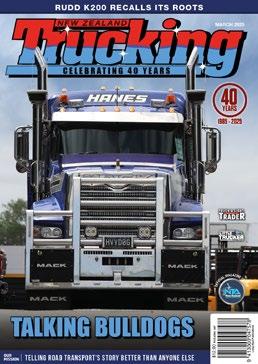

CELEBRATING 40 YEARS

New Zealand rally car driver Hayden Paddon is teaming up with Caltex New Zealand this year to put its market-leading Caltex Havoline engine oil to the test.

Hayden is New Zealand’s most successful rally driver, nationally and internationally. In 2011, he became the first person in the southern hemisphere to ever win a World Rally Championship and since then has graced the World Rally Championship and New Zealand Rally Championship podiums on several occasions.

After a successful 2024 season, the 2025 season marks a new era for Hayden and his motorsport team, Paddon Rallysport

Group (PRG), as they continue to build their strength locally and embark on more international competitions.

To help Hayden and his team on their quests to victories this year, Hayden and PRG have partnered with Caltex to maximise vehicle performance with Caltex oil.

The partnership between Hayden and Caltex New Zealand seemed like a natural fit for the rally car driver, having watched New Zealand rally legend Possum Bourne partner with the brand many years ago.

“As a kid, I remember vividly Possum in the Caltex Havoline colours – something that was synonymous with rallying in the early 2000s. To now have our team

representing Caltex Havoline is a proud moment and it is helping us with products to keep our cars performing at a high level,” says Hayden.

Caltex’s Havoline oil will be put to the test by PRG this year in a double rally campaign, involving a full rally championship in both New Zealand and Australia, something that has never been done by any team.

“To help us win on the stages, we need the best of everything and the range of Havoline products we are now using in our Hyundai Rally2 car complements our whole programme,” says Hayden.

“To help us win on the stages, we need the best of everything and the range of Havoline products we are now using in our Hyundai Rally2 car complements our whole programme,” – Hayden Paddon

With New Zealand Trucking magazine celebrating 40 years, it made Caltex reflect on its oil evolution over that time.

Caltex Delo – likely the more known product range by truck and heavy fleet drivers – is the premium oil used by thousands of trucks across the country. Since its introduction in 1971, Caltex Delo 400 Multigrade SAE 15W-40 has set a high standard for engine oil performance. It was the first product to address the lubrication needs of both diesel and petrol engines, establishing itself as a universal solution for a rapidly growing automotive industry.

Over the decades, Delo has continuously evolved to meet the demands of modern engines, culminating in the development of the advanced Delo 400 SLK SAE 15W-40 that is now sold to customers.

In response to the growing demand for improved emissions compliance, fuel efficiency, and advanced engine protection, Chevron introduced the Delo 400 SLK SAE 15W-40 under the Caltex brand in the Asia-Pacific region. This next-generation oil embodies the company’s commitment to continuous innovation, incorporating advancements in lubricant technology.

Caltex is a market leader in engine oils, and with distributors around the country the products are easily accessible and used by thousands of customers.

To find out more about the product range scan the code or visit: www.caltex.co.nz/for-businesses/about-lubricants

DIRECTOR

Margaret Murphy

EDITORIAL DIRECTOR

Dave McCoid

027 492 5601

dave@nztrucking.com

EDITOR

Gavin Myers 027 660 6608 gavin@nztrucking.com

For all advertising enquiries:

ADVERTISING MANAGER

Pav Warren 027 201 4001 pav@nztrucking.co.nz

Mike Devon 027 332 4127

mike.devon@nztrucking.co.nz

Maddy McCoid 027 336 6811 maddy@nztrucking.co.nz

SUB

021 182 4803 shannon@nztrucking.co.nz

Craig

Niels

Tim

New Zealand Trucking magazine is published by Long Haul Publications Ltd. The contents are copyright and may not be reproduced without the consent of the editor. Unsolicited editorial material may be submitted, but should include a stamped, self-addressed envelope. While every care is taken, no responsibility is accepted for material submitted. Opinions expressed by contributors are not necessarily those of New Zealand Trucking or Long Haul Publishing Ltd. All rights reserved. This magazine is subject to the New Zealand Press Council. Complaints are to be first directed to: editor@nztrucking.co.nz with “Press Council Complaint” in the subject line. If unsatisfied, the complaint may be referred to the Press Council, PO Box 10 879, The Terrace, Wellington 6143 or by email at info@presscouncil.org.nz

Further details and online complaints at www.presscouncil.org.nz

6 months (6 issues) $70

One year (11 issues)

1 Year Australia (11 issues)

1 Year digital (11 issues) $45

In September 2000, I had a pivotal experience. I’d just turned 12, and for my birthday, a good family friend gifted me a subscription to Car Magazine – ‘The motoring journal of Southern Africa’, as it was tagged at the time.

Being mad about anything with wheels and an engine –especially cars – I devoured every word and image on every page for the next decade and then some. Over time, I added to the collection with past issues going as far back as I could find and read those, too. My enthusiasm for reading each issue cover to cover only really abated once I’d had a few years of writing for a living. Funny how that works.

The pivotal bit? That subscription put me on a path to a career in magazines. By 15, I knew what I wanted to do with my life; I wanted to be editor of Car

I didn’t realise that ambition. But I did become motoring editor of a newspaper and work my way up to editor of three individual magazines – two of

Adecade has passed since I first sat in the editorial office at Fairfax Media on the two-month journey to my first solo magazine – the June 2015 issue (magazine months remember, not calendar).

I’d contributed to the magazine from not long into its life – thank you Jon Addison for taking the punt on a bunch of truck-crazed young blokes from within the industry. But the hot seat was a different world entirely, the learning curve beyond vertical.

Why did I take it on? There were two reasons. One, I’d been mildly critical of our old ‘bible’ in the preceding year or so,

which were truck magazines, one of them being the title you’re reading right now.

Even then, as I finished school and began my journalism studies, people questioned the decision to go into print. The internet was on the rise, rapidly.

But, Car is still going and only a couple of years away from its 70th anniversary, and despite being well settled in New Zealand, I maintain a subscription. I’m sentimental like that…

Likewise, New Zealand Trucking celebrates 40 years of publication this month, and it’s still going strong. It’s nothing short of an honour to be a part of the magazine at this point in its history, as No.7 in the editor’s hot seat, driving content.

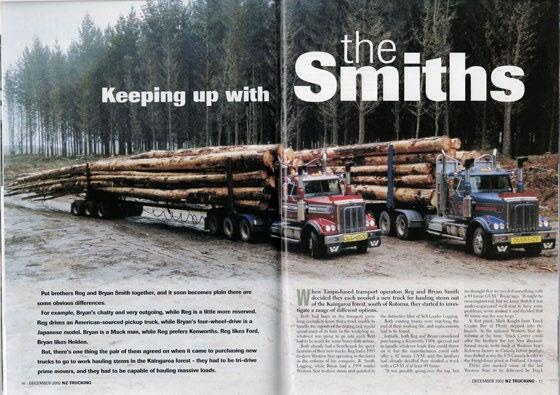

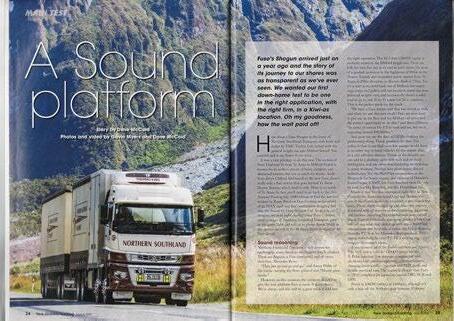

Having paged through our archive of past issues to compile some of the historical content you’ll see beginning (by chance) on page 40, it’s clear that it hasn’t changed a bit in some ways, while in others, it’s changed a lot. The foundations are still all there – great content, editorial

which put me in an interesting position. I’ve witnessed drivers over the years criticise ops guys, yet decline the opportunity to take control of the phone, RT, and dairy. I therefore had no choice if I was to hold to principle.

Two; I wanted to prove that one of us could look after our own magazine in the event we needed to. I wanted to do the driving community proud.

I’m still terribly starstruck when meeting and interacting with those in the industry I consider heroes, especially when they ring me, their name and number lights up on the phone – ‘Is this for real?’ I think.

In my 10 years at the helm,

integrity, a passionate team and dedicated writers. Of course, over four decades, it’s been necessary to keep up with the times … much of the content published then would never fly today, and much of today’s content wouldn’t have appeared in even the most creative pieces then.

That gift subscription created a genuine passion in me for magazine media. And in an increasingly digital world, I derive real joy in seeing a publication thrive, especially when so many others have been lost. Is it a tougher environment than 20, even 10 years ago? Unquestionably. And a far cry from the glory days of the 1980s and 1990s.

But they’re funny things, magazines. Despite all the moves to digital, with its instant access to any content you could want and the ability to consume it in

I’ve got to see, photograph, write about and interact with every corner of an industry I have been passionate about from the time I saw my first truck. It’s always been trucks … when life has derailed me, it’s trucks that have re-railed me.

Then there are the people I’ve met within, those I worked for, and those who have worked with me – partners and co-workers. Every day, I underserve those who devote their work lives to making New Zealand Trucking Media’s content vehicles the best they can be. They’re an incredible group of inspirational people, utterly dedicated, and I can’t do enough to try and do better by

moments, magazines are still the most highly regarded. They’re still the authoritative media. They’re tangible. Permanent. There’s real value in that and we know people only part with their hard-earned cash for things they value. We never forget you could just as easily choose to get your trucking content for free elsewhere, which is why we’re driven to improve New Zealand Trucking magazine, year after year, decade after decade. Thank you for being a part of our journey. I hope you’ll truck along with us for the next four decades and more.

Gavin Myers Editor

them. To them I say, it has been one of the honours of my life to be part of yours.

Lastly, the two names that are the reason all of us are here.

The two blokes who took a deep breath and launched a magazine in March 1985 where nothing had been before. They changed the course of their lives and ours. To Trevor and Jon, every single one of us will be eternally grateful. Here’s to 40 fabulous years that’s been, and hopefully 40 fabulous years ahead.

