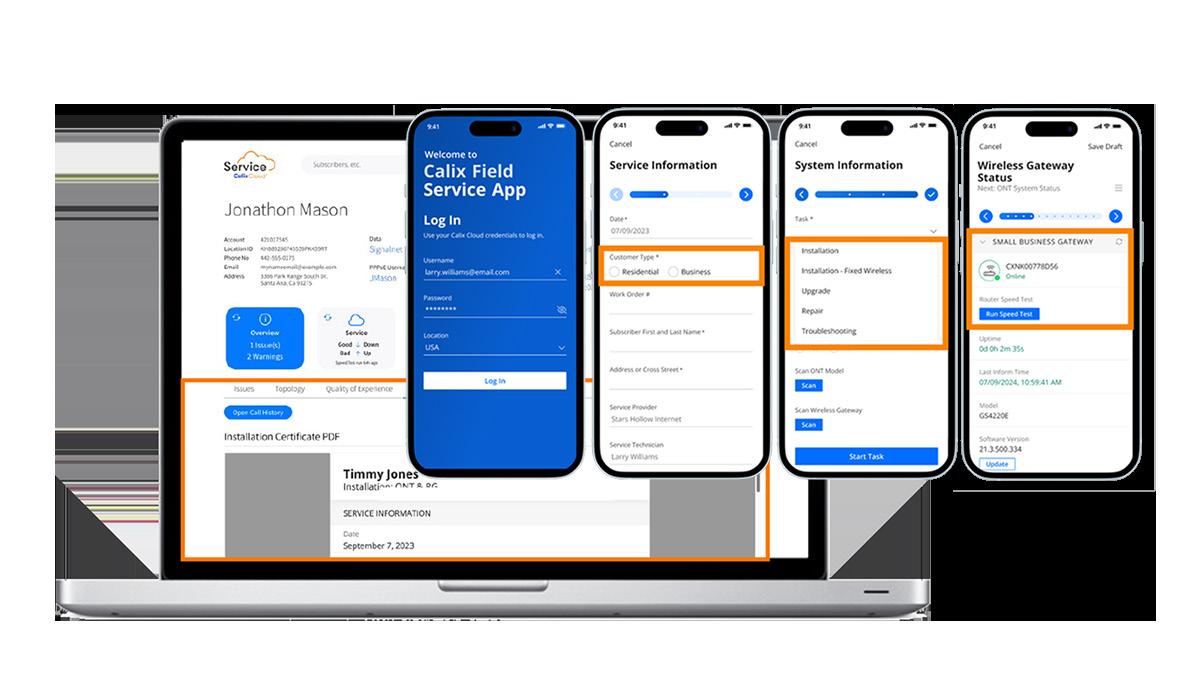

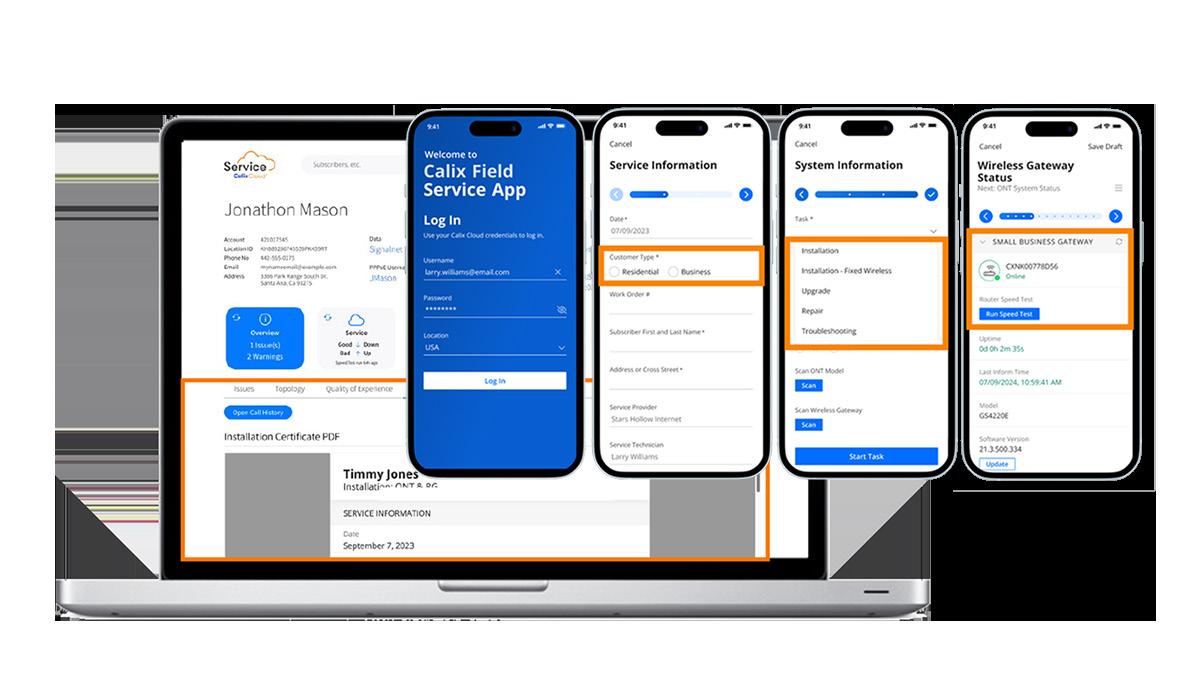

One powerful platform with unlimited possibilities

As Vice President of Supply Chain at Calix, Tim Leight is driving a bold transformation rooted in visibility, agility and digital innovation. From orchestrating AI-led planning and building a real time digital twin, to strengthening supplier partnerships and deploying sustainability commitments, his leadership reflects Calix’s culture of continuous improvement. In this interview, Tim shares how the company is redefining supply chain resilience, embracing talent development and scaling with purpose to support Calix’s long term growth strategy.

What major transformations have you led or implemented within Calix’s supply chain, and what outcomes have they delivered?

Within a few months of joining Calix, I recognised the strength of both our Demand and Supply Planning teams. They were highly capable but operating under different reporting lines, which created some natural barriers to alignment. With support from leadership, we brought those functions together under one organisation. That shift allowed us to further enhance our Sales and Operations Planning (S&OP) process and improve demand planning accuracy by nearly 30 percent, with continued gains quarter over quarter.

We also took the opportunity to standardise how we manage product transitions. Whether a customer is scaling up or moving to next generation technology, they need the experience to be smooth and predictable. So, we developed a cross functional playbook spanning NPI, transitions and wind downs by partnering across product, sales, finance and marketing.

These changes are rooted in our Calix motto: “Better, better, never best.” It’s a mindset that drives constant improvement, even when things are already working. That’s the culture I try to build in our supply chain, where we celebrate progress but never stop pushing.

Artificial Intelligence is rapidly transforming supply chain operations. How is Calix leveraging AI or advanced analytics to optimise forecasting, inventory and fulfilment?

AI is fundamentally reshaping how supply chains operate, and we’re leaning in early. As Calix prepares for significant growth in the years ahead, we know our supply chain must scale intelligently. That’s why we’re building our Next Generation Supply Chain, with AI and data intelligence at its foundation.

One of the biggest opportunities is in planning, where we are already applying AI to improve forecast accuracy and anticipate shifts in customer behaviour. In manufacturing, we’re deploying AI driven solutions to boost first pass yield, detecting quality issues earlier, reducing rework and increasing overall reliability.

