The results are in and we couldn’t be happier. Scania has been voted the number one* truck brand in the country by the people whose opinion we value the mostNew Zealand truckies.

We’re chuffed to have rated highest on all measures, including most preferred, comfort, safety, sustainability, performance, efficiency, service and parts. Thanks New Zealand. It means a lot.

A Kiwi Fertiliser MAN TGS 26.540 travels along SH36 heading towards Rotorua, here entering the Mangorewa Gorge in the early morning. Photo: Gavin Myers.

A Kiwi Fertiliser MAN TGS 26.540 travels along SH36 heading towards Rotorua, here entering the Mangorewa Gorge in the early morning. Photo: Gavin Myers.

EDITORIAL DIRECTOR

Dave McCoid

Ph: 027 492 5601

Email: dave@nztrucking.com

EDITOR Gavin Myers

Ph: 027 660 6608

Email: gavin@nztrucking.com

For all advertising enquiries:

ADVERTISING MANAGER

Pav Warren

Ph: 027 201 4001

Email: pav@nztrucking.co.nz

Mike Devon

Ph: 027 332 4127

Email: mike.devon@nztrucking.co.nz

SUB

Tracey Strange, Faye Lougher

EDITORIAL

Carl Kirkbeck, Craig McCauley, Shannon Williams, Russell Walsh.

Craig

Alison

Press Council, PO Box 10 879, The Terrace, Wellington 6143 or by email at info@ presscouncil.org.nz

Further details and online complaints at www.presscouncil.org.nz

6 months (6 issues) $52

One year (11 issues) $99

Two years (22 issues) $175

1 Year Australia (11 issues) $198

It feels like just the other day that I wrote my first editorial for 2023. To paraphrase myself: just like that, the last issue for 2023 is on the shelves!

Was the year a smoother ride than 2022, as I’d hoped? In some ways, I suppose it was. We could enjoy a full January to December cycle without Covid-19 and lockdowns dominating the headlines (that’ll be the last mention of that here), and the country could crack on with the next big thing on its agenda – the 2023 general election.

But first, a cyclone. Gabrielle simultaneously reminded us about what was really important in life and impressed upon us that the country can’t operate with a weak roading infrastructure for much longer. With cyclone recovery still ongoing, infrastructure served as one of the many talking points in a battleground of campaigns, debates and other political wranglings in the lead-up to October.

Right now, that all feels like a whirlwind that rushed in, picked us all up and deposited us … well, we don’t exactly know yet. Hopefully, Luxon, Seymour and Peters can play nice and agree before I write my first editorial of 2024… (Or even, perhaps, before you read this one.)

Maybe ‘battleground’ is a bit of a strong word to use in that instance, considering the situation in the Middle East and the Russians’ continual assault on Ukraine – albeit now going on almost quietly in the background. All things considered, it has been a bit of a tumultuous year as far as the local and global state of things is concerned.

As for the road transport industry… Sure, there has been a spike in operating costs and a natural flowon effect on consumers. Fuel prices, labour shortages, ping-ponging RUC discounts, stranded ferries and cyclone-battered roads all contributed – all issues the industry

will unfortunately continue to run up against, it seems.

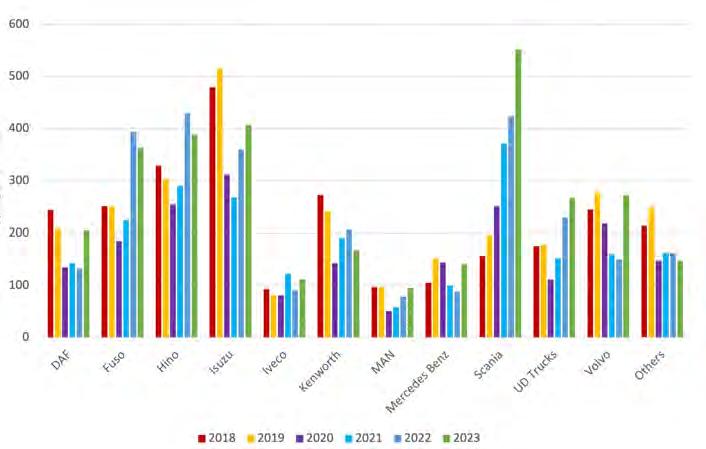

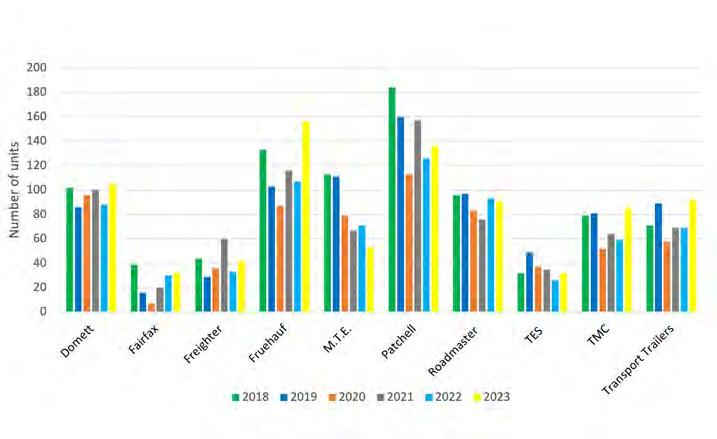

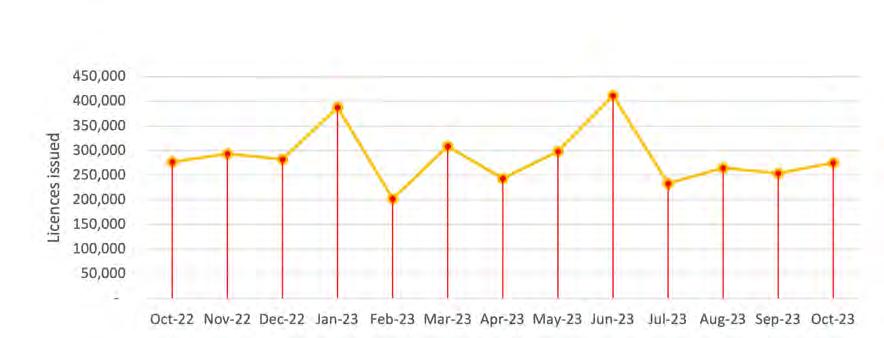

But there were plenty of positives. Commercial vehicle sales have truly recovered to pre-pandemic (argh, damn!) levels, having long surpassed last year’s final numbers. Local and overseas truck shows were back on in full, spectacular form, as were the many industry conferences. And in it all, a convoy for a young truckmad lad grew exponentially from a simple request for a birthday ride and made international news. There was certainly no shortage of gear taking to the road and no dearth of good stories for us to fill these pages with.

And so to 2024. To say the New Zealand Trucking Media team is excited for the new year would be a mild understatement. We’re buzzing about new opportunities in the pipeline to bring you even better magazine content each month. We plan a ramp-up of our digital content, too.

Of course, our phones are always on, so let us know what you want us to deliver in New Zealand Trucking magazine, on our YouTube channel, the Keep on Moving podcast and Trucking Radio 24/7

Finally, a personal word of thanks to every person who had a hand in producing the content we delivered in 2023. It truly takes a village. So, thank you all for your hard work and dedication. And, most importantly, thank you to our readers and supporters. I hope you enjoyed each issue as much as we enjoyed bringing them to you.

Happy holidays one and all!

Another incredibly big year at Long Haul Publications – a significant year – and as I write this we are busier than ever. I know I speak on behalf of my business partner Margaret Murphy also when I say I can’t think of a group of people more deserved of a Christmas break than our crew.

We are humbled every day, week, and month at the level of interest, commitment, and engagement the team all have in pursuing our fundamental mission of telling New Zealand’s road transport story better than anyone else.

It is an absolute privilege to work with you all, I’m always a better person for every day spent in your company – I mean that sincerely, especially in light of the loyalty and enthusiasm you’ve all showed in a year that at times has been far from easy. It is thrilling to see you all actively and freely participating in where the company is going, and what it might look like in the years ahead.

To our suppliers, we thank you for your support across whichever of our media vehicles you chose to tell your customers your story. Aligned with our fundamental mission we believe sales and marketing to be another form of the road transport story. Whether informing potential customers of great deals, or cementing your place and purpose into the hearts and minds, your message will best served in the care of truly committed people at Long Haul Publications.

And to our readers, listeners, and all who enjoy our content, without you, none of us would be here, none of what we do would be possible. We are all incredibly grateful for your support of our products, and for your love of the road transport industry. It is without doubt the most interesting time there’s ever been to be involved in trucking, that’s for sure.

To each and every one of you, from all of us here at Long Haul, please, travel safe over the Christmas/New Year holidays. Have a wonderful time, and a great rest.

See you all in 2024!