Dave McCoid Editorial Director

Enquire about our new van refrigeration package

Enquire about our new van refrigeration package

Enquire about our new van refrigeration package

Enquire about our new van refrigeration package Enquire about our

New range of HE (High Efficiency) fridge product due out on Truck and Trailer

New range of HE (High Efficiency) fridge product due out on Truck and Trailer

New range of HE (High Efficiency) fridge product due out on Truck and Trailer

New range of HE (High Efficiency) fridge product due out on Truck and Trailer

Enquire about our service and safety check packages on all the Dhollandia tail lifts

Enquire about our service and safety check packages on all the Dhollandia tail lifts

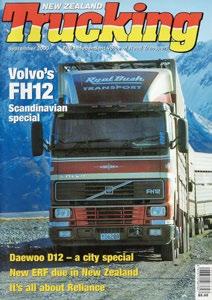

Volvo Trucks has made the all-new fuel-saving Aero range available in the New Zealand market.

After debuting in Europe in early 2024, the FH Aero range showed efficiency improvements of up to 5% in testing.

The FH Aero will be available in New Zealand with a choice of 13L and 17L Euro-6 ICE

powerplants, as well as Volvo’s heavy-duty electric driveline.

Operational results show that the ultimate fuel saver will be the FH Aero with I-Save. This turbo compound unit is rated at 372kW (500hp) yet punches out 2800Nm of torque.

The proven 13L 402kW (540hp) also remains an option for Aero, as does the new D17 powerplant in ratings from (447kW) 600hp and 3000Nm up to 581kW (780hp) and 3800nm. Aero cab options span sleeper, Globetrotter XL and Globetrotter XXL options.

The aerodynamic improvements of the Aero range have been attained by extending the front of the existing FH cab by 240mm, allowing for a smoother, more rounded cab front. This is shown to reduce drag and, as a result, energy consumption.

“We’re pleased to be launching the Aero range in New Zealand. This truck represents another great improvement from Volvo to progress sustainable transport, with the added benefit of lowering running costs for operators,” said Scott Robinson, national sales manager, Volvo Trucks New Zealand.

Volvo’s newly launched Camera Monitor System (CMS)

also comes as standard on FH Aero. CMS features a zoom-out function, automatic panning that tracks the vehicle’s rear while negotiating intersections, fixed reverse panning, and an infra-red mode for low-light conditions. CMS drastically improves the driver’s field of view around the truck.

The system’s camera lenses are heated and automatically activate depending on the outside temperature to ensure a clear view in all weather conditions.

“The drive experience of this vehicle is very impressive. The performance of our new generation I-Shift transmission, Euro-6 engine range and powerful electric drivetrain, and the range of powerplant, including the new D17, provides options that allow operators to tailor the Aero perfectly for their application,” said Robinson.

“It’s remarkably smooth and quiet to drive. Given that safety is a primary focus for Volvo, the Aero comes with the added driver support features like Pilot Assist and Front Short Range Assist to detect vulnerable road users, available across the Volvo heavy-duty range.”

Booth’s Logistics has announced the public release of B CONNECTED, a next-generation customer portal designed to transform how businesses manage their freight and logistics.

Available now for all existing and new Booth’s customers, the stage one release of B CONNECTED provides public track and trace functionality for all general freight and container movements available at booths.co.nz.

In addition to this, all Booth’s Logistics customers now have access to their own customer portal, designed to provide them with one central port of information for all their general freight and container movements.

“B CONNECTED offers you, your team, and your customers real-time data and makes available all the mission-critical customer tools when and where you need them,” said Dallas Vince, Booth’s Logistics CEO.

Inside B CONNECTED, customers can submit and book new freight jobs, including accessing estimates for quoting, get track and

trace visibility on the status of all freight consignments, subscribe to SMS or email notification for tracking and delivery events, submit enquiries regarding all freight jobs, get details about freight and transport rates, see network status updates, including any weather disruptions, ferry delays, and so on, see a fully embedded reporting suite of logistics services and carbon emissions.

Booth’s Logistics has an ambitious roadmap for B CONNECTED, with intentions to integrate warehousing, health and safety, finance, and even carbon emissions reporting.

The rollout of B CONNECTED has received a strong response, with over 500 companies and 1000 users onboarded over the past few months.

To help streamline the onboarding process, Booth’s has also created an online training hub. This includes an overview video, a series of FAQs, a user manual, and stepby-step how-to guides to help ensure a smooth experience for all existing and new clients using the portal.

Trust Ixom and SCR for dependable AdBlue supply in NZ. Contact us at sales@scrsolutions. co.nz or 0800 145676 for all your bulk, packaged, and dispensing equipment needs. Reliable, secure solutions when you need them 24/7.

Rotorua’s Mills-Tui has just completed its 50th medium water tanker for Fire and Emergency New Zealand.

The truck is a Hino FG1628 AT SPRING and features a 280hp engine, Allison automatic transmission, vehicle stability control and alloy wheels.

Mills-Tui specialises in designing and manufacturing a full range of heavy transport truck and trailer units, fire-fighting and other related emergency vehicles. It

communities, as well as defence applications. Its water tankers support fire appliances where water supply is an issue.

The company’s medium water tankers are now nationwide, working to help protect rural New Zealand communities, including eight incident support vehicles

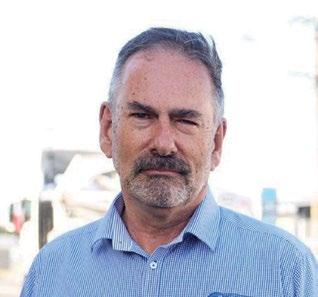

Penske Australia & New Zealand has made two new appointments to its executive leadership team. Gary Bone has joined the

leader with a strong track record of achievement, Gary will utilise his comprehensive industry experience in managing our onand off-highway operations.

leadership that will hold him in good stead as he brings a fresh approach to this newly created role.”

Most recently, Gary held

Following the sale of Hyster New Zealand to Adaptalift Group Australia on 28 February, general manager Mike Rule stayed within the Sime Motors group, taking on the role of general manager, Hino Distributors NZ.

Over the past eight years, Mike has worked across three Sime Motors New Zealand businesses, gaining extensive knowledge of the commercial transport

industry. Before joining Hyster NZ in 2022, he filled senior roles at TWL and Truckstops.

“Mike has consistently displayed a collaborative, handson leadership style that adds operational value while building a strong team,” said general manager for Sime Motors Commercial, Michael Doeg.

“Most recently, he has successfully worked with the Hyster team and Adaptalift to deliver positive outcomes for both businesses. After rising to the top of the list in a competitive recruitment process, we are delighted that Mike’s chosen to stay within the group.”

Hino Distributors NZ imported the first Hino trucks from Japan in 1964. The Sime Motors NZ Group (formerly Sime Darby Motors NZ) bought the distributorship in 2004.

“I’m looking forward to working with another world-class brand,” said Mike.

“My focus will be on supporting the team to ensure Hino is represented to its full potential in the New Zealand market. With Sime Motors’ backing, I’m excited to be in a position to lead the team and grow market share through the delivery of a great customer experience.”

On 31 January, Sime Motors NZ announced it has entered into an unconditional sale and purchase agreement to sell its Hyster New Zealand business to Adaptalift Group. Adaptalift has been the sole dealer for Hyster Yale in Australia since 2009 and opened its first New Zealand branch in East Tāmaki two years ago.

“When our parent company, Sime Darby Berhad, acquired Toyota forklifts as part of the global purchase of UMW at the end of 2023, it had a downstream impact on our dealership agreement with Hyster Yale in New Zealand,” explained Michael Doeg, general manager Sime Commercial Sales NZ. “We invested a lot of time selecting the right business to take Hyster New Zealand forward, with a key focus on offering attractive terms of employment for employees and a clear vision for the future. Adaptalift was the right fit on both counts.”

“Hyster New Zealand is a strong business with deep customer relationships, great technical expertise and a nationwide footprint. Our initial focus is on supporting business continuity, working closely with the team and customers to ensure service levels are maintained and optimised,” said Steven Taylor, Adaptalift CEO.

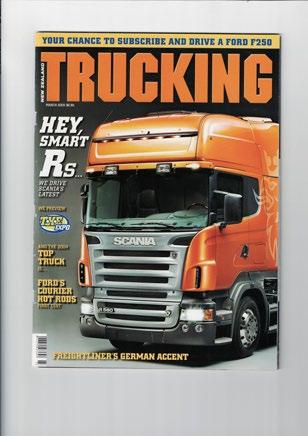

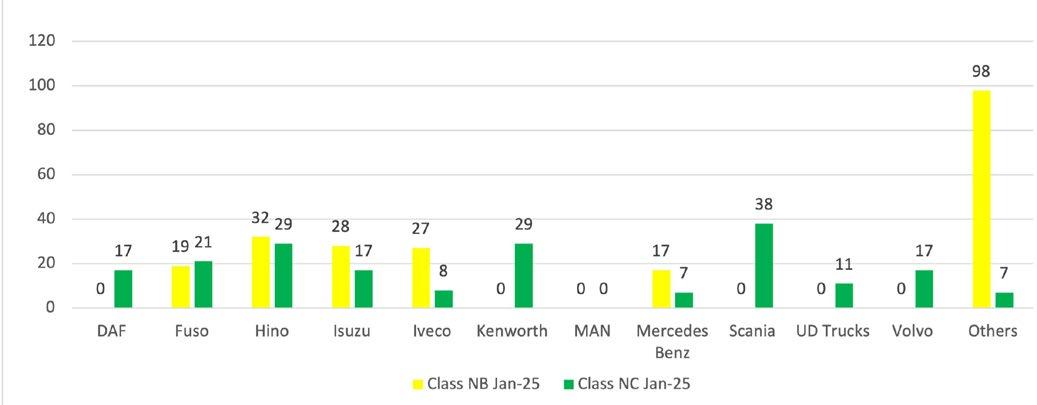

Scania New Zealand has achieved remarkable success by securing the No.1 position in market share for heavy trucks for the fifth consecutive year in 2024.

The brand gained a market share of 22.9% and registered 646 heavy trucks in 2024.

In addition, Scania is ranked among the top five brands for all new trucks and buses over 3500kg, with 649 registrations. This underscores the company’s strong presence in the overall market while focusing on heavy trucks above 16,000kg.

This accomplishment comes despite challenges in the current economic environment, as highlighted by managing director Victor Carvalho.

“I’m incredibly proud of our team here at Scania New

Zealand – to be No.1 for five consecutive years is a fabulous achievement.

“We also have the largest 10-year rolling fleet in the country, so these achievements are not only a testament to the

team but also to the loyalty of our valued customers, who have contributed to a successful year in what has been a challenging and competitive landscape,” said Carvahlo.

