A Western Star 4900SXC off-highway unit operated by RFH heads to Kawerau along the Million Dollar Highway with a load out of the

DIRECTOR

Margaret Murphy

EDITORIAL DIRECTOR

Dave McCoid

027 492 5601 dave@nztrucking.com

EDITOR

Gavin Myers 027 660 6608 gavin@nztrucking.com

For all advertising enquiries:

ADVERTISING MANAGER

Pav Warren 027 201 4001 pav@nztrucking.co.nz

Mike Devon 027 332 4127

mike.devon@nztrucking.co.nz

Maddy McCoid 027 336 6811 maddy@nztrucking.co.nz

SUB

Shannon

021 182 4803 shannon@nztrucking.co.nz

CONTRIBUTORS

Craig

Niels Jansen (Europe) Paul O’Callaghan (UK, Europe,

New Zealand Trucking magazine is published by Long Haul Publications Ltd. The contents are copyright and may not be reproduced without the consent of the editor. Unsolicited editorial material may be submitted, but should include a stamped, self-addressed envelope. While every care is taken, no responsibility is accepted for material submitted. Opinions expressed by contributors are not necessarily those of New Zealand Trucking or Long Haul Publishing Ltd. All rights reserved. This magazine is subject to the New Zealand Press Council. Complaints are to be first directed to: editor@nztrucking.co.nz with “Press Council Complaint” in the subject line. If unsatisfied, the complaint may be referred to the Press Council, PO Box 10 879, The Terrace, Wellington 6143 or by email at info@presscouncil.org.nz

Further details and online complaints at www.presscouncil.org.nz

6 months (6 issues) $70

One year (11 issues) $129

Two years (22 issues)

1 Year Australia (11 issues) $270

1 Year digital (11 issues) $45

We are proud to again be the best-selling Heavy Commercial Truck brand in New Zealand and wish to thank all of our valued customers across the country for being part of the Isuzu Trucks team.

isuzu.co.nz

*Based

Canterbury-based transport and logistics firm Hilton Haulage has announced it will acquire Austin Transport Services, which will see the company expand into the Nelson-Tasman region.

Effective 1 April, the move will further strengthen Hilton Haulage’s network and expand its service offerings.

Based in Richmond, Nelson, Austin Transport Services has more than 30 years of experience in the trucking industry. Since 2005, it has been operated by Bryan and Lisa Austin, with a fleet of more than 30 trucks, from its depots in Richmond, Auckland and Christchurch.

“With this expansion, we bring enhanced transport solutions, greater efficiencies and a continued commitment to delivering exceptional service to both new and existing customers,” the company said in making the announcement.

“As we join the Nelson Tasman community, we look forward to fostering new partnerships, supporting local businesses, and helping drive the growth of the region.”

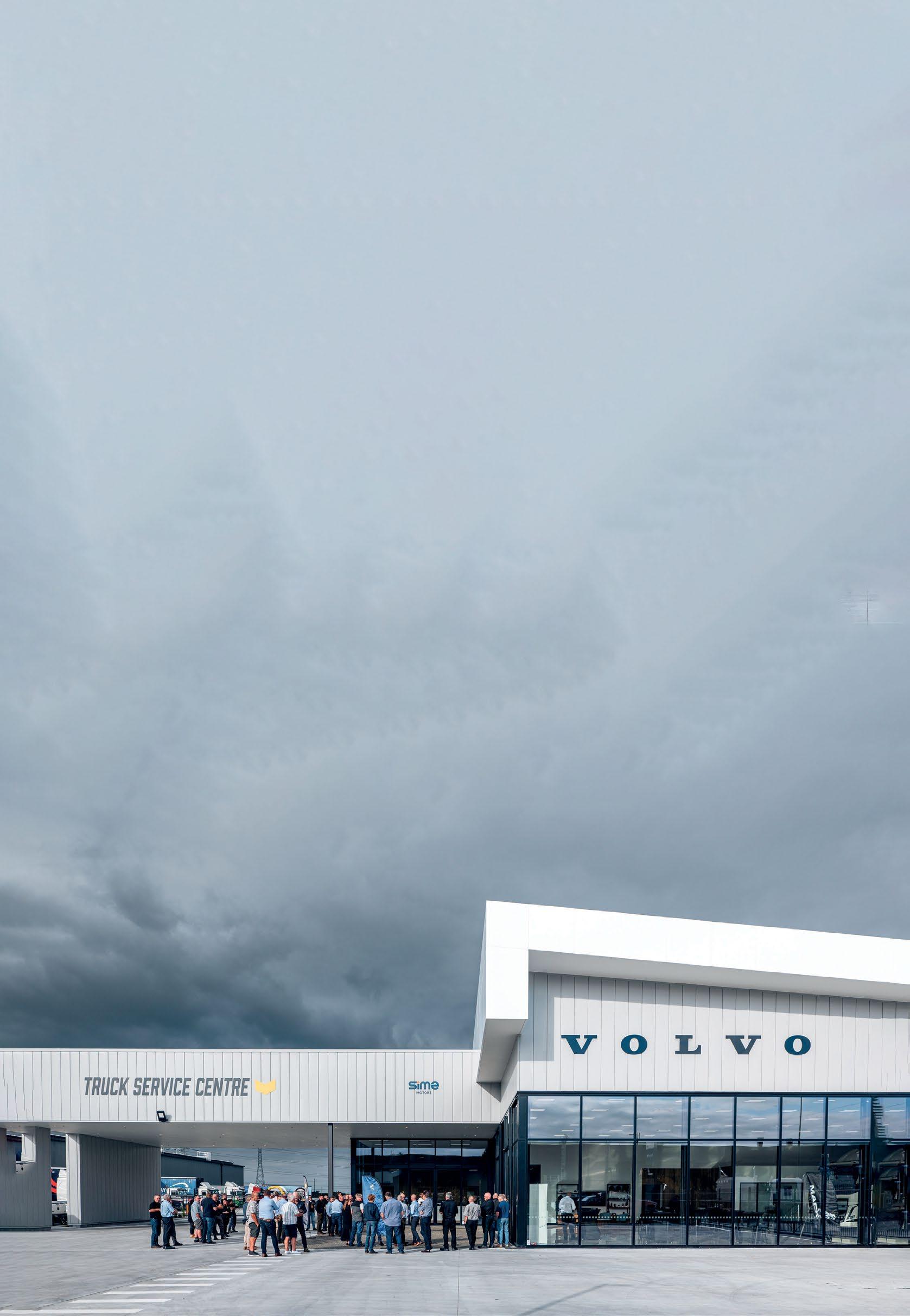

Sime Motors NZ has opened opened the first flagship showroom and Truckstops service centre for Volvo Trucks and Mack Trucks in Christchurch.

The opening was celebrated at a launch event including VIPs from Volvo Group Australia (VGA) and Sime Motors and industry guests.

At the event, Sime Motors unveiled the new 19,000m2 facility, which includes a large Volvo Trucks and Mack Trucks showroom and handover bay, customer meeting rooms and an extensive 28-bay Truckstops service centre.

Sime Motors managing director for New Zealand, Pat McKenna, said the facility was specifically designed to deliver a premium customer experience for Volvo Trucks, Mack Trucks and Truckstops customers in the South Island.

“Today is the culmination

of significant planning and investment – and a physical demonstration of our commitment to the Volvo and Mack brands, now and into the future,” he said.

The opening is the first of three new Volvo and Mack facilities and premium truck service centres, with two

more due to open in Ruakura, Hamilton and Tauriko, Tauranga, by the end of 2025/early 2026. New premises for TWL and a distribution centre to supply truck and trailer parts across the South Island are also part of the new Sime Motors hub at Waterloo Business Park in Christchurch.

Drivers with a class 1 licence can legally operate electric trucks up to 7500kg under a new exemption announced by the NZ Transport Agency.

The Land Transport (Driver Licensing) Rule 1999: Drivers of Electric Trucks (up to 7500kg) Exemption Notice 2025 came into effect on 28 February.

Vehicle dimensions will remain the same.

The notice says the change is due to the additional weight of batteries in electric vehicles, which can push an electric truck over the usual class 1 threshold.

“The land transport system is facing a challenge between the availability of cost-efficient heavier electric vehicles and

our current driver licensing system,” NZTA said.

Keeping battery electric trucks below the 6000kg weight threshold for class 1 driver licences greatly reduces payload due to the weight of the batteries. The notice said achieving the equivalent payload in a battery electric truck required the driver to move up to a class 2 licence, creating a barrier in the uptake of BEVs.

“These BEVs require a higher driver licence class and may sit within the work time and logbook regime, making more sustainable and lower-emission commercial transport options less attractive. This imposes compliance costs on industry for no safety benefit,” it said.

To qualify under the exemption, electric trucks must be within the same model range as a diesel equivalent, have the same braking system and carry the batteries integrated within the chassis.

The electric variant must not exceed the dimensions of the largest diesel version in the up-to-6000kg range.

The vehicle must comply with the following:

(a) The vehicle’s braking systems must include regenerative braking, automatic emergency braking and electronic stability control.

(b) The vehicle must have lane departure warning or lane keep assist.

(c) The vehicle’s batteries for generating motive power

must be placed as low in the chassis as possible. Vehicles with batteries mounted above the payload centre of gravity height are not eligible for this exemption.

The combined effect of these features, all other things being equal, would be to reduce the likelihood of a crash occurring, the agency said.

The transport agency said it was a temporary solution while potential wider changes to the Driver Licensing Rule are progressed. All other driving requirements and obligations remain unchanged.

The notice expires on 28 February 2028 and may be amended, replaced, or revoked under the Land Transport Act 1998.

Understanding your business is our first step to becoming your

Volvo Trucks was the European market leader in heavy trucks, 16 tonnes and above, for 2024.

It is the first time the truck maker has held the position in the region.

The company had an overall market share in Europe of 17.9%, and 56,331 Volvo trucks were registered in the region. The markets with the most registered Volvo trucks during the year were the UK, France, Germany, Poland and Spain.

“We are very proud to be the market leader in Europe. This is clear proof that our customers appreciate the fuel efficiency, safety and uptime of our trucks and that we have a very attractive product offering,” said Roger Alm, president, Volvo Trucks.

“Our new FH Aero trucks that were launched in 2024 are just outstanding. These trucks are available with electric, gas and diesel powertrains and they have quickly become very

popular on the market,” he said. “Transport companies choose Volvo because our products and services help them grow their business and reduce CO2. I wish to extend a big thank you to our customers for their trust in us and also to our dealers, suppliers and our colleagues within the Volvo Group for this achievement.”

Globally, Volvo Trucks increased its market share in 25 countries in 2024. In Brazil, Volvo became the market leader

in heavy trucks for the third year with a market share of 23.7%. The company’s flagship, the Volvo FH, was the most sold truck model of all brands in Brazil in 2024. In Australia, Volvo’s market share was 18.2%. In North America (US and Canada), Volvo Trucks had a market share of 10.5% (10.2% in 2023).