Dave McCoid Editorial Director Gavin Myers Editor

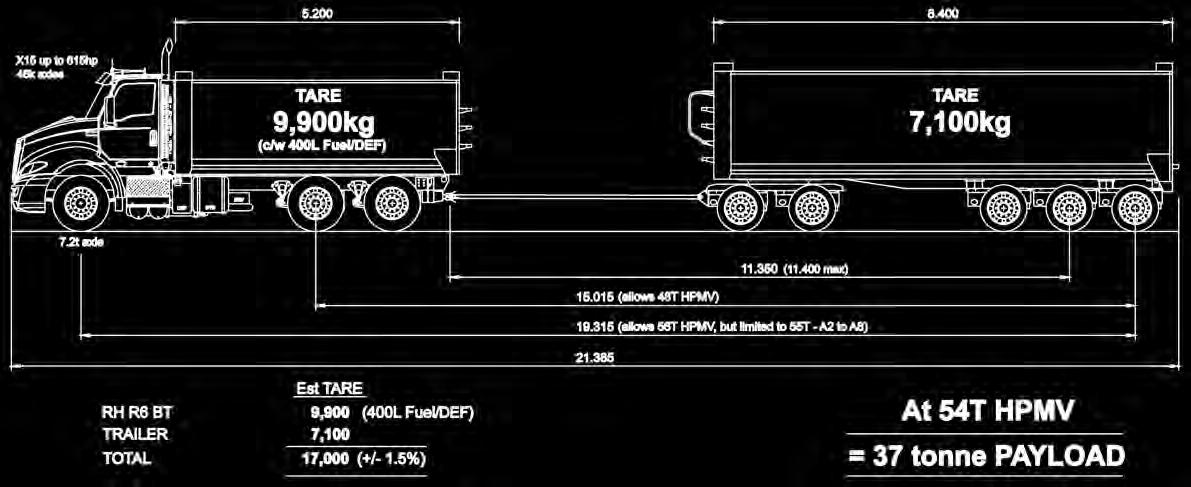

PROVEN to be the HIGHEST TURNOVER truck in NEW ZEALAND

NEW INTERIOR Released CLASS LEADING DIGITAL INSTRUMENT LAYOUT LOADED with NEW FEATURES for the DRIVER

• Up to $90,000 p.a GAIN in PAYLOAD REVENUE compared to similar power train brands.

• BODY SLOTS booked with T&G and MILLS TUI during 2024 to OPTIMISE DELIVERY schedules.

• RATED by DRIVERS AS THE BEST CONVENTIONAL for VISABILITY, TURNING CIRCLE and COMFORT.

LOWEST TRUCK TARE in NZ | More PRODUCTIVITY | BIGGER PROFITS

Volvo Trucks’ FH Electric range has been elected International Truck of the Year 2024 by a jury of 24 commercial vehicle editors and senior journalists representing 24 major trucking magazines throughout Europe.

It is the first time in the 47-year history of the IToY

awards that an electric truck in series production wins this prize. Four vehicles out of five on this year’s ITOY Awards shortlist are battery-electric models with zero tailpipe emissions. It’s proof that the energy transition is gaining momentum in the transportation sector, even though a suitable enabling

ecosystem for BEV is still not in place in the EU.

With a winning score of 84 votes, the Swedish truck manufacturer’s heavy-duty electric range fought off tough challenges from MercedesBenz’s eActros 300/400 battery electric truck (BEV), and Scania’s 45S BEV.

The annual award goes to the truck introduced into the market in the previous 12 months that makes the most significant contribution to road transport

MAN’s autonomous driving projects ATLAS-L4 and ANITA have won the 2024 Truck Innovation Award.

It’s the second time MAN Truck & Bus has won this trophy, after the inaugural Truck Innovation Award of 2019 in recognition of its AFAS level 4 automated driverless safety truck.

The IToY jury offers the Truck Innovation Award to acknowledge the automotive sector’s enormous technological changes and energy transition. With a winning score of 97 votes, MAN’s advanced projects fought off the competition from ZF’s electrified eAxle; Quantron-as-a-service (QaaS),

a zero-emission platform provider for fuel-cell and battery electric commercial vehicles; and Westwell Q-Truck, an autonomous electric heavy-duty truck for innovative container logistics.

The ANITA project (Autonomous Innovation in Terminal Operations) started in 2020 to automate handling between different modes of transport. ANITA aims to use autonomous trucks to stabilise the processes involved in transferring containers from road to rail, making them more efficient, easier to plan and, at the same time, more flexible.

The ATLAS-L4 research and development project (Automated Transport between

efficiency. This judgement relies on several critical criteria, including technological innovation, comfort, safety, driveability, energy efficiency, environmental footprint and total cost of ownership (TCO).

The IToY journalists praised the performance, seamless acceleration, quietness and vibration-free behaviour of the FH Electric’s electric powertrain, based on two or three electric motors, of 330 or 490kW continuous power, coupled with the latest generation I-Shift gearbox. Equally crucial in FH Electric’s winning score for regional cargo transport were the vast axle configurations for tractors and rigid, the availability of four cab versions and the modular portfolio of battery packs.

IToY chairman Gianenrico Griffini commented: “With the introduction of the FH Electric, Volvo Trucks has delivered a state-of-the-art BEV range, suitable for a wide array of transport operations. It’s proof that the energy transition is gaining strength even in today’s challenging business environment.”

Logistics Centers on level 4 Expressways) aims to put level 4 autonomous trucks on the road in real-world operations. The project stems from the German law on autonomous driving approved in 2021, which, in principle, allows automated driving on defined routes under technical supervision.

The IToY journalists praised the advanced characteristics of both projects, the contribution to hub-to-hub and intermodal

transport automation and the fruitful cooperation between MAN Truck & Bus, component suppliers, research institutions and public authorities.

IToY chairman Gianenrico Griffini said: “MAN’s ANITA and ATLAS-L4 projects are proof that autonomous driving is feasible today and can have a role in making transport operations safer and more efficient, laying the foundation for innovative transport and logistics concepts.”

Within the New Zealand transport industry, there are many stories of innovation, determination and perseverance. The latest life member inductee of the New Zealand Truck-Trailer Manufacturers Federation has the above in spades.

Ian Stevenson started his transport engineering career in 1951 as an apprentice fitter-turner with WP Walker of Hamilton. It was here that Ian learnt and perfected his craft. During his time at WP Walker, Ian met and befriended fellow apprentice Bill Box. The pair were ambitious, with big dreams of starting their own enterprise. Bill had just completed his apprenticeship, and Ian was still six months away from signoff. Not deterred, the two set about venturing out on their own, launching the Transport & General Engineering Company, now known as Transport Trailers. Ian remains one of a select few who started a company while still completing an active apprenticeship.

The first workshop was established on Kent Street, on the outskirts of Hamilton. Much of the early work was general engineering; however, within the first year of operation, Ian landed his first commission – a single-axle semi for a kauri logging operator based on the Coromandel. This was the inception of a long-standing history of trailer manufacturing that spans the best part of 70 years.

A turning point for the business was an aluminium truck and trailer body Ian built for Roose Industries of Mercer. Ian admits he and Bill had their reservations about an aluminium trailer. However, they persevered, pioneering technology that would revolutionise the industry. Marketed under the Transport Trailers brand, the duo found by the end of 1972 that virtually the entire output of their workshops was aluminiumbodied trailers.

MyTrucking has won the Innovation Award at this year’s WBS Wairarapa Awards, powered by Business Wairarapa. The awards recognise and celebrate the success of outstanding local businesses, shining a light on the businesses, organisations and people doing amazing things across the Wairarapa.

“To win the Innovation Award, kindly sponsored by Prue Hamill of Harcourts, Hamill Realty, solidifies our continuing endeavour to keep innovation at the core of our business,” said Sara Orsborn, head of sales and marketing.

“It’s what drives us and pushes us to think outside the box. It’s something we are fiercely passionate about because our innovation has one end goal in mind – to make life easier for our customers. It was our mission when we started out and continues to be our mission today.

“Innovation is a thread that can be followed through all aspects of our business. From our technology innovations like our DriverApp, integration partners and ever-expanding list of features and supports to our

Today, the company Ian and Bill started is thriving. Transport Trailers now operates from three separate sites, two in Hamilton and a new service centre in Drury, Auckland, part of a nationwide service and support network.

A member of NZTTMF since 1961, Ian has been an active advocate for technology within transport, with his time and input generously given. Ian served on the TTMF council from 1979 to 1983, also serving on the drawbar safety standards committee. He also hosted and convened the first TTMF subcommittee for HV brakes in 1980. In 1981, Ian also sat

team. The introduction of Tony Warwood as our new general manager and Nikola Berryman’s newly established role in Australia are just a few examples of this.

“Our customers inspire us

daily to push the boundaries of what could be possible and, by so doing, are the reason behind our success. So to our customers, we say thank you.”

From left: Dave Gilles (TTMF life member), Matt Gilles, Kate Bucknell, Harry Clark, Brian MacDonald (life member), Neil Boys, Rob Johnston. on the TTMF subcommittee that developed the code of practice for designing and manufacturing suspension systems. Stevenson receiving his TTMF life membership with his son Mike.Don Hutchinson and current IRTENZ president Chris Carr have been awarded life membership of the organisation. Don was also awarded the IRTENZ Outstanding Industry Service Award.