What excites me most is how AI enhances decision making without replacing the human element. In fulfilment and logistics, for example, we’re testing tools that recommend more efficient warehouse routing and inventory strategies, but it’s our team who interprets and applies those insights with context.

It all ties back to our culture. AI isn’t a one time initiative, it’s a mindset. We are committed to continuous improvement as we learn, test and evolve at scale.

In an increasingly complex global environment, how are you enhancing end to end supply chain visibility and agility at Calix?

I believe the answer is twofold. It starts with robust tools and processes, but it’s enabled by trusted relationships grounded in transparency.

At Calix, we’ve built a strong foundation for real time visibility with our key suppliers. Through our Oracle portal, they can access rolling forecasts and submit supply commitments directly, creating a continuous feedback loop. We also share 24-month outlooks so they can proactively plan, not just react. This transparency and trust enable us to address demand upsides within lead times or respond quickly when truly disruptive events occur, such as natural disasters.

That transparency fuels a shared mission and enables agile response when unexpected challenges hit. Take Hurricane Helene in late 2024: French Broad EMC leveraged Calix SmartTown® to deploy 1,600 free hotspots within days, expanding to 3,200 as demand grew. That connectivity wasn’t just a number, it meant residents could access emergency updates, stay connected with loved ones and utility teams could restore services efficiently.

Ultimately, end to end visibility isn’t just about seeing, it’s about collaborating. That’s how we stay prepared for both forecasted demand and the unexpected.

Calix’s ecosystem relies on a strong network of partners. How do you cultivate and maintain strategic partnerships across the supply chain to drive innovation and resilience?

Strategic partnerships are central to how we operate at Calix. We don’t just supply systems and software, we build collaborative frameworks that align with our partners’ long term goals, whether that’s operational efficiency, inventory planning or shared ESG outcomes.

Our partnership with CityFibre is a solid example. CityFibre have also undergone a significant transformation of their own supply chain, spearheaded by Phil Ash, Procurement and Cost Transformation Director. Phil has been instrumental in bringing maturity and structure to CityFibre’s processes, guiding them as they transition from being a startupbuild company to a highly efficient operational company. This transformation is a testament to the hard work and dedication of Phil and his team, and it positions CityFibre for even greater success in the future.