“We stand stronger than ever thanks to the complete renewal of our global product portfolio in 2024,” Alm said.

With branches in Auckland, Hamilton, and Christchurch—plus a trusted service network—Transcold keeps your fleet moving.

We offer expert support for Carrier refrigeration technology and Dhollandia tail lifts, minimising downtime with fast, reliable servicing.

From tailored maintenance plans to hands-on technician training, we go beyond just supplying products—we keep your business running smoothly.

Stay on the road with Transcold.

Positive public sentiment towards truck drivers is strong, new polling from Transporting New Zealand has revealed.

Public polling done by independent survey firm Research New Zealand for road freight association Transporting New Zealand, surveyed 1005 New Zealanders across a representative population sample.

The research showed more than seven times as many people have a positive perception of road freight drivers compared with those taking a negative view (52% to 7%).

The survey respondents noted truck drivers’ professionalism and skill,

essential service, economic contribution, hard work and long hours as the leading reasons for the results.

Fifty-two percent of respondents had a positive perception of truck drivers, while 35% were neutral and 7% held a negative perception.

Support for truck drivers was consistent regardless of what form of private transport the survey respondents used (car,

public transport, walking, bike or motorcycle or other).

The public polling was completed as part of the 2025 National Road Freight Survey, including surveying road freight industry participants.

Transporting New Zealand policy and advocacy lead Billy Clemens said the results were a great recognition of the work of New Zealand’s 33,000 professional truck drivers,

moving nearly 93% of the country’s freight task.

“Seeing that the public recognise the professionalism and skill of drivers, the economic contribution they make (over $8.6 billion per year), and the hard work road freight operators put in is a real endorsement of our driver workforce,” he said.

“Transporting New Zealand has consistently said our people are the industry’s most valuable

asset, and that’s reinforced by these results.

“Over the past few years, the road freight industry has dealt with COVID disruption, supply-chain issues, natural disasters and an increasingly pot-holed roading network. Throughout all these challenges, truck drivers have kept shelves stocked, businesses supplied and infrastructure projects moving. I think that’s reflected in the positive perception that the public has.”

Clemens said that while the results were positive, the survey results also showed a minority of respondents had concerns about truck drivers, mainly based on road safety and driving behaviour.

“All road freight businesses need to be setting clear

expectations for their drivers around compliance and defensive driving to help keep everyone feeling safe on the road.

“Transporting New Zealand will also keep advocating for investment in overtaking lanes, road widening and corner easing, freight bypasses, and other infrastructure that improves safety and productivity outcomes for all road users.”

Transporting New Zealand is also encouraging all road freight industry participants to complete the 10-minute-long 2025 Road Freight Industry Survey, which will provide valuable insights on industry priorities and challenges and complement the public polling.

See page 112 for more.

TDX has renewed its partnership with Shell Lubricants as the appointed Shell Lubricants distributor in New Zealand for another five years, following the initial three-year agreement signed in 2020 which was subsequently extended to five years.

“This renewal ensures that our customers will continue to benefit from Shell’s innovative and high-performance lubrication products, backed by the local know-how and service

experience of the TDX team,” said Jason Steele, business manager - Shell Lubricants, TDX.

TDX recognises the evolving demands of the industry, particularly the growing emphasis on sustainability, low-emission solutions, and environmentally responsible practices. The company is actively working with partners to align with Toitū carbon certification standards and supports the use of Panolin biodegradable lubricants in key applications.

Trust Ixom and SCR for dependable AdBlue supply in NZ. Contact us at sales@scrsolutions. co.nz or 0800 145676 for all your bulk, packaged, and dispensing equipment needs. Reliable, secure solutions when you need them 24/7.

GCA7

• Unique non-directional traction patterns ensure optimum traction and prolongs tread life.

• Superior sidewall cut resistance.

A• Good self-cleaning with groove stone ejector.

• This deep tread is particularly suitable for loaders and dump trucks operating in quarries or mining.

GCA3

• Applications: Articulated dumper, dozer, loader, and graders.

the 2022 Long Lap, and Keith Newey’s Mack R-model at the recent Kamo Touch-

• Non-directional traction and standard tread depth pattern design.

depth pattern design.

• Excellent performance supported with heat resistant compounds.

GCA8

Superior sidewall cut resistance. ceptional casing durability. Enhanced stability and riding comfort.

GCA8

• Superior sidewall cut resistance.

• Unique non-directional traction patterns ensure optimum traction and prolongs tread life.

GCA3

fter 19 years of sterling service behind the wheel of the Northern Classic Commercials Club, Ray and Fiona Reid are handing over the running of the club to a new bevvy of classic-truck crazed stewards. A meeting was held on Sunday 16 March at the Ross Bros Museum in Cambridge to determine who would take on

• Excellent performance supported with heat resistant compounds.

• Primarily designed for mining, off the road, and muddy surfaces.

The extra-deep tread pattern is specially designed for loaders.

• Long tread life, exceptional casing durability.

Excellent performance on extremely rocky surfaces, in open pits, quarries, and underground mines.

• Enhanced stability and riding comfort.

• Primarily designed for mining, off the road, and muddy surfaces.

• Superior sidewall cut resistance.

• Good self-cleaning with groove stone ejector

• The extra-deep tread pattern is specially designed for loaders.

Non-directional deep tread pattern designed for muddy and soft surfaces.

Excellent traction and floatation offer comfortable handling.

• Excellent performance on extremely rocky surfaces, in open pits, quarries, and underground mines.

Superior long tread life and excellent puncture resistance.

Low rolling resistance and fuel economy

GCB5

• Articulated dumpers, rigid dumpers, loaders, graders.

• With excellent traction and buoyancy performance.

• Outstanding stability and operating comfort, with large pattern plate and long service life.

GCA3

• Applications: Articulated dumper, dozer, loader, and graders.

• This deep tread is particularly suitable for loaders and dump trucks operating in quarries or mining.

• Non-directional traction and standard tread depth pattern design.

• Applications: Articulated dumper, dozer, loader, and graders.

• Excellent performance supported with heat resistant compounds.

• Non-directional traction and standard tread depth pattern design.

• Primarily designed for mining, off the road, and muddy surfaces.

• Excellent performance supported with heat resistant compounds.

• Primarily designed for mining, off the road, and muddy surfaces.

GCA2

• Non-directional deep tread pattern designed for muddy and soft surfaces.

• Excellent traction and floatation offer comfortable handling.

• Superior long tread life and excellent puncture resistance.

• Low rolling resistance and fuel economy.

the mantle of leadership and direction at the club.

“We were heartened to see an enthusiastic core of members who have put their hands up,” said Fiona. “The new team is headed up by Michelle Miller, with other team members being Cassandra and Bryan Robinson, Don Gorrie, Keith and Carolyn Newey, Neil and Carol Shayler, and Brian Murdoch.”

Michelle added, “We are committed to ensuring the club continues, allowing us to enjoy our classic vehicles and foster the wonderful friendships.”

Of course, the Reids are not going far and will still be in the background offering their full support and taking part in the wonderful events the club runs.

Fiona said, “Ray and I wish the new team the very best going forward and as always we look forward to catching up with you on the next run!”

Contact: Michelle Miller on 027 478 8876 or brettmich@gmail.com

AutoSense has installed almost 6000 AI-powered Guardian by Seeing Machines systems in New Zealand vehicles and has released its latest findings into fatigue and distraction.

Last year, the Guardian cameras captured 21,670 mobile phone distraction events by drivers on New Zealand roads, making up 41% of the total distraction events recorded on the cameras in the 12 months until 31 December 2024.

“Last year, an astounding 52,560 driver distraction events and 21,470 driver fatigue events were recorded by Guardian cameras,” Charles Dawson, AutoSense CEO said. Guardian cameras recorded an average of 594 total distraction events and 417 total mobile phone events

weekly. More distractions occurred between 9am and 10am than at any other times during the day and night.

“The peak distraction time aligns with the time when parents are setting out with pre-schoolers for morning activities, retirees and seniors are heading to appointments and shift workers may be finishing nightshifts or heading to mid-morning shifts,” Dawson said.

“By shedding light on the insights that the Guardian data provides us, we hope to influence driver behaviour, making driving on New Zealand’s roads safer for everyone.”

According to the NZ Transport Agency, there were 341 road fatalities in 2023, and about 25% of road deaths and serious injuries are

work-related. The impact of that is far-reaching.

“The social cost of road fatalities to all New Zealanders is colossal. As well as the loss of life and life quality, there’s a loss of productivity and big financial implications with medical costs, legal costs and property damage costs,” said Dawson.

In per-crash terms, this average social cost is estimated at $5,374,100 per fatal crash, $551,700 per serious injury crash and $30,800 per minor injury crash.

AutoSense recently launched its Safe Driving Policy service, aligned with the NZTA’s safe driving practices and designed to help businesses reinforce responsible driving habits that can protect their teams and others on New Zealand roads.

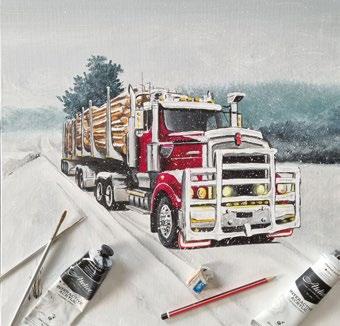

If you’re moving wood, Mills-Tui are the experts for innovative design to maximise your productivity. With 5 axle tare weight from 5,680kg and a class leading 5yr/1,000,000km chassis warranty, you know Mills-Tui has got your back.

Fans of pilot vehicles, heavy and ungainly loads, many axles and brutish prime movers – rejoice! For the second consecutive issue, we’re lucky enough to feature a heavy-haul unit with a big, yellow machine on its back, and some innovative technology underneath it all.

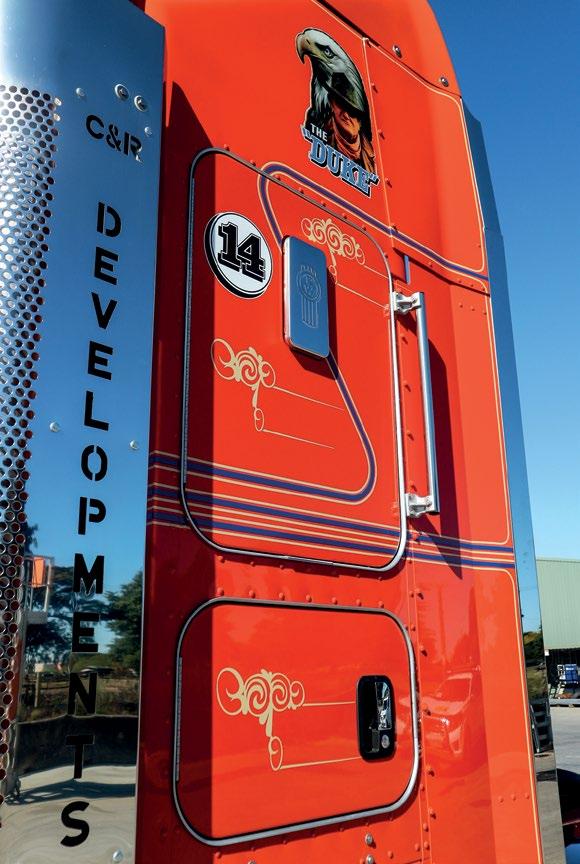

Just a short trip south on the Waikato Expressway from Horotiu-based Hanes Engineering – the cover star of our March issue – is the township of Hautapu, just north of Cambridge. It’s known historically for its 140-year-old dairy factory, and in more recent times – and especially to the transport and earthmoving fraternities – as the home of C & R Developments. You’d no doubt have noticed the company’s yard alongside the expressway. Missing the expanse of big yellow earthmoving machinery and bigger green sheds is impossible. Head into the premises, and you’ll find the company’s fleet of big orange trucks – four Caterpillar bulk units, a five-axle K200 crane truck and five heavy-haul Kenworths. The company operates more than 200 major plant items, plus 11 heavy trucks (soon to be 12) and a fleet of smaller support vehicles and utes.

