The breakthrough star embarks on his first arena tour, backed by

One of the UK’s most compelling and visionary performers hits the road

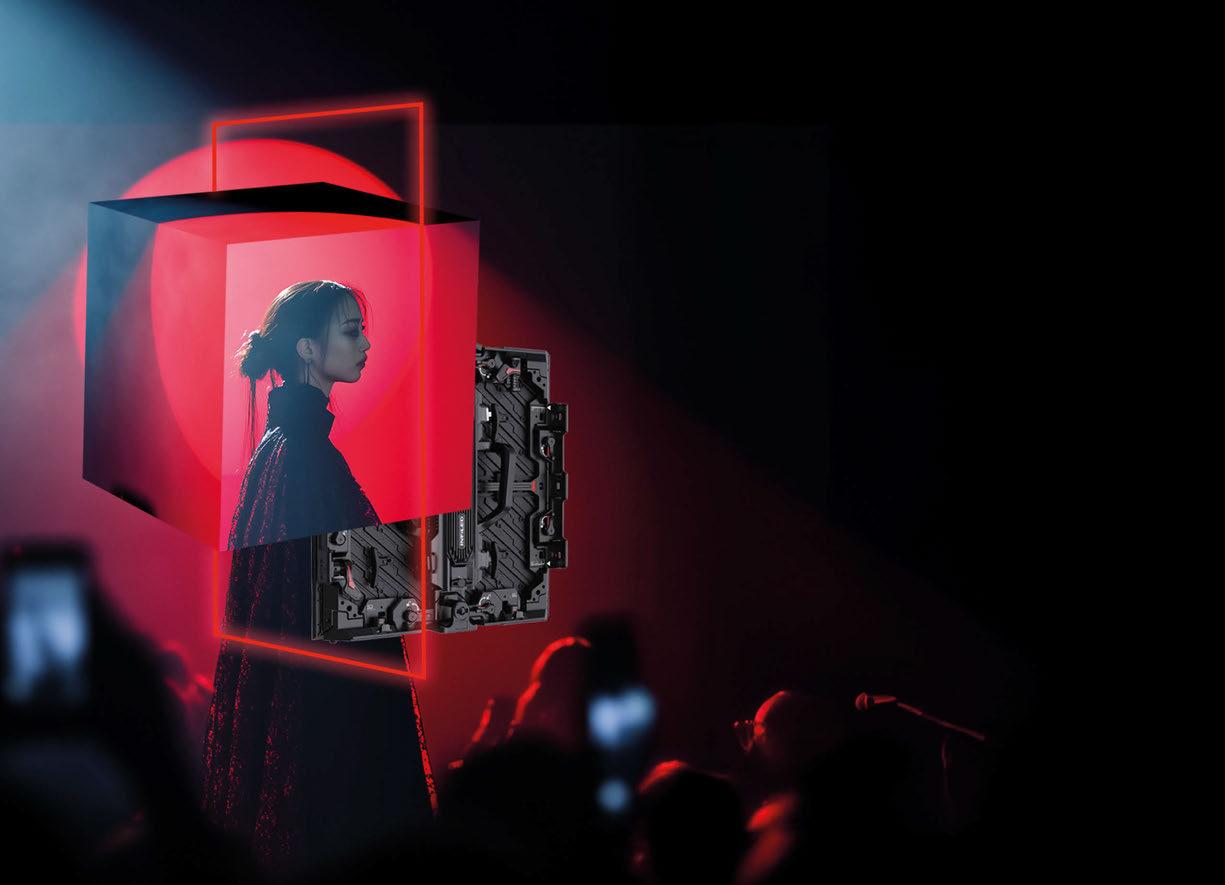

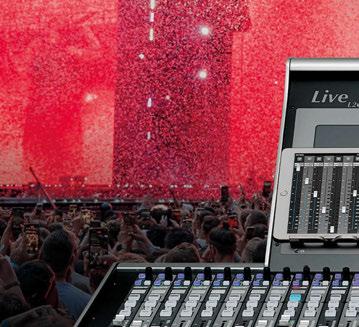

The artist’s team bring audiences closer than ever to the on-stage action

The breakthrough star embarks on his first arena tour, backed by

One of the UK’s most compelling and visionary performers hits the road

The artist’s team bring audiences closer than ever to the on-stage action

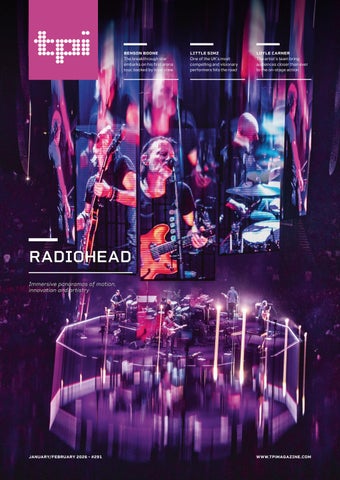

Immersive panoramas of motion, innovation and artistry

Create curved truss systems without extra components.

Leave mounted video modules in the truss during transportation.

Mount lighting equipment at the transition between two trusses.

Extremly extensive structural analysis.

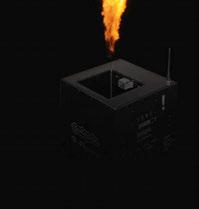

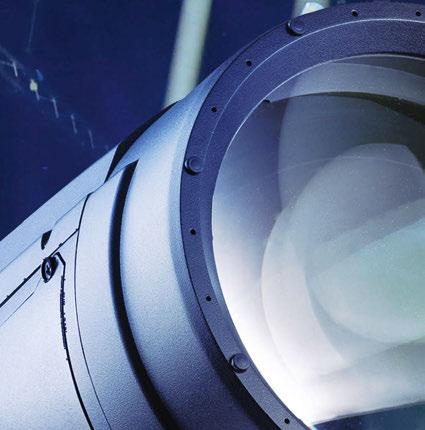

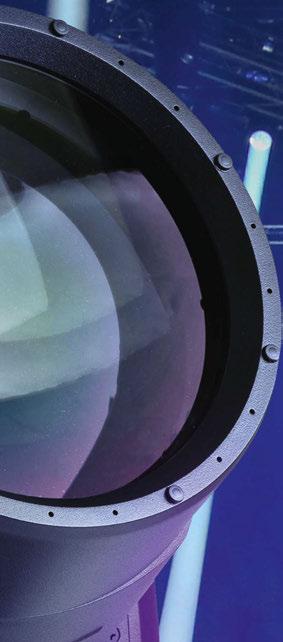

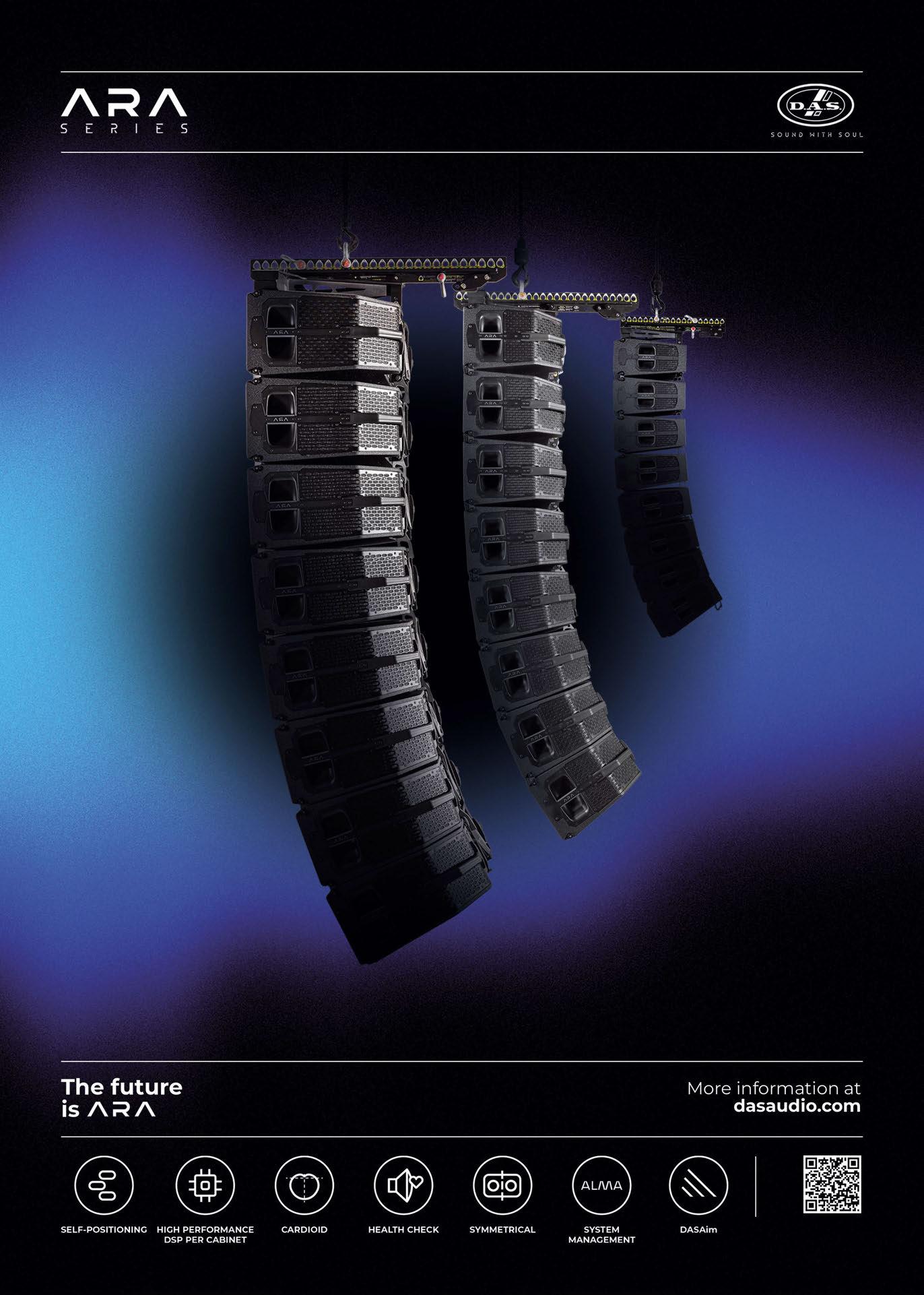

EagleStrike was born from a bespoke request for a signature luminaire. It stands as the first LED-source followspot in Ayrton’s range, engineered for intensive outdoor use across long distances where precision is paramount. To create this uncompromising and unmatched extreme-luminaire, Ayrton developed an oversized 270 mm front lens that delivers a record-breaking illuminance of over 100,000 lux at 10 metres, with the beam narrowed to just 2.9°.

Illuminance at 10m > 100,000 lx

Zoom Aperture 2.9° to 43° Weight

Perhaps it’s too on the nose, but as I sit here writing this to Pink Floyd’s The Great Gig in the Sky, desperately trying to lock in and shake off the end-of-year rust, I’m reminded of the luxury of our jobs as roving reporters who get to go behind the scenes of some of the world’s best shows. Generally, when we arrive on site, a large portion of the hard work has already been done by the riggers, local crew, stagehands, truck drivers, and, of course, the touring crew.

We t hen spend the next few hours being whisked between departments to try and catch up with the crew members who are always polite and welcoming despite being interviewed while they are still focussing lights or doing a line check. What makes it into print is generally a summation of those stories. However, for every feature, countless individuals behind the scenes don’t make it to the final copy. Promoters, booking agents, warehouse technicians, office staff, wardrobe, the list goes on.

As always, we strive to make sure everyone is name-checked, but as the adage goes, ‘it takes an army’, and the ever-patient printers can only withstand so much ink. This isn’t a plea for forgiveness but an acknowledgement that we, as a magazine, can do better to share these invisible roles and among the long list of targets we set ourselves at TPi, this is one of them.

Don’t be a stranger. Our emails and phone lines are open, and unlike sound engineers, we welcome feedback.

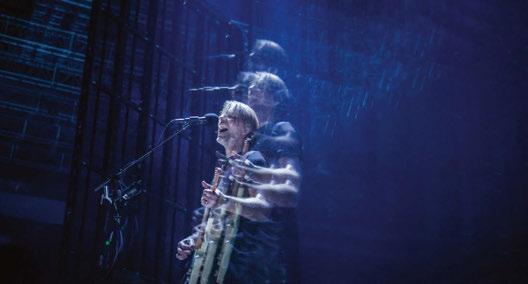

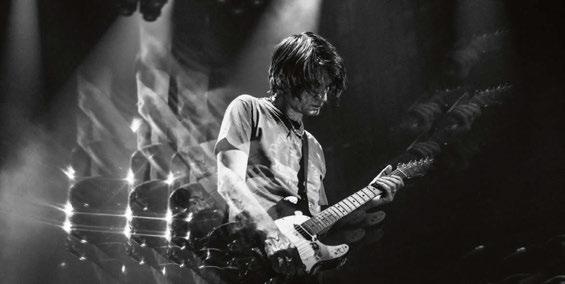

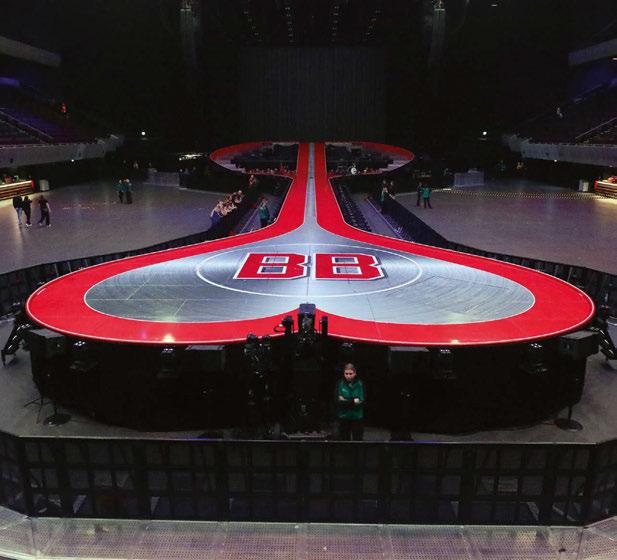

If t his print edition of curated tales from the touring circuit is anything to go by, we are all set for a busy year ahead. Our cover story documents Radiohead’s record-breaking ‘in the round’ production, which, despite its scale and technical complexity and creative impressiveness, brings crowds closer than ever to a band who have

been away for seven years [p48]. Likewise, Loyle Carner’s latest live campaign provides that same level of intimacy, as Ali discovers [p42].