Long-serving member John de Pont was also recognised following his retirement from the International Forum for Heavy Vehicle Transport & Technology (HVTT) board this year.

Hutchinson

Don Hutchinson is the NZ Transport Agency principal engineer, technical regulatory team. He has been a member of IRTENZ since 1995.

Hutchinson started in a regulator role with the Ministry of Transport’s traffic engineering branch in 1980. He became interested in how to manage the heavy vehicle fleet so that it was safe and productive. That led to directing the size and mass of the fleet along with vehicle configurations. He was an early adopter of utilising performance-based standards to benchmark innovative vehicles against standard vehicles to introduce a range of policies, permit regimes, and new legislation with the vehicle dimensions and mass rule. This includes the recent HPMV scheme. He was responsible for introducing the static roll threshold legislation and writing the truck loading code, parts of the road code and myriads of heavy vehicle safety initiatives. At a mid-career point, he moved into senior

management roles and worked closely with other ministries and ministers to improve the rules set for New Zealand vehicles.

Hutchinson has worked closely with several industry associations, including Transporting NZ, National Road Carriers, Log Transport Safety Council, the Truck Trailer Manufacturers Federation, the Motor Industry Association and IRTENZ. He tends to offer solutions rather than obstacles, and in his 40-plus years, he has helped these groups achieve numerous industry initiatives across the line.

“Thank you all. It’s quite a surprise. Honestly, I wasn’t expecting this. I’m really honoured. IRTENZ is one of those groups that’s been a great asset of information. As a regulator, you need to get a balance between doing the right thing and making a mistake and causing extra unnecessary compliance cost or perhaps an undue safety risk you haven’t contemplated. Being able to reach out to individuals makes a huge difference when you’re in the decision-making process. I’ve got a lot out of this group, so thank you very much, it’s appreciated,” said Don via Zoom link.

Chris Carr

Chris Carr is the current president of IRTENZ and director of Carr & Haslam. He is the fifth generation in a business that began in Auckland in 1862 with a horse and cart.

Carr has always been one to speak his mind and lead by his

actions, volunteering a huge amount of his time to improve the road transport sector. Besides being an active member of IRTENZ, he has been on the Axle Weights and Loadings Advisory Group for more than 30 years, and regularly attends the Ports of Auckland transport operator meetings group committee.

Carr was a foundation member of the Northern Infrastructure Forum, which was set up to ensure that Auckland progresses its strategic transport network as rapidly as possible and to keep pace with Auckland’s population and economic growth.

He was one of the key organisers of the successful 2008 truck protest – what would turn out to be a show of solidarity, cooperation and dedication within the transport industry and the country. Carr was an inaugural member of the NZRTA Region 1 board before its merger with National Road Carriers and was bestowed life membership of NRC in 2015.

In addition to transport, Carr is also a board member of the Auckland Business Chamber, a past director and chair of Rally NZ, has been involved in the New Zealand Scouts and is a former member of the Auckland Regional Land Transport Committee.

“It’s amazing to be recognised by your peers for something that’s quite important to me. The transport industry has fed me, my family and many others for a long time. It’s only right that when somebody feeds you, you feed them back, and it’s been a pleasure for me to put back into the industry we support and work for. It’s an amazing industry full of amazing people – we do some incredible stuff, and the company would not

run without us. Thank you to the institute!” Carr said.

John is a mechanical engineer. He graduated from the University of Auckland and achieved a PhD in engineering from Cambridge. The Department of Science and Industrial Research was New Zealand’s government science agency, and the closing down of its branch of heavy transport expertise led to John and Peter Bass establishing Transport Engineering Research New Zealand (TERNZ) in the late 1990s. TERNZ quickly became the preeminent independent private researcher and advisor on heavy transport safety and engineering in New Zealand.

De Pont has led many work and papers, including vehicle dynamics, pavement performance, vehicle suspension surface transport modal share –and even the stability effect of dead hanging pigs. His expert advice has been important for heavy road transport in many other areas, including road user charges, and performancebased standards would not have advanced in New Zealand or been as successful without his involvement.

De Pont’s diverse range of expertise in heavy vehicle engineering is unparalleled in New Zealand. He is an internationally recognised expert and an exceptionally good communicator, and he has always been willing to share his knowledge, expertise and experience at national and international levels. He has also

played a lead role in the OECD’s international infrastructure research projects. He has written and presented papers at all HVTT symposia, has held numerous roles in the association and was inducted onto the HVTT honour roll.

“The industry has given me as much as I’ve given it. It has been my career. I ended up in transport by accident. I was doing computer-aided design, and one of my colleagues had a large project looking at the effect of vehicle dynamics on pavement wear, and I was tasked with taking over his work in about 1987. HVTT1 followed that, then the OECD committee, so really, I fell into it. But it’s been a great career,” De Pont said.

Waka Kotahi will invoice for unpaid RUC using data collected by weigh-in-motion scales from the middle of 2024. The data will enable the agency to identify RUC non-compliance 24/7. It intends to move to an automated invoicing process in future.

Historically, RUC compliance assessment was based either on weight records kept by the operator (despite not all industries being required to keep weight records) or on the roadside assessment of a truck’s weight, which is labour-intensive and manual. Eric van der Plank, senior manager commercial services, described the move as a step change for RUC compliance monitoring.

“This data takes us a long way towards levelling the playing field for the heavy vehicle

Mills-Tui steel tippers are innovative and built to last, manufactured tough from high-wear resistant steel. We’re ready to help build New Zealand’s infrastructure so gives us a call now on 0800 MILLS-TUI

industry, which it’s been wanting for years,” he said. “The new process, driven by the revenue compliance team, will be a game-changer for us because the current RUC invoicing process is manual and timeconsuming.”

The in-pavement, weigh-inmotion scales work in tandem with roadside cameras, which capture vehicles’ number plates.

“The data we collect will enable us to do a much better job of targeting non-compliant operators – those whose trucks are persistently overloaded. We’re focused on recovering underpaid RUC. Unless we see repeated offending, we won’t fine operators for overloading,” said Van der Plank.

Weigh-in-motion scales will be placed at each of the 12 commercial vehicle safety centres that will make up the

commercial vehicle safety programme. So far, two centres have been built, at Paengaroa in Bay of Plenty and Glasnevin in North Canterbury. A third, at Rakaia in South Canterbury, will open early next year.

Work is also underway on building a site at Ohakea, and a tender for a site at Mackays Crossing (Kapiti) has been awarded. When completed, the 12 sites will monitor 10 million truck trips yearly and cover 46% of heavy vehicle kilometres travelled in New Zealand.

Van der Plank said that when all 12 safety centres were operating, Waka Kotahi anticipated the RUC revenue collected would increase by at least $10 million a year. “That’s money that goes straight into the Land Transport Fund to build and maintain roads and roading infrastructure.”

file for bankruptcy.

The move comes after supply difficulties made it hard for the EV start-up to raise funds.

Volta, headquartered in Sweden and with operations in Britain, said the bankruptcy in August of electric vehicle parts supplier Proterra and uncertainty over its battery supplier had cut the number of trucks it could produce and made it hard to raise sufficient capital.

The company will also shortly file for bankruptcy in Britain.

The company’s board of directors said it had “not taken this course easily or lightly and is fully aware of the significant impact this will have on the organisation’s dedicated workforce”.

It had raised about €300 million (about $500 million) from investors and said it had an order book of more than 5000 vehicles.

Volta Trucks had picked a factory in Austria to make its trucks and had been working toward mass production.

Keith Andrews Trucks recently ran a 100% EV truck evening at its Hamilton facility. Existing and prospective customers and interested parties were invited for an update on the eCanter’s journey Down Under, along with testimonials from those embracing the next era in landbased transport and useful takehome information from network providers and bodybuilders. The underlying theme was that the barriers are now gone, and getting on board sooner rather than later will pay dividends in terms of operator welfare, reduced R&M and personal IP as the impetus ramps up.

Keith Andrews GM sales and customer experience manager Kathy Schuler, sales manager Alisha Francis and Fuso New Zealand product planning manager Ian Porter were on hand to address questions from an interested transport community.

As well as in-house information, there were testimonials. “Making sure everyone is part of the journey is essential; operations, drivers and trainers, all learning together,” said Alex Thompson, general manager vehicle logistics at Carr and Haslam in Auckland.

Jason Howarth, national training and development manager at Carr and Haslam, was made project manager for the eCanter in the business, and he reinforced Thompson’s comments, saying they had also used the truck to blood new recruits into the road transport business via the Road to Success programme. “We had far more curiosity within the business than pushback.”

Howarth started operating the truck within a 20km radius of the firm’s Mt Wellington depot, stepping that out as charging capacity and knowledge evolved.

“With our 60kW charger, we’re getting four or five cycles

per day, and the eCanter is matching, if not better, than a 616-equivalent diesel model in terms of operational productivity. To date, we’re coming up to 40,000km of trouble-free use.

“Everyone has now had a go in the eCanter, and they all come back with the same feedback. It’s super quiet, tight and doesn’t rattle. There’s a lack of fatigue, they’re more relaxed.”

