packaging solutions are the cream of the crop looking to improve e�ciency, sustainability

recognition, let us help.

formats and needs Sustainable materials

Reduce plastic use with renewable paper-based materials.

E�cient automation

Improve uptime, line speeds and operational throughput.

Connected Solutions

Meet FSMA requirements and improve inventory management.

sustainable paper and packaging solutions, Smur�t Westrock is committed you adapt and thrive in today’s environment with e�ective, packaging solutions.

EXECUTIVE DIRECTOR

Alex Walsh

BUSINESS OPERATIONS MANAGER

Leanne Ziemba

PRESIDENT

Daniel Lausch Lactalis USA – Commonwealth

VICE PRESIDENT

Rebecca Wallick HP Hood

TREASURER

Adam Seybolt Stewart’s Processing Corp.

SECRETARY

Ryan Elliott Byrne Dairy

PRESIDENT

Daniel Seitzer Ecolab

VICE PRESIDENT

Paul Knoerl

Pactiv Evergreen

TREASURER

Ryan Osterhout KCO Resource Management

SECRETARY

Bruce Alling

Double H Plastics, Inc.

PUBLISHER

Bill Brod billbrod@nedairymedia.com

CONTENT DIRECTOR

Steve Guglielmo steveg@nedairymedia.com

RESEARCH & DEVELOPMENT COORDINATOR

Athena Cossette athena@nedairymedia.com

COPYWRITER

Nicole Smith

CONTRIBUTORS

Courtney Kless

Mike Marks

Steve Thompson

Mark A. O’Donnell

GRAPHIC

Renate Wood, Robin Barnes

SALES

Tim Hudson thudson@nedairymedia.com

Lesli Mitchell lmitchell@nedairymedia.com

Jake Horodnick jakeh@nedairymedia.com

PRODUCED BY

Northeast Dairy Media

Editorial correspondence should be directed to steveg@nedairymedia.com

Advertising correspondence and materials should be sent to lmitchell@nedairymedia.com

An official magazine of the Northeast Dairy Foods Association, Inc., a nonprofit organization. This publication carries authoritative notices and articles in regard to the activities and interests of the associations. In all other respects, neither the association nor the producer of the publication, Northeast Dairy Media, is responsible for the contents thereof or the opinions of the contributors.

The entire contents are © 2025 by Northeast Dairy Media. Nothing may be reproduced in whole or in part without written permission of the publisher. The association and Northeast Dairy Media reserve the right to print portions or all of any correspondence mailed to the editors without liability on its part and no such correspondence will be returned.

Visit The Northeast Dairy Foods & Suppliers Associations online at ndfsa.org for current information on association programs and services, or call the association at 315-452-MILK (6455). Questions and comments may also be sent to the association at leanne.ziemba@ndfsa.org

BY DANIEL LAUSCH PRESIDENT, NORTHEAST DAIRY FOODS ASSOCIATION

his issue is covering the subject of Innovation. In our dairy industry, that could include a long list of items, even if the base year was Y2K.

That was shorthand for the year 2000, when we advanced to the 21st Century and when quite a few older computers just stopped working when 1999 ended. I remember folks arranging holiday travel plans to not fly in an airplane on New Year’s Eve, December 31st, 1999, for fear of the airplane dropping out of the sky when the computers crashed. When those computers were built, the manufacturer never considered a year that did not start with “19.”

Now, we have lactose-free and whole milk sold in sizes other than the “standard sizes” like quarts and gallons, including liters. Different package sizes and designs are aimed at both being more convenient and attracting the consumer’s eye as they walk down the retail grocery store aisles. In addi-

tion, products can now also be purchased online, creating the need for more shipping boxes. What about bar codes and QR codes? There is no longer any need to put the company’s phone number on the side of the package in today’s world of consumers.

There have certainly been a lot of changes in recent years! I’m looking forward to attending the September Fall Convention and reconnecting with folks in our industry who are able to attend this year in a great location with the Big E just across the big highway. As you look ahead to 2026, start thinking about sending a newer employee to the Dairy Blender and the Clam Bake who would benefit from seeing the breadth of the industry that has afforded so many of us a lifetime of employment.

Enjoy the articles and advertisements in this Northeast Dairy Foods Magazine.

We can help make your process a success. Talk to our sales team today!

BY DANIEL SEITZER, PRESIDENT, NORTHEAST DAIRY SUPPLIERS ASSOCIATION

was speaking with a dairy company executive a few weeks ago when I recognized we were saying essentially the same things about human effectiveness, value delivery, and brand protection. It made me pause to assess how everyone in this dairy business inherently knows the challenges, but we put our own spin on it based on experiences, especially painful ones, that we’ve had. One thing this individual and I both agreed on is the need to view change as a positive thing and to embrace it as a solution and not a cause of more problems. We spoke about employees and leadership, which we’d seen struggle with low trust or just not understanding the mission when something new became a priority. Frustrating for sure, but definitely something that can be traced back to how clearly we define a “why behind the what,” so they can connect the dots about what we’re asking them to drive towards.

What was most interesting was when we spoke about innovation. We were 100% aligned on inflation driving costs and many customer behaviors lately, and a clear need for each organization to decide when the right time was to make a push for innovation of a new process, product, or policy. “No place for fear” sounds great, but it IS scary to get out of your comfort zone and into things you need to grow new muscles to do.

So, how does this apply to a dairy periodical article about Innovation? Easy. We all go through hard times and we sometimes need to be reminded why. Our customers are evolving, plain and simple. People want a clean label, they demand responsible and sustainable practices in the products they support, and they are always looking for something to improve their lives a little more than where they are. Consumers have choices and they are laser-focused on a positive experience, no matter what you produce.

Here’s the thing, these aren’t just technological shifts with new equipment or software. It’s rethinking strategy and how

you manage your resources, too. So, here are some of the key developments and innovations transforming our markets in 2025:

Sustainability is now a keystone of modern dairy processing, with producers understanding that they are expected to be leading the way in executing strategies to reduce their environmental impact. Producers are prioritizing water conservation, energy efficiency, and reducing emissions, driven by both regulatory pressures and consumer expectations. Many are turning to renewable energy sources and implementing economic strategies focused on minimizing waste throughout the production cycle.

Packaging innovation plays a crucial role in these efforts, with a focus on recyclable and biodegradable materials. Sustainable practices not only align with environmental goals, but also position companies as leaders in responsible production. The industry’s commitment to sustainability is reshaping its “brand,” fostering greater transparency and trust among consumers.

The challenges of numerous global disruptions have prompted a move towards localized supply chains in nearly all producers, regardless of their market category. Shortening supply chains reduces logistical risks, improves product freshness, and enhances traceability, which is increasingly important to consumers. Local partnerships also help producers meet sustainability goals by cutting down on emissions from transportation.

However, the transition to localized models requires investment in regional infrastructure and careful planning

to balance efficiency and cost. Producers that embrace this trend can build strong connections with local communities and suppliers while meeting growing demand for transparency and quality. This approach not only enhances resilience in challenging market conditions but also aligns with a mindful movement towards sustainable and accountable production.

Plant-based alternatives have become increasingly important, driven by consumers looking for lactose-free, vegan, or eco-friendly options. Products made from soy, almonds, oats, or other plant sources are now mainstream, challenging traditional dairy offerings on supermarket shelves. The rise of hybrid products, which combine dairy with plant-based ingredients, is another emerging trend. These innovations appeal to customers who desire the familiarity of dairy with the perceived benefits of plant-based additions.

The success of these types of products relies on the ability to render the textures, tastes, and nutritional profiles of traditional dairy. Producers are applying their investment dollars in research and development to improve formulations while maintaining cost-effectiveness. This trend not only expands market opportunities but also highlights the need for manufacturers to blend innovation with authentic experiences of taste and flavor that we’ve grown to expect. The demand for transparency in sourcing ingredients and acceptable production processes further adds to the complexity of this shift, emphasizing the importance of a consumer’s trust.

Precision Fermentation has become a significant innovation in dairy production, offering a sustainable alternative to traditional methods. By leveraging microorganisms to produce key milk proteins like casein and whey, manufacturers can create animal-free products that mimic traditional dairy in both taste and nutrition. This technology is particularly attractive for its resource efficiency and its ability to scale up which makes it a very viable solution for the future of dairy.

In addition to fermentation, advancements in dairy machinery are reshaping production processes. Automated milking systems, quality monitoring tools, and AI-driven data analytics are becoming standard across the industry. These technologies automate operations, increase total cost of operations by reducing waste, and ensure product consistency. By integrating these innovations, producers can meet increasing demand while maintaining high standards of quality and sustainability.

Automation is revolutionizing the dairy industry by improving efficiency and ensuring consistent quality across production lines. Robotic systems are being utilized for milking, processing, and packaging, reducing labor costs and minimizing human error. These advancements are particularly advantageous for meeting the rising demand for high-quality products at scale.

In addition to physical automation, digital tools like AI and IoT (Internet of Things) are enabling real-time monitoring of production processes. These technologies provide insights into performance, allowing producers to identify inefficiency and optimize operations. Automation is not just about cost savings, it also ensures that products meet strict regulatory and quality standards, boosting consumer confidence in our Dairy industry.

The dairy sector is responding to consumer interest in health and wellness by developing products that cater to specific nutritional needs. High-protein, low-sugar, and fortified dairy items are gaining traction among health-conscious buyers. Innovations in functional foods, which include ingredients with potential health benefits, are expanding the role of dairy in supporting healthy populations.

Producers are exploring new formulations that enhance the nutritional profile of traditional dairy products while maintaining their taste and appeal. This trend underscores the importance of understanding consumer priorities, particularly as dietary preferences become more personalized. The ability to deliver health-forward products will be a key driver of success in the evolving market.

I started with a story about a conversation that was rooted in innovation and change; our roads and experiences may vary slightly, but we need to embrace that which takes us forward. Will you break a few eggs along the way? Surely. But those concepts are unavoidable and key to an industry that is forever improving its perception. From plant-based alternatives to automation, the best producers are embracing these innovative ideas to meet the demands of a diverse and health-conscious consumer base. Sustainability, technology, and localized strategies are central to this evolution, ensuring the sector remains a strong presence and forward-thinking choice of its consumers.

BY ALEX WALSH, EXECUTIVE DIRECTOR

s we have passed the halfway point of the year, we reflect on the first half, where there has been a ton of excitement and growth, both with the associations and in the dairy industry, itself. It’s been fantastic to see the enthusiasm from members at our events, and in the northeast region, as we continue to build on our prominence as a global leader. With the leadership of the association’s staff, directors, committees, and members, it is certain that this momentum of growth will resonate for years to come.

The associations have grown by leaps and bounds in the last couple of years, in particular with our advocacy efforts at the state levels. We continually build upon our strength as a trusted source, not only for the members of the associations, but with policymakers and regulatory agencies as well. The presence of the Northeast Dairy Foods & Suppliers Associations has not only perpetually increased, but so have our efforts to carry out the messages – the voices of our members and the industry – in the halls of capitols.

We also continue to partner with other organizations, both inside and outside the industry, on important policies that impact our members. A prime example of this was on full display at Dairy Day, the association’s annual advocacy day, at the New York State Capitol in June. Not only was this a way to recognize and celebrate the significance of the dairy industry in New York, right as National Dairy Month commenced, it’s also an excellent event for our members to meet with legislators and staff, discuss challenges and opportunities, express policy priorities, and build relationships with policymakers. For those who have attended this event and met with legislative offices, you also know that there is an educational com-

ponent that goes into this day. The day serves as a way for us, as ambassadors of the industry, to inform members of the legislature how certain policies are, or will, impact operations. It’s also a great way to expose your brand and products to hundreds that pass through the event area.

The day that many of you all look forward to each year, the second Wednesday of July, the annual Bruce Krupke Memorial Golf Tournament & Clambake, was another tremendous success this year! This time, without a tornado! We surpassed last year’s ticket sales again, selling 930 tickets for this year. We express our sincere gratitude to all of the sponsors and donors who help make this yearly event successful, as well as to the tremendous support from the membership. An oddity that occurred this year was that the golf tournament filled up much sooner, about a month prior, than ever before. We had 200 players register and had nearly 30 more on the waitlist. Keep that in mind for next year and be sure to sign up early! The afternoon at the Clambake was about as perfect as it gets.