While they exist to support the company’s core task of shifting earth, the C & R Developments trucks are as synonymous with the company as one of its Caterpillar bulldozers – most certainly in the North Island. But, while we’ve featured some of the company’s truck fleet over the years, none has ever had the honour of gracing the cover until now – with the arrival of the company’s latest Kenworth T909, The Duke.

Owned and operated by brothers Mike, Tony, Tim and Simon Ross, C & R Developments has built a reputation for excellence in civil earthworks and bulk earthmoving. The thing about operating a fleet of

earthmoving machines is that they need to be moved to and from jobs. And when the plant needs to move, it needs to move.

“We bought the transporters to work in with our civil jobs,” says Simon Ross. “It got to the stage we’d grown too big to be relying on others to move our gear – it became too tough getting trucks when we wanted them, so it was crucial to get our own transporters.”

First in was the company’s 1997 T950, an ex-B.R. Satherley Transport unit that C & R acquired about 14 years ago. “It’s been a great old girl for us, but it just does light duties now,” Simon says.

After the 950, the company acquired Pistol Pete, a C15-powered 2008 T908 out of Australia. Until the arrival of The Duke, this unit was driven, cared for and loved by the affable Murray ‘Muzz’ Peake – who did well over a million in it.

The company’s first T909 arrived in 2012, driven by Tony Goodwin, and in 2020, the company rebuilt a C15-powered, 2003 Kenworth C501 Brute – another truck out of Australia and reserved for the heavier stuff with its 200-tonne rating and TRT six-line ESS Platform Trailer.

“It wasn’t in as good a nick as we thought it was when we bought it, but it got a new lease on life and now does the hard yards,” Simon says with a smile. (The full story on the Brute can be found in the November 2020 issue of New Zealand Trucking.)

As operators, the Ross brothers were not necessarily dedicated ‘Kenworth guys’. “Our first transporter back in the days of Baker Construction was an IH,” says Simon (see sidebar, The boys and

their (big) toys). “We later had an International S-Line. Before that, way back in the 1970s, Cambridge Heavy Haulage did all our transporting. Then Porters took over until we bought the 950.”

Adds transport manager Andrew Stevenson: “The trucks are essential. When the gear needs to move, we can’t rely on another party that might give other gear priority. And when a truck breaks down, we need to get another one out there immediately, not next week.”

“The Kenworths have been good machines generally; we’ve had no real issues from them,” Simon notes.

“They’re a lot more comfortable than they used to be, compared to the 950 …” adds Andrew, who then throws in a comment that strikes us as both interesting and insightful in 2025’s world of increasingly technologically advanced trucks.

“They’ve been proven for years – that’s why so many of them are put on heavy haul. And our mechanics can fix them in our workshop … They’re ‘simple’, good, solid trucks. And for the age of some of them, they’re not often in the shop.”

Almost before he can finish his sentence, Simon adds a point relevant to the entire industry, but exponentially more so when it comes to this line of work: “You can have all

the best trucks, but if you have the wrong buggers on them … We’re lucky with the guys we have, who are so good on the gear. They’re bloody passionate guys with long-term experience, real truckies who love their trucks. There’s no need to ask them to go out and wash them; they’re blinged up all the time. We have a good crew, that’s for sure.”

Part of the C & R family for 14 years now, Muzz is exactly that kind of truckie – passionate, professional and personable; he takes immense pride in the job and his unit.

“I still enjoy this work. It’s challenging, keeps your mind sharp. Every load is different. You can have two similar machines on the trailer on the same day, and both will load and ride differently,” he says.

The key to making the job easier is the gear. As far as Muzz’s new 909 is concerned, it follows a tried-and-true recipe, running the same mechanical spec as his old 908, save for the motor – the 908 running a Caterpillar C15 ACERT that was ‘breathed upon’ to produce in the region of 700hp, the 909 running the venerable Cummins X-15 at 459kW (615hp).

Otherwise, it runs the same 22-series 18-speed Roadranger, Meritor MFS73 front axle on

“We’re lucky with the guys we have, who are so good on the gear. They’re bloody passionate guys with long-term experience, real truckies who love their trucks.”

7.2-tonne Kenworth suspension, and Meritor RT52-185G rear axles geared at 4.89:1 (with diff locks and oil cooler), riding on NeWay AD246-10 air suspension for a 20.8 tonne rear-axle rating. It’s dimensionally the same, too, running a 5500mm wheelbase –short and manoeuvrable but still stable. In all, it’s rated to a GCM of 155 tonne.

“It’s a spec we know works,” says Andrew.

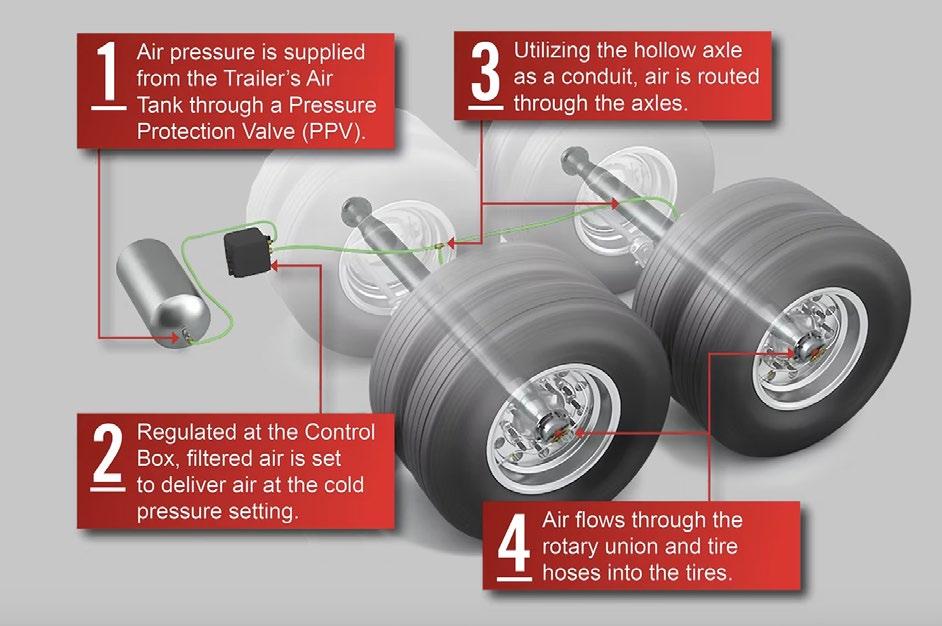

SI Lodec scales, TRT Traction Air central tyre inflation, and a Jost 90mm oscillating turntable on a TRT subframe all play a supporting role.

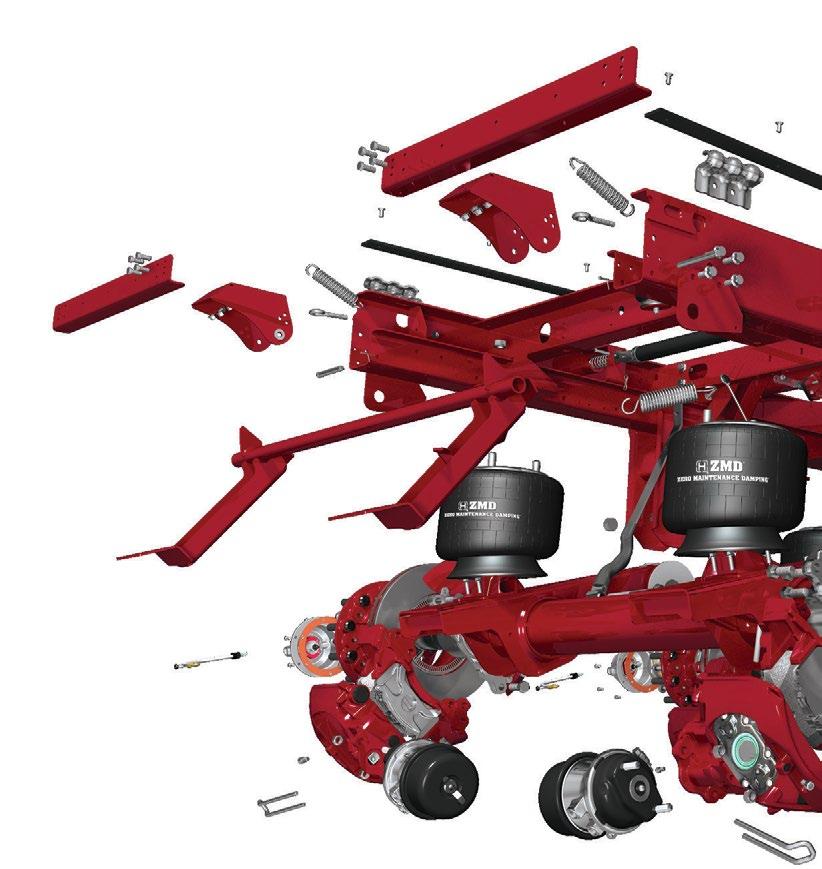

Arguably, however, the star of the show is what hooks up to the Kenworth: a TRT FourRows-of-Eight ESS Widening

Low Loader, the first of three the Hamilton engineering firm has so far built in exactly this spec. It replaces Muzz’s old MTE fourrows-of-eight and, where that was a relatively straightforward unit, the new TRT four-row ESS trailer changes the game. It’s a first of its kind, and the C & R team worked closely with Jeremy Carden, trailer sales specialist at TRT, and Jason McLuskie, who led the design, during its development.

The innovation is combining TRT’s electronic steering system and double-acting suspension with a float. Each axle can steer to 45 degrees, and the trailer height can be altered from 815mm to 1515mm.

Jeremy explains the different

systems built into the unit: “The axles are driven by a ram that sits in the well under the deck, which pushes on the steering quadrant to activate the steering arm on the axle leg. Each leg’s kingpin housing is built into the separate decks allowing for the 45-degree steering angle either side of centre, compared to a standard rows-of-eight assembly where the axle beam goes through the main webs.

