their drug and alcohol policies and address the ever-changing and unique challenges posed by substance use.

TDDA recommends the following testing methods for

alcohol detection:

• Breathalyser: the same technology used by roadside police to demonstrate presence. Primarily used in mobile testing clinics for on-site screenings and spot testing.

• Alcohol hair testing: a hair sample collection that is used to demonstrate lifestyle alcohol use. Primarily used for court-ordered testing or pre-employment screening of professional job applicants.

tonnes of green hydrogen per

year. Since opening the plant, Tūaropaki Trust and Obayashi

refuellers needed to be located

routes as possible, hence the refueller’s location in Manukau.

The refueller can be relocated as customers’ needs change.

Halcyon’s model of hydrogen hubs, including the Mōkai

supplied from one source,

providing economies of scale.

“Reliable, local hydrogen supply gives our customers the confidence to invest and innovate,” said Dave Binnie, general manager energy at

Further to being the site location for the refueller,

Coregas’ manufacturing and supply experience was critical to the project’s technical and compliance requirements.

“Taking charge of Halcyon’s express refueller enables us to provide our expertise in managing H2 distribution while supporting the transport evolution for New Zealand,” said Peter Neate, general manager at Coregas NZ.

“The transport and trucking

sector in New Zealand remains a largely untapped opportunity for hydrogen-fuelled heavy vehicles, which deliver a lighter, longer-distance solution combined with fast refuelling and high payload capability.”

In the same week as Halcyon’s launch, Hiringa and Waitomo launched New Zealand’s first hydrogen refuelling network. Turn to page 100 to read about that.

We specialise in

suit

We specialise in high quality, mesh and PVC covers to suit trucks, trailers and farm bunkers. All of our covers can be easily operated from the ground using a silky smooth cable system, eliminating health and safety risks.

We specialise in high quality, mesh and PVC covers to suit trucks, trailers and farm bunkers. All of our covers can be easily operated from the ground using a silky smooth cable system, eliminating health and safety risks.

All of our covers can be

We specialise in high quality, mesh and PVC covers to suit trucks, trailers and farm bunkers. All of our covers can be easily operated from the ground using a silky smooth cable system, eliminating health and safety risks.

Aglobal survey of 1800 supply chain leaders shows average response time is five days, hindering progress on resiliency and risk mitigation.

New research has found slow progress in making supply chains more flexible and resilient.

The IDC research, sponsored by Kinaxis, also highlighted response time.

The survey of 1800 supply chain decision-makers worldwide found most struggle to keep their operations agile and adaptable amid an onslaught of disruptions from geopolitical conflicts, natural disasters and other volatility.

“It’s more common than ever on quarterly earnings calls to hear that supply chains

address these compounding trends and make chief supply chain officers the heroes instead of the scapegoats the next time trouble appears on the horizon.”

Although respondents in all regions are overwhelmingly not “very satisfied” with their business’ ability to withstand and respond to supply chain shocks, they remain optimistic about technology’s potential to

• 42% of consumer product respondents rate their supply chain orchestration as mature, the highest among all verticals.

• 25% of respondents plan to move to new technologies in the next year to improve resilience.

• 33% want supply chain orchestration platforms that offer AI/genAI capabilities. 63% view their supply chain

Hammar is the world leading manufacturer of Sideloaders, self-loading vehicles for containers and more. A competetive quality solution for container logistics, special transports and terminal handling.

+ Made in Sweden since 1974, delivered to more than 122 countries world-wide

+ Lift, transport and transfer up to 50 tonnes

+ Increase safety and efficiency with grounded containers

+ One vehicle, one driver, anywhere, anytime

First, there was red. Then black, blue, green and maroon. Now, in May 2024, purple joined the fray as JT Fossey Trucks in Tamworth, New South Wales, released the latest custom Mack Super-Liner in its Outlaw series.

Outlaw 6 entered build in November 2023 and has now taken to the road with its new owners, the Ramien family of Collarenebri in western New South Wales.

“Outlaw 6 is a great example of the continuation of this amazing series, showcasing what Mack Trucks can offer to their new and loyal customers. The Outlaw series Mack SuperLiner gives the driver every possible option to make their driving experience the best and most enjoyable it can be,” said John Saint, dealer principal of JT Fossey Trucks.

“Like the first five trucks in the series, Outlaw 6 features unique colour coding, scrolls, graphics, a bulbar, and other polished stainless adornments.”

Like the first five trucks in the series, Outlaw 6 features unique colour coding, scrolls, graphics, a bulbar, and other polished stainless adornments, with the interior theme matched to the truck’s exterior.

“Congratulations to Julia, Allan and Jasen. We truly appreciate your support and new business relationship. A massive thank you to all the businesses and associated people who have spent hours getting this truck built and presented to our customers,” Saint concluded.

The Outlaw series will eventually comprise 10 unique Super-Liners. To find out more, check out our feature Outlaws Roam, in the July 2023 issue of New Zealand Trucking.

Outlaw 6 in all its custom, purple glory.

Outlaw 6 in all its custom, purple glory.

Our winner this month is Murray Peake from C&R Developments near Cambridge. Murray captured this shot of his T908 Kenworth, loaded with an International 433 scraper, while stopped for a chain check just south of Taupo in amongst some solid rain. Well done Mate, your prize is on it’s way to you. Now get your entries in for the July competition...

ENTER NOW TO BE IN TO WIN A PAIR OF PETERSON’S SUN GLASSES

Send your best night bling photo as well as contact details into nightmoves@nztrucking.co.nz to enter

Two long-standing names in trucks and trucking have come together, proving how the right gear in the right environment can have a positive impact company-wide.

Earl Edwards and Gavin Myers

Earl Edwards and Gavin Myers

We speak about it often in the pages of New Zealand Trucking magazine: Company culture and all it encompasses within successful businesses … Enabling your people to do and be the best they can, giving your clients the highest level of service possible, and implementing the right tools and

processes to do the job as efficiently and safely as possible. Every company will have a different definition and different ways of making it happen but, if done right, the results are longevity, loyalty, respect, pride and success.

So often when it comes to trucking, culture is built over decades and stems from the hard work and

Photos and video bydedication put in by the company’s pioneers right from the beginning.

Auckland’s Tom Ryan Cartage is one such company, started by Tom in 1979 and incorporated as Tom Ryan Cartage in 1985.

After 45 years in the game, Tom is still active in the business, though general manager Alan Spilhaus now coordinates day-to-day running.

“Tom comes in three or four times a week and provides valuable stewardship and guidance. Being honest, he loves the trucks, loves his workshop. He’s a truckie through and through,” says Alan. “I’m more of a bean counter – finance and money,” he adds with a laugh.

The company’s story leaves little doubt as to how its culture was

formed. “It starts in 1979, with Tom and a little Bedford,” Alan explains. “Tom had worked for his dad’s meat haulage business and effectively woke up one morning with the desire to buy a truck. That was the Bedford, and he got straight into it. Within three years, he was looking after Dysart ITM. That grew in the 1980s to running more than

Photo: UD Trucks.10 trucks predominantly due to his level of service, still servicing Dysart ITM and Manukau Timber, which later became Placemakers Frame and Truss.”

The 1990s was a period of significant growth for the company via acquisition.

“We diversified into truck-mounted cranes, containers, a bit of air and sea freight, warehousing and shipping and barges along the way,” continues Alan. By 2004, Tom Ryan Cartage also had a presence in the South Island.

“The height would’ve been around the 2008 GFC, with 267 staff, four ferries and 180 trucks. But a real period of rationalisation followed that, a realignment in terms of how we balanced service and never saying no, with sensible business decisions: ‘Yes, we can do that, but under these terms and conditions,’” Alan explains.

And so the container division was divested to L.W. Bonney & Sons, the South Island operation to Northern Southland (which subsequently sold it to Toll), and the ferries were taken over by Sealink.

“It’s been a pretty good time since,” says Alan. Today, the company is home to 110 staff, with a truck fleet of just over 100, split between its two Onehunga premises

in Alfred Street and Galway Street. “Galway Street is currently the workshop, serviced by a team of nine mechanics who do a lot of our R&M. It was Tom’s original premises. We moved into Alfred Street in 2002. It’s the old McIvers yard. We added the Approved Transitional Facility (ATF) for container packing, unpacking and warehousing.”

In addition to warehousing, Tom Ryan Cartage today has a general freight division, an air and sea freight-transfer division and a truck-mounted crane division. By far the biggest area of the business, the fleet of 65 truckmounted cranes mostly serves the city’s construction industry. While these are “the bread and butter”, comprising 65% to 70% of the business, they are also supported by a range of flatdecks, trombones and tipper units.