These events are a true testament to the power of networking and engagement with members, processors, manufacturers, distributors, and suppliers, all gathering together to recognize and acknowledge each other’s contributions to the industry, enjoy companionship, and conduct some business in a casual setting. Each year, we receive positive feedback about how valuable this event is to meet with industry professionals and build relationships and connections. It really is amazing, and satisfying, to see folks meeting each other and having conversations with new people, making introductions that turn into future possibilities.

The networking events that the Northeast Dairy Foods &

Suppliers Associations host each year are a key component and benefit of being a member of the organization. As we head into the fall, with the Dairy Blender, Dairy Day, Golf Tournament & Clambake behind us, we look forward to the annual Northeast Dairy Conference. As always, in conjunction with the New York State Cheese Manufacturers Association (NYSCMA), as well as the Pennsylvania Association of Milk Dealers (PAMD), we have a solid, valuable, and educational business session of the agenda lined up with some influential speakers on important topics facing the industry.

The conference, being held September 17-19 in Springfield, Massachusetts, provides a platform to learn about various topics, network with industry professionals, and enjoy a new scene outside of the office for a couple of days. More information about the Northeast Dairy Conference can be found later on in this issue, as well as on the associations’ website at ndfsa.org/events. We look forward to seeing you there!

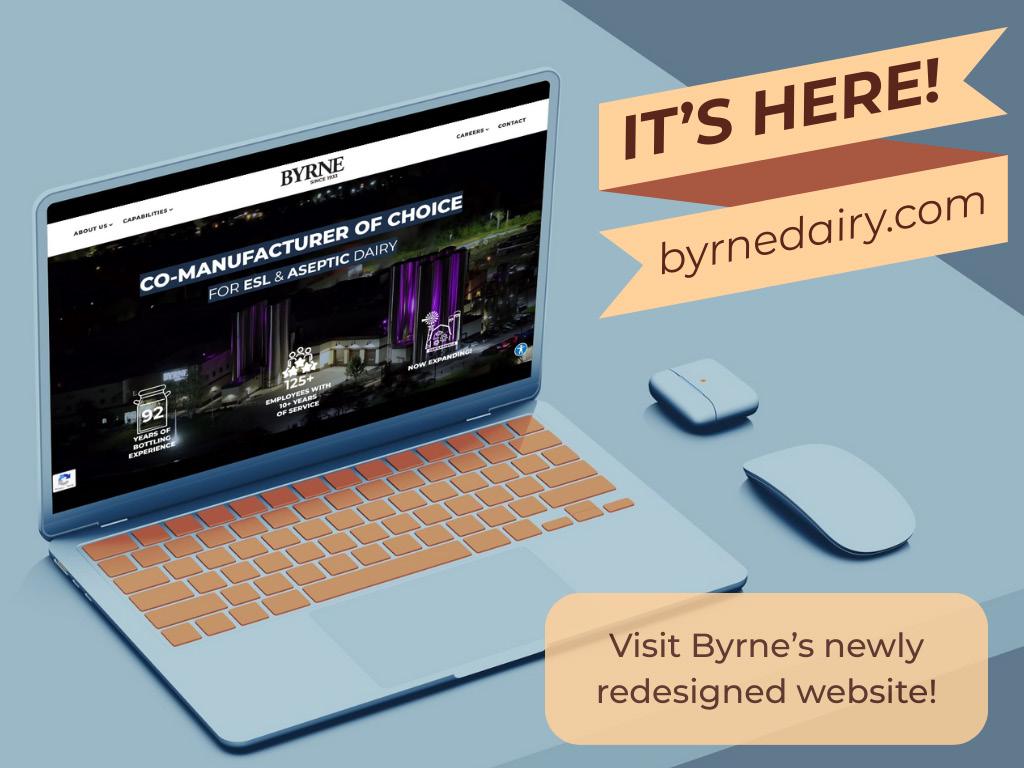

Additionally, the industry has seen some exciting growth in the last few months. It’s been an honor to see members such as Chobani, Cayuga Milk, Byrne, Hood, and others, announce expansion projects as they grow and succeed, and there’s more to come! New innovations, both technologically and with products rolling out have made the industry not only more efficient, but more competitive as well. Northeast Dairy Foods & Suppliers Associations remain committed to our members and the industry to support your growth.

On behalf of the staff and our boards of directors, thank you for your membership and support. A big shout-out to our Events Committee members as well who greatly help in guiding the direction and progress. If you are interested in serving on one of the associations’ committees to help shape the future of the organization and be more active and engaged, please reach out to us! We look forward to seeing on-going success, growth, and seeing you at the conference!

The presence of the Northeast Dairy Foods & Suppliers Associations has not only perpetually increased, but so have our efforts to carry out the messages – the voices of our members and the industry – in the halls of capitols.

Biofilms can thrive in hard-to-reach areas of whey processing lines, shedding microbial contaminants that impact product quality, yield, and shelf life. QualiTru’s aseptic inline sampling systems enable early detection and help validate sanitation—giving you visibility where it matters most.

Don’t let biofilms reduce your returns. Visit qualitru.com or scan the QR code to learn how to safeguard your whey production.

For this issue, we asked board members from the Northeast Dairy Foods Association and the Northeast Dairy Suppliers Association the following question: What technology or innovation has had the greatest impact on our industry in the last several years? How is technology helping you do business with dairy processors and manufacturers? This is what they said.

Our integration of artificial intelligence across key operational areas—such as policy checking, contract review, and claims analysis—has significantly enhanced efficiency and accuracy throughout our processes. By automating routine and complex tasks, AI enables our teams to focus on higher-value activities, reduces turnaround times, and minimizes human error.

Among the most significant advances in the corrugated industry in the last five years has been digital printing. Smurfit Westrock now has equipment which can produce photo quality printing in short-run quantities on all types of corrugated substrates. This allows our customers to utilize the best printing methods for promotional products as well as growth brands. Additionally, the use of QR codes enables greater consumer engagement, which is important to dairy processors who launch new products requesting customer feedback.

We are singularly focused as a converter of paper-based packaging for bulk ice cream. As such, my responses may not have as much application or consideration for the broader membership; however, we see the impact in our scope from:

• Re-formulations of recipes to move toward ever-cleaner ingredient labels has had knock-on effects in terms of other areas of the ice cream producers. Increasingly, a positive impact of social engineering solutions, as the consumer is holding producers to higher levels of expectation and accountability to broader impacts. This has been more of a catalyst for the elimination of harmful materials in the ice cream industry, like sharp metal strips that can cut employees, as well as produce metal shavings and/or dust that can and do contaminate the ice cream.

• Real-time monitoring systems - laser sensors, camera-based systems to improve quality, safety, and to drive greater efficiencies in production.

• Data-driven decision making - advanced analytics tools allow companies to track energy use, water consumption, and waste, helping them optimize operations and meet sustainability goals. AI represents an opportunity for greater depth of input consideration and scenarios for most effective solutions.

• Sustainability - prioritizing recyclable and eco-friendly packaging. Challenging the norms and generating potential solutions for customer and consumer evaluation. We do recognize, though, that the price acceptance of “green” remains extremely low when general conversion costs are also considered. Truly, this is a case where if a solution is not “green” on the bottom line, it will struggle to be put into practice, no matter the sustainable points it may offer.

• Automation within the processors and manufacturing plants. All producers are struggling with recruitment

and retainment of their workforce. While nothing new, it is acutely impactful now and looks to remain so for the foreseeable future. The efforts by Cornell’s introduction program (definitely worth more exploration on its own), creation of industry-based formal apprenticeship programs and individual company efforts to find creative avenues to show the value of their positions to interested people will only rise in criticality. The concept of automation has moved from a perceived threat to the individual team members to one of absolute requirement for many businesses to be able to continue to operate at their current levels.

The consumer demand of protein in dairy has vastly changed dairy processing plants objectives. The production of ultra filtered milk is exploding and in high demand from processors. Diafiltration equipment in plants is essential to us when producing ultra filtered milk.

The first and probably most popular is how AI is revolutionizing dairy operations in many ways. Here are two that are making a direct impact:

• Predictive analytics for data analysis, cow health, breeding cycles, and milk yield

• Real-time quality control in milk processing, detecting bacterial contamination and optimizing fat composition

In addition, I would say the food structure optimization that has improved the component make up in milk; mainly the increase in fat and protein levels leading to increased yields that some dairy operations are seeing.

BY ALEX WALSH, EXECUTIVE DIRECTOR

As many of the northeast states concluded their legislative business for the year, it is with great pride that the Northeast Dairy Foods & Suppliers Associations can inform you of some victories. While we are not out of the woods yet, as special sessions could potentially be called in the last few months of the year, and the legislative calendar will start back up again in January, it was an overall success at the state level in 2025 thus far.

First, a major policy that the industry is keeping a close eye on, preparing for, and heavily engaged on, is the on-going debate with Extended Producer Responsibility (“EPR”), especially in New York. The Empire State, in the last few years, has been targeting this policy, and each year it has moved along, inch by inch. New York has also been battling with California on EPR, as well as some other pieces of legislation, as to which state can be the most progressive, especially when it comes to recycling and environmental issues. The last two sessions, here in New York, the state senate has passed a version of EPR (2025 S1464) sponsored by Senator Harckham. The assembly version, sponsored by Assemblymember Glick, (2025 A1749) however, did not make it to the floor, despite a whirlwind of activity and rumors in the final days and even hours of session. This, through intel received from sources close to the assembly, is due to the fact that support had dwindled for this version, as a second version was introduced following the finalization of the state budget. The “industry friendly” version – which, to its credit, is more favorable and workable than the Harckham/Glick version – was introduced by Senator Martinez (S5062) and Assemblymember Jackson (A6191). This bill provides a more comprehensive and collaborative framework for waste reduction, similar to

Minnesota's Packaging Waste and Cost Reduction Act. Both laws set targets for waste reduction, recycling rates, and the incorporation of post-consumer recycled content, aiming to drive continuous improvement in packaging sustainability. It establishes PRROs and an inclusive advisory board that ensures multiple stakeholders including businesses, municipalities, and environmental groups, have a voice in the decision-making process. S5062/A6191 also takes a broader approach to waste reduction, not just focusing on packaging but addressing waste management holistically.

The funding mechanism in S5062/A6191 is more equitable, ensuring that all parties in the supply chain contribute fairly without disproportionately impacting businesses or consumers, and also more clearly defines legal obligations and a needs assessment. With this alternative for legislators to consider, it created enough hesitation for the assembly to not act and allow for more time to review the options and hear from stakeholders. NDFSA has made this bill a top policy priority and will continue to monitor and be highly engaged during the process, especially if the assembly returns for a special session at some point during the remainder of the year.

What we hope was a flash-in-the-pan moment was another highly concerning bill that was introduced in the final days of session that would alter the Concentrated Animal Feeding Operations, known as CAFO for short. Two legislators from New York City, with minimal to perhaps zero agriculture in their districts, introduced a bill that would limit the size of dairy farms to 750 cows. Therefore, if a dairy producer had less than that and was planning to expand herd size, they cannot exceed the 750 maximum to grow their operations. Any dairy farms that already have more than 750 cows, could not expand at all. This piece of legislation, driven by an environ-

mentalist group, would be a detriment to the dairy industry in New York, a top five producer of milk in the country. In addition to that, with all the growth and expansions recently announced by processors and manufacturers in New York alone, it would greatly inhibit the milk supply to meet the increased demand.

As the state has partnered and invested public funding for these expansion projects, it’s a direct contradiction to the direction the industry is going in the region and one of the more asinine concepts to come out of Albany recently that would negatively impact the dairy and agriculture, which are leading economic sectors in the state. Through our advocacy efforts, the bills have not moved, and it does not sound like there will be any interest or traction in taking up these pieces of legislation. Northeast Dairy Foods & Suppliers Associations have also been very vocal on this issue, advocating against it and ensuring the voice of the industry is heard.

