Designing Resilient Supply Chains

Ravi Dosanjh on Leadership, Innovation, and the Ecosystem Mindset at Caliber.global

Better, Better, Never Best

Tim Leight on Building a Future Ready Supply Chain at Calix

Leading with Purpose

Cornelis Dees’s insights on Humanitarian Supply Chain Leadership

Growing Your Online Presence Through Innovative Methods

Innovation

Dear Readers,

Welcome to the latest edition of The Supply Chain Ledger, where we explore the strategies, technologies, and people powering transformation across global supply chains.

We open with a thought-provoking guest feature from Art of Supply, where Kelly Barner examines how BlackRock’s multibillion-dollar purchase of ports along the Panama Canal could reshape global trade flows and U.S. influence in critical supply corridors. As geopolitical dynamics increasingly intersect with supply chain operations, this piece offers timely context and compelling insight.

Our front cover feature spotlights Caliber.global, where CEO Ravi Dosanjh shares an ecosystem-led supply chain model designed for scale, collaboration, and measurable outcomes. His perspective sets the tone for an edition focused on practical innovation and purposeful execution.

We’re proud to spotlight Ebru Sebat of Norwex, whose unwavering focus on sustainability offers a roadmap for building resilient, eco-conscious supply chains. From Germany’s clean energy transition with Enpal’s Sven Pulsack to Joe Ward of Quirch Foods on strategy, culture, and agility across the Americas, innovation and purpose shine through every conversation. Adrian Reyes of MT Unirepair reveals how circularity is driving after-sales excellence, while Tim Leight of Calix shows how AI, digital twins, and continuous improvement are redefining the meaning of “future-ready.”

We also feature Simon Harman of Mitsui E&P Australia, offering a grounded perspective on local impact and supply resilience, and Floyd Wiltz of Tools for Humanity, who brings military precision and social purpose together in a tech-enabled logistics mission.

Our Executive Insights delve deeper. Holly Taylor reflects on supplier relationship management, and Dirk S. van Doorn of DHL Namibia outlines a bold vision for green logistics across Africa.

We’re joined by Sanjeev Wewerinke-Singh of Varuna Marine Services, who shares how the company is steering maritime innovation through digitalisation, emissions compliance, cybersecurity, and sustainability. With over 15 years in the industry, Sanjeev offers a forward-looking perspective on navigating maritime complexity with confidence and technological strength.

Lastly, we’re honoured to feature Cornelis Dees of the IFRC, who shares the human-centred principles guiding humanitarian supply chains where every logistical decision can mean life or death.

From sustainability to scalability, talent to technology, this edition is filled with practical insights and bold thinking from those shaping the future of supply chain leadership.

Enjoy the read!

EDITOR

Christopher O’Connor

CREATIVE DIRECTOR

Martyn Oakley

DESIGN SUPPORT

James Pate

SOCIAL MEDIA MANAGER

Summah Buisson

PROJECT DIRECTORS

Stuart Irving

Denitra Price

Cisco Loevendie

PRODUCTION MANAGER

Ewa Piwoni

No.159, Field Maple Barns, Weston Green Road, Weston Longville, Norwich, Norfolk, NR9 5LA

ACCOUNTS

Emilio Vences

Joseph Heaton

MANAGING DIRECTOR

Phillip Forde

CHIEF OPERATING OFFICER

Fabian Stasiak

CHIEF EXECUTIVE OFFICER

Alex Barron

If you would like more information about ways in which The Supply Chain Ledger can promote your business please email | info@thesupplychainledger.com

The Supply Chain Ledger does not accept responsibility for omissions or errors. The points of view expressed in articles by attributing writers and/or in advertisements included in this magazine do not necessarily represent those of the publisher. Any resemblance to real persons, living or dead is purely coincidental. Whilst every effort is made to ensure the accuracy of the information contained within this magazine, no legal responsibility will be accepted by the publishers for loss arising from use of information published. All rights reserved. No part of this publication may be reproduced or stored in a retrievable system or transmitted in any form or by any means without the prior written consent of the publisher.

One Deal, Three Ports: How BlackRock’s Purchase of Panama Canal Ports Increases U.S. Influence

Designing Resilient Supply Chains: Ravi Dosanjh on Leadership, Innovation, & the Ecosystem Mindset

Leading Sustainable Supply Chains: Ebru Sebat’s Vision for Innovation and Resilience at Norwex

Driving Sustainable Scale: Sven Pulsack on Logistics Innovation at Enpal

Building Partnerships That Last: Holly Taylor on Strategic Supplier

Better, Better, Never Best: Tim Leight on Building a Future Ready Supply Chain at Calix

Driving Circular Excellence: Adrian Reyes on Sustainable Supply Chains at MT Unirepair

From Strategy to Shelf: Joe Ward on Scaling Quirch Foods Through Innovation, Culture, and Global Agility

MITSUI E&P AUSTRALIA (MEPAU)

Strategic Strength and Local Impact: Simon Harman on Leading MEPAU’s

DIRK S. VAN DOORN

Driving Sustainable Progress: Dirk S. van Doorn on DHL Namibia’s Vision for Greener Logistics in Africa

Mission-Driven Movement: Floyd Wiltz on Building a Global, Tech-Enabled Logistics Backbone

Leading with Purpose: Cornelis Dees’s insights on Humanitarian

Steering Maritime Innovation: Sanjeev WewerinkeSingh on

One Deal, Three Ports: How BlackRock’s Purchase of Panama Canal Ports Increases U.S. Influence

Kelly Barner, Head of Content and Operations, Art of

Procurement

The Panama Canal has long been one of the most strategically important pieces of infrastructure in the world, holding significant power when it comes to global economies. Stretching 51 miles and trimming nearly 8,000 miles off shipping routes between the Atlantic and Pacific Oceans, it handles around 13,000 ships per year, representing 5-6 percent of global trade.

Holding a bit of a rocky history, the canal has once again been thrust into the geopolitical spotlight because of a recent multibillion-dollar deal involving asset management giant BlackRock.

The Canal’s Keepers

Contrary to some assumptions, Panama owns the canal itself, operating it under the Panama Canal Authority, an agency of the Panamanian government. The question of ownership–and sales–apply, instead, to the ports located on either side of the canal. Until recently, two of the largest ports, Balboa on the Pacific side and Cristobal on the Atlantic, have been owned by Hong Kongbased conglomerate CK Hutchison, who took them over in 1997. That ownership drew scrutiny over time as, since the company operated under Chinese financial and security laws, it gave the country influence over the operations of this invaluable trade route. That concern grew even more in 2018 when Panama, became the first Latin American country to sign on to the Belt and Road Initiative, China’s infrastructure-based outreach program. Within that deal, China opened the Confucius Institute in Panama, provided the country with a grant to build a railway, and sponsored media training to Panamanian journalists to cover the alliance. Even with China’s support, the canal has faced some hard times over the last few years, with a 2023 drought causing a 30 percent drop in traffic. However, when the canal plays such a critical role in Panama’s economy–contributing nearly $5 Million (23.6 percent) of the country’s annual income in 2024–one has to wonder how current events will impact its overall operations.

BlackRock’s Opportunity

In 2024, BlackRock, the world’s largest asset manager, agreed to purchase 90 percent of the Panama Ports Company from CK Hutchinson. Although the sale of the Balbao and Cristobal ports received the most attention, they are a small part of the 44 port, $22.8 Billion deal. Amazingly, this massive deal only took a month to put together–but why did it move so quickly?

Back in 2021, CK Hutchinson’s contract automatically renewed, with no scrutiny or bidding competition. Critics claimed it provided unjustified tax benefits to a foreign-owned country. That led to Panama’s Attorney General announcing an audit of the contract, calling it “unconstitutional,” and opening the door to a slew of legal battles and political fallout.