Worlds apart, stylistically, yet bonded by their ability to command arenas, and beyond, Little Simz [p62] and Benson Boone’s [p74] respective production crews put the naysayers professing a lack of headliners to bed. These stories, and the grand reveal of the TPi Awards shortlist [p24], signify a sector that enters the year not merely resilient, but creatively restless. See you on the road, ISE, or the TPi Awards...

Jacob Editor

Issue #291 January / February 2026

Managing Editor

Stew Hume Tel: +44 (0)161 476 8360

Mobile: +44 (0)7702 054344

Email: s.hume@mondiale.co.uk

Editor Jacob Waite

Tel: +44 (0)161 476 8360

Mobile: +44 (0)7592 679612

Email: j.waite@mondiale.co.uk

Assistant Editor

Alicia Pollitt

Tel: +44 (0)161 476 8360

Mobile: +44 (0)7508 441986

Email: a.pollitt@mondiale.co.uk

Commercial Director

Fran Begaj Tel: +44 (0)161 476 8360

Mobile: +44 (0)7852 336728

Email: f.begaj@mondiale.co.uk

Senior Account Manager

Matilda Matthews Tel: +44 (0)161 476 8360

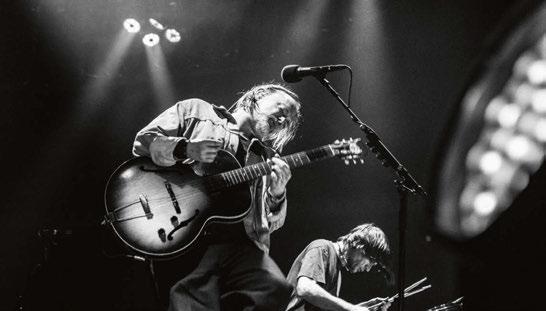

Mobile: +44 (0)7413 555978

Email: m.matthews@mondiale.co.uk

Account Manager Tom Dyson Tel: +44 (0)161 476 8360 Mobile: +44 (0) 7306505230 Email: t.dyson@mondiale.co.uk

Account Manager Sophie Edwards Tel: +44 (0)161 476 8360 Email: s.edwards@mondiale.co.uk

Digital Content Manager James Robertson Tel: +44 (0)161 476 8360 Mobile: +44 (0)7725 475819 e-mail: j.robertson@mondiale.co.uk

Marketing and Events Manager Alice Clarke Tel: +44 (0)161 476 8360

Mobile: +44 (0)7752 392465

Email: a.clarke@mondiale.co.uk

Marketing and Events Assistant Charlie Moore Tel: +44 (0)161 476 8360

Email: c.moore@mondiale.co.uk

Editorial Director Peter Iantorno Tel: +44 (0)161 476 8360 Mobile: +44 (0)7763 233637 Email: p.iantorno@mondiale.co.uk

Chief Executive Justin Gawne Tel: +44 (0)161 476 8360 Mobile: +44 (0)7768 850767 Email: j.gawne@mondiale.co.uk

Accounts Lynette Levi / Sarah Miller: ar@mondiale.co.uk

Mondiale Group Chairman Damian Walsh

Graphic Design & Production

Dan Seaton: d.seaton@mondiale.co.uk

Jez Reid: j.reid@mondiale.co.uk

Cover Photo

Radiohead by Alex Lake

Printed By Buxton Press • www.buxpress.co.uk

Annual subscriptions (including P&P): £42 (UK), £60 (Europe), £78/$125 (RoW).

Subscription enquiries to: Subscriptions, Mondiale Media Limited, Strawberry Studios, Watson Square, Stockport, SK1 3AZ, UK. Tel: +44 (0)161 476 5580 Email: subscriptions@mondiale.co.uk www.tpimagazine.com www.tpiawards.com www.gtlsessions.com

Total Production International (TPi) is a controlled circulation magazine, published six times a year by Mondiale Technology Media Limited under licence. ISSN 1461-3786

Access our complete range of globally available professional AV equipment and request your rental quote online.

Stay up to date with the latest innovations and product r releases from our partner brands.

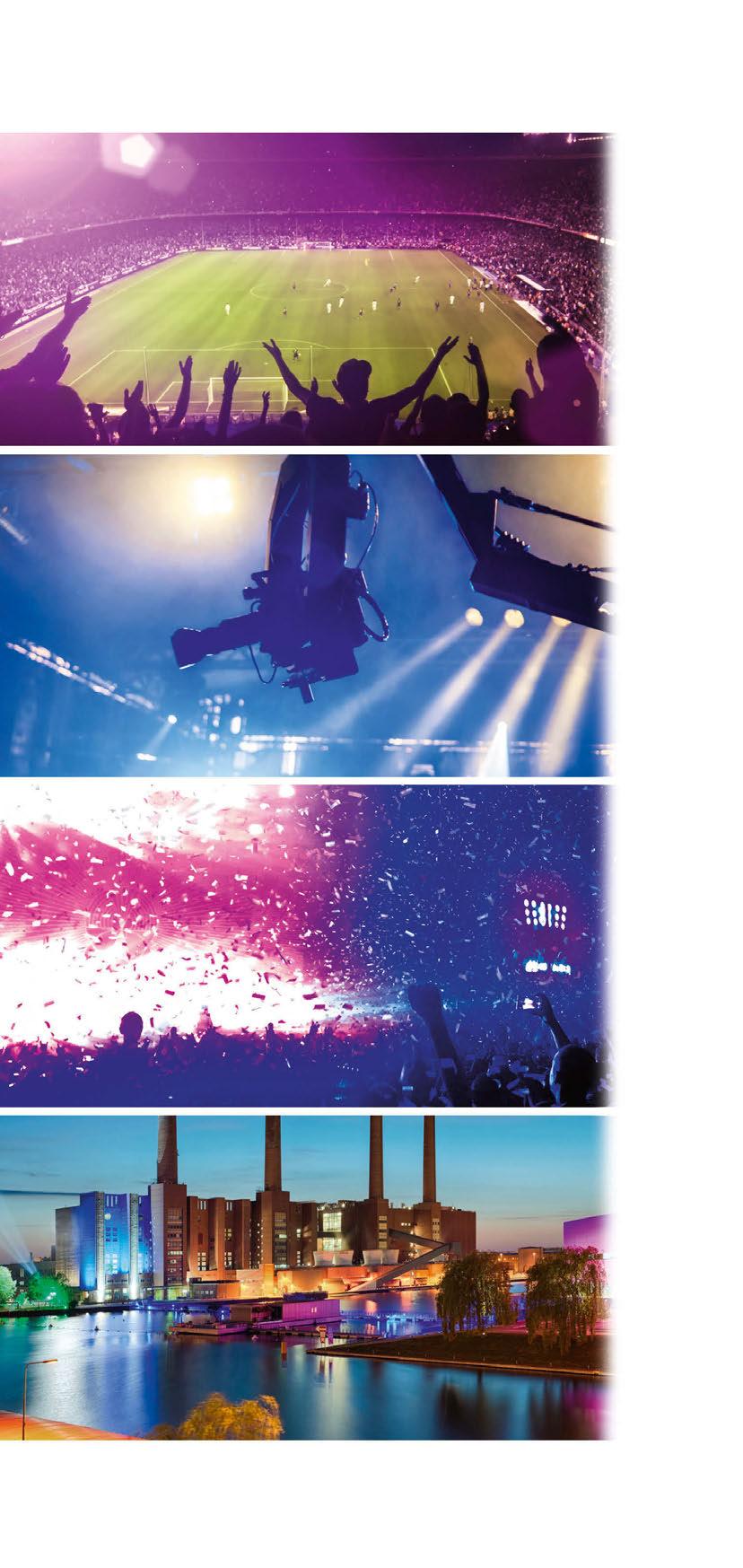

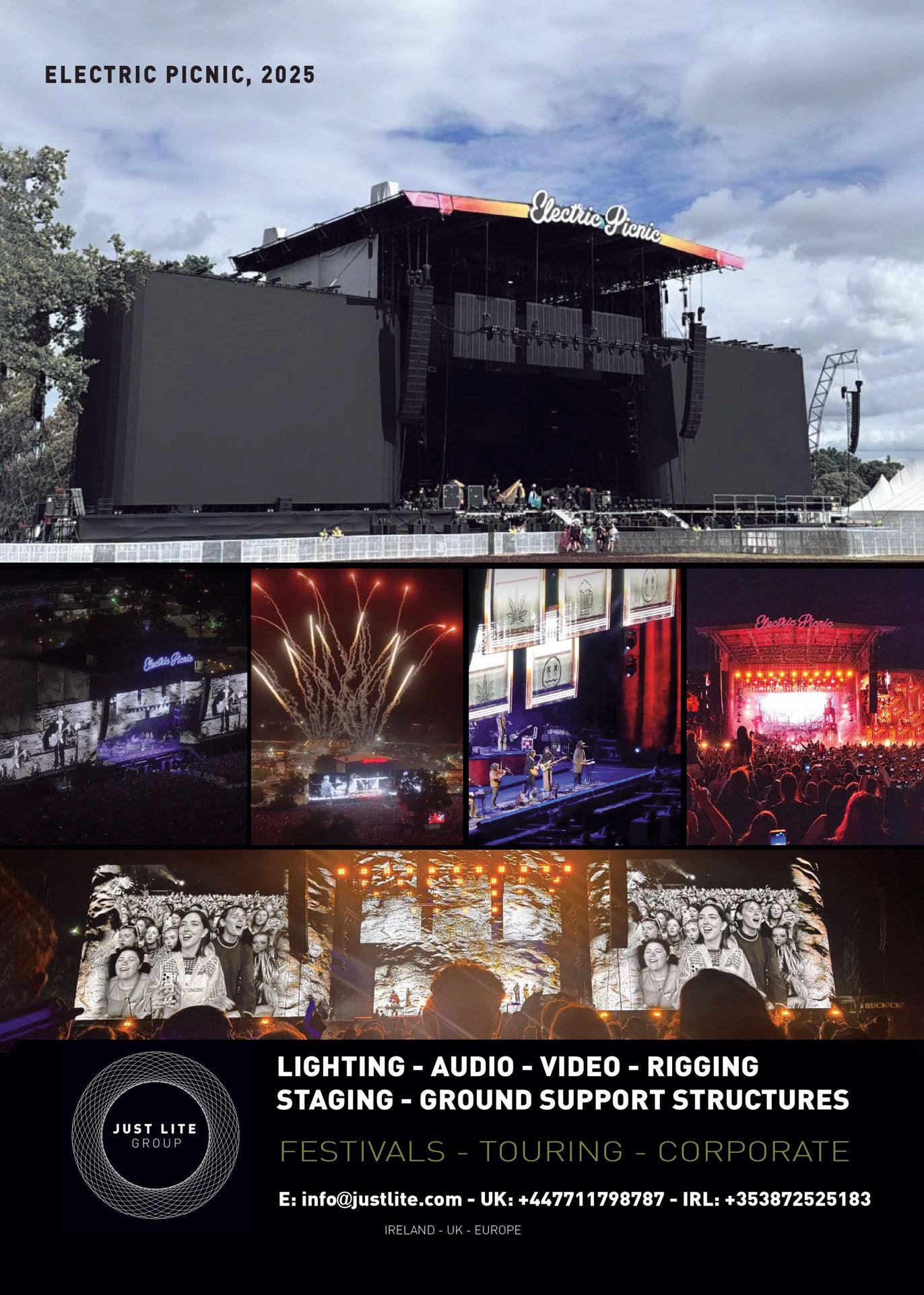

The band and their touring team transform arenas across Europe into immersive panoramas of motion, innovation and artistry, breaking attendance records along the way.

EVENT FOCUS

12 Busted and McFly face off amid a nostalgic co-headline tour. 18 Ed Warren creates an ‘impossible’ line of light for Four Tet.

An AeroAVA drone show lights up Royal Edinburgh Military Tattoo.