“The electronic steering system is guided by a slew ring built into the skid plate and a wedge plate that sits in the truck’s fifth wheel. Two encoders read the angle between them as the truck turns, sending the signal to the Rexroth controllers. The transducers on the steering

rams then interpret this info and move the wheels accordingly.”

Jeremy adds that the axles are spaced at the maximum 2.4m and, compared with a traditional rows-of-eight axle, each leg has its own suspension unit. “This allows control of the ride height when its empty and loaded and locking off of single axles with a single valve. For example, when changing tyres with a machine on, there’s no need to block axles up to get a tyre off.”

A hydraulic compensating gooseneck with 650mm stroke means the trailer doesn’t strain the truck’s chassis when on uneven ground, and can create an incline to help with loading. A single shut-off valve is placed at reach on the outside of the

gooseneck so that it can be easily locked off.

The remote control – familiar to anyone who’s operated a house-moving trailer – gives full independent control of height, steering, ramp control and widening. “It’s safer than getting under the trailer to use levers,” says Jeremy. “Various manual steering modes allow you to override the slew ring, and the operator can completely control each axle up to 45 degrees in slow-speed manoeuvring. You can make the axles do all sorts of wonderful things, like artificially create a pivot point to get around tight obstacles.”

It’s all powered by an integrated Yanmar diesel watercooled engine. Two Bosch

Rexroth RC controllers are the ‘brain’ of the machine. The only connection to the truck is a cable that runs to the dash-mounted remote display.

“People hear the word electronic, and they worry it won’t last. But it’s pretty simple and very robust: 95% mechanical and hydraulic with 5% electronics to control it,” Jeremy comments.

TRT has tried to keep a reasonably long beavertail, given the need to accommodate the steering mechanism for the last axle row beneath, while ramps are standard 2.8m single fold, with options to go longer if requested.

One disadvantage of the trailer is it can’t close to 2500mm width; the platforms close to 3090mm

and widen to 4390mm. The deck length measures 13.2m from the front of the deck sheet to the ramps, or 12.65m of clear deck space from the base of the gooseneck. Tare weight is between 23.5 and 23.7 tonne.

“You’ve got seven tonnes of tare weight up your sleeve compared to a traditional four-line platform lead trailer with a removable ramp module,” Jeremy says.

Other features include a removable 20-tonne Hammer winch pack, a manifold greasing system, fully welded coaming rail protectors, polished Alcoa wheels (which Jeremy says help reduce tare weight by about 350kg over steel rims on a fourrows unit), Ausbinders rather than chain twitches on the

ramps, and lights on each axle group, the gooseneck and the ramps.

“Muzz wanted the lights – his trailer has 12-work lights, 28 side markers and eight marine plug sockets for additional lighting.”

It’s midnight on a late-February Wednesday when we gather at the Hautapu yard to accompany Muzz and The Duke on its maiden job – a Caterpillar D10T bulldozer headed to the Port of Auckland, to be shipped down to the Lyttelton Port where it will join half a dozen of the firm’s other machines, including dumpers and graders, for stage two of the port’s reclamation project. C & R had completed

Over the years, we’ve told bits and pieces of the C & R Developments story. However, since this is the first cover story to feature one of its trucks, it’s only right to recap. We can’t, of course, assume everyone’s read everything we’ve ever published. So, whether you know the C & R story or not, head with us back to 1998, when brothers Mike, Tony, Tim and Simon Ross established the company.

Standing for Coleman and Ross, the roots of C & R’s story actually run back to 1960

… The brothers’ father, Jim Ross, was a stalwart of the Kiwi trucking industry midcentury, having started Ross Todd Motors in Leamington, near Cambridge, with Norm Todd in the post-war years. That company would eventually become TRT, but in 1960, Jim decided to get into earthmoving.

With chance backing by Arthur Baker – a well-known businessman, whose interests included farming, land development, fertiliser, and agricultural aviation – Jim formed Baker Construction, which enjoyed

success on projects from the Hutt Motorway (the company’s first), Twizel, the Cromwell Gorge realignment, Runanga Deviation on the Napier-Taupō Road, Huntly coalfields, Auckland Airport, as well as offshore in Australia, and even the Hong Kong airport development.

In 1994, Baker Construction was bought out by Downer Mining Ltd (DML), with the Ross brothers running the business by then with well-known surveyor Mike Coleman, who became involved in the early

stage one as a joint venture with Heron Construction that began in 2019, dredging 5ha of seabed and replacing it with 3.5 million tonnes of selected aggregate material.

Andrew would later explain the rationale for shipping the gear: “We have a contract with the port, and it works out cheaper to send it from the Port of Auckland. The majority of our running is in the North Island and we tie in with Satherleys in the South Island. A lot of gear goes in, but not a lot comes out. So, because they’re based there, it helps to work with them. Even if transporting it ourselves, we’d come back empty and that’s a big cost.

“The South Island is a bit hard for this work. There’s bugger-all roads we can use between Blenheim and Amberley; you can’t be more than 3.1m wide. We can’t go down

The TRT Four-Rowsof-Eight ESS

Widening Low Loader makes negotiating roundabouts a doddle.

1990s. Following the buy-out, the brothers explored several other successful business opportunities. However, when DML largely quit the local market, it didn’t take long for local clients to start reaching out to the Ross brothers once more, and C & R was born. (For a more comprehensive account of the story, see New Zealand Trucking, November 2020.)

Based alongside the Waikato Expressway at Hautapu, C & R Developments specialises in civil earthworks and bulk earthmoving – the team does it all, from roading, major subdivisions, quarrying and mining, overburden removal and transporter services.

The plant fleet ranges from five-tonne to 200-tonne machines, with a fleet of five transporters tasked with getting them to and from jobsites. Almost all aspects of keeping these behemoths in operation are managed at the comprehensive in-house workshop,

particularly machinery maintenance.

Staff members number more than 200 and include civil engineers, surveyors, mechanical engineers, health and safety managers, mechanics, data analysts and, of course, drivers. Many staff have spent their entire careers with the company, some joining straight from school.

“A lot of our work is repeat business, work for quarrying companies and mining, anything requiring bulk or civil earthworks,” explains Simon. The company is currently involved in several major projects across the North Island, including Project REWA, the new inland port development at Ruakura. While primarily operating in the North Island, C & R Developments does work in the South Island, too, such as the Lyttelton Port reclamation project in the South Island – as discussed in the main story, starting page

16 – and has even completed projects in Western Australia and Hong Kong.

The Ross brothers’ story is one of those that epitomises the sentiments of loving what you do and doing what you do well. It’s always been, and continues to be, a familyrun business – the brothers’ office is the C & R boardroom, with Mike, Tony, Tim and Simon working together around the one table. It’s about clear communication and quick decision-making, says Simon. They’re hands-on, operate on a personal basis with clients and staff alike, and have no intention of stopping anytime soon.

As Simon says, “Moving dirt is the only thing we know how to do. From playing in the sand pit as young fellas and then our parents instilling the business in us from a young age from their company Baker Construction.”

the Kaikōura Coast because of the tunnels. To cross some of the South Island bridges, we have to unload the machine and walk it through the creek – if it’s not been raining …” he explains.

“Getting the machines back is different because sometimes the ships will come back into Wellington. So, we might drop gear off in Wellington and bring them back from there.”

And, that’s assuming you have all the necessary permits to traverse the roads on your route – every state highway in the country, really.

Speaking of which, it was this that scuppered The Duke’s originally planned maiden voyage the night before when it was supposed to shift a machine to Whangārei. But hey, that’s trucking … The 908 stepped in,

As they say, on the journey of life, if opportunity knocks and doors open, walk on through with purpose and make the most of what’s presented.

Murray ‘Muzz’ Peake’s resume plays from this songbook, reading like a roadmap of strategic moves that have directed him towards the senior driver role he holds at C & R Developments today.

“Yeah, it’s funny. I ended up driving trucks by sheer accident, really,” Muzz reveals with a laugh. “When I left school, I started out operating machinery, excavators and bulldozers for Mullin Brothers and Waihi Earthmovers. From there, it was to Fletchers doing the same thing at the Golden Cross Mine at Waitakauri, just west of Waihī. With Fletchers, I was able to transfer to Australia and did a 12-month stint for them over there. But then, when I returned back home to Waihī and started back up at Golden Cross, we were all laid off.”

Back from Australia and in need of a job, Muzz started driving trucks for Regal Haulage out of Tamahere, where his career in road transport really got off the ground. It was relief work, though, and in need of full-time work, Muzz tried his hand as an owner-driver at Turua Transport with a TM Bedford. This arrangement lasted for about 18 months, when the loss of a contract had Muzz looking for gainful employment again.

“I called on my connections at Regal Haulage and ended up starting back there again, this time as a full-timer. I ended up

doing nearly 12 years there with them. It was a great place; a good bunch to work with, and I got to drive some iconic trucks there as well. They first gave me an old daycab K-model Kenworth bulk tipper unit. Then I was given an upgrade, No.27, again a K-model Kenworth bulk tipper combination, but this time a full sleeper-cab version with an 8V92 Detroit and a four-axle trailer. It was a real cool bit of gear to drive. I went everywhere in that as well as it was also set up for grape harvest, so I definitely saw a bit of the country in that one. Then it was onto a new T440 bulk unit.”

Looking for variety and a change of scenery, Muzz took up an offer to move

across to the general freight side of the business, and again, he found himself wheeling another well-known truck in the fleet, the drop-sider 6x4 Mitsubishi FV415 that ran a turbocharger off a Mack SuperLiner. “Yeah, that one sure was a bit different, with the big single turbo hanging out the back of the cab. But, for what it was, it went well and again I covered a lot of both islands in it. From there, I got a Foden dropsider and eventually moved on to a FLB Freightliner.”

The best part of 12 years cruising the country was wearing thin, and Muzz started looking for something different. A job with Phil Rouse out of Tokoroa operating a

the job got done, and here we are in the early hours of the following day ready to head out with the D10T. With it being loaded the day before, Muzz fires up The Duke and the trailer’s Yanmar and begins his pre-trip inspection.