Although ships don’t have to pass through the Balbao and Cristobal ports to enter the canal, they process approximately 40 percent of canal traffic. Balbao is particularly valuable because it serves the Canal’s busiest route, Asia to the U.S.’s east coast, and connects to the Panama Canal Railway.

If the deal goes through, BlackRock’s ownership of these two ports would give significant influence back to the United States.

A Geopolitical Chess Piece

Prior to this deal, two of the four major ports were owned and operated by CK Hutchinson, one by the U.S., and one by Taiwan. If BlackRock’s purchase is approved, three of those four ports will be owned and operated by the U.S. This makes the acquisition more than a business decision– it’s a strategic geopolitical move. When the U.S. Secretary of State chose Panama as his first foreign trip, it signaled the country’s renewed importance to the U.S. economy and global supply chains and Panama agreed to pull out of China’s Belt and Road Initiative. Are these decisions based on business or diplomacy?

According to a New York Times source quoted by Investor’s Business Daily, “The deal provides an ‘off-ramp’ for tensions between the U.S. and Panama in response to strong statements made by President Trump about ownership of the canal and the cost to U.S. ships to travel through it.”

Meanwhile, the news of this deal has reportedly angered Chinese leader Xi Jinping, who is frustrated with CK Hutchison’s decision to sell the Panama Canal adjacent ports to a U.S.-led consortium without permission from Beijing. China had reportedly planned to use the Panama Port issue as a bargaining trip in negotiations with the Trump administration.

Trade as a Path to Influence

As much as BlackRock and CK Hutchinson want to put pen to paper, this deal is still pending. If it goes through, the U.S. will have a much stronger hold in the operations of one of the most significant trade routes in the world. That shift carries symbolic weight, especially as Panama tries to balance foreign investment with national sovereignty. What’s clear is that the Panama Canal remains more than just a shipping shortcut. It’s a mirror reflecting the global balance of power.

DESIGNING RESILIENT SUPPLY CHAINS

Ravi Dosanjh on Leadership, Innovation, and the Ecosystem Mindset at Caliber.global

With over 25 years of experience in supply chain leadership, Ravi Dosanjh brings a strategic and hands-on approach to his role as Chief Operating Officer at Caliber. global. As construction supply chain planning, sourcing, manufacturing and logistics becomes increasingly complex and vulnerable to disruption, Ravi is leading the charge in redefining how companies approach strategy, resilience, technology integration, and sustainable procurement. Under his leadership, Caliber.global has embraced an ecosystem-based philosophy, where collaboration, clarity, and datadriven innovation guide the company’s efforts to deliver smarter, faster, and more sustainable outcomes. In this interview, Ravi shares his insights on cultivating talent, embedding sustainability into operations, and leveraging proprietary technologies like the TRACT Control Tower and Digital Twin to future-proof supply chains.

Enhancing Supply Chain Resilience

In today’s volatile global market, supply chain resilience is paramount. How does Caliber.global proactively identify and mitigate risks to ensure uninterrupted operations for its clients?

At Caliber.global, we take an ecosystem-based approach to risk management, embedding ourselves within our clients’ supply chains to not only understand their needs but to influence outcomes across their broader network.

We operate across three core segments: Industrial (e.g., manufacturing clients), Branded Food & Beverage (e.g., restaurant and café chains), and Retail Fashion (e.g., high-density retail). In Fashion, for example, we stay tightly connected with various ecosystem partners. On the customer side, we maintain tight working relationships with construction design, supply chain, facilities and real estate working with embedded finance and procurement to orchestrate the “Perfect Project”. On the customer supplier and Caliber supplier side, we interact with many parties from FF&E manufacturers, local transportation providers, global freight forwarders, trades (structural, interior construction, MEP and speciality) and general contractors to orchestrate “On Time in Full”. Leveraging this entire ecosystem, we can directly and indirectly control, influence and prevent disruption.

Our control tower platform, TRACT, provides real-time visibility and insights, allowing our teams and clients to proactively detect risks and act early. We don’t just track activity—we help shape decisions across the ecosystem. We complement this with detailed business continuity planning and the ability to time interventions precisely. Ongoing investments in AI, automation, and predictive analytics help us stay ahead in a volatile global market. This philosophy, at the heart of a future Ecosystem Supply Chain book Dr. Derek Westfall of Oregon State University and I are working on, emphasises that true resilience comes from being a strategic, informed, and agile partner within the entire system.

With Jeroen Scholten Caliber.global CEO at Intel Ohio Site Tour

Enhancing Supply Chain Resilience

In today’s volatile global market, supply chain resilience is paramount. How does Caliber.global proactively identify and mitigate risks to ensure uninterrupted operations for its clients?

At Caliber.global, we take an ecosystem-based approach to risk management, embedding ourselves within our clients’ supply chains to not only understand their needs but to influence outcomes across their broader network.

We operate across three core segments: Industrial (e.g., manufacturing clients), Branded Food & Beverage (e.g., restaurant and café chains), and Retail Fashion (e.g., high-density retail). In Fashion, for example, we stay tightly connected with various ecosystem partners. On the customer side, we maintain tight working relationships with construction design, supply chain, facilities and real estate working with embedded finance and procurement to orchestrate the “Perfect Project”. On the customer supplier and Caliber supplier side, we interact with many parties from FF&E manufacturers, local transportation providers, global freight forwarders, trades (structural, interior construction, MEP and speciality) and general contractors to orchestrate “On Time in Full”. Leveraging this entire ecosystem, we can directly and indirectly control, influence and prevent disruption.

Our control tower platform, TRACT, provides real-time visibility and insights, allowing our teams and clients to proactively detect risks and act early. We don’t just track activity, we help shape decisions across the ecosystem.

We complement this with detailed business continuity planning and the ability to time interventions precisely. Ongoing investments in AI, automation, and predictive analytics help us stay ahead in a volatile global market.

This philosophy, at the heart of a future Ecosystem Supply Chain book Dr. Derek Westfall of Oregon State University and I are working on, emphasises that true resilience comes from being a strategic, informed, and agile partner within the entire system.

Leadership Strategies in Supply Chain Management

With over 25 years in supply chain leadership, what core principles have you found most effective in driving strategic growth and operational excellence within Caliber.global?

For me, leadership starts with clarity, being crystal clear on deliverables, aligning the right people to the right roles, and relentlessly focusing on execution. I coach my team to understand not just their tasks, but their impact and how that impact directly drives our AOP while positing them to play the most effective and strategic role possible.

Another foundational principle is listening, really listening to our clients. Our CEO, Jeroen Scholten, built this company on a simple idea: listen first, remove unnecessary red tape, and focus on driving cocreated solutions with our customers. Strategic growth comes when we don’t just deliver services but co-create solutions. We work closely with our clients to understand their vision, anticipate needs, and build strategies that support long-term success.

That mindset has led to innovations like our Digital Twin, which simulates supply chain scenarios for smarter planning, and TRACT, our control tower platform that provides real-time visibility and early risk detection. These tools are a direct result of asking the right questions and solving the right problems, together with our clients.

In a complex, fast-moving world, execution, alignment, and collaboration are what drive meaningful, resilient results.

Cultivating Talent in Supply Chain Teams: Building a skilled and adaptable workforce is crucial. How does Caliber.global attract, develop, and retain top talent to maintain a competitive edge in the logistics industry?

At Caliber.global, we focus on hiring not just for today’s roles, but for the leaders of tomorrow, those who must have an entrepreneurial spirit. I personally look beyond job roles and titles to ensure we’re identifying people with not only the tactical skills but also the right mindset. We seek individuals who bring professional, kind communication, a strong sense of ownership and teamwork, and the ability to thrive in a collaborative environment.

It’s also important for teams to feel connected to the results. We’re proud to work with world-class clients and globally recognised brands, which naturally draws talent but also keeps them deeply engaged because they can see the real impact of their work. However, retaining that talent requires intentional development.

