Building for humans in the age of AI

MISSION-DRIVEN MOVEMENT

Floyd Wiltz on Building a Global, Tech-Enabled Logistics

Backbone at Tools for Humanity

From leading logistics operations in the U.S. Army to driving global distribution at the forefront of AI and proof of human innovation, Floyd Wiltz brings a rare combination of discipline, agility, and purpose to his role as Head of Logistics at Tools for Humanity. With a footprint spanning more than 25 countries, Floyd’s team plays a mission-critical role in enabling access to cutting-edge technologies like the Orb, empowering underserved communities with secure proof of human and financial tools.

In this interview, Floyd shares how Tools for Humanity is building a resilient, tech-enabled logistics infrastructure from the ground up. He discusses how AI, IoT, and automation are shaping supply chain agility, how strategic partnerships have accelerated global rollouts, and why sustainability and continuous team development are foundational to scaling impact. For Floyd, logistics isn’t just about movement, it’s about delivering purpose at speed and at scale.

Professional Journey

Can you share your career path and what led you to your current role as Head of Logistics at Tools for Humanity?

My professional journey began with a 20+ year career in the U.S. Army, where I specialised in operations and logistics across global deployments. This experience laid a solid foundation in largescale logistical coordination, compliance, and team leadership.

After transitioning to the private sector, I brought that same operational discipline into roles across international supply chains, which eventually led to my current position as Head of Logistics at Tools for Humanity. In this role, I oversee global post-production distribution, managing the movement of our hardware and fixtures from manufacturing to the public across 25 countries.

I was drawn to this role by the unique opportunity to build a global logistics infrastructure from the ground up, one capable of supporting cutting-edge proof-of-human technologies and enabling high-volume international launches. The mission to empower financial access for people globally, particularly in underserved regions, aligns closely with both my values and professional ethos.

Logistics’ Role in Tools for Humanity’s Mission

How does the logistics function contribute to Tools for Humanity’s mission of building tools for humans in the age of AI?