ER Productions joins Parkway Drive’s 20-year celebrations. 38 MOTOR Stage Automation powers Sabaton’s latest live show. PRODUCTION PROFILE 42 LOYLE CARNER

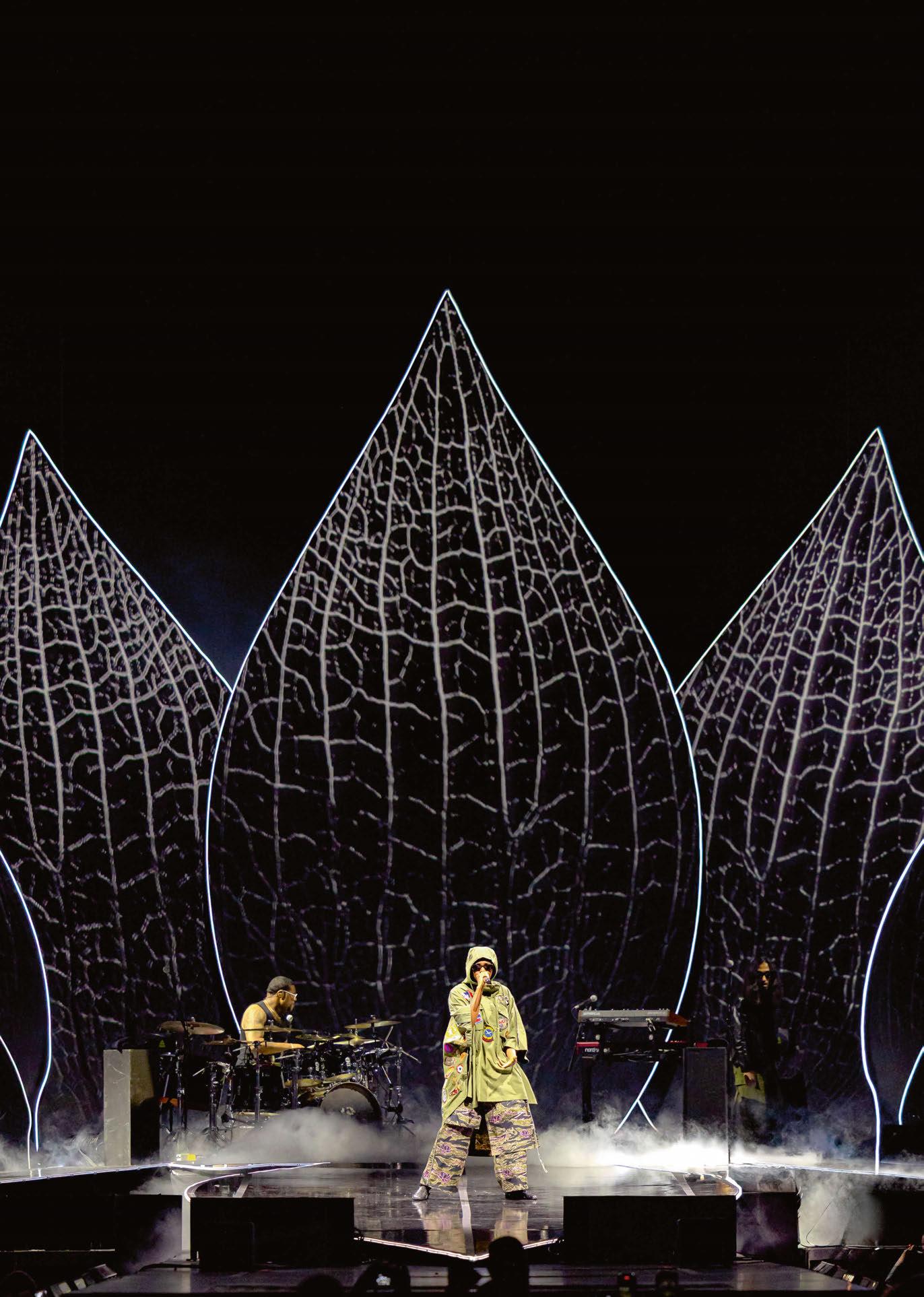

The artist, his crew and technical suppliers bring audiences closer than ever to the action. 62 LITTLE SIMZ

One of the UK’s most compelling and visionary performers hits arenas with her team in tow.

74 BENSON BOONE

With an exuberant production and performance, the artist embarks on his first arena tour.

INTERVIEW

88 Jaakko Kaivonen takes on the role of CEO at d&b group.

92 Funktion-One showcases the next evolution of sound solutions.

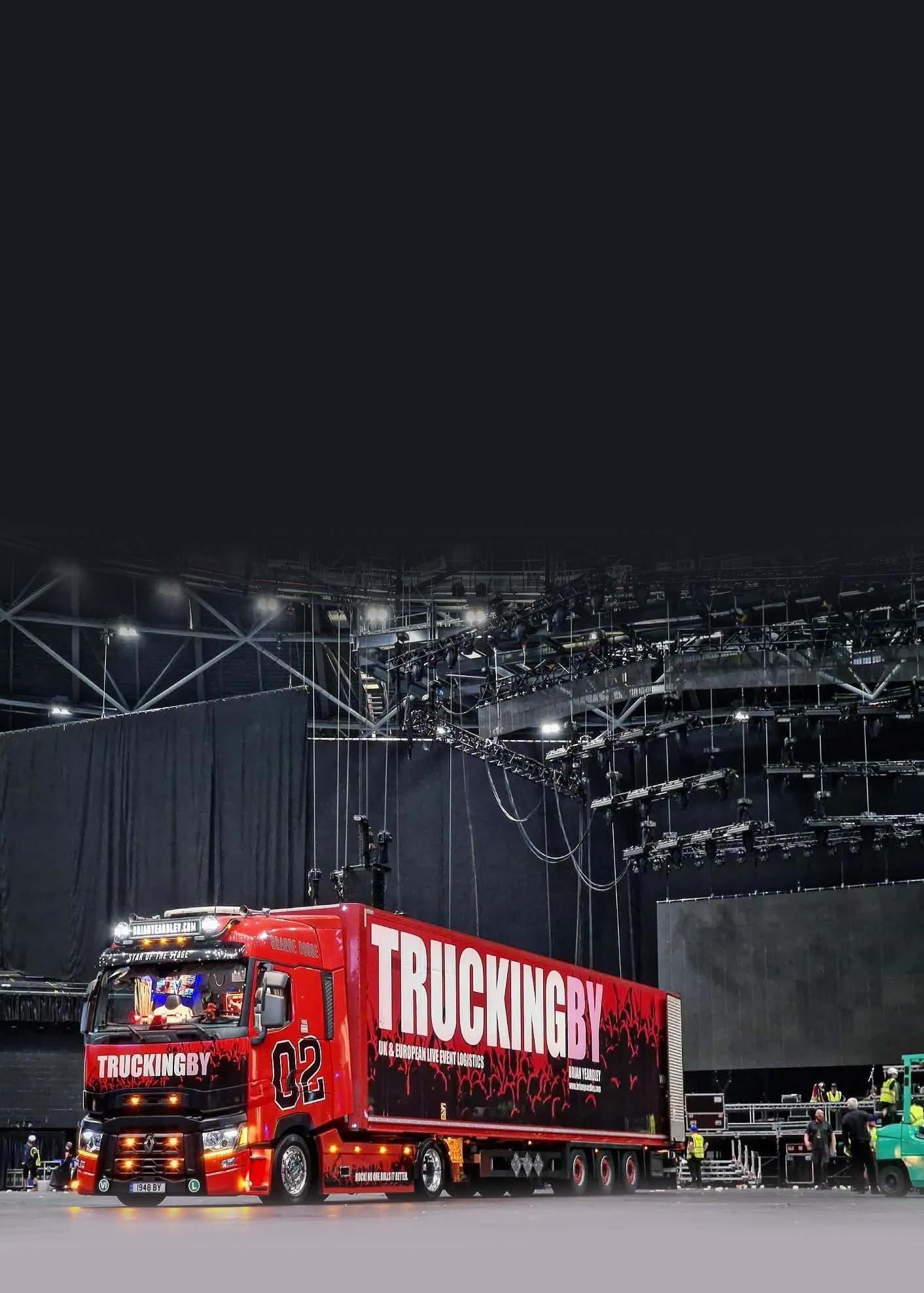

96 Spartan Crew reflects on the pursuit for reliable crewing.

IN PROFILE

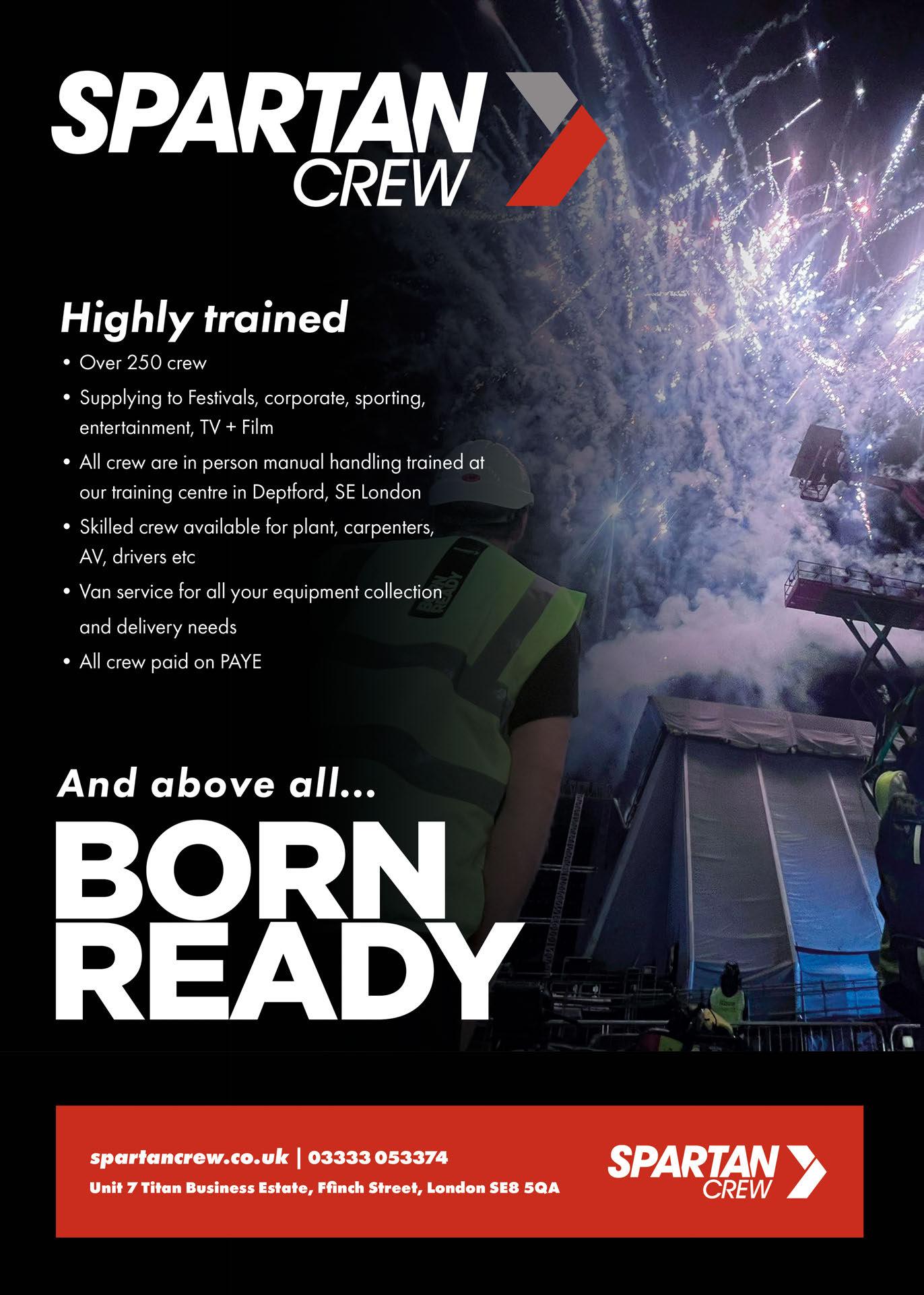

100 TRUCKINGBY celebrates 50 years of business.

106 TPi visits Dutch Barrier Services’ Netherlands HQ.

PRODUCTION FUTURES

112 Celebrating 2025’s Breakthrough Talent Award winners.

114 Matrox Video releases the ConvertIP Series.

116 Matt Wright highlights the minds behind live event logistics.

118 TPi heads across the Atlantic for THE Conference: Live at Lititz.

122 PSA amplifies crew welfare resources to normalise support.

126 Chance Stahlhut shares Concert Stuff Group’s mission to foster a culture of collaboration.

Fira de Barcelona I Gran Via I 3 - 6 February 2026

The world-renowned annual tech show is back. At our last edition, 20,495 leading Venues & Live Events affiliated professionals joined us for a taste of state-of-the-art industry tech. This year, that number’s set to grow as we Push Beyond.

So don’t miss seeing, hearing and feeling it first. Test what’s next – and what’s possible – in the world of Venues & Live Events.

GET YOUR FREE TICKET

Register with code: tpimagazine at iseurope.org

With creative direction inspired by the world of wrestling, the two bands face off in a nostalgia-fuelled co-headline tour.

Words: Stew Hume

Photos: Dylan Swann and Fran Parry

Since forming in the early 2000s, the stories of Busted and McFly have always been interwoven. From the days of Popworld’s Simon Amstell joking that they were so similar, to the later years when the shared camaraderie of the groups was seen as they toured together under the moniker of McBusted. However, for some time behind the scenes, a plan was put in place to create a tour that would pit the two bands against each other for the ultimate co-headline tour.

The difference between B usted vs McFly compared to many other co-headline tours is that instead of flip-flopping w ho headlined each night, t he t wo bands created a t ruly shared performance w ith several face-offs’ and collaborations throughout.

W ith t he show overseen by Production

Manager, Iain W hitehead of Production North and creative direction courtesy of David Spearing, t he resulting t wo-month tour, comprising 35 shows, ended up being t he biggest arena tour of t he UK in 2025.