My personal leadership approach focuses on building capability in three key areas: tactical execution to meet daily needs; supply chain acumen to stay sharp across the plan-source-make-deliver spectrum; and professional development to ensure our people are prepared for what’s next, both in business and in personal fulfilment.

We’re also proud to be certified as a Great Place to Work across North America, EMEA, and APAC, which to me is a strong proof point. Invest in your people, reward high performance (not just showing up), and give them room to grow professionally and personally.

Implementing Sustainable Practices in Supply Chains

Sustainability is increasingly a focus for businesses worldwide. What initiatives has Caliber.global undertaken to minimize environmental impact and promote sustainable practices within its supply chain operations?

As a Dutch company, sustainability is part of our DNA. In the Netherlands, environmental responsibility isn’t a trend, it’s a way of life. The majority of our employees in EMEA drive an electric car or use a bicycle to get to the office. That culture has also influenced me to walk or bike to work when the schedule and Arizona weather permits! Whether it’s biking to work, circular design, or strict waste regulations, there’s a national culture of pragmatism and stewardship that naturally shapes how we operate globally. That mindset has carried through to Caliber.global’s global operations. We are proud of our current Ecovadis Bronze Certification in EMEA, AMER and APAC and are working towards Gold Certification as we speak.

We’ve embedded sustainability into both strategy and execution. Our Digital Twin technology helps clients simulate low-impact supply chain scenarios before making real-world moves, reducing emissions, minimising waste, and optimising trade-offs between cost, speed, and environmental impact.

Our TRACT control tower platform identifies inefficiencies in real time—consolidating shipments, improving container utilisation, and selecting lower-emission modes and routes. These aren’t side projects; they’re fundamental to how we operate.

We also collaborate with clients on material and equipment reuse strategies, smarter packaging, and partnerships with sustainable carriers, particularly in Retail Fashion and Branded Food & Beverage, where expectations are rising fast.

Sustainability at Caliber isn’t just a box to check. It’s a reflection of who we are, where we come from, and how we believe global supply chains should evolve.

With Karrie Matthews Director of Logistics Procurement at Caliber.global North America

Innovations in Procurement and Sourcing

Efficient procurement and sourcing are vital for operational success. How does Caliber.global leverage technology and strategic partnerships to optimise these processes and deliver value to clients?

Our sourcing strategy centers on strategic alignment and long-term value. Internally, we concentrate the majority of our direct spends across transportation, warehousing, FF&E materials and speciality trades with a focused set of core partners. This gives us the ability to co-develop strategies with those providers and anchor around clear expectations for performance, volume, service timelines and investments. It’s a deliberate win-win approach that drives consistency, accountability, and innovation across our portfolio.

We also offer various managed services, acting as an extension of our clients’ procurement teams, managing spend with their suppliers, our suppliers, or a combination of both. This model gives clients greater control, speed, and visibility without the overhead of building internal sourcing infrastructure. Our TRACT platform provides real-time visibility into procurement activity, vendor performance, and milestone tracking, empowering clients to make smarter, faster decisions.

In addition, our WEBSHOP environment aggregates sourcing activities and contracts across both our and our clients’ ecosystems. WEBSHOP enables users to quickly find and purchase pre-vetted services and materials at pre-negotiated bulk-buy rates, streamlining execution while ensuring quality and compliance at scale.

With a global network of 1,200+ partners and a data-driven strategy, we help clients orchestrate sourcing, not just execute it, with precision and purpose.

Breton Manufacturing Italy Site Tour

Technology Integration for Supply Chain Optimisation

Caliber.global emphasises technology-driven logistics services. Can you discuss how integrating platforms like TRACT and MercuryGate TMS has enhanced supply chain visibility and efficiency for your clients?

Many companies still operate in fragmented systems, where visibility is delayed and decisions are reactive. At Caliber.global, we’ve tackled this challenge head-on by developing TRACT, our cloudbased control tower, through strategic partnerships with Oracle, Talend, and MercuryGate. TRACT connects all parties in the supply chain on a single platform, delivering real-time, actionable insights.

This integration allows us to detect risks and opportunities early, optimise the flow of information, and align stakeholders across sourcing, transport, warehousing, and installation. By giving clients centralised visibility, we help them shift from reaction to prevention, ultimately improving on-time performance and reducing inefficiencies.

The embedded integration with MercuryGate TMS further enhances transportation performance, driving route optimisation, carrier performance management, and cost control. Together, these platforms not only improve speed and accuracy but also allow us to influence outcomes, not just track them.

In today’s environment, visibility without action is just noise. Our goal is to turn data into advantage, and that’s exactly what this tech stack enables.

828 Logistics is a leading third-party logistics (3PL) company dedicated to delivering excellence in logistics solutions. With a mission to provide best-in-class service through seamless operations, we specialize in offering cost-effective and efficient logistics services tailored to meet our clients’ diverse needs.

At 828 Logistics, we understand the critical role logistics plays in business operations. That’s why we’re committed to providing round-the-clock support with a team of dedicated logistics professionals. Whether it’s managing transportation, warehousing, distribution, or supply chain optimization, we prioritize reliability, flexibility, and transparency in every aspect of our service.

Our commitment to customer service sets us apart. We believe in building strong relationships with our clients, understanding their unique requirements, and delivering personalized solutions that exceed expectations. With a customer-centric approach, we strive to be more than just a logistics provider—we aim to be a trusted partner in our clients’ success.

Join us in redefining logistics excellence. Experience the

with 828 Logistics—where every shipment

Adapting to Global Supply Chain Disruptions

The past few years have seen significant global disruptions. How has Caliber.global adapted its strategies to navigate these challenges and maintain service reliability?

I view disruption as the new normal. The pace of change, whether from tariffs, geopolitical shifts, or logistics constraints, demands not just resilience, but agility, clarity, and judgment.

We don’t just help clients understand what can be done, we also guide them on what should be done, based on timing, risk, and long-term impact. For example, in response to the Trump administration’s recent tariff adjustments, many clients considered repositioning inventory, redirecting volumes, or even shifting manufacturing. Using our Digital Twin platform, we modelled multiple scenarios and provided fast, data-backed options. But in some cases, the most strategic action was to take no immediate action, to wait and watch the policy unfold before making a costly move.

That level of insight, knowing when to move and when not to, is part of what sets us apart. We combine real-time visibility through platforms like TRACT, simulation and forecasting through Digital Twin, and strong partnerships across sourcing, transportation, and warehousing to provide tailored, executable strategies.

By preparing for uncertainty and staying close to our clients’ ecosystems, we’re able to keep operations reliable, even when the world isn’t.

Balancing Cost Efficiency with Quality in Procurement

Achieving cost efficiency without compromising quality is a common challenge in procurement. What approaches does Caliber.global employ to strike this balance effectively?

We approach procurement through the lens of total cost of ownership, understanding that the real cost of a product or service includes far more than the initial price. We look holistically at supplier performance, operational impact, service levels, and future flexibility.

As mentioned, instead of spreading spend thinly across countless vendors, we take a targeted approach to supplier development. We consolidate procurement across high-impact categories, such as transportation, warehousing, FF&E, trades, and indirect materials, into strategic supplier ecosystems where we can drive continuous improvement, scale advantages, and co-create longterm value.

We manage these relationships through structured scorecards that measure the right things, not just cost and delivery, but alignment, innovation, and responsiveness. This lets us continuously reassess and refine where we invest our time and spend.

We also work collaboratively with suppliers on value-driving initiatives, whether that’s reducing lead time variability, optimising service models, or improving packaging to reduce damage and waste. This is how we balance efficiency with quality: by making smarter, longer-term decisions that serve our clients and scale with their needs.

By giving clients centralised visibility, we help them shift from reaction to prevention, ultimately improving on-time performance and reducing inefficiencies.

With Oren Klaff CEO of OK Stone and author of “Pitch Anything

Future Trends in Supply Chain Management

Looking ahead, what emerging trends do you foresee in supply chain management, and how is Caliber. global positioning itself to stay ahead of these developments?

