With a career shaped by hands-on experience in engineering, trading, and international supply chains, Javad Mohammadi brings a unique, cross functional perspective to procurement leadership. As Group Chief Procurement Officer at Mammut Group, a diversified conglomerate spanning trailer and truck manufacturing, construction, sandwich panels, and automotive, he oversees procurement strategy across one of the region’s most complex industrial ecosystems.

In this exclusive interview, Javad shares his journey from managing his first import as a teenager to leading digital transformation and sustainability initiatives at scale. He offers insights into the Group’s approach to supplier collaboration, AI integration, risk management, and the evolving role of procurement in driving both innovation and operational excellence. His forward looking perspective highlights what it takes to lead with impact in today’s rapidly changing supply chain landscape.

Can you share your career journey and what led you to your current role as Group Chief Procurement Officer at Mammut Group? What experiences have most influenced your approach to procurement and leadership?

My career began with a background in mechanical engineering, but it was my early involvement in my father’s trading business during high school that sparked a deep interest in procurement and supply chain management. I even managed my first importation as a teenager, facing real world challenges that laid the foundation for my future career.

Professionally, my transition into procurement evolved organically. In my third year of work experience, I took on responsibilities in localisation, importation, and overseas sales at a medium sized company. These multifaceted roles broadened my understanding of procurement’s strategic impact, extending beyond traditional functional boundaries.

A pivotal milestone in my career came when I was promoted to lead importation operations for 16 automotive OEM companies. This role significantly deepened my expertise in managing complex, multi company supply chains and sharpened my strategic outlook.

I was drawn to my current role as Group Chief Procurement Officer by the opportunity to operate at a larger scale and drive transformation within a holding company structure. The challenge, coupled with the company’s values, aligned perfectly with my professional ambitions.

Over the years, my approach to procurement leadership has evolved through three key phases: beginning with cost optimisation, progressing to supplier development, and most recently, spearheading digital transformation initiatives. This evolution reflects my belief that procurement is a strategic enabler of business value, not merely a cost centre.

I describe my leadership style as data driven and hands on. I prioritise total value efficiency, comprehensive risk management, and the cultivation of strong supplier relationships. Empowering my teams by developing both their technical capabilities and soft skills is central to how I lead.

Procurement has transformed considerably since I started, from transactional importation to strategic, localised sourcing empowered by digital tools. Looking ahead, I firmly believe the future of procurement leadership will be defined by data driven decision making, strategic digitalisation, and organisational resilience. I’m committed to embedding these principles into our team and processes to ensure sustained success.

Procurement is critical in ensuring the quality and reliability of manufacturing. How does your procurement team support Mammut Group’s commitment to high-quality engineered products?

As a diverse group spanning automotive, trailer and truck manufacturing, construction, and solar energy, our procurement function plays a crucial role in maintaining the high standards of our engineered products. Our Supplier Relationship Management (SRM) team leads rigorous supplier evaluation processes, assessing technical capabilities, production capacity, and alignment with our strict quality requirements.

From the outset, we ensure early collaboration between procurement, engineering, and quality assurance teams. This cross functional alignment guarantees that suppliers meet both technical and operational standards before production begins.

We apply a flexible sourcing strategy that balances cost, quality, and supply risk. Our approach is tailored to the specific sourcing context, enabling us to mitigate potential disruptions through measures such as dual sourcing and robust contract management. Supplier performance is continuously monitored through our ERP systems, allowing for real time tracking and data driven improvements.

Our SRM practices also prioritise long term supplier development. By continuously assessing and supporting our partners, we ensure alignment with Mammut Group’s commitment to high quality products and operational excellence.

Sustainability is becoming increasingly essential across industries. How is Mammut Group integrating sustainable practices in its procurement and supply chain operations?

Our company is fully committed to sustainability within procurement and the broader supply chain, with a strong focus on waste reduction, emissions control, and responsible sourcing. Key initiatives include the development of a 10 hectare waste separation site, the implementation of advanced waste treatment processes, and the adoption of technologies aimed at restructuring high emission production lines. In parallel, we are investing in renewable energy, with plans to supply over 15 MW of solar power to our operations through panel installations across our industrial facilities.