Scania NZ has appointed Thomas McDonagh as its new dealer director north.

McDonagh comes from his previous branch manager role at Scania Rotorua, which he held for nearly four years, and replaces Mark Wright in the dealer director north position.

The role is responsible for managing the four Scania branch managers at Whangārei, Auckland, Waikato and Rotorua and ensuring the branch network has the resources required to deliver Scania’s premium customerfocus on parts and servicing.

“I am very motivated about my new leadership role within the Scania NZ team.

The good thing is after working alongside the branch managers for a number of years, I’m very familiar with the dynamics of the team, and I look forward to getting the very best out of my high-quality colleagues so we can continue to do our very best for our clients,” said Thomas.

Scania NZ has one other dealer director role (dealer director south) held by Kelly Henshaw, who covers the remaining five branches located across southern and central New Zealand.

Dealer directors are part of Scania NZ’s executive management team, reporting directly to managing director Victor Carvalho.

The International Truck of the Year (ITOY) Group has announced that Florian Engel, ITOY member for Austria, and Fabien Calvet, ITOY member for France, have been elected chair and vice chair of the Truck of the Year organisation, respectively.

Gianenrico Griffini, who has been chair for the past 16 years, will become the chair’s special advisor.

Florian Engel, Fabien Calvet and Gianenrico Griffini will work closely further to develop the organisation’s initiatives and international presence.

The ITOY Group is also pleased to announce that Joseph P. Howard, vice president and executive editor of Transport Topics, has been appointed ITOY Associate Member for the US, joining a team of 35 commercial vehicle journalists

and trade publications with a combined readership of more than 1.2 million truck operators worldwide.

From us at New Zealand’s Associate Member publication, welcome to Joseph and Transport Topics and a heartfelt congratulations to Florian and Fabien. Gianenrico’s tenure at the helm has left big shoes to fill. We look forward to working with you all in the coming years.

Southern Automobiles dealer principal Michelle Findlater is the 2025 recipient of the Janet Lane MNZM Scholarship, awarded by MITO and the Inspiring Futures Foundation in their annual scholarship awards. Michelle will use this scholarship to complete the Harvard Division of Continuing Education’s Certificate of Leadership Excellence in Strategy and Innovation.

The Janet Lane MNZM Scholarship is awarded to a single individual each year to support an intensive and comprehensive course of management and leadership study. Named to honour MITO’s former longstanding chief executive, Janet Lane, the scholarship is designed to enhance and accelerate opportunities for individuals

whose development of leadership capabilities will have a significant impact on the performance, productivity and profitability of their sector.

Michelle Findlater, who has over 20 years’ experience in the automotive sector, is just such an individual.

Before joining Southern Automobiles in 2024, she held senior roles at Scania NZ and GWD Motor Group and has a demonstrated commitment to governance and leadership. She has also shown an exceptional dedication to continued learning, having completed bachelor’s and master’s degrees in applied management alongside her employment.

Earlier in her career, Michelle completed MITO’s Certificate in Automotive Electrical Engineering and Certificate in Business (First Line

Management). In 2016, she won the Motor Trade Association’s Female Achievement in the Motor Industry Award, and in 2021, she completed the MTA’s Aspiring Directors programme.

“This opportunity represents a critical step in my academic and professional journey, and I look forward to the possibility of learning from and contributing to the esteemed Harvard

- 32 Hastie Avenue, Māngere Bridge, Ph: 09 634 8500 Hamilton - 38a Maui Street, Ph: 07 849 5128 Tauranga - 12/45 Kaweroa Drive, Tauriko, Ph: (07) 282 9910 Palmerston North - 25 Bisley Street, Ph: 06 355 9033 Christchurch - 38a Parkhouse Road, Ph: 03 343 6814

community with the support of MITO and the Inspiring Futures Foundation,” said Michelle.

The certificate programme will take a year to 18 months to complete and Michelle, who, as a condition of the scholarship, has already registered with and been accepted by the Harvard Division of Continuing Education, will begin her studies immediately.

MODEL: JH6-T6HR

5th wheel included

3 YEAR, UNLIMITED Km WARRANTY

BRIEF SPECS: JH6 6x4 High Roof, Flat Floor Sleeper Tractor

ENGINE: FAW CA6DM3: 550hp | 1917 ft/lb Peak Torque

TRANSMISSION: ZF AMT 12 Spd | Manual Mode Selection

Intarder with 4 Stage Brake Selection

BRAKE SYSTEM: Disc Brakes, Knorr Bremse | Wabco System

FRONT AXLE: Rated 7.7T, Parabolic 3 Leaf Springs

REAR AXLES: Rated 26T, Diff Locks, Inter-axle Lock

REAR SUSP: ECAS | 8 Bag with Shocks and Stabalisers

SAFETY FEATURES: AEBS, LDW, ESC, FCW, EBS, 360d Camera Display

CAB SPECS: 4 Bag Cab Suspension | 1.95m Ceiling height

760mm Wide Bunk | Fold-away Upper Bunk

ISRI Seats with Fridge Drawer under bunk

10” Display Multiple Function Touch Screen

FRAME RAILS: 700 MPA Tensile Strength | 300 x 80 x 8mm

MODEL RATINGS: GVM 25,500kg | GCM 70,000kg (90T on application)

SOLID BUSINESS REASONS to BUY a FAW:

● Intertruck is an Experienced and Trusted Importer with PARTS Stock in New Zealand

● FAW is backed by 21 Nationwide Dealers and Service Centres in New Zealand.

● Lower Cost of your new Fleet Asset allows Growth in other areas of your Business.

● JH6-T6 leads South Africa in Fuel Economy.

● Over 500kg LIGHTER than Euro Brands.

● FAW is a well known and Respected Brand in 80 Countries Worldwide.

Excluding GST, Includes ORC, no trade: $221,000 8160kg +/- 1% TARE Premium Interior Layout

Napier-based electric vehicle charging startup

Kwetta has closed an oversubscribed $17.5 million series A funding round.

The company said the milestone would help address one of the biggest bottlenecks in EV adoption – unlocking the electricity grid, especially for applications like heavy transport, fleets and large-scale charging hubs.

Kwetta was founded in 2021 and has rapidly expanded its footprint in New Zealand’s charging infrastructure with 39 high-powered charging outlets, with more on the way.

“At Kwetta, we’re electrifying

transport for a more sustainable future,” the company said.

“When we started in 2021, our vision was clear: create technology that enables largescale electrification without the usual roadblocks for customers of high costs and delays.

“Today, the Prime Grid Gateway, our grid-first innovation, is turning that vision into reality by unlocking grid capacity for ultra-fast EV charging without expensive upgrades or batteries. This funding allows us to take that mission global, scaling faster and innovating further.”

The new funding, led by Blackbird Ventures and

supported by Virescent Ventures (backed by the Clean Energy Finance Corporation), Icehouse Ventures and others, will enable Kwetta to expand into new markets like Europe and Australia.

“Heavy transport is electrifying faster than anyone

expected, and the demand for solutions like ours is exponentially growing,” the company said.

“Thanks to our team’s hard work and our partners’ confidence, we’re ready to help fleets, trucks, and buses electrify while keeping the grid intact.”