NDFSA has also been very active on the New York Food Safety and Chemical Disclosure Act (A01556-E/ S01239-E). Although amended, this bill continues to threaten food access, affordability, small businesses, and culturally significant foods across New York. It duplicates federal oversight, imposes costly mandates, and risks undermining national food safety reforms now underway. While presented as a food safety and consumer protection bill, the legislation threatens to create an unworkable regulatory patchwork that will burden small businesses, disrupt food supply chains, and reduce food access across the state, without delivering meaningful public health improvements.

The bill creates an entirely new state-specific GRAS (Generally Recognized as Safe) disclosure regime

that duplicates federal FDA oversight under the Food, Drug, and Cosmetic Act. Manufacturers must submit duplicative data and proprietary safety analyses already reviewed by the FDA. It also requires public disclosure of GRAS safety reports, including sensitive scientific and business data. Additionally, limited trade secret redactions leave businesses exposed to competitive harm and potential litigation. With this framework and food processors and manufacturers facing legal and regulatory uncertainty, some national and global manufacturers may exit the New York market entirely or look to expand elsewhere rather than comply with conflicting state-specific mandates.

The challenges with regulatory policies will never go away entirely, unfor-

tunately, but that’s why the Northeast Dairy Foods & Suppliers Associations are here – to be your voice, your advocate, and protect our members and the dairy processing and manufacturing industry from harmful policies. Through the work with the organization’s legislative committee and in collaboration with industry partners, we will continue to carry the flag and be prepared when legislatures return to their chambers.

You can contact him by email at alex.walsh@ndfsa.org

BY GARY LATTA

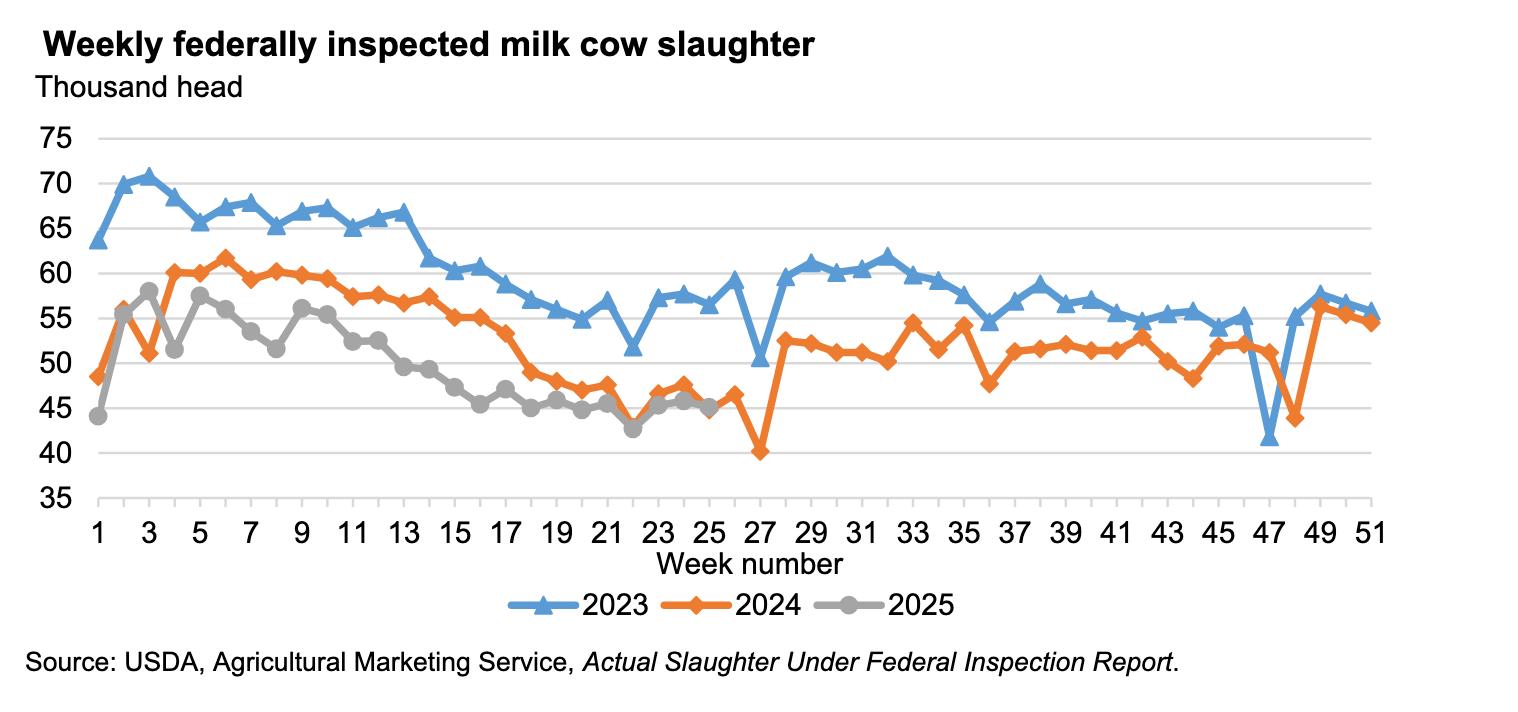

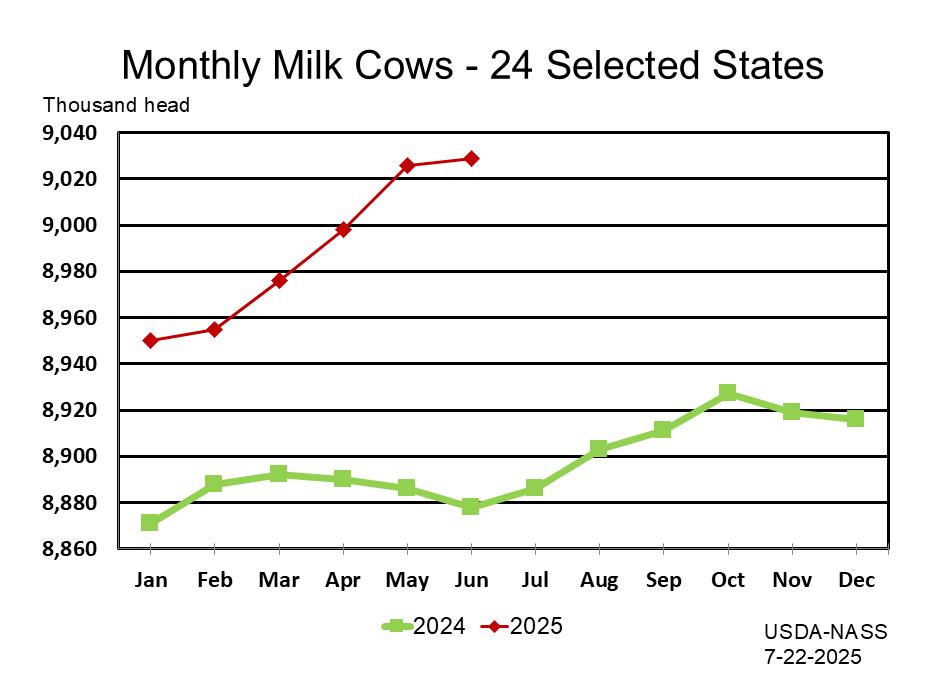

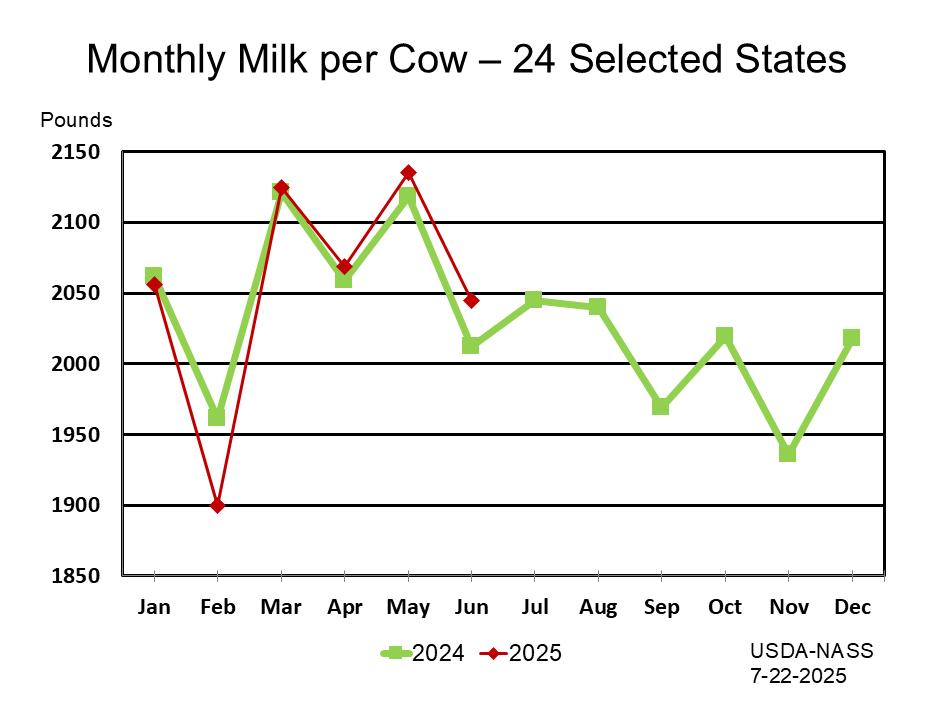

The June Milk Production Report got the attention of industry observers. Milk production in June for the 24 major states was up +3.4% from the same month last year. This followed May’s increase of +2.4%. Many USDA reports capture the 24 major states, which are responsible for about 96% of U.S. milk production. The top five dairy states are responsible for just over 53% of U.S. production.

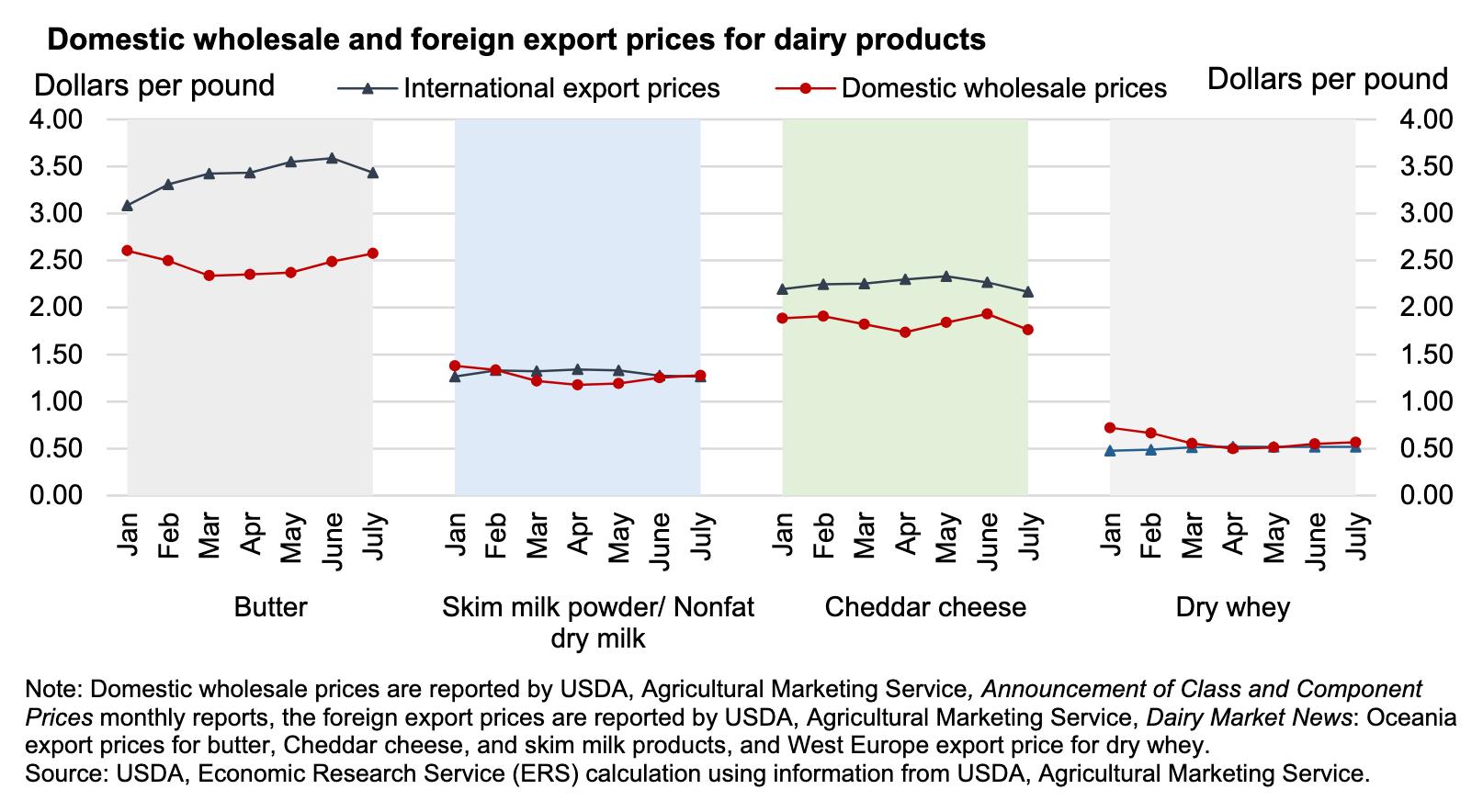

These back-to-back monthly surges in milk production have put some downward pressure on U.S. milk prices, but are also helping to keep us competitive with exports in the world market.