Greeting TPi at FOH in Manchester’s Coop Live, Lighting Designer, Sam Parry – w ho oversaw t he v isual dialogue for both acts –walked t hrough t he creative process for t he tour. T he LD had crossed paths w ith both

bands, having worked for McFly for several years w hile working for Busted f rontman Charlie Simpson’s other band, Fightstar, during an OVO Wembley A rena performance. The Fightstar show led to a positive relationship with Charlie and w hen t his tour began to t ake shape t he creative consultants were happy to have me look after both acts,” Parry explained. A lthough many departments including backline and audio were split for both bands, Parry and his v ideo counterpart, Media Server Operator, T homas Hunter, acted as a creative throughline. We had a long lead-time into t his show,” explained Parry. “ I still approached t he projects as if I was designing for t wo bands and early on, we k new w hat t he overall look for the stage would be w ith t he massive monolith diamond shape above t he band.” To ensure t hat both bands were still able to have t heir own looks during t heir t ime on st age, versatility in t he fi xtures on t he r ig was at t he top of Parry’s list. V ia t he tour’s lighting, video and automation supplier PRG, t he lighting department deployed many Ayrton fi xtures including 100 Zonda 9s, 52 Veloce Profiles and 14 Perseo Profiles. “ I t hink we managed to achieve different looks for both bands t hanks to how much choice we had w ith t he colour

spectrum we had f rom t he fi xtures we chose,” commented t he LD. “ The 100 Zonda 9s are up in t he grid on t he four pods and hats off to t he team at A mbersphere for helping us source so many.” He f urther praised t he “incredible” Veloces. “ It’s almost upsetting as t here is nothing to criticise,” he chuckled.

The LD selected 34 “uber-punchy” ROXX Lighting Clusters. “ They are not ‘actual’ blinders, w hich means we are not pulling a lot of dimmers around w ith us,” stated Parry.

In addition were 14 GLP JDC Burst 1 strobes and 14 impression X5 units. Lining t he stage were 20 ACME PIXEL LINE IP striplights. “ The PIXEL LINE has been everywhere over festival season. T hey look incredible and are not too heavy, making t hem very versatile.”

For key light, Parry used seven Robe iFORTE LT X w ith PRG’s G roundControl FollowSpot system. “ I didn’t k now we’d be able to use the G roundControl for t he Robe fi xtures, but they’ve been great,” stated Parry.

T he production had seven stations, w ith one spare. Two of t he lighting crew worked t he spots for t wo of t he musicians w ho went into the audience during t he show, w ith t he other spots being looked after by some of t he tour’s dr ivers. “ The drivers have all done a great job

and they’ve really learned the show, which makes my job much easier,” he commented. On the topic of crew, the LD was keen to praise the work of his wider lighting team of Aidan McCabe, Adam Hodgson, Tom Begley and George Wilson. “They’ve all been wonderful. I also must give a shout out to our automation team of Ameer El Elryan and Toby Bale.”

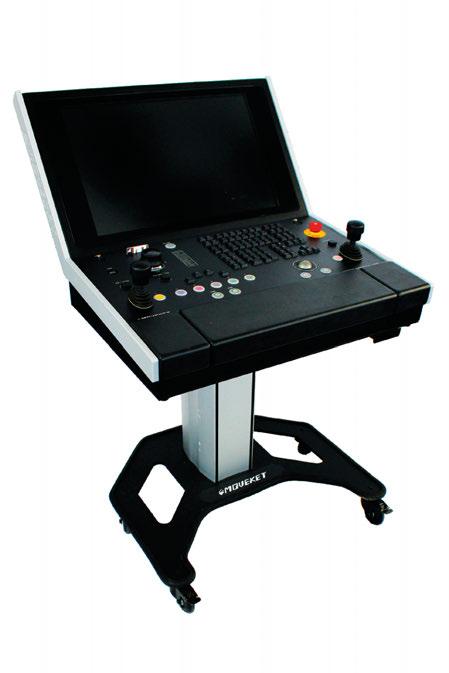

The automation in question was a MOVEKET system that gave motion to the four independent square lighting pods, set as a diamond offset to mirror the stage below.

“T here is a lot going on up there and although I’ve used MOVEKET before, I never had the chance to push what it would really do,” commented Parry. He went on to point to his favourite looks, such as when McFly singer Danny Jones went right up to the audience and ‘commanded’ the whole rig with all the elements closing right in on the performance. “It was like he was using the force,” he said. As well as its technical capability, he also enjoyed the back-end software options of MOVEKET. “The software does all the calculations for the loads on each point and gives me a technical previsualisation to show me the gradient and angle relating to those hoists before anything even moves. I can just say what I want the pods to look like, and the software calculates the weights, angles and speeds, which is much easier to work with.”

For control, the LD used MA Lighting grandMA3. “We have two full sizes and a light out with us. The two mains have been from PRG and they have been rock solid. I was thrown into the deep end when I moved onto the MA in 2023 for a McFly tour, but both the software and hardware have been very good.”

To close, Parry gave his thoughts on supplier PRG and its contribution to the project: “We opted to go with PRG as our supplier because they had what I wanted with people that I knew. We’ve had a good relationship for several years and my experience has always been positive. Working with Steve Major and Yvonne Donnelly Smith especially has been great. They deliver what I want every single time I ask for it.”

Sat to the right of Parry at FOH was Thomas Hunter, Media Server Operator and overseer of all the screen content on both the rear wall and the large banner screens. “I’ve worked on a variety of jobs for PRG, but Disguise is not usually my world,” admitted Hunter, who had to learn the entire Disguise system and workflow ahead of this tour. “It’s been fun to see some of the ways it works. The media distribution has been particularly interesting.”

Hunter had roughly a terabyte of video files on one machine, which due to its internal

distribution system is then manually backed up. Alongside the two Disguise GX3 machines, Hunter utilised Notch to varying degrees for both bands.

“For McFly, a lot of the Notch effects are quite subtle such as a bit of smoke on the image, but for Busted, there are some more prominent Notch looks including background removal and edge detection that are used to create the ‘punky’ block colour look graphics.”

The rear LED wall was made up of INFiLED AR5.9 with NovaStar MX40 processors. The flown banner LED was made up of ROE Visual Vanish 8T using ROE’s EV4 processors.

“One of my favourite looks for the show happens during the song What Happened to Your Band,” continued Huner. “All the musicians come up on lifts and we use the LED almost like a lighting effect, which provides a silhouette of all the guys on stage. What’s great is that you really can’t capture it on a camera – believe me I’ve tried – which means it’s an experience just for those in the crowd.”

For almost all the bands’ sets, the visual teams took cues from timecode, bar a few songs in McFly’s set – Five Colours in Her Hair and It’s All About You. “They have never played to timecode on those songs,” interjected Parry, explaining that they always want to play them at the pace they are feeling that night. That means it was all hands-on deck for the lighting

designer and the media server operator. Video Director, Chris Keating ensured each element was captured for the IMAG. “It’s been a fantastic tour to be involved with,” stated Keating. “It’s a great crew and it’s good to work with Iain Whitehead again who I’ve known since 1999.”

From t he first moments he s aw t he renderings of t he set, Keating knew it was going to be a good show. “The set is quite unconventional and adds an extra layer to the camera shots. It’s a strong visual presentation with the large upstage screen, two portrait IMAG screens and the four-sided overhead banner screen.”

In total there were seven cameras deployed, including two long lenses at FOH and two cameras on track in the pit.

“It’s a busy, high-energy show, with lots for the camera guys and myself to play with,” stated Keating. “There’s been a good cohesion between the various visual elements of the show, with lights, video content and cameras. It all makes for a great-looking show.”

Aiding Keating and Hunter in the video department were Video Crew Chief, Steve Jones alongside Brad Baker, Chris Hobson, Matt Heitman, JJ Mikinzi and Gavin Brunton.

Closing out the extensive 35-date run at the start of November, Busted vs McFly set the bar for other 2000s nostalgic acts looking to also head out on the road and prove that despite their heritage, productions such as these can still push modern technical innovation. www.busted.komi.io www.mcfly.com www.prodnorth.com www.prg.com

Production and Lighting Designer Ed Warren masters multi-fixture geometry, creating an ‘impossible’ line of light supported by Lights Control Rigging for Four Tet at London’s Alexandra Palace...

Words: Jacob Waite

Photos: Luke Dyson

When pioneering electronic artist Four Tet returned to Alexandra Palace’s Great Hall, the brief was as deceptively simple as it was ambitious: create a vast, communal dancefloor experience anchored not by a performer, but by light, geometry and feeling. For award-winning Production and Lighting Designer Ed Warren, the challenge was irresistible, as TPi discovers.

A long-time collaborator, Warren has worked with Four Tet’s Kieran Hebden for 17 years, and that history shapes every iteration of the project. He designed the entire room concept and layout, programmed the artist’s latest show’s, and operated the lighting live, busking.

“T he core principle has always been that the dancefloor is the focal point, not Kieran onstage,” he explained. “The aim is for everyone, wherever they stand, to feel fully immersed in the experience.”

Sc aling up to Ally Pally, and to arena-size rooms beyond, required a fresh architectural gesture. Warren found it in what would

become the show’s defining feature: a single, uninterrupted axis of light. “When we learned we were scaling up, I knew I wanted a continuous line of light running down the centre of the room,” he recalled. “The first question was: ‘How long can we physically make this?’ Once that was established, the geometry of the entire show grew from that single decision.”

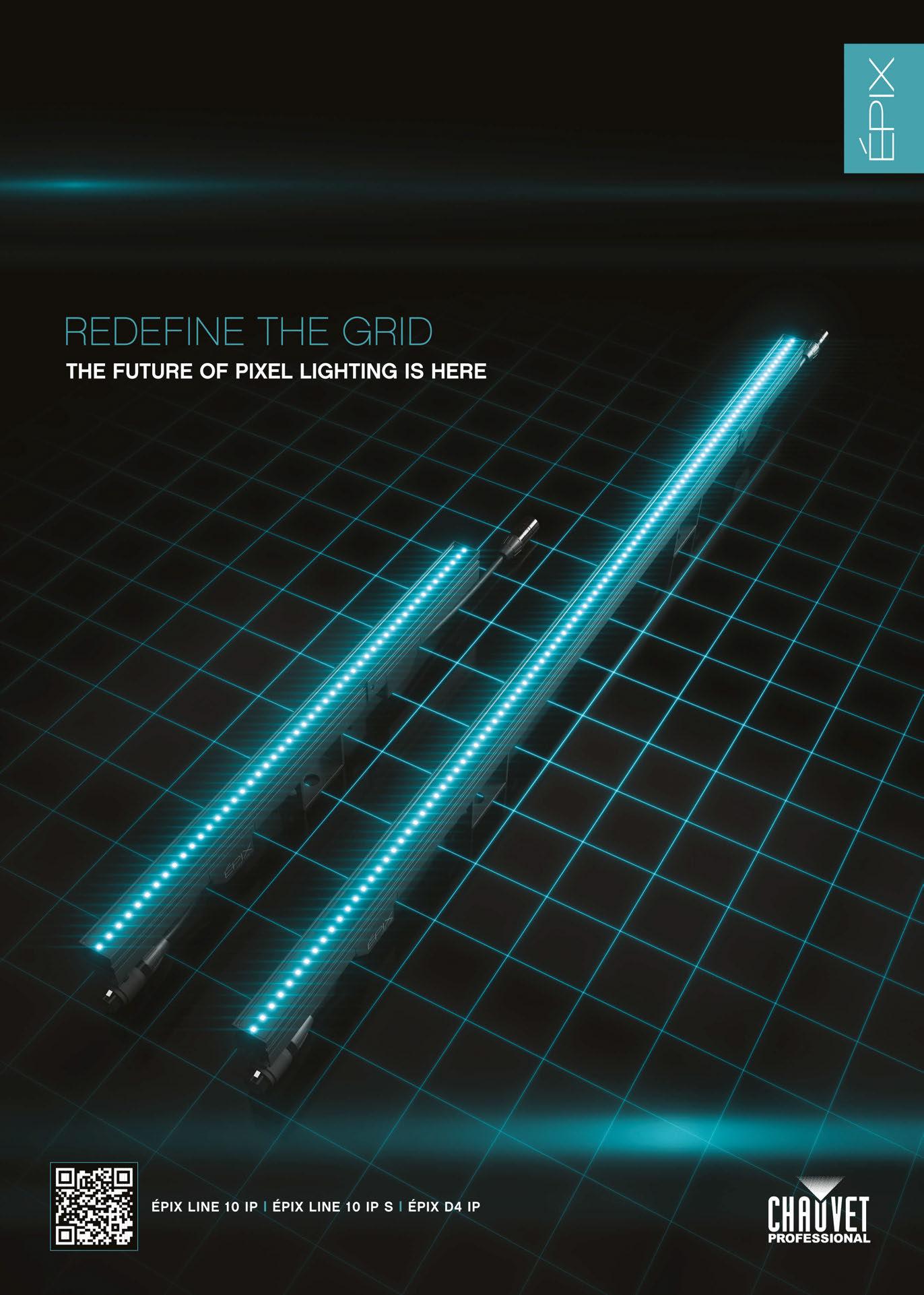

The result was a 58m line of CHAUVET Professional COLORado PXL Curve 12s, suspended on Kinesys and capable of descending to just above the audience’s heads or tilting into angled formations. “It shrinks an enormous arena into something that feels intimate, like the small clubs where Kieran first started DJing,” Warren noted.

Each PXL Curve houses 12 individually tilting pixels, giving nearly 700 controllable points in a perfectly straight line. “I spent a long time experimenting with effects across that array,” he said. “During the previsualisation stage, the results looked almost impossible, and they were even better. At times, it became

this slow, ominous sheet of bending light; at others, a room-filling rainbow broken into hundreds of moving pieces. It suited my love of symmetry and geometry perfectly.”

Some of the show’s most striking moments came from just two fixtures. “We drop two Ayrton Kyalami into the centre of the room, just above head height,” Warren noted. “With a single rotating beam each, they create a rotorblade effect overhead that slowly accelerates with the music. For nearly ten minutes the room runs on just those two fixtures. In a 10,000-capacity production, that kind of restraint is incredibly powerful.”

Supporting the central truss are four straight runs loaded with Ayrton Rivales and GLP JDC1s, simple tools deployed with precision. “Often the simplest looks were the most effective. A single bounce-dimmer chase running the length of the JDC1s could transform the space. Simplicity is always the guiding principle, especially as we deliberately avoid video content.”

