For the second year running the results are in and we couldn’t be happier. Scania has once again been voted the number one* truck brand in the country by the people whose opinion we value the most - New Zealand truckies.

We’re chuffed to have rated highest on all measures, including most preferred, comfort, safety, sustainability, performance, efficiency, service and parts. Thanks again New Zealand. It means a lot.

EDITORIAL

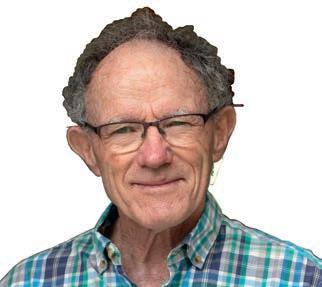

Dave McCoid

Ph: 027 492 5601

Email: dave@nztrucking.com

EDITOR Gavin Myers

Ph: 027 660 6608

Email: gavin@nztrucking.com

For all advertising enquiries:

ADVERTISING MANAGER

Pav Warren

Ph: 027 201 4001

Email: pav@nztrucking.co.nz

Mike Devon

Ph: 027 332 4127

Email: mike.devon@nztrucking.co.nz

Maddy McCoid

Ph: 027 336 6811

Email: maddy@nztrucking.co.nz

SUB

Further

6

One

1

Budgets, pothole funds and speed reviews … It’s been a busy month for those interested in roads or transport.

By now, Finance Minister Nicola Willis’ Budget 2024 announcement on 30 May has been dissected to exhaustion. The industry has salivated at a full $1 billion for the accelerated delivery of the Roads of National Significance and major public transport projects, as well as a further $939.3 million to continue recovery works to roads damaged by last year’s severe weather events.

I commented on these and other notable allocations in my EDM editorial of 31 May, Bouncing around the billions. As good as the funding is for the industry and road users in general, I go back to my main concern outlined in that piece – support for Interislander remains conspicuous by its absence. I’ll save you the effort of seeking it out, because the point bears repeating … Interislander is as much a part of the country’s transport infrastructure as any of the Roads of National Significance or any KiwiRail trunk line. Clearly, though, little thought has gone into replacing the ageing barges in the time since the new government axed the

iReX project after coming into office.

Yes, other pressing commitments need their share of the pot. But it’s as much a transport issue as it is to do with infrastructure and resilience – so why not fund it in part from each of those budgets? And if needed, the argument could also be made for it being a climate-change initiative – new boats will doubtlessly be more efficient and environmentally friendly than the old clunkers that have each done about 100,000 trips across the Strait, according to Interislander.

It’s been said before, the longer this ferry-replacement debacle is kicked down the road, the greater the threat to safe and efficient passage between the islands becomes.

But what of safe and efficient passage within the islands? We’ve been told that the forthcoming 2024-2027 National Land Transport Programme (NLTP) will deliver a record $2.07 billion for state highway pothole prevention and $1.9 billion for local roads – respective increases of 91% and 50% over the 2021-2024 NLTP. This appears to be in addition to the establishment of a $500 million Pothole Prevention Fund, as promised in National’s electioneering campaign

– though, the announcements have come so thick and fast, how the funding all fits together is a little murky … I guess we’ll have to wait for the final Government Policy Statement and NLTP to reveal all.

Regardless, the key here is that this funding will be ringfenced for resealing, rehabilitation and drainage maintenance works. This is encouraging, considering Transport Minister Simeon Brown expects long-term maintenance outcomes of 2% of the state highway network renewed each year and 9% of it resealed each year … This with requirements that potholes will be fixed within 24 hours. I’m not sure how they’ll make that a reality, but this might just be the time to get into the roadworks game!

And we’ll need roads maintained to such a degree if the higher speed settings proposed in the new Land Transport Rule come to fruition. But I’ll reserve comment on that for another time.

Eagle-eyed readers will notice a small but significant change to the cover of New Zealand Trucking magazine from this issue on – the phrase, ‘Telling Road Transport’s Story Better than Anyone Else.’ Every good company needs a strong mission statement, and this is the one we have adopted to underpin all New Zealand Trucking Media brands – New Zealand Trucking magazine, Little Trucker Down Under, Trucking Radio 24/7, the Keep on Moving podcast, and Truck and Light Commercial Trader Everything we do is encompassed in that statement. Every story we tell, news item we share, or advertisement we run is in its pursuit. It guides our team internally, but to truly live it, we must make it our promise to you. And so, it’ll be as visible as we can make it.

Thanks as ever for your support of all our brands. We hope we continue to live up to the promise.

Gavin Myers Editor

The M729II Eco is the successor to the M729 and Ecopia M749 drive tyres. Its development represents another step towards Bridgestone’s evolution as a sustainable solutions company.

The M729II Eco is the successor to the M729 and Ecopia M749 drive tyres. Its development represents another step towards Bridgestone’s evolution as a sustainable solutions company.

The M729II Eco is the successor to the M729 and Ecopia M749 drive tyres. Its development represents another step towards Bridgestone’s evolution as a sustainable solutions company.

The M729II Eco is the successor to the M729 and Ecopia M749 drive tyres. Its development represents another step towards Bridgestone’s evolution as a sustainable solutions company.

Available sizes

Available sizes

Available sizes

Key Features

Key Features

Key Features

Key Features

• M729II Eco delivers the market leading wear life of the M729 with a 20 percent lower rolling resistance, while also boasting the benefits fuel saving and emissions reductions.

• M729II Eco delivers the market leading wear life of the M729 with a 20 percent lower rolling resistance, while also boasting the benefits fuel saving and emissions reductions.

• M729II Eco delivers the market leading wear life of the M729 with a 20 percent lower rolling resistance, while also boasting the benefits fuel saving and emissions reductions.

• M729II Eco delivers the market leading wear life of the M729 with a 20 percent lower rolling resistance, while also boasting the benefits fuel saving and emissions reductions.

• Delivers industry-leading wear life and durable reputation with up to 10 per cent better wear life than its predecessor.

• Delivers industry-leading wear life and durable reputation with up to 10 per cent better wear life than its predecessor.

• Delivers industry-leading wear life and durable reputation with up to 10 per cent better wear life than its predecessor.

• Delivers industry-leading wear life and durable reputation with up to 10 per cent better wear life than its predecessor.

• Contributes to a reductions in C02 emissions through reduced fuel.

• Contributes to a reductions in C02 emissions through reduced fuel.

• Contributes to a reductions in C02 emissions through reduced fuel.

• Contributes to a reductions in C02 emissions through reduced fuel.

Your Local Expert

Your Local Expert

Auckland Central, Auckland North and Northland

Auckland Central, Auckland North and Northland

Auckland Central, Auckland North and Northland

Bay of Plenty and Gisborne

Bay of Plenty and Gisborne

Bay of Plenty and Gisborne

Rodney Wallace 021 220 2466

Auckland Central, Auckland North and Northland

Rodney Wallace 021 220 2466

Rodney Wallace 021 220 2466

Rodney.Wallace@bridgestone.co.nz

Rodney Wallace 021 220 2466

Rodney.Wallace@bridgestone.co.nz

Auckland South and Waikato

Rodney.Wallace@bridgestone.co.nz

Rodney.Wallace@bridgestone.co.nz

Auckland South and Waikato

Auckland South and Waikato

Trevor Bunyan 021 718 861

Christchurch, Nelson, Marlborough and West Coast

Trevor Bunyan 021 718 861

Rodney Morkel 027 216 3734

Bay of Plenty and Gisborne

Trevor Bunyan 021 718 861

Trevor Bunyan 021 718 861

Christchurch, Nelson, Marlborough and West Coast

Christchurch, Nelson, Marlborough and West Coast

Trevor.Bunyan@bridgestone.co.nz

Trevor.Bunyan@bridgestone.co.nz

Trevor.Bunyan@bridgestone.co.nz

Trevor.Bunyan@bridgestone.co.nz

Wellington, Wairarapa, Manawatu, Hawke’s Bay and Taranaki

Wellington, Wairarapa, Manawatu, Hawke’s Bay and Taranaki

Wellington, Wairarapa, Manawatu, Hawke’s Bay and Taranaki

Christchurch, Nelson, Marlborough and West Coast

Michael Sharpe 027 582 0682

Michael Sharpe 027 582 0682

Michael Sharpe 027 582 0682

Michael Sharpe 027 582 0682

Michael.Sharpe@bridgestone.co.nz

Michael.Sharpe@bridgestone.co.nz

Michael.Sharpe@bridgestone.co.nz

Canterbury, Otago and Southland

Michael.Sharpe@bridgestone.co.nz

Evan Armstrong 021 190 4929

Rodney Morkel 027 216 3734

Auckland South and Waikato

Rodney Morkel 027 216 3734

Rodney Morkel 027 216 3734

Wellington, Wairarapa, Manawatu, Hawke’s Bay and Taranaki

Rodney.Morkel@bridgestone.co.nz

Rodney.Morkel@bridgestone.co.nz

Rodney.Morkel@bridgestone.co.nz

Rodney.Morkel@bridgestone.co.nz

bridgestone.co.nz

bridgestone.co.nz

bridgestone.co.nz

bridgestone.co.nz

Evan Armstrong 021 190 4929

Evan Armstrong 021 190 4929

Evan.Armstrong@bridgestone.co.nz

Evan Armstrong 021 190 4929

Evan.Armstrong@bridgestone.co.nz

Evan.Armstrong@bridgestone.co.nz

Evan.Armstrong@bridgestone.co.nz

Canterbury, Otago and Southland

Canterbury, Otago and Southland

Paul Robertson 027 274 3437

Paul Robertson 027 274 3437

Canterbury, Otago and Southland

Paul Robertson 027 274 3437

Paul.Robertson@bridgestone.co.nz

Paul Robertson 027 274 3437

Paul.Robertson@bridgestone.co.nz

Paul.Robertson@bridgestone.co.nz

Paul.Robertson@bridgestone.co.nz

Daimler Truck brands Mercedes-Benz Trucks and Freightliner will soon have a general distributor locally in New Zealand.