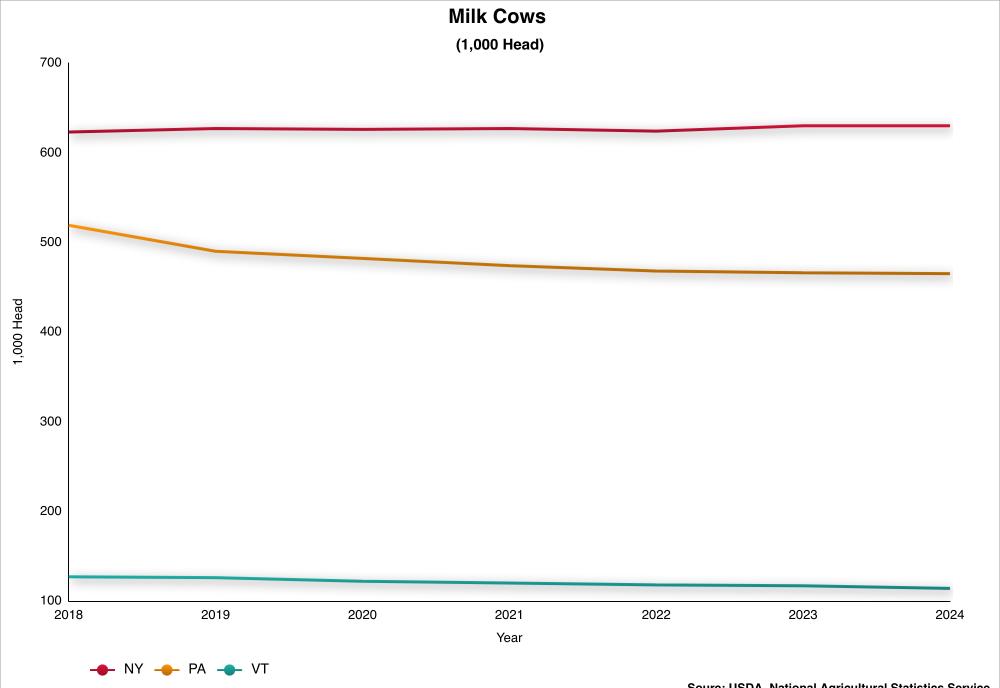

The addition of more dairy cows, along with growth in per cow production, are fueling the production increases. From May to June, cow numbers in the 24 major states increased 3,000 head. The June total of 9.03 million head was 151,000 head above June 2024. The 24 major states in June averaged 2,045 pounds per cow, 33 pounds over June of last year. July’s Livestock, Dairy, and Poultry Outlook noted that the rise in cow numbers can be partially attributed more to reduced culling than heifer additions. In essence, producers are extending the productive life of their

herds. The USDA report pointed out that butterfat and protein components are growing. In May, milkfat production was up 3.3% and skim solids was up 2.1% compared to May of last year.

No doubt, the $10 billion processing expansion underway is generating a sense of optimism within the industry.

A few states outside the northeast had June milk production gains worth noting. California +2.7%, Idaho +9.7%, Kansas +19.0%, Michigan +4.8%, Ohio +2.3%, and Texas +9.5%. Collectively, the 24 select states, representing 96% of U.S. milk production, were up +3.4%.

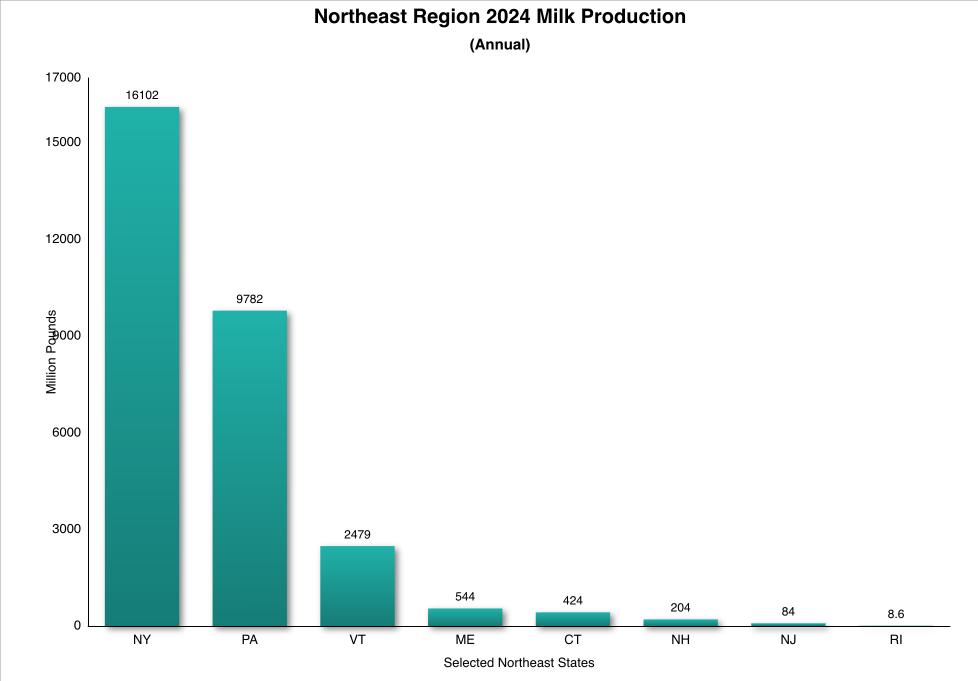

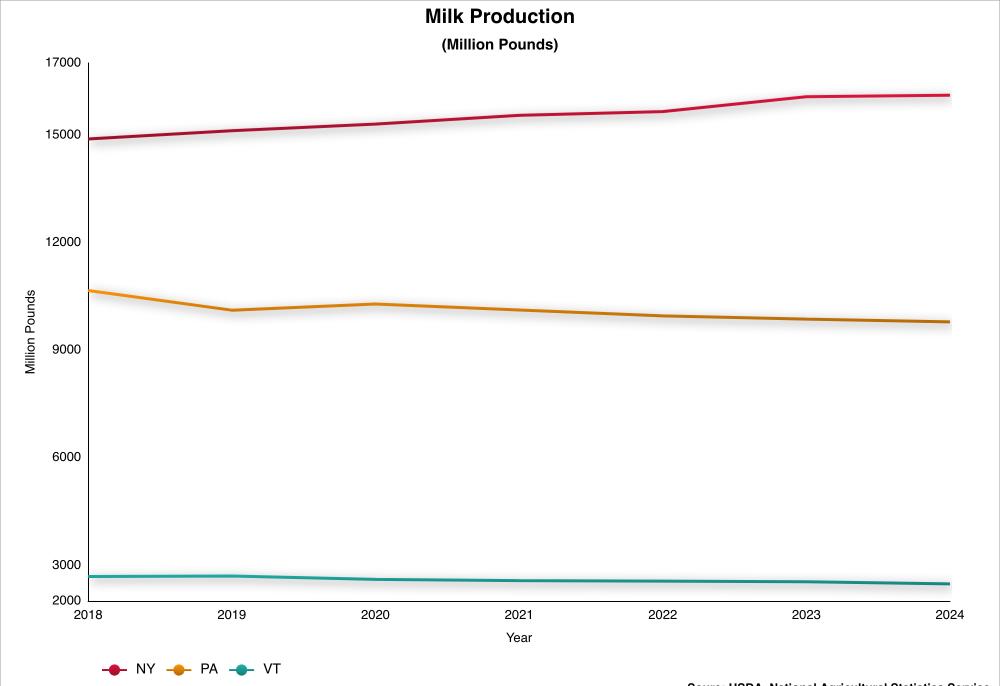

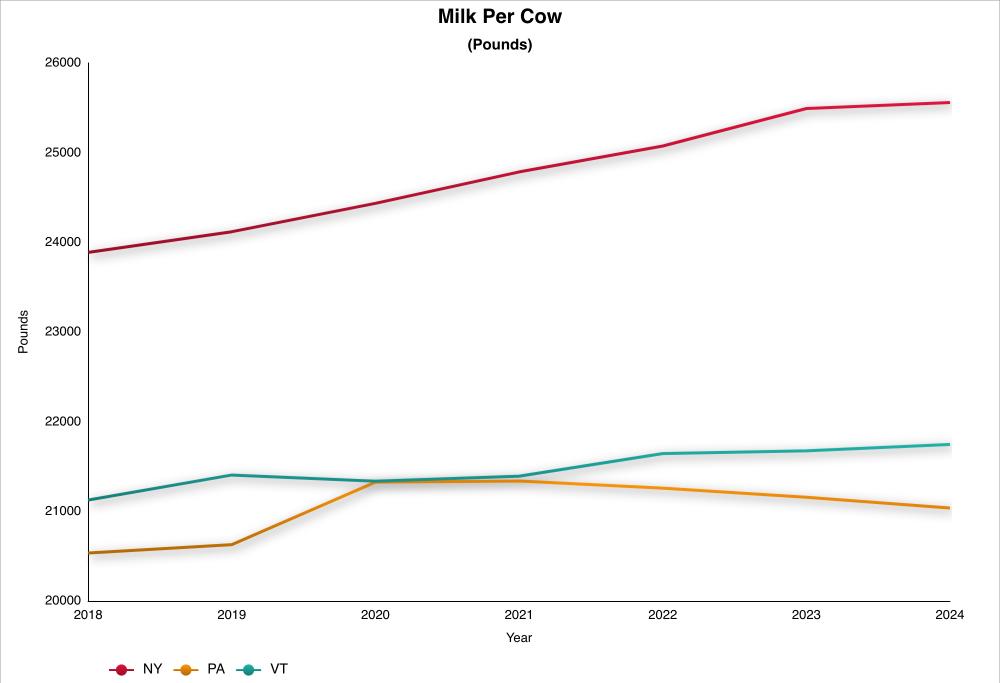

If we take the USDA 2024 annual production data for the northeast states, we get an idea of where the milk is being made in the region. New York, Pennsylvania, and Vermont are among the 24 USDA points to in its many reports.

A snapshot of June 2025 milk production vs. June 2024 of the three major milk-producing states in the northeast is shown below. June milk production in New York was up + 27million pounds, Vermont was up + 2 million pounds, and Pennsylvania was down -2 million pounds.