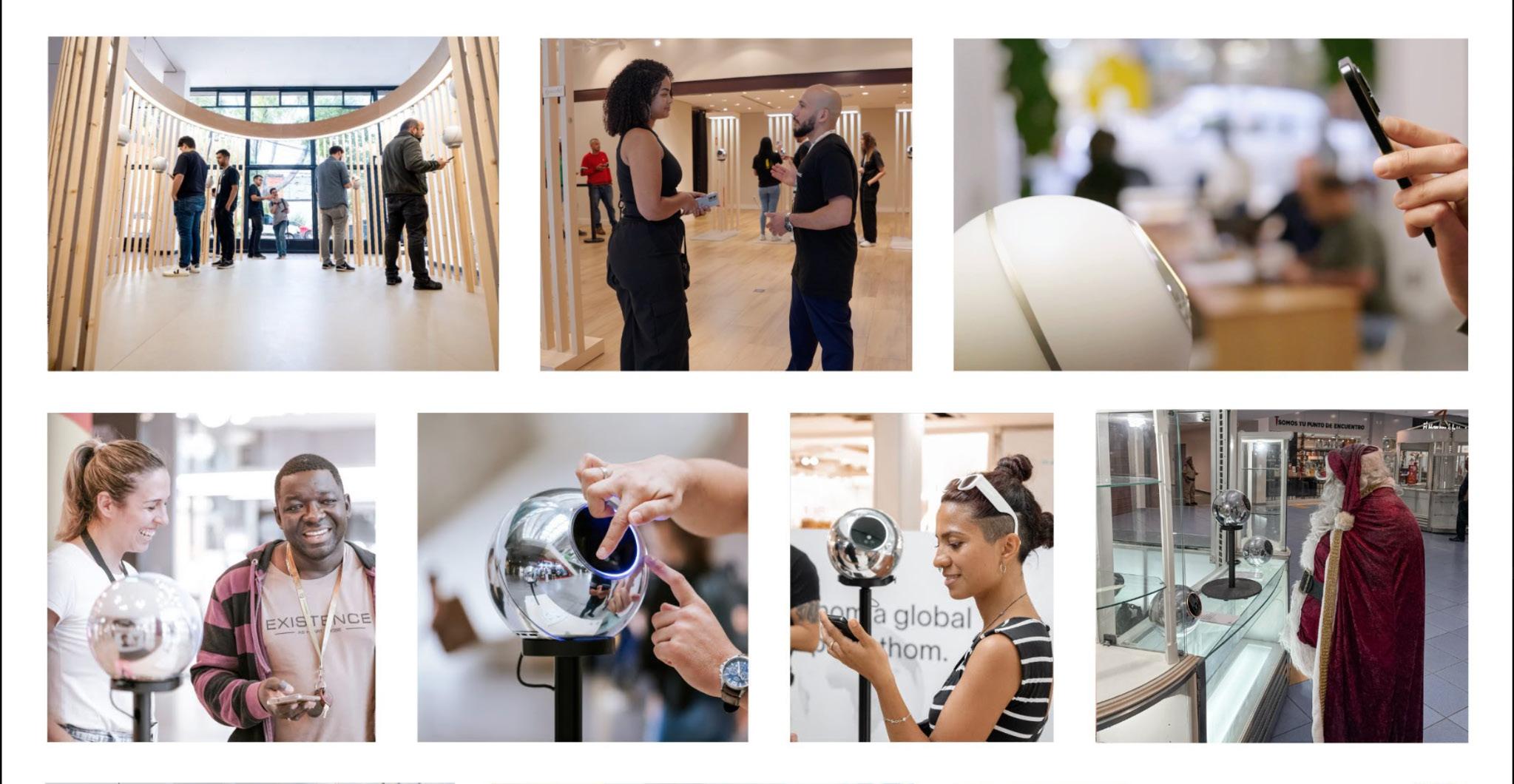

At Tools for Humanity, logistics is more than just movement, it’s mission-critical. Our logistics function directly supports the company’s goal of delivering secure human verification tools globally. We ensure that Orbs, the devices used to verify unique humanness, reach operators efficiently, no matter the region.

This requires a tightly synchronised global operation that spans air and sea freight, customs compliance, Importers of Record, local warehousing, and final-mile delivery. My team manages this end-to-end process, optimising routes and timelines while ensuring full compliance and traceability.

Our logistics strategy is intentionally designed to support our mission of inclusivity whether we’re delivering Orbs to remote areas in LATAM or enabling seamless deployments in urban U.S. markets. It’s a function that turns innovative technology into real, tangible impact on the ground.

Digital Transformation in Logistics

In what ways has digital transformation been integrated into your logistics operations to enhance efficiency and transparency at Tools for Humanity?

Digital transformation is at the heart of our logistics evolution at Tools for Humanity. As part of our commitment to innovation, we’re upgrading our automation landscape through the integration of cutting-edge Transportation Management System (TMS) and Warehouse Management System (WMS) platforms. These systems are already delivering greater transparency and operational agility.

I’ve prioritised enabling near real-time tracking, milestone monitoring, and proactive exception handling. Our ultimate goal is full integration with TFH’s custom Enterprise Resource Planning (ERP) and customer support platforms, providing stakeholders with timely insights across the entire supply chain.

These efforts not only improve operational performance but also enhance the customer experience by delivering more reliable updates and reducing delivery times. In a mission-driven organisation, tech-enabled logistics means we can reach communities faster and with greater confidence.

Building Resilient Supply Chains

What strategies have you implemented to build a flexible and adaptable supply chain capable of withstanding disruptions?

Resilience is engineered into our logistics framework through redundancy, decentralisation, and proactive risk planning. We’ve established multiple regional hubs and distribution centres from Argentina to Japan, each capable of rerouting shipments and absorbing supply chain shocks.

We pre-clear shipments with customs, maintain buffer inventories, and work with multiple freight and final-mile carriers to ensure continuity. This structure proved where we managed simultaneous installations across six cities. Backup warehousing, alternate routing plans, and onsite logistics oversight ensured smooth execution even in the face of unexpected delays or disruptions.

Technological Integration

How are emerging technologies like AI, IoT, and blockchain being utilised to optimise logistics and supply chain management at Tools for Humanity?

We leverage custom-built emerging technologies developed by our Core Application Team to boost logistics efficiency. AI is playing an increasingly important role in demand forecasting and route optimisation, while IoT devices provide real-time shipment tracking ensuring end-to-end visibility from production through to final delivery.