Keith Andrews Holdings, which currently has the distribution rights for FUSO vehicles and parts through its wholesale organisation FUSO New Zealand, will soon take over the distribution of fellow Daimler Truck brands Mercedes-Benz Trucks and Freightliner.

Currently, Mercedes-Benz Trucks and Freightliner vehicles are distributed in New Zealand by Daimler Truck Australia Pacific based in Mulgrave, Victoria.

Daimler Truck Australian president and CEO, Daniel Whitehead, said the distribution change would benefit New Zealand customers.

“The general distributor model will deliver the best outcome for Daimler Truck customers in New Zealand because no one knows local customers better than locals,” said Whitehead.

“The team at Keith Andrews has helped FUSO become a successful brand in New Zealand and we are confident they will enable Mercedes-Benz Trucks and Freightliner to reach their full potential.”

As a Daimler Truck Regional Center, Daimler Truck Australia Pacific will continue to provide support to New Zealand customers by delivering the best-in-class technology, products and services to Keith Andrews and its New Zealand dealer network.

Keith Andrews Holdings executive director, Kurtis Andrews, said the team was looking forward to serving all Daimler Truck customers across New Zealand as the distributor for Mercedes-Benz Trucks and Freightliner brands,

in addition to FUSO products.

“We are delighted to be given the opportunity to take on the distribution of Mercedes-Benz and Freightliner trucks in New Zealand. From our role of selling and supporting these brands over many years, we know how much value customers can extract from these class-leading products.

“We’d like to thank Daimler Truck for its faith in our hard-working team at Keith Andrews, which is excited to show the full potential of the amazing Daimler Truck products in New Zealand,” Andrews added.

Currently, Keith Andrews represents Mercedes-Benz Trucks and Freightliner retail in the North Island, and CablePrice represents the two brands in the South Island.

To deliver all New Zealand customers the full benefit of the general distributor appointment, Keith Andrews Holdings is working with CablePrice regarding the ownership and operation of selected FUSO, Mercedes-Benz Trucks and Freightliner sales and service sites in the South Island (see sidebar).

Keith Andrews Holdings aims to maintain all existing operations and personnel to determine a smooth transition and maintain the current high level of customer support.

“CablePrice has been a fantastic partner of Daimler Truck in New Zealand and we are thrilled they will continue to provide their exceptional customer support at a number of their existing locations,” Whitehead said.

The exact details of the distribution change will be finalised and communicated closer to implementation, which is expected sometime early next year.

Following the appointment of Keith Andrews Holdings as general distributor across the Daimler Truck brands in New Zealand from early 2025, discussions have now moved to the future direction of the dealer network.

Currently, Keith Andrews represents Mercedes-Benz Trucks, Freightliner and FUSO in the North Island, and CablePrice represents the three brands in the South Island.

To deliver all customers the full benefit of the general distributor appointment, Keith Andrews Holdings is now working with CablePrice on the sale and acquisition of selected South Island Daimler Truck sales and service sites.

Discussions are currently focused on CablePrice’s Christchurch, Tīmaru and Dunedin truck dealerships, with remaining dealerships maintaining their Daimler Truck service and parts (2S) status as part of CablePrice.

“The CablePrice team has achieved great success with FUSO in particular and been an integral part of market-leading truck and bus sales efforts in the past three years,” said Keith Andrews Holdings executive director, Kurtis Andrews.

“We are thrilled by the prospect that they will continue to provide fantastic customer support in the mainland, either as part of CablePrice or Keith Andrews.”

CablePrice managing director, Aidan Mahony, said: “I am extremely proud of what our team has achieved since becoming the South Island dealer for Mercedes-Benz, Freightliner and FUSO trucks, and I believe all customers will benefit from having a New Zealand-based and -focused general distributor.”

Andrews and Mahoney said their teams and customers will be kept updated as the transition progresses.

“Keith Andrews Holdings and CablePrice aim to maintain all existing operations and personnel to ensure a smooth transition and a high level of customer support.”

•

•

•

•

•

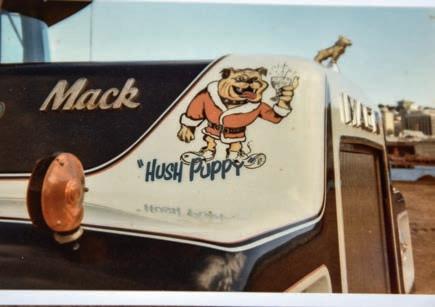

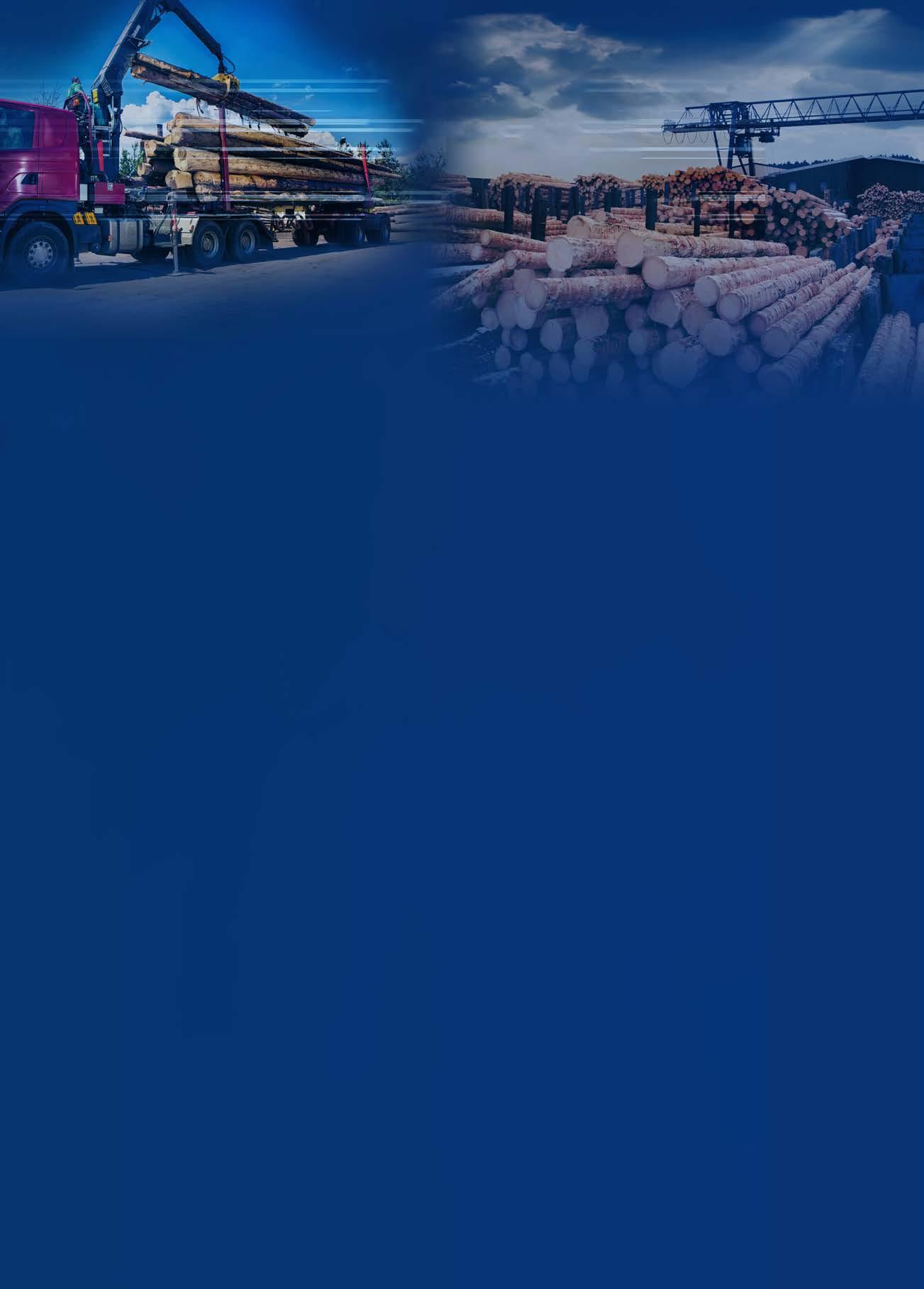

Mack Trucks is launching its most powerful drivetrain yet, as the allnew Euro-6 range is revealed to New Zealand.