Sustainability is a critical factor in our supplier evaluation process. While we prioritise suppliers who align with our environmental goals, we also recognise the financial challenges many of them face, especially during periods of economic uncertainty. To address this, we adopt a pragmatic and collaborative approach, working closely with suppliers to encourage sustainable improvements without compromising cost effectiveness.

We maintain close collaboration with our HSE and R&D teams to ensure full compliance with ESG standards, embedding sustainability across every phase of product development, sourcing, and supply chain management. While our ability to track sustainability metrics within our ERP systems is still evolving, we are actively working to integrate these capabilities for improved transparency and accountability.

Looking ahead, we have made it a requirement that all new production plants be designed as green factories. This ensures that sustainability remains a foundational element of our growth strategy and operational practices.

What strategies do you use to build strong, transparent relationships with suppliers, and how do you ensure suppliers consistently meet the high standards required for quality and safety?

At our Group company, we have developed a sophisticated, metrics driven approach to building robust and transparent relationships with suppliers, while upholding the highest standards of quality and safety across our diverse portfolio of industries.

Our supplier relationship management (SRM) strategy begins with a comprehensive evaluation process. Subsidiary procurement teams identify potential partners, after which my team at the Group level conducts rigorous assessments using key performance indicators (KPIs). These KPIs cover a wide range of criteria, including production capabilities, financial stability, reliability, industry references, logistical efficiency, technical expertise, and flexibility in trade terms. This thorough vetting ensures we select suppliers who align with our values and commitment to operational excellence.

For our strategic suppliers, those essential to our long term success, we foster trust and transparency through structured engagement. This includes regular feedback sessions and scheduled conference calls, which help maintain open communication, align expectations, and drive continuous improvement.

To uphold our stringent quality and safety standards, our dedicated quality assurance and control teams require industry recognised certifications and conduct supplier audits based on established benchmarks. These audits, combined with continuous performance monitoring through SRM metrics, ensure that our suppliers consistently meet expectations, even within the complex landscape of a multi industry operation.

By prioritising strategic partnerships and leveraging data driven insights, we not only maintain exceptional quality and safety standards but also cultivate long term, collaborative relationships that drive innovation and contribute to our sustained operational success.

How is Mammut Group leveraging digital technology to enhance supply chain operations, and what recent advancements have had the most significant impact on efficiency and transparency?

Mammut Group, which manages subsidiaries across the trailer, sandwich panel, construction, and automotive industries, has embraced digital transformation as a core strategy to optimise its global supply chain. Among the most impactful advancements is the integration of artificial intelligence (AI), which has become a key driver of efficiency and transparency across our operations.

Operating in diverse sectors, we leverage a suite of digital technologies including SAP’s ERP system (with modules such as Material Management, Controlling, and Financial Accounting), IoT for vehicle monitoring, automation in manufacturing, and advanced data analytics. However, our recently launched AI driven performance project has become a cornerstone of our transformation strategy.

AI is being used to analyse performance data across multiple functions, enabling our teams to develop data driven strategies that improve decision making. Within the procurement function, AI powered analytics, supported by a dedicated data analytics specialist within our newly consolidated digital and IT subsidiary, generate dynamic management dashboards. These dashboards give stakeholders actionable insights and improve visibility into supplier performance and selection processes via our Supplier Relationship Management (SRM) system. This enhanced transparency allows us to optimise supplier relationships and build a more resilient, responsive supply chain.

Beyond procurement, we have deployed IoT solutions through a dedicated subsidiary, enabling real time data collection from trucks and trailers. This data provides critical operational insights to both drivers and logistics partners, improving fleet management and end to end visibility. On the manufacturing side, automation such as our automated paint line for trailers and trucks has delivered substantial efficiency gains, reducing painting process costs per vehicle by 50 percent.

SAP underpins these efforts by streamlining inventory, financial, and operational workflows across our global operations. However, it is AI’s unique ability to synthesise and analyse data from across these systems that is proving truly transformative, enabling predictive insights and strategic planning at scale.

How does your team approach inventory management and demand forecasting to ensure availability while optimising costs, especially given the fluctuating demands in your industry?

At our Group company, managing subsidiaries in the trailer, sandwich panel, construction, and automotive industries, we employ a strategic and data driven approach to inventory management and demand forecasting. Our goal is to ensure consistent product availability while optimising costs in response to fluctuating market conditions. Planning teams across our subsidiaries utilise SAP’s Material Management (MM) and Advanced Planning and Optimisation (APO) modules to generate accurate forecasts and manage inventory. The outputs from these systems feed directly into the Group procurement function, ensuring alignment with production schedules and operational requirements.