One of the most significant emerging trends in supply chain management is the growing importance of data and specifically, how AI will help us use that data in ways we couldn’t before. As technology evolves, AI will transform how we extract insights, predict disruptions, and optimize decisions in real time. This shift won’t just make supply chains smarter and more efficient; it will fundamentally reshape how people and technology work together in making supply chain decisions.

But it’s also worth remembering that AI learns from us, much like a child watches its parents. If we train it well, with the right values, transparency, and accountability, it will help us build resilient and ethical supply chains. If we cut corners, AI will reflect that too. The future is in how we guide it!

At Caliber.global, we’re positioning ourselves at the forefront of this trend by developing and enhancing smart supply chain solutions like our TRACT Control Tower and features such as our Digital Twin. These technologies enable us to collect and analyse data in ways that drive optimisation, from real-time shipment tracking to predictive analytics for better decision-making. By continuing to innovate and refine these tools, we ensure our clients can leverage the latest technology to stay competitive and agile in an increasingly data-driven world.

In the coming years, we expect data will continue to be the key to success in supply chain management, and we’re excited to be leading the charge in this transformation.

Measuring Success in Supply Chain Initiatives

What key performance indicators (KPIs) does Caliber.global prioritise to assess the success of its supply chain initiatives, and how do these metrics influence strategic decision-making?

In the construction supply chain space, outcomes are binary, either you deliver on time and in full, or you’re holding up a multimillion-dollar project. That’s why at Caliber.global, our relationships, KPIs are built around ecosystem, accountability, and proactive risk mitigation set us apart. We prioritise metrics that reflect end-to-end performance and influence real-world project outcomes. For example, we closely track our manufacturing suppliers supplier’s readiness and pickup reliability to ensure tier 2 materials are ready when promised, allowing downstream schedules to stay intact. We also monitor post site delivery activity, making sure the right product, in the right condition, at the right time, was installed correctly.

Another key metric is our claims ratio, which captures the percentage of deliveries impacted by damage, quality issues, or misalignment that require rework or dispute resolution whether we directly or indirectly managed the logistics. We assess the total cost to deliver by benchmarking true ‘allin’ costs from soup to nuts against project budgets. We protect material quality and availability, ensuring spec-compliant products without introducing schedule risk. And we capture indirect cost efficiencies too from reduced labor hours and admin time to smarter consolidation and less waste.

These KPIs aren’t just numbers on a dashboard, they shape how we interact, influence and manage the ecosystem, allocate resources, and simulate scenarios in our Digital Twin. All of this drives one clear result: helping our clients deliver on time, in full, and under budget, with the confidence that every decision is backed by real data and practical insight!

Caliber.global delivers tailored supply chain solutions through its Tract® platform, combining logistics expertise with real-time data visibility. Supporting global brands across retail, F&B, and construction, Caliber drives operational efficiency, cost savings, and project success. Headquartered in the Netherlands, the company operates worldwide with a strong focus on innovation and partnership.

Ravi Dosanjh COO

LEADING SUSTAINABLE SUPPLY CHAINS

Ebru Sebat’s Vision for Innovation and Resilience at Norwex

As the Global Operations and Supply Chain Director at Norwex, Ebru Sebat is at the forefront of driving sustainability in supply chain management. With a career dedicated to eco-conscious practices, Ebru has played a pivotal role in enhancing Norwex’s operations, ensuring that sustainability is not just a goal but a core value woven into every step of the supply chain. In this exclusive interview, Ebru shares her journey, the challenges she faces in building resilient and sustainable supply chains, and her vision for the future of eco-friendly products.

Career Journey

Can you share your career journey and what led you to your role as Global Operations and Supply Chain Director at Norwex? What experiences have been most influential in shaping your approach to supply chain management?

From an early age, I was determined to pursue a career in supply chain management, drawn by the opportunity to shape global operations and make a meaningful impact on businesses and customers. This passion led me to study business, with a focus on supply chain management and embark on a career that has taken me across multiple countries, cultures, and industries. After graduation, I had the privilege of kick-starting my career by leading the supply chain aspect of large-scale, multi-million-euro worldwide projects for a tech company in France, where I consistently achieved 98% customer satisfaction. This role honed my analytical thinking, attention to detail, and ability to deliver under pressure, all essential qualities for success in supply chain management.

In 2017, I joined Norwex Germany to establish supply chain activities for the European markets and implement the forecasting tool Blue Yonder, which significantly enhanced demand planning accuracy and operational efficiency. This role required not only technical expertise but also a hands-on approach to process development, strong interpersonal skills to align stakeholders, and resilience to navigate the challenges of rapid organisational growth. A year later, I transitioned to the headquarters in Malta, where I expanded my responsibilities to include the APAC region. This experience further deepened my ability to navigate cultural complexities, foster collaboration across diverse teams, and approach problem-solving with a global mindset.

Since January 2021, as Global Operations and Supply Chain Director at Norwex Malta, I have led the entire supply chain and operations function, ensuring high-quality products are delivered worldwide in a cost-efficient and timely manner. I take pride in aligning operational excellence with Norwex’s commitment to sustainability and innovation, fostering a culture of continuous improvement. My approach to supply chain management is driven by a strategic vision, adaptability, and a dedication to empowering my team. I believe in creating an environment where individuals feel valued, motivated, and inspired to contribute to shared goals. I also thrive on solving complex challenges, leveraging both data-driven decision-making and creative thinking to deliver measurable results. Working with Norwex is particularly fulfilling, as it allows me to combine my professional expertise with the company’s commitment to protecting the environment and promoting sustainability.

Sustainability in Supply Chain Operations

Sustainability in Supply Chain Operations: Norwex is known for its commitment to sustainability. How does your team ensure sustainable practices across Norwex’s global supply chain, from sourcing to production and distribution?

At Norwex, sustainability is deeply embedded in every aspect of our global supply chain. We are committed to sustainable sourcing, production, and distribution processes that minimise environmental impact.

We begin with sourcing by implementing our “No-No List,” which bans over 2,700 harmful substances and is continually updated. This goes beyond avoiding common chemicals like sulfates and parabens, relying on scientific research to ensure our product standards are uncompromising. Additionally, Norwex follows a rigorous 360° Product Safety Review, evaluating ingredients and formulas for safety, sustainability, and quality against global standards, such as the EU Cosmetics Directive and the US EPA. This process guarantees that our products are safe and sustainable, earning the “Norwex Clean” label.

In our pursuit of sustainability, we also offer USDA Certified Biobased Products, which are made from renewable biological resources, reducing reliance on non-renewable resources. Norwex is also EWG Verified, ensuring transparency and confirming that our products are free from harmful ingredients. Recycled materials are another key focus. We use microfiber yarn made from over 12 million plastic bottles, and repurpose plastic waste collected from coastal areas, preventing it from entering oceans. This reclaimed plastic is used in our packaging and product components, contributing to cleaner oceans and reducing waste.

Ethical production is equally important. Our textiles are certified free from harmful substances through the STANDARD 100 by OEKO-TEX® certification. We also partner with SEDEX to evaluate sustainability practices within our supply chain and ensure our suppliers adhere to ethical labor standards, prohibiting child and forced labor.

We also focus on responsible distribution. Our microfiber recycling program converts used products into renewable energy, and we use sustainable, recyclable packaging. By offering long-lasting, reusable alternatives to disposable items, such as paper towels and plastic straws, we help customers reduce waste and prevent singleuse items from ending up in landfills and oceans.

These efforts integrate across our supply chain to deliver on our promise to protect the planet, all while meeting the growing demand for sustainable products. Through these practices, we ensure that sustainability is not just a goal but a reality in our operations.

Challenges in Eco-Friendly Product Supply Chains

What are some unique challenges you face in maintaining a supply chain for eco-friendly products, and how does Norwex address these challenges to remain aligned with its environmental goals?