Palfinger is the crane of choice. “They consistently hit the mark, have excellent aftersales and have always been on the money with parts, crew and turnaround. They continue to perform, and we’ve always been pretty happy with them,” Alan says. The cranes are supplemented by

two rigid units fitted with Moffett truckmounted forklifts and four articulated lowloader units that carry Ausa forklifts. Why the rigid/Moffett, low-loader/ Ausa combinations? “The Ausas have a 2.5-tonne lifting capacity but weigh 4.5 tonne. As a traditional forklift, they’re more terrain-able and can efficiently and quickly unload 19 tonne of palleted product onto sites where cranes aren’t the right solution. But it’s a bloody artic unit running around Auckland … we get sent to places like Parnell with these things, and it’s ridiculous,” Alan explains.

“As rigids, the Moffett units are much smaller and more agile. We can get up so many more streets with these trucks. Yes, the artics give us more payload but can be a headache on the site. So, even if the Moffetts themselves are a little less capable on undulating terrain than the four-wheel Ausas, that mix is about right for now.”

By all accounts, Alan takes a no-bullshit approach to his role as GM, so when he makes a statement about plant, staff, industry or operation, you can believe he’s calling it like it is. He elaborates on the need for these different units coming down to having the right tool for the job

No.552, a new 430hp Quon, is one of 10 Coregas-branded units.

in an increasingly complicated operational environment.

“If we could run everything as a truck and trailer, life would be simpler and more efficient. But we’re addressing the challenges presented by building sites in the city, and finding solutions has become harder over time, with development of the city … in-fill housing, brownfields developments have made it more difficult.

“There’s also been a lack of, or loss of, knowledge – the merchant sales force who used to go out and do a site inspection on these new sites and might have been a builder or in transport or had some operational relationship … that’s faded away.

“The other problem is every site is different every day, so your hazards and challenges change throughout the build, and in that sense, we rely on builders who know what’s going on – some are very engaged and aware and give great facilitation, they invest in positive outcomes for their sites. But there are still those who sub out everything, and the subbies don’t care how it all happens. So, we then take on this duty of care in how we operate with the likes of traffic management, when really, it’s a site issue.

“We’re always operating in that grey area of managing the situation around what’s operationally feasible without jeopardising safety. All too often it comes down to getting a more suited truck, and that’s where having those options comes in. In places like Herne Bay, our guys can be onsite mucking around for three hours at a time.”

But Alan adds that there has been a lot of progress from all role players. “Twenty years ago, sites didn’t want to know, but many of the builders have come along. Worksafe’s engagements with sites have improved their understanding of compliance and safety. Auckland Transport and consents from council and the changes to the building code did change the way we engage.

“Overall, I think safety is managed well across the industry. As an occupation, you’re about 13 times more likely to die per day trucking. Construction is the same … Our guys are on a truck, and then on a building site – you don’t get much more dangerous for an operator out there on their own. Yes, we’re introducing risk to a site, but at the same time, we’re attending sites that are full of risk. So it really is about that shared responsibility.”

Truck No.217, a new 460hp unit, is one of two new Moffett-equipped UDs to join the fleet.

Truck No.217, a new 460hp unit, is one of two new Moffett-equipped UDs to join the fleet.

As one would expect of a metrobased haulier operating at city speeds and lighter weights, Tom Ryan Cartage has long had an association with Japanese trucks – historically Hino and, in more recent times, Isuzu.

“We had a good relationship with Hino and operated about 50 of them over the years. In time, we shifted to Isuzu. Their price points were similar for a long time but then Isuzu really came in aggressively. Their trucks were good for us. With the long decks

on the crane trucks, we could get a bit more on. But having run about 30 Isuzus over the years, we found some persistent issues that became a problem in our operation. It wasn’t solely down to those issues, but they were among the pushers for us to consider other options,” says Alan.

Given the laws of natural progression, one would assume that meant a step into a UD showroom, and today Tom Ryan runs 16 Quon units from the brand.

“The relationship with Marvin

Fynn [UD Trucks key account manager] has been good – and the others were good, too. But it’s just natural progression. At the moment, as those come up for replacement, the UDs are joining the fleet. Their price point was only a little higher, and they have performed very well out of the box, though we’re still relatively new in the relationship. While I focus on price and reliability, they offer a fair technological jump as well. For the drivers, it feels like a new adventure. The only gripe we’ve had moving to the UDs so far is

the lower clearance on approach angles, especially with the hiabs at construction sites. And that’s a small thing,” Alan says.

The oldest of the current UDs is a 2018 model that has covered 120,000km. “We have 20 years’ useful life from our trucks. If we see 1,000,000km on a truck after its 20-year life with us, it’s a big thing,” Alan says.

“We don’t do big Ks. On average, our trucks do 150km a day. Unlike most truckies who get paid for putting Ks on the clock, we get paid when not moving. We make our profit on

site loading and unloading. So, again, that’s why we shop in the band of the market we do. We’d love to buy all Volvos or Mercs, but they’re 50% more. Our capital investment isn’t in the trucks – I’m happy to put a $400,000 crane on a $150,000 truck, for example … If someone were paying me to, I’d spend $300,000 on a truck, sure, but fundamentally, we get paid for lifting capacity.”

The newest of the 16 UDs in the fleet are five of the latest Quon models enhanced for the 2024 model year. The big

1) Overhead storage is just about adequate. 2) Overall, the cabin remains unchanged, but the modernised instrument cluster brings enhanced information to the driver. 3) We’ve commented on the Quon’s sea of cubbies dominating the centre of the cab before … Like it or loath it, there’s plenty to please those who abide by ‘a place for everything, and everything in its place’, including a cool box and heated/cooled cupholder. 4 & 5) Warning lights for the Smart Blind Spot Information System and Smart Lane Change Support are located discreetly on the A-pillars. 6) Radar units mounted to the front wheel guard. Seems a bit vulnerable …

talking points are greater safety spec, better fuel efficiency from the GH11/ESCOT-VI powertrain, and a bump in outputs across the board. Given the unique opportunity to get up close to a range of these new models with the same operator, we lined up the new Quon CG 32 460 and CG 32 430, each in a different business area, to see what’s what.

Truck No.217 is one of the two new 8x4 flatdeck Moffett units. Almost as fresh out of the box as can be, it had only been on the road for three weeks and covered just 2400km when we jumped aboard with driver Shashi Singh and took to the wilderness of West Auckland.

We first meet Shashi at 8am on a cool autumn morning outside a domestic building site in Avondale, the first of his four deliveries for the morning. The truck’s carrying 10.5 tonnes of blocks, bricks, pavers and tiles to be distributed to building sites in Avondale and Massey, with a drop-off at Bunnings New Lynn in between. With the three-tonne Moffett M8 NX on its rear, Shashi’s UD is good for a 15-tonne payload, or about 12 pallets.

As we’d find in the course of meeting Shashi, and fellow drivers Ritesh Chand and Jin Chung, the company’s culture is clearly one that resonates with its staff. A consistent theme in the way the drivers describe their jobs is that they’re empowered

with the trust and autonomy to get on with it and get the job done properly. There’s a real sense of ownership. It’s clear in how Shashi operates, too.

His managers know that he’s good on the job, treats the gear as his own, and has an engaging manner with the customers, which comes as no surprise after more than a decade on the job – Shashi has been with Tom Ryan for 11 years and a master of the Moffett for 10, and boasts a 30-year driving career in total.

“Tom Ryan is only the second company I’ve worked for in New Zealand since I came here from Fiji in 2007. I don’t chop and change. Tom is a good lad, a good boss. We don’t get to see him much, but he knows every one of us,” he comments.

Shashi is pedantic about his work environment, coning-off the truck at all sides before lowering the Moffett, especially considering he’s forced to park on the other side of the road at this first drop. It’s a quick drop – only three pallets – but that doesn’t mean shortcuts are taken.

“Safety is a big thing. We’re out here doing this job on our own, on the road. Cars don’t stop for us and that makes it risky. We have to be very careful,” he comments.

The consistent variance in building sites also requires a different set of skills on the Moffett, compared to hiab or traditional forklift operators. “You need to know the technique for driving them,” Shashi comments.

Loaded up and ready to head out at Firth Hunua Quarry.

Loaded up and ready to head out at Firth Hunua Quarry.