The importance of partnerships was made apparent during the event, engaging experts to assist with depot charging strategies and infrastructure – as well as bodybuilding – suited to the eCanter. To this end, there was representation from WeEV, a subsidiary of Wel Energy Trust specialising in EV transition, as well as bodybuilders Elite Truck Specialist, Ten4 Engineering and Tru Group.

The mood at the event was one of engagement over resistance.

Keep an ear out for the January 2024 Keep On Moving podcast to hear New Zealand Trucking Media talk to Keith Andrews’ Alisha Francis and Fuso New Zealand’s Ian Porter.

Ian Porter (left), product planning manager Fuso New Zealand, and Alisha Francis, sales manager Keith Andrews Trucks, talk through the eCanter’s journey before taking questions from the audience. Like any light truck, the eCanter’s uses are limited only by imagination. Swedish electric truck maker Volta Trucks willAutoSense will host the NZI-sponsored Transport Leaders Forum breakfast at the Due Drop Events Centre in Auckland on 22 February 2024.

Speakers, including life coach and BBM founder Dave Letele, motorsport legend and road safety advocate Greg Murphy and Coda Group CEO Deena Clarkson, will address the important issues facing the transport industry.

Autosense CEO Charles Dawson said the agenda would cover some of the key challenges senior transport leaders and their management teams face today: health, safety and innovation.

“The forum will prioritise the crunchy conversations such as creating safe work environments for people in transport, combatting the sedentary nature of the job leading to

health issues, and the work-life balance challenges associated with shift work transport and logistics workers face daily.”

Dave Letele’s business aims to motivate people to get fit and transform their lives. He was named the New Zealander of the Year Local Hero last year and is a living testament to overcoming obesity. Formerly weighing 210kg, he will take the audience through his emotional roller coaster, highlighting the power of determination, perseverance and the importance of mental and physical fitness in building a strong team culture.

Coda Group CEO Deena Clarkson will discuss the health, safety, and wellness strategy of one of New Zealand’s largest logistics providers. She will share insights into leading through a changing landscape, implementing health, safety

and wellness initiatives, and achieving breakthrough results and a lift in staff retention.

“We recognise there is a lot of noise going on for people outside of work that directly affects their work, especially in the mental health space. We launched annual health checks a couple of years ago, asking our teams to come in and have an hour-long session with a registered nurse to check for sleep apnoea issues, heart health and eyesight. We have genuine examples now of our employees benefitting from this,” said Clarkson.

Greg Murphy will talk about his motorsport career, emphasising the importance of driver safety. Murphy, who has more than 400 V8 supercar race starts, will shed light on the team environment, culture and technology used to enhance performance.

He recently visited the Coda Group to speak to the team about the group’s installation of safety technology, including camera systems, as a minimum fleet requirement.

“Greg engaged with our team in a way that made our drivers sit up to listen, with the strong message, ‘As all professional drivers, we need to be putting safety first every day.’ Some of our generational drivers were worried about the new safety camera technology ‘watching them’.

“Culturally, he helped us to bust that myth, and they now know the tech is designed to keep people safe, and we have seen a shift in our drivers’ perceptions.”

Tickets for the breakfast event can be purchased at autosense. co.nz/TLF.

Looking for something to do in January 2024? Head to the Thames for the fifth Wings and Wheels event on 27 January 2024 at Sir Keith Park Airfield.

The event has grown yearly from a static display of planes and vehicles of all shapes and sizes. All special interest vehicles and planes are welcome, so the public is treated to a wide range of past and present modes of transport.

Planes range from small to large, home-made models, single seaters to bigger military types.

Motorbikes also range in age and style with a few kick-starters. Military vehicles and trucks also have a presence on the airfield.

One of the highlights of the day will be an air display by NZ Warbirds. It is quite special to be able to host the NZ Warbirds in Thames, where there is a permanent replica of Sir Keith Park’s Hurricane plane, which flew in the Battle of Britain, on display.

More than 300 cars, approximately 40 motorcycles, 70 planes and an assortment of trucks and military vehicles attended the last Wings and Wheels event in 2021.

There will be food stalls, bands will play throughout the day and visitors are invited to bring the family, deck chairs, umbrellas and gazebos to sit back and enjoy the event.

This year there will be a chance to win $5000, with the purchase of a programme for $5 on the day. The winner will be drawn at 2.45pm. The winner must be in attendance to collect the prize.

Display vehicles must be parked on the airfield by 9.30am, with public admission between 10am and 3pm. The entry for show vehicles is free for one driver and one passenger and $15 per extra passenger.

Public parking is at Rhodes Park rugby grounds adjacent to the airfield. Shuttle transportation will be available for the disabled. Entry fee for the public is $15; 12s and under are free.

TRT has launched advancements in its Central Tyre Inflation System, the new Traction Air EM Series.

It follows the Traction Air E-Series introduced to Australia and New Zealand in September 2019.

“As with all our TRT manufactured products, Traction Air has made significant strides in terms of design, capability, and functionality,” said TRT’s managing director, Bruce Carden.

The Traction Air CTI-EM Series aims to redefine the standards of tyre pressure monitoring and control. The new system, designed to accommodate a variety of diverse conditions, integrates CAN-BUS protocols that are interface-capable with telematics.

The new EM Series features a simplified and improved manifold design that optimises airflow and improves pressure distribution. This enables the system to perform more efficiently, delivering improved responsiveness for traction.

The design enhances the system’s efficiency, resulting in improved tyre performance. The new EM Series consists of versatile, high-flow compact valves enabling increased airflow and comes with a userfriendly plug connection for convenience.

The innovative pressure cell’s design is 50% more compact than the existing model, allowing for enhanced installation flexibility

in tight spaces. This simplicity ensures that the system can be seamlessly integrated into a vehicle, regardless of size or configuration.

The new pressure cell is housed in a robust yet lightweight composite cover, providing protection against environmental elements without adding unnecessary weight to a vehicle. It is self-purging to eliminate moisture and dust contaminants.

“The new Traction Air EM Series is yet another example demonstrating our commitment to delivering the best possible solutions for our valued customers,” Carden added.

Traction Air was introduced over two decades ago to address the unique challenges of the Australian Outback. Today, it is a part of more than 4000 vehicles, primarily in New Zealand and Australia.

MD Engineering is celebrating its 100th custom trailer build, for Dunedin owner driver Terry Hucklebridge who contracts to Mainfreight.

MD Engineering has been specialising in custom builds since 2003, and over the past 20 years the business has grown to 11 staff members.

“We don’t chase how many we build a year, nothing we do is exactly the same,” says MD Engineering’s Michael Jelley.

Sounds like the start of a great yarn … and with the 100 Years of Kenworth celebration set to take place in February 2024, we are about to find out.

“The show is a significant investment by Southpac Trucks,” says CEO Maarten Durent, “but this is our chance to recognise those who have been so loyal to the brand over the years.”

“From the first flags you see on Mystery Creek Road right down to the line-up of trucks, KW100 will be a once-in-a-lifetime event. We have made sure that everyone has a chance to share the celebration in some way.”

Richard Smart, general sales manager at Southpac Trucks, has some top tips for those planning their travel. “First up, if you plan to bring a truck, register now. We

don’t want anyone to miss out.”

A highlight of the registration list is the Uhlenberg Haulage fleet, with each of their six registered trucks having special significance. As Tony Uhlenberg explains “We are bringing an SAR from four different models: T610, T409, W924 and a new Legend W900. We’re also bringing a W923 S2 from 1982, owned since new, and another old favourite: the 1985 W924 that we bought new, sold, and then re-purchased.”

The first two days of the event are dedicated to parking up trucks in the order they arrive.

“From the time parking opens, we will have merchandise, food, and drink vendors operating. Entry to the venue over these two days is limited to the driver and passenger of each registered

truck,” Richard says.

Saturday is Show Day and the public can attend to view what is believed to be the biggest singlebrand truck show ever held.

There will be facilities for those staying on-site in their sleeper cab trucks. All trucks must stay in place until 7pm on the Saturday.

“We’d love to be able to suit everyone,” Richard says, “but the reality is when we look at keeping people safe, and the value of the trucks involved, there needs to be clear limits in

Blind spots are a major contributing factor in heavy vehicle vs pedestrian/cyclist interactions, particularly in left hand turns. MAX-SAFE have a range of solutions to help increase the driver’s awareness of vulnerable road users around their vehicle. Our solutions include optional visual and audible alerts for both the driver and the vulnerable road user i.e. inside and outside the cab. One such offering is MAX-SAFE Side View™: an affordable solution based on an AI camera that detects and protects pedestrians/cyclists – ultimately enhancing safety.

place.”

It’s the two-day part of the event that Tony Uhlenberg is particularly looking forward to.

A loyal Kenworth enthusiast for many years, Tony says that the nostalgia aspect is a draw-card.

“I’m looking forward to a trip down memory lane, catching up with old faces and new over the Thursday and Friday. It will be great to share that Kenworth magic with the public on the Saturday.”