We’re also exploring tailored modules for customs and compliance documentation to improve transparency and reduce processing times. While these technologies are still evolving, they’re already helping us tackle key challenges such as tracking accuracy, customs delays, and inventory misalignment.

As we continue to scale globally, technology enables our lean team to operate more efficiently keeping our logistics function agile, responsive, and intelligent.

We’ve established multiple regional hubs and distribution centres from Argentina to Japan, each capable of rerouting shipments and absorbing supply chain shocks.

Risk Management in Logistics

How do you identify and mitigate risks within the logistics process, especially considering the global scale and complexity of your operations?

Risk management starts with visibility and preparedness. We map every supply chain node and assess potential failure points whether it’s customs delays, carrier issues, or political disruptions. I’ve implemented contingency strategies that include redundant partners, backup storage, and localised support teams.

For example, during our U.S. rollout, we stationed logistics leads at key hubs and pre-cleared goods with customs to avoid last-minute issues. We also leverage milestone monitoring to detect deviations early and respond swiftly.

These strategies ensure that, even when risks arise, our operations continue with minimal disruption keeping our logistics flow resilient and dependable.

Partnerships and Collaborations

In addition to partnerships with brands like Razer and Match Group, Tools for Humanity works with global logistics innovation enablers such as Geodis and Logistics Plus. How have these collaborations contributed to strengthening your logistics and supply chain operations?

Strategic partnerships are fundamental to the strength and agility of our logistics and operations. For example, later this year, select Razer Stores across the U.S. will host Orbs, expanding our distribution network through their established retail presence and creating new, localised fulfilment points.On the logistics front, collaboration with global innovation enablers like Geodis, Logistics Plus, and other key partners has been vital in scaling our infrastructure. These partners bring specialised expertise in areas such as warehousing, last-mile delivery, importer of record services, and the development of operational hubs.

Working closely with these providers enables shared learning and collaborative problem-solving, allowing us to adapt quickly to shifting market needs and logistical challenges. Ultimately, these partnerships support our global expansion while ensuring reliable, high-quality execution in every region we serve.

Adapting to Market Changes

How does your logistics team stay agile and responsive to market fluctuations and global supply chain disruptions?

We maintain agility through modular processes and a responsive operating model. Our logistics team actively monitors global market trends, freight capacity, and evolving customs regulations. We also conduct scenario planning to anticipate disruptions and adjust inventory positioning as needed.

For example, during both the Thailand and U.S. launches, we dynamically reallocated stock across hubs based on real-time demand and transit conditions. Our lean structure enables rapid decisionmaking, while strong cross-functional coordination allows us to pivot quickly.

This level of agility is essential for supporting innovation and managing risk in today’s volatile global landscape.

Team Development and Training

What measures are in place to ensure your logistics team remains skilled and knowledgeable about the latest industry trends and best practices?

We prioritise team development through cross-functional training, hands-on execution, and strategic exposure. My logistics staff are trained not only in core operational tasks but also in areas such as compliance, trade laws, and emerging technologies.

I ensure the team stays informed through regular briefings, targeted workshops, and access to industry certifications. Everyone from logistics specialists to regional managers is empowered to make decisions and optimise their area of responsibility.

This approach fosters a resilient, knowledgeable team that can scale with the business and adapt quickly to evolving challenges.

Future Outlook for Logistics at Tools for Humanity

Looking ahead, what are your key objectives for advancing the logistics function at Tools for Humanity, particularly concerning innovation and sustainability?

Looking ahead, our logistics priorities are centred on innovation, sustainability, and global expansion. I’m focused on enhancing automation, integrating real-time systems, and scaling our network into underserved markets.

Sustainability is another key pillar. We aim to reduce emissions through packaging redesign, shifting modes of transport from air to sea, and optimising delivery routes. We’re also exploring green partnerships and local sourcing strategies to minimise our carbon footprint.

As we continue to grow, the logistics function won’t just support our mission, it will amplify it by enabling smarter, faster, and more sustainable delivery of our technologies worldwide.

Tools for Humanity is a technology company building for humans in the age of AI, co-founded in 2019 by Alex Blania and Sam Altman. With over 400 engineers, scientists, engineers, designers, creatives and economists globally, they develop open-source human verification tools like the Orb and applications like World App, designed to uphold privacy and trust in the AI era.

Floyd Wiltz Head of Logistics