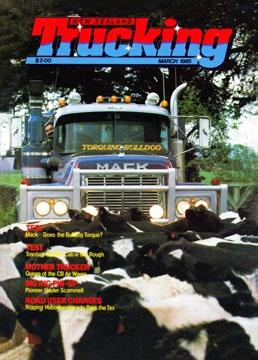

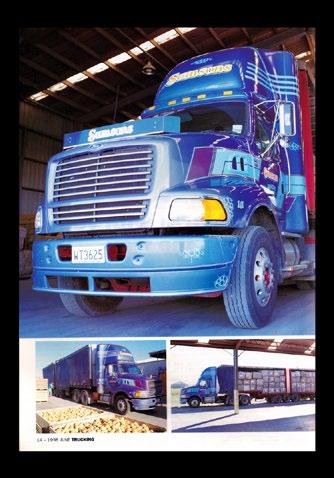

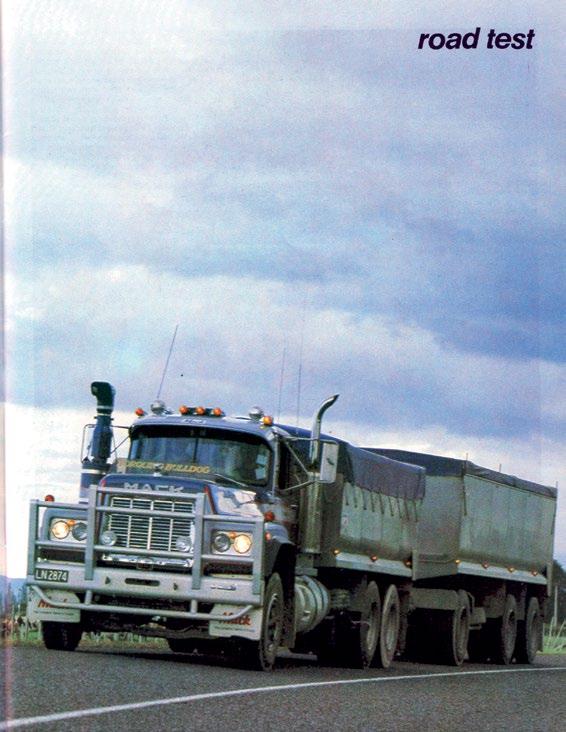

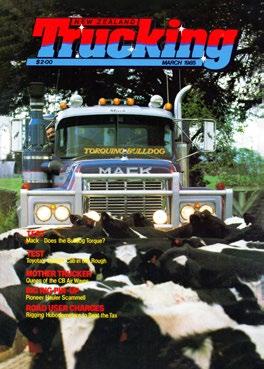

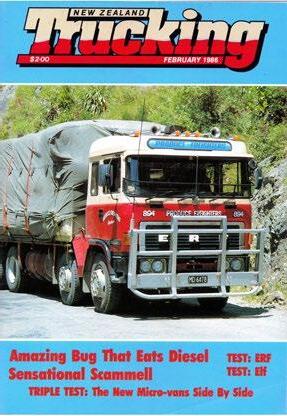

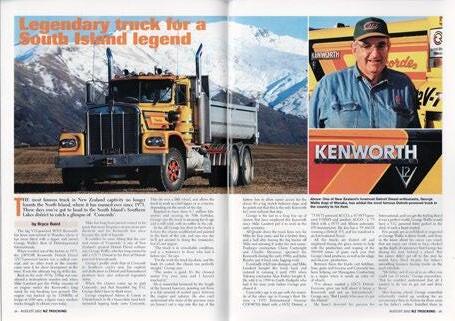

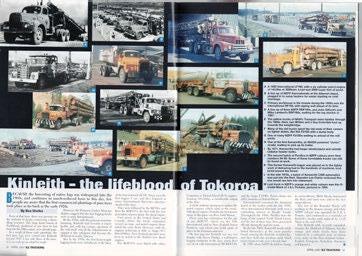

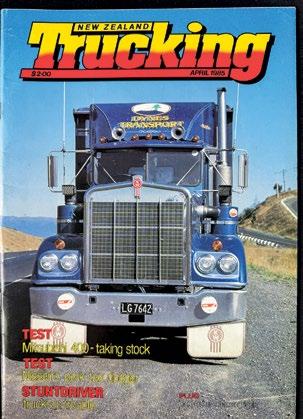

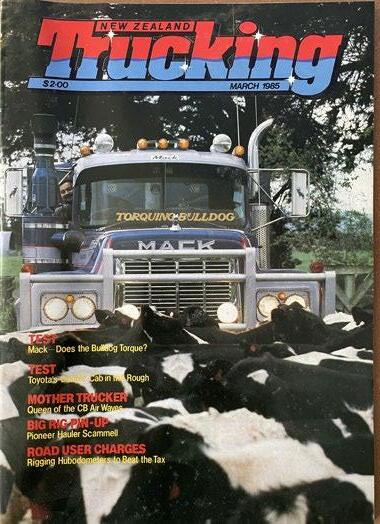

The first issue of New Zealand Trucking magazine hit the shelves with a blue R-Model Mack from the Waikato adorning the cover. The truck’s name was Torquing Bulldog and it was owned by the magazine’s co-founder, Trevor Woolston, a contractor to Dibble Independent Transport at the time. Forty years to the month, we wanted a blue Mack from the Waikato on the cover again. Holy cow! Did we hit the nail on the head with the truck(s) we chose and the story behind the incredibly humble family who owns them.

One of the neatest things about my time at New Zealand Trucking magazine has been the ability to unlock many personal mysteries. Take Hanes Engineering, the wee forklift business on the side of SH1 Te Rapa – on Hamilton’s northern approaches. Ha ha, I hear you, but phrasing it that way was an intentional time stamp because that’s when the mystery started for me: riding in stock trucks to the neighbouring Horotiu freezing works, and then years later, rolling by in the MH Mack with a load of sawn timber for somewhere in Hamilton’s interior. It was a place bound to invoke an inquisitive reaction from any diesel- or machine-head passing by, posing far more questions than its humble presence could ever hope to answer. It always seemed there was more going on.

And now, decades later, here I am, sitting in a room at that very site, with current patriarch Chris Hanes. There are detailed answers to every question I’ve ever pondered and a confirmation that this is far more than a building and an eclectic collection of

used forklifts … all available to industry at a price sealed with a handshake.

Of course, the increasing presence of the company’s road fleet in recent years does more than hint at a hidden complexity. I was right! There was more going on. Four Top Trucks in New Zealand Trucking magazine also points to someone amid it all for whom trucks are more than Trojans of utility, serving to tell the world a little about the pride you have in what previous generations of your name have achieved. And that brings us to the question …

Other than a blue Mack form the Waikato, we had sort of hoped for, but realised it would be a little unlikely, a company celebrating a birthday. This is, of course, our 40th birthday issue and Rudd Transport, which owns the bedazzling Kenworth K200 gracing the poster in this issue (page 48), is 40 this year also. “Hmmm?’, we thought. ‘A birthday hat-trick? Is that even possible?’

Although we weren’t going to attempt the full OCD with three companies turning exactly 40 –one of whom just happened to be based in the Waikato with a recently purchased blue Mack – we did feel we’d won Lotto when the Hanes name popped back up on our radar. They had the truck, you couldn’t get any more Waikato-based if you tried, and last year, the business turned 70! Plus, they’re an old friend, always willing when we call, so that was kind of nice, too. In fact, they support either publication when they call, so hats off for that to them, too.

It was early summer when I popped in, and Deb Hanes (wife of Simon – generation three) greeted me. “Simon’s away overseas, but I reckon he’ll be up for that, for sure! Call him when he’s back.” We did … he was … bingo!

Let’s not forget either, that any small local business that had been trading for over a decade when Neil Armstrong took one giant leap, saw JFK’s worst day, witnessed Norm Kirk pass away in office, Muldoon’s downfall, has survived the oil shocks of the early 1970s, the stock market collapse of the mid-1980s, the GFC, a pandemic (good grief!) … that firm has something to teach us all – and now would be a good time, all things considered.

One big lesson we’re retaught at Hanes is hierarchy. I ask Chris what his position is to get a fix

on where he and the two of his four sons in the business, Simon and Christopher, mesh. Chris stares back across the table, contemplative, with almost a baffled look. “I’m generation two, and Simon and Christopher are three – Carter is four. Well, I’m still here,” he chuckles, “so I guess, I suppose I’m … um.”

And there it was, right there in that moment – leadership is about the respect you’ve earned, not the label you slap on your chest plate, and believe me that respect walked in and out of the office all interview long. Anyone and everyone felt comfortable wandering in, and they were there simply to update Chris on what was going on, or seek a snippet of wisdom that would contribute to a decision they were making – not one being made for them. Let good people do what you trust them to do. The style is endemic through generation three also, and like so many long-standing businesses of their ilk, the hardest game to play in the dayto-day operation at Horotiu is ‘spot the Hanes’.

The other interpretation of the question points to the company’s activities. Walk through the gates at Horotiu and it appears the answer is ‘everything’. There are sheds and trucks, cleaning bays, engineering shops, painting bays, all buzzing with people here, there and everywhere. It’s largely container sheds and well-established portacoms, and Simon says to a greater extent

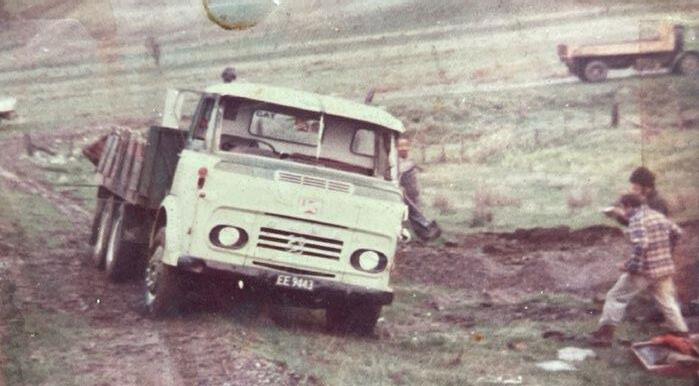

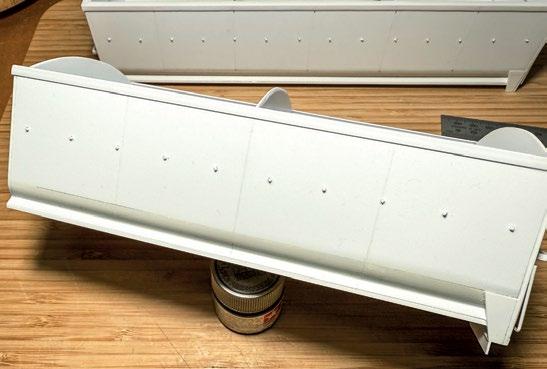

1) The original sand drying and screening plant at Horotiu. 2) The Commer shortly after it was stood up post mishap. She was all good … on we go. 3) The Nissan Diesel Tasker with a typical return load from a buying trip. 4) The Bedford TM with a hopper Chris took to Wairoa. “We had to jack it up to clear some bridges.” 5) The Fiat arrived in the same era as the TM. An ex-Shell tanker, Chris said it was a good machine to them. 6 & 7) Although the Fiat ended up in the blue livery, the ERFs were the real pioneers of eye-catching trucks at Hanes. 8) The TM in all her glory and almost ready for Wheels at Wanaka 2025.

that’s a zoning thing as much as an expediency thing – there are other facilities elsewhere.

The deck/smoko room combo typifies the camaraderie that appears woven into the company’s DNA, a place where everyone goes to chill and chat.

Where does it all start then?

The engineering shed out at the roadside recently adorned with the 70-year logo, still the family engineering firm today. That shed, and Chris’s father Ivan Hanes … Well, sort of.

“We hail from Gisborne originally, my mother Elaine was

a Huntly girl. Dad came to the Waikato to work for his uncle Vesti Thomas who had Hamilton Engineers and Traders, and between he and my grandfather they sort of got Dad established.

“My grandfather Charles Herbert Hanes was an only child and New Zealand-born in 1896. Neither of those two things were overly common for the era,” says Chris. “It was Charles’ predecessors who immigrated, 1844 I think it was. Carter and his generation are actually the fifth New Zealand-born generation.”

A World War I veteran, Charles worked for the New Zealand Loan and Mercantile Agency Company in Gisborne, that company eventually merging with Dalgety & Co in 1961 to become Dalgety and New Zealand Loan. “He eventually ended up the New Zealand boss for Dalgetys, and it was he who helped Dad with the seed money for Hanes Engineering. Charles lived to 102, passing away in 1997, so I knew him very well.”

Chris was one when the family relocated to Horotiu

from the one-room shed they’d rented off Dick Wymer down by his sandpit on River Road in Hamilton. With his new shed up, Ivan was in business on 24 June 1954, taking on whatever needed building or re-engineering. In time, the lastever Keith Hay house moved from Auckland to Hamilton arrived also – the Hanes was established!

As a subcontractor to Clyde Engineering, he was heavily involved in the truck repowering era so prevalent in the wider region post-war, up to the

early 1970s. The big Americans were still a way away and the demand for more capable trucks was insatiable on the back of exploding regional growth, forestry, and infrastructure projects. “Perkins 6354s, Caterpillars, and 6V53 GMs all into Commers were common. Mahons, the circus people, they liked Cats in their Commers. John Mahon has still got one in his shed,” says Chris.

“It was different then. When I said he’d do anything, that meant anything to make ends meet, and that might mean digging drains if the engineering was slow. Although we still have a dedicated engineering business, and always will, it was his willingness to do anything in the early days that resulted in what we have today.