PROVIDES ASSISTANCE to the driver.

• SAFEGUARDS the side of the VEHICLE.

• PROTECTS PEDESTRIANS, cyclists and motorcyclists.

• HIGH ACCURACY – detects people (stationary and moving).

• MORE AFFORDABLE than sensor systems.

• SUITABLE for most ANZ CONDITIONS.

• Provides ALERTS and AUDIBLE WARNINGS.

• STATE-OF-THE-ART AI TECHNOLOGY.

• GREATER SAFETY and PEACE OF MIND –for Drivers & Fleet Managers.

• Part of the MAX-SAFE SAFETY ECO-SYSTEM.

This month’s winner is one of the standout Kenworth K200 combinations owned and operated by Guy & Helen Knowles of Palmerston North. Driver Mark Hocking sent us this impressive early morning photo, taken while doing his pre-flight checks at the home-base yard.

ENTER NOW TO BE IN TO WIN

Send your best night bling photo as well as contact details into nightmoves@nztrucking.co.nz

Tokoroa-based Central Equipment Movers is founded on decades of hard work and opportunity-seeking by James family patriarch, Colin. The company’s latest Scania 770S prime mover is an exquisite tool that will make a heavy job that much lighter for the business’ next generation: Colin’s son Matt.

Story by Gavin Myers and Dave McCoid

Story by Gavin Myers and Dave McCoid

and video by

Photos Gavin Myers, Dave McCoid and Carl KirkbeckThere are some days when you don’t care if you have to be out of bed at 2am after just three hours sleep. The reason just makes it worth it: buzzing with childhood excitement, wideeyed alertness and a ‘let’s do this!’ attitude. Okay, so we had to be up at 5am, after what could be considered a full night’s sleep, to meet Matt James and his new

Scania 770S at Shaw’s Wire Ropes in Cambridge by 6.30am. But the excitement was all the same…

Now, whether it’s the machine, the company, the operator’s story, or a combination of these, all the trucks that grace the cover of New Zealand Trucking magazine are special. Some, though, rise above what one might otherwise consider ‘run of the mill’ to be that little bit more

special. Sure, anything with more than 700hp can be considered a little special – but when leisurely cruising the highways at a ‘mere’ 58 tonne, it’s working well below its designed potential.

No, what we’re getting at is big gear moving plus-size loads in tough country. In this instance, we’re talking 770hp, more than 80 tonnes, and the guts of logging in northern Hawke’s Bay,

about 21km off the beaten track up some gnarly dirt road.

It’s not often we get the opportunity to pursue an oversize load – pilots and all. The last time we had this opportunity, we’d followed the Prestige Building Removals Peterbilt 389 from Auckland to Kinloch for our October 2020 issue.

It’s fair to say house moving

is the pinnacle of shifting oversized goods – when you’re in the cab alongside the driver, the mind boggles witnessing the continuous communication and constant teamwork between driver and pilots to navigate past obstacles ahead, to the sides, above and below.

In house-scale terms, Matt’s load today isn’t quite a Remuera mansion, but it’s certainly more four-bedroom villa than tiny home. With the Sany SY415H Pro tracked excavator positioned on Matt’s MTE three-rows-ofeight widening low loader, we’re measuring 24.5m long including truck and dolly, 3.7m wide and 4.8m high. Weight is about 86 tonnes all up.

“This isn’t the biggest we

do,” Matt says. “Those real big log haulers get up around 80 ton alone, and they’re higher and wider. Though we try to stay under 5m height, because anything over that you have to get power board permits.”

Be that as it may, she’s still an impressive load. This one might require a little bit of effort…

The Sany is a shiny new unit fitted with a New Zealandmade Woodsman Pro 850 tree harvester, supplied by Shaw’s and destined for a skid site on Pukeorapa Road, inland from Mōrere in northern Hawke’s Bay.

The quirks of shifting oversized loads being what they are, our route will take us down the Waikato Expressway, over the Kaimais to Tauranga, through

Whakatane to Taneatua, on to Opotiki and the Waioeka Gorge, before we overnight in Gisborne. Day two sees us continue south on SH2 into Hawke’s Bay.

From there we’ll turn off the beaten path just past Mōrere, onto Mangaone Road, which leads us to Pukeorapa Road and deep into the hills.

Guiding us along the way are class 1 pilots Nadine Bell and Tom Mitchell of Overdimensional Transport Services. Nadine has been on the job since 2006, and most of 71-year-old Tom’s career was spent behind the wheel, including heavy haulage for Smith and Davies and Hawky Haulage, before piloting. Auckland-based, servicing the North Island, the two have been

working together for four years and, from what we saw, make a formidable team.

It’s a picture-perfect morning when we arrive at Shaw’s. Matt’s already got the Sany positioned on the trailer and is beginning to chain it down. Rarely do we arrive to be greeted by an obsessively spotless machine positioned perfectly in the morning sun, just waiting for the cameras to come out. It’s a perfect opportunity, so while Matt finished up, we oblige the big Scania. It’s gorgeous in pictures but even more so gleaming in the early morning sunlight. Scania’s ivory white provided the canvas for Marty’s

of Mt Maunganui to apply the dark silver, orange and grey colour scheme. The truck has 138 Narva lights on it (270 if you include the trailer), but in no way does it look overdone. The more you look, the more you see, the more the little details stand out – like those awesome little V8 lights at the base of the mirror arms. It’s a superb-looking machine, a conversation-starter if ever there were one – as we’d be reminded every time we’d stop for a bit.

As he does his final checks, Matt takes the opportunity to talk us around the trailer. It’s a refurbished MTE three-rows-ofeight Linkwing widening low loader coupled to a MTE tworows-of-eight dolly.

“MTE builds a good low loader,” comments Matt. “We spec our trailers differently to, say, run-of-the-mill builds. We use bigger Linkwing pins to cope with the off-highway bits at big weights. Our ramps are 300 to 400mm longer and have cut-outs in them so when we do a hauler with a pole, we put a bar through the ramps and we can just sit the machinery on there and away we go.

“The trailers have remotecontrolled, double-acting ram (powered up and down) hydraulic suspension, so if I need to level the trailer as I’m moving along, I can do it from the cab. And our existing four-rows clipon goes straight onto it, which makes it more versatile.”

Loaded up and ready to leave Shaw’s.

Cruising down SH2 Tauranga Eastern Link.

Kaimais? No challenge.

The Scania was built to handle the rough stuff. Moving through the spectacular Waioeka gorge.

Loaded up and ready to leave Shaw’s.

Cruising down SH2 Tauranga Eastern Link.

Kaimais? No challenge.

The Scania was built to handle the rough stuff. Moving through the spectacular Waioeka gorge.

Before we know it, the V8 is eagerly purring. Nadine and Tom file into position, and the big Sany begins its journey to its new home. Immediately, the radio lights up with Nadine and Tom calling the way forward. The chatter is constant and awesome to listen to, and it’s obvious Matt, Nadine and Tom have a good working relationship.

“We’ve got our own pilots, but there’s so much going on at the moment. Nadine is our first port of call when we need a subbie. She’s very good, very thorough … normally pilots don’t tell you

enough, Nadine almost tells you too much,” Matt says with a laugh.

Likewise, Nadine has the utmost respect for her client.

“We’ve worked with CEM for a while. The Jameses are a lovely family. Genuine, down-to-earth, hard-working people,” she says. As we’d witness over the two days, it’s a model example of customer and contractor working with utmost trust, in perfect congruity, as efficiently as possible.

The Waikato Expressway poses no challenge to the big Scania,

while the Kaimais are dispatched at nothing less than 30km/h. Before long, we’ve passed Tauranga and are headed for the Matata Straights bound for Whakatane.

This would be our first real obstacle, as bridge restrictions between Awakeri and Taneatua mean Matt has to detour through the town. He crosses the Whakatane River Bridge, turns onto Landing Road, negotiates the roundabout at King Street, and makes for Taneatua Road.

It’s tight at some points, and lunchtime traffic through the

town doesn’t make it easier. But the Scania makes easy work of the leg from Taneatua to Opotiki, and before long we’re barrelling into the Waioeka Gorge. By the time Trafford’s Hill has been pummelled into submission, the beautiful bluesky morning has given way to thick grey cloud and sheets of rain. That wasn’t the most depressing part of the trip, though, as through the gorge Nadine had been drawn into a little spat with an indignant road worker who would not shift road cones in the way of the truck for

Matt descends Trafford’s Hill, Gisborne bound.

Matt descends Trafford’s Hill, Gisborne bound.

it to get through.

For pilot and operator alike, the ignorance among other road users (including some road workers with a mightier-thanthou attitude) is not only the biggest frustration of the job, but also the greatest hazard too.

“Road users and other traffic are what we have to watch out for most. You have to be vigilant. If I move into that grass, it’ll throw me over. So if I have to sit on the centre line, then I’ve just gotta do it,” says Matt. “You get the odd person who bitches and swears, but it’s just one of

those things. They get plenty of warning, especially if the pilots are far ahead like they should be.