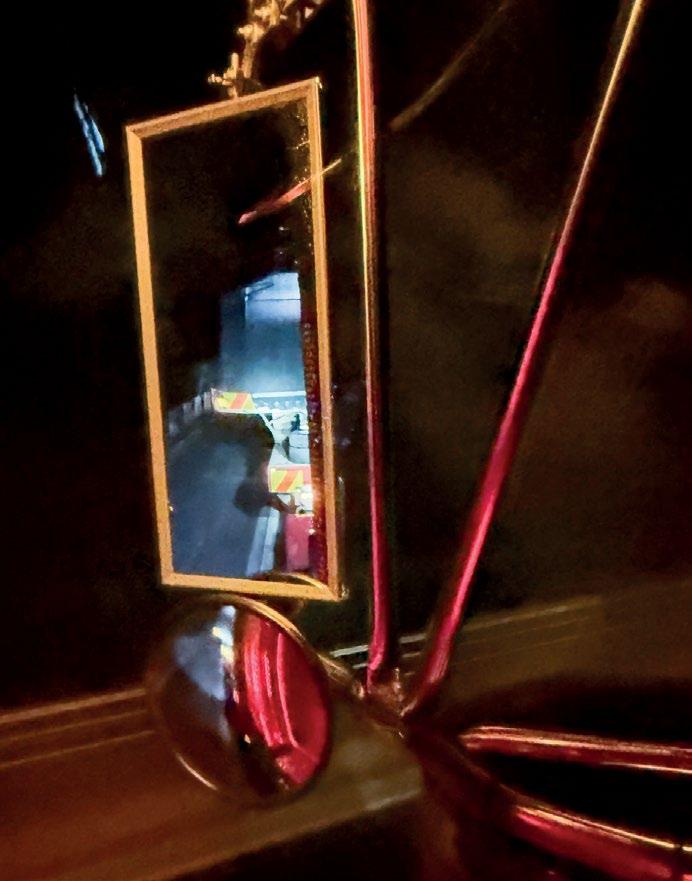

Immediately, the advantage of the trailer’s lights – along with five on the cab’s back wall – is clear. There are few parts of the combination not clearly visible and when a large portion of the job is undertaken in the dead of night, that can only be a good thing. “It’s great to see where my axles are placed when I’m manoeuvring it,” Muzz comments.

The trailer was delivered in September 2024, and Muzz has already done about 20,000km with it. That’s a fair amount, considering he also spends time towing the six-rows

unit, so he’s well accustomed to its operation now. “You can’t beat it when it comes to the steering. That is really good,” he says. As we’d later see, it does indeed follow the truck impeccably.

Pilots Richard McHugh and Geoff Hindrup lead us out of the yard, with Jamie Ashby following the truck. Muzz is running at 4.9m high, 5.2m wide and at 99 tonnes. It doesn’t take long for the team to encounter the first obstacle on the route – the recently installed Hautapu roundabout on Victoria Road/SH1B. Even though C & R successfully lobbied for an extra metre of road along one of its edges, its non-steerable units would still have to negotiate it down the oncoming side when widened and heading for the motorway. (More on roundabouts and the other

Story by Carl Kirkbeck

bulldozer got his attention.

“I drove that for a bit over a year, and it was all good, but a colleague that I worked with at Regals, Ian Scatchard, caught up with me and offered me the driver’s seat of his Mack CL Elite E9 575 – and that was it, pretty much – I moved back into the cab of a truck. It was an awesome truck to drive, back on the bulk tipper work, it had a cool look and sound. But, yeah, unfortunately, after only about a year and a half, a change of business direction had Ian putting it up for sale.

“From there, I saw an advert for machinery operators with Lance Magee at Magnum Contracting. It turned out to be a real good move, lots of interesting projects. I was with

them for about 11 years and worked my way up to a supervisor role. The straightening of the infamous ice corners on the north side of Taihape was one of the bigger jobs for me, but we worked all over the place: the last 20km to Cape Reinga, the Kerikeri heritage bypass … yeah, some good projects that’s for sure.”

A dry spell of incoming work for Magnum had Muzz contracted out as a machine operator to C & R Developments. “I came here to simply drive machinery for a stint. I’d been here a couple of months and we got rained off a job, so I called into the office to have a coffee, and Andrew asked, ‘You couldn’t do us a favour, could you,

and take the transporter out and go shift a 20-tonne digger?’ Because at the time, he was off driving with a crook knee. So, I said, ‘Yeah, no worries’, and that really was it. I have been there ever since, at the wheel of a transporter.

“I first started out on the old ex-B.R. Satherley Transport T950, then moved into the Aussie import T908. I have done a bit in the rebuilt C501, and now this new one, which in the scheme of things is funny really, because when I left the Regals work, I swore black and blue that I would never get back in the cab of a truck again, ever … and what, look at it now, 12 years later, I’m still at the wheel. WTF,” laughs Muzz.

challenges the heavy-haul industry faces in the sidebar Same as everyone, just worse.)

Tonight, though, Muzz faces no such drama. He approaches, turns in, follows much the same line as he would in any conventional unit, and blasts out with incredible ease. No tyre scrub, no dragging the trailer over the inner curbing, no strain on gear or operator.

Much like Mark Dennis in the Hanes Engineering Mack Titan in our March issue, Muzz can run up the Waikato Expressway to Auckland’s Southern Motorway at Ramarama, from which he’ll have to follow the heavy-haul route along Great South Road through the southern suburbs. But whereas last month we exited for our destination before Penrose, this time, Muzz will continue a little further to Green Lane West and turn off at Mt Eden Road. From there, it’s a straight run to the city at Symonds Street, which runs virtually to the entrance of the port at Tinley Street.

The Duke has done just 1200km, and with this being its first outing, it’ll still need a bit of loosening up. We’re hitching a ride from the Huntly Bypass to Ramarama and Muzz – ever the Cat man and with the 908 still holding firm in his truckdriving psyche – gives his initial impressions. “It’s feeling all right … I stayed in high range all up the Huntly Bypass, which is good.”

With the Waikato Expressway largely devoid of other traffic, it’s an easy trip north as The Duke continues to stretch it legs –the 909 registering an interior noise level just about on par with the Hanes Titan, a perfectly comfortable 74db.

That is until we encounter two house-moving units ahead, parked on the hard shoulder of the expressway with one of their vehicles broken down. Radios light up between pilots and drivers of both crews. “We’re coming through with 5.2!” is the call; there’s nothing for Muzz to do but continue his approach.

“Muzz, it’s going to be f$&%ing tight to get our blade past,” calls Geoff.

True to his laid-back character, Muzz is unfazed. “Ah, okay,” he responds.

“All clear on the back door, Muzz,” Jamie adds.

Muzz brings The Duke to a crawl and lines up as close to the central barriers as he can, the Caterpillar’s blade just clearing it. With eyes trained on his mirrors, Muzz guides the unit through. Jamie provides guidance from behind: “Good on your left, Muzz … Five hundred on your right … Plenty of room, mate, you’re all right …”

It’s all about communication,

patience and experience. “We come across all kinds of stuff; I’ve seen it all,” Muzz comments once we’re safely past.

“This job is different. Every load is different. It’s sort of like driving a stock unit; you can’t just change direction. Once you’ve picked your line, you have to stick with it. It’s all about common sense. Slow down and assess. You can’t drive around at 100km/h with something like this behind you. It’s a whole different ballgame. You’ve got to pick when you’re going to do everything, like letting someone pass. It comes with experience, and this job is not everyone’s cup of tea. It takes a certain

kind of driver. But it’s like that in other areas of trucking too.”

Soon, we reach the Bombays, The Duke’s first real test.

The weight of the D10T is immediately apparent as Muzz approaches and begins to drop gears. The pyro needle climbs and the fan kicks in. She’s pulling, but Muzz has to drop into the low box. The latter part of the climb is completed at about 16km/h at 1400rpm in third, the X-15 just in its torque peak of 2779Nm (2050lb/ft) at 1200r/min. (Max power is 459kW (615hp) at 1800r/min.) By the time we reach the Nikau Road overbridge, the X-15 begins to pick up speed once more.

Everything the trucking industry in general must deal with, so too must the heavy-haulage sector. The difference is the effects are magnified at these lengths and weights. From the drivers and their gear to the road condition and the times of operation, everything in heavy haulage needs to be thoroughly considered and carefully approached to get the job done safely and with minimal disruption to the public.

A simple discussion with Simon Ross and transport manager Andrew Stevenson about the TRT Four-Rows-of-Eight ESS Widening Low Loader led to insight into the challenges C & R Developments, and others in the industry, face daily.

“… when we took the trailer for a test run with TRT, and we saw it go around a roundabout, I thought, ‘Wow, that was easy.’ No going out wide or taking the oncoming lane. It doesn’t rip out the road with tyre scrub. We save a lot of money on tyres with the steering trailers,” Andrew says, opening two points of discussion.

“We don’t measure tyre life by the kilometre, but by the day. With non-steerable trailers, you could change tyres every two or three weeks, depending on what it’s been carrying. They ruin tyres. They roll over on themselves and scrub in corners. The steerers extend the life of the tyres immensely. They still wear, but nowhere near the same.”

Simon picks up on the issues of roundabouts. “They’re getting harder and harder to move around, especially with our big gear. Some of the designs are getting ridiculous.”

One look at the tyre tracks around the inner kerbing of modern roundabouts indicates they’re not just tight for oversized units; some are too tight for common nineaxle units.

“We had them put another metre on the Hautapu roundabout,” Andrew adds. “Soon as we’d start winding it around with something on the back, we couldn’t get around. The drivers had to take the oncoming side.”

Raised crossings, too, are an obstacle to a heavy-haul unit. “They’re not ideal,” says Andrew. “We have to slow right down and, running low anyway, you’re scraping. With the old fixed trailers, we’d have to virtually stop before crossing them. With the ESS double-acting suspension, it’s not so bad, but still not good – you start loading up axles, and you get one axle in the middle that takes the point loadings. It’s hard on the vehicles at the weights we’re running already.”

Simon adds that being able to raise the suspension also helps when crossing bridges. “Some of these old one-lane bridges with concrete sides … you can barely get across them. There’s a bridge on the road to the Whitehall Quarry that’s been there since the 1940s. The road either end of the bridge is at different angles, so to get it lined up …”

Continues Andrew: “Yeah, you get it straight but when you go over first with the tractor unit and the dolly, the trailer’s coming straight and you have to turn it to get off … It can be challenging. We are waiting for the bridge to break one day. They know it needs to be fixed.”

“A lot of these bridges are the lifeline to the quarry. If they go down and we’re responsible for the damage, that’s bad. We’ve got one outside the Brookby Quarry, you near have to pull the machine apart to cross it. Now, at least, we can just raise it,” says Simon.

“Our problems are the same as the rest of the industry, just bigger,” Andrew reiterates. “Many of the heavy-haul guys struggle with roads that are not ideal. Take the heavy-haul route through Auckland – once you get to

Greenlane, it can take you three hours to get through to the [Johnstones Hill] Tunnels.

“Going through the middle of Orewa on a Thursday evening and asking everyone sitting outside enjoying their night to move as we come through … They ask why are we coming this way, ‘There’s a perfectly good road up there’ … Yeah, we know!”

It’s often no easier once out on the state highway network, especially with new median barriers, says Simon. “Some of them come in too narrow. If you have a problem, a popped tyre or whatever, you have nowhere to pull off. Even considering tail swing, the boys have trouble getting through places like Dome Valley.”

“We had a machine through there the other day that we had to take up the wrong side right from the bottom to the top, about 6km. It still was not easy, but the bit of extra room on that side of the road is miles to us,” Andrew adds, noting that the new expressways are making the job a little easier.