“They can be tricky in the wet, on mud and loose metal if you’re inexperienced. We need a forkhoist licence, but some companies require you to have additional certification to drive the Moffett. We do refreshers every few years.”

By the time Shashi makes his last drop for the morning in Massey, his next job comes through from despatch, and we head south to Firth’s Hunua Quarry to collect a full load of blocks and pavers. The drive down Auckland’s western motorways in an unladen truck is nothing to talk about, but it allows us to explore the Quon’s enhanced active safety features. These are all intended to detect and mitigate potential road hazards. As standard, the

enhanced Quon features UD’s Smart Traffic Eye Brake, Smart Blind Spot Information System (BSIS) and Smart Lane Change Support (LCS) on both sides of the truck, Smart Traffic Eye Cruise, and, optional, the Driver Alert System that monitors for driver fatigue.

“It’s a nice and easy drive,” Shashi says as he talks me through the features. “The cruise control with distance control maintains the pace to the car ahead, great on the highway. But to be safe when I’m not using it, I’ve set a speed-limit warning on the GPS too,” he adds. “Overall, the safety systems are really helpful.”

Having become familiar with the truck’s sensitivities, Shashi creeps up a little closer to the car

ahead to demonstrate the UD’s Smart Traffic Eye Brake system. A loud, rapid acoustic warning fills the cab, and a warning is flashed on the driver’s display. If Shashi had kept the accelerator pinned, the UD would’ve applied the brakes to avoid a collision.

He comments that the BSIS and LCS systems are incredibly helpful, especially when it comes to pedestrians and cyclists around the truck. If a vehicle alongside the truck activates the feature, the truck issues a double beep and the indicator light in the A-pillar flashes. Again, a warning is issued in the instrument cluster.

About an hour later, we’re pulling out of Firth onto Hunua Road, with Shashi bound for a drop in Whitford. The roads heading north up the eastern fringes of Auckland offer a good amount of variance to see how the revised GH11 at 338kW (460hp) performs. While the power of this top model remains unchanged, torque output has gone up by 50Nm to 2250Nm (1659lb/ft), and it also comes in 100rpm sooner, at an even 1000rpm, and is maintained to 1250rpm. It’s still coupled to the ESCOT-VI 12-speed AMT, but there’s a new high-strength clutch and flywheel now making the connection.

Accelerating from a junction, the CG 32 460 pulls off in fourth and skips to sixth, eighth and 10th at 1500rpm, shy of the 1700rpm power peak. Acceleration and shifts are smooth, and soon we’re up to open road speed, and the ESCOTVI selects 12th. Truck-only, at these weights, it’s easy going. Getting into the hills, it drops one ratio to maintain the pace.

“I like that the engine doesn’t race,” comments Shashi. “The previous truck was a 400hp Isuzu, and it had an 18-speed Roadranger, which I’ve only ever driven. This gets along perfectly on its own. I enjoy the higher power and I leave the gearbox to do its thing.”

Managing the pace is a fourstage engine brake, which is more than strong enough at

Trucks you can buy and sell, but the operators are the tricky ones. We have an ageing driver force but a pool of really good, seasoned drivers who come from an era where they were in the cab at five and trucking was well in their blood by 12. By 18, they were licenced and actively working and knew where to stand or how to throw a chain,” says general manager Alan Spilhaus as we discuss the industry’s current challenges.

“It’s a generational shift, let alone trucking’s lost a lot of its sex appeal. So much of the solution is getting good guys and hanging onto them. We’re a family business, and that’s always been part of our ethos … Tom Ryan started the business as one-man one-truck in 1979, and it still is Tom Ryan – just with a few more trucks! It is about being part of a family. Guys leave to chase the dollars, and they come back five or six years later, and I just say, ‘Knock on the door’.”

Like many larger operators, Tom Ryan Cartage has looked to the immigration market to

get men behind the wheel.

“Over the past 15 years or so, we’ve worked a lot with the accredited employer immigration scheme and had many good drivers come to us. We’ve had a lot of success with drivers out of Fiji, who come engaged in the type of work we do.”

That much was patently obvious in our time with Shashi, Ritesh and Jin. For his part, 53-year-old Shashi Singh got his start in the forests of Fiji, as a bulldozer and digger operator on logging sites.

“We had to go into the bush, cut the logs and bring them down to the sawmill. One day, my boss said, ‘You can drive trucks, so why not start taking the machinery into the forests?’ So that got me into transporting machinery and loading logs to bring out. I did all that for about 10 years, until one day in 2007, I saw a job vacancy in the Fiji Times newspaper for an Auckland roading contractor looking for a transporter driver. It was a good move. I came here alone, and the company helped me

bring the family over.”

With his time as a transporter operator, Shashi boasted all the tickets that would make him a perfect fit at Tom Ryan – bridge engineering, self-supervision, piloting, WTRC …

“I started with Tom Ryan as a hiab operator with some training and later got on a lowloader with an Ausa. They were looking for a good machinery driver to replace someone coming off one of the old Moffett units, so I trained with him, and I’ve been on it since.

“If the company looks after me, I look after them,” he comments.

Alan would add: “It’s difficult … We can offer the drivers being home every night, and in good times, there’s a regularity to the work. One-guy onetruck gives them a level of ownership and comfort.”

Also from Fiji, 41-year-old Ritesh Chand started driving on his family’s sugar cane farm. “My uncle used to drive tractors and I started learning how to drive them at age six or seven. Then I moved onto cars

Ritesh Chand, Jin Chung and Shashi Singh – two decades from youngest to oldest, almost two decades of loyal service to Tom Ryan Cartage.

and trucks in the field, learning how to manoeuvre them and drive along slowly as the trucks were loaded in the fields. I got my licence and started driving my own sugar cane trucks. After school, I started driving a local bus, which I did for seven or eight years.”

Ritesh’s move to New Zealand came in 2009 when he first drove a tipper truck for a civil engineering company. In 2014, he dipped his toe into metro work with a move to Mainfreight, though it wasn’t quite his thing, and so the move to Tom Ryan in 2018.

Back to Alan: “We’ve looked at cadetship programmes and know of firms that have done it successfully … but it costs. Probably the biggest differences we’ve found is those who fall into trucking from a

different path have a different relationship with the job than those who land up in it via natural progression.

“Take crane operation; a lot of it is natural aptitude. You can learn it with a good teacher, but again, that’s part of the problem. There’s not much motivation for firms to invest in training when trucking has such low margins.”

To get a taste of this side of the business, we spent a morning with Jin Chung in his pre-enhancement Quon CW 26 390 6x4 with a Palfinger PK 26002 crane. At 32 years old, Jin is one of the youngest drivers in the team and also one of the newest, having joined Tom Ryan less than six months ago.

“I generally have been one of the youngest drivers wherever I’ve worked. I don’t know any others my age who drive; my

friends aren’t interested. One of my main goals is to be able to jump into any vehicle and be able to drive it.”

Born in Vietnam and having lived in New Zealand since age nine, Jin studied IT but realised it wasn’t for him after two years. So, 10 years ago, he went driving. “Trucking wasn’t a thing for me as a kid. I wanted to do programming. I got into trucking and loved it. I’ve been on hiabs for five years now.”

Jin is smooth and methodical with his crane operation. “The hiab thing … it was a skill that came up unexpectedly. Forty hours training to get my ticket and almost eight months to be good and do it by feel … Yes, I had a little mentoring. I listened to good advice when it was given to me, and quickly worked out what works. Tom

Ryan gave me my truck within two days and let me get on with it. The other drivers have been good too. It’s hard to find a good company.”

Alan concludes: “We’ve had some good, solid guys come to us from challenging backgrounds. And a decade later, you look back at the hard work they’ve put in to change their lives overall. I think they’re partly a solution to solving the driver shortage – income and a sense of purpose solves many problems.

“We [the industry] should continue to work on these sorts of things to solve our own problems. The crunch on skills is a serious problem, especially if Aussie can afford to pay more. We have to find ways to compete.”

Shashi frees the load for delivery.

these weights, even on the descents that require the most care.

Having experienced the construction-service side of the business (read more in Right People, Right Company, page 28), we used the opportunity to dip into the general freight side of Tom Ryan Cartage and experience one of the new CG 32 430 units on gas-bottle duty. The company has had a longstanding 12-year relationship with Coregas and operates 10 Coregasbranded trucks.

Ritesh Chand is the driver of No.552, which has just passed the 11,000km mark,

covering Hamilton, Cambridge, Morrinsville, Te Awamutu and Te Kuiti, with the odd transfer to Tauranga. Ritesh is another seasoned employee, having celebrated seven years with the company, all that time on a Coregas Isuzu in which he covered 300,000km.