“Dad died in 2008 aged 80. We only had the one truck then and he said, ‘You know, I can see the day where we’ll have six trucks.’ I wonder what he’d think of it today with 11 in the fleet.” Visibly emotional, Chris says, “When he was close to passing, I remember him telling me, ‘Don’t

forget where you come from.’ I’ve held that close ever since.”

Aside from the engine conversion work, road cleaners built on S Bedford chassis for Dick Wymer, coal carrying decks for Watt Brothers in Ngāruawāhia, and reconfiguring NZCDC TK Bedford 4x2 tractors for their second life on-farm or elsewhere, were all part of the Hanes’ work profile.

As the business grew, Ivan chose not to keep up with the emerging mass-produced structural market – sheds and barns, etc. “Dad could see it was an area of growth, but too competitive and low margin. Although we did a lot of structural engineering, it was all quoted jobs.”

Growing up in and around the business was Chris’ life, and he remembers his early involvement in the truck work. He followed the family path, qualifying as a fitter turner and fitter welder, and in time, worked on some of the biggest jobs, like welding in the foundation sections of the

Huntly Power Station chimneys, welding on the sheet piles during the building of the first shore-to-ship slurry pipeline at Taharoa, and tank assembly at Wiri Oil Services.

Innovation and opportunity can pop up when there’s a dearth of key materials in an economy buzzing with big projects. By the early 1970s, one of those key materials was blasting sand.

“The demand for dry, clean, and multi-grade blasting sands was increasing and at the same time, there was a move away from silica-based sands, mainly for health reasons. Going to places like Whiritoa on the Coromandel, or Roose’s up the road for our sand was out of the question.

“We sought and were awarded a mining licence on the West Coast north of Te Akau at Matira. I’d been out there looking and it was really good stuff – I had it analysed at the DSIR [Dept of Scientific and Industrial Research] and it was 98% iron, it was the best in the country.”

The plan was to cart it back

to Horotiu in the business’ trusty Commer, where it would be screened and then put through a dryer Ivan had built from an old rail concrete mixer ex the Turangi power project, heated using a Cat D8 injector pump and atomiser fed with waste oil. From there, it was cooled in a series of large hoppers. “Cooling it was the problem; once it was through the kilns you couldn’t get the heat out of it; it would stay hot for weeks. You couldn’t bag it due to heat and weight. At times, we had trouble carting it because it would melt the covers on the truck.

“Of course, access to and from the mine was the issue, you had to cross private farmland and the locals weren’t too excited about trucks on the terrible roads west of Te Akau village. Permission to access was a contingency of the licence and therefore the mine’s location. Luckily, we found a willing farmer who saw huge personal value in the access road we would develop from his place, out to the coast proper. Another condition was no trailer, truck only, even though local stock Over size coming through.

trucks ran trailers.”

With a Ruston-Bucyrus RB10 dragline on site and ready to go, the Commer TS3 with a 6354 Perkins repower set forth on cartage duties, a young Chris at the wheel most of the time. Having 120hp (90kW) on tap, a five-speed transmission and two-speed diff, it was no real match for the access road, or the rural roads that led away from the farm for that matter.

“The first hill away from the load-out was a big one. If it ran out of power before the top, I’d simply roll back and take some off … then have another go. The days we had three loads to do were long, I can tell you.

“We only had one ‘oops’. I laid it over on the access track. Dad came out and the farmer helped us. We winched the deck back into place on its side so the ram wasn’t damaged, stood it up, chucked the popped windscreen in the cab next to me, and off I went. You just sorted stuff in those days. Now there’d be all sorts of people out there, probably a helicopter, goodness knows what.”

With more than enough product to meet their own

requirements, word soon got around and before they knew it the Haneses had an additional enterprise on their hands.

“We carted to Rotorua, you’ve got no idea how long it took to get there in the Commer …” Chris says with laugh, shaking his head. “Three and a half to four hours.”

The Commer was replaced in time with a Nissan Tasker 6x2 they converted to 6x4. The truck’s four-cylinder, twostroke engine was buggered and replaced with a 6V71 GM at 250hp, backed up with a 10-speed Roadranger.

“It was still truck-only out to the mine, although in time, we would sneak out with a trailer. We got away with it because we were never a threat. We’d be courteous on the road, and when asked about the chance of bringing a load of metal out, we would always deflect the request away to ‘Skin’ Henry, or Te Akau Transport.”

Marsden Point, Taranaki, Rotorua, Ōhāki, Wiri, they were all destinations for the Tasker.

“If you looked over the sides, it looked like you had nothing on the deck. I remember being

pulled into a weighbridge on the way up north once – I was often pulled up but never weighed. The cop asked if I had much on and I said no, of course. He looked over the side and said, ‘Oh hell no, that’s nothing, off you go.’ I was close to 50 tonne when I got there! It was 98% iron, you see. It looked nothing!

“The sand wasn’t a daily thing you realise. I did an Auckland load weekly, but the rest was as required by the customer,” Chris adds.

By the late 1990s, the blasting sand business was succumbing to a combination of a drop-off in the Think Big projects and bigger players in the sand and aggregate supply businesses moving in on the action.

It was the late 1980s when Ivan was down at the pub one night and did a deal to buy Gene Horne’s 661 Machinery Centre located on the Te Rapa straight where The Base shopping centre is now. Gene dealt in forklifts and all manner of machinery, purchasing, wrecking, on-selling.

He had the contract to purchase New Zealand Forest Products’ excess forklifts, it was a good business.

“I had to get the truck and go down and cart it all back here. That was the start of the forklift wrecking, parts and refurb business, still a core in the Hanes business today. It’s diversified a lot, but that was the start.”

The 661 purchase got the Tasker involved in a whole new world of cartage – linehaul!

“We were always travelling to auctions and sales – still do – to bring back stock we could strip for parts, reconfigure, or tidy up and on-sell. We modified a twoaxle tilt deck trailer to carry the forklifts, fitting hydraulics and a winch to carry forklifts, to go behind the Tasker.”

Chris remembers one memorable trip to Whanganui for a railways auction. “Me, Fergus King and a very young Simon left Horotiu at 2am and headed down through the Paraparas. I bought a couple of F20 forklifts – they’re 14 tonne each – plus a bunch of stuff, compressors and the like. By the time we loaded it and headed for home it was about

eight or nine at night. We ran out of power on one of the hills in the middle of the Paraparas somewhere. I kept the engine running and held the brakes while Fergus headed off into the night to find help. He came back with a farmer and a D-Series Ford and we managed to get going. The farmer offered to follow us through to the end in case we got stranded on the last climb just before Raetihi. We crested the top under our own steam at about 1000rpm; she was dropping off real quick. We syphoned diesel out of the forklifts to get us home on that trip. In those days, it was all cheques and often places wouldn’t take a cheque for fuel from an outsider, so we’d often carry fuel in case we needed it. We arrived home about lunchtime on Sunday, I think. Yeah, I’ve had a few horsepower issues over the years.”

Dealing with the constabulary in the pre-deregulation era proved eventful and timewasting on occasions also. In those days Hanes only carted its own product, but Chris recalls one occasion on a weighbridge near Levin where the Queen’s representative took some convincing. “Dad had to drive down from Horotiu with the paperwork before I could move!” (Who said emails and texts were a pain in the arse?)

“We’ve bought lots of stuff over the years. Three AvelingBarford dump trucks from Wanganui Road [Marton] – I brought them home on the Commer, two stripped down and one whole. One of them was turned into a forklift. World War II dump trucks reconfigured to forklifts for Delta Timber here in Ngāruawāhia. People don’t realise it now; you just couldn’t get forklifts back then.”

The truck fleet has increased steadily from that time on the back of growth and diversification in the core modern-era businesses –engineering and forklifts. The venerable Tasker was replaced

with an ex-Shell Fiat 619 tractor set up to cart forklifts, with a new Rawhiti Farms three-axle transporter on air suspension allowing the rear to drop down. “That was a good truck, 260hp with a Roadranger. Everyone knocked the shit out of me for having the air suspension on a transporter, but they didn’t understand our needs. Forklifts are a very specialist item to move – they’re high, point loading is huge, they need full decks, the ramp angles and all that. Most transporters are built to cart bulldozers and big gear. Our transport business was built on the back of no one wanting to move our forklifts.

“The Fiat was really the first truck we did outwork with on a regular basis. Simon has expanded the business as a specialist transporter of forklifts and scissor-lifts, the hard-to-cart materials-handling equipment.”

The Fiat was also the first truck to wear the Hanes blue livery. It was joined by a TM Bedford and trombone semi, the trailer obviously a support to the engineering business also. The TM is still in the company’s keep, recently undergoing a full restoration for the up coming Wheels at Wanaka 2025.

Truck brands at Hanes have been a mixed bag over the years. An R-Model Mack, ERF EC10s ex the UK, Freightliners in bonneted and cabover guise, IVECOs, they’ve all contributed to the wider business and materials-handling transport story. Today, the fleet reflects that evolution with highprofile units like Volvo FHs and Scanias pulling purposebuilt B-trains, and an IVECO S-Way semi combination, each encompassing everything learned over four decades in the business of hauling materialshandling equipment. The technology available in modern trailer systems has certainly played its part also.

Then there are the two big Macks set up in a more traditional vein for bigger, brutish loads. “Nick Kale at MTD has been great to deal with on the Mack purchases,” says Simon.

“He’s super passionate about the Mack product and it shows.”

Trailers are varied in terms of brand also, says Simon. “We have units from both local suppliers, and find TRT is great for the hi-tech stuff with the smarts it builds into the trailers, and MTE fits the big, heavy role really well.”

In classic Hanes style, the culture fostered around the trucking side of the distribution work celebrates the individual discipline, evidenced by not just the four Top Truck posters on the roll of honour, but most recently the Best Fleet Award at this year’s Bombay Truck Show.

“One man, one truck, and we’re now able to give them really good equipment. Plus, it is challenging work at times and that appeals to the good operators who like to be tested.”

The entrance to the Hanes business today still belies the activity and operations encompassed therein. The traditional cornerstones of engineering and all things forklift comprise the bulk of daily toing and froing, but it’s a case of how far can you take an idea.

“The distribution of OEM forklifts works really well with the parts and refurb business because we can often take traded stock off them,” says Simon. “With the exception of the Manforce off-road forklift, we don’t sell new. It just keeps us out of everyone’s way.”

(Shades of not treading on the

local carriers toes in the sand recovery days.)

“We do some storage of inventory. We have the room so we’re able to help; there’s a lot going on all the time. I just go where I’m told.