“The Brynderwyns is still a problem … people get irate when we stop them at the top from coming down while the machine is moving up.”

As we notice each time riding with an oversized vehicle, the average motorist is almost oblivious to the purpose and operation of pilot vehicles. “Yeah, that’s an issue. And the abuse from motorists made to wait … We’re doing it for their safety; it’s 30 seconds at the most,” continues Andrew.

“Then, we do a lot of this at night, and you never know who you’ll meet on the road and what they’re out for at those times,” says Simon. “We’ve said to our guys, we don’t care how long it takes you to get through, as long as everyone is safe and the machine gets through with no damage. If you have issues and it takes longer, it’s fine.”

“I was a good half a gear to a full gear down at various points there, compared to the 908,” he comments. “I’d have been doing about 22km/h in that. But, overall, it wasn’t bad; it’ll loosen up.”

By 2.30am, we reach Ramarama, and those lights at the trailer axles allow a good view of it tracking the truck beautifully through the bends and turns on our route to the port. With Auckland (mostly) asleep, it takes us another 80 minutes to reach our destination, and 45 minutes later, Muzz and The Duke emerge, trailer empty and narrowed up for the return home in the early hours of the morning.

Day or night, watching an oversized heavy-haul unit at work is always a treat. The cool heads and teamwork between the drivers and their pilots, and their interaction with others on the road, as they work their way past the many obstacles on route to their destination is always inspiring and invigorating.

From an observer’s perspective, the entertainment and engagement value is undeniable – and the admiration and respect for the teams that do this each day, immense.

Of course, having good gear always makes the job that much easier, and if the Kenworths currently in the C & R fleet are anything to go by, The Duke should serve Muzz well and manage the task admirably. And as far as the TRT Four-Rows-ofEight ESS Widening Low Loader is concerned, the term ‘gamechanger’ was used more than once.

And, really, none of that is at all surprising when you consider the amount of IP that went into speccing it all – Kenworth being able to supply the right truck fitted with the right componentry, TRT being able to call on decades of engineering experience and ingenuity, and the team at C & R who knew exactly what they wanted from their gear and their suppliers to make their job easier, safer and more productive in a sector fraught with challenges.

Our sincere thanks to Mike, Tony, Tim and Simon Ross for allowing us into your business once again and to Simon and Andrew Stevenson for sharing some valuable insight into the world of earthmoving and heavy haul.

Thanks to Murray, Richard, Geoff and

Tare: 11,150kg (load cert)

GVM: 28,000kg (load cert)

GCM: 155,000kg (load cert)

Wheelbase: 5500mm

Engine: Cummins X-15

Capacity: 15L

Power: 459kW (615hp) at 1800r/min

Torque: 2779Nm (2050lb/ft) at 1200r/min

Emissions: Euro-5 via SCR

Transmission: Eaton Roadranger RTLO22918B 18-speed manual

Clutch: 2250lb/ft Easy Pedal Advantage 3 VCT+

Chassis: 273mm x 89mm x 9.5mm rails, 251mm x 73mm x 6.4mm full insert

Front axle: Meritor MFS73 (7.3-tonne)

Front-axle rating: 7200kg (load cert)

Front suspension: Kenworth 7.2-tonne taper leaf

Rear axle: Meritor RT52-185G at 4.89:1 (with oil cooler and RR diff lock) (23.6-tonne)

Rear-axle rating: 20,800kg (load cert)

Rear suspension: NeWay AD246/10 21-tonne extra-heavyduty airbag

Brakes: Drum. ABS, EBS

Auxiliary braking: Jacobs engine brake

Additional safety: ESP, automatic traction control, drag torque control, FUPS

Fuel: 2x 650L

DEF tank: 225L

Wheels: Alcoa Dura-Bright

Tyres: 385/65 R22.5 (f), 11R 22.5 (r)

Electrical: 12V

Cab exterior: Aero roof 36in integrated sleeper, flat rear, right-hand sleeper access door. Stainless sun visor. Bunkmate rear cab two-airbag suspension. Left-hand door peeper window. Dual roof-mounted air horns. Heated mirrors. LED headlights with LED high beam and DRL. 2x utility spotlights, LED mirror-mounted rear-facing floodlights, LED floodlights on back of the cab sleeper. Roof-mounted deflector

Cab interior: Grey Graphite trim. ISRI Pro air-suspended driver and passenger seats, power plug in driver seat base. 21-gauge pack, gold bezels. 8in touch-screen infotainment with navigation, dual USB ports. Kenworth integral heater/air conditioner. Sleeper fan

Jamie for having us along on The Duke’s maiden job. It was a privilege to watch you work.

And to the teams at Southpac Trucks and TRT – two stalwarts of the Kiwi trucking industry and purveyors of some incredible gear. Thank you both for your

ongoing support of our publication. Thanks to Adam McIntosh at Southpac Trucks for the technical info on The Duke and Jeremy Carden at TRT for taking the time to give us a deep dive into the new Four-Rows-of-Eight ESS Widening Low Loader.

Every cover truck holds a special place in the history of New Zealand Trucking magazine. We love to see where their road has taken them.

APRIL

McCafferty Metal Cartage director Steve McCafferty says the Volvo has been “unreal, a really great truck”.

Currently owned by: McCafferty Metal Cartage, Gisborne

Current odo reading: Just over 800,000km

Mechanical work: None under McCafferty’s ownership

Current work profile: Bulk metal cartage

Currently driven by: Simeon Whitley

Basic original spec: Volvo D13C at 373kW (500hp), Volvo I-Shift 12-speed AMT, Volvo single reduction, 2.83:1 What we said in 2015: “Climbing into the FM is easy. The cab is lower than the FH and there are only two steps.

Although it’s a day cab, it feels roomy. Vision, especially via the mirrors, is excellent.”

Story by Gavin Myers Photos by Gavin Myers, Dave McCoid and Carl Kirkbeck

A star of the Keith Andrews stand was this 50th anniversary Atego sprayer for Philip Wareing; harking back to the company’s roots.

Royans is increasing its presence in the New Zealand market and had some impressive gear

Napa Autoparts had a big display including NZ Super Trucks race trucks, and offered visitors rides around the showgrounds in Quality Demolition’s mini truck.

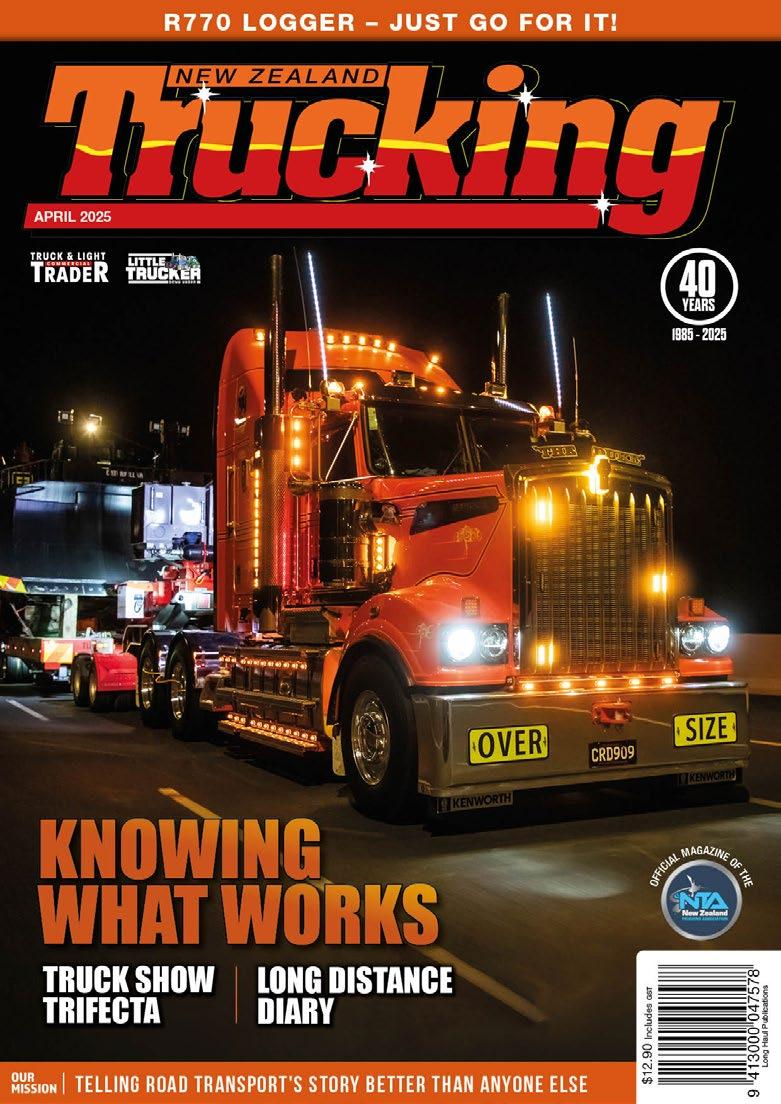

The 2025 TMC Trailers Trucking Industry Show returned to the Canterbury Agricultural Park on 7 and 8 March.

Since 2014, the TMC Trailers Trucking Industry Show has been one of the biggest trucking get-togethers in the South Island – bringing together OEM and trade exhibitors, classic trucks, and Show ‘n Shine entrants.

While there was all that and more this year, it was disappointing that the show was smaller than expected, with some notable names missing. Nonetheless, with about 350 trucks on display, the crowds filled the park grounds on Saturday, the day the event was open to the public. The day might have started a little gloomy, but, as they say, always trust the locals … “It’s clearing from the south; she’ll be right,” they said. And it was. Before the morning was out, the sun had joined the show, and the rest of the day was a pearler.

A highlight of the show this year was the TR Group Trucking Relay competition, which allowed operators to go head-to-head and show off their loading/unloading, precision driving and teamwork capabilities. Hosted by TR Group’s Mark Harvey, the competition attracted entrants from all corners of the industry –including a media team of Glenn ‘Yogi’ Kendall from Truckin’ Life and Outback Truckers, Casuarina Smith (Trucking with CJ), and our own Dave McCoid.

All participants clearly had fun showing off their skills, and the Trucking Relay winners were:

First: Good Bastards (Hilton Haulage)

Second: Mullet Madness

Third: Better Bastards (Opzeeland)

Special mention: Concrete Chicks – least penalties (Allied Concrete)

Best dessed: Opzeeland (Trucking with CJ Award)

Truck of the Show and Best Kenworth was RT Southern Linehaul’s always immaculate K200 2.8m Aerodyne, Bad Habit.

The show has always been about promoting the trucking industry, celebrating the industry’s professionalism, showing off hundreds of New Zealand’s best working trucks, and inspiring the next generation. In this instance, the Careers Transport showcase allowed students from local schools to visit relevant exhibitors and learn about the opportunities in the industry.

There were hundreds of working and classic trucks on show, mainly from the South Island but also from the North. It’s one of the few shows that allows full combinations. The Classic Trucks Showcase and

Legends Lawn were highlights this year, celebrating trucks from yesteryear.