Maintaining a supply chain for eco-friendly products presents unique challenges, including limited supplier availability, cost pressures, and the need for extensive quality and performance testing.

At Norwex, creating eco-friendly products begins with sourcing sustainable materials that meet our rigorous environmental and safety standards. As mentioned earlier, our “no-no list” bans over 2,700 harmful substances, ensuring that the materials we use are safe for both consumers and the environment.

However, sourcing these sustainable materials can be difficult due to the limited availability of suppliers and the higher costs compared to conventional materials. To address these challenges, Norwex builds strong, long-term relationships with trusted suppliers to ensure a reliable supply of sustainable materials. We also conduct rigorous testing on recycled materials to ensure they meet the same high-performance standards as virgin materials, guaranteeing that our eco-friendly products deliver the quality our customers expect. For example, our microfiber products are certified under OEKO-TEX® Standard 100, ensuring they are free from harmful chemicals and safe for the environment.

Norwex also focuses on innovation by designing eco-friendly products that minimise waste. Key initiatives such as refillable products, reusable solutions, and recyclable packaging help reduce the environmental impact of our products while empowering customers to make sustainable choices. With a global presence, another challenge is the complexity of aligning with diverse regulatory requirements across the countries in which we operate. Norwex ensures compliance with local regulations while promoting environmentally responsible practices worldwide.

At Norwex, these strategies are more than just solutions, they are opportunities to innovate, inspire, and stay true to our mission of creating a cleaner, safer, and more sustainable world.

Supplier Relationships and Ethical Sourcing

How does Norwex build and maintain strong relationships with suppliers, and what measures are in place to ensure that ethical sourcing standards are upheld throughout the supply chain?

Norwex builds and maintains strong supplier relationships through collaboration, transparency, and a shared commitment to sustainability.

Building trust is fundamental to these relationships, and many of Norwex’s suppliers have been longterm partners for over 20 years.

To uphold ethical sourcing standards, Norwex conducts regular audits and follows a strict protocol for selecting new suppliers, ensuring they align with our sustainability goals. Additionally, we use tools like SEDEX (Supplier Ethical Data Exchange) to assess and select suppliers based on their sustainability and ethical practices.

Norwex is also committed to partnering with suppliers who share our values, particularly in relation to ethical labor practices. We require strict adherence to labor standards that prohibit child and forced labor, ensuring that our supply chain reflects our core principles.

Quality Assurance for Eco-Conscious Products

In producing eco-conscious products, how does Norwex ensure the highest quality standards? What role does the supply chain play in achieving consistent product excellence?

Ensuring the highest quality standards for eco-conscious products requires meticulous oversight throughout every stage of production, from raw materials to finished goods. Our 360 Product Safety Review involves rigorous testing of raw materials, guided by our “no-no” list, and collaboration with our ISO 9001-certified factory or trusted suppliers to uphold the highest quality standards.

Finished products undergo thorough testing by our quality assurance team before they are approved for distribution to global warehouses. Additionally, our commitment to surpassing international eco-certifications, such as OEKO-TEX® for textile products, reinforces our dedication to maintaining exceptional quality.

The supply chain plays a crucial role in preserving product excellence. By adhering to strict quality guidelines during sourcing, production, distribution, and storage, particularly for temperaturesensitive personal care products, our supply chain ensures that products meet our high standards from manufacturing to delivery.

Inventory and Demand Management

How does Norwex manage inventory and demand forecasting, especially given the growing consumer interest in sustainable products and fluctuations in global supply?

Norwex manages inventory and demand forecasting with the help of an advanced tool called Blue Yonder, known for its robust capabilities in inventory management and demand planning.

This tool is used at both local and global levels, enabling local sales teams to track inventory and forecast demand while providing a comprehensive overview globally. Blue Yonder analyses past sales data for each country and factors in elements like seasonality to predict future trends. By aggregating global demand, it provides valuable insights into the necessary purchase and manufacturing volumes worldwide.

This software ensures that Norwex maintains optimal inventory levels, aligning production and purchasing with forecasted demand. It helps the company meet the growing consumer interest in sustainable products, even amidst fluctuations in global supply.

Risk Management in Global Operations

What strategies does Norwex use to manage risks across its global supply chain, and how do you ensure continuity and resilience in the face of potential disruptions?

Norwex manages risks across its global supply chains through a operational approaches aimed at anticipating, addressing, and recovering from disruptions while maintaining both efficiency and cost-effectiveness.

Key strategies include comprehensive assessments to identify potential risks, such as geopolitical instability, natural disasters, port strikes, and From a planning standpoint, Norwex develops robust contingency plans, incorporating alternate sourcing and transportation strategies to ensure continuity during disruptions.

As mentioned earlier, building strong relationships with key suppliers is another essential element of our approach. These partnerships encourage transparency, mutual support, and shared risk mitigation efforts. Additionally, maintaining buffer stock of critical raw materials and products helps mitigate the impact of temporary supply disruptions, ensuring operational resilience.

Future Trends in Sustainable Supply Chains

What trends do you see shaping the future of sustainable supply chains, and how is Norwex preparing to lead in this evolving landscape?

The future of sustainable supply chains will be shaped by a fun linear supply chain model to a circular one. While a linear sup dispose” approach, a circular supply chain functions as a close materials, and resources are constantly reused, recycled, and r

As part of its commitment to sustainability, Norwex is investin durability and recyclability. For example, we’ve implemented cl to return long-lasting microfiber cloths, which can be converted

There is also growing awareness among companies and consumers a of plastic waste, driving a shift towards biodegradable and rec trend, Norwex is transitioning to fully sustainable packaging s mission and further reducing our environmental footprint.

Advice for Supply Chain Professionals

As a leader in supply chain management, what advice would you offer to those looking to make an impact in supply chain and operations, especially within the sustainable products sector?

As a leader in supply chain management, my advice for professionals looking to make an impact in supply chain and operations, especially within the sustainable products sector, is to first focus on creating an agile supply chain. In today’s fast-paced world, businesses must remain adaptable to unexpected internal or external changes while maintaining financial stability. Given the frequent disruptions, delays, and regulatory changes, the ability to pivot effectively is essential. Agile supply chain management allows businesses to stay ahead of the curve, meet customer expectations efficiently, and mitigate risks associated with supply chain disruptions.

Second, I recommend building strong relationships with key partners who share similar sustainability values. By fostering open communication, aligning on sustainability objectives, and collaborating on innovative solutions, supply chain professionals can drive operational excellence and create longterm value for all stakeholders.

Lastly, embracing new technologies is crucial to advancing supply chain management. Tools like blockchain enable full traceability of raw materials, ensuring ethical sourcing and transparency. AI plays a pivotal role in optimisation, reducing waste, and improving operational efficiency. Additionally, IoT (Internet of Things) devices provide real-time data to monitor energy usage, emissions, and resource consumption, leading to more informed decision-making and a reduced carbon footprint.

By integrating these strategies, supply chain professionals can drive measurable impact, align operations with sustainability goals, and deliver eco-friendly products to the market more effectively.

Norwex, established in 1994, is a global company dedicated to reducing harmful chemicals in homes by providing sustainable cleaning and personal care products. Their innovative microfiber technology and eco-friendly solutions promote healthier living environments. Operating in multiple countries, Norwex is committed to improving quality of life through environmentally responsible practices.

Ebru Sebat Global Operations and Supply Chain Director

DRIVING SUSTAINABLE SCALE

Sven Pulsack on Logistics Innovation at Enpal

As Director of Logistics at Enpal, Sven Pulsack plays a pivotal role in advancing Germany’s clean energy transition. With a background that bridges operational discipline and startup agility, Sven leads a logistics operation designed to scale efficiently, sustainably, and customerfirst. From optimising warehouse flows to managing site-specific last-mile delivery, his team supports Enpal’s mission to make solar energy accessible and affordable for homeowners across Germany. In this Executive Insight, Sven shares how Enpal integrates logistics into the core of its purpose-driven model, why technology and antifragility are essential to growth, and how sustainable logistics is not just a metric but a mindset.