Like Shashi, Ritesh fully buys into the Tom Ryan culture. “I started at Tom Ryan and straight away went for a week’s training. Management trusts us and looks after us – they don’t bother us but sort out things on the spot if there are problems. Alan is good. He understands and has feeling for his drivers. But he doesn’t do bullshit; he needs us to be honest.

“I love this job. It can be physical, but I don’t mind. On a busy day, I can do 16 deliveries between 5am and 7pm.

That’s more than 170 bottles, depending on size. A full load of bottles is around 13.5 tonnes,” he says.

Gas bottle trucks are simple but nifty units. The custom deck by Hamilton-based Dreambooster Engineering (new to the scene but good at what they do, says Alan) offers 10 locations for steel pallets, which are locked in place when the drop-down sides are raised. An elevated walkway down the centre of the deck keeps everything level and allows Ritesh to access the bottles he needs easily. An electric Dhollandia DH-VO 15 tail lift provides smooth, silent, easy lifting of the bottles during deliveries.

“I’m happy to load my truck, so I can know the weight and balance. The boys at Coregas

Row above: Bottles on, bottles off. The gas-bottle trucks are simple but nifty. Dhollandia electric tail lift and raised walkway between the steel pallets makes moving them easy.

strap the bottles to the steel pallets, and I forklift them on,” Ritesh comments. At site, the truck’s mobile scanner allows him to easily log each bottle as he moves from job to job. “I always do my best to finish a run so nothing hangs over to the next day. But some jobs can take up to 45 minutes if I have to do pressure testing.”

It’s much easier going today; we only have 68 bottles. When we meet up with Ritesh, he has already made his first drop at Fonterra’s Te Rapa facility. After a couple more drops in the area, it’s time to head for Morrinsville.

“Alan asked me if I wanted the UD or another Isuzu. I said I’ll try the UD,” Ritesh explains as we make for the Hamilton Bypass. “I like it. It’s only 430hp, but it’s comfortable and fine on the highway with a full load.”

In the enhanced Quon range, the GH11 in 430hp guise offers up 7kW (10hp) more power than its 420hp predecessor, as well as an additional 100Nm torque. Peak outputs are now 316kW (430hp) at 1600rpm and 2000Nm (1475lb/ft) from 950 to 1450rpm.

In achieving higher outputs from the GH11, UD has redesigned and improved the cylinder block, cylinder head, injection system, pistons, crankshaft, connecting rods, lubrication system and auxiliary drive. The results are not only improved outputs, but a claimed 2.5% improvement in fuel efficiency. Indeed, Ritesh’s CG 32 430 is returning 2.8kpl, slightly better than Shashi’s fresh-outthe-box CG 32 460 at 2.5kpl.

Unfortunately, as Ritesh is running very light, the opportunity isn’t quite there to

assess the 430’s performance. Regardless, there’s no doubting the engine and gearbox combo is as competent as it is in the 460, and the exhaust brake is well overqualified for the Coregas life. “I only use it up to stage three; the full braking force is too strong in this application,” says Ritesh.

In an application such as a gas-bottle truck, one can never have too much safety. Ritesh is as

complimentary as Shashi about the enhanced Quon’s active safety systems. “It’s good to have all the new tech and safety … that these trucks are at the same level as modern cars. I find it all quite handy. People complain about these types of systems being too sensitive, but it all depends on how you drive,” he comments.

Both the lane departure warning and Smart Traffic Eye

Ritesh crosses the bright and sunny Waikato.

Ritesh crosses the bright and sunny Waikato.

can be disengaged (the latter only temporarily), and as we traverse rural Waikato’s narrower roads, the lane departure rarely issues its soft rapid beep warning.

Just last month, UD celebrated 20 years and two generations of the Quon. The second generation, all-new Quon, launched in 2017 and so has been with us for a while. With this latest enhancement to the range, UD has improved the Quon in the areas it matters most …

There’s little changed in the interior. Just about the only noticeable difference is the new five-inch colour LCD driver information display. Build quality is top drawer, with more than enough space and storage. Comfort and ride quality remain very good, and refinement levels are in the Euro-truck neighbourhood – both the 430 and 460 returned an average

69dB interior noise reading.

Importantly, though, UD is continuing to deliver where it matters most – on the job.

“So far, UD is hitting the mark and knows when to say a truck is or isn’t suited to a particular application. We put a lot of trust in them … we’re specialists in moving freight, not truck specialists. We want trucks that go from A to B consistently and reliably, with driver comfort and safety,” Alan comments.

The last time we featured a Quon on the cover was March 2022, a pre-enhancement CG 32 460 belonging to Mt Maunganuibased McLeod Hiabs, a company also big on cultivating a positive culture. After a few days in the company of the team at Tom Ryan Cartage, we can’t help but think the Quon is the type of truck that easily finds a home among companies that value good culture.

That’s not to take away anything from other brands or operators, but can it be just coincidence?

Tare: 430 – 11,580kg / 460 – 14,230kg (load certs.)

GVM: 32,000kg

GCM: 430 – 55,000kg / 460 – 60,000kg

Wheelbase: 5885mm

Engine: 430 – UD GH11TC / 460 – UD GH11TD

Capacity: 10.8L

Power: 316kW (430hp) at 1600rpm / 338kW (460hp) at 1700rpm

Torque: 2000Nm (1475lb/ft) at 950–1450rpm / 2250Nm (1659lb/ft) at 1000–1200rpm

Emissions: pPNLT/Japan2016 – Euro-6 equivalent

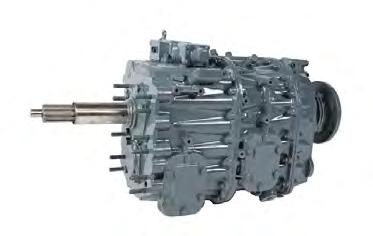

Transmission: UD ESCOT-VI AT02612F AMT

Chassis: High-tensile carbon steel. 300mm x 90mm x 8mm

Front axle: Reverse Elliot I-Beam

Front-axle rating: 14,200kg

Front suspension: Parabolic leaf spring with shock absorbers

Rear axle: Single reduction, hypoid gear, cross locks. 4.13:1

Rear-axle rating: 20,000kg

Rear suspension: Eight-bag electronic controlled air suspension

Brakes: Disk. ABS with EBS

Auxiliary braking: Four-stage exhaust plus engine compression brake

Additional safety: Passive – Side door beams, front underrun protection system (FUPS), SRS driver airbag. Driver’s side seat belt with pre-tensioner. Steering wheel and column with impact absorption. Active – Smart Traffic Eye Brake System, Traffic Eye Cruise Control with auto stop and Driver Initiate Go, lane departure warning system, electronic stability control, automatic hill start assist, lane change support, blind spot information system

Productivity: ECO mode, ESCOT roll, acceleration limiter, soft cruise control, Nenpi coach, idle shutdown

Fuel / DEF: 400L / 50L

Thanks to Alan Spilhaus and the team at Tom Ryan Cartage for being so accommodating and going out of your way to get us into three trucks for this feature, and for sharing your insights into your operation and just what it takes to cultivate a good culture.

Thanks to Shashi Singh, Ritesh Chand and Jin Chung for having us along, telling us your stories and showing us what you do.

Thanks to Marvin Fynn for providing us the details on the enhanced Quon range and to the team at Sime Darby Motors for your ongoing support of our publication.

Wheels / Tyres: 8.25in x 22.5in / 275/70 R22.5

Electrical: 24V

Cab exterior: Four-bag air-suspended cab with four dual-acting shock absorbers and dual automatic height-control valves. Heated and electrically operated main mirrors. LED low-beam headlamps, LED daytime running lights

Cab interior: Air-suspended driver seat. Remote central locking with immobiliser. Five-inch colour driver information display. Fully automatic climate control. 6.5in touchscreen infotainment with Bluetooth and USB input, wifi-enabled, built-in gyro, GPS, four camera inputs, hardwire reverse camera input with CAN interface

Proudly supporting Tom Ryan Cartage Ltd and New Zealand Trucking Media. 10 Nelson Street, Pukekohe, New Zealand P: 022 658 6194 | info@idealservices.co.nz

Scan below

Every cover truck holds a special place in the history of New Zealand Trucking magazine. We love to see where their road has taken them.