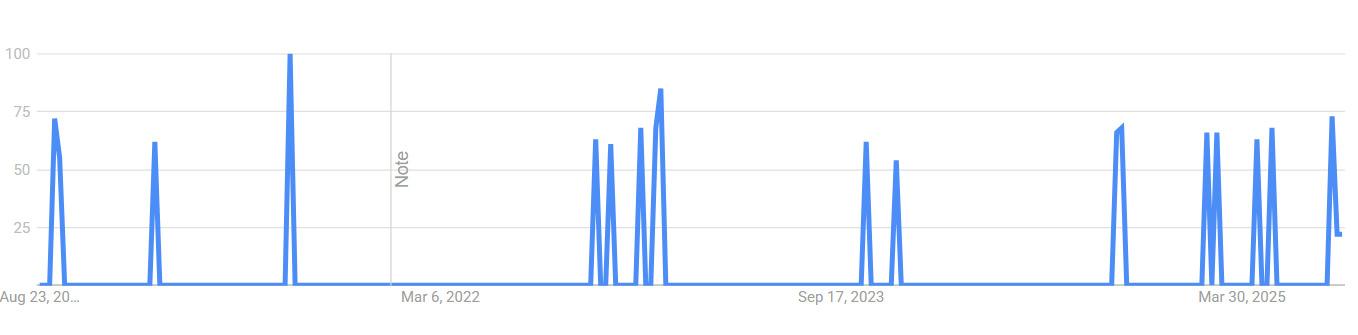

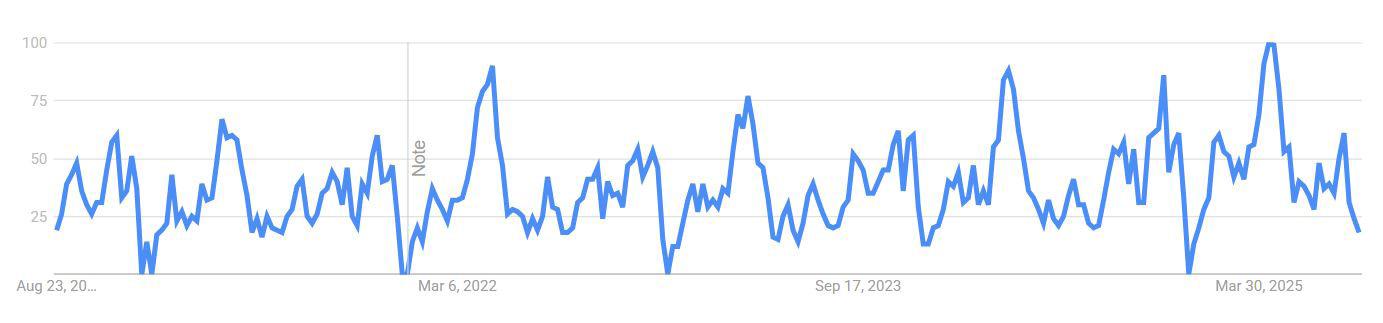

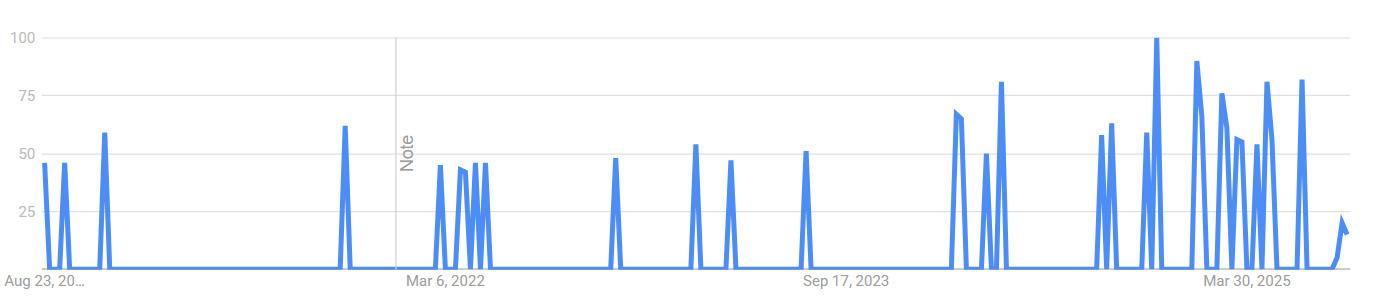

The images that follow show the trends in milk production for the last seven years for these states.

USDA’s latest forecast for both 2025 and 2026 shows increases in the number of cows, production per cow, and therefore total milk production based on these factors:

• Recent data on milk cow inventory (growing)

• Dairy cow slaughter rate (down)

• Favorable farm margins, near term (good)

• Good domestic and export demand (competitive)

The all-milk price forecast per hundredweight for 2025 increased a nickel to $22.00 and increased $0.35 to $21.90 for 2026. Strong demand for butter and nonfat dry milk is expected to continue and export projections have been revised upward for both years.

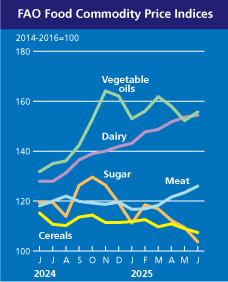

Many news headlines in July pointed to the latest Food and Agriculture Organization (FAO) Price Index rising on higher meat, vegetables, and dairy prices. FAO Food Price Index up slightly in June due to higher meat, dairy and vegetable oil prices. The Food and Agriculture Organization (FAO) is the United Nations agency that oversees international efforts to overcome hunger. Their primary purpose is to promote access to good-quality food and healthy living for all globally. There are 195 members who work in 130 countries around the world.

The FAO Food Price Index is a monthly report measuring the change in international prices of five food commodities. The overall FAO Food Price Index in June was up 0.5 percent from May. The changes in the five categories reported from May to June were:

• The Sugar Price Index down 5.2%

• The Cereal Price Index down 1.5%

• The Vegetable Oil Index up 2.3%

• The Meat Price Index up 2.1%

• The Dairy Price Index up 0.5%

Source: Milk Production (July 2025) USDA National Agricultural Statistics Service

The FAO just released a new publication, The State of Food Security and Nutrition in the World 2025. The report is worth taking a look at if you have an interest in global food price inflation, food security, and how U.S. dairy exports play a role.

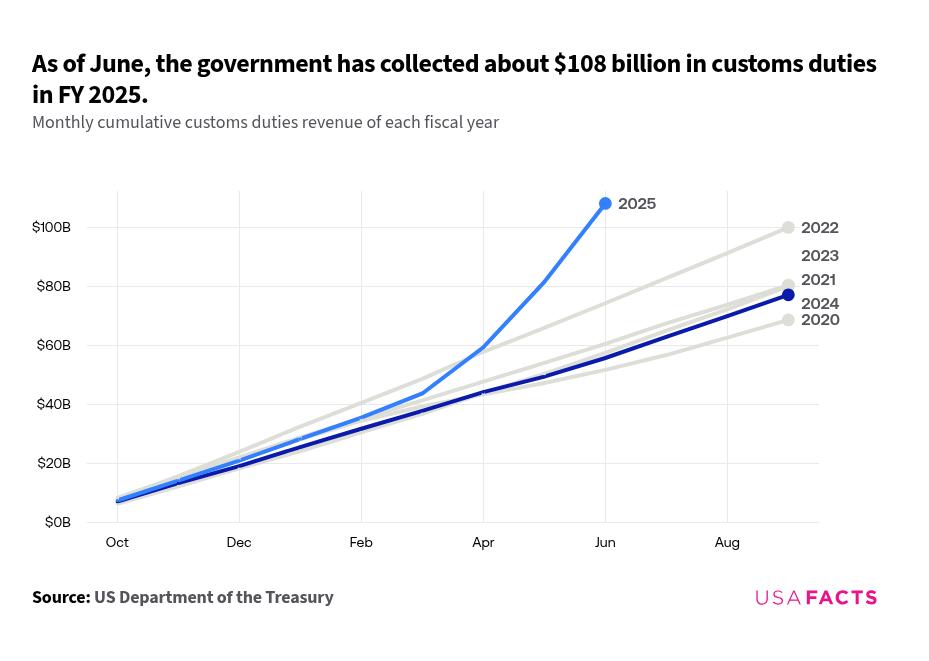

Since the Trump inauguration on January 20, we have seen a dizzying amount of new legislation, tariffs, trade deals, stock market gyrations, foreign military actions, border closings, immigration roundups, and more. Seasoned news agencies and reporters are challenged in keeping up with the administration’s on-again, off-again switching gears and direction. In just six months into his second term, Trump has signed 178 Executive Orders. The Federal Register does a good job in keeping up with all of these and publishes a timeline with summaries that can be followed: Federal Register: Executive Orders.

On the first of February, Trump’s first executive order was a 10% tariff on China and 25% tariff on both Mexico and Canada, citing a national emergency due to fentanyl smuggling and illegal immigration. From there, a whirlwind

Over 90% of organizations are overpaying for services but don’t know it and most of the money being wasted is lost forever, not refundable.

• No financial risk to our clients

• We are paid from the refunds and/or savings

• We require minimal effort from our clients (2-4 hours from one person)

• Initial findings in as little as 2 weeks

• Our objective and unbiased approach ensures we are aligned with our clients’ best interests

• No requirement to change vendors

• Over 30 years of subject matter expertise in waste disposal, utilities, textile rentals, and telecom

of daily and weekly tariff announcements followed aimed at countries around the world. Keeping up with all the tariff announcements and revisions challenged many news outlets. Many say the dizzying whirlwind of on-off, on-again, off-again, reconsiderations, twists, false-starts, fakes, and about-faces are a part of the president’s strategy as a dealmaker.

One of the easier to read timelines of Trump’s tariff implementation was prepared by Amenda Macias at Fox Business. The print version is more user friendly: A complete timeline of Trump's tariff implementation strategy across the globe

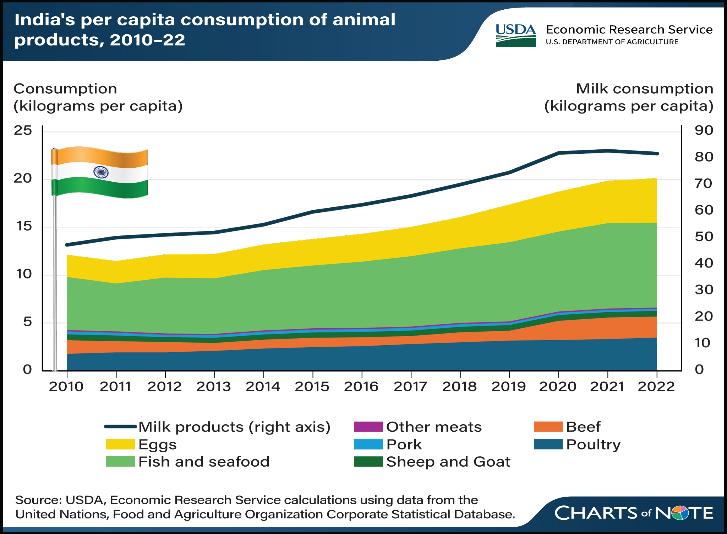

Several of Trump’s best trade deals have been made over the past few months. The EU in mid-July then Japan, Indonesia, and the Philippines. Japan is our fourth largest market for agricultural products and Indonesia is seventh largest. All three countries have a growing middle class and seek more dairy products in their diet. These recent trade deals will help anchor U.S. dairy exports to the Asian pacific. Canada and India are standing firm in protecting their domestic dairy industry from potential U.S. exports. India has not been shy letting the world know that it wants to protect its dairy farmers from being displaced by foreign milk and for religious reasons. It is estimated there are over 75 million dairy farms in India. Most are very small family-owned operations. Nearly 80% of these farms have just 1 to 5 animals.

India’s population continues to grow and has surpassed China in numbers. Urbanization and rising incomes are growing India’s middle class. This segment is demanding more animal products including dairy. Still, many Indians have strict dietary standards and consume less animal products than other countries. Seafood, poultry, and dairy consumption are rising there and expected to continue doing so. U.S. dairy exporters should continue knocking on their door.

So far, Trump’s tariffs have not had a devastating effect on the U.S. economy as some predicted. In recent weeks, several major news agencies have expressed their surprise and optimism.

• NY Times 7/16: The Economy Seems Healthy. Were the Warnings About Tariffs Overblown?

• NPR 7/27: Here's a puzzling question: Why are stocks at record highs despite looming tariffs?

• Wall Street Journal 7/29: If Trump’s Tariffs Are So Bad, Where’s the Recession?