Control for all of this comes from Warren’s own ChamSys MQ500M Stadium Console, the same surfaces he uses in his studio. “They are perfect for a busked show of this scale,” Warren said. “They let me build and manipulate multiple effect types across whichever fixtures I select, quickly and flexibly. I busked a four-hour show with almost 200 fixtures from a single page of faders and buttons.”

Lights Control Rigging (LCR) supplied all lighting and handled the rigging advances, including coordination with audio. “I work directly with LCR Senior Account Manager, Rob Watson, who brings a huge amount of care, detail, and consistency to every project. From prep to plots to onsite support, the whole team is solid – reliable gear, meticulous work, and a genuinely collaborative attitude,” Warren said.

Having first worked with Production Manager Matt Barker and the Four Tet team at Glastonbury Festival, Watson, alongside LCR Project Manager Sam Dilworth, LCR Crew Chief Gaz Horridge, Lighting Technicians Richard Griffin, Ashley Tutt, Ben Webster, Rich Hoxley,

Jon Barlow and Dan Turner, Kinesys Operator Tom Darby and Production Rigger Zack Wade, oversaw the deployment of five static trusses and one Kinesys truss, each measuring 60m, as well as 48 rigging points for the audio infrastructure and cable management.

KB Event supplied four 45ft Megacube trucks, steered by long-time drivers Ian Botham, Marcus Baugh, Steve Parks, Alister Stone and Mike McCord.

“We evaluated fixture types to make the logistics feasible. It all loaded in on the same day as the first show, four and a half trucks’ worth of LCR gear, on what was essentially an in-show day with no production rehearsals,” Watson recalled, speaking to TPi following a recordbreaking 2025.

The project’s primary challenges, as ever, were time and the sheer volume of infrastructure required: five, 60m of lighting truss alone, 10 cable bridges for lighting and four for audio. Three trucks’ worth of truss were stacked and transported ready to be rolled out. On site, the team ensured perfect symmetry among the

210 mm x 150mm W x

Production manager: Matt Barker

Lighting Design: Ed Warren

lighting fixtures using laser measurements.

“It was a challenging feat, but the result made it all worthwhile. We love working with Ed Warren, he is a lovely human being, flexible yet someone who knows exactly what he wants,” Watson said, emphasising that collaboration was fundamental to the project’s success.

“Every department had to liaise and work together to deliver this show.”

With no support act, Warren used GLP JDC1s to create a warm white palette that could easily be mistaken for house lights. Dynamic lighting looks were introduced slowly, and at 8.30pm the first Kinesys move took place. All the data in the dimmer areas were driven by Luminex. The wider rig incorporated 1,250kg and 500kg hoists as part of a Kinesys Apex automation system.

“Seeing the audience realise that a truss was moving above their heads out of nowhere was a special moment,” Watson said. “It is a greatlooking show, nothing is overdone. There is a moment where a small truss in the middle of the room, with two Ayrton Kyalami on it, drops in

for one song, does a clockwork spin, then rises again. There was a surprisingly diverse range of looks, despite it being a busked show.”

The main challenge for Warren was rigging above a densely packed dancefloor. “Every cable bridge and drop had to be extremely discreet and clean. Beyond that, the rig itself is deceptively simple: five straight trusses. The real challenge was using that minimal geometry to create a show that stayed varied, coherent and uncluttered over four hours.”

Among his favourite moments is one that happened almost by accident. “I was splitting the PXL Curve pixels into symmetrical, morphing shapes while running a full-length rainbow chase across them,” he said. “It was entirely busked, but it created a moment of pure visual magic.”

And, of course, the rotor-blade sequence remains a personal highlight.

“T he slow build, the restraint, and then the release when the full show comes back in… it hits hard every time,” he added. “For a production of this scale to rely on two small

fixtures for that long, that contrast is exactly what makes it so powerful.”

Reflecting on nearly two decades with Hebden, Warren is clear about why this partnership continues to evolve.

“Working with Kieran for so many years says everything,” he said. “He trusts my instincts completely and gives me the freedom to experiment, while also pushing me to challenge expectations of what a show should look like. There is no ego, no compromise, just a shared commitment to making the experience better every time.”

According to the production and lighting designer, the shows journey is far from over. “The show will continue to develop; every iteration teaches us something new,” Warren revealed. “We are only just getting started…” www.fourtet.net www.edwarren.org www.kbevent.com www.lcr-rental.com www.chamsyslighting.com

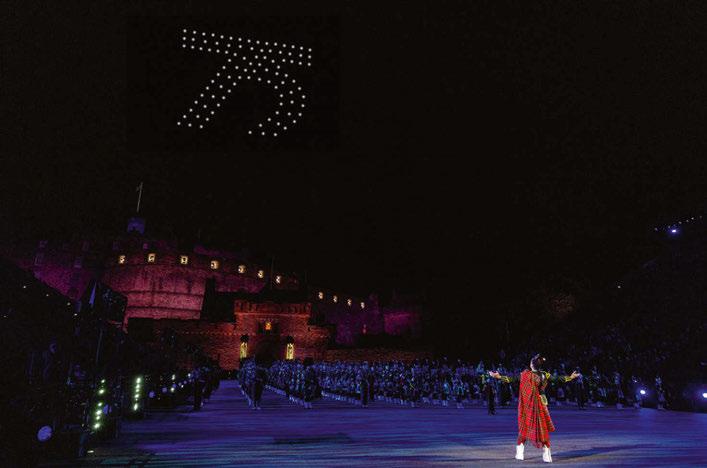

AeroAVA drones take centre stage amid the 75th anniversary of The Royal Edinburgh Military Tattoo. Back on the ground, the team shares the hoops it must fly through to make such an event happen.

There’s no doubt that drones had a greater presence within the live events landscape in the UK throughout 2025. Whether it was hailing the coming of Oasis to stadiums across the country or their multiple appearances at festival grounds throughout the summer, it seems more creatives are looking to extend their visual canvas into the sky. Another famed event that sought aeronautical excellence in ’25 was the Royal Edinburgh Military Tattoo, with organisers bringing in AeroAVA to add drones into the wider creative conversation.

Discussing the company’s involvement with the project was Tom Rees, Managing Director of AeroAVA. Having first discussed the event challenges with Harry Guthrie, Production Director of the Tattoo, at the PLASA show in 2024, the seed was planted that drones could reliably and safely play a part in the production’s 75th anniversary, with AeroAVA Technical Director, Chris Bradbury, starting to plan site visits in the first part of the year. “We wanted to deliver not only something unique for the show, but also give something to the whole city as part of Edinburgh’s 900-year celebrations,” noted Guthrie. “The Tattoo is a unique event with unpredictable weather conditions, and has a daily audience of 9,000. Everything must work perfectly every single night. AeroAVA truly went above and beyond to ensure this exceptional collaboration went ahead.”

“A big part of this project was a close collaboration with Historic Environment Scotland as well as the ASSU [Aviation Safety and Security Unit within Police Scotland],” explained Rees, who stated that cooperation was vital both in the build-up, rehearsals and during the shows where planned flights took

place. “We were in regular contact with all stakeholders throughout the show evolution process, coordinating with the Police when necessary and even had to cancel a small number of shows due to Storm Floris. In fact, one day the entire castle was closed due to the storm, the first time a Tattoo show didn’t happen in 75 years,” explained Rees, highlighting the importance of flying safely and planning for every eventuality.

On t hat note, one reason why the MD explained AeroAVA presented a good use case for the organisers was the company’s 2:1 separation to audiences. “Up to 50m of flight height, there is a rule of a minimum 50m separation from the audience. For most other drone companies, every extra metre above this height usually means that the crowd also needs to be an extra metre away. But due to our flight analysis and safety systems, we’ve proven a safe separation that works on a 2:1 ratio, meaning drones can fly in closer proximity and as high as 180m.”

Rees emphasised that his company’s involvement with the Tattoo was not to provide a stand-alone drone show, but to complement the overall production. The show featured 100 drones revealing the number “75”, 150m above the Edinburgh Castle Esplanade, synchronised with cast cues, sound and pyrotechnics for full audience engagement. Beginning with a young female piper pointing an illuminated torch skyward, the drones responded by revealing the anniversary motif, then rotating 360 degrees so the entire city could witness this historic milestone for the event.

Additional sequences throughout the display honoured military heritage and Scottish identity

through 2D and 3D formations and lighting animations depicting military symbols, the Victoria Cross, musical representations, and Scottish symbolism, including a striking thistle formation representing how Scottish values spread across the world. Each look was designed and sequenced to timecode in line with all the other production departments.

Due to the special aviation clearances issued by the Police Air Safety and Security team, AeroAVA was able to provide two other elements within the overall production. The first was a stand-alone SFX moment separate from the swarm of 100 drones. Nicknamed ‘Tinkerbell’, the company provided a customised drone, with a specialist pilot, that acted as a ball of light, which the narrator of the show appeared to magically conjure up in his hands before soaring skyward.

“We also provided aerial filming services for the BBC broadcast of the event,” stated Rees, explaining the multiple solutions he and his team could provide for the overall project. “While drone display technology is evolving fast, our approach is focused on combining flight resilience, safety and creative boundary pushing,” mused Rees as he and the team look to the future of drone technology and its place within the wider events space. “These drone displays and effects serve the story, not the other way around, and our job is to deliver them to be efficient, reliable and creative. At AeroAVA, we’re also looking at the future of integrating digital technology, how it is evolving across the board with all different kinds of interactions, and what really excites me is what a drone show will look like in two to five years.”

www.edintattoo.co.uk

www.aeroava.com

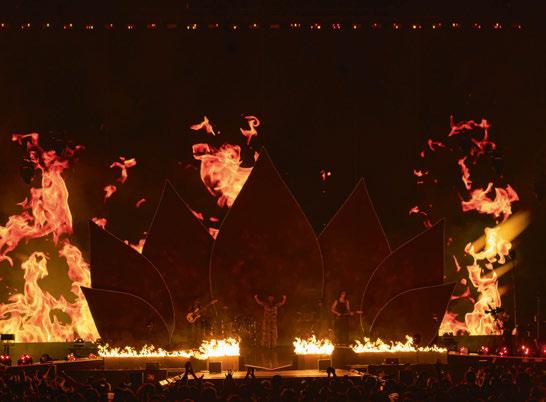

To celebrate two decades of the Australian metal act’s live shows, the band’s creative team enlists ER Productions to create a jaw-dropping show with pyrotechnics and special effects aplenty…

Parkway Drive have long been a mainstay of the alternative music zeitgeist, steadily elevating their production values and becoming certified headliners across festivals and arenas worldwide. For their latest anniversary tour, the Aussie metal group pushed their stage show to new heights, deploying an eye-watering level of pyrotechnics and special effects.

Clips quickly went viral on social media including one moment where pyrotechnics were fired from an automated bridge above the audience while the entire stage was engulfed in flame, firmly capturing the attention of fans and industry professionals alike. With the tour coming to an end, TPi jumped on a call with ER Productions to learn how a show with this much firepower comes together. “We were approached last summer to work on the Australian leg,” began ER’s Dan Mott.

ER Productions had worked with the band previously as well as collaborating with the band’s Creative Designer, Sam Tozer on several occasions. “Ben Fenwick, the band’s Production Manager, flew to the UK from Australia for a creative meeting that helped set

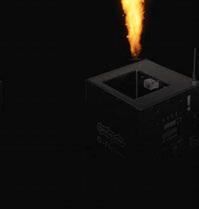

the vision for the tour,” explained Mott, who got to show Fenwick several of the company’s new products, which included FABER Engineering’s new FlamebER.

With the tour kicking off in Australia, ER’s relatively new outpost in the country handled the first iteration of the production. “We only opened our Australian office a few years ago so it was great to bring out a show of this scale from that base,” mused Mott, also commending the work of the entire team making some of the looks achieved possible despite Australia’s stringent health and safety measures.

The road team comprised Michael Morey, Tom Freeman, Matthew Marwick, Ron Spizak, Jay Scrivener and Sam Wakerley. For the UK and European run, Freeman and Marwick stayed on and were joined by Dan Wilce, Michael Attkinson, Gary Sharpe, Paolo Roselli, Eden Mclachlan and Sam Batchelor. “We had six crew out on the road at one time, as well as an arctic worth of equipment,” stated Mott, praising Project Manager, Nina Clements. “Project Managers are often not mentioned but she did a great job,” stated Mott. Despite some slight alterations, the Australian and European

shows were very similar with ER providing 80 FlamebERs – a solution created by ER Productions’ FABER Engineering division – 40 G-Flames, 14 Liquid Flames, six Stadium Shots, seven Luminous Hydrotech heads and eight Eco2Jets. ER Productions also provided Low Fog, with effects controlled by Galaxis software and an MA Lighting control surface.

Freeman, one of the key players of the SFX team on the road, walked through how all the looks were choreographed: “It’s a collaborative process between artist, production and ER. Together we design pyro effects and moments that match artist expectations, to fit in the venues and around other supplier equipment, all while being able to fire safely. When all of this comes together in rehearsals, we check that there are no surprises or changes, and that it all will work as planned.”

With the looks set, the team began programming all the pyro cues that created the best visual impact. “We’ll do a couple of band rehearsals without pyro and SFX, so we can see where the band will be at the specific moments. Once we’re happy, we’ll do flame and pyro commissioning for ourselves with a closed

stage – only us on stage with our air guitars – to test each individual unit and its direction of effect before putting the band up there for a ‘hot’ rehearsal.”

Freeman stated that it was great working with such a seasoned band that had played their material for many years and knew exactly where to be on stage “and more importantly where not to be,” he said. “There were 77 individual flame fixtures and 20 pyro positions on the stage, most of which were active at the busiest points of the show! There really were only four places on stage that weren’t on fire, and we had a band member in each. Knowing the guys were going to be in the right place was a huge help.”