Our demand forecasting process relies heavily on market trend analysis, enhanced by predictive data for strategic commodities through SAP APO. This capability enables us to anticipate market shifts and adopt flexible inventory strategies. In favourable market conditions, we proactively increase inventory levels to secure supply and take advantage of procurement opportunities. Conversely, during market downturns, we strategically reduce inventory levels to optimise cash flow and maintain cost efficiency.

These decisions are supported by regular cross functional supply chain meetings, where procurement and planning teams review key performance indicators (KPIs), such as On Time Delivery (OTD). This collaborative process allows us to identify bottlenecks and ensure production line demands are consistently met.

The procurement function leverages SAP outputs to coordinate effectively with suppliers. However, we continue to face challenges such as local supplier delays that affect import timelines, and the need to renegotiate large volume orders with strategic suppliers in response to shifting market demand. We address these issues through close monitoring of OTD metrics and active supplier collaboration, adjusting order volumes where necessary to strike a balance between availability and cost optimisation.

By combining market intelligence with predictive analytics for key commodities, we continue to refine our inventory and forecasting practices, ensuring agility and efficiency across our supply chain, even in highly volatile environments.

With the complexities of global supply chains, how does Mammut Group manage risks to ensure continuity and resilience in its supply chain operations?

At Mammut Group, we take a proactive and multifaceted approach to managing risks across our global supply chain. Our aim is to ensure business continuity and resilience, even amid complexities such as market volatility, supplier delays, and geopolitical disruptions. By prioritising key risks and leveraging strategic processes, we maintain operational stability across our diverse industries.

Market fluctuations and geopolitical instability are among the primary risks that influence our procurement decisions. To stay ahead, we closely monitor global market trends and geopolitical developments. This includes ongoing collaboration with our marketing and sales teams to track shifts in demand, allowing us to adjust procurement strategies in real time and remain responsive to evolving dynamics.

To mitigate these risks, we implement continuous scenario planning, analysing a range of potential disruptions using observed data and market inputs. Our corporate governance function applies structured risk assessment frameworks to evaluate critical factors, including geopolitical instability and supplier reliability. This systematic approach supports risk prioritisation and informed decision making.

Supplier diversification is a core strategy for managing delays, particularly those associated with local sources. By reducing dependency on single suppliers, we enhance resilience across the supply chain. However, in the case of strategic commodities where alternative sources may be limited, we focus on maintaining strong relationships and leveraging negotiation to ensure supply continuity. This has proven effective in recent instances where we have had to adjust large orders with key suppliers in response to market downturns.

By integrating continuous market monitoring, scenario planning, structured risk assessment, and selective supplier diversification, Mammut Group ensures our procurement function is resilient, adaptable, and equipped to manage disruption. This strategic approach enables us to maintain efficiency and continuity across our global supply chain, even in the face of volatile and unpredictable conditions.

What are some of the unique challenges you face in procurement for the engineered products industry, and how does Mammut Group address these to maintain a competitive edge?

In procurement for engineered products such as truck trailers, cars, sandwich panels, and steel structures, Mammut Group faces a range of unique challenges that require a strategic and flexible approach. One of the most pressing issues is long lead times, particularly due to constraints within the local supply chain. While international suppliers also experience market wide disruptions, we have found their flexibility has diminished over time, necessitating a more proactive approach to risk management.

Our supplier strategy balances reliability with diversification. For strategic, high impact components, we rely on credible and trusted suppliers with proven capabilities. For mid level or less critical items, we maintain a broader supplier base to mitigate risk and encourage competitive pricing. To manage procurement effectively, we leverage SAP ERP systems that support demand forecasting, order tracking, and supplier relationship management. Quality assurance remains a top priority. We employ a combination of rigorous in house audits, inspections, and third party testing to ensure all sourced materials meet our strict quality standards.

Risk management within procurement is structured across multiple layers. For strategic items, we maintain safety stock and activate credit lines to ensure supply continuity. For mid tier products, we split orders across several suppliers, reducing reliance on any single source and increasing supply chain resilience.