HEQ309 was one of two Weatherells CT630s written off in accidents. Steve Weatherell reckons the vehicle had covered about 900,000km running produce from Gisborne to Auckland.

and it’s been hard to get replacements with the change of ownership at Fairfax. But they have been bloody brilliant over 10 years. Most still have the original fridge units.”

HEQ309 was paired with an innovative Fairfax quad-fridge unit, vacuum-formed in one piece using a patented process that bonded high-strength structural foam insulation to the inner and outer skins. The 15.65m, 22-tonne trailer also caught attention with its side air skirts exposing only the rear-steer axle.

“We didn’t get the fuel efficiency we were hoping for with the C15s. We were hoping to do the same or better as the T404s at the time because of their shape and the work that went into the aero of the trailer. They ended up averaging 2kpl,” says Steve.

HEQ309’s innovative Fairfax semi is still going strong, says Steve. “We built 10 of them. Bit by bit, the fairings have fallen apart,

• Basic original spec: Cat ACERT C15 at 410kW (550hp), Eaton RTLO-20918B 18-speed Roadranger, Meritor RT46-160 at 3.9:1.

• What we said in 2014: “The tractor’s low-set sleek appearance is somewhat deceptive for what is every inch a heavy-duty highway unit.”

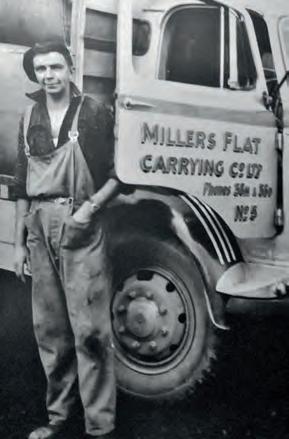

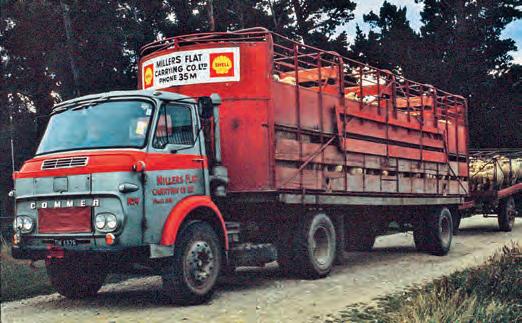

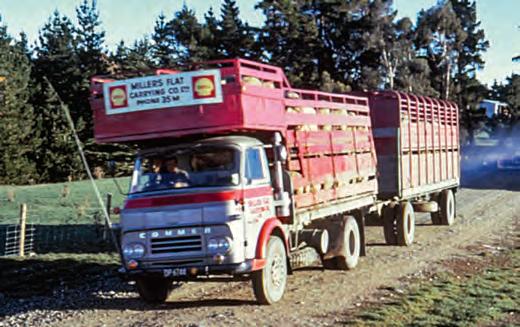

The Millers Flat Carrying Company was a legendary Central Otago trucking institution. We chronicle the company’s 31-year history.

Millers Flat is the first town in Central Otago as you leave coastal Otago on SH8. Entering the town, you are greeted by a familiar brick pub, and as hard as it is to go past it, you have to turn right to get into the heart of the town itself. In the process, you cross one of the country’s best bridges, one that Millers Flat Carrying Co trucks crossed many times during the ownership of Roy Tosh and Forbes Knight from 1954 to 1985. Forbes and Roy were working at Clutha Carrying when their

aspirations to own their trucks started gathering steam. Forbes had done time in the army as a driver and worked on farms and Roy had also come off farms, so neither was a stranger to hard work. Forbes recalls unloading bagged super at nearby Carterhope when at Clutha Carrying: “Two hundred tons of it, and 12 bags to the ton,” he says. That is about 84kg per bag, so no wonder he ranted somewhat. But they got on with it – as you did.

The men became aware of a three-truck business coming up for sale over in Millers Flat.

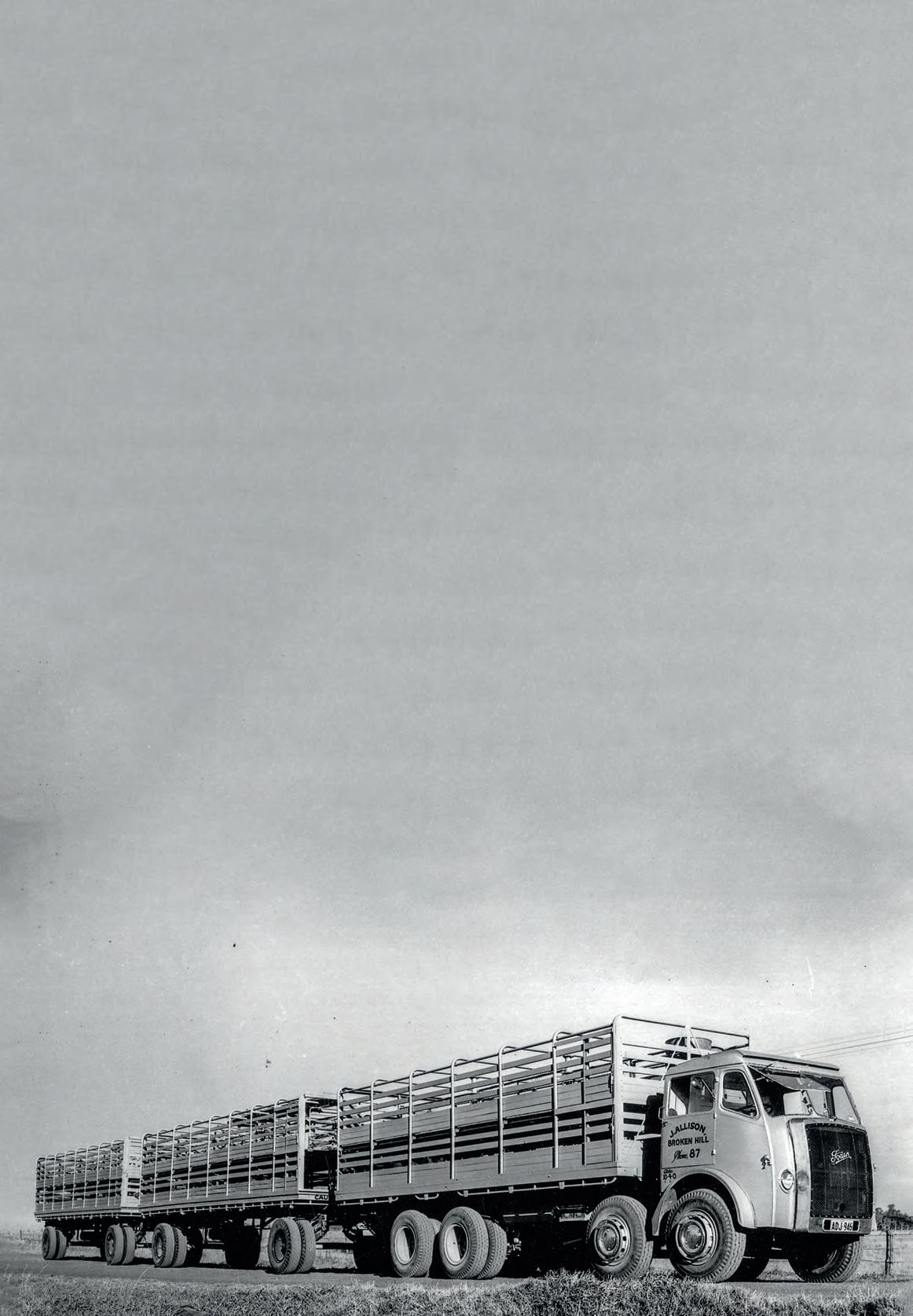

They gathered finance through family and, in 1954, bought L Brady Carrier. Forbes was 22 years old and Roy somewhat older. The business consisted of the depot and three Ford V8s, with work consistent with most rural carriers of the day: livestock, fertiliser, coal and whatever else could fit on the back of a relatively small four-wheel truck.

The trucks weren’t great. In fact, they were “hopeless”, according to Forbes. They constantly blew diffs and overheated regularly. It is a hilly area, though, and the trucks were likely pushing their limitations every time they drove out the gate.

New diffs weren’t cheap but Syd Brenssell, a transport operator over at Edievale, suggested Fordson tractor diffs

as a cheaper replacement, and that worked.

The company came with a licence to cover all of Tuapeka County through to Burnside in Dunedin, which was handy as there was livestock processing in Burnside. Some of the work was gravelling roads for the county, giving them quite a range.