Available to order now, with the first vehicles expected to hit the road in early 2025, the new range of Mack drivetrains includes an all-new, range-topping 581kW (780hp) 17L MP11 engine with a stumppulling 3800Nm of torque. The engine features optimised internals and is paired with an upgraded mDRIVE transmission.

transfer that power directly to the engine crankshaft. The result is 373kW (500hp) and a hefty 2800Nm torque figure, significantly higher than the standard Mack MP8 engine.

efficiency in heavy transport applications across New Zealand is truly game-changing for Mack.

“Ultimately, the biggest winners are our customers,” he said.

“From demanding heavy haulage and house-moving to forestry operations and bulk cartage, Mack Trucks has now, more than ever, the ability to deliver a better driving experience, greater up time and lower running costs.”

Joining the new big-block engine is a revamped 13L eSCR Euro-6 MP8 which, like the rest of the new Euro-6 range, benefits from new low-friction cylinder liners, wavetop pistons, a more efficient turbocharger, and a revised electronics system to provide more precise fuel delivery and combustion. It is available in 324kW (435hp), 373kW (500hp), 399kW (535hp) ratings.

The Mack Anthem’s efficiency has also been given a shot in the arm with the arrival of the new MP8HE (high-efficiency) engine platform. The MP8HE utilises turbocompound technology to scavenge extra energy from the engine’s exhaust flow and

The progression of safety features continues to be an important hallmark of the Mack Euro-6 offering, with Mack’s evolution of Bendix Wingman Fusion and new Mack infotainment system with Apple CarPlay, Android Auto compatibility and wireless phone charging. With a standard rear-view camera and optional additional cameras, Mack customers will benefit from an improved level of visibility and safety on the job site.

The fully integrated 70in, walk-through sleeper will also be available for order with Euro-6 Super-Liner and Titan products. They feature multiple configuration options, including single and double bunks. New cab suspension, tilt and telescoping steering column and driver seat with air suspension also improve driver comfort.

“We are excited to bring this new range of engines to the New Zealand market,” said Rob Woods, general manager, MTD. “To be able to offer this level of power and

Kenworth showcased its SuperTruck 2 demonstrator vehicle at the ACT Expo in Las Vegas last month, a project developed over six years in collaboration with the US Department of Energy’s SuperTruck programme, which challenged truck makers to improve freight efficiency using a diesel engine as the primary power source.

“The goal was a 100% freight efficiency improvement over our 2009 Kenworth T660. We

surpassed the performance of that model to improve efficiency by up to 136%,” said Jim Walenczak, general manager of Kenworth and PACCAR vice president.

This was achieved by improving fuel efficiency up to 18.3L/100km and reducing weight by about 3175kg.

“SuperTruck 2 provided us with the opportunity to investigate new technologies at an early stage. We learned what worked and what didn’t. As a

result, we can commercialise new technologies much quicker than we would have otherwise.”

Joe Adams, Kenworth’s chief engineer, said that while the “unique look” of the Kenworth caught most of the attention, the powertrain and driver amenities were just as impressive.

“We started with an ideal aerodynamic shape and we asked ourselves, ‘What does the next-generation vehicle for long-haul transportation look like?’ What we produced

pushes the limits in reducing aerodynamic drag while it also incorporates a new powertrain.

But, with everything Kenworth, we wanted the SuperTruck 2 to embody ‘The Driver’s Truck’. The result was a systematic approach to developing a futuristiclooking, yet relevant vehicle with technologies that have the potential to be refined and commercialised.”

Kenworth’s SuperTruck 2 utilises a PACCAR MX-11 engine, rated at 328kW (440hp), which The Kenworth ‘aero family’.

Shockless

Shockless Ride Technology

Our Innovation Built In™ philosophy yields some of the most innovative, durable, lightweight and costeffective suspension systems and components for the global transportation industry. Hendrickson’s ZMD™ ZERO MAINTENANCE DAMPING™ eliminates conventional shock absorbers by integrating the damping function into the air springs.

Our Innovation Built In™ philosophy yields some of the most innovative, durable, lightweight and costeffective suspension systems and components for the global transportation industry. Hendrickson’s ZMD™ ZERO MAINTENANCE DAMPING™ eliminates conventional shock absorbers by integrating the damping function into the air springs. Tel: +64 9 570 4721 www.hendrickson.com.au

Kenworth SuperTruck 2 makes significant advances in efficiency with a diesel engine. Right: Central driving position very different to any other Kenworth on the road.

is driven through a PACCAR TX-12 automated transmission. In addition, the truck features a 48V electric generator. This creates a mild-hybrid system and leverages next-generation lithium-ion batteries, recharged through regenerative braking. This allows Kenworth’s SuperTruck 2 to operate electric fans, steering, and coolant and HVAC pumps.

The aerodynamic design allows for a 48% reduction in drag compared with Kenworth’s

baseline vehicle, and the layout is powertrain agnostic, supporting zero and near-zero emissions solutions like fuel cells and hydrogen tanks.

Enabling more payload was a critical element in the design for the Kenworth engineering team, which also utilised a specific trailer design. The combination came in at 11,838kg.

The SuperTruck 2 also features a “centre driver” cab and a new sleeper compartment designed to resemble a bullet train. The

driver-side door has a large opening, and the extendable bottom step supports a stairwaylike entry and exit. “We made the windshield very parabolic in ‘plan’ view and smooth to the flow. The integrated digital mirror system enables enhanced rearview monitoring, with trailer tracking capability and night vision enhancements, technology currently available in Kenworth T680 models,” said Duncan. The truck is trialling a bed that folds down over the sofa,

providing a separate sleeping and sitting area.

“Kenworth just celebrated its 100th anniversary, and SuperTruck 2 builds on Kenworth’s history of providing value to its customers,” added Walenczak.

“This project represents Kenworth’s innovation to ensure that our company’s future and our customers’ needs remain at the forefront. This truck is an important milestone for us,” he said.

The Windrose E1400 is coming to New Zealand later this year. Arjan Velthoven, editor of TTM.nl, and Dutch member of the International Truck of the Year jury, had a preview drive in Europe.

Chinese electric heavyduty truck developer

Windrose Technology is keeping its foot on the accelerator for 2024.

In April, it announced the completion of the second phase of its series B financing, raising the total funding for this round to US$110 million (about $179 million).

The proceeds of this series B financing will be used to accelerate the testing and

deployment of Windrose Technology’s electric longhaul trucks globally, to set up a new supply chain centre and production facility, and to implement a fast-charging infrastructure.

The company’s first electric long-haul truck has a range of 670km under a full load of 49 tonnes. The Windrose EV truck has an 800V high-voltage fast-charging platform and can replenish 400km of range in under 36 minutes.

Windrose intends to launch a European 4x2 specification in the fourth quarter of this year. The vehicle will be an estimated 7.4m long, with 520hp. Its weight will decrease to about 9.5 tonnes.

The company is currently looking for transport companies to partner with and

additional investors.

“We are looking for partners. We need investment to set up a distribution and aftersales network,” said Eric Gauthier, Windrose head of operations Europe and responsible for Windrose’s rollout in Europe.

“Financially, we have a solid foundation. We want to debut on the New York Stock Exchange later this year.”

The new Windrose EV has already been driving in France for Decathlon, and in Belgium, the company managed to snare Gilbert de Clerq as a pilot customer. The port of Antwerp was looked at, and Windrose became a main sponsor of the basketball team Antwerp Giants.

The truck is a long and tall vehicle, at 3.90m high and

8.10m long. On the rear axles, there are two electric motors each, which are good for a peak power output of 1043kW (1400hp) – more than any European e-truck. The battery pack consists of three stacks of two battery modules each, suitable for six modules in total and 729kWh at a voltage of 800V. The battery pack, supplied by an external supplier, is sufficient for a 670km range at a total weight of 49 tonnes. It boasts a drag coefficient of just 0.275, considerably lower than that of the similarly styled Tesla Semi (0.36).

The Windrose EV cabin is large, measuring 280cm in length, 220cm in width and 245cm in height. The bed, with a thin mattress, is 88cm wide. A second seat can be optionally fitted. Against the

rear wall, there are three large cupboards. Under the sloping windscreen, there is a reasonably wide dashboard with plenty of storage space and a minimal number of buttons.

There is an instrument display right behind the centrally located steering wheel and two large screens on either side of it. The Windrose EV only has rearview cameras, so there are screens in the cabin for that, too.

During a brief drive, we quickly got used to the

With 80 confirmed exhibitors and hundreds of registered attendees, organisers are expecting big crowds at this year’s EROAD Fleet Day, taking place on Wednesday 7 August.

Enterprise business development manager at EROAD Matt Buckle said the event was moving to Mystery Creek, Hamilton, due to its significant

confirmed as the keynote speaker. There will be two panel sessions, a networking area and interactive demonstrations, and heavy and light stages.

A highlight of the event will be a vehicle crash simulation, where two cars are dropped from a 200-tonne crane.