• The Hill 7/31: Even JP Morgan CEO Jamie Dimon, an early Trump critic and tariff skeptic, has changed his tune.

As this goes to print, reports are that the U.S. collected a record-breaking $29 billion in July. Total tariff revenue this year is now more than $152 billion. So far, some U.S. companies are choosing to eat the tariff expense rather than pass cost increases on to their customers. Who knows if this behavior will last and how long stockholders will tolerate it.

The “One Big Beautiful Bill Act”, - H.R.1 was passed by both Congressional Houses and signed into law by President Trump on July 4. There is a lot of dairy and agriculture in this bill. Most of the news reports from agriculture and farm-related groups that followed were favorable overall. H.R. 1 is too massive and complex to cover in detail here with limited space constraints. However, a short summary of a few key dairy-related pieces in this bill are:

• Renews the Dairy Margin Coverage program through year 2031 and raises tier 1 coverage to six million pounds from five million pounds. The largest production year between 2021 and 2023 can be used as

the enrollment base point. Producers committing to the program will be entitled to a 25 percent premium discount as an incentive. The Dairy Margin Coverage Program is an important tool that provides a “safety net” for U.S. producers.

• Mandates that USDA conduct biennial processing and manufacturing cost surveys on products used to establish Class prices in Federal Milk Marketing Orders. This will ensure that current costs are being used to determine formula make allowances.

• Provides for extensions and updates to many tax-related programs commonly used by farmers and ranchers.

• Mandates USDA spending on animal disease research via the National Animal Disease Preparedness program. Expands research and response to threats like the H5N1 bird flu virus and screwworm. To work toward swift diagnosis, response, and coordination with state officials.

Overall, the agricultural community is pleased with the passage of the One Big Beautiful Bill, H.R. 1.

The Purdue Center for Commercial Agriculture just released its August Ag Economy Barometer revealing 74% of farmers feel U.S. policy is headed in the right direction.

Summaries of Purdue’s Ag Economy Barometer are available in both text and video format.

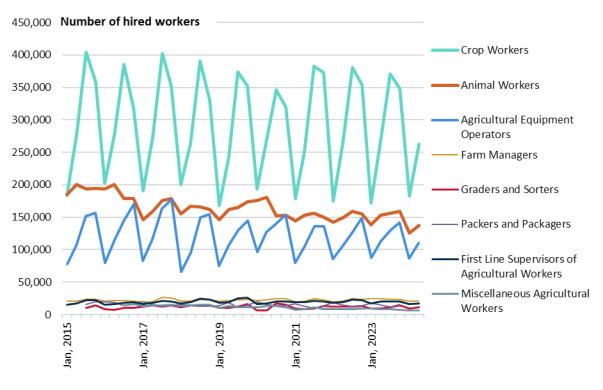

U.S. immigration policy is at the forefront of the news and is high on the list of concerns for everybody, especially those connected to food and agriculture. Foreign labor plays an important role in U.S. farming, processing, manufacturing, and distribution. The employment of undocumented labor varies by commodity and level of agricultural intensity within the states.

According to the National Milk Producers Federation (NMPF), 51% of all U.S. dairy labor is performed by migrant farm workers. Farms utilizing migrant labor are responsible for producing 79% of the U.S. milk supply. These are impressive statistics.

In early July 2025, the Economic Research Service (ERS) updated their publication Farm Labor

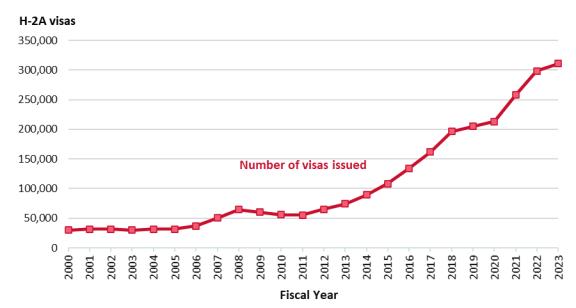

The current H-2A program has substantial direct and indirect costs for agriculture businesses. According to farmdoc daily, the rising costs tend to disproportionately

disadvantage smaller farms. While this program is suited for many operations needing temporary or seasonal workers, it is less than ideal for dairy operations who need daily employees throughout the year. Larger operations work 24 hours daily in shifts. The Growing Role of H-2A Workers in U.S. Agriculture, Christian Valencia and Nick Paulson, Department of Agricultural and Consumer Economics, University of Illinois. July 9, 2025.

“Employers complain that the H-2A program is costly and complex, and worker advocate complain that H-2A workers are vulnerable and easily exploited. The H-2A program is expanding and will likely surpass 400,000 jobs certified in FY25.”

The Rural Migration News, The Regents of the University of California, Davis, July 16, 2025 H-2A: AEWRs, Regulations

- Rural Migration Blog | Migration Dialogue

The total H-2A visas issued per year has grown significantly in the last two decades. The Congressional Research Service (CRS) shows this growth from 30,201 in year 2000 to 310,676 by 2023. Bureau of Consular Affairs data also show that the countries whose nationals were issued the greatest numbers of H-2A visas in 2023 were Mexico (284,247), South Africa (12,762), Jamaica (4,653), Guatemala (3,600), and Nicaragua (1,166). Source: Measuring Employment in the Agricultural Sector in the Context of the H-2A Visa Program, CRS Report.

The “seasonality” aspect for crop workers compared to the steadier animal workers is depicted below.

President Trump seems sincere in wanting to do something to help farmers and agriculture emplyers legally employ an immigrant workforce. His ideas seem to shift and evolve over time. He acknowledges farmers and the agriculture community are a big portion of his base of support. Trump however is caught in the middle between the agriculture community and his hardline supporters in the GOP. These MAGA hardliners are a chunk of his support base. There are

Source: Measuring Employment in the Agricultural Sector in the Context of the H-2A Visa Program, CRS Report

many members of Trump’s cabinet and inner circle in favor of finding a solution, but there are many against it. Members of Congress have avoided crafting a solution. Trump has been floating the idea of doing something by executive order to allow Congress time to sort out a permannt solution. In the meantime, there is activity with a few bills floated in Congress to address the farmworker immigration issue. One that has been around for a while and reintroduced on May 7 is the Farm Workforce Modernization Act of 2025 H.R.3227. The Farm Workforce Modernization Act has been around for a while. It was passed twice in the House of Representatives. Once in the 116th Congress (2019-2021) and again in the 117th Congress (2021-2022). On each attempt, it failed to advance in the Senate. The Act was reintroduced in May of this year

and awaits debate.

To avoid reading the full 230 page text above, An official one-page summary of the bill is available here: H.R.4319 - 118th Congress (2023-2024): Farm Workforce Modernization Act of 2023 | Congress.gov | Library of Congress

One of the bill’s main sponsors, Representative Susan Ellen "Zoe" Lofgren (D-CA), has prepared a couple of summaries that are worth reading:

• Two-page summary

• Section-by-section outline

The key parts of the Farm Workforce Modernization Act of 2025 provide:

1. A route to legalization. Creates a new temporary visa for undocumented workers that have a U.S. work history.

No criminal record. Ceation of a Certified Agricultural Worker (CAW) status. Workers can apply for residency after a given time.

2. Reforms for the H-2A Visa program. It refines the program to react better meet the needs of employers. Enhances the H-2A program to make it available to employers with a year-round need for workers.

3. Mandatory verification. Employers must use an enhanced E-Verify system designed to minimize fraud and abuse. To afford protection for both employer and employee.

Many feel the Farm Workforce Modernization Act is a step in the right direction and provides good framework for a starting point. The bill needs more refining and massaging to make it better. Some organizations have wage rate concerns that should be addressed if the bill moves forward. New legislation must guarantee enough year-round extended H-2A visas to benefit dairy farms, milk processors, manufacturers, and like operations. These agricultural employers, like many in the food and hospitality industry, are not seasonal and require a daily year-round workforce.

The Cato Institute also took a close look at the H-2A program back in 2020 and concluded, “Congress could expand on this successful program by making H-2A visas available to year-round industries and streamlining its rules and regulations.” H-2A Visas for Agriculture: The Complex Process for Farmers to Hire Agricultural Guest Workers

New York’s Cornell College of Agriculture and Life Sciences is home to the Cornell Farmworker Program that offers a variety of resources for farm owners and their employees. The program maintains a website and guidebook specifically designed to help dairy farm owners and non-citizen employees address challenges related to cultural differences, language barriers, and team building.

In mid-July, U.S. Senator Alex Padillia reintroduced S.2468 - Renewing Immigration Provisions of the Immigration Act of 1929.

This Senate bill has some cosponsors from the northeast, Cory Booker (D-N.J.), Edward J. Markey (D-Mass.), Chris Murphy (D-Conn.), Bernie Sanders (I-Vt.), and Elizabeth Warren (D-Mass.). A one-page summary can be found here

At a June 12 televised news conference, Senator Padilla scuffled with Homeland Security agents and was removed in handcuffs. His bill provides a pathway to lawful permanent resident status. With no republican support, S.2468 has little chance of becoming law.

Another bill, with some Republican support, was intro-

duced in the House on July 15th by Representative Maria Elvira Salazar (R-Fla)., and Representative Veronica Escobar (D-TX) called the Dignity Act of 2025. They were joined by a mix of twenty cosponsors from both sides of the aisle including three Republicans and three Democrats from the northeast. Congressman Mike Lawler (R-NY), Mike Kelly (R-PA), Brian Fitzpatrick (R-PA), Adriano Espaillat (D-NY), Laura Gillen (D-NY), and Jake Auchincloss (D-MA).

Following its July 15th introduction, Reps. Salizar and Escobar went on a media blitz seeking support for the Dignity Act of 2025. Their pitch was no handouts, no citizenship, no amnesty. Limited stay seven-year temporary permits would be issued. To be eligible, participants must have been working in the U.S. prior to year 2021. Funding for the bill would come from participant restitution payments. The bill creates a legal pathway to remain in the U.S. for work but does not lead to citizenship. Permits are renewable every seven years.

Escobar and Salizar tout their bill as a compromise permitting a path to stay and work under protected status without citizenship. Participants must have a clean criminal record, pay taxes, and provide $7K in restitution payments during their work stay. There would be no access to federal programs or benefits.

Summaries of the Dignity Act of 2025 can be found on Representative Salazar’s website

With the White House and Congress politically unified, the time to craft a permanent solution to the agricultural worker problem will never be better. If it is going to get done, then President Trump needs to get seriously involved. The agricultural community is a considerable part of his support base, but not all of his supporters agree on a solution.

Ultimately, Congress must pass a bill. This is a bipartisan issue seeking a solution. The Farm Workforce Modernization Act, having passed the House twice in prior sessions, is a good restarting point. Combine it with some of the ideas from the Dignity Act and Congress might create another beautiful bill. .

Gary Latta is a dairy product specialist consultant for the Northeast Dairy Foods Association, Inc. He has more than 30 years of experience in providing economic analysis, statistics, and information to the dairy processing industry.ation to the dairy processing industry.

Introducing our new and improved single serve filling machine: N-200 Eco-Pak® It will help preserve the shelf life of products such as white, flavored milk and juice for school, institutional and single serve markets, filling up to 20,400 cph. Designed with input from filler operators, the

• Decreased maintenance

• Increased line efficiencies

• Improved performance

• Easy access to machine components

From packaging breakthroughs to process efficiency, NDFSA members are redefining what it means to meet the evolving needs of the dairy and food industry.

BY STEVE GUGLIELMO

Innovation has always been at the heart of the dairy and food industry. From the earliest mechanical advances on the farm to the latest breakthroughs in packaging, processing, and sustainability, the companies that thrive are those that anticipate change and adapt to meet new challenges. Today, that pace of change has never been faster. Pressures around efficiency, food safety, regulatory compliance, sustainability, and consumer preferences are driving suppliers and manufacturers alike to think differently about how dairy products are produced, packaged, and delivered to market.

Members of the Northeast Dairy Foods and Suppliers Association (NDFSA) are at the forefront of this transformation. Their work spans every corner of the industry: packaging that reduces plastic waste and extends shelf life, equipment that increases speed and reliability on production lines, software that flags hidden cost savings, and biosolutions that improve taste, nutrition, and yield while reducing waste. Each innovation shares a common purpose—helping dairy processors deliver safe, high-quality products more efficiently and sustainably.