But, like all small towns, the railway line running through it led to the restriction of transport against rail; a measly 30 miles (48km) but later increased to 40 miles (64km). From Millers Flat, it was the Hercules Line, which ran from Clarkesville to Hercules Flat just shy of nearby Roxburgh. It would eventually close in 1968.

There wasn’t much in the way of

Photos: Millers Flat collection and as credited

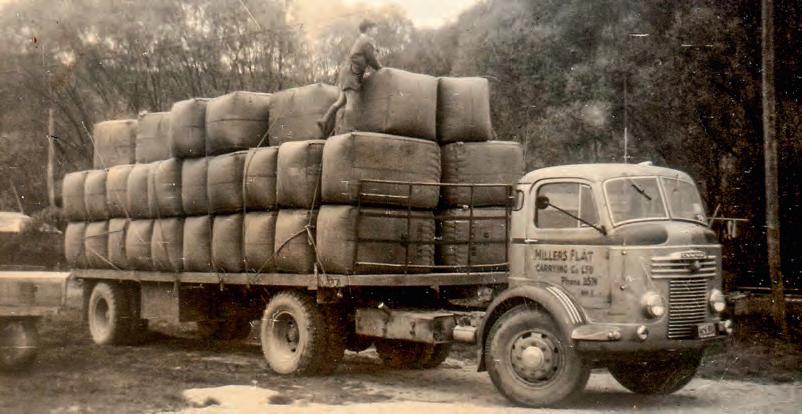

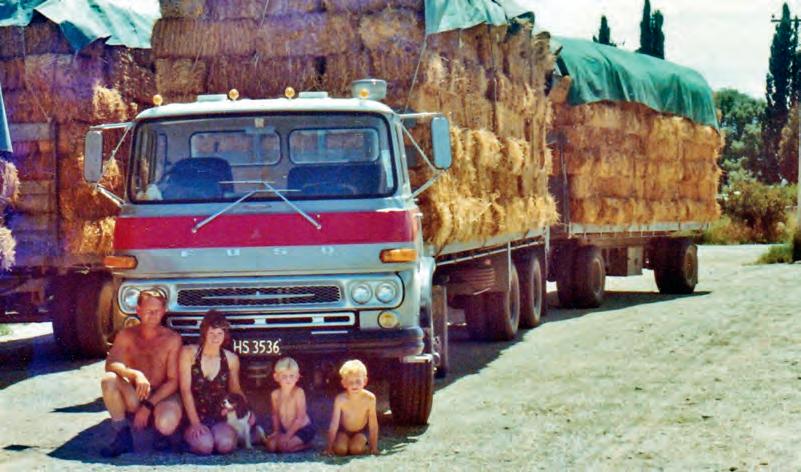

1) A young Roy Tosh with Commer No.5. Photo: Tosh family collection. 2) The three original, troublesome Ford V8s still to have signwriting applied. Photo: Roy Tosh. 3) A Commer driven by Roy Tosh with a healthy load of wool. His son Ewan stands on top. Photo: Roy Tosh. 4) Roy loading apples at Fiveash’s orchard. Photo: Fiveash family collection. 5) Donald Gilmour in front of his Fuso with Fiona Tosh (Roy’s daughter) and Donald’s two sons. Photo Roy Tosh.

livestock back in the 1950s. Most of the land was grazed by rabbits and farms were still being broken in. Two of the Fords would spend time carting sand for the Roxburgh hydro project under contract for Fulton Hogan. Due to their constant issues, the Fords were all replaced with Commers and one of the first jobs for the new trucks was to cart away the working men’s huts from the Roxburgh hydro. The Commers were better, but like the Fords, they did more than they were designed to do. Gardner Motors in Dunedin supplied the first models and VTR Motors in Invercargill, the later ones. Roy and Forbes both drove, and Roy would oversee most of the company’s daily operations. The work was mostly manual and very hard. Take a look at old photos of truck drivers back in the 1950s, 1960s and 1970s, and you can tell it was physical work. The Commers were doing well and would become the company’s backbone through the 1960s and into the

1) The new Rhino beside its older little brother. Photo: Melhop collection. 2) The Nissan Rhino parked in Caversham, Dunedin. Photo: Unknown. 3) A pic taken from a Nissan Diesel ad, the Taska kitted up with period cabover pen livestock crates and two-axle trailer. 4) The Rhino carting lambs away after weaning at Avenel Station. Photo: Jack Garden.

mid-1970s. Most of them would eventually pull a trailer.

Donald Gilmour was to become one of the senior drivers for Millers Flat Carrying. He was also the company mechanic, but his forté was engineering. He built some lovely cattle boxes for the company. Donald was working at the Millers Flat lucerne company, driving a GMC. It would cart raw lucerne into the factory for processing into powder and pellets. When the factory closed down, the machinery was trucked on the back of Millers Flat Commers to a new home in Hinds, where it is still in use today. Donald went to the Carrying Company and onto one of the Commers. He would go onto a petrol-powered tractor unit pulling a semi with another single-axle trailer behind that. This Commer would later be replaced with a diesel version. Donald was said to be the ultimate driver and could back an A-train combination effortlessly without a locking pin. Plenty of drivers would come and go over the years, but Forbes believed in employing local drivers when possible.

Colin South, George Beel, Ray Kerse, Merv Hume and Jimmy Adams from Tulloch Transport fame also did time at Millers Flat Carrying.

An unemployed Lenny Davis rocked up on a post bus and slept on the bench outside the local shop before going down to inquire about a job – probably after finishing at Hydro Haulage after the completion of the dam project. Plenty of casual work was available during the summertime, especially when there was hay to be made.

5) Commer No.14 with the company’s first tipping trailer.

Photo: Charlie Skevington.

6) Commer TS3 No.4 with its two trailers. Photo: Jack Garden.

7) No.1 Commer TS3 sower.

Originally a tractor unit, it was replaced by No.4, which also became a sower when it was replaced by the Fuso. Photo: Rusty Wright.

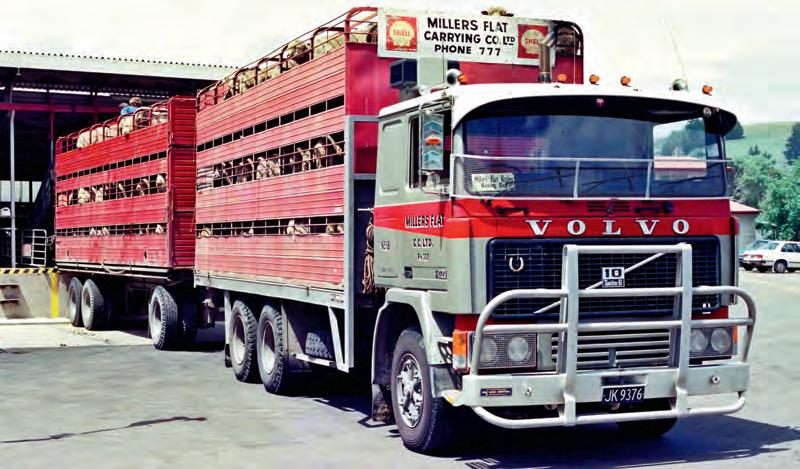

Along with the rural sector work, carting fruit was also an income stream. Central Otago is well known for its orchards, which start about Millers Flat and continue through to Cromwell. The good climate and irrigation from the nearby Clutha River make conditions ideal for growing. Most fruit was trucked to Ettrick, where the NZ Apple and Pear Board had its cool stores, and also to a cooperative pack house next door. From there, it would be loaded onto a train and taken to Dunedin. In 1968, the Apple and Pear Board wanted to truck fruit directly from the cool stores in Ettrick to Dunedin. Forbes and Roy had trucks carting locally into the cool stores, giving them a chance to get into this venture. They decided to trial a new truck and trailer for this work. The big issue was the 40-mile restriction against the rail. They couldn’t cart the fruit when the train was already there. Forbes requested that the Apple and Pear Board sort this or there would be no point in the trial taking place. With that, they contacted the minister for transport, who happened to be Peter (JB) Gordon, and asked if it was possible to lift the restriction. It coincided with government plans to shut the Hercules Flat line, so everything fell into place. This work saw a departure from the Commer brand. Forbes and Roy took a punt with a new 4x2 Nissan Diesel Taska, boasting 170hp (127kW), and trailer to trial the fruit cartage. It was the first of its type assembled in New Zealand and had done the rounds as a demonstrator. The work literally proved fruitless

as Dick Holgate, who was also going for the work, won the contract. The rest you could say on that front was history – the pink Volvos of Holgate and Anderson would become synonymous with carting fruit for the next three decades.