Our work with CityFibre on maturing the supply chain function has been a true partnership, focusing on long term planning, forecasting and efficiencies. We’ve also developed strategies together to withstand unforeseen events and disruptions, while jointly assessing and reducing supply chain risks. As Phil shared, “What impressed me most was the transparency Calix brings to our collaboration and the tools and processes that they put in place to secure our demand. They have highly integrated, efficient supply chain processes that give us confidence that we’re building a resilient and forward–looking supply chain together.”

This collaborative foundation is strengthened through independent recognition and rigorous sustainability commitments. In 2024, Calix ranked 16th out of 140,000 companies on Resilinc’s Supply Chain Resilience Index, surpassing major industry players and validating our proactive partnership model. Calix also holds an AA ESG rating from MSCI, placing us within the top 18 percent of evaluated companies. That upgrade from A signals progress in human capital, social responsibility and sustainable innovation.

Our broadband platform outperforms the EU’s Broadband Communication Equipment Codes of Conduct, enabling broadband providers to reduce network power consumption by up to 50 percent. And through partnerships with EcoVadis and Resilinc, we assess and improve supplier performance, covering carbon targets, Scope 3 emissions, ethical sourcing and continuity planning.

By merging deep customer collaboration, like with CityFibre, with industry leading environmental and resilience credentials, we build supply chains that are efficient, responsible and future ready.

As sustainability becomes a central business imperative, what steps is Calix taking to align its supply chain practices with environmental goals?

Sustainability at Calix is a company–wide commitment, reflected in how we design our platform, manage our supply chain and operate as a global organisation. It is embedded in the way we build long term impact, from product innovation to procurement to day–to–day operations.

Our broadband platform is engineered for environmental performance. Service providers deploying Calix can reduce network energy consumption by up to 73 percent and cut in home power use by over 50 percent through a single, consolidated subscriber system.

We extend this impact across our supply chain. We benchmark supplier performance with EcoVadis, integrate ESG metrics into sourcing and support improvement through the EcoVadis Academy. We’ve expanded our use of recycled materials in packaging and hardware and introduced real time power monitoring to increase transparency and accountability.

To ensure sustainability remains central to our growth, we appointed Martha Galley as Chief Sustainability Officer. Her leadership drives alignment across governance, supplier engagement and continuous improvement, ensuring we meet ambitious goals across the value chain. At Calix, sustainability is not an initiative. It’s a product, supply chain and operational imperative.

What frameworks or tools do you use to assess and mitigate supply chain risks, particularly in light of recent global disruptions?

We take a multi layered approach to risk, combining real time visibility, predictive insights and strategic modelling. Our use of Resilinc allows us to monitor global disruptions continuously, earning Calix a top 20 ranking in their 2024 Supply Chain Resilience Index. That’s just the starting point.

We’re expanding beyond conventional visibility to explore causal AI, tailored to Calix specific factors like tariffs, manufacturing lead times and geopolitical exposure. These models are helping us scenario plan complex shifts, such as nearshoring options in North America, in a way that is both financially grounded and forward looking.

Internally, our S&OP process ensures rapid, aligned action. Externally, we maintain strong supplier partnerships and transparent communication, ensuring agility when real world events hit.

We don’t rely on a single tool or threshold. We use multiple lenses to stress test our assumptions and protect growth.

How do you ensure that your supply chain teams remain agile and upskilled to meet the demands of a digitally transforming supply chain landscape?

Digital transformation demands new skill sets and new ways of working. At Calix, we’re rethinking both. We’re shifting from siloed roles to integrated operations leadership, where individuals own planning through to fulfilment. These roles require broader thinking, faster decision making and fluency in digital tools.

To support this shift, we’re investing in hands on training in scenario modelling, AI interpretation and supply demand orchestration. We’re also hiring for adaptability, people who embrace change and think beyond traditional workflows.

We know that AI will reshape supply chain jobs. What matters is how quickly and responsibly we evolve. By giving our teams real exposure to the tools and data now, we’re building the talent engine that will scale with us.

What are your top priorities for the next 2 to 3 years in terms of supply chain innovation, digitalisation and supporting Calix’s growth strategy?

Our next phase is about orchestration at scale. We’re investing in a digital twin, a real time model of our supply chain that simulates scenarios and links operational data directly to strategic decisions. This will give us the foresight to model what if events, identify friction points and align capacity planning with Calix’s growth roadmap. But it’s more than technology, it’s a mindset. It enables dynamic decision making across the business, not just in operations.

We are also evolving how we work with suppliers, co-developing risk models, sharing forecasting insights and increasing ESG accountability.Finally, talent remains foundational. Our strategy is only as strong as the team executing it. So, we are scaling our capabilities with people who can translate insights into action, combining digital fluency with business judgement.

Calix provides cloud and software platforms and services that help communications service providers (CSPs) transform their networks, business operations, and subscriber experience. With its Calix Cloud and Customer Engagement Platforms, Calix empowers CSPs to deploy and monetize broadband, smart home, and IoT services—driving growth, efficiency, and subscriber satisfaction across North America and beyond.