Professional Journey

Can you share your career path and what led you to your current role as Director of Logistics at Enpal?

I started with a classic apprenticeship in logistics at TNT Express, followed by a business degree that I completed alongside my full-time job. The turning point came in Berlin, where I was surrounded by the dynamic energy of eCommerce and start-ups. That environment taught me how to combine process thinking with entrepreneurial speed.

Over time, I developed a leadership approach grounded in stakeholder empathy and continuous improvement. Logistics is both exciting and intense, it touches every part of the business and demands constant cross-functional alignment. One key lesson I’ve learned is to never see a supply chain as “done”, there’s always room to optimise.

At Enpal, I found the ideal environment to bring that mindset into a purpose-driven mission, where logistics is not just a support function but a key growth driver.

Logistics Strategy in Renewable Energy

How does Enpal’s logistics strategy support its mission to make solar energy accessible and affordable for homeowners across Germany?

Enpal’s logistics is built to scale the energy transition. Our goal is to make solar energy affordable, and every element in the supply chain from manufacturing to last-mile delivery directly impacts that goal. The final price of a solar system reflects each logistics step: overseas shipping, warehousing, transport, and installation.

To keep systems affordable, all steps must be efficient, predictable, and fairly priced. That’s why we focus on smart routing (from a warehouse perspective), strong carrier partnerships, and leveraging logistics technology. We don’t see logistics as a cost center, but as a value driver lowering costs, reducing delays, and enabling seamless solar rollouts at scale.

Customer Experience in Logistics

How do you ensure a seamless logistics experience for customers – from scheduling to final delivery and installation?

This isn’t easy, many different teams within Enpal are involved. Once a customer is confirmed, the order flows through several interfaces to our warehouse partners. From there, we guide the customer through a transparent post-purchase journey.

We use multiple scan points such as picking, staging, and carrier handover to keep customers informed in real time. Communication is key. We rely on tools like Parcellab to send timely updates and minimise delivery surprises.

Our goal is to proactively manage expectations and give each customer a sense of control and clarity throughout their solar journey. In that sense, logistics becomes part of the customer experience not just an operational layer.

Integration of Technology

What role does technology play in optimising Enpal’s logistics processes, and are there any recent innovations that have significantly improved efficiency?

Technology is essential. We’ve built a logistics setup that connects our ERP system, warehouses, and carriers to enable informed, data-driven decisions. Every process must be considered end-to-end, with full awareness of its downstream impact.

For example, we use digital tools to determine where a system should be picked and packed, which carrier is best suited, and where the goods are currently located. This all relies on accurate data and well-integrated interfaces.

We’re constantly balancing priorities, warehouse capacity, speed, cost, and customer needs. It’s a daily challenge to allocate resources effectively. Good logistics tech doesn’t just automate processes. It empowers smarter decision-making.

Why E npal re li es o n J unkbu ste r s

… to kee p t he ir sol a r mission cl ea n, f a st, a n d compli a n t

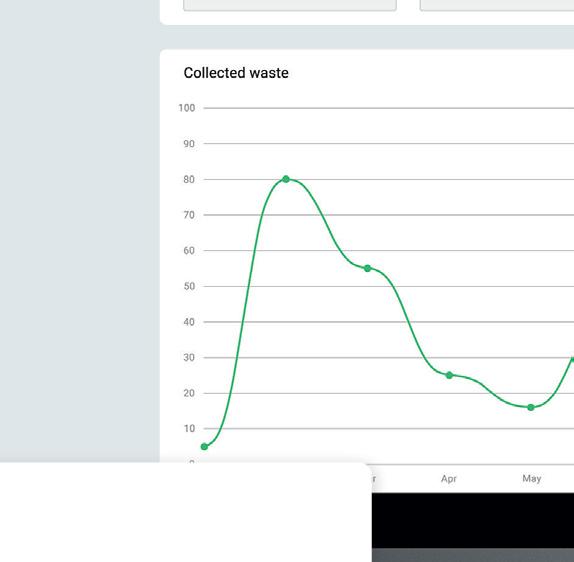

As Enpal’s solar and heat pump installations grow, we make sure that one thing never gets left behind: the waste.

We manage all waste generated during Enpal’s installations—directly on-site, all over Germany—so that installers never have to take materials with them That means fewer delays, less hassle, and more focus on what matters: clean energy. And because we fully automate the process from pickup to repor ting, Enpal can scale operations without scaling complexity

What we deliver ever y single day.

We suppor t Enpal with a holistic, end-to-end waste logistics solution that includes:

On-site collection at thousands of locations across Germany

Fully automated order handling and direct customer coordination

Smar t, eco-efficient route planning to reduce CO 2

Pre-sor ting of waste for optimal recycling per formance

Full data transparency through digital repor ting

A custom-built inter face with real-time project access

“

Junkbusters is a benchmark par tner for us at Enpal. Combining reliability, efficiency, customer-centric thinking, and a deep commitment to sustainable practices. Even in challenging situations, they consistently provide forward-looking solutions that help us deliver on our promises to our customers.

Sven Pulsack | Director Logistics | Enpal

Data at your finger tips.

We believe that data makes the difference. That’s why we provide Enpal with the market-leading digital waste repor t:

Detailed recycling and recover y rates

CO 2 footprint covering ever ything from transpor tation to waste treatment

Project over view with real-time status, photo documentation, and more

Key KPIs like average lead time and cost development

Enpal can access all data 24/7 via our custom inter face ensuring full control, compliance, and scalability

Sustainability meets operational excellence

We don’t just collect waste. We ensure it’s handled in the most eco-efficient, transparent, and customer-friendly way possible. By minimizing distances, pre-sor ting materials, and aligning with modern recycling facilities, we help reduce the CO2 footprint of ever y pickup And because we handle communication with Enpal’s customers directly ahead of time, there are no missed pickups, no unnecessar y extra costs, and zero wasted time

Built to scale. Built to last.

With strict regulations across the EU and increasing expectations for CO 2 transparency, waste logistics have become a critical par t of ever y supply chain We make it easy

In a fast-scaling environment like ours, we need par tners who can match our pace without compromising on quality. Junkbusters excels here. Not only through operational excellence, but also through their strong customer orientation and their ability to proactively navigate even complex situations with solution-driven approaches.

Sven Pulsack | Director Logistics | Enpal

Together with Enpal, we ’ re setting a new standard: real-time insight, operational speed, and measurable sustainability

Want to clean up your supply chain?

Learn more at www.junkbusters.de/360-g rad-entsorgung/

Challenges in Logistics Operations

What are some of the key challenges you face in managing logistics for a rapidly growing renewable energy company, and how do you address them?

Speed is both a blessing and a challenge. Enpal moves incredibly fast. With new ideas, new products, and new markets emerging all the time. We’ve structured the logistics team to stay agile, with the capacity to handle both short-term fixes and long-term improvements.

One key principle we follow is “antifragility”, we don’t just want to survive volatility; we want to grow from it. At the same time, we support “speedboats”, fast-moving initiatives or new business ideas that demand flexibility and urgency.

Balancing these two worlds takes empathy, clarity, and discipline. We focus on prioritisation, iteration, and honest retrospectives. No logistics setup is ever perfect, but with the right mindset, it gets better with every cycle.

VIDEO

Balancing Central Oversight and Field Execution

How does your logistics strategy balance central control with meeting the on-site needs of local installation teams?

Our team serves two core stakeholders: the end customer and the installation teams. Both need reliable information, clarity, and precise timing. We design tools and workflows that enable communication in both directions, top-down and bottom-up.