“We want to show what an accident looks like at 80km/h, and also 120km/h, to highlight

Accelera by Cummins, Daimler Trucks & Buses and PACCAR have completed the formation of their joint venture, now known as Amplify Cell Technologies.

The joint venture aims to localise battery-cell production and the battery-supply chain in the US and advance zeroemissions technology for electric commercial vehicles and industrial applications.

Amplify will soon begin constructing a 21gWh factory in Mississippi, with potential for further expansion. The factory is expected to create more than 2000 US manufacturing jobs and is targeting the start of its production operations in 2027.

Accelera, Daimler Truck and

PACCAR each own 30% of the business. EVE Energy serves as the technology partner, with 10% ownership, and contributes its battery-cell design and manufacturing expertise to the venture. EVE Energy is a global technology leader in manufacturing LFP battery cells for the vehicle industry.

“Cummins’ power solutions are at the heart of the economy, and we have the responsibility to decarbonise in a way that meets our customers’ varied needs as they navigate the energy transition,” said Jennifer Rumsey, chair and CEO, Cummins Inc.

“Amplify Cell Technologies will enable PACCAR to offer customers cost-effective

premium-quality battery-electric powertrains that meet their operational and sustainability needs,” said Preston Feight, PACCAR chief executive officer.

John O’Leary, president and CEO of Daimler Truck North America, said: “For Daimler Truck, a strict focus on costs and smart capital allocation are the key levers to succeed on the path toward truly sustainable transportation. This partnership enables economies of scale beyond Daimler Truck. It is a key puzzle piece of our battery industrialisation strategy, ensuring access to the right battery cell technology at the right cost and right time for our customers.”

Volvo Trucks is developing trucks with combustion engines that run on hydrogen.

On-road tests with trucks using hydrogen in combustion engines will begin in 2026, and the commercial launch is planned towards the end of the decade.

Volvo said trucks running on green hydrogen were a significant step towards its net-zero goal and supported customers to reach decarbonisation targets.

“Hydrogen trucks will be especially suitable over longer distances and in regions where there is limited charging infrastructure, or time for, recharging of batteries,” the truck-maker said.

Volvo trucks with hydrogenpowered combustion engines will feature high-pressure direct injection (HPDI), a technology in which a small amount of ignition fuel is injected with high pressure to enable compression ignition before hydrogen is added. The advantages of this technology include higher energy efficiency with lower fuel consumption and increased engine power.

Volvo Group has signed an agreement with Westport Fuel Systems to establish a joint venture using HPDI technology.

ENTER NOW TO BE IN TO WIN A PAIR OF PETERSON’S SUN GLASSES

The joint venture is anticipated to become operational in the second quarter of 2024, following formal closing.

“Trucks where the traditional internal combustion engine remains but runs on hydrogen will have the same performance and reliability as our diesel trucks, but with the added benefit of potentially net zero CO2 emissions wellto-wheel,” said Jan Hjelmgren, head of product management and quality, Volvo Trucks.

The hydrogen-powered combustion engine trucks will complement Volvo’s offering of other alternatives, such as battery electric trucks, fuel-cell electric trucks and trucks that run on renewable fuels, like biogas and HVO (hydrotreated vegetable oil).

Volvo trucks with combustion engines powered by green hydrogen have the potential to deliver net zero CO2 well-to-wheel when using renewable HVO as ignition fuel and are categorised as zero-emission vehicles under the agreed-upon new EU CO2 emission standards.

“It’s clear that several kinds of technology are needed to decarbonise heavy transport, based on transport assignment, available infrastructure and green energy prices,” said Hjelmgren.

Our winner this month is Amy McCune of Nelson with the Mack Trident she drives for Mytton Transport. This moody shot worthy of a Mack Trucks advertisement was snapped by Amy while waiting at Port Nelson to be unloaded. Great shot Amy, your prize is on its way. Now get your entries in for the August competition.

Send your best night bling photo as well as contact details into nightmoves@nztrucking.co.nz to enter

The Freightliner Cascadia has been with us now for four and a half years, and it was time to see how it’s faring Down Under. Is Cascadia living up to the promise? After a little searching, we found just the right truck, driven by just the right bloke.

Regular readers will recall the extensive coverage we gave to the Freightliner Cascadia’s build-up in this part of the world, culminating in the November 2019 Sydney launch. Our first cover truck came in the November 2021 issue, a brand new 116 bulky owned by Cromwell-based McNulty Transport.

The daily task was a short-haul aggregate supply run ex the company’s Amisfield

Quarry on the western side of Lake Dunstan, to Firth batching plants in Wānaka and Queenstown, with an occasional trip out to the East Coast chucked in for good measure.

Although a great ‘Kiwi style’ application, this time we wanted to have a look at a Cascadia 116 in a role more closely aligned to the truck’s original US intention. We also wanted one with a little use under its belt.

To embrace the full US vibe, ideally it

needed to have an aero kit, and be rolling up the road with a big semi-trailer plugged into the fifth wheel. Easy enough you might think, but our ideal truck took a little finding. Shortlisted was one of the seven Hall’s Cold Chain Logistics units that hit the road in 2021, purchased through CablePrice’s Trevor McCallum before his retirement. They fitted the brief to a T, and a quick call to Christchurch transport manager Hayden Reed had us aiming for the immaculate fleet No.7201, domiciled in Dunedin and driven by career wheel-man, Phil Taylor.

It’s an interesting and cautionary lesson in life: in a country and industry as small as ours, your reputation is only ever three marker pegs ahead of you. In the weeks leading up to the phone call to Hayden, every time we chatted to folk about what

Story by Dave McCoid Photos and video by Carl Kirkbeck and Dave McCoid

it was we were looking for and mentioning one of the Hall’s units were on our radar, eight times out of 10 the reply would come back, ‘I know it’s a long way down country, but if it’s Hall’s, it’s gotta be the Dunedin truck’ – or in the case of those who know Phil, ‘It’s got to be Phil’s one in Dunedin, he keeps that bloody thing immaculate! It wouldn’t be fair to not do Phil’s.’

Now, if I may pause momentarily for any industry outsiders embarking on a whole new world of print entertainment. ‘That bloody thing’ in the context of the previous statement is an industry generic term of endearment when a bunch of truck types reference any machine a dedicated operator keeps in fine condition. I’ll give you, it’s an odd turn of phrase considering truck drivers love the machines of their industry and would never refer to their own mechanical companion as a ‘thing’ on almost any

occasion. Stand in the shadows at a truck show, however, and I promise you’ll hear it all day long ‘Shit he/she keeps that thing sharp/mint/on-point/ immaculate!’ A funny quirk for sure, but something that makes us, us. Consider it truckers’ love language … but a word of caution, don’t try it on the spouse.

Not sure about me, but Bruce McLean’s certainly are, and it has to be said the Dunedin and Invercargill Hall’s fleet falling under his operational care all look on point and pearly white. A truck man hailing from a long and broad lineage of lower south pedallers, Bruce’s infectious enthusiasm for his industry and the machines at its core would even rub off on Francis Bourgeois!

Bruce manages the Invercargill depot and runs truck operations at both

Invercargill and Dunedin, with colleague John Warburton managing operations at the Dunedin depot. Day to day he has about 15 trucks in his keep and additional to them are any floating linehaul units from outside the area travelling south of Christchurch, looking to get back north.

“Ours is a mixture of local, linehaul, and floating. The business is dynamic, and customer requirements and order size can change in a heartbeat, so we have to be ready. I’m a customer service man to the core; I get a real buzz out of the operations role and the challenges it presents. We’ve got a great crew across the two depots at the moment. Invercargill is always settled. However, the amount of trucking based in and around Dunedin makes it a competitive labour market and creates a higher level of churn. It’s just the way it is.

“Workwise, things have really

picked up again after a quiet winter in 2023. We were fine through Covid, but had a lull last winter, the first one we’ve really noticed through the whole pandemic era. Thankfully, that’s passed and we’re off again.

“The Freightliners, yeah, they’ve been interesting. Fundamental mechanicals have been bulletproof; they haven’t let us down at all. But they’ve been a little niggly at times with silly things like marker lights and minor electrical-type stuff, and we had one that broke the door handle! The bit you grab ... broken!

“We used to have one based here from new on linehaul and it racked up 220,000km in 12 months. The drivers rated it highly on comfort, quietness, and handling. However, because they’d come off a DD15 in the Western Star, they felt a bit hard done by with the DD13 when they got to places like the Northern Motorway out of Dunedin or the Kilmog.

“Now the business has moved to Scania R590s for the linehaul function, so they’re back to 16L and 590 horsepower, so you know they’re all over them, and you can’t blame them. The Cascadias have found their home in the regional function with the occasional longer run when required.”

It’s an interesting assessment from the man who runs them, and soon we’ll move to the man who lives with one.

There’s a whole lot to unpack in Bruce’s comments and it speaks volumes about linehaul trucking in New Zealand and what is required when perishable consumables and food products are at stake.