“This job is not for everyone. In heavy haul, you either have it or you don’t, there’s no in between,” he continues. “It looks easy just burning along like this, but I’ve been doing this for 16-odd years now, that’s why I’ve written that…” he says pointing to the sun visor.

…is inscribed on the back of the sun visor. Matt reads the phrase

each time he gets into the cab. Watching Matt load and operate his unit, it’s obvious that’s his approach to the job.

“It’s one of those jobs you could do 100 times and it would be different each time. The machine’s position on the trailer makes a huge difference; you could go around corners 10km/h slower because it’s too far forward. Stuff like that. There are so many variants in heavy haulage, there’s so much more involved. You’ve absolutely gotta cross your Ts and dot your Is.”

Those who know CEM

will know the company is synonymous with big Kenworths. For Matt, the Scania represents “a massive change from American gear”.

“There were a few reasons for ordering a Scania,” he explains. “First, I wanted to give something else a try. Plus there’s a history with the name in the family –dad’s nickname being ‘Scania’ [an amusing story for later]. Add to that the insurance policy and worry-free operation that is ScanPlan, plus what you get for the purchase price … you just couldn’t not.”

Moving out of ‘straightforward’ American gear into the techfest 770S meant learning to drive it as efficiently as possible was important, and Scania driver trainer Radu Radulescu was just the man for the job. “Radu’s given me a whole different outlook on how to drive it. I can’t talk about him enough; the product knowledge he has is incredible. His tuition is so important with these vehicles. You can try drive it like an idiot and no matter what you try and do to it, it looks after itself – but it’s capable of so much,” says Matt.

Making life behind the wheel that little bit more comfortable doesn’t hurt efficiency either. By now we’re well acquainted with S-cab Scanias. We last sampled one as recently as September with Fenco’s 660S, and before that in April when we hopped aboard Martinborough Transport’s S770 stock unit. We went into a full description of the big Swede’s interior environs in that article and there’s not much more we can say about it that hasn’t already been said – save for the fact that Matt’s is a flatfloor unit (770S as opposed to S770), doesn’t have the upper bunk, and is short the coffee machine.

But the norm isn’t Matt’s style, and he’s gone all out to truly make his truck his own. To begin with, he ordered the cab with full black upper trim, with only the lower dash and door panels left in the standard grey. Upon landing on our shores, the customisation wizards at RVE were enlisted to work their

Caption: 1) Wise words. 2 & 3) RVE does it again. 4) Matt is very much at home in the big Scania. 5) Not much we haven’t said about a Scani NTG cockpit ... except, in this instance, there’s a third pedal! Matt spec’d a clutch for those extra-precise manoeuvres. 6) Comfort, convenience, home away from home.

magic, re-profiling the seats into deeply bolstered buckets and covering them, the back wall, ceiling, upper walls and door centres in black leather with red stitching.

Combine that with the full air suspension and fully airsuspended cab, and the big Swede offers up one of the cushiest rides in the business. And just as well … it’s day two and we’re heading out of Gisborne south on SH2, and it doesn’t take long to begin to question your powers of perception. It’s honestly amazing the road we’re on is SH2. “Well, look at SH1, it’s a joke. The roads are rooted,” Matt quips.

If the first leg of our journey was relatively easy-going, this leg certainly highlights the 770’s strengths. The road surface is rougher, its width is narrower, the inclines and descents are steeper, and Nadine’s call ahead of almost every bridge is, “Crawl central, 10km/h”. It’s only a two-hour drive out to Pukeorapa Road in the Scania, but there’s a lot going on. The radio is alive between the pilots, Matt, and other truckies.

“One light vehicle coming over the brow … braking.”

“Oncoming three-seven wide, driver, if you wouldn’t mind easing up and moving hard left through the bends.”

“Third bridge is just around the bend – keep central.”

“Vehicle keeping oncoming. God, they’re ignorant eh!” Through it all, communication is critical. Complacency is not an option.

The Whareratas stretch for about 30km from some way south of Muriwai to just about Nuhaka, crossing the boundary between Gisborne and Hawke’s Bay somewhere near the summit. Each side would be considered steep under normal circumstances; moving 86 tonnes up and over the hill is a whole other challenge.

At the foot of the climb, Matt finds a spot to pull over and

allows the traffic build-up to pass. Then we’re off. First gear, second, third, fourth … The 770 moves off like a big, hefty car. Not a hint of strain, no bucking or protest. It’s like 80-plus tonne is nothing. Into its stride and we’re climbing at a steady 30km/h at 1600rpm in seventh.

“This truck just sets the standard on the highway,” Matt says. “Sure, a lot of heavy hauling is in the gearing; the gear ratios must be suitable for the job. We’ve gone for a 4.38:1 axle and 4.21:1 hub reduction. That’s also part of why this thing goes so well.”

On the point of axle spec, the front axle is another important piece of the heavy-haul puzzle, and Matt’s 770 is thought to be the first in the world – certainly the country – with an eighttonne front axle on air.

He continues: “We’re up and down hills, so I’m running the power divider in as well. Some wouldn’t, but for me, it’s peace of mind. If we can eliminate wheelspin then why not? The way I see it, it’s better to have two diffs working for you than one. It’s got to be better on the gear.”

We’re still climbing and the 12+2 OptiCruise ushers in another gear. It’s almost imperceptible, with hardly any interruption to the flow of the V8’s 3700Nm. It just shifts gear and carries on. Superb!

It’s not long before we’re into the steepest section. The 770 drops to sixth and holds 23km/h at just under 1500rpm … 20km/h … 18km/h … 17km/h … It drops two gears and recovers to 19km/h at 2000rpm in fourth – before grabbing the next gear and building the momentum again riding a wave of torque.

We summit at 22km/h in fifth at 1800rpm to the soulful tune of a large-capacity V8 earning its crust. And boy, does it ever. No doubt either that with just less than 20,000km under its wheels, there’s still more in it.

Over the top and Matt explains he’s got the Scania’s downhill

This page: All in a day’s work… Matt removes the Sany, loses the dolly, narrows the trailer, reloads the Sany with some guidance from Tom, chains up once more, and gets ready to head up the hill.

speed control set to 43km/h with a 3km/h overspeed, but it’s not an option right now. “The problem with that here is I need to control it. I need to slow it right down and do what I need to do to control the momentum,” he says.

With that he sets the retarder to the third of its five stages, with the revs sitting in the 2000 to 2200rpm blue sector of the tach, which indicates the optimum engine speed range for the retarder.

“The retardation is incredible,” he comments. “You often find yourself backing it off, even at this weight.” We progress

down the hill at a smooth and consistent 25km/h. With the rain having now drenched the road, Matt comments he can feel the wheels begin to lock up and applies a bit of balance with the trailer brake. However, all feels smooth and in control from the passenger seat.

Before we know it, we’ve arrived at Mangaone Road, the start of our dirt-road climb into the hills and our destination almost 600m above sea level. As it is, the route up is challenging –tight, twisty and steep in places.

Current rainfall has only added to the task, and in places has turned the dirt beneath our

feet – as our good Captain K put it – to porridge. Matt’s plan is to off-load the Sany, disconnect the dolly and leave it behind, narrow up the trailer as much as he can without risking the merchandise, drop the CTI, and go for it. The narrower trailer means reduced stability, but it’s the only way to make the tighter bends.

It’s just on 9am by the time we get moving again, but today slow and steady wins the race – thankfully the rain has stopped but we still won’t get to the offload site for another 90 minutes at least.

The drive up is spectacular, a real challenge for the driver, sure,

but there’s more than enough time to take in the scenery. Climbing higher we enter the clouds, and from the point of view of Nadine’s car ahead, the Scania’s lights cut through the fog as the beast emerges. Epic.

Behind the wheel, Matt’s attentive, vigilant, feeling his way through the constant changes in the surface below. The Scania’s doing remarkably well maintaining traction, though Matt’s got some nifty tricks up his sleeve when it starts to scrabble.

To aid progress, he uses the load transfer to shuffle the load between the drive axles by adjusting the pressure in the

airbags. This allows him to load up the rear of the truck and, with the power divider engaged, the Scania digs in its heels and keeps climbing. And if needed, Matt can also lock out a drive axle to make it single drive.

The biggest feather in the Scania’s cap probably came from the grader driver who gives real heavy stuff a helpful tow up a particularly difficult section: “That was the easiest tow I’ve ever done – and I’ve done hundreds!”

Indeed, riding in the Scania, Carl noticed the wire rope was slack most of the way up except for a few tight turns.

We reach the drop-off site

and the chains come off the big Sany. It still has to go another kilometre into the hills to reach its skid, but it can do that on its own. Heavy haul being what it is means there’s no return load for us to follow Matt home with, and so arriving back in Gisborne our time tagging along comes to an end. Not that we felt short changed – not one little bit. Indeed, while this wasn’t our first taste of a Scania 770, it was certainly a special way to end 2023. Special doesn’t quite sum it up though … no, each time one of us climbed from the cab, we summed up Matt’s machine with one word: Effortless.