Visitors numbered in the tens of thousands over the two-day event (official numbers were still to be released before we went to print), with a festive vibe among everyone there to celebrate trucks and trucking.

Paul Fellows, Australian Truck Safe chair, Jenny Fellows 2024 ATA National Trucking Industry Woman of the Year, and Kevin Walsh, Truck Safe manager ATA, also travelled across the ditch to visit the show. “Your presence strengthens the bonds between our associations and countries and our ongoing collaboration,”

said New Zealand Trucking Association CEO Dave Boyce. He also congratulated all Show ‘n Shine entrants: “The effort you guys and gals put into your gear is amazing. I’ve polished a few trucks in years past and I know the amount of work that goes in; it’s pretty impressive. We want to celebrate your dedication and pride. Well done to you all.”

He also thanked the team behind the scenes: “The association is a small but dedicated team, and their tireless effort made this possible. Led by Carol with Debbie, Bill, John and Katie, the NTA board and volunteers, your passion and

commitment to this event and the industry as a whole deserves a huge round of applause.”

The NTA thanks all sponsors and exhibitors, with special mention to TMC for its ongoing support as title sponsor, as well as event partners Teletrac Navman, BP and TR Group.

Special thanks also go to the following sponsors, Ancra Cargo and Transcold (networking happy hour), Sime Darby (Best Hino, Best Mack, Best UD, Best Volvo), Penske (Best MAN, Best Western Star), Palfinger (Best Mounted Crane), Transpecs (Best Fleet, Best Tipper), Keith Andrews (Best Mercedes-Benz, Best Freightliner, Best FUSO),

Category

0-50,000km Jesse Rout Nyroad Civil

1,000,000km+ Hayden Hilhorst Pokuru Farms

50,000-500,000km Daniel Mott Melx Linehaul

500,000-1,000,000km Craig Hayward Steve Martin Contracting

Best Chrome Kerry Inns K+T Trucking

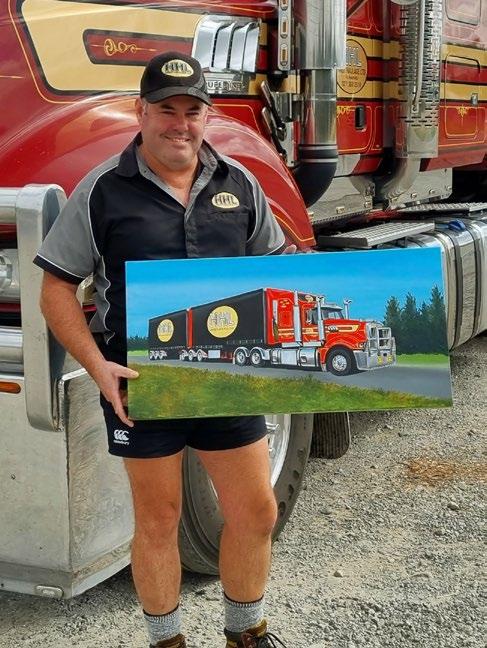

Best Combination Neil Harpur Hilton Haulage

Best Container Craig Murphy Hilton Haulage

Best Curtainsider Hailey Lilley APL Direct

Kenworth T909 (328)

Mack Ultra-Liner (293)

Kenworth K200 (308)

Kenworth T610 (103)

Kenworth K104 (291)

Kenworth T410 (170)

Kenworth T410 (165)

Scania R-Series (313)

Best DAF Andrew Bascik Transport DAF CF85 (230)

Best Flat Deck Burnell & Son

Best Graphics Jo Neustroski Mainline

Kenworth K200 (293)

Kenworth K200 (306)

Best Hino Paul Highstead Fiveash Contracting Hino 500 (337)

Best International Murray Taylor Sprout Central International (320)

Best Isuzu Sheryl Kinsman Allied Concrete Isuzu F Series (126)

Best IVECO William Reilly SML IVECO Trakker (148)

Best Kenworth Rob Jefferies Bascik Transport

Best Logging Will Cowan SML

Kenworth K200 (237)

Kenworth T659 (133)

Best Mack Hayden Hilhorst Pokuru Farms Mack Ultra-Liner (293)

Best MAN Nick Welbeloved Darkside Linehaul/Strait NZ MAN TGX 640 (276)

Best Mounted Crane Anja Liemburg Hilton Haulage Scania P500 (171)

Best Scania Neville Ward ED Swain Scania R620 (215)

Best Stock Mike Hislop Ellesmere Transport Volvo FH16 (289)

Best Tanker Iain Donnelly NPD Scania 770 (258)

Best Tipper Gavin Rowe Road Metals Volvo FM (243)

Best Transporter Jake Taylor Porter Haulage Kenworth T909 (100)

Best UD Bradley Dakon Ocean Spray UD Quon CG460 (333)

Best Under 10 tonne Brett Flower Tyre General Isuzu A Series (281)

Best Volvo John Bell Hiab & Transport Solutions Volvo FM

Best Western Star Adriaan Bourke SML Western Star

Best Working Rig Reece Martin Steve Martin Contracting Kenworth T610

Best Mercedes-Benz Erik Crosse Hilton Haulage Mercedes-Benz Actros

Best Freightliner Quentin Rodgers S.R.SS Transport/Move Freighliner FRL Argosy

Best FUSO Jonny Brown Mackleys Fuso

Best Service Vehicle Brett Flower Tyre General Isuzu A Series

Best Small Fleet (4 Trucks) Chris and Tracy Hancock Hiab & Transport Solutions

Best Fleet (5+ Trucks) SML

Peoples’ Choice Erik Crosse Hilton Haulage Mercedes-Benz Actros

Drivers’ Choice Earl Rolfe Titus Transport Western Star

Owner Driver Best Truck Mark Amer Mark Amer Transport Kenworth SAR Legend

Women In Trucking Diezal Mattingley Blue Diamond Haulage International 9870

Truck Of The Show Rob Jefferys Owner Driver/Bascik Transport Kenworth K220

Best Classic Truck Chris and Tracy Hancock Hiab & Transport Solutions Mack Super-Liner

Oldest Truck At Show Andrew Kane Akaroa Distribution Diamond T

Most Original Truck Murray Taylor Sprout Central International T Line

Best Classic Ford John Baillie Baillie Transport Ford N5036

Best Classic Fleet Shane Pearson

Best Classic American Mark Chalmers Dynes Kenworth

Best Classic European Andy Protranz Volvo N10

Up And Coming Talent Traye Mckenzie Owner-Driver/Strait NZ Kenworth K104

Best Truck On A Stand Cooltranz Kenworth K220

The teams had to load and secure two IBCs, the driver had to complete the course with the guidance of the director without the use of their mirrors, and then the IBCs had to be offloaded, all while incurring the least amount of penalties.

New Zealand Trucking’s Dave McCoid took on the direction role, CJ was the driver and Yogi the forklift operator.

TWL (Best Small Fleet, Best OD Truck), Hammar (Truck of the Show), Spartan Finance (Peoples’ Choice, Drivers’ Choice).

Turn to the NTA’s column on page 108 for more on the show, including the Friday industry networking events and sessions, and to page 120 for more highlights from Little Trucker Down Under junior reporter Dustin Wright.

The 2025 Kamo Touch a Truck event was another outstanding success, bringing community together and raising funds for the Kamo and Ngunguru fire brigades.

This year, Northland’s iconic Touch a Truck Show saw a significant increase in participation, attracting a total of 109 truck entries, up from 80 the previous year.

However, the actual turnout of trucks on the day was affected by adverse weather conditions from the day before, with some exhibitors – including Northpower – losing two trucks to storm damage in Mangawhai.

Despite these challenges, 82 contenders competed for the coveted Truck of the Show title, showcasing a diverse range of impressive vehicles.

The event kicked off with a spectacular convoy of close to 60 trucks that travelled the 12km route from Semenoff Stadium to the show venue at Hurupaki School, thrilling spectators and participants alike.

Although the weather posed some difficulties, the

family-oriented event drew about 3000 visitors, a drop from the 3500 attendees recorded in 2024.

While gate revenue was down this year, other areas, such as food sales and truck entries, experienced growth. The total revenue is estimated to be about $10,000, which is comparable to last year’s figures. This revenue will be shared between the Kamo and Ngunguru fire brigades, supporting essential services and community initiatives.

Local policeman and volunteer firefighter Andrew Ivey, co-organiser of the show, emphasised its importance and the funds raised. He says the contribution plays a crucial role in maintaining brigade facilities and ensuring safety within the community. One critical use of the funds is to install necessary CCTV systems at fire stations, which help

protect equipment and vehicles during emergency calls.

Andrew expressed gratitude to the drivers and owners who displayed their vehicles. “We extend our heartfelt gratitude to those who opened their cabs to the children and the public, allowing them an up-close experience. This interaction embodies the spirit of Touch a Truck, making the event special for families and truck enthusiasts alike.”

He also thanked the sponsors for their valuable support.

The prize-giving at the end of the day was a highlight, as various prize packs were

awarded to winners.

“Although this event may not be a significant fundraiser – since we could potentially earn more through other means – the community atmosphere and the joy it brings to families is what truly makes this event worthwhile.

“It’s a day of celebration, connection and fun, embodying the spirit of our community and reinforcing the bonds that bring us together.”

Kamo Touch a Truck would also like to thank all the prize sponsors, particularly Fulton Hogan, Domett Trailers, and Springs Flat Roadhouse.