Three years after our launch articles, Freightliner continues to wield the big hammer in the domestic US class 8 heavy truck market at about 37.9% (87,000 trucks pa approx.) and Cascadia is without doubt the

undisputed golden child, still. In many ways the brand lives up to the dream of its founder Leyland James, who sought a light, powerful, economical truck that optimised payload. Dominance in modern times has its roots with Daimler’s top truck man Martin Daum, who turned a flagging market share around with the arrival of the new Cascadia in 2007 and a clear instruction to his people at Daimler Trucks North America (DTNA) that they will deliver a 5% reduction in TCO on the model every two years from that moment on. Yikes! R&D nirvana.

Of course, we got the benefit of all this in 2019 when it was decreed the ANZAC nations will fall under the wing of DTNA. Paradoxically, it did mean losing the Argosy, which caused barely a ripple in Australia while sending New Zealand into apoplectic seizure. A valuable lesson, reminding us the hammer we swing when it

1 & 2) It’s the little things that make big differences, WABCO TailGUARD, integral door catches and levelling valves. I bet the pioneers of refrigerated transport would have loved them!

comes to influencing the global heavy truck market is actually made of polystyrene; probably worth remembering just at the moment.

Never fear though, a bonnet it might have, but at least there would be an 8x4. Well, that was until the regional launch function at the Sydney Opera House in 2019 when Mr Daum put that rabbit in the crematorium, saying such oddness would fall under the wing of the new Western Star when it came; Western Star being the vocational truck in the DTNA lineup.

What it all meant is the road

Down Under on the eastern side of the Tasman would not be an easy one for one of the world’s most dominant commercial motor carriages, and that has played out with only 33 of the 116 model, and 10 of the 126, hitting the road here since launch. (The model number denotes bumper to back-of-cab measurement in inches.)

What we omitted from the list of original requirements when scouting for our truck was a level-headed, well-versed, and experienced driver, who would offer an objective view on the machine. As it turns out, lady luck was with us and, in Phil Taylor, we got the Powerball on that one.

We first met Phil and his Cascadia 116 on the northbound bypass at Balclutha. We’d been held up on our run north from Invercargill and he had happily paused on his way home from the Silver Fern Farms Finegand freezing works to allow us catch-up time. We would learn in the succeeding two days that such accommodation was just who he was. When Phil Taylor says “All good, no problem”, he means it. After a quick meet and greet, Phil continued his way north and we commenced image capture.

If you didn’t know you were in New Zealand, who Hall’s were, or that day cabs and fouraxle reefers are not a thing in linehaul US, motoring north could easily have been a scene from somewhere in the North Carolina countryside. Here was a 13L 6x4 Freightliner Cascadia, with a roof kit, side fairings, no sun visor, and hood mirrors, towing a big semi along the road. This was exactly what we wanted.

Phil was on his way home to Hall’s Cold Chain Logistics Kaikorai Valley depot in Dunedin. It marked the end of his day as a rule, having started the morning with his usual routine of one or two metro deliveries ex the depot, followed up with the run to Balclutha, sometimes making calls to supermarket outlets on the way down. Time permitting, he may also have a couple of afternoon deliveries on his return.

When volumes dictate, he also heads to Invercargill, a couple of hundred kilometres south – more often than not a Monday mission by all accounts.

Under normal circumstances, he might only rack up 250km to 300km a day, so it’s very much a regional role.

We arrive at the Dunedin depot and meet operations supervisor John Warburton, who instantly aligns with the approach and accommodation we’ve encountered since entering the Hall’s world. So far, we were three from three and any thoughts that Hayden, Bruce, and Phil might be outliers in the bell curve of company culture are being rapidly cast to the wind.

The truck made the whole thing quite a buzz really – it’s all so Cascadia, especially if you’ve spent some time in the land of the free. As Phil backed in to the dock, we wondered how many times has a Freightliner Cascadia backed in to a dock? “Surely that number is well into the tens of billions by now?” I said. “It’s like watching an Air Tractor topdress, it’s what they were born to do.”

We met Phil the following

morning on a windy and showery Dunedin waterfront morning. Fryatt Street is the quayside access from the city to the inner Otago Harbour berths. At the far northeastern end, a large business estate is home to ENZA and Talley’s cold storage facilities, and it’s from deep within these corridors of cool that Phil emerges and we leap aboard. First impressions count and the inside of the Cascadia is as immaculate as the outside; you could literally eat off the floor. It’s all so apparent now why so many in the know pointed us toward Phil.

“It’s a lovely truck to drive,” says Phil. “I really like it in that sense. There’s plenty of room in, around, and behind me, and the dash layout is superb – nicely wrapped around and everything in reach. There’s a little rattle in the back wall that’s cropped up recently, that’s why your seat was reclined back against it.”

The space, the big lazy wrap in the dash, they generate a feeling of airiness. All things we remember the designers striving hard to nail, and here their work

was being vindicated by the only jury that counts.

The rattle? Find a US truck that’s rattle- or squeak-free and I’ll show you an abandoned Mt Everest in the middle of climbing season.

“Visibility is superb, and the mirrors are fantastic. You can just see everywhere, and the bonnet almost isn’t there, is it? I don’t notice it, and it certainly doesn’t compromise manoeuvrability,” says Phil Manoeuvrability and Dunedin – now there’s the makings of an oxymoron. There’s no place quite like ‘Dunners’. Well, actually, there is – it’s called Wellington. There’s no escaping it, both islands have a city that tests a truck driver’s spatial awareness to the nth degree. Whether it’s the streets or delivery locations, there’s no quarter given in the Otago capital, and any momentary lapse in concentration will result in a ‘gark’ somewhere on the unit. Even motorway off-ramps, like the northbound exit to Kaikorai Valley that feels like you’re on an ever-diminishing

taper ending in a quirky little 90° left-hand corner with an immediate kink right onto a narrow two-lane bridge split with a kerb median. I wouldn’t say it’s challenging, but first you have to remember it is a motorway off-ramp; and second, if you happen to be thinking about the roast for tea tonight just at that moment … Let’s just say it’s very Dunedin. And when you take into account the traffic the valley absorbs through that wee complex, it starts to boggle the mind.

Fantastic then that both man and machine come into their own and the fact the Cascadia and semi are as straight as the day they were manufactured, speaks absolute volumes about its captain. This is Phil’s home, these are the streets his trucking teeth were cut on, and it shows.

The Detroit Diesel DD13 is your typical modern 13-litre with a hearty voice that makes the mid 70dB recorded in the cab a most enjoyable experience. The match with the platform AMT is on the button and the Detroit DT12 picks away

at the gears as Phil negotiates his way around the city’s front apron, onto and up Lookout Point then back toward the depot.

With Eaton’s Endurant now in the mix also, isn’t it a relief Uncle Sam’s OEMs have finally got a suite of auto-shifters in the marketplace that all work as an AMT should?

Anyway, we’re back in the valley and swing into the depot. Phil spins around in the adequate albeit cosy yard – fine if you’re a Dunedin native. In the 116 Cascadia he can see terra firma 3.75m in front of the hood, so he can nose right up to the fence in order to get the unit straight prior to backing onto the dock. By now, regular readers will be well versed on my views regarding

versus real-world helpful ones, and the WABCO TailGUARD system sits in the latter category perfectly. Big trucks and trailers are hard to see around and anything that gives you additional visibility on the ‘dark side of the moon’ so to speak, is certainly worth its weight in gold. Backing onto a dock in a busy DC or depot is a perfect example. TailGUARD keeps the reversing speed under 9km/h and warns the driver of anything within two metres of the rear of the trailer and stops the unit complete at 500mm (the stop distance is configurable between 300 and 700mm). By default, that includes the dock. Part of the awareness process is the sidelights flashing with increased cadence the closer an object is. It’s a canny system.

stopping,” says Phil as we inch our way back. “That’s the trailer doing it by itself. Here, I’ll go forward and start again, you watch the side lights. See, it’s detected the dock. If I’m happy I can continue back, otherwise there’s something there I may not have seen. I think it’s a great tool. Anything that helps, eh?”

The external modular panel look of the 15.54m Fruehauf NZ Schmitz-Cargobull semi instantly tells an industry onlooker whose show it is. The Hall’s unit sports the company’s clean, smart, contemporary look with the snowflake logo and obvious accoutrements of social licence, like side and rear under-run protection. It’s a robust, bulletproof setup with known longevity built into it beyond the Fruehauf NZ

Spec like SAF undercarriage and JOST full-load landing legs and alloy wheels. There’s also kit like a BroLube central lube system to ensure a long and happy life, and EROAD to help keep on top of the compliance and admin chores. It’s a unit designed with continuous movement as the key focus, just as it should be in trucking.

Phil leaps aboard the forkhoist and starts loading product for the daily run south to Balclutha. He points to the Schmitz Cargobull Double Decker racking system. A series of vertical rails with inbuilt racking that can drop to any height down the vertical, meaning you can optimise space in a second layer, regardless of the height variation in the base load.

“Love that! It’s a great

obviously, but you can’t have everything I guess.”

One thing that stood out in the Hall’s depot was a lack of incessant horn tooting from the forkhoists as they moved around, which as a rule, completely desensitises you to horn tooting … it’s a ‘how we’re built’ thing. The clue as to why the ambiance was so pleasant was in the blue lights darting around the floor, emanating from units mounted on the ROPS on the forkhoists. They warn the onlooker there’s a forkhoist approaching. It’s a brilliant system, especially when you consider we are designed to acknowledge and respond to movement … it’s a ‘how we’re built’ thing, and that system is a far better use of it.