Matt would like to give special thanks to all those who helped get the Scania on the road and support CEM’s business. So, in no official order:

Andrew Lane and Emma Okeefe (Scania Finance) – “They were so good to deal with. Nothing was a problem and I can’t thank them enough.”

Radu Radulescu – “An unsung hero of the Scania team.”

Robin, Lloyd, Grant, Harry and the boys at MTE – “They’re all awesome to deal with. Nothing was ever a problem getting the low loader refurbished.”

John, Hayden, Josie and Josh at Lilley HT Trailers, Rotorua – “They did a phenomenal job on the deck plates, guards and rear-end set-up on the tractor.”

Tim Patterson and the team at Narva – “They came to the party hugely with all the lighting. We went to them with some way-out ideas and they looked after us.”

Shaw’s Wire Ropes –“We have a real good working relationship. They’re a good bunch, honest hard-case straightshooters.”

Nadine Bell and Tom Mitchell of Overdimensional Transport Services –“Honest, hard-working, valuable partners. A top team.”

Another Sany/Woodsman Pro 850 combo, supplied by Shaw’s Wire Ropes, arrives to start work.Ha! He thinks he’s going to retire and I’m going to pay him to drive a campervan around America!” laughs Matt James. “I could pay him four million dollars to retire, and he’d turn up again the next afternoon. This place is him.

“But that’s good, that’s okay you know, I need him … he’s got so much knowledge.”

Thirty-six-year-old Matt is the eldest of two sons who both work in the family business their parents started in 2005. Taylor, 29, is New Zealand’s No.2 drift car driver in the D1NZ National Drifting Championship (‘2-NZ’ as it’s referred in sliding circles) with goals and aspirations one would quite rightly have with that level of talent.

“T’s on a different path; his focus is always the car, and he itches to get back to it. I’m a truck person. I love the business, what we do, and love the trucks. Don’t get me wrong, he does too. He’s just in a different place at the moment. I love putting what the business provides back into the gear – as you can see.”

Born in Auckland, schooled in Puriri near Thames and Tokoroa, Matt’s official – outside the family – introduction to trucking came in the form of 100-tonne payloads in the Pureora Forest off-highway when working his first job for JB Logging.

“It was pretty cool, I was 17 carting to the super-skid.”

Still with JB Logging, from there he took a 6x6 Scania to the Hawke’s Bay forests for a spell.

Like his dad, his first gig in on-highway truck driving came in the famous colours of T Doidge under Digby Cameron, before a couple of years with one of Tokoroa’s other famous transport sons, Alan Forbes.

Like so many in his generation,

Matt’s grown up in a busy economy with historic low unemployment. That’s allowed him the opportunity to explore the options available and gain broad experience in whatever spins his tyres.

Linehaul freight for local Tokoroa company Fletcher Transport and Waihi’s John and Irene Lockley, even a stint for John Kelly’s HHA in Australia, appear in the Matt James life book – the latter described as interesting, eye-opening and short-lived.

Home from Australia towards the end of the century’s first decade, Matt went shares with his dad in an ex-demonstrator Cat CT630 bulk tip unit for about two-and-a-half years. Readers will remember it in striking yellow and black Cat livery.

“I love bulk work. It’s great, but the big players trim it up so much you can’t make anything out of it. We had the truck for three years and sold it on to Ray Lincoln.”

From there it was a stint with Pollock Cranes in Mt Maunganui before working for the late Ronald ‘Huck’ McCready, first at Partridge’s Rotorua in an operations role prior to taking the wheel in the ex-Land Tech Scania, also owned by Huck, and then on to the Rowe Motors Western Star, out of Mt Maunganui.

He then made the move home to the family business, where he’s well settled with eyes on the future.

“Yep, I’ve got plans for the future. Dad’s comfortable in the forest and I want to get into a bit more work outside that environment, just to spread the risk a little. That’s part of the reason for this,” he says, pointing to the Scania.”

Then he trots out a bolshy Matt James classic!

“There’ll be many judges, many characters, and plenty with a lot

(Top) Matt and (middle) brother Taylor secure another Sany. (Bottom) The General in its latest role – D1NZ drift car transporter for Taylor.

to say, but at the end of the day, they’re leaving someone else alone if they’re talking about me.

“It’s just a next-generation thing, ideas and that. Dad can be quite set in his ways and we won’t and don’t agree on everything, but we get on and it’s great he’s

here, still so passionate and active in the business, and letting me have some responsibility to make decisions. Like I said, there’s so much knowledge with him and we’re writing the next part of the story.”

The forest plantations of the central North Island are incredible places. In their silence they speak to so much – endeavour, challenge, camaraderie, a sense of purpose. As a result, they spawn wonderful communities of people, a specific type of people. People who understand good

times and bad, who understand opportunity is one thing –recognising and acting on it is another. That nothing comes without effort, and work-life balance is whatever you make it. Historically, these folk often grew up, worked and grew old together. ‘Balance’ was centred in the word community, not

delineated by the act undertaken. There was no burden in the need to work, especially when you worked in and around your mates.

The forests have provided a life and lifestyle for many they themselves might not have thought possible as kids kicking stones on their way to school. Again, the opportunity was all around them, they just had to see it.

A giant natural and commercial ecosystem, it engenders a sense of contribution without grandiose – thinking you’re bigger than the whole will never do here. The fact you revisit a forest compartment twice, sometimes three times in your life, teaches, even subconsciously, that although your contribution is critical and of huge worth, all this was here before you came, and it will be here after you’re gone.

As a result, success can be difficult to spot. These people are often all about the journey. That’s not to say it’s short on characters. Humility is allowed

a larger-than-life personality; they’re in no way mutually exclusive.

Although the forest economies have felt the pressures of modern times – a lack of people, and a generation for whom choice in a borderless world is a way of life – it’s not hard to find true forest folk who honour it all. Even better, folk who have passed onto their own the sense of opportunity the green giants hold. It’s why we’re at the Central Equipment Movers Old Taupo Road depot in Tokoroa, to meet the James family.

Colin James, aka ‘Scania’, is a Tokoroa son and child of the mighty Kinleith Forest that surrounds the pulp and paper mill bearing the same name. He was born and grew up not 200m from the Central Equipment Movers yard, and the house he and wife Deb live in today. He’s the living embodiment of everything that’s great about the area and people. Sharp as a tack, he’s a hardworking, jovial, cheeky, charismatic character who will always give an already happy

‘Scania’ on the

Loading Gordon ‘Boot’ Hill and moving to the next skid to top off – you have to get your ute there somehow.

Returning to the same place in a different era. This big Scania has his name on the door though. Maybe it will inspire a wide-eyed kid somewhere.

Proudly in the bush, NZFP Crew 12 – Colin at far right.

Returning to the same place in a different era. This big Scania has his name on the door though. Maybe it will inspire a wide-eyed kid somewhere.

Proudly in the bush, NZFP Crew 12 – Colin at far right.

1

) The truck that started it all and (2) the truck that sealed the deal: the

gathering, ‘that little bit extra’. He will hate all this being said, and run for cover – that’s the forest in him. He’ll probably try and stop us printing that line, but son Matt will no doubt help us there. He and sibling Taylor are chips off the old block, dead straight barrels with few prisoners taken – a spade is a spade.

‘Scania James’. A label assigned to him in connection with a big, largely white, cabover Scania truck – not the one parked in the yard below the office. Like the trees all around them, you could say things have come full circle. But the new one is Matt’s brainchild, not Colin’s. I guess just because you revisit a compartment years later, doesn’t mean you replant it each time.

“The Roundwood yard over the fence,” says Colin, sitting in the office and pointing out the south-facing window. “It used to be GM Fellingham Ltd. I lived just over there,” he says, pointing out the front window facing northeast, “and spent all my time riding around with drivers Graham Duff and Murray Bayer (a well-regarded old-school driver who later drove for us for many years) in one of their three TK Bedford trucks. They repowered his truck with a DS8 Scania motor, and then in time bought New Zealand’s second Scania truck – an LB80… I think John Beasley had the first?

“Anyway, that was followed by another LB80, then a 111, and then an LB141 with the 375 V8. That was big gear in the early 70s! Pretty much the equivalent of that thing down there […he loves it really]. Apparently, at school and then even later on in the bush, I wouldn’t shut up about these Scanias.”

There you go, how Scania got his name, and why the 770S has ‘The man, the myth, the legend’ as a holographic watermark on the rear sleeper wall.

Colin’s dad worked in the silviculture and fire prevention side of the forest industry. Not surprisingly, Colin’s first job out of school in the late 70s was at Fellingham’s as the loader driver. From there he went into the bush, doing his time with a harvesting gang before

coming out and working for three years on the Kinleith weighbridge. In this time, he secured the coveted HT and trailer licence courtesy of New Zealand Forest Products’ Kenworth, fleet No. 71.

“I would spend all my spare time hanging around at places like Dahms and the local trucking community generally.”

A short period driving stackers at Kinleith preceded his first on-highway driving job at one of Tokoroa’s true iconic trucking brands of the era, and International stronghold, T Doidge.

In his time at Doidge, Colin drove an International S-Line, a truck he really rates in his career. He recalls company owner at the time, Ray Mildenhal and says with a laugh, “it was the good old days.”