Sustainability is playing an increasingly important role in our procurement decisions. For example, we have facilitated the installation of solar panels at our factories to support the use of renewable energy. We also prioritise working with suppliers who demonstrate strong ESG commitments, aligning with Mammut Group’s broader green factory initiatives.

One recent success was the consolidation of our freight charge suppliers, which significantly improved the efficiency of our import supply chain. In addition, by consolidating insurance policy vendors across the Group, we enhanced our insurance risk coverage, choosing to prioritise strategic risk management over short term cost savings.

What truly sets Mammut Group apart is our deep engineering expertise, built over more than 30 years, combined with strong collaboration with world class partners in the automotive and trailer manufacturing industries. This foundation enables us to maintain a competitive edge through uncompromising quality in both our products and procurement practices.

Sustainability is playing an increasingly important role in our procurement decisions

What trends do you see shaping the future of procurement and supply chain management, and how is Mammut Group preparing to adapt to these changes?

At Mammut Group, we see several key trends reshaping the future of procurement and supply chain management. Among the most impactful are deeper supplier collaboration, digitalisation, and the growing integration of AI and advanced analytics.

In our automotive sector, supplier collaboration has become a top priority. We actively engage our partners to support production efficiency, drive innovation, and uphold shared quality standards. In the industrial processes sector, we have already launched a comprehensive digital transformation project that lays the groundwork for the integration of AI and machine learning. This will enable the creation of a more intelligent procurement system, where advanced analytics inform decision making across cost, quality, and risk dimensions.

We are also focused on strengthening supply chain resilience. Our strategy begins with close cooperation with suppliers and extends to market trend analysis and diversification, particularly for mid tier components. This approach allows us to adapt more effectively to disruptions while maintaining agility in our sourcing practices.

Sustainability is becoming increasingly embedded within our supply chain operations. One notable development is the integration of ESG performance into our Supplier Relationship Management (SRM) platform, where it will soon be tracked as a formal KPI during supplier evaluations. This aligns our external partners with Mammut Group’s internal green factory objectives and long term environmental goals.

Looking ahead, we view co development with suppliers as a critical path forward. Rather than maintaining purely transactional relationships, we are focused on building long term partnerships centred on joint innovation and continuous improvement. This collaborative approach is at the heart of Mammut Group’s future ready procurement strategy.

As a leader in procurement and supply chain, what advice would you give to those looking to advance their careers in this field, especially within manufacturing?

One key piece of advice I always share is never underestimate the value of soft skills. In today’s procurement and supply chain environment, particularly in manufacturing, technical knowledge is important, but it is resilience, analytical thinking, and interpersonal skills that truly set leaders apart. The ability to communicate effectively, build trust, and influence cross functional teams is absolutely critical.

Our strategy begins with close cooperation with suppliers and extends to market trend analysis and diversification, particularly for mid-tier components

Personally, I have found that inspiring teams to perform at their highest potential and gaining experience in cross functional roles has been essential to my development as a leader. Understanding the broader business landscape and aligning procurement strategies with overarching company goals can make a significant difference in delivering value and driving impact.

For young professionals aiming to move into leadership roles, I strongly recommend building and maintaining professional networks, both within and beyond your organisation. Take the time to understand your business from end to end, and focus on creating practical solutions to real world challenges. It is that combination of relationships, business insight, and problem solving ability that shapes the next generation of procurement and supply chain leaders.

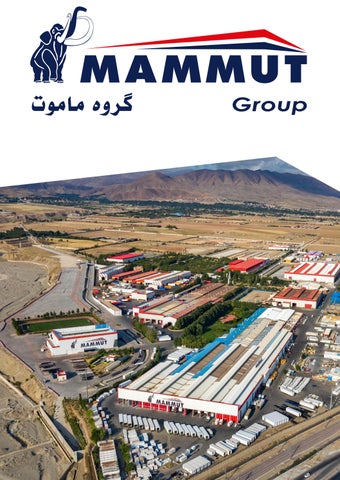

Mammut Industrial Group, founded in 1370 (1991 CE), is a privately held Iranian conglomerate active across automotive, construction, transport, and infrastructure sectors. Known for its innovative product development and recruitment of top talent, it operates globally through subsidiaries specializing in trailers, vehicles, and engineering solutions