This feature highlights a range of NDFSA member companies that are bringing new ideas and technologies to life. Their stories show how creativity, technical expertise, and a willingness to embrace change are shaping the future of dairy. More than a showcase of products, this collection is a look at how innovation, in all its forms, is driving progress for an entire industry. If your company has an interesting innovation that you would like to highlight in our weekly newsletter or an upcoming issue of Northeast Dairy Magazine, please email steveg@nedairymedia.com

Innovation has always been a part of Stanpac’s commitment to providing the dairy industry with new and improved packaging solutions. Over the years, the company has continually evolved by investing in research, technology, and materials to meet the changing needs of both dairy producers and consumers.

“From our SecurTEC™ line of tamper-evident composite closures to our Dispersion Barrier Coating (which replaces traditional PE coating on ice cream packaging with recycling and industrial compostability), Stanpac not only helps our customers stay relevant, but also anticipates future trends by staying at the forefront of packaging innovation,” the company says.

In recent years, Stanpac identified a growing gap in the bulk ice cream market: a need for a fully printed, paper based bulk scooping container that combined durability, sustainability, and premium branding. Its recent launch of the bulk ice cream container and lid directly addressed this need and stands out as one of our most innovative achievements in recent years.

“Looking ahead five years, innovation will continue to be a driving force behind Stanpac’s growth. We are focused on the ever emerging and advancing technologies that allow for more recyclable and compostable packaging. We are also developing new package configurations and sizes for an ever-changing market,” the company says. It concludes, “Stanpac embraces innovation across all our departments. Team members are always encouraged to bring forward new ideas or explore better ways of doing things—whether that’s through product development, manufacturing, or customer service.”

Innovation has long been central to Burkert Fluid Control Systems’ role in the dairy and food industry. The company has evolved through advancements in automation, digitalization, and hygienic design, using intelligent sensors, modular valve technologies, and decentralized automation systems to deliver precise process control, improved efficiency, and seamless integration with digital platforms. These efforts support Industry 4.0 while also advancing sustainability with energy-efficient valve designs and process solutions that minimize water, energy, and compressed air usage, all while ensuring food safety and regulatory compliance.

“Burkert’s biggest differentiator and most innovative achievement is our development of intelligent, networked automation and flow measurement solutions, specifically the FLOWave flowmeter, tailored to optimize key dairy processes such as Clean-in-Place, raw milk processing, and filling,” says Jim Larsen, Core Industry Manager.

Going forward, Burkert is committed to advanced digitization, sustainability, and intelligent automation. Key initiatives include expanding digital platforms with real-time diagnostics, predictive maintenance, and data-driven process optimization, with a focus on dairy and biotech industries. The company is also investing in sustainable manufacturing, including partnerships with Green Elephant Biotech and GEA to enable more efficient cultivation and production systems.

At MAC LTT, innovation is at the heart of how the company supports the dairy and food industry. By working closely with haulers, MAC LTT has developed solutions that improve safety, efficiency, and trailer performance in real-world conditions. Over the years, this has included

“As a family-owned company, Burkert’s culture embraces innovation, encouraging creativity, initiative, and interdisciplinary collaboration,” Larsen concludes.

experimenting with new jacketing materials and colors for improved temperature control, designing a single conical tank, and enhancing safety with features such as integrated spill dam lighting and the fully illuminated rear Glow Head, which ensures drivers are visible on the road and

during loading or unloading in low-light conditions.

The company says one of its most groundbreaking achievements is the Glow Head, a feature that significantly enhances visibility on rural roads, highways, and in poor weather conditions. Just as important is the company’s dedication to solving real-world challenges through custom solutions, creating trailers that fit each customer’s unique operation.

Looking ahead, MAC LTT is committed to exploring new ways to improve safety, performance, and efficiency by evaluating emerging technologies and ideas that can move the industry forward. The company says its culture of curiosity, collaboration, and continuous improvement ensures

At Lochhead Vanilla, we understand that the food industry is constantly evolving, and we pride ourselves on staying ahead of the curve. One of our company's goals is to support our customers by identifying potential trends early and producing vanilla solutions that address them.

A recent example of this is the growing demand for high-protein products. As these products are being formulated, and certain proteins are added, off-flavor notes can occur. Our team of vanilla specialists saw this and created vanillas that can mask these undesirable flavors, while still enhancing the good flavors in the products.

This innovation has already helped many of our customers in the dairy industry whether they make ice creams, yogurts, or beverages.

As a company we are committed to continue to develop new vanillas that will help our customers in the dairy industry achieve their flavor goals. Whether that be to enhance, masks, or match flavors, we are constantly creating.

Since 1930, Clayton Industries has defined steam innovation with a patented steam generator design that continues to shape the industry. The system integrates forced circulation water flow, a counterflow heat exchanger, and a mechanical steam separator to deliver higher energy efficiency, reduced operating costs, and steam quality that sets the benchmark. Its low water volume design not only improves responsiveness but also removes the risk of catastrophic explosion, reinforcing Clayton’s reputation for both performance and safety.

For nearly a century, Clayton has been a trusted partner to the food and dairy industry, where steam plays a critical role in processes from pasteurization and cooking to fermentation and clean-in-place sanitation. Clayton’s systems are engineered for precision temperature control and unmatched purity, with steam quality exceeding 99%. Their modular boilers reach full output in less than five minutes, helping producers maintain efficiency in fast-paced operations, while compact designs minimize installation space and complexity.

Feldmeier Equipment has built its reputation on more than 77 patents, with additional patents pending, making innovation a defining part of its identity. Every part or system is designed to help customers produce dairy and food at the highest quality levels, exceeding industry standards. From patent-pending spray ball cleaning technology to easy-clean caps, Feldmeier continues to create solutions that transform how manufacturers approach sanitary equipment.

The company says its customers have come to expect unique, industry-changing solutions delivered with an uncompromising commitment to cleanability, quality, and service. Feldmeier contributes to the development of standards for organizations such as ASME-BPE and 3-A, while also introducing new designs that improve practices across the industry.

Looking at the next five years, Feldmeier is investing in automation and advanced machinery across its manufacturing process. State-of-the-art facilities and technology allow team members to work more efficiently as demand grows. The company emphasizes in-house support even after instal-

As industries worldwide focus on reducing emissions and improving energy efficiency, Clayton continues to lead with sustainable innovation. Its steam generators can be equipped with ultra-low NOx technology to comply with stringent emissions regulations, while heat recovery boilers capture and reuse energy that would otherwise be lost. The company’s newest release, the V-Series Electric Boiler, represents its ongoing commitment to clean energy solutions and a lower carbon footprint without compromising performance.

At the heart of Clayton Industries is a customer-first culture. Every system is designed around the unique and individual needs of our customers rather than a one size fits all approach. This commitment to innovation, safety, and reliability ensures Clayton remains a trusted name in steam well into the future.

lation, ensuring equipment performs at the highest level with minimal downtime.

Feldmeier’s culture of innovation stretches back to its founder and is carried forward today by President and CEO Colby Clark. “We encourage our teams to think outside the box on every project, pushing boundaries to deliver the best results for our customers,” the company says.

For Axiflow Technologies, innovation means pushing the boundaries of what twin screw technology can achieve. In the coming years, the company says it will continue to test new applications that improve product feed systems, enhance productivity, and keep maintenance costs low. Even in an industry with limits to how many ways product can be moved, Axiflow is committed to finding new efficiencies that benefit its customers.

That spirit of advancement has already shaped how the company operates today. With more than 125 years of combined experience in the processing industry, the Axiflow team has developed a pilot plant for customer testing, giving manufacturers the ability to validate solutions before fullscale production. This, combined with expanding product lines and comprehensive after-sales support, distinguishes Axiflow from competitors who may not offer the same level of ongoing service.

The company says its culture is centered on delivering complete fluid handling solutions rather than just pumps. By listening closely to customer needs and encouraging its team to innovate, Axiflow ensures that each project is supported from design through installation and beyond. Heading into 2026 and beyond, the company plans to strengthen its services while expanding its technology to meet future demand.

At Huhtamaki, sustainability is the cornerstone of innovation. The company says it has responded to the evolving dairy industry by developing packaging solutions that reduce environmental impact while maintaining product safety, freshness, and shelf appeal. In refrigerated dairy, fiber-based alternatives help minimize plastic in the waste stream without compromising performance. Among its most significant achievements are ICON® containers, a recyclable fiber-based packaging solution for frozen desserts that can be recovered through existing paper recycling streams. Its paperboard cup for the U.S. dairy market has also set a new standard for fiberbased packaging in refrigerated applications.

Huhtamaki’s ability to navigate complex sustainability mandates is one of its defining strengths. With expertise in regulatory frameworks such as Extended Producer Responsibility, the company helps customers stay ahead of compliance requirements while collaborating to create pack-

The Probst Group stands out for its ability to tackle the dairy industry’s toughest wastewater challenges with a combination of technical innovation and forward-thinking design. The company says it has delivered solutions that not only address immediate issues but also set clients up for long-term success. One example is reclassifying certain dairy wastewater sludge as fertilizer, reducing regulatory restrictions while giving farmers access to valuable nutrients. Another is the first-of-its-kind solution in the food industry to evaporate and crystallize chlorides for reuse in production, transforming a costly disposal problem into a valuable resource.

These achievements build on the company’s deep engineering expertise and a mindset rooted in problem solving. By participating in industry round tables and maintaining close collaboration with clients, Probst constantly seeks ways to refine processes, test new technologies, and design systems with flexibility to meet future regulatory or production changes.

Looking ahead, the company says innovation will be critical as water scarcity and rising operational costs put new pressure on the dairy industry. Its focus is on lowering the cost barrier to water reuse, making sustainable practices more efficient, accessible, and affordable.

Probst fosters a culture where innovation is more than a buzzword, it’s a daily practice. “Our team has the freedom to test new ideas, challenge the status quo, and uncover breakthrough solutions that help the industry thrive,” the company says.

aging that balances sustainability, functionality, and performance. Its paperboard cup for the U.S. dairy market has also set a new standard for fiber-based packaging in refrigerated applications.

As we head into the new year, Huhtamaki says innovation and legislation will guide its path forward. The focus is on next-generation technologies that scale circularity, enhance recyclability, and align with shifting consumer expectations and regulatory requirements.

The company emphasizes a culture of experimentation, collaboration, and long-term thinking. “Our innovation is not just about new products, but about transforming the role packaging plays for our customers in support of consumers and the planet,” the company says.

Hydrite’s biggest differentiator is the structure of its RITE Team™, which unites experts in equipment, applications, membranes, and microbiology to deliver integrated solutions and deep technical expertise. Supported by the company’s state-of-the-art Technical Center, this team has driven the development of standout products such as HydriVision RT™, SLM RT™, M3ASURE™, and HydriPro™ equipment. Just as significant is Hydrite’s service model, which places program managers inside customer plants daily to provide hands-on, data-informed support that enhances food safety, reduces CIP cycles, and drives operational efficiencies.

“Innovation at Hydrite is deeply connected to how we approach ingredients,” says Lindsey Marsh, Executive Director of Food Ingredients. “We’re constantly exploring new technologies and data-driven strategies to help our customers optimize ingredient performance, reduce waste, and enhance food safety. It’s not just about what goes into the product—it’s about how we support every step of the process with smarter, more sustainable solutions.”

Looking forward, Hydrite says its future will be shaped by predictive analytics, AI, and real-time monitoring to optimize sanitation, improve consistency, and reduce resource consumption across ingredients, cleaning, and wastewater management.

The company emphasizes that innovation is more than technology, it’s cultural. “At Hydrite, innovation isn’t just

For more than 77 years, Nelson-Jameson has built its reputation as a one-stop shop for food and dairy manufacturers while continuing to innovate in response to customer needs. “Our unique recipe of creating deep strategic partnerships with manufacturers, plus growing our teams with subject matter experts, has allowed us to meet the changing needs of the dairy and food industry,” says Devon Vogel, VP of Corporate Strategy. By listening closely to customers and identifying pain points, the company has expanded beyond supply into education and service, making those its highest priorities.