On a side note, Dick Holgate was also working at Clutha Carrying and left around the same time as Roy and Forbes. Dick bought Lauder Transport in Ōmakau.

The fruit cartage was an opportunity lost for Millers Flat Carrying, but the Nissan was to remain in the fleet. UD shouted Forbes a trip to Japan to have a look at another Nissan – this time, its big brother, a 6x4 Rhino. Forbes and Roy bought that as well.

Forbes’ thoughts on the Taska can’t really be expressed in a G-rated magazine. It would overheat often and crack heads traversing all the hills around this neck of the woods. The new boy on the block wasn’t cutting it with its British stablemates, so the boffins at Nissan Japan sent engineers over to evaluate and troubleshoot its woes. As it was the first in New Zealand, it was good to be seen to be backing their product. However, they were somewhat taken aback when they saw what the truck was doing and what landscapes it had to contend with. In Japan, they put tunnels through their

hills, keeping things flat … but not here, where we wind our way around and over. The Japanese didn’t put a trailer behind their trucks either and ran their permitted weight … not here, though. ‘Load ‘em up and make them work, and then put a trailer on behind.’

The evaluation was the truck doing what it wasn’t designed to do. The Rhino went well but was noted to crack its head at least once. It was a big beast, though. An extra axle was added in front of the tandems to help get the weight balance right. It made for an impressive truck and

Forbes was its main driver. It was a tipper and had its own crates, pulling a two-axle trailer most of the time.

Charlie Skevington drove it later and had an unfortunate incident travelling home one night after taking lambs to the Fairton freezing works. With his girlfriend Fiona, later to be his wife, they hit a horse at full noise on the Hilderthorpe Straights just north of Ōamaru. The horse’s head hit the windscreen but didn’t go all the way through, and the cab was pretty much broken off the chassis and the trailer crate came off and hit the

back of the truck. It was repaired and lived to fight another day.

When the rail was open, the train would bring in Southland Phosphate Company fertiliser and coal and would be unloaded. However, when it closed in 1968, the carrying company had to go over to West Otago Transport at Heriot to get its Southland Phosphate fertiliser – some farmers preferred that product. Heriot still had its rail coming into town and would retain that until 1978, when the big floods made it uneconomical to repair the line. The product was loaded into the trucks with Fordson clamshell loaders, which were popular then. If it were a busy day, Millers Flat would take its own loader over or use the ones owned by West Otago Transport. Many companies had them for this purpose, and for unloading from trucks and trailers that didn’t have a hoist. As tipping decks became standard and the rail slowly disappeared, the clamshell loaders fell the same way.

1) A lovely snap from an unknown photographer of the T81 Fuso parked on the main street of Millers Flat. 2) Commer No.14 on the easy way out of Ravensdown … via the Burnside freezing works unloading ramps.

Photo: Charlie Skevington.

3) John Rae with his Fuso outside the office and workshops. Photo: Roy Tosh. 4) John in his 330 V8 Fuso, the highest horsepower truck the fleet ever had. Photo: Roy Tosh.

In winter, Donald Gilmour would take his Commer into Burnside for fertiliser, but would wait until three in the afternoon to leave, giving the Manuka Gorge time to thaw out fully. The single-drive Commer struggled to gain traction on some corners when it was icy, but at certain times of the year, Manuka Gorge never thaws out. The Kempthorne Prosser and Dominion Fertiliser works at Burnside had a steep entry point, which was also the exit point. Some trucks couldn’t get back out fully loaded, especially the single drives like the Millers Flat Carrying Commers. Charlie Skevington, who drove Commer No.7, a 1968 model, and then a new Commer, No.12, found it easier to exit via the freezing works by going over a bridge and through a tunnel where the livestock trucks unloaded.

The loathed Taska was shown the door in about 1972 after being written off in an accident when its brakes failed at Shingle Creek. It ended up down a hill

and in a bank. A K-Series Dodge with a Perkins 510 V8 was bought as its replacement, and another new Commer arrived at the same time. Ian Pringle, who was on the Taska, was put onto the Dodge, which had a front-ofbody hoist. The Commers were all twin-ram under-body types. The Dodge had a two-deck cabover pen stock crate and pulled a two-axle trailer.

John Rae joined the company in 1973 and went onto Commer No.7. Tony Omand was also with the company, on Commer No.9. He had arrived in the late 1960s from Gardner Motors in Dunedin, where he was a mechanic and he was also a mechanic at Millers Flat Carrying. Donald Gilmour was still on his No.4 Commer but received a new T81 Fuso in 1974; another four-wheeler tractor unit pulling two trailers and again supplied by VTR Motors. His original TS3 Commer would become a spreader, as would its Commer replacement (No.4).

Junction and Edievale on SH90, in particular. It was frustrating as the alarms are loud, so John installed a cut-off switch to eliminate the problem and relied on the temperature gauge to keep matters in hand. The Fuso also spent three months off the road when a car pulled out in front of John going through Waihola. It was only six months old when that happened.

The Nissan Rhino was next to be pensioned off. In 1976, Forbes and Roy purchased a new six-wheeler G88 Volvo with a three-axle trailer. The G88 had a new Sutton three-pen crate, but the trailer had a new Toko Engineering one. Toko was in its infancy as a company, and it was not a popular sheep crate. Forbes would drive the G88 most of the time and would often flog John’s Sutton-crated trailer and use that, as it was more userfriendly. While Forbes was driving the G88, Roy was driving a TK Bedford, which replaced his No.5 petrol-powered Commer.

Spreading wasn’t a big thing for Millers Flat Carrying. As mentioned, the area is covered in hills and a single-drive Commer, even with chains on the back, wouldn’t really cut the mustard – so it was left for the aeroplanes to do most of the work. It was the job of the carrying company to get the fertiliser up to the airstrip, though. Commer No.4 was evidence of that when it rolled and needed a new cab.

Ewan Tosh remembers going along for ride when he was a young fella. “A convoy of Millers Flat Carrying trucks headed into Beaumont Station, all overloaded to hell with superphosphate, and I had to open 30-odd gates all the way through.”

The poor bloke at the end of the convoy had to close them all again. Overloading wasn’t uncommon in such a scenario, as the convoy opted for back roads. One would imagine that they would have taken the main road

back afterwards when empty…

The T81 Fuso went well, so it prompted the purchase of a second one in 1975. It was a 6x4 rigid with the new-style cab and was the first in the fleet to get a three-axle trailer with three-deck Sutton crates, which, back in 1975, were a load in themselves. It did have an aluminium deck all the same…

This T81 was a 330hp (246kW) V8 model, so it sounded good. John Rae was its driver, and the Fuso was a big step up from anything else in the fleet, but it would turn out not to be the most reliable truck. An undersized radiator caused most of the grief, and the clutch wasn’t that great, either. Again, like the early Ford V8s and the Nissan Taska, it was prone to overheating and cracked a head occasionally. The Kysor temperature warning alarm would sound often, usually when a hill would come into sight … the Devil’s Elbow between Raes

The Volvo was a big step up again and the reason for its purchase was its light tare weight and the fact that quite a few were now proving themselves as good, reliable, comfortable trucks on the roads of Central Otago. Teviot Transport, Cromwell Transport, Upper Clutha Transport, Radford’s, Turners … and let’s not forget those iconic pink Holgate and Anderson Haulage ones. They were popular trucks.

The Volvo theme repeated in 1980 when Tony Omand received a new F10. As the replacement in New Zealand for the G88, it was also a popular truck. This one received Nationwide livestock crates.

The last purchase was another Volvo: an N1025 bought set up as a spreader with a twistlock body, so it could also be a tipper. It was purchased from Dalhoff and King, which had bought it off McDougalls, which had depots in Invercargill and Winton. Originally a tractor unit, Millers Flat had it stretched for the fert spreading bin.

John had a stint on it and recalls his first load: “The first

load I sowed was a mixture of super and oats. I drove to the paddock, set the computer, walked around to make sure everything was right and hopped in and set off. I looked in the bin after the first round and it was all

gone! Turns out I had turned the power switch the wrong way and put the bin in stationary unload. What an expensive mistake … Not long after that, Ian Beel took over and was a dab hand at sowing!”

Winter periods were a chance to get on top of maintenance, painting sheep crates and getting staff away on holidays. There was a lot of coal to be

delivered as everyone had an open coal-burning fire back then. There was always a coal shed to be filled with a hand shovel.