CATEGORY SPONSOR WINNER

Truck of the Show

– Drivers’ Choice TWL

Truck of the Show

– People’s Choice Golden Bay

Best Mack Mack NZ

Ellwood Transport Scania (40)

Whangarei Diesels Mack (52)

Newey Transport (71/72)

Best Volvo Volvo NZ Golden Bay (13/61)

Best Mercedes-Benz Keith Andrews Trucks

Ellwood Transport (43)

Best FUSO Keith Andrews Trucks Alden Chick Transport (32)

Best Freightliner Keith Andrews Trucks Semco (55)

Best Kenworth Commercial Diesel CV Compton (74)

Best DAF Commercial Diesel

TDL/Semco (57)

Best Isuzu CAL Isuzu Virgin Concrete (15)

Best Hino Hino/CDL

Exclusive Boat Haulage (97)

Best UD UD Trucks North Harbour Towing (22)

Best Western Star Penske New Zealand Harrison Transport (92)

Best MAN Penske New Zealand

Best Scania Scania

Mainfreight – Sahib (111)

Ellwood Transport (40)

Best Curtainsider Scania Semco (53)

Best Logger Mills-Tui

Best Specialty Rig Get Delivered

Best Linehaul TWL

Douglas Logging (81)

Golden Bay (13/61)

Ellwood Transport (40)

Best Tipper Black Stag Deli Alden Chick Transport (32)

Best Tractor Unit Mainfreight

Exclusive Boat Haulage (97)

Best Fleet Golden Bay Mainfreight

Furthest Travelled

MODEL: JH6-T6HR

5th wheel included

3 YEAR, UNLIMITED Km WARRANTY

BRIEF SPECS: JH6 6x4 High Roof, Flat Floor Sleeper Tractor

ENGINE: FAW CA6DM3: 550hp | 1917 ft/lb Peak Torque

TRANSMISSION: ZF AMT 12 Spd | Manual Mode Selection Intarder with 4 Stage Brake Selection

BRAKE SYSTEM: Disc Brakes, Knorr Bremse | Wabco System

FRONT AXLE: Rated 7.7T, Parabolic 3 Leaf Springs

REAR AXLES: Rated 26T, Diff Locks, Inter-axle Lock

REAR SUSP: ECAS | 8 Bag with Shocks and Stabalisers

SAFETY FEATURES: AEBS, LDW, ESC, FCW, EBS, 360d Camera Display

CAB SPECS: 4 Bag Cab Suspension | 1.95m Ceiling height

760mm Wide Bunk | Fold-away Upper Bunk

ISRI Seats with Fridge Drawer under bunk

10” Display Multiple Function Touch Screen

FRAME RAILS: 700 MPA Tensile Strength | 300 x 80 x 8mm

MODEL RATINGS: GVM 25,500kg | GCM 70,000kg (90T on application)

Excluding GST, Includes ORC, no trade: $221,000 8160kg +/- 1% TARE

Premium Interior Layout

SOLID BUSINESS REASONS to BUY a FAW:

● Intertruck is an Experienced and Trusted Importer with PARTS Stock in New Zealand

● FAW is backed by 21 Nationwide Dealers and Service Centres in New Zealand.

● Lower Cost of your new Fleet Asset allows Growth in other areas of your Business.

● JH6-T6 leads South Africa in Fuel Economy.

● Over 500kg LIGHTER than Euro Brands.

● FAW is a well known and Respected Brand in 80 Countries Worldwide.

Story and photos by Dave McCoid

An event that was all about the kids –Nelson’s Kids n Rigs held in February this year brought industry together with those who will drive tomorrow forward, putting on a show that would embed itself in the hearts and minds of families who turned up in droves.

“We haven’t had a Nelson Truck Show since 2019,” says co-organiser Chris Webby. The brainchild of Drummond Transport driver Darren

‘Dingle’ Letham, he and Chris got together with a posse of volunteers to put something on with a different angle. Aiming the show at the young ones and getting them up close and even inside trucks is nothing new – however, the plan was to make entry for families free, and everything for kids inside the grounds free also.

“We wanted families to come and enjoy a day out that wouldn’t hit their pockets at a time when there’s not a lot of discretionary income about,” says Darren.

“As at 1pm on Friday we had 25 trucks registered,” says Chris.

“We thought, ‘Oh well, it’s the first for a while and it’ll take a year to get going’. Then by 5pm, we thought about 55 would likely show based on the phone calls we were getting, and look, there are 87 here. Now we’re running!” Neither could the pair speak highly enough of the support they’ve received from local businesses. “Bread, sausages, water, ice creams – even infrastructure like BBQs and fridge trailers to keep it all hot and cold – you can’t overlook that,” says Chris. “The kids can have a ball and families feel they can just come along.”

Aside from the great turnout,

there were endless activities, food and refreshment stalls. Local carriers provided a ride-in-a-truck fleet, a huge hit as you might imagine.

Even with the lost-cost model the committee put into action, the show was still able to raise $6000 for the Child Cancer Foundation.

Thanks team!

Darren and Chris want to thank the amazing team who came onboard to help: Reuben Eggers, Tamara Eggers, and Grant Wilkins.

1) We know this man well (New Zealand Trucking August 2024; The Family Tradition). Grant Wilkins giving back to the industry he loves, taking the eager masses for a ‘burn’. 2) S & K Hill’s Kenworth W900B was a popular, throaty, ‘rolling coal’ choice for the those in the queue.

Top Truck – Stuart Drummond Transport – Kenworth K200 (PBK613)

2nd in Show – Quail Valley Free Range – Freightliner Argosy (JLA457)

3rd in Show – Borlase Transport – Volvo FH16 (MRA498)

Best Japanese – Sollys Freight – FUSO HD FS3147 (PJN42)

Best European – K&M Trucking (O/D to MOVE) – Scania S770 (PQM872)

Best American – Austin Transport Services – Kenworth K200 (KML748)

Best Classic – S & K Hill – Kenworth LW924 (1973KW)

Judges’ Choice – Cotton Heavy Haulage – Kenworth K108 (GAK629)

Peoples’ Choice 1st – NJP Logistics Ltd (O/D to Daily Freight) – Scania

Peoples’ Choice 2nd Equal – Tama Solly Contracting – Kenworth T659 (JFQ886), and Nelson Tow & Salvage – Kenworth W900 (KW900L)

Local fleets on display in front of their local communities. 1) AC Palmer and Sons. 2) Westhaul from Motueka. 3) The amazing Lift N Shift fleet of artisan crane operators. 4) Borlase Transport was absolutely spectacular.

Tama Solly proved that class is eternal – one of the all-time great Kenworth models, the T650, giving no hint to the uninitiated that it is in fact a classic.

Story by George Barrow Photos by Euro NCAP

ITOY

We bring you exclusive truck industry content from fellow International Truck of the Year member publications.

Euro NCAP revealed the first-ever Truck Safe star ratings for heavy trucks at the end of last year. How did the fleet of 2024 get on?

Volvo’s FM and FH Aero have been named the safest trucks on the market by renowned automotive safety testing body Euro NCAP.

The first Truck Safe 2024 results for new heavy goods vehicles awarded the maximum five-star rating to the two Volvo models. The Scania G-series and Renault Trucks T tractor units were awarded a four-star rating, while the MercedesBenz Actros L, Scania R-series, MAN TGX and DAF XF were all given four-star scores.

The IVECO S-Way scored the lowest, with a one-star rating.

Euro NCAP began addressing commercial vehicle safety in 2021, introducing a commercial

van rating based on the standard equipment levels found in LCVs.

Euro NCAP hopes the launch of new truck testing will help inform businesses and fleets about their purchases while promoting greater levels of standard safety systems.

The introduction of the EU’s General Safety Regulation 2 (GSR2) has increased the amount of standard equipment commercial vehicle manufacturers have to fit to their vehicles, but Euro NCAP’s more stringent testing goes further than minimum safety system requirements.

As a result, two of the initial HGVs tested (IVECO’s S-Way and the Mercedes-Benz Actros) have underperformed as the

manufacturers did not wish to participate by supplying the most up-to-date models.

The testing looks at active and passive safety, with Euro NCAP currently rating the trucks in two main categories, with plans for further assessment classifications later.

For now, testing criteria cover safe driving, looking at the systems and overall design that will prevent the risk of an accident, and collision avoidance, where safety systems intervene to prevent an accident. A third classification for postaccident rescue, assessing how emergency services can gain access to or make a vehicle safe, has seen all vehicles scored the same but will evolve

as more vehicles (including electric trucks) are tested.

All manufacturers were invited to submit their largest tractor units for testing, with Scania and Volvo opting for additional testing of their G-series and FM models, respectively.

“Euro NCAP is voluntary, and we are only celebrating those manufacturers that go above and beyond,” explains Matthew Avery, Euro NCAP director of strategy development. “We’re recognising manufacturers that offer significantly enhanced safety from what is required by law. A lot of manufacturers go above and beyond; vision is a good example of this. DAFs, which have excellent direct vision, are ahead of the regulations,

and the regulations won’t go beyond what DAF currently does until 2029,” continues Avery.

The DAF XF scored the highest percentage for a full-size cab in the safe driving category with a score of 85%, bettered only by the 87% achieved by the smaller and lower Volvo FM. Euro NCAP praised the XF for its vision performance, recognising it as having class-leading sight lines with very deep windows, low belt lines, a lower door window and a camera monitoring system (CMS) replacing traditional mirrors. Unfortunately, it was let down by its collision avoidance score, registering only 35% with no lane support system, cyclist detection and only an adequate performance for its

IVECO’s own GSR2-compliant vehicles are in the process of being rolled out.

advanced emergency braking (AEB) for vulnerable road users.

“It [DAF XF] is three stars with really good vision, securing a top safe driving score. However, the collision avoidance technology is only average. Generally, manufacturers have either put the emphasis in stage one [safe driving] or stage two [collision avoidance],” Avery says.

In addition to the overall star ratings, a number of vehicles were also given a City Safe Award to recognise the truck’s suitability in an urban delivery environment. As well as the DAF XF, the Volvo FH Aero, Volvo FM and Scania G-series were given city-safe status.

The IVECO S-Way has received a one-star rating largely because

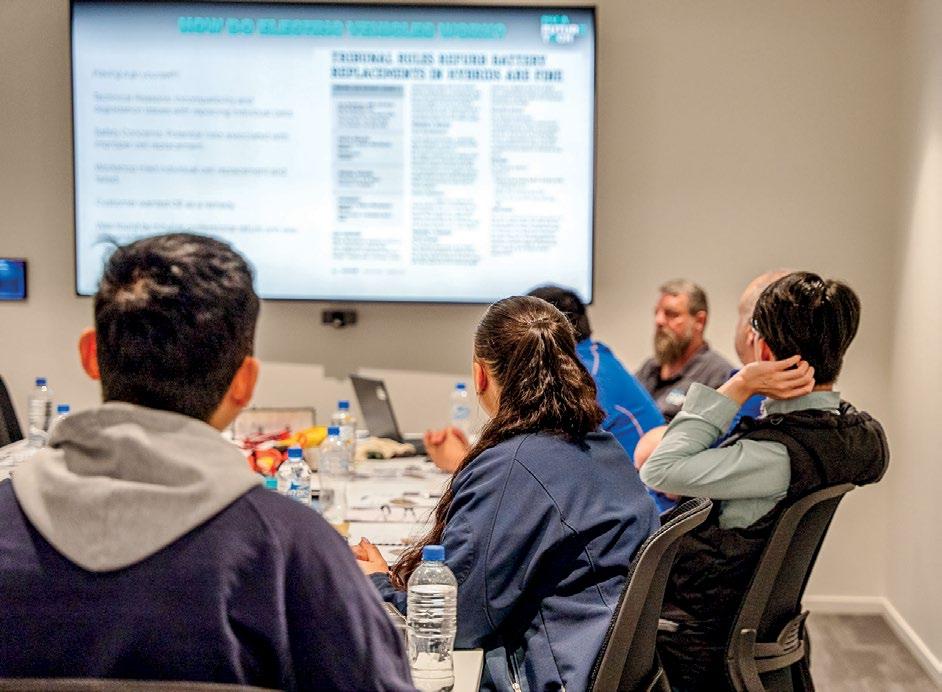

“For now, testing criteria cover safe driving, looking at the systems and overall design that will prevent the risk of an accident, and collision avoidance where safety systems intervene.”