“Every aspect of what we do is specialised. Our ethos is we chase customers, not work. We don’t go looking for work, we look for commercial relationships and we focus on looking after them – we can offer a lot more than merely cartage. Many of our clients have been with us for a long time.”

Big, little, on- and offshore, there’s nothing this humble operation and its people won’t have a go at building, fabricating or moving.

“Our people are everything,” says Chris, always turning the limelight away from himself. “All our engineering boys are ticketed, and we do stainless. We’ve just completed a big cooling tower project. Last year we built a boutique meat plant in Central Otago, and we help with maintenance and shut work next door at AFFCO Horotiu.

“Greg Belk runs the engineering division. The Belk family has worked with us a long time – three of Greg’s sons work in the business and Greg’s late uncle Kevin also worked here for many years. They are wonderful craftspeople and a

Much easier to change lanes on the expressway when the trailer is narrowed up...

November 2015 / April 2021

Two of the four Hanes Top Trucks to have featured over the years.

wonderful family; we would do anything for them.

“Dave McGrath in the transport operations does a wonderful job for us. He despatches and pilots, and knows where everything is and what’s happening.”

In terms of succession, it looks like the incredible Hanes story is far from over. “There are four boys. Simon and Chris work in the business. Simon is taking over from me, and his wife Debbie handles a lot of the commercial arm. Christopher manages all the technical and compliance side of things. Their brother Karl works in law enforcement in Queensland and Mark is CEO at the Huntly Power Station, says Chris.”

Generation four is also present with Carter (21), currently driving the SuperLiner, and a diesel mechanic in his own right. Like all great family businesses, there’s no coercion or pressure on each generation to pick up the banner – but with engineering, machines and trucking all vocational occupations, it’s oddson someone’s going to grow up wanting to get involved from the moment their eyes can focus.

In a lovely touch to round out this part of the story, we end at the beginning recalling Ivan’s counsel to his son about never forgetting where you come from. On the day I interviewed Chris, I had to wait a few moments before we could sit down and start yarning. Chris was doing a deal on a forklift with John Mahon, current generation at Ngāruawāhiabased Mahons Amusements, a firm so entrenched in the fairground business in New Zealand, it almost qualifies as Kiwiana. Here, amid the hustle and bustle of the 2025 business, was a customer/supplier relationship as old as the Hanes business itself, with the two patriarchs having a yarn over a machine, a yarn that ended with a handshake.

“We’re turning into our fathers,” John said, laughing. “We can’t throw anything away!”

Enthusiastic and happy to chat, always up to tackling a challenge, and individualistically old-school, 49-year-old Mark Dennis is the type of driver who fits an operation the style of Hanes like a glove.

Having grown up in Morrinsville, Mark’s parents bought a farm near Tauranga before he finished school, which he did at Tauranga Boys’. Like many, growing up on farms meant an interest in machinery that naturally morphed into a career driving.

“I’ve been driving since I was 18; this is all I’ve done,” he says. Mark’s first job was driving an eight-wheel Leader for Renco in Tauranga, and only a couple of years later, he graduated to long haul with Regal Haulage.

“I saw an ad for this company near Hamilton that went all over the country. So I shifted over and stayed with my sister in Hamilton. I was with Regals for five or six years, and came back later for a couple of years. I loved it there as a young fella.”

Mark started interisland work in 1996 on an old drop-side International T-Line with Regals, taking a load of NZ Woman’s Weekly magazines from Auckland to Christchurch. “None of those trucks had power; it was a slow trip!” he says.

The bulk of his driving work has been on curtainside flatdecks or transporters – he’s been driving for Hanes full-time for six years, on heavy haul, but has been associated with the company for about two decades.

“I worked for LCL (pre-Altranz) and Hanes had one transporter when Simon had his ERF; we were subcontracted to do all the extra work. I enjoy this. Sure, you get your moments when it gets stagnant and you do your smaller loads or have three weeks of runs into Auckland, but I’ve never liked doing the same old repetitive work. That’s why I’ve never been into general freight, I can’t be bothered with it.”

Brought up on Macks and Kenworths – “I’ve always been a Mack fan, but Kenworth are good

gear” – Mark’s personal truck-owning history includes an Argosy and an MAN, a truck he rates highly.

“In 2015, I went to buy this Aussie-import Western Star at Penske in Auckland, but the truck was actually at another branch. The salesman suggested I take their MAN demonstrator for a drive, and I really liked it. It was something different, I’d never driven auto and never had all that tech. The newest truck I had was the Argosy from 2002.

“So he talked me into it and I bought a new tractor unit. I had it for four years and did about 400,000km, and out of all the trucks I’ve driven that was one of the better trucks I had. It held its own with only 540hp, and it was dangerously fast with its intarder … You’d go downhill at 50t and not touch the brakes once. It was a good truck; I really rated it. Never had an issue with it other than it chewed tyres.”

It was with this truck Mark taught the youngest of his two daughters (now 23 and 21) to drive off the wash bay at the age of 12, and passing on his knowledge to the younger generation is something he sees huge value in. “My girls didn’t follow me into the industry, but that’s okay. I try to coach the young fellas – that’s why we come in on Saturdays. It’s all about doing tyre pressures, fixing marker lights, all that,” he says.

Having enjoyed a life of driving, Mark’s kept a record of his travels in one of the coolest ways we’ve heard about. “I’m old school. I used to always buy the old AA maps at the service stations, and I’ve kept all of my old AA maps from around the country. I don’t go and buy them now obviously, but I’ve got a huge map on the wall at home, which I mark with a felt pen every time I drive a new road. That’s interesting! The whole map’s covered. It’s cool, too, because I get to mark the spots I want to holiday. I have a bad habit of not taking holidays. So when I do, it’s good to pick the cool spots!”

PART 2

Story by Gavin Myers

orklifts. When we think of these wonders of 20th century industrial equipment, the first to come to mind would likely be your typical counterbalanced unit zipping around a yard or warehouse moving pallets of goods from point to point. But look up types of forklifts and these plus everything from the simplest pallet jacks to truckmounted side loaders, and reach stackers to container handlers, is included in the definition.

And, as you’d have read in part 1, Hanes Engineering has specialised in selling, hiring, fixing and moving them all countrywide for decades. Well, maybe not the humble pallet

jack, but certainly the motorised types. Today, we’re at the larger end of the scale, shifting the second of three Hyster 48-16CH container handlers for KiwiRail from a rail siding yard in Frankton, Hamilton, to the KiwiRail Southdown terminal on Nielson Street, Onehunga, Auckland.

With any normal truck, this would be a roughly 120km journey straight up SH1, taking about two hours with a clear run. Today, though, we’re carrying about 45 tonnes of machine and grossing out at just over 75 tonne, meaning that once we get to Ararimu Road, Ramarama, we need to zigzag our way along the heavy-haul

route, which follows Great South Road through Drury and Auckland’s southern suburbs.

“The Super-Liner picked up all the attachments yesterday. It takes six loads altogether to move the three handlers,” explains Simon Hanes when we meet him, Dave McGrath (dispatcher/operations), and Mack Titan driver Mark Dennis at the Kent Street siding yard at 8am.

This work is all about time – and taking as much of it as you need, whether loading up or threading through morning urban traffic … taking it slow, thinking, checking and doublechecking, leaving plenty up your sleeve to deal with issues

and get the job done without incident. Though the oversize load can’t hit the road before 9am, the men already have the Hyster positioned and chained to the MTE three-rows-of-eight (and clip-on) Linkwing widening low loader.

With nothing to do but wait, it’s the perfect opportunity to take it all in and learn about the job. To accommodate ‘big yellow’, a fourth-row clip-on is attached, though we’re running without a dolly. “It would look impressive for the photos, but it’s not really needed for this job. This trailer does the job well with the clip-on,” says Simon, adding Hanes runs MTE on the heavy-haul trailers.

1) Door card continues the theme of chunky interior fittings. 2&3) In-house-made lockers, guards and other bits add a touch of individuality and showcase the Hanes capability.

The business currently has a fleet of 11 trucks and eight full-time drivers, with Mark’s Titan and [Simon’s son] Carter’s Super-Liner specced for the heavy lifting. We say “Mark’s” and “Carter’s” because Hanes generally follows a ‘one truck, one driver’ policy. “We try to keep it that way if possible. Some of the guys still have the delivery plastic on parts of their cabs!” says Simon.

“They treat the trucks as their own, and I treat it that way, too. But Dave and I will still jump in if needed. We have a couple of small round-town trucks for local deliveries, and even the long-haul drivers will jump in those if they’re hanging around with nothing to do.”

“It reminds them where they came from and how good they get it the rest of the week,” Dave says with a laugh.

“Yeah, it’s good to have drivers for whom nothing’s a problem,” Simon continues.

“You’ve got to be careful asking them if they can do stuff, though, because they’ll say yes regardless. They could be going to their own wedding and they’ll still say yes!”

Considering what we learnt in part 1 of the Hanes Engineering story, we wouldn’t be at all surprised to learn there’s a hint of truth behind that comment.

Like most other sectors, the digger and forklift markets began 2025 in a bit of a lull. “Diggers have crashed lately across the board, not even the little two- or three-tonne ones are moving, and a lot of those that are are just going into storage,” says Simon. Forklifts have slowed

Interested in a classic Hanes masterpiece where looks can be incredibly deceiving?

Look no further than this doozy. On a clear summer morning in East Tamaki, we’re at the premises of Aisle Master New Zealand, the local agent for the incredibly versatile Combilift range of material handlers.

For those who thought Combilift’s Multi Directional fortklifts were not a ‘big’ deal, meet

It takes a team: Simon, Carter and Aisle Master’s operations manager Mitchell Corliss guide the 3.51m-wide C14000JD Combilift onto the Super-Liner’s MTE three rows of eight.

the C14000JD – a real Combilift monster.

This brand new machine, headed for a customer in Mt Wellington, will be one of only two of its kind in the country. With its wide backrest, it tips the scales at just over 20 tonne, which, in heavy-haul parlance, doesn’t fire anyone up … but, oh, the awkwardness. A tad over 3.51m wide at the chassis with a 3.19m track, the tricycle design

means there’s a centre wheel that needs accommodating, not ideal when you start to widen a transporter. Unbelievably, it was well over-height too, and that’s an optical illusion if there was ever one!

Aisle Master’s operations manager Mitchell Corliss was on hand, and on the job from Hanes were Simon Hanes, Dave McGrath on piloting duties and, at the wheel of the

suburbs.