This isn’t always easy, given the different systems and priorities involved. But if logistics only thinks from the warehouse outward, we risk overlooking the needs of the teams on-site. That’s why we work closely with operations, project managers, and installers to ensure that deliveries are timely, accessible, and aligned with real-world constraints.

Central control gives us structure but true success comes from how effectively we empower those executing in the field.

Sustainability Reporting

Enpal published its first sustainability report detailing its carbon footprint across the entire value chain. How does the logistics department contribute to these sustainability metrics?

At Enpal, sustainability isn’t a parallel track it’s embedded in our day-to-day decisions. For every logistics optimisation, we evaluate not just the financial impact but also the effect on our carbon footprint.

A recent example is our new packaging solution for solar modules: by switching to a more compact pallet layout and optimised cardboard structure, we improved load factors, reduced material usage, and lowered transport emissions. It’s a win-win, both cost and CO2 go down.

We also work closely with our waste logistics partner, Junkbusters, to refine pick-up routes and improve recycling rates for leftover materials post-installation. They provide us with detailed reports that allow us to track emissions, diversion rates, and recovery volumes feeding accurate logistics data into Enpal’s broader sustainability reporting.

Ultimately, logistics has a tangible impact across Scope 3 emissions from packaging and transport to end-of-project waste. By being intentional with our setups, we ensure operational excellence and climate responsibility go hand in hand. Sustainability isn’t a side KPI, it’s the lens through which we evaluate every improvement.

Carrier Management and Transport Strategy

How do you approach carrier management and transport optimisation to ensure cost-efficiency and service quality at scale?

We work closely with two logistics partners to manage our carrier network. Our delivery model, B2C site deliveries to private homes under construction, isn’t standard. Not every carrier is willing or able to serve this niche, which is why we carefully select partners who understand the complexity and can still offer competitive rates.

We avoid one-size-fits-all setups. Instead, we strive for antifragility: always improving, never accepting the status quo. We benchmark performance, track KPIs, and align incentives. Carrier partnerships are more than just contracts, they’re collaborations built on shared goals and a common mindset. That makes all the difference.

Reverse Logistics and Site Clean-Up

How do you handle waste and reverse logistics after installation?

Once the system is installed and generating clean energy, our logistics job isn’t over. We need to remove packaging, leftover materials, and recyclable waste from the customer’s property quickly, cleanly, and with minimal disruption. That’s why we’ve built a dedicated “Reverse & Waste Logistics” stream as an integral part of our customer journey.

Our key partner here is Junkbusters. Together, we offer a nationwide on-site waste service that relieves our installation teams from any cleanup responsibility so they can focus purely on delivering quality work. Junkbusters handles customer communication directly, including appointment scheduling, reminders, and confirmations via email and SMS to ensure nothing gets missed.

Logistically, routes are planned for maximum eco-efficiency, and waste is pre-sorted to achieve the highest recycling rates possible. Beyond the physical process, we rely on a market-leading digital waste reporting system. It provides Enpal with real-time insights into every active and completed project, full transparency on recycling rates, CO2 impact, and operational KPIs.

This isn’t just a post-installation task. It is a continuation of service, environmental responsibility, and a chance to learn and optimise together. For us, holistic logistics means delivering energy and taking everything else responsibly with us when we leave.

Future Outlook

Looking ahead, what are your key priorities for advancing logistics operations at Enpal to support the company’s growth and sustainability objectives?

It may sound simple, but execution is everything. We focus on three main pillars: efficient warehouse processes, high-quality transport through a multi-carrier setup, and proactive communication with customers.

We’re exploring electric last-mile solutions, autonomous vehicles, and robotics but we remain realistic. Infrastructure, regulations, and economics still limit the speed of rollout. In the meantime, we double down on what we can control: clear responsibilities, measurable performance, and strong feedback loops.

Logistics at Enpal is constantly evolving but always with the goal of making our operations more resilient, scalable, and customer-centric.

Advice for Logistics Professionals

What advice would you give to logistics professionals aiming to integrate sustainability into their operations within the renewable energy sector?

Start small but stay consistent. Don’t wait for the perfect strategy. Just begin. Whether it’s smarter packaging, CO2 tracking, or switching to greener routes, sustainability needs to become a habit, not a side project.

Collaborate with partners, challenge assumptions, and use data to guide your impact. Most importantly, tie sustainability efforts to real business outcomes. The energy sector offers a unique platform to make logistics a force for good lean into that.

Many small, smart changes will outperform one big initiative. And don’t forget to involve your team, sustainable logistics is a team sport.

Enpal is the market leader for solar systems in Europe, the market leader for heat pumps, and the largest competitive smart meter operator in Germany. Our artificially intelligent Energy Trader is at the heart of our technology. It connects electricity storage systems, charging stations, and heat pumps with the electricity exchange.

Sven Pulsack Director of Logistics

BUILDING PARTNERSHIPS THAT LAST

Holly

Taylor

on Strategic Supplier Relationship Management

In this Executive Insight, Holly Taylor shares her practical approach to building resilient, value driven supplier partnerships. With a clear emphasis on communication, governance, and getting the basics right, she explores the key elements of strong SRM. From handling conflict and driving innovation, to embedding diversity and inclusion throughout the supply chain. Holly’s insights reflect a leadership style grounded in transparency, accountability, and purposeful collaboration.

What are the key factors you focus on to build strong relationships with suppliers?

Building and maintaining strong supplier relationships is fundamental to achieving core outcomes. A key element is establishing transparent communication channels to build trust, align on deliverables, and encourage collaboration, with the ultimate goal of forming a true partnership. Communication should be a mix of both formal and informal mechanisms. Formal governance should focus on key issues, risks, performance, and pipeline, while the benefits of informal mechanisms should never be overlooked. I’m a big believer in the simplicity of picking up the phone, saying thank you when a supplier goes above and beyond, being direct when the answer is simply no, and continually seeking feedback.

It’s also important to get the basics right: pay the supplier on time, explain clearly when something isn’t working and what can be improved, and operate on a no surprises basis.

Being clear on business objectives and how the supplier partnership contributes to achieving those outcomes is also key to building a sustainable relationship.

Finally, it is imperative to have an appropriately resourced team that is skilled, engaged, delivery focused, and understands the importance of supplier relationships.

How do you handle conflicts or issues that arise in supplier relationships?

The reality is that conflicts or issues are often inevitable in supplier relationships, particularly when these relationships are underpinned by contractual mechanisms. When managing a dispute, it’s important to understand each other’s perspectives. A supplier might be driven by dollars, while the customer may require a product to be delivered within a specific timeframe or to a certain quality. Listening, communicating, and identifying where positions differ, and then working to find common ground, is key. This may involve thinking outside the box in terms of how the partnership is structured and re setting the relationship if needed.

Jointly establishing timeframes and clear escalation paths to resolve the issue is important, as it ensures small concerns don’t escalate into bigger, unmanageable problems.

However, by far the best way to manage disputes is to prevent them in the first place. This can be achieved by conducting proper due diligence as part of the sourcing strategy, setting clear expectations, ensuring contracts are reasonable and include dispute resolution terms, and defining realistic, achievable performance targets that are consistently monitored.

How do you measure the performance and success of your supplier partnerships?

Essentially, the performance and success of a supplier partnership should be measured by the supplier’s contribution to delivering the organisation’s strategic objectives. This ties back to the start of the relationship, transparently communicating those strategic objectives and ensuring that deliverables are underpinned by agreed performance metrics. For example, I’ve led supplier engagements where we structured contracts to incentivise suppliers to help us achieve our goal of being first to market or capturing greater market share. This positioned the supplier as a key partner in delivering our objectives and significantly strengthened our ability to succeed together.

It’s also imperative to have the right governance, tools, and technology in place to regularly measure and monitor performance, identify risks, gather feedback, and explore opportunities for improved collaboration. Undertaking supplier segmentation is also beneficial in identifying and managing vendor risks and opportunities, and in aligning performance monitoring to the appropriate level.