As Phil completes the loading

the lid on the Cascadia. It is a snug fit for the 13-litre, with the signature drop in the frame so the radiator is set as low as is able, allowing the sleek and slippery wind profile. All the daily checks are on the left and I know I’m showing my age and level of residual paranoia, but I’m a fan of daily checks on things like oil and coolant, and it’s one area a bonnet has real advantages. With it lifted, all is revealed – and you can quickly see what’s rubbing, seeping, loose – anything that may end up irritating your Monday or ruining your Friday.

Bonnet down and standing back, it’s a clever fleet-spec rig, again with proven components like the Holland fifth wheel, but also from the cosmetic standpoint. There are enough

interested if they want to get into a bit of polishing, yet for the skilled operator who’d rather go fishing than attend a truck show, it will come up just fine with a good honest once-over on a regular basis.

With 14 or so tonne on the deck we tip the scales at 33,450kg. Phil can put about 22 tonne on comfortably and says being a 6x4, you have to be aware of how you’re loading it when reaching the upper limits.

With a power to weight ratio well north of 7kW (10hp) to the tonne, the Cascadia launches away with little or no effort, and it’s here you really appreciate the fit of the machine in New Zealand.

While 13L and up to mid-500 horsepower isn’t going to set many wheels spinning in daily HPMV linehaul duties north of 50MAX, it’s a superb regional distribution spec that is easily able to leap into the breach in the event one of the big-boys ‘has a moment’, and can’t front up at the go-line. There would be no drama plugging into the loaded B-train for a couple of nights if it means customers are kept happy. In all reality, you might be surprised at the trip time differential.

The DD13 in this installation is set at 377kW (505hp), delivering 2508Nm (1850lb/ft) of torque, and as we’ve said, it is backed up by a Detroit DT12 AMT, with Meritor GP46-160s on Airliner air suspension. Up front, the Meritor

FG94 7.5-tonne front axle sits on taper-leaf suspension. Brakes are disc. At the price point offered of recent in some outlets, you couldn’t go wrong with a couple of these in the mix.

We head out of town in the traffic and crest the Saddle Hill in seventh at 1300rpm and 35km/h. The 2021 Cascadia has had a pleasant life with only 220,000km on the clock, and Phil at the helm for the 12 months he’s been with the company. To date, the consumption is sitting at 47.4L/100km (2.11kpl). Reading that in the context of what the truck does, there’s not much to complain about. Outside of the occasional lash to Invercargill, the longest stretch of flat running it gets is the 33km between Allanton and Milton.

“I don’t mind it at all. Like I said, it’s roomy, comfy and quiet. It steers well and goes fine for what is asked of it. I’m an American-truck person, and it’s got a bonnet. Some of my mates reckon the bonnet mirrors ruin it, but they’re a real US thing, and I tell you, they’re bloody handy. I actually use them a lot. And on this raked bonnet they’re great reference points.”

Out across the flood-free north of Waihola at cruising speed and we’re heading for Milton and the first of our two drops en-route at the local SuperValue, the second being New World Balclutha. As is always the case, the big semi certainly reminds you it’s there, especially so considering the competitive tare weight of the tractor at 8300kg and the deteriorating state of our roads. “If it’s loaded wrong, slightly forward too much, say, it’s really horrible to ride in,” says Phil. That of course is not the truck’s fault in any way.

The Cascadia’s cab and vehicle operation from within are state of the art. You don’t become one of the most successful heavy trucks in history with a crappy cab, and it would be the archetypal negative Nelly who would find real fault in how it works.

Access is as easy as it gets, and the driver’s position is superb and fully adjustable. Everything falls easily to hand and the cockpit setup is in the familiar format with gauges and telematics in the binnacle and additional gauges, HVAC, vents, coms/entertainment up

high in the wrap, and switches, valves, and Aux power down low. The headlight control is low down on the right of the steering wheel. There’s a Daimler platform familiarity to the smarts on the steering wheel, and located off the steering column wands are indicator, wipers, and dip on the left, and direction/shifter on the right. For me, a wand shifter is superior to button type, allowing the console area to be clear of intrusions like shift-towers. In Phil’s line of work, having crosscab access is handy.

It’s a day cab bonneted truck so there’s only so many rabbits you can pull out of the storage hat. However, the caddy between the seats, overhead cupboards, and stows both overhead and in the doors, plus room under the passenger’s pew, more than meet requirement in this application.

Fit and finish seemed fine; we had a poke and prod, and three years in, things appeared to be holding up. Materials are highly serviceable and there’s a nice woodgrain pattern through the dash.

Obviously, there’s the recent ‘Budgie’ that’s arrived in the rear wall lining, and of course Bruce’s comments on the collapsed door handle. Hopefully, it’s all being fed back to DTNA. I know first-hand how seriously things like that are taken there.

As it turns out SuperValue in Milton is a cinch, with access off Shakespeare Street and

Great relationships are the key to good business at all levels. Phil says cousins Nicole and Jodie Thompson on the chilled and frozen docks respectively are the best, whether it’s efficiency or just the people they are.

exit onto Spencer. There is an innocent power pole on the left of the unload area that would appear to be minding its own business, but occasionally it leaps sideways and gives the odd truck a tap according to Phil, especially if they attempt to exit back onto Shakespeare. We’re in and out in no time; it’s

a typical friendly Phil exchange – how easy is it for customers when you have a skilful and engaging driver on a regular basis.

Being a semi the back-in was as easy as it gets. However, when talking to Bruce earlier he did say it’s a skill in ever-shorter supply. “Everything we do loads

in and out of the rear, so we have to have people who can back competently – big semis and B-trains. That’s not as easy to find as you might at first think.”

On to Balclutha and Phil happily talks about his place of work. “I’ve worked at plenty of places and it’s as good a place as

I’ve ever been, probably better. The crew I’m with all get on, and everyone knows what they’re doing. Bruce [McLean] and John [Warburton] know what they’re doing and leave you to get on with it. The conditions are great, the gear’s good, and the pay is fine. There’s a bonus system they run worth $100 a week tied to things like driving hours, PODs, CHEP recovery, all the basic stuff a driver should be doing anyway. Guys from our generation shake our heads at those sorts of things needing to be incentivised. There is nothing onerous and it’s easily achievable – if you do your job properly, you’ll get the bonus. On the occasions I’ve missed, it hasn’t been because it’s unachievable, it’s because I’ve buggered something up and that’s annoying … for me, I mean. And there’s no pressure on hours or to do silly things – that’s a big no-no.”

Continuing the theme of keeping compliance easy, Hall’s runs electronic logbooks housed in the same little Zebra device as the dispatch, consignment, coms, and pre-check/maintenance information. “Again, it’s all a bit easy for someone raised in another trucking generation. There it all is,” says Phil holding up the device. “It’s that simple, there’s nothing difficult about any of it.

“The Seeing Machine? A lot of people hate them, I’m not sure why. Yeah, it’s gone off a couple of times for no reason I can fathom, but I’ve got nothing to hide, and it’s a good safety device. It’s a more professional world now and I can only see things like that saving arguments.”

And with that we’re at the Balclutha New World for a twocarton delivery and then on to the huge Finegand freezing works located just to the southeast of town on the Owaka Highway. Hall’s does a lot of transfer work for its customers as well as delivery work, and today we were bringing the bulk of our load down in here, as well as loading out 22 pallets for places far away.

“That’s the chilled loadout

‘Taylorville’

IT’S NOT A BAD PLACE

I’ve had plenty of jobs, I’ll be the first to admit that, and I’m sure plenty you talk to when you say you’re doing this will tell you also,” Phil pauses and chuckles as we trundle along.

“But I’ll also say I’ve enjoyed pretty much all of them, and I’ve gained a lot of experience in a lot of things. I’ve had a lot of fun and met a lot of people. I guess I’ve just managed my life with my happiness and wellbeing as the first priority.”

Looking from the outside observer’s position, you’d have to say there’s merit in the man’s philosophy – never feeling like life has him trapped. He’s not rushed in his approach, nor it appears prone to ‘fizzing’ up. Think back to Jodie on the forkhoist at Finegand, “We love Phil, he’s great.” Surely part of the reason for her saying that is consistency of character when he arrives each day. Nothing is more settling for all parties than knowing ‘who’ is getting out of the cab.

“I’ve never done stock or fuel,” he says, which is ironic

considering both his dad Stewart and grandfather Gordon drove Europa fuel tankers between Dunedin and Haast. The grey-haired set north of 50 years old will remember the Europa fuel brand back in the 1970s and early 1980s.

“I don’t know what my grandfather drove but Dad drove a Leyland Mastiff. It took all day to get there, and then all day to get back.” In the warm, spacious, and comfortable confines of our present ride, we both shook our heads at the grit and tenacity of those hardy old buggers. “Dad eventually went onto buses before a complete change to greenkeeping. Something he loved and did really well. He ended up president of the national federation.”