Super-Liner, Simon’s son Carter. “If it’s a tricky one, I’ll always go along to support,” said Simon. “There’s nothing nice or easy about these. You could easily fit it on sideways – it’d be 2.55m wide and all the wheels would have a wide pad to sit on – but with the mast retracted and down, it would be horribly lopsided weightwise, so that’s out.”

The MTE transporter has a solid central catwalk just for this type of beast, although care has to be taken with steering as the machine comes on. The drive system means gradeability on this model is also limited, so

ramp angles need to be considered.

“When you know what you’re doing, it looks easy, but you’ve got to keep your wits about you, there are so many traps with these.”

It took about an hour from arrival to departure by the time lashings were in place and all the marker points highlighting the dimensions to the motoring public were accounted for. The three men work in perfect synchrony and Carter’s 21 years on the planet belie the experience and approach he demonstrates. This young man has grown up in the business, just like his dad and grandfather – he not only understands the job, but also relationships … chatty, convivial, mature.

Height and width meant the route was a little convoluted, working our way to Mt Wellington via Highbrook to Ōtāhuhu, down Great South Road to the top of Mt Richmond, right into Panama, left into Carbine and then Gabador Place on the right, and the destination was just down the road.

There’s no point in discussing how a Mack Super-Liner 685 handles a payload in the low 20s tonnage-wise, but the lighter weight does certainly mean Carter can concentrate on working his way through Auckland traffic and deal with motorists who simply don’t mentally process what’s coming towards them.

Dave appears at the intersection of Great South and Panama. It’s a tricky 90° right-hander with recalcitrant trees and kerbside cars narrowing available road width. He shoots down the road and stops traffic, allowing Carter the full width through the intersection. It’s all over in a blur –the Mack pulls away like a car.

Although rated to 120 tonne, the bulk of Carter’s work is single semi – this kind of thing.

Carter backs the big Bulldog into the customer site and the three men have the Combilift unlashed, allowing Aisle Master’s David Edmonds to proudly drive it off and commence the handover to another happy customer.

down, but are at least still moving, he adds.

“We’ve seen forklifts die down before too, but we’re lucky it’s keeping moving at the moment,” he says, adding that bigger corporate companies haven’t stopped moving forklifts.

“But the cheap brands have slowed right up,” adds Dave. “The good brands are bought by operators who follow replacement cycles. No one who buys cheap is replacing those units.”

“It’s just the way the market goes,” says Simon. “We just have to sit tight and wait till it comes right again.”

With that bit of market insight, the clock strikes nine and we’re into it. Mark’s driven for Hanes fulltime for the past six years and has been on the Titan since new; about 15 months and 100,000km now. We jump in with him straight away for the trip out of Hamilton and partway up the expressway. Simon’s on pilot duties, with Dave playing wingman through Hamilton to help ease progress through the morning traffic.

Immediately, the radios light up and Simon and Dave help clear the way. Approaching our first intersection at Hall Street, Mark stops well back from the intersection and calls the leftturning trucks through. With the pilots holding traffic, he turns right into the right-hand lanes as there’s a traffic island playing obstacle to the combination’s path. Manoeuvre successful, Mark puts the boot into it and climbs the Massey Hall Overbridge, the 510kW (685hp) MP10 lighting up with enthusiastic turbo whistle and the 14-speed mDRIVE sharply ushering in a few more ratios.

We turn right onto Lincoln Street, SH1C, and begin our run north out of Hamilton. It’s a relatively short, direct run from here to the Waikato Expressway, but it’s always interesting to watch pilots work from the cab of a heavy-haul truck. Simon and Dave may have been holding traffic at one of the roundabouts, for example, but that didn’t stop some motorists still entering only to stand on the brakes when they eventually registered the very large Silverado with its ‘Wide Load’ signs blocking their way.

“It’s every man for himself, eh,” says Mark. “People are oblivious. Once you get used to it, though, you just accept it. But dealing with traffic really doesn’t worry me. If you can’t deal with traffic, you shouldn’t be a truck driver. I’ll just sit in the queue and go with the flow. I don’t let that shit stress me.”

No doubt the pilots also develop a feel for what motorists are going to do. Regardless, it’s clear motorists could do a bit better to make the heavy-haul job a little easier.

Reaching the expressway, Dave peels off to the Hanes Horotiu yard and the Titan settles into an easy cruise, Auckland bound. Mark explains it was added to the fleet in replacement of an old T409 Kenworth.

“I liked the Kenworth, it was a good, sound truck. But, it was very old, it was ex-Australia and had already done its life there towing road trains before we got it. In this job, we have to have reliable trucks and be reliable for our customers, but it was getting a little harder to keep the Kenworth going. When

Simon asked me what I wanted to replace it with, I actually chose a Volvo …

“I drove our FH700 for a couple of years and I like the way they run; they’re a really well set up truck. But when we started speccing them for this sort of tonnage, it was too expensive. So that got squashed and Simon said, ‘Let’s look at a Mack.’ I grew up on Macks, I’ve driven plenty of

them, so that was okay with me.”

With its 11mm thick chassis and 150-tonne GCM, the Titan is well up to the task. Key specs are the aforementioned 16.1L MP10 outputting 3118Nm (2300lb/ft) coupled with the 14-speed Mack mDRIVE AMT with XHD deep reduction gearing, a 7.6-tonne front axle on parabolic springs, and 21-tonne hub-reduction rear axle on Mack Air Ride

suspension.

The run up the expressway is about as easy as it comes and the Titan lopes along with us sitting in comfort with an average 73db of noise intrusion in the cab. It’s a smooth, easy ride, the only challenges posed being the Huntly bypass and the Bombays. We’re onboard for the former, and the Titan takes it well in its stride at 55km/h

at 1850rpm in ninth, with the mDRIVE offering up smooth, quick, well-timed downshifts.

According to Mark, the heavier the load, the better the drivetrain responds.

“Mechanically, I think these will be good to us. It does the heavy stuff really well. The other day I did a load over the Napier-Taupō that was close to 100 tonne and it surprised me. It really gets into it up the hills; does it brilliantly at those weights.”

Mark says the heaviest load he’s moved so far was in the region of 115 tonne. Surprisingly, though, it’s with the lighter payloads that he finds the Titan to be a little less settled. “I find it can keep the revs too low, which I’m not a fan of. I’m a firm believer in keeping it hot in that sweet spot without being hard on the gas. I still can’t get used to that. It just doesn’t react the way I want it to react and driving it in manual is impractical because the mDRIVe’s control panel on the dash is hard to reach when driving.”

10am

Just over an hour later, we turn off at Ramarama and Mark and Simon make for the heavy-haul route. With the exception of some roadworks at Drury and the need to move off the main road to cross the motorway at Bremner Road, it’s a straightforward but slow run

through the southern suburbs.

And man, doesn’t the Titan look good doing it? There’s deceivingly little bling. With the truck featuring in-house painted tanks and guards, the King Bars bullbar, air intakes and stacks are the largest shiny bits, and the big Mack wears the Hanes blue, silver and grey livery smartly.

“I don’t like polishing,” Mark says with a laugh when we later walk around the truck, taking in all the details and in-houseengineered rear guards, centre plates and small stainless additions. Symmetry is the name of the game, with dual square tanks either side of the chassis broken by the AdBlue tank on the left and a covered exhaust cassette on the right. The front tanks hold 1000L of fuel, while the rear right holds the hydraulic fluid and the rear left 440L of water. That water tank is quite nifty, with an outlet between the drive wheels under the rear guards.

“We wanted it all to match, square and painted,” Mark says, before showing off the Hanesmade vertical lockers behind the cab [the talented Greg Belk at work]. An example of very neat, very clever engineering, these are packed with everything Mark would need for the job and to “get out of sticky situations”.

“It’s all there; you’ve got to have it to do the job properly,”

Tare: 12,300kg (load cert.)

GVM: 28,500kg (load cert.)

GCM: 150,000kg (load cert.)

Wheelbase: 5800mm

Engine: Mack MP10

Capacity: 16.1L

Power: 510kW (685hp)

Torque: 3118Nm (2300lb/ft)

Emissions: Euro-5 via SCR

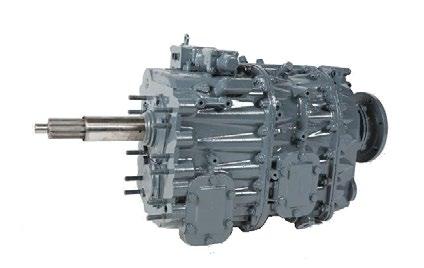

Transmission: MACK TmD12AO23 mDRIVE, 14-speed AMT, XHD deep reduction gearing, multispeed reverse.

Chassis: 11mm with heavy-duty crossmember

Front axle: Mack FXL 16.5 with Unitised Hubs

Front-axle rating: 7500kg

Front suspension: Parabolic

Rear axle: Mack 2610B Hub Reduction 26T, 4.12:1

Rear-axle rating: 21,00kg

Rear suspension: Mack Air Ride, road-friendly

Brakes: Disk. Six-pole ABS

Auxiliary braking: Mack PowerLeash+ engine brake

Additional safety: Mack Road Stability Advantage. Traction control.

Additional productivity: Heavy-duty radiator, transmission oil cooler with high-performance oil. Extralarge propshaft. Telematics Gateway with 4G and WLAN. Driver-controlled diff locks – both rear axles. Pre-trip Assistant Diagnostics Inspection.

Fuel: 1000L

DEF tank: 150L

Wheels: Alcoa Dura-Bright

Tyres: 295/80 R22.5 (f), 11 R22.5 (r)

Electrical: 12V

Cab exterior: Side close-view mirror, heated and motorised exterior mirrors. Tinted window glass. 4.2m-height exhaust stacks. Stainless-steel nut covers. Bright finish grab handles and bonnet hood latch. Stainless-steel sun visor. Stainlesssteel air rams. Dual roof-mounted air horns. LED roof lamps. Bug screen. Three warning triangles. Outback Pack.