Frost fighting was a huge thing during the autumn and winter. Shell would supply the diesel to three tanks in the depot, and Millers Flat Carrying had a couple of tankers to deliver diesel to frost pots throughout the many orchards in the area. There was one rigid tanker and one semi-trailer tanker carried around by the Commers. Charlie Skevington and Donald Gilmour would do this and would be up all night getting on top of it.

“Winters were so much harder back then, not a good time to hang your washing out with all the frost pots burning,” says Charlie. John Rae adds: “You would get up in the morning and go outside and the sky was black with smoke.”

The burning of pots would usually happen during the blossom period and could go into November if unlucky.

Pre-lamb shearing would kick off around August, so there was also wool to cart. Early lamb drafts would start in about November after the weaning. Lambs would be the morning loads and then the crates would come off for hay cartage into the night. Doing hay was a massive, labour-intensive job back then, with mostly small bales. Friday and Saturday were big hay days and Sunday a big day for carting livestock. Sheep and bales of hay equated to the same – one small bale was the same as one sheep when loading.

It was the time before log books, so big days were the norm during the busy season. Livestock would be carted through to May and then there was the fruit to do.

John Rae recalls a 42-hour day! “Millers Flat to Burnside and back to Millers Flat, and then

1) The N10 when it arrived as a sower. Ian Beel was its driver for most of the time. Unknown photographer. 2) The N10 loaded with wool in Dunedin. 3) The N10 at Burnside, Dunedin. Photos 2 & 3: Big Rig Fotos. 1 2 3

4) Five of the Commers all loaded up with lambs. What a sight.

Photo: Tosh family collection. 5) A Summertime staple – doing hay the hard way. Commer No.12 driven by Charlie Skevington. 6) John Rae hooking up his trailer under Ray’s watchful eye, with all of three ropes on the load of that truck… Photos 5 & 6: Charlie Skevington collection.

7) Roy’s TK Bedford sitting at the Apple and Pear Board in Ettrick.

Photo: Roy Tosh. 8) Another load of newly weaned lambs heading away from Avenel Station. Photo: Jack Garden.

up to Smithfield in Tīmaru, then back to Raes Junction just shy of Millers Flat for calves to go back up to Orari in Mid Canterbury … admittedly, I squeezed in two hours’ sleep at Raes,” he says. This was back in 1974 and in the K Series Dodge pulling a two-axle trailer. There were three trucks from the company doing that work that day. They all stayed in Makikihi on the way home.

Charlie Skevington recalls something similar about the long days. “Roy’s wife would prepare food for us, so we always ate well, and we were given an overnight or away allowance. This would somewhat backfire as we would stop at places like Dunsandel, Makikihi, St Andrews or Palmerston, and then spend our allowance on alcohol and have to sleep in the cabs of our trucks,” he laughs. “And Roy would always have his bedroom light on until he knew you had made it safely home, no matter what time of the night it was.”

In 1985, Forbes and Roy decided to sell up. After 31 years in business, Roy was ready to retire. Ultimately, the fleet consisted of three Volvos, two Fusos, two Commers and the TK Bedford. That there were Commers to the end showed they were great trucks and reliable as the tide. Yes, every now and then, one would fail – such as John seizing one at Crookston with a full load of lambs bound for Mataura. Tony Omand always had a spare engine in the workshop, ready

to be fitted when needed. It was usually about the 90,000-mile (144,000km) mark when another motor was required.

Roy passed away in 1985 after the company was sold, so sadly, retirement was short-lived. He was a very communityorientated man. He started up the fire brigade in town with a car and a pump trailer, obviously making a statement that having some sort of fire response in the town was very important. He was also very handy when it came to fixing valve radios and televisions. Often, in the evening, he would be out with his bag of replacement valves fixing the locals’ TVs and radios. Hewsons in Tapanui trained him up to do this.

Forbes still lives in Millers Flat and is now in his 90s, and has spent his life supporting horse racing clubs and sports in general.

The company was sold to Mount Benger Timber which had sawmills in Ettrick, Palmerston and Ranfurly. It wanted its own trucks to cart logs into the sawmills as well as running the rural side as usual. Within two years, that company went under and took what was left of the carrying company with it.

“Work was hard, but you made things work for you to make things slightly easier. It was hard, but a great place to learn,” says John Rae.

Charlie Skevington echoes John’s words: “It was a great grounding and a great place to work.”

We are nice people at New Zealand Trucking Media, and if we put you through the wringer one month, we’ll be less gnarly the next. This one shouldn’t trouble you, really – it’s on a substantial corridor in our nation, one that has featured before in the competition.

To enter, flick us an email at editor@nztrucking.co.nz

Subject line: Where’s that road? June 2024

Tell us your answer, and let us know your postal address.

Note: Please include the subject line above, or your entry might get lost in the pile. We’ll randomly pick a winner from the correct entries and see what’s in the prize basket. The competition closes at midnight on 30 June 2024.

Our 100 year history proves that when you do everything with heart, nothing is too heavy.

Mitsubishi from Centra, moving New Zealand forward.

You can hire a Mitsubishi Forklift on a fixed term hire contract, maintenance included on terms from day to day right up-to 7 years

• New or Used, ex fleet forklifts available

• Huge range to choose from

• Delivery within 24hours

Auckland - 32 Hastie Avenue, Māngere Bridge, Ph: 09 634 8500

Hamilton - 38a Maui Street, Ph: 07 849 5128

Tauranga - 12/45 Kaweroa Drive, Tauriko, Ph: (07) 282 9910

Palmerston North - 25 Bisley Street, Ph: 06 355 9033

Christchurch - 38a Parkhouse Road, Ph: 03 343 6814

Yep! You got it. It doesn’t matter where we go; someone knows exactly where our bit of mystery road is. Having said that, there were only three correct entries this month, so we did have you pacing the room and scratching your heads a wee bit.

Our winner this month is Dick Emi from the Whanganui region, so maybe he knows the Hapokopoko Stream Bridge, Mathews Road junction on SH4 well! Well done, Dick. You’re in an exclusive club this month!

SH4 Hapokopoko Stream Bridge, Kakatahi.

SH4 Hapokopoko Stream Bridge, Kakatahi.

Designed for New Zealand. Ready for your business.

The D16 engine with 650HP, provides a full 3150 Nm of torque, making this Volvo FH16 tractor unit hard to beat. Combined with Volvo’s leading I-Shift technology, smart features, advanced safety, and three year drivetrain warranty, this is the optimal choice for your operation.

Stock is limited. Contact us for specifications or to request a quote.

Volvo Trucks. Driving Progress.

Last held in 2021, the Taranaki Truck Show returned over Easter Weekend 2024. The biggest event yet, it had clearly been missed.

The 2024 Taranaki Truck Show kicked off at 9am on Sunday 31 March with an impressive convoy from Centennial Drive at Port Taranaki in New Plymouth to the show’s traditional venue, Hickford Park, Bell Block.

A Trade Me auction was held

to determine the lead vehicle, which was won by JD Hickman.

It was a beautiful Easter Weekend, sunny with a cool breeze – and great views of the mountain.

According to the Taranaki Truckers Group Committee, the 2024 show presented the largest

turnout of trucks yet, with an estimated 180 attending. The show attracted local enthusiasts and families alike, with several having picnics alongside their trucks. There were food stalls aplenty and activities to keep future little truckers entertained.

The local fire department

Story and photos by Michael Beesley

Uhlenberg Haulage was a deserved Best Fleet winner.

Story and photos by Michael Beesley

Uhlenberg Haulage was a deserved Best Fleet winner.

John Langlands from MC Fale Transport took out Best Mercedes-Benz with his Arocs, a truck familiar to readers of the September 2022 issue.

Shannon Bulk Haulage’s exquisite Kenworth

Best Tanker went to Tyson Mascull in the BHL Feeds Kenworth T610 SAR.

W923R.

The Reliable Distributors Freightliner Argosy of Stewart Rolls took out the Best Freightliner and Best Flat Deck awards.

Best Tanker went to Tyson Mascull in the BHL Feeds Kenworth T610 SAR.

W923R.

The Reliable Distributors Freightliner Argosy of Stewart Rolls took out the Best Freightliner and Best Flat Deck awards.

put on a great demonstration, alongside Hato Hone St John in attendance.

After the last show, Michielsens Transport was the reigning champion of the Uhlenberg Haulage tug-owar challenge, but this year, the Taranaki Truckers Group Committee won out.

A total of $17,719 was raised for the Taranaki Retreat and Waimanako, a suicide prevention initiative.