Mosgiel was home for Phil growing up and his early life was spent in and around all of the above and local truck action in general. Key was inspirational time spent with cousin and mentor Peter Alexander, who worked at Thomas Transport.

Peter moved on to drive at Mainfreight in Dunedin before heading to the North Island and working at Candy Transport in the Bay of Plenty, and then Toll. Not only was he a great mentor to Phil, he also drove, and eventually ran, some cool gear – trucks like the FR Mack he had while at Mainfreight, and the ex-Keith Howells Ghetti Express Kenworth K100G he owned while at Toll. “The FR Mack really kick-started my love of trucking.”

Phil’s own career began courtesy of Mt Cook Line freight division contractor Mike Knopp and the loan of a truck in which to secure his heavy traffic licence. Success led to aroundtown delivery relief work and of course a trailer licence. From there, the usual pattern of progressive escalation followed, just as it did for anyone in that era who had what it took – the thing older heads observe in a young one that tells them ‘this one’s a keeper’. Phil was off and rolling.

Logs, freight, and general for various employers took place

in the succeeding years. Like so many in the industry he headed for Australia with the intention of ticking that box in the list of things he wanted do to, while poking a hole in the mortgage.

“The work was good, I was running Brisbane/Sydney for Armesto’s Transport, initially in a Western Star and then a K104 Aerodyne. What I couldn’t handle was the weather, the heat and humidity, and I wasn’t getting the rest I needed in my breaks. It ended in a fatigue moment –nothing happened, there was no crash or anything, but I found myself following close behind another unit. When I asked my mates travelling with me where he’d come from, they said he had overtaken me. I had no recollection of that happening. That scared the shit out of me and I pretty much binned it and came home. It was a shame because I really loved doing it, but I just couldn’t see how I would get on top of it. The climate wasn’t about to change.”

Outside of the Australian experience, Phil’s driving has been South Island-based, and drilling down one step further again, dominated by south of Christchurch. “I’ve never really wanted to get into the interisland thing full time. The thought doesn’t really excite me.”

In his 37 years behind the wheel, 55-year-old Phil has worked for some of the industry’s iconic names and driven some cool trucks … Christchurchbased AZTEC Haulage in a 440 V8 Mack Ultra-Liner with a 12-speed Maxitorque, carting produce and general between Christchurch and Dunedin. “That was a highlight! What a machine, you couldn’t get enough of it.”

An 8V92 Detroit-powered W-Model Kenworth towing a curtainside B-train between Dunedin and Invercargill for John and Morgan Rob at Regan Carriers: “Drove the doors off it! It was a symphony,” he says with a laugh.

A Tranzlink CH Mack for Mike Nevin, and The Patriot Western Star for Brenics … It’s been the truck-buff’s dream in many ways. The recent passing of Alex

‘Mac’ McLellan prompted memories from Phil also. “I worked for Mac for a time, driving an Isuzu on a regular freight run to Dunedin. What a top man, salt of the earth. I was only 18 then, green as grass, and Mac took me under his wing, jacked me up with accommodation initially also. He always had time to have a yarn with you, just catch up. He will be a huge loss to the industry.

“I came into the industry at an amazing time, when it was at its peak in terms of mentors and role models for a young bIoke. Learning the industry when you’re surrounded by people like my cousin Peter, the Mac McLellans and Steve Martins of the world … how can you go wrong?“

Today, Phil lives just over from Mosgiel in Dunedin proper. He has an immaculate V8 Holden Ute and a Harley-Davidson, and enjoys cruising with soulmate Hollie, and spending spare time with his two grown-up children Karla and Deanna. “Life’s great, eh?”

They say the ultimate truck driver is the 55-year-old head on the 25-year-old body. Like the rest of us, Phil would be the first to admit the second half of that equation has long left the stable. However, he’s the living embodiment of the first. He knows trucking, that there’s something new to learn every day, and the moment you drop your guard or think you know it all, it’ll ‘run over your toes’, metaphorically speaking. Yet his years in the industry also bring a comfort from the skillsets he has amassed, the watchful eye that checks it all as he walks around the rig, the calm unpanicked approach. There’s nothing left to prove, no reason to rush in order to impress. He’s immensely comfortable in who he is, which makes him always open to new things.

He’s at that career sweet spot of enjoying the job, enjoying the truck, enjoying the people, enjoying the industry, enjoying the scenery, which equals … enjoying your life.

dock run by Nicole Thompson,” he says as we idle in. “And this one we’re backing into is the frozen run by her cousin Jodie Thompson. They are two of the best, there are no other words for it. They keep this place running like clockwork. They are so friendly and make your work life so easy. I’d go so far as to say they’re just good friends now. We’re all going out for a social occasion next month.”

Phil has the semi in the dock in no time, and his commentary on the leading ladies as we drove in was instantly vindicated by the delightful Jodie who wheeled up in her electric forkhoist and welcomed us to the frozen loadout at Finegand, taking interest in what we were there for. “You’re going to be famous Phil!” she says, laughing. “We love Phil, he’s great,” and with that she was off with the first pallet disappearing into the bowels of the giant plant. If only the world was full of happy glass-half-full people, eh?

Experience is everything in trucking, and it’s the little things that make all the difference. Once unloaded, Phil tweaks the raise/lower valve on the semi-trailer so the deck slopes fractionally down from back to front, making the task of escorting the pallets on his pallet trolley to the front of the trailer that much easier.

“It’s safe, too,” he says. “If I slip or something, it’s going to want to roll away from me, never back toward me; and you should never be in front of it with it coming toward you … ever!”

In no time at all, the 22 pallets we were there to receive

post-unload were onboard, and away we went.

At the end of the day the truck is a tool of utility, and one indicator of a good truck might be adaptability. In its homeland, there is no argument the Freightliner Cascadia is a giant. The sheer numbers on the road there perplexes the mind. But we are not the United States. We don’t have 75,000km of lazy rolling interstate, or corporate 1000-plus truck fleets. We carry more on our general access and HPMV trucks – lots more – and our road pricing mechanism means we love collecting axles … even steering ones. It all means Cascadia will never be the colossus here it is there.

But that’s not to say this immensely capable, comfortable, and easy to drive machine doesn’t have a place in Godsown. Cascadias have found happy homes in the bulk and aggregate tip markets, often emulating what this Cascadia does at Hall’s. Take the McNulty truck; local work with the occasional run out to the coast.

Yes, sales might have been modest, but to get a fair comparison you need to measure them against all bonneted US 13-litre 6x4s over the same period.

With a proven driveline capable of backing up the big boys when needed, and with good support after the sale, it would be hard to do a lot better for the outlay.

Tare: 8300kg

GVM: 26,000kg

GCM: 65,000kg

Wheelbase: 4325mm

Engine: Detroit Diesel DD13

Capacity: 12.8L

Power: 377kW (505hp)

Torque: 2508Nm (1850lb/ft)

Emissions: GHG17 (exceeds Euro-6)

Transmission: Detroit DT 12-1850-OH2

Clutch: Detroit HD AMT

Chassis: 11 x 85 x 287

Front axle: Meritor FG941

Front-axle rating: 7500kg

Front suspension: Freightliner Taper leaf

Rear axle: Meritor RT46-160GP (DCDL on both axles)

Rear-axle rating: 20,900kg

Rear suspension: Airliner 46K

Brakes: Disc. EBS, ABS

Auxiliary braking: Jacobs engine brake

Additional safety: Detroit Assurance – 5 (ABA, ACC, LDW, SGA, Intelligent high beam, Detroit Connect)

Fuel: 604L

DEF tank: 47L

Wheels: Alcoa Dura-Bright alloy

Tyres: 275/70 R22.5

Electrical: 12V

Cab exterior: Aluminium cab construction with faring and side extenders, utility lights on rear of cab, day running lights, fog lights, hood-mounted heated mirrors. Aluminium DEF tank cover, and polished battery box

Cab interior: ISRI high-back driver’s seat and ISRI fixed passenger seat. Black leather cover on driver’s seat. Leather steering wheel. AM/FM entertainment system with USB, iPod, Aux, USB

Now, that was a really interesting story to put together, and demonstrates our uniqueness as a wee nation. A huge thanks to the Hall’s team for their enthusiasm and willingness to help whenever we pop our heads up. One of the truly great trucking brands. Especially Hayden Reed, Andrea Albertyn, Bruce McLean, John Warburton, and of course industry ambassador supreme – Phil Taylor.

Theo Ferreira at CablePrice, it’s always a pleasure, as it is also Trevor McCallum; thanks also to Steve Young.

Yvette Mear and Paul Cranston at Fruehauf NZ Schmitz Cargobull – legends! Thanks so much.

•

•

•

•

•

•

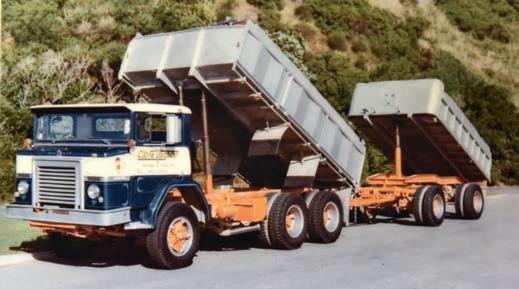

Every cover truck holds a special place in the history of New Zealand Trucking magazine. We love to see where their road has taken them.