As w ill come as no surprise, safety was paramount, with ER deploying a comprehensive package of safeties and E-stops, both at control and at various points around the stage. “Come show time, the audience see a show that hopefully made some memorable moments for the fans, whilst keeping the band safely performing amongst the effects and pyro night after night,” he stated.

For one notable moment during the show, lead singer Winston McCall was elevated high above the crowd on a bridge and then, when it was at a set height, flames shot horizontally above the crowd. For this moment the team taught McCall specific signals that he would give if he was not happy, so they could stop the effects.

Mott highlighted other safety measures incorporated in the package: “We had the Magic FX Safety Arm System on all our flames,” he said. “It’s relatively new and gives operators the ability to have remote E-stops on specific

Open the Trade Expressway. GETshow helps you, Easily expand into the international market. Zone

We cordially invite you to visit and purchase professional lighting and audio systems in Guangzhou,China

Welcome to contact and register for exhibition services!

Booth consultation : Ms.Tina :+86 18138780160

URL: https://www.getshow.com.cn/ E-mail: info@getshow.com.cn

bi-directional

•A range of control options including DMX512, 12-24V, ext. contact, radio and RS-485 offer unparalleled versatility

•The internal fitted battery provides up to 110 h stand-by time with no tethered power cables giving greater portability

•Water resistant, with improved water drain system

•Operation with readily available and inexpensive gas canisters, aerosol canisters or gas cylinders possible

•Fuel canisters are completely encased in the housing and therefore well protected

•Canister holder fitted with non-return valves for additional safety

•All components are equipped with quick-couplers for fast assembly

•Independent operation when used with the optional Advanced radio module or wireless DMX receivers

•Integrated fine filter prevents particle ingress and leakage of solenoid valves

•Equipped with two solenoid valves connected in line for increased safety

•Electronic flame monitoring by means of a highly selective optical sensor

•Equipped with digital tilt sensor for maximum safety

•Bi-directional communication with the PFC Advanced controller and USB Radio Modem PFM Advanced for remote programming and remote data requests

•Prepared for quick mounting on stands and truss elements

•Illuminated text display with convenient menu navigation

•Optical warning when armed

•Delayed ignition after gas release programmable (Atomic Effect)

•Fast step sequences possible because the flame extinguishes within a short time of solenoid valve closure, even during canister operation

•Additional features: Flame quota, flame duration limit and optional sleep mode

Control Inputs:

•Radio: -

-

•External

•Voltage

•DMX512,

fixtures as well as a warming system when it is about to fire.” He further explained that the E-stop allowed operators to disarm the fixture without it powering down. The protocol also means that a spotter can shut down a specific fixture without losing all the effects in the show.

Mott highlighted the use of timecode to fire the show: “It was a necessity as there were simply too many effects to busk. With the effect firing via timecode, it also meant the team are

just focussing on the safety, both with the Magic FX Arm system as well as a DMX safety via the faders on the console.”

He closed by stating that setups like the one deployed on Parkway Drive really showcase the maturity of the industry. “We’ve been using timecode to launch effects for around 10 years but these days it’s becoming the go-to rather than busking. It also requires a different set of skills as an operator. Before we were always

looking for people with musical timing but now there is a far bigger focus on the programming side,” Mott added. “It was a pleasure working with the entire team. It was such a unique show, and incredibly exciting to collaborate with an iconic Australian band – first through our Australian office, and then by supporting the same tour and design from our UK office.” www.parkwaydriverock.com www.er-productions.com

No compromise IP65/66 high-output low footprint

LED WashBeam and FollowSpot

Discover more

Castles, catwalks and control: MOTOR Stage Automation helps power Sabaton’s latest live offering…

Sabaton and their 200-strong touring crew have announced themselves on the European arena circuit with a production that matches the Swedish power metal band’s reputation for theatrical, history-infused live performances. Their latest touring design features a towering castle, a support orchestra, an automated drawbridge with integrated lighting and smoke, a rising and descending drum riser encased by inflatable hands, and fire-breathing dragons – an ambitious brief which required equally ambitious engineering.

MOTOR Stage Automation, based in Denmark, began its relationship with Sabaton a year ago, flying a tank set piece during the band’s set at Sweden Rock Festival in front of 60,000 fans. Drummer Hannes Van Dahl performed inside the tank itself. “A strange request, but one we certainly rose to,” recalled Jimmy Johnson, Automation Project Manager for The Legendary Tour and Technical Sales at MOTOR Stage Automation.

Production Manager, Johan Bengs wanted a system that was quick, safe and efficient –not only to meet tight show-call demands, but to give the crew adequate rest on an intense touring schedule. The band, known for spending time among their fans, also required a stage architecture that let them physically connect

with the audience. “The best way to do that was to utilise our automation solutions and integrate them fully into the show,” said Jimmy.

Central to this was MOTOR Stage’s M:CAT automated catwalk, which would become a defining element of the tour. Early conceptual meetings saw MOTOR Stage sharing Vectorworks drawings and product catalogues with the band and creative team, among them bassist, band manager and co-designer, Pär Sundström and Lighting Designer, Bertil Mark.

“T he aim was to achieve their vision – the castle, the inflatable hands, the drawbridge, while guaranteeing the level of safety essential for any automated system,” Jimmy explained.

Af ter initial prep at MOTOR Stage HQ in Horsens, Denmark, production rehearsals continued for two weeks at BBM Clair in Berlin.

The design was informed by available inventory – including a 70m cable limit for floorbased drive racks, which set strict parameters for positioning the B-stage and the connection to the main stage. “This is one of the band’s largest shows to date, and their fanbase has grown accordingly. Everything needed to scale up safely,” Jimmy added.

Safety was overseen by Blumano Associates, brought in as specialist consultants. “There are a lot of ‘what if’

questions, from engineering to working at height,” Jimmy said. “If we can remove doubt for the artists, that’s when they can truly perform.”

For the drum riser, Hannes was secured in a restraint harness, with eight RCF Light Locks, some double-stacked, sub-hired from Neg Earth Lights to prevent platform drift.

A deadlock system ensured the riser could not move unless Hannes was fully strapped in. Integrated lighting within the MLT4 system was installed via MOTOR Stage’s sister company Vigsø, with wiring by PRG as part of their master rig. The truss and catwalk were fully pre-rigged, supported by collaboration with HOF, who helped further develop the M:CAT system.

Their dollies allowed the MLT4 elements to be sent quickly into the rig “much like you would approach with lighting,” said Jimmy.

The smooth integration of automation, rigging and lighting impressed him most: “Head Rigger Yose Lawson worked closely with UK Rigging to ensure clear paths and safe working zones. Service hoists meant we could fix issues without climbing.”

As Automation Programmer and Operator, Kentaro ‘Ken’ Johnson ensured the full automation package operated seamlessly on

site, as part a team of four overseeing 14 hoists on the catwalk leading to the B-stage, plus four 1250kg units on the drum riser – each hung on two separate mother grids built from MLT4 truss. One grid sat above the lighting, the other extended above the audience to the B-stage.

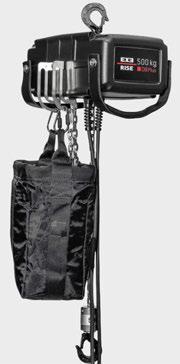

MOTOR Stage Automation deployed a full MOVEKET system with dual Expert desks (primary and backup) and an automation barge housing all drives and low-voltage motor control in the grid. “Load-in and load-out is straightforward,” Ken explained. “Two caddies of cables come straight out and into the roof –we’re live within half an hour of powering on. It’s a very efficient system.”

MOVEKET was chosen for its suitability over audiences and its compliance with EN 17206. “Each hoist has its own configured drive. Once set in prep, it stays consistent throughout the tour,” Ken said.

With over a decade’s rigging experience, he stressed the value of load understanding: “We’re moving a lot of weight – the drum platform is just over two tonnes with pyro and lighting; the bridge is just over five tonnes; and around eight

tonnes including hoists and catwalk suspended from the mother grid.”

MOVEKET’s SIL3 rating was a key factor. “All the technology talks to each other – load monitoring, fault reporting, global E-stops, deadman switches on everything. The data feedback gives the operator real confidence,” Ken added.

Additional safety layers were built in, including an isolation switch for the drum riser. “If a spotter or drum tech isn’t happy, they can isolate the riser instantly. It cannot be controlled until it’s safe.”

Two mechanical constructs defined the show’s automation: the drum platform and the main drawbridge leading to the B-stage. The riser moved between load-in height and balcony level – Hannes mounts at the mid-position before ascending to full height, performed twice during the set. The drawbridge is the show’s signature moment, used for band entrances and audience interaction. “It’s a very theatrical show, so actors distract the crowd during movements,” Ken said. During Attack of the Dead Men, smoke machines under the catwalk

activate as the bridge lowers over the audience. “Automation becomes part of the storytelling, not just a transport mechanism.”

The 24m catwalk and 30m bridge (28m with stairs deployed) run on a combination of 1250kg and 500kg hoists.“MOVEKET treats the whole thing as one object, providing synchronised movement. If any error is detected, the entire construct stops – ideal from a safety perspective,” Ken noted.

Touring with 42 stagehands – trained during rehearsals – brought consistency to daily workflows. With 26 trucks, including three dedicated to automation (one for the catwalk alone), the tour required tight scheduling. Advanced rigging meant hoists were hung before the touring crew arrived. “We start unloading at 9am and are fully assembled by midday. Automation rolls in ahead of lighting –the catwalk has integrated wheels, so it glides straight out,” Ken added.

“MOTOR Stage is brilliant,” he continued. “With a four-person automation crew, we can rotate and rest which makes an enormous difference.” The wider automation team featured MOTOR Stage Automation Project Manager, Jimmy Johnson; Operations Manager, Daniel

Klausen; Special Projects Engineer, Valdemar Enemark; Automation Crew Chief, Martin Kirch; Automation Programmers and Operators, Samuel ‘Sam’ Colclough and Kentaro ‘Ken’ Johnson as well as Automation and Performer Safety Technician, Gareth Sumnall.

Having wrapped projects with Dua Lipa in South America, Lewis Capaldi and now Sabaton, 2025 marked a landmark year for MOTOR Stage Automation. “Production managers and designers value a personal touch,” Jimmy concluded. “We’re a family-orientated company – from the office to the road. We’re excited to see the HOF MLT4 pushed to its limits. It’s fast, efficient, and made for this kind of show.”

Speaking to TPi backstage, Sabaton drummer, Hannes Van Dahl concluded: “This tour has been in the works for two years, and it takes a great deal of time to prepare and decide what we want to do. It’s been a long journey to get here but it’s been a blast – 200 people all working their asses off to deliver a truly great show. It’s a dream come true and we’re incredibly grateful for that.”

www.sabaton.net

www.motor-stage.com

www.moveket.de

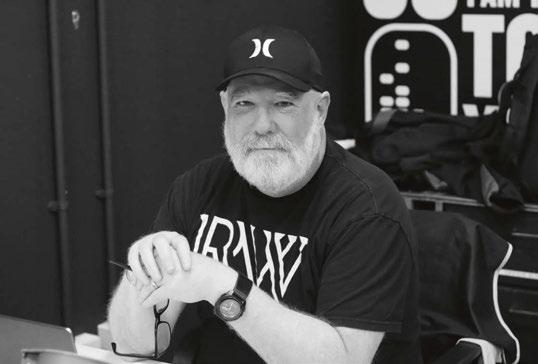

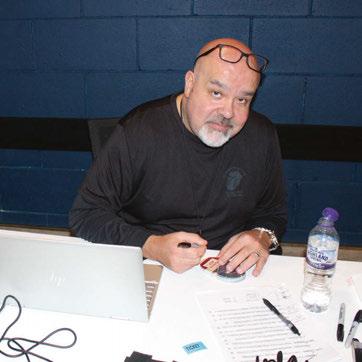

Automation Project Manager, Jimmy Johnson of MOTOR Stage Automation with Automation and Performer Safety Technician, Gareth Sumnall, Automation Crew Chief, Martin Kirch and Automation Programmer and Operator, Kentaro ‘Ken’ Johnson on site at Manchester’s Co-op Live.

The artist, his crew and technical suppliers bring audiences closer than ever to the on-stage action…

Following one of this year’s most talked about Glastonbury Festival headline performances, Loyle Carner returned to the touring circuit with a live show stripped back in performance and production, which sees the same band involved in his most nuanced album yet take to the stage with him.

Meeting TPi at the stage door of the O2 Academy Brixton on the second day of Carner’s four-day residency at the venue was Production Manager, Eric Wade of EZ Services and Tour Manager, Chris Tyler. “The show is very dynamic, eye-catching and in tune with everything you would want in a performance. This is genuinely sonically and visually, one of the most accurate messages conveyed in a live show from concept to fruition that I’ve had the pleasure of working on,” Wade began.

Aiding the production manager on the road was Colour Sound Experiment (lighting), Britannia Row Productions (audio) and All Access Staging & Productions (staging).

“T hese suppliers are a ‘no-brainer’,” he explained. “Britannia Row has been a long-time ally of the camp and being able to lean on its global coverage has been beneficial. Colour Sound Experiment always looks after any production I’m involved in, from prep to the road. I have such a fondness for the team. I’ve collaborated with All Access for the past three years when it comes to staging and I don’t see any reason to change.”

Delving into the meetings before the tour began, Tyler explained that the line the team

worked toward was ‘big stage intimacy’. He elaborated: “We didn’t want the usual fanfare, and as we were working towards this huge headline on The Other Stage at Glastonbury, we also had the tour on our minds, but the idea was to invite fans into the warm, intimate world of his music.”