Nelson-Jameson’s biggest differentiator is its multi-faceted approach, bringing customers both tangible services and the breadth of products needed to run their facilities successfully. The company says that no single competitor covers all it

a goal. It’s part of our culture,” says Mitch Fay, Executive Director of Technology. “The RITE Team™ exemplifies this by bringing together cross-functional experts who collaborate daily to solve complex challenges in food safety, sustainability, and operational efficiency.”

provides, from cultures to make cheese and lab equipment to ensure quality, to safety products, in-plant services, and even vertically integrated trucking. A recent achievement has

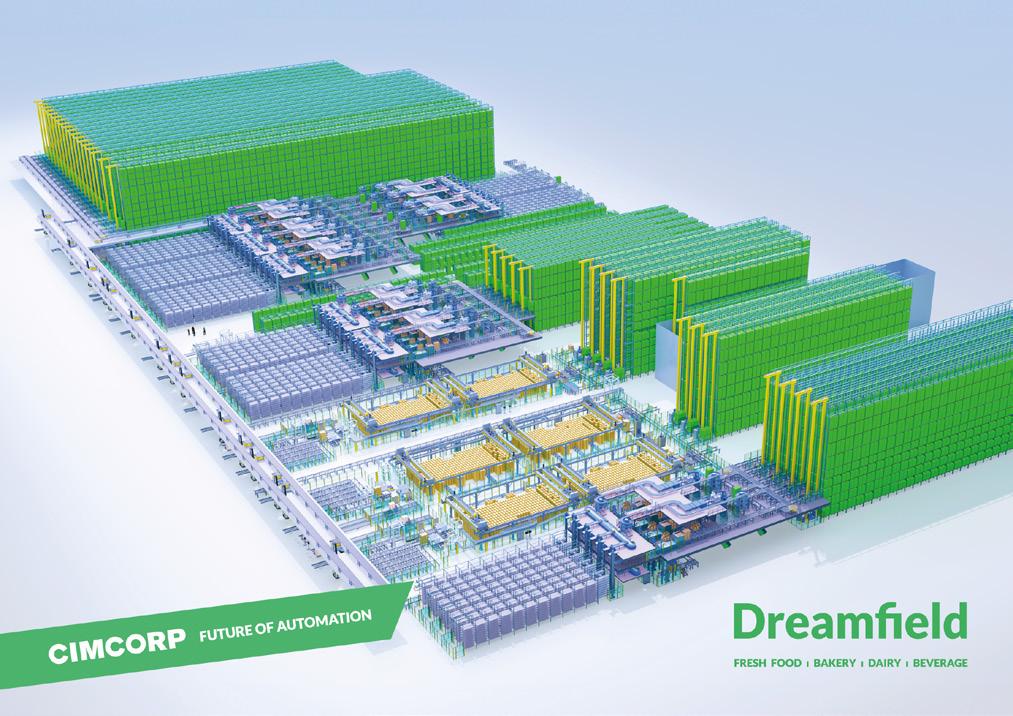

Cimcorp’s automated storage and picking systems are among the most compact and comprehensive in the industry. The company says its solutions manage everything from bulk storage and case or crate picking to item picking, palletizing, labeling, and sequencing, all within a tightly integrated system. What further sets Cimcorp apart is its WES and WCS software, designed specifically for the dairy and food sectors to provide full visibility and control across operations.

With more than 25 years of experience in the dairy industry, Cimcorp has continually evolved to address challenges such as flattening demand, labor shortages, and rising cold storage costs. Its automation solutions prioritize space optimization, system flexibility, and productivity, helping processors streamline operations in an increasingly competitive landscape.

Going forward, Cimcorp says its focus is on making automation smarter, more responsive, and easier to integrate. The company is exploring how AI could enhance planning and operational insight, driving the next generation of warehouse solutions.

Innovation is embedded in Cimcorp’s culture. “We foster a ‘fail fast, learn faster’ mindset that empowers employees to experiment boldly,” the company says. Through innovation sprints, hackathons, and cross-functional committees, ideas are turned into tangible improvements that keep both customers and teams moving forward.”

been the expansion of its nationwide Service & Repair program, addressing industry-wide strains on maintenance services and becoming a Neogen laboratory equipment authorized service provider.

Moving forward, Vogel says the company is investing heavily in elevating their e-commerce presence, embracing AI, and automation to streamline ordering and improve efficiency. “We openly encourage our employees to ask why, challenge past processes, and adopt new technologies to better serve our customers.”

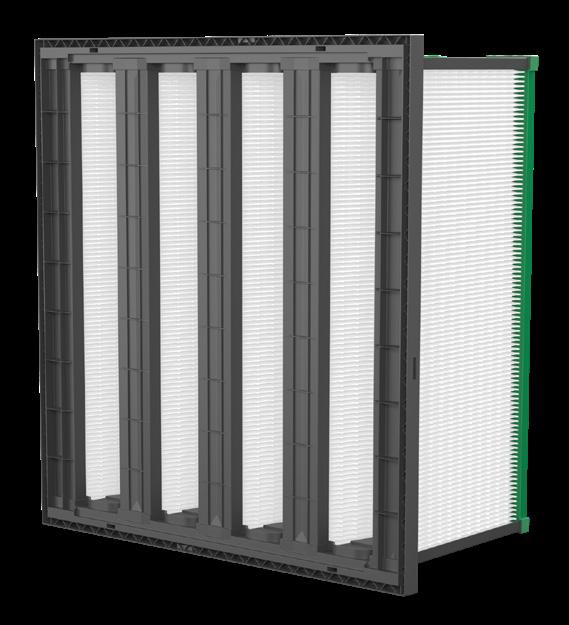

Camfil USA has responded to labor shortages and rising energy costs with air filters that deliver performance guarantees unprecedented in the industry. The company says the Durafil® ES3 final filter is guaranteed to provide the highest energy savings and outlast any other filter in its class. Likewise, the new Absolute VG HEPA filter is half the weight of a typical HEPA filter, making installation easier for maintenance teams while maintaining strength and low airflow resistance. Both solutions help food and beverage plants reduce labor and energy costs while improving indoor air quality.

A key differentiator is Camfil’s ability to maintain rated particle removal efficiency, known as MERV-A, throughout a filter’s service life. “Many filters lose efficiency over time, risking compliance and compromising food safety. Our commitment to consistent performance sets us apart,” the company says.

Looking to the future, Camfil is developing longer-lasting filters integrated with sensors to monitor air quality in real time. These systems will

optimize service schedules, minimize the need for outside vendors, and reduce labor hours.

Backed by six global R&D centers and four U.S. mobile laboratories, Camfil leverages advanced testing and proprietary Life Cycle Costing software to ensure reliable performance. This culture of innovation continues to shape the future of air filtration.

Fogg, a ProMach Product Brand, was founded in the dairy industry when Clyde Fogg began rebuilding and improving OEM dairy fillers nearly 70 years ago. Since then, the company has used innovation to expand across food, beverage, automotive, and healthcare markets while maintaining a strong focus on dairy. The company says its technologies mitigate foaming products through custom valve designs, product supply level controls, and mechanical foam mitigation systems. More recently, Fogg has advanced into ultra-clean and aseptic capabilities, incorporating microbial log kills, extended shelf-life features, and bottle and cap sanitization pre-treatment systems.

A major differentiator is Fogg’s robust R&D infrastructure, which includes microbiological lab experience, sanitary validation, and fill testing stations for thousands of valve designs. These resources have led to space-saving filling solutions that increase speed by up to 30% and new gaseous sanitization systems that reduce water and chemical use while supporting sustainability.

Moving forward, Fogg says it is implementing pressure differential and non-contact fillers, as well as gaseous bottle sanitization, to elevate sanitary standards and expand into higher viscosity products.

“Innovation is built into our mission and culture,” the company says. “We constantly refine our technologies to enhance customer experience, support growth, and improve profitability.”

Altium Packaging has made innovation and sustainability central to its evolution in the dairy and food industry. One of its most notable achievements is Dura-Lite® Light Weight Packaging, which reduced bottle weight from 62 grams to 56 grams while maintaining top load strength and compatibility with conventional filling lines. The company says this advancement has saved more than 48 million pounds of virgin HDPE and earned the 2021 AmeriStar Beverage Category Award.

The Dura-Lite® portfolio stands as Altium’s biggest differentiator in recent years. Standardized across multiple plants, it ensures processors have access to excess capacity when needed, strengthening supply chain reliability. Since launch, the portfolio has sold more than 3.3 billion packages, demonstrating its success and broad industry impact.

Novolex (formerly Pactiv Evergreen) has redesigned and updated all gable top filling equipment over the past eight years to enhance efficiency and operation. These improvements have led to a considerable reduction in annual maintenance, increased fill accuracy, and easier operation for plant personnel. Key upgrades include improved visibility of machine functions, enhanced safety features, and the implementation of servo technology with updated Rockwell PLCs and other electrical components.

The design of the new fillers was informed by extensive interviews with major customers and feedback from field technicians and engineering staff. Improvements were specifically made to reduce complexity and training requirements for plant personnel, a direct response to customer challenges with staffing shortages.

A significant differentiator is the company's location in Iowa, which facilitates 24/7/365 customer support, parts, and service across the United States. Novolex in Cedar Rapids maintains an extensive service staff throughout the country and offers comprehensive training programs both in house and at customer sites. The company is the only U.S.-based manufacturer of high-speed ESL gable top filling equipment.

Future plans include continuous performance improvements for the existing product line and the introduction of new models. These new models will address emerging packaging and product innovations that customers are looking to introduce in North American and international markets. The potential use of robotics will also be explored to further

Looking ahead, Altium is investing in Open Innovation initiatives that bring in external partners to accelerate new ideas. These include developing advanced 3D printing technologies for more durable blow mold tooling and expanding packaging options for premium product lines such as fortified milk, plant-based beverages, creamers, and cold-brewed coffee.

The company says its culture of innovation is supported by Studio PKG, its in-house design service department, and Envision Plastics, a supplier of PCR materials like EcoPrime™ HDPE PCR approved for food and beverage use—reinforcing a long-term commitment to creativity and sustainability.

improve production line efficiencies at customer facilities. Additionally, the Novolex is proud to introduce the all-new SmartPour™ Pourable Containers and Filling Machine. This packaging features an easy-to-pour and resealable closurefilled by equipment specifically designed to fill everything from Cereal to Pet Food into a variety of SmartPour packaging sizes.

Exergy has built its reputation on delivering superior thermal efficiency in a compact design. The company says its biggest differentiator has always been the large amount of heat transfer its exchangers provide in a small footprint. Recent innovations include CVD surface treatment to enhance performance and the development of solutions that help customers meet sustainability goals by increasing efficiency and reducing both product and utility waste.

As dairy and food manufacturers continue to focus on maximizing production while keeping costs under control, Exergy has responded with a diverse product line supported by robust R&D capabilities. Its compact heat exchangers are engineered to provide reliability and efficiency, aligning closely with the industry’s demand for cost-effectiveness and sustainable operation.

Looking ahead, Exergy says it will continue to expand its products and services to meet evolving customer needs and market opportunities. The company is committed to staying ahead of changing requirements by introducing engineering solutions that improve performance and sustainability.

Ecolab’s biggest differentiator is its unique integration of science, digital technology, and personalized service. The company says this combination has enabled it to pioneer AI-powered water management solutions that deliver measurable sustainability and operational value for customers worldwide. These advances position Ecolab as a leader in helping industries address critical challenges in water, climate, and food safety.

For the dairy sector, Ecolab focuses on brand protection, efficiency, sustainability, and long-term success. Its innovations include Ultrasil™ Connected, an enzymatic cleaning program that reduces chlorine use, improves performance, and provides digital insights and analytics for real-time visibility. Other solutions include Active OX+™, a no-rinse sanitizer that supports organic production; Synergex™, the only EPA-claimed no-rinse sanitizer proven to penetrate and kill biofilms; and Oxy-Pak™ 34, a sterilant for aseptic packaging that extends production runs.