GCA8

• Superior sidewall cut resistance.

• Long tread life, exceptional casing durability.

• Enhanced stability and riding comfort.

• The extra-deep tread pattern is specially designed for loaders.

• Excellent performance on extremely rocky surfaces, in open pits, quarries, and underground mines.

GCA2

• Non-directional deep tread pattern designed for muddy and soft surfaces.

• Unique non-directional traction patterns ensure optimum traction and prolongs tread life.

• Superior sidewall cut resistance.

• Good self-cleaning with groove stone ejector.

• This deep tread is particularly suitable for loaders and dump trucks operating in quarries or mining.

GCA3

• Applications: Articulated dumper, dozer, loader, and graders.

GCA8

HFS71 has recently been re-certed but will

• Excellent traction and floatation offer comfortable handling.

•

• Superior long tread life and excellent puncture resistance.

• Low rolling resistance and fuel economy.

• What we said in 2014: “Cab comfort is another advantage over older designs. There is some clever technology and suspension tuning under

•

• Non-directional traction and standard tread depth pattern design.

• Excellent performance supported with heat resistant compounds.

• Primarily designed for mining, off the road, and muddy surfaces.

The DAF was one of two to enter service in the fleet of Northland logging contractor Steve Segetin.

Superior sidewall cut resistance.

GCA8

Long tread life, exceptional casing durability.

Enhanced stability and riding comfort.

• Superior sidewall cut resistance.

The extra-deep tread pattern is specially designed for loaders.

• Long tread life, exceptional casing durability.

Excellent performance on extremely rocky surfaces, in open pits, quarries, and underground mines.

• Enhanced stability and riding comfort.

GCA3

and

• Primarily designed for mining, off the road, and muddy surfaces.

Non-directional deep tread pattern designed for muddy and soft surfaces.

Excellent traction and floatation offer comfortable handling.

• Excellent performance on extremely rocky surfaces, in open pits, quarries, and underground mines.

Superior long tread life and excellent puncture resistance.

Low rolling resistance and fuel economy

GCB5

• Articulated dumpers, rigid dumpers, loaders, graders.

• With excellent traction and buoyancy performance.

• Outstanding stability and operating comfort, with large pattern plate and long service life.

• Unique non-directional traction patterns ensure optimum traction and prolongs tread life.

• Superior sidewall cut resistance.

• Good self-cleaning with groove stone ejector

• The extra-deep tread pattern is specially designed for loaders.

GCA3

• Applications: Articulated dumper, dozer, loader, and graders.

• This deep tread is particularly suitable for loaders and dump trucks operating in quarries or mining.

• Non-directional traction and standard tread depth pattern design.

• Applications: Articulated dumper, dozer, loader, and graders.

• Excellent performance supported with heat resistant compounds.

• Non-directional traction and standard tread depth pattern design.

• Primarily designed for mining, off the road, and muddy surfaces.

• Primarily designed for mining, off the road, and muddy surfaces. GCA7

• Excellent performance supported with heat resistant compounds.

GCA2

• Non-directional deep tread pattern designed for muddy and soft surfaces.

• Excellent traction and floatation offer comfortable handling.

• Superior long tread life and excellent puncture resistance.

• Low rolling resistance and fuel economy.

Story and pictures by

Dave McCoid and

as credited

There are drive events, and there are ‘drive’ events, and Penske’s 2024 gathering at Wacol in Queensland at the end of May was an absolute doozy. Little surprise considering the man whose name fronts the enterprise. Over the next two months, we’ll cover off the happenings, starting with the Lion’s share.

Nothing speaks to an OEM’s confidence in its product more than a yard full of trucks loaded to the gunnels and company representatives asking, “What are you standing there for?”

Penske’s 2024 drive event was exactly what a drive event should be, big trucks and a decent two-and-a-half hour lash behind the wheel of the ‘jiggers’ we’d selected in the weeks prior.

After brief addresses from

Hamish Christie-Johnston, managing director for Australia and New Zealand, Craig Lee, executive general manager for on-highway, and head of Western Star Kurt Dein, it was up to the products to do the ‘torquing’.

We’ll split the Penske offering into its two constituent marques, focusing on MAN this month and Western Star next.

Without wanting to unstitch myself here, the only vehicles us

Kiwi fellas weren’t able to drive were the two MAN B-double units. They are now considered multi-trailer combinations and as such, the NHVR requires you do hold an MC (multi-trailer combination) licence. Sad as that may be, it was the last truck for me and concluded the event, so a cruisy yarn was fine.

The lack of a drive was no real biggy as the 26.580 TGX tractor unit is a spec well known to us. With a headline GX cab, it was the true line hauler’s home with 2070mm headroom inside, and all the ‘fruit’ both inside and out. Running gear was the 15.2L D38 in Euro-6e trim, a combination we’re familiar with. On this occasion, it was presented in 433kW (580hp) and 2900Nm (2139lb/ft) guise. Just as I did, you might well ask ‘Why not the full monty 640?’ The old chestnut

of people thinking they need more than they often do was the response from driver and chaperone Wayne Wallace, head of retail truck sales for Australia. It means keeping some powder in the demo keg to impress should the need for more ‘oomph’ be real. “You can never bring them back down when it comes to power.”

Our route took us 70km due west of Brisbane on the A2 to a rest out past the Gatton trailer hook-up heading toward Toowoomba. It’s a four-lane expressway circa Waikato style, with one hill called the Minden which you’d say is akin to St Stevens for the North Islanders, and northbound into Greta Canyon for the Southerners.

At 64-odd tonne GCM through the lazy rolling country, the 580 D38 appeared to be putting

about as much effort into proceedings as the 640 in the Ramsay machine last August did when climbing away from Taupō onto the Rangitaiki at 54 tonne. It’s a gorgeous big thumper filling the cab in that subdued, muffled locomotive groove we’ve commented on before.

The MAN TipMatic 12 30 OD AMT

Big, smooth, and majestic. The 26.580 TGX with GX cab is one of those machines that makes Aussie East Coast B-Train linehaul a no-issue proposition. There’s no replacement for displacement.

transmission (MAN configured ZF TraXon) does a beautiful job of seamlessly swapping cogs, and the eight-bag ECAS suspension was stability personified in an environment that offered it no real test.

As we motored west, Wayne lamented the road surface and all I could think was how happy

I’d be if our carriageways of national disgrace came even close to this.

The flagship of the drive day fleet bristled with all the safety and productivity kit you’d expect and only fools and horses would bemoan the added situational comfort tech like adaptive cruise and active braking have brought to high-speed, high-weight haulage.

This motor loves the basement on the tachometer, and the big Lion easily maintained a steady 100km/h (Aussie remember) for 90% of the open road time, yet with eco-roll and the insulated cab environs, often the sensation was of nothing much happening.

When a rise did rob it of the top 15 or so ‘clicks’, it was effortlessly regained.

Our unit ran the 3.36:1 final drive, which means by application it can be rated to 120 tonnes – handy if it needs to help in a proper multi-trailer environment. Having rounded up the Minden in ninth at 1050rpm, Wayne was keen to demo MAN’s EVBec auxiliary brake descending the other side. Delivering an impressive 627kW (840hp), it is the most powerful in its class. A quick recap of the system: a flap upstream of the turbo closes and combines with targeted airflow of high-speed gas from the remaining opening, back to the exhaust side of the turbo increasing turbine speed

on both sides. This increases back pressure through the entire top end of the engine, resulting in a prodigious braking effect. It will blend with the transmission once the throttle-actuated descending control is activated. The system easily held the show even with gravity pressing hard.

As a place of work, the TG3 cab is as impressive now as it was on first viewing in 2018 in Munich. I’m not sure if it was me, but the Aussie incarnation seamed a little softer than the Ramsay truck – maybe it’s hitting the road deformities that little bit quicker. Driving position, controls and information feedback are stateof-the-art and the SmartSelect wheel as a means to manage swathes of information has lost

me right from the selection list. Yes, it was Euro-5 but, for me, it wasn’t about the engine on this occasion, there were other reasons afoot. First, this genre of TG3 MAN is popping up more and more in regional distribution work at home, and after this experience, it’s not hard to see why. All other reasons aside –and there are many, as you’ll see – this unit in Aussie would set you back a hair over AU$240,000 as it stood with steel wheels.

Second, as I age, I wonder about life after work and would I be happy relieving and ‘playing’ when needed in a more modest carriage of social utility.

My truck host on this jaunt was Sergio Carboni, a wonderful character who fills the regional business manager role for greater Melbourne. Settled in the cab, with those gathered watching us leave, this truck had me gripped from the get go … well, once we found it was in creep mode and switched that off, LOL. (For a moment I wondered how much you’d get through in a day with a top speed of 8km/h.)

True design genius is getting into a totally new truck and feeling like you just put on your favourite pair of shoes. You could position it without thinking; it turned on a dime, zipping around like a kitten chasing a ball of wool.

none of its appeal.

We turned the TGX GX for home and chatted our way back to Wacol, wondering what it would be like to work for a living.