Having headlined OVO Arena Wembley on his last album cycle, the stripped-back attitude extended towards the venue choices for the hopefully ! tour, with the artist choosing to do multiple dates in smaller venues in each city instead, bringing him closer to audiences. “The team didn’t want the anonymity that comes with the bigger rooms for this record,” Tyler said. “Intimate has definitely been the word of the tour and has been the world we’ve been aiming for show on show.”

Wade echoed Tyler’s statement and described the benefit of walkaway shows for this specific production: “There is a comfort in being able to work the same schedule for a couple of days in each place, which has been great – the crew on this have been fantastic and steadfast in their dedication to the show,” he said. “They are continuously making the show better each day for the rooms that we’re in, they are always tweaking something and making the show a higher standard.”

For the tour and production management duo, the dynamic within the camp was a specific highlight. “We both attach a huge importance towards interpersonal dynamics. My company is called Golden Rule Production,

and the golden rule is: ‘Be nice’. We know touring is hard and stressful, so we’re trying to create a safe space where people can come to us if they need to,” Tyler explained.

Wade concurred: “It’s been a joy. This camp, this tour, is something precious I’m holding close to my heart and will do for a long time.”

With deep-seated closeness at the heart of the creative on the tour, Lighting Designer Will Reeve and Unlimited Dream Company (UDC)’s George Thomson worked hand in hand to convey the album’s feeling into a live show. “The creative for the hopefully ! tour is based right back to the beginning of the album creation process,” Thomson said. “Loyle Carner wanted to make a record with his live band, so they went into the studio and did it all together – it was important for him to show the audience how that experience felt for him and bring them into the ‘jamming’ process.”

Thomson utilised his foundations in architecture to convey that atmosphere on stage, beginning his design process through paintings and Photoshop which resulted in a band setup that gave each musician a view of each other, which echoed the album creation process. “We wanted everything to be restrained, stripped back and raw, just like the album,” Thomson explained. “The band looking at each other for the show makes it feel like more of a collective, it also means Avi [Aviram Barath, Musical Director] can act upon

opportune moments, and we get to see more improvisation from the band, which is great.”

Thomson and the team at UDC, with Glastonbury and the subsequent tour in mind, wanted to bring audiences into the same world but had the challenge of recreating the feeling for a field of 50,000 people compared to the venues, such as Brixton, with a 90% decrease in capacity. “We brought in a video package supplied by Vanta for Glastonbury, and they made a custom-fabricated mic stand camera for the occasion to bring people as close as possible,” Thomson explained. “But if we were to bring video into these venues, it would have the complete opposite effect and it was important to keep the core intimacy of the show.”

The lighting rig included CHAUVET Professional STRIKE Array 2, Color STRIKE M, COLORado PXL Bar 16 and COLORado Solo Bar 1; Ayrton Huracán LT and Rivale Profile; Robe iFORTE LTX; Martin MAC AURA XIP, and ARRI SkyPanel S60-C lighting solutions with a Smoke Factory Tour Hazer II providing atmospherics. Reeve cited the Martin MAC AURA XIP as the ‘workhorse’ fixture of the rig, situated on the overhead truss. ARRI SkyPanel S60-Cs also stood out to the designer, providing keylight. “We emphasised as little front light as possible on this show; we had the standard front and back spots, which we would utilise to silhouette him, and he was more than happy just to bask in that,” Reeve explained. “We had

to navigate when he did and didn’t want to be silhouetted and that’s just all down to watching his reactions on stage and knowing how to shine that the music stands for itself.”

Reeve utilised Syncronorm Depence software for previsualising the show, making the initial technical drawings using Vectorworks. On the road, Lighting Operators, Matt Davies or Johnny Myers conducted Reeve’s design from an MA Lighting grandMA2 console.

Reeve praised Colour Sound Experiment’s crew and support on the tour, both in the lead up and on the road: “It feels very full circle to have Colour Sound back on the gig, because they were with Loyle Carner when he was starting out and to have Alex Ryan to deal with directly has been such a treat; they have been attentive and on the ball.”

Musical Director, Aviram Barath, ensured the studio album’s sound translated live. “The aim is to bring the attitude of the album into the show by being as respectful as possible towards the decisions we made in the album process,” Barath said. “At the same time, we’re allowing enough space for real-time decisions and musicianship so the momentum remains.”

Intimacy, the word that reverberated through the camp, was also crucial to Barath’s process when working with Loyle Carner to portray the same dynamic in a live setting that was

All the features you ever dreamed of – in one unit.

TheTRUe INDOOR FIXTURE

Lightweight and Compact. No compromises.

TheTRUe

HIGH CRI UNIT

No filters. No LED changes. Always accurate.

No filters. Just a real Fresnel or PC lens.

IP54 rated. Built for the real world.

Over 20,000 lumensVariable CRI up to 93.

cultivated between the band in the studio. “Ben didn’t want to be in front with a faceless band; it’s more that the stage is now a group of friends who have created lots of music together, and we’re inviting them to come along with us,” Barath explained.

“We’re enjoying ourselves in the hope that other people can come enjoy it, too,” he added. “Verbal language has its limitations. Whenever we try to describe music, it always feels a bit stupid or reductive, but with this show, Loyle Carner has surrounded himself with people who he has an ongoing musical communication with – we don’t have to talk much but we’re closer to the vision.”

FOH Engineer, Jay Thomas Heigl mixed on a Solid State Logic L550 console with Universal Audio Live Racks, Waves Audio servers and a Pro Tools Saramonic SmartRig+. “I’ve been using SSL for years; I originally moved over to see if I could get a better quality from the preamps. When we were working on Loyle Carner’s Royal Albert Hall show a couple of years back I was working with 64 Neve 1073 DPX Dual Preamps, and I was blown away by the quality I was getting into the desk and I wanted to see if I could replicate that quality and make it tourable, and SSL was the route I took.”

For Heigl, energy was paramount: “Ben is moving in a different space right now, and the

difficulty for me was bridging the gap between what we have been doing in the previous campaign and trying to find the nuance in between,” he commented. “I’m focussing on musicality and colour, whereas before it was all full of energy as a rap show – I’m still trying to find those moments when I need them, but now I know when to pull it back.”

The hopefully ! tour was the first time Loyle Carner had sung on stage, which saw some adaptations from Monitor Engineer, Matt Wickens, who utilised a DiGiCo Quantum 338 console with Sennheiser Spectera wireless system. “The workflow on DiGiCo is so crucial to my show. The Macros system saves me so much time, and since the Quantum series I lean heavily on Mustard and Quantum processing the flexibility is a bit of a no-brainer for me,” Wickens said.

Loyle Carner’s in-ear monitors of choice were Cosmic Ears C8A, with some of his band utilising a mixture of Ultimate Ears and Cosmic Ears models with Wickens selecting JH Audio.

“I have moved onto digital ears recently, and I try to keep it as locked into the DiGiCo console as possible. I’ve been working with Cosmic Ears and Sennheiser on this tour, as it is a flagship tour for the working relationship between them,” he stated. “I have found Sennheiser Spectera to be second to none for

audio quality. The noise floor is incredibly quiet – I have 16 stereo mixes, and the scalability is very good.”

Bot h engineers praised the support from audio supplier, Britannia Row Productions, and shouted out Olesya Lesyk, who joined the camp from the vendor, and Account Executive, Ed Shackleton. “The support Olesya has given us has been incredible and is a perfect demonstration of the entire Britannia Row team,” Heigl commented. “Ed will always make sure we have everything we need, whether it is last-minute or not.”

Shackleton reflected on his involvement: “It’s been another great experience working with Loyle Carner’s production team. His stage prowess at Brixton Academy was amplified by brilliant engineers who we are very proud to support with full audio services.”

With Loyle Carner reaching new heights following the release of his fourth studio album, the Hopefully tour favoured old-school sensibilities with a personal performance style that brings fans closer to the artist than ever before, thanks in part to the dedicated crew. www.loylecarner.com www.allaccessinc.com www.coloursound.com www.britanniarow.com www.unlimited-dream.com