For a young fella with the level of enthusiasm Colin had, there was any and all manner of driving available.

“Errol Hanley carted short pulp out of eastern Taupo with a Cat 450 V8-powered cabover Kenworth. Just unheard of power. He asked me once to drive it on a Saturday because he had a wedding or something to go to. ‘Let them put a good load on you, and keep the boot up it. You shouldn’t have to drop into the low range between eastern Taupo and here.’

On the way home I was in the low range about four times, and remember thinking ‘What the bloody hell am I doing wrong?’ I crossed the weighbridge at 58 and a half tonne. Doh!”

We all invariably end up with some little anecdote in our careers, something quirky or cool, but ‘Scania’ has a real doozy. “I carted the last docketed load over the Kinleith weighbridge in a Doidge International R190. My truck was in the workshop and Mildenhal pointed at the 190 and said, ‘You can drive that’. ‘Really?’ I said. It was the last of them and it was for sale.

“When I got back to the yard, Mildenhal said, ‘they’ve sold that truck so that’s the last Doidge R190 load ever into Kinleith.’ Pretty, cool all right. Funny, we recently shifted a machine

from up Cashmore Road where I got that load from.”

From Doidge’s, Colin went to Trailways for some full-on Kaimai Ranges action, and under Brent McCombe’s management, he almost stepped into his first owned truck.

Stretching his legs, he and wife Deb’s next move was up the road a little to the bright lights of Auckland where Colin worked for a couple of years for Danny Lendich. “He was a good boss to work for. He had his own ways but that was all good.”

The couple’s first venture in business was to follow with the purchase of Addis Cranes. “That came with three trucks and a bit of gear, but let’s just say it wasn’t all it was made out to be. We ended up walking away from it after about three years. It was just too hard.”

By this time, Matt was on the scene, and the family moved to Puriri near Thames and Colin took on work with Provincial Freightlines, first as a driver and then in operations. “That was a good period. I had brought some work and contacts with me, and Dave Malanaphy did a revenue share thing for the work I brought to the table. There were loads out of Pukepine, and Roundwood from down here. I’d call in and stay at Dad’s when I was home.”

The home fires beckoned however, and in the mid-1990s the James family moved back to Tokoroa, after which Taylor arrived on the scene. Colin worked driving a transporter for Colin Sargison’s Rotorua Forest Haulage before heading back in the bush to operate a hauler for Alan Sinton. He also did a four or five-year stint in the bush driving loaders for Gordon Dahm at Rob Dahm Ltd, loading out logs in the ‘cold deck’ loading days.

With the depth and breadth of experience in and around the industry, Colin made an obvious choice for a key front man when Trevor Woolston launched Logger magazine in 2003, taking the role as machine field tester and business development manager for the first couple of years. He was able to give a great publication for the forest industry real credibility. “Bloody production weeks! You

GM Fellingham Bedford TK repower and the LB141 V8.

know what they’re like. I don’t miss those at all,” he says with a laugh.

As is so often the case, it was a beer with some mates that would lead to the family’s commercial destiny. “I was having a beer with Alan Sinton and some mates, and he was really pissed off with the service he was getting from his supplier for machine shifts. Back then there were no contracts, and the crews could use whoever they liked, paid for by the forest company. He said, ‘I should buy a truck and get going’.”

And so in 2005, Central Equipment Movers was born. The first machine was as close to a sure-fire bet as you could get, one of the legendary original T900 Kenworths bought by Mike Lambert. T9005 was driven new by Andrew Douch, and was now being called upon to help stand up the fledgling enterprise.

“A four-and-quarter Cat, 18-speed, 44,000lb rears at 4.56. Lambert bought them all with Jacobs and Brake Saver, they had power dividers but no diff locks.” Although a modest rear end for transporter work, nothing was altered beyond the shortening and set-up for heavy haul.

If you wanted to make sure your first unit really did have all the good juju, then hooking the late Dale Hoyt’s dolly and three-rows transporter behind the Kenworth was certainly one way of doing it.

“She’s done 3,000,000km, plus whatever’s on the clock now – about 180,000 I think. Great

5) The single stack tells us this shot is early in the The General’s life with the company. What a classic image cresting Tarr Hill on SH1, southbound. 6) State trooper with the last ever 009 Madill hauler leaving Kinleith. 7) A classic Central Equipment Movers scene. Big Red was eventually lost to fire, but here the big Kenworth C508 leads the T909 through the Kinleith forest with a pair of Sany processing machines on board.

3) HT licence secured courtesy of NZFP fleet No.71. 4) The first on-highway permanent drive, an International S-Line for T Doidge.

3) HT licence secured courtesy of NZFP fleet No.71. 4) The first on-highway permanent drive, an International S-Line for T Doidge.

machine.”

Today the Kenworth tows Taylor’s drift car trailer, so still gainfully employed in family duties.

Enthusiastic, service-focused, and part of the local community, Central Equipment Movers has grown steadily in its 18 years and has been well served by the bulk of its trucks. The first new truck was the 4900 Series Western Star State Trooper that Colin and Matt say was a magnificent machine.

“It had a C16 Cat in it, and not far into its life I fitted a set of C18 injectors. Soon after, I took a hauler over the saddle from Turangi to National Park and it was drinking fuel at the rate of .01kpl – that’s a litre every 10m. The crew at Goughs couldn’t believe it, and it was on their wall of honour for years. The foreman at the time said if you were standing on the motor and poured it in with a bucket, you still couldn’t get it in as fast.”

It’s not all been plain sailing: Big Red the C5 series Kenworth, was lost to fire, but all in all, it’s a typical James’ journey – looked on as an adventure, and enjoying the ride.

It’s a fascinating work profile with much of it undertaken away from the public eye and VDAM compliance. In the bush, haulers and machines can be moved fully rigged, even with the spar up on occasions, and GCMs in the 110 to 130-tonne range are common. It makes for an impressive photo collection, that’s for sure.

Today the fleet comprises five transporters. A Kenworth T909 bought new, the ex-Jilesen

Contractors sleeper-cab T908, two T404 Kenworths ex-T Croft in Greymouth (nicknamed Mario and Luigi – trucks Matt says have been a bloody good buy), and of course the 770S Scania – named Suspicious Minds, both a tribute to Colin’s favourite Elvis song and Matt’s observation on the transport industry. Bringing up the rear is an Isuzu 8x4 crane truck, used for all manner of support and on-site mill work. There’s also a quad-trombone for the long and longer.

In terms of succession, we have the answer to that in this story. Matt has the bit between his teeth and is intent on honouring the values his folks have built the business on in its first two decades. It’s typical of the ilk, again, like a repeat visit to a forest compartment, that he’s being given the opportunity to put his stamp on the operation and grow in the business. “Dad said ‘it’s your turn to buy a truck’, and here it is.”

We end the story in the corner of the yard, in ‘the shed’. A shrine to all things – trucks, business, memorabilia, stories, and recollections. A celebration of life, great people, and adventure. It’s a typical James’ venue, a place that allows everyone – whoever they might be – to simply be themselves. Who you might find in there at times would drop your jaw – yet the reason they choose to congregate at this place speaks volumes to the family who create the environment.

Colin sits at the leaner, “I’ve got a couple more years, and that’ll be enough I reckon.”

Yet another Tui ad!

Tare: 10,640kg (load cert)

GVM: 34,000kg

GCM: 150,000kg

Wheelbase: 4425mm

Engine: Scania DC16 123

Capacity: 16L

Power: 566kW (770hp)

Torque: 3700Nm (2729lb/ft)

Emissions: Euro-6

Transmission: Scania GRSO926R Opticruise 12-speed + 2 crawler gears

Clutch: K432 70 – manual and automatic operation

Front axle: Scania AM622S

Front-axle rating: 8000kg

Front suspension: Scania full air, extra-stiff anti-roll bar

Rear axle: Scania AD400SAP at 4.38:1, with hub reduction at 4.21:1

Rear-axle rating: 26,000kg

Rear suspension: Scania full air

Brakes: Disk. ABS, EBS

Auxiliary braking: Exhaust brake, Scania R4100 retarder

Additional safety: Hill hold

Fuel: 300L x 2

DEF tank: 80L

Wheels: Alcoa Dura-Bright alloy

Tyres: 385/65 R22.5 (f ), 295/80 R22.5 (r)

Electrical: 24V

Cab exterior: Highline 2m sleeper cab, Comfort airsuspended cab with mechanical tilt, Tinted windscreen, External sun visor, automatic LED headlamps with LED daytime running lights, automatic wipers, heated mirrors.

Cab interior: Driver identification, tilt and slide V8 steering wheel, Premium seats with RVE custom treatment, RVE custom cab treatment, black leatherette V8 door trim, Premium audio system with Bluetooth and rear-facing camera, Premium climate control system, 8001000mm widening bed, microwave, refrigerator.

What a supremely awesome few days spent with Central Equipment Movers! Matt and Colin James, thanks for your time, your stories and your enthusiasm for us to feature Suspicious Minds