Finally, it’s important to remember that reduced cost shouldn’t always be the primary success metric. I’ve worked on countless engagements where spend was relatively low, but the associated risk was high, these are suppliers who, if mismanaged, can halt your operations. Supplier relationships need to account for and actively manage those types of risks.

Being clear on business objectives and how the supplier partnership contributes to achieving those outcomes is also key to building a sustainable relationship.

How do you encourage suppliers to contribute to innovation and value creation?

The ability to create value, innovate, and evolve is core to any organisation. In a true supplier partnership model, value creation is often the very reason the supplier was engaged, so it’s fundamental that they are part of this process. Communication channels with the right representatives should be dedicated to forward thinking, strategic activities and treated as a highly beneficial and necessary part of the partnership. The supplier is often the expert, so as customers, we need to treat them as such. They frequently bring innovative concepts, insights, and ideas from other markets or geographies, which can be incredibly valuable.

Commercial arrangements should foster win win outcomes that support innovation and value creation. For example, a supplier may gain positive media exposure or financial benefits when helping a customer deliver a higher quality product or service.

That said, I cannot stress enough the importance of getting the basics right before embarking on value creation initiatives. Too often, suppliers have approached me with innovative ideas to add value, yet they are still struggling to meet the basic contracted requirements. As with any relationship, you must master walking before you attempt to sprint.

Holly Taylor

How do you approach supplier diversity and inclusion in your SRM strategy?

Supplier diversity and inclusion is key to any successful SRM strategy. Leveraging more diverse suppliers can unlock innovative opportunities, create resilience, and improve productivity. More importantly, there is an ethical and broader economic benefit, engaging diverse suppliers contributes to wealth creation, improved health, education, and greater equality.

There are practical mechanisms that can be implemented, such as including diversity as part of procurement evaluation criteria, setting clear targets, and ensuring that suppliers also embrace diversity throughout the broader supply chain.

There is also value in undertaking targeted programs to encourage greater diversity. I’ve led supplier initiatives focused on regional organisations and Aboriginal and Indigenous vendors. These programs helped us better understand our customers, introduced niche services in previously untapped markets, and more broadly contributed to job creation and education opportunities.

Progress should be measured, for example, by tracking the number of diverse suppliers engaged, total spend, and ongoing improvements. Engaging with not for profits or local organisations with relevant expertise can be incredibly beneficial, as can ensuring you have dedicated team members with the necessary knowledge to lead and drive this strategy effectively.

BETTER, BETTER, NEVER BEST

Tim Leight on Building a Future Ready Supply Chain at Calix

As Vice President of Supply Chain at Calix, Tim Leight is driving a bold transformation rooted in visibility, agility and digital innovation. From orchestrating AI-led planning and building a real time digital twin, to strengthening supplier partnerships and deploying sustainability commitments, his leadership reflects Calix’s culture of continuous improvement. In this interview, Tim shares how the company is redefining supply chain resilience, embracing talent development and scaling with purpose to support Calix’s long term growth strategy.

Transformational Supply Chain Strategy

What major transformations have you led or implemented within Calix’s supply chain, and what outcomes have they delivered?

Within a few months of joining Calix, I recognised the strength of both our Demand and Supply Planning teams. They were highly capable but operating under different reporting lines, which created some natural barriers to alignment. With support from leadership, we brought those functions together under one organisation. That shift allowed us to further enhance our Sales and Operations Planning (S&OP) process and improve demand planning accuracy by nearly 30 percent, with continued gains quarter over quarter.

We also took the opportunity to standardise how we manage product transitions. Whether a customer is scaling up or moving to next generation technology, they need the experience to be smooth and predictable. So, we developed a cross functional playbook spanning NPI, transitions and wind downs by partnering across product, sales, finance and marketing.

These changes are rooted in our Calix motto: “Better, better, never best.” It’s a mindset that drives constant improvement, even when things are already working. That’s the culture I try to build in our supply chain, where we celebrate progress but never stop pushing.

Leveraging AI in Supply Chain

Artificial Intelligence is rapidly transforming supply chain operations. How is Calix leveraging AI or advanced analytics to optimise forecasting, inventory and fulfilment?

AI is fundamentally reshaping how supply chains operate, and we’re leaning in early. As Calix prepares for significant growth in the years ahead, we know our supply chain must scale intelligently. That’s why we’re building our Next Generation Supply Chain, with AI and data intelligence at its foundation.

One of the biggest opportunities is in planning, where we are already applying AI to improve forecast accuracy and anticipate shifts in customer behaviour. In manufacturing, we’re deploying AI driven solutions to boost first pass yield, detecting quality issues earlier, reducing rework and increasing overall reliability.

What excites me most is how AI enhances decision making without replacing the human element. In fulfilment and logistics, for example, we’re testing tools that recommend more efficient warehouse routing and inventory strategies, but it’s our team who interprets and applies those insights with context.

It all ties back to our culture. AI isn’t a one time initiative, it’s a mindset. We are committed to continuous improvement as we learn, test and evolve at scale.

End to End Visibility

In an increasingly complex global environment, how are you enhancing end to end supply chain visibility and agility at Calix?

I believe the answer is twofold. It starts with robust tools and processes, but it’s enabled by trusted relationships grounded in transparency.

At Calix, we’ve built a strong foundation for real time visibility with our key suppliers. Through our Oracle portal, they can access rolling forecasts and submit supply commitments directly, creating a continuous feedback loop. We also share 24-month outlooks so they can proactively plan, not just react. This transparency and trust enable us to address demand upsides within lead times or respond quickly when truly disruptive events occur, such as natural disasters.

That transparency fuels a shared mission and enables agile response when unexpected challenges hit. Take Hurricane Helene in late 2024: French Broad EMC leveraged Calix SmartTown® to deploy 1,600 free hotspots within days, expanding to 3,200 as demand grew. That connectivity wasn’t just a number, it meant residents could access emergency updates, stay connected with loved ones and utility teams could restore services efficiently.

Ultimately, end to end visibility isn’t just about seeing, it’s about collaborating. That’s how we stay prepared for both forecasted demand and the unexpected.

Partnerships and Collaborations

Calix’s ecosystem relies on a strong network of partners. How do you cultivate and maintain strategic partnerships across the supply chain to drive innovation and resilience?

Strategic partnerships are central to how we operate at Calix. We don’t just supply systems and software, we build collaborative frameworks that align with our partners’ long term goals, whether that’s operational efficiency, inventory planning or shared ESG outcomes.

Our partnership with CityFibre is a solid example. CityFibre have also undergone a significant transformation of their own supply chain, spearheaded by Phil Ash, Procurement and Cost Transformation Director. Phil has been instrumental in bringing maturity and structure to CityFibre’s processes, guiding them as they transition from being a startupbuild company to a highly efficient operational company. This transformation is a testament to the hard work and dedication of Phil and his team, and it positions CityFibre for even greater success in the future.

Our work with CityFibre on maturing the supply chain function has been a true partnership, focusing on long term planning, forecasting and efficiencies. We’ve also developed strategies together to withstand unforeseen events and disruptions, while jointly assessing and reducing supply chain risks. As Phil shared, “What impressed me most was the transparency Calix brings to our collaboration and the tools and processes that they put in place to secure our demand. They have highly integrated, efficient supply chain processes that give us confidence that we’re building a resilient and forward–looking supply chain together.”

At Calix, we’ve built a strong foundation for real time visibility with our key suppliers

This collaborative foundation is strengthened through independent recognition and rigorous sustainability commitments. In 2024, Calix ranked 16th out of 140,000 companies on Resilinc’s Supply Chain Resilience Index, surpassing major industry players and validating our proactive partnership model. Calix also holds an AA ESG rating from MSCI, placing us within the top 18 percent of evaluated companies. That upgrade from A signals progress in human capital, social responsibility and sustainable innovation.