Cab interior: Remote central locking. Premium Grey interior trim. 460mm leather grip steering wheel with cruise control, radio and phone switches. Five-inch full-colour Driver Information Display. Auxiliary gauge pack (engine oil temp, trans oil temp, pyrometer, manifold pressure). Red ambient floor lighting. Electronic HVAC. ISRI Premium Big Boy driver seat, ISRI Premium Air passenger seat, Performance leather seat upholstery, driver and passenger seat arm rests. In-cab 2.5kg fire extinguisher.

says Mark. “I’ve got duplicate tools on both sides so I don’t have to run around or throw tools under the trailer. And it’s all been used. I’m going to

Invercargill tomorrow and if we have a blowout or something goes wrong, we can still keep going.”

another insight into the Hanes culture. “Many other companies don’t stock your toolboxes or allow you to change your own tyres on the road. But blowouts can happen on these trailers at these weights, and there’s the risk you could rip a hose from the brake pot. If it does, I’d rather just attend to it myself and get going again. If I have the pilot to help me, it’s a few minutes and job done – when you’re in the middle of nowhere you need to get into it and get it done.

“But this work is good fun, especially when you get dramas; I like the drama that can come with it. Changing tyres at the side of the road, fitting into spots you shouldn’t be able to … it’s good like that, it adds to the job, makes you think a bit.”

12pm

A little over three hours after leaving Hamilton, Mark rolls into the Southdown terminal, and within minutes, the big Hyster is offloaded and the Titan emerges back onto Nielson Street. With the trailer narrowed up, you really notice its length with the clip-on – 14m of deck space and 18m overall from the fifth wheel to the ramps.

There’s a small pick-up to be made in Highbrook before heading back to Horotiu, and Mark encounters one of those little ‘dramas’, having to back

the unit up the drive. “Yeah, the extra length of the trailer makes it a little more difficult to back in. It’s deceiving, but you get used to it,” he says as he ratchets down and measures the load.

“With this sort of work, we get jammed up in places and the trailers take a few knocks. Every couple of years, whoever wants to can put theirs in the sandblasting and paint sheds for a week, to keep the gear looking good.”

With that, we say our thanks and goodbyes, head for home down the Southern Motorway, and are left reflecting on an incredibly insightful morning. Hanes Engineering may be a comparatively small company when it comes to transport, but seven decades of history teaches a lot and entrenches a rich culture its employees are happy to buy into.

There’s no hierarchy or pecking order as such (though were told Dave is affectionately known as The Commander) and the camaraderie within the small team means relationships are built on working together to overcome any challenges and get the job done. Everyone understands the task, thinking it through and taking their time, treating the gear as their own and – most of all – enjoying the ride. As it was seven decades ago, and as it should be today.

We couldn’t thank Chris and Simon Hanes, Dave McGrath and the Hanes crew enough for providing us not one but two extraordinary trucks to feature in this anniversary issue – and, of course, for telling the story of Hanes Engineering and all the lessons encompassed in it. We’ll be back for that podcast!

Thanks to Mark Dennis for your time, story and putting the Titan’s best foot forward. And to Carter Hanes, a pedigreed young operator fortunate to pedal a wonderful machine.

Finally, to Nick Kale at Mack Trucks NZ for the technical detail, and the team at Sime Motors NZ for your highly valued continual support of our publication.

it differently

Every cover truck holds a special place in the history of New Zealand Trucking magazine. We love to see where their road has taken them.

The Axor is still going strong for Carr & Haslam – this photo was taken in February as the truck returned to Auckland from a trip to Christchurch. “It is a very comfortable truck to drive, with full air suspension on every axle, truck and trailer. The Australian Anybody Commercial Coach Builders top-lift deck has been trouble-free,” says director Chris Carr.

IT’S HOW WE ROLLED!

Currently owned by: Carr & Haslam

Current odo reading: 824,000km

Mechanical work: Engine rebuilt and cab replaced following an accident in 2023.

Current work profile: Vehicle transport predominantly around Auckland, Waikato and the Bay of Plenty.

Currently driven by: Froilan Vinluan

Interesting facts: Original driver Phil Stout now drives a Carr & Haslam despatch desk.

Basic original spec: Mercedes-Benz OM926LA at 240kW (326hp), Mercedes-Benz G211-16 16-speed Telligent AMT, Mercedes-Benz H6 at 3.077:1.

What we said in 2014: “There are plenty of trucks that could do this job, but Mercedes’ proven track record and availability of the correct spec ex-factory makes the Axor ideally suited to the Carr & Haslam application.”

The 6x2 truck and two-axle semitrailer combination measured 22m but proved surprisingly manoeuvrable.

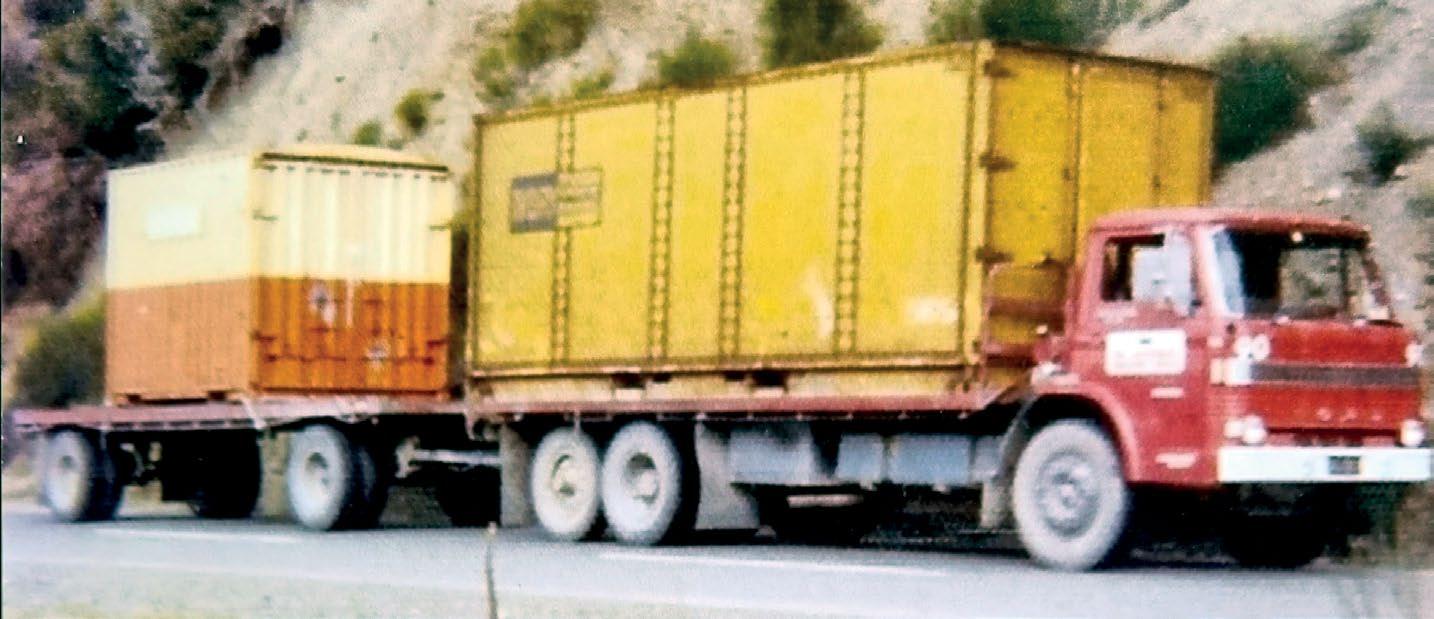

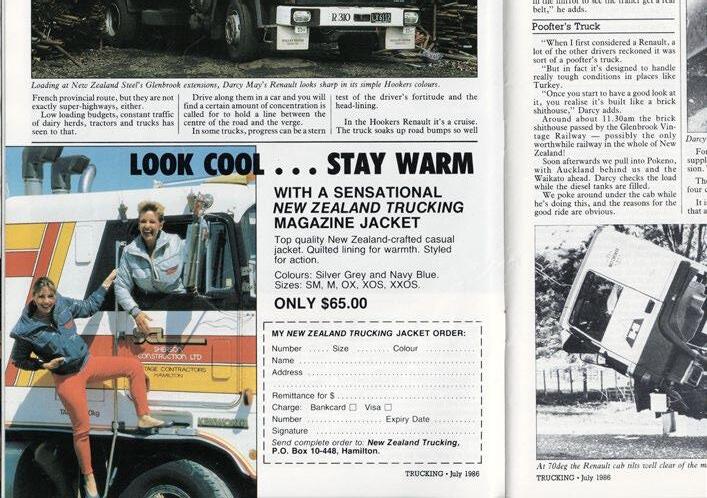

In this crazy world of compliance gone mad, we bring you a new photo section called It’s how we rolled!, with mages from the days when the only KPI was getting shit done, photographs that would turn today’s compliance zealots inside out. If you’re from another time and have some whacky cool images that fit the bill, send them in to editor@nztrucking.co.nz

TWIST OR TO CHAIN?

Reader Kevin Ager sent in images of the 1973 Ford D1000 he drove from new for Mid-Canterbury Transport. He says this photo was taken when he carted containers from Christchurch to Springcreek, Blenheim, via the Lewis Pass, for New Zealand Railways after the railway line on the Kaikōura coast was washed out in 1973/74. “You’ll note the containers were just chained to the deck and not held on with twist locks,” he adds. Protranz has fully restored the truck, and it is now on show at Levels Museum, South Canterbury. Thanks for sharing, Kevin.

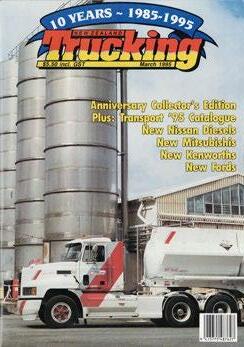

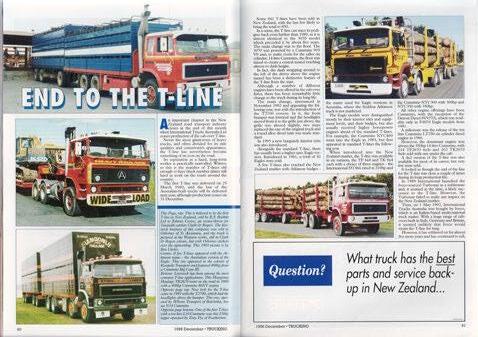

It all began in March 1985. Forty years and 441 issues later, New Zealand Trucking magazine celebrates four decades of continuous publication – not even Covid-19 could apply the Jakes. In that time, the global and Kiwi trucking industries have changed almost unrecognisably and experienced many significant events along the way. New Zealand Trucking magazine has been there to document it all for Kiwi truck operators and enthusiasts. Join us as we recount some highlights of the road transport story as told through these pages.