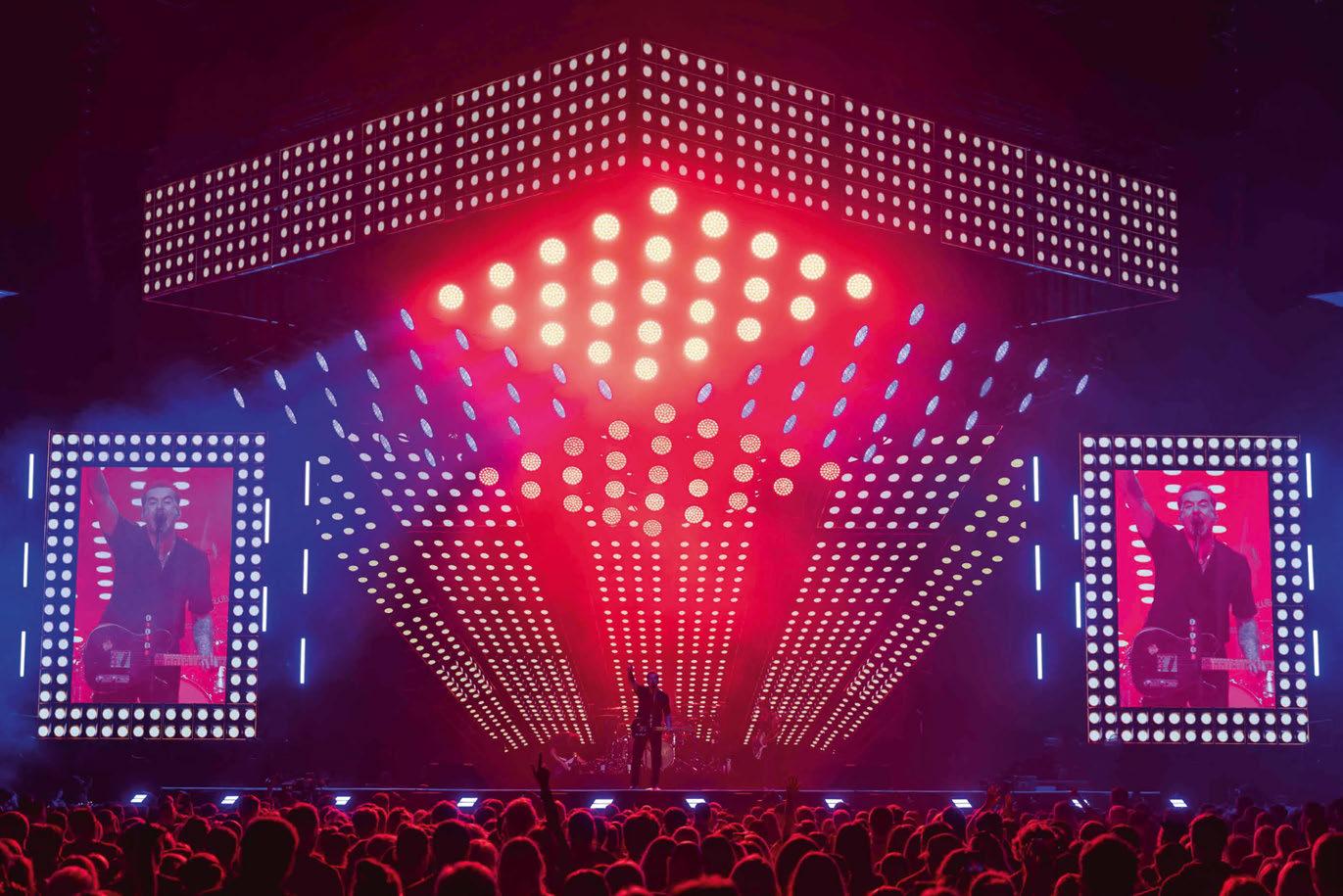

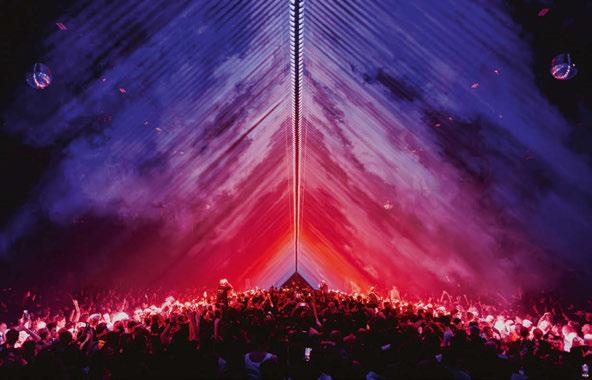

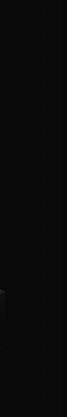

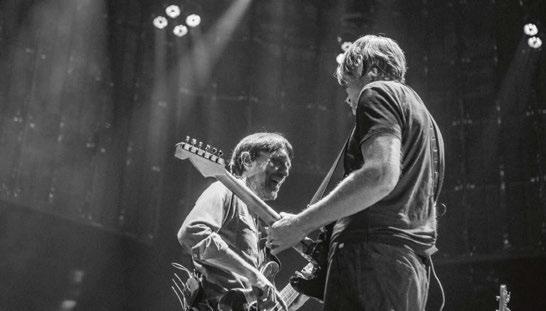

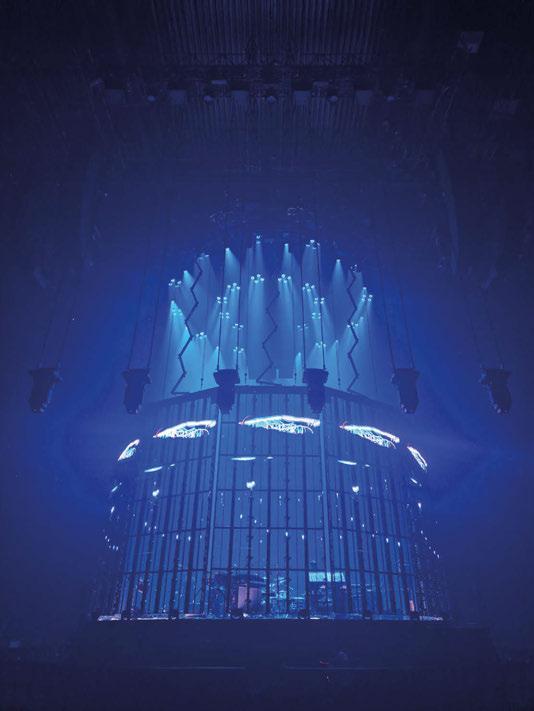

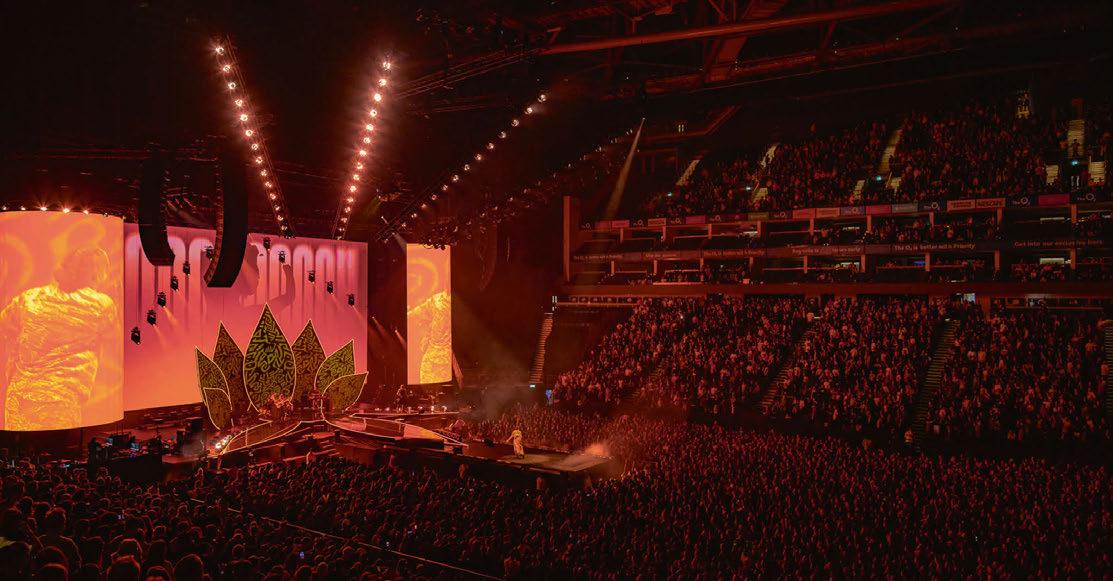

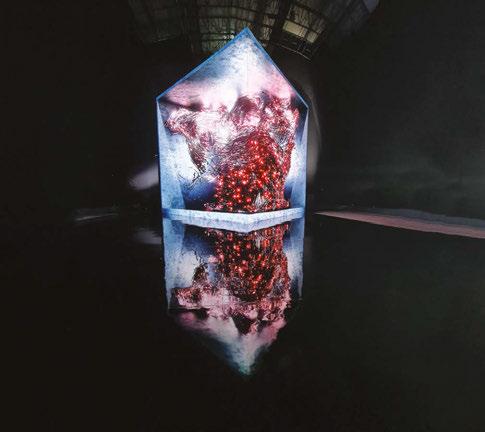

Radiohead and their touring team transform arenas across Europe into immersive panoramas of motion, innovation and artistry, breaking attendance records along the way. Well, what did you expect from a band renowned for redefining the live experience?

After seven years away, Radiohead returned to the stage with one of their most technically ambitious productions to date – the band’s first ever ‘in-the-round’ concert experience, featuring an automated video ‘halo’ with 100% real-time driven visual content, a Metallicainspired TM Array, and the largest ever touring use of kinetic lighting winches among the production highlights.

Having wrapped up eight months on the road with Robbie Williams’ BRITPOP Tour [see TPi #289], Production Manager, John Lafferty – who has orchestrated the logistics of the band’s touring exploits since 2017 – flew from Istanbul to London to assemble the campaign. “It’s great to be back with this band,” he began.

“T hey are such great people who have a lot of time for their crew. The organisation between management and booking agencies is like no other.”

Production Designer, Sean Evans, put together a design for the tour in February 2025, enlisting Wonder Works for CAD drawings and the idiosyncrasies of figuring out cable management and dealing with technical vendors. “We worked hand in hand for months to get it where it is now,” Lafferty stated, proudly, showing TPi around the floor ahead of the band’s final show at The O2.

The tour’s suppliers included Britannia Row Productions (audio), Lite Alternative (lighting), WHITEvoid (KINETIC LIGHTS), Universal Pixels

(video), WICREATIONS (automation), TAIT (staging), Popcorn (catering), McGuinness (trucking), Phoenix (artist travel), Equinox Travel (artist and crew travel agents), Surfhire (radios, digital communications, Wi-Fi and RF licensing), among others.

The production loaded into Fly By Nite Rehearsal Studios on 11 October 2025 with two weeks of tech and programming while the band rehearsed at The Church Studios. “Radiohead were one of the first artists we welcomed when we opened in 2016,” FBN Studios’ Scottie Sanderson commented. “The crew are all relaxed, and it is a finely tuned production team. It was a pleasure to host them.”

Closer to the tour, the band moved to AED Studios in Lint, Belgium. “We needed a minimum of a 20m rigging height, as anything lower compresses the show, so to find a place for seven days was a blessing,” Lafferty recalled. “However, the challenge with it being a broadcast studio is hanging it, so it meant we had to get spreaders for us to make it work. A collaboration between us, Stageco and PRG Belgium to make it happen.”

To t ransport the production from A to B, McGuinness Trucking provided 16 production trucks and one merch truck. Lead Truck Driver, Noel O’Regan and Truck Driver (2nd), Linda Scoffin were supported on the road by Drivers, James Finnegan, Dirk Mullers, Luigi Mainiero, Rui Pinto Nogueira, Piotr Kostanski, Sergejs

Pavlenko, Imants Glaudans, Tamas Osvath, Igor Kusnarjovs, Miguel Rodrigues, Manuel Jimenez, Neringa Narkeviciene, Attila Kiss, David Bereczki and Merch Truck Driver, Tom O’Dwyer.

“We’ve been involved with Radiohead tours for the past 25 years, and they’ve always been incredibly loyal and supportive. When the 2021 tour had to be cancelled because of COVID-19, they honoured all their commitments and checked in with us throughout, which meant a great deal,” McGuinness Trucking Director, Siofra McGuinness, commented. “It’s a longstanding relationship built on trust, and it’s always a privilege to be part of what they do.”

Phoenix Bussing provided a 14-berth double decker from its fleet for the artist party. “It’s been a great tour for James Baugh, the driver; as ever, Ade Bullock and SJ have looked after him extremely well,” said Phoenix Bussing’s Garry Lewis. “Hopefully, this has whetted their appetite for more touring.”

St arting at 4am with mark out, tipping catering and production, by the time the mark out is done, the production team were into rigging. “We try to give the riggers around two hours before we start encroaching. It works well; since we have the whole arena floor, we can start staging and pre-building before we roll into hanging motors,” Lafferty said.

Assembled by Head Carpenter, Stu Sims, Carpenter, Stephen ‘Xumi’ Schumacher and a team of local crew, TAIT supplied a

custom-built dodecagon stage, complete with integrated LED deckettes to provide foot lighting around the perimeter.

The team also produced a manual drum revolve, FOH platforms, custom decks to allow for stair removals during sets, and audio monitor hammocks that housed the monitors beneath the stage, using circular grills to allow sound to travel up through the stage. The under stage area was designed to remain as clear as possible, giving the crew unobstructed access.

TAIT Project Manager, James Pemblington collaborated with John Lafferty and Wonder Works’ Jeremy Lloyd throughout rehearsals and the build. “The process was smooth, with only a few minor refinements made on the ground,” Pemblington said. “As someone who’s followed Radiohead for years, it was a privilege to contribute to one of their productions.”

The wider 2025 Radiohead Tour team included: Managers, Brian Message and Julie Calland; Tour Manager, Ade Bullock; Assistant Tour Manager, Sarah-Jane Pearson; Assistant Tour Manager and Physical Therapist, Shannon McEwen; Security, Cory Price, John Novo, Simon Preston and Advance Hotel Security, Dario Campos; Venue Security Director, Colin Lish; Venue Security Lead, Dave White; Venue Security, Darren Edwards; Production Coordinator, Jil Aram; Production Assistant, IT, Communications and Eco, Katie Friesema; Tour Accountant, James ‘JB’ Bullock; Stage Manager, Jesse Thayer; Assistant Stage

Manager and Utility, Chris Roper and Pieterjan ‘PJ’ Nouwynck; Head Rigger, Reuben Pinkney; Rigger, Matt Lazenby; Merchandisers, Morty McCarthy and Neil Bunn; Furniture Technician, Scotty Thawley.

“T he reception has been unbelievable. This production is different to any other Radiohead show,” Lafferty stated. “The visuals are stunning. The setting is different. The band feeds off the audience. Like many others, I’ve grown up listening to the band.”

Tour Manager, Ade Bullock, has worked with Radiohead in different capacities since 1997. However, this campaign marked his first as TM: “I’ve never seen them happier,” he said of the band. “The shows are amazing! There are no bad seats. They walk to and from the stage and it adds to the build-up of the show. There is something about this band that makes everyone go the extra mile, as they treat us all well and we’re all fans.”

‘INTIMACY AND INNOVATION’ Wonder Works was appointed to lead the technical design, coordination, and technical direction of the production, transforming the creative brief – a video-led, in-the-round show – into a touring reality.

Working closely with Creative Director Sean Evans, Lighting Designer Pryderi Baskerville, and Video Director Ellie Clement, Wonder Works developed the engineering solution for the moving transparent LED screens, kinetic

lighting system, stage, audio sub-frame design, and rigging, lighting, and audio integration. The kinetic lighting system was supplied by KINETIC LIGHTS (WHITEvoid), whose technology enabled precise, programmable motion for each individual fixture.

The concept placed Radiohead at the centre of a constantly shifting visual environment. The band performed inside a ring of 12 ROE Visual Vanish 8T LED panels, forming a suspended halo that enveloped the stage and moved independently throughout the show. Each screen could rise, lower, and rotate, allowing the structure to transform fluidly in response to the music. Live camera feeds were blended with Notch effects to create an evolving visual language that ensured every performance felt distinct yet unmistakably Radiohead.

This was far from a standard arena setup. The in-the-round format demanded 360° visibility and uncompromised sightlines. The design team replaced traditional lowering trusses with 60 individually controlled winches, each carrying a moving light that travelled independently above both stage and audience. The result was a kinetic, sculptural lighting system that shifted dynamically without obstructing the view from any angle.

The same level of precision applied to the sound design. Working with System Designer Josh Lloyd at Britannia Row, Wonder Works helped develop a custom central rigging frame to suspend four hangs of L-Acoustics KS21

subs in a compact configuration, maintaining the band’s signature low-end presence while preserving visual clarity.

Wedge monitors mounted beneath the stage, with grilles built into the decking, further reduced the production footprint and kept the aesthetic clean and unobtrusive.

Weight distribution proved one of the most significant engineering challenges. With more than 50 tonnes of equipment suspended at the centre of the arena.

Wonder Works – alongside Production Rigger Reuben Pinkney – coordinated and optimised the rigging for all departments to ensure safe, repeatable deployment.

Sustainability and touring efficiency also underpinned the design approach. The system was built primarily from rental stock, with minimal custom fabrication and efficient truck packs. Wonder Works co-Director Jeremy Lloyd commented: “Radiohead has always pushed the relationship between music, art, and technology. This show was about finding the balance between intimacy and innovation – delivering a production design that felt alive and reactive but never distracted from the performance itself.”

‘KEEPING IT FLUID’

Production Designer Sean Evans first posed the ‘in-the-round’ concept to the band,

ensuring the overall vibe felt welcoming and natural. “I thought they’d really dig the in-theround idea – being immersed in the crowd. I’m a huge fan of 2008’s In Rainbows – From the Basement feel, and the idea of replicating that in a larger room, making it feel like you’re in the studio, seemed like a cool vibe,” he explained.

“I’ve seen them play countless times and they’re amazing. No backing tracks – just six guys on stage making music. They’re musos, so having them concentrated in one space and able to interact is thrilling.”

A major design goal, he noted, was accommodating the band’s fluid set list. “You can’t do anything on a strict timeline – everything must be flexible. Being able to present something experimental and a bit weird is a joy when you’re collaborating with a band like this in a live setting,” Evans said. “I love the idea that the cheap seats get the best show in the house.”

Evans undertook extensive previsualisation. “A lot of the early sketches were built in the venue using a CAD model, constantly evaluating sightlines to make sure the vibe was right for everyone. I like taking an arena-scale design and making it feel intimate. It’s meant to feel communal,” he said.

“T heir shows always look and sound fantastic but doing it all in the middle of the room is particularly cool.”

Automation, he added, opened a wealth of possibilities. “There are all kinds of patterns and mapping within those patterns. Sometimes the screens move in a slow undulation – it might even be imperceptible to the audience, but it creates a great energy. The combination of automated screens and lighting lets us shapeshift the room. The ‘fan-out’ moment during Karma Police is brilliant.”

All visual content was driven through Notch. “We generate weird content to keep it fluid –there’s no need to worry about a timeline, and we’re not mangling the band. It’s a simple VHS look, but all the distortion is controlled by hand on sliders, so it’s easy to keep in time. I love Notch – it’s fun to use and super powerful. Not having to render content, having everything in real time, is amazing. And the way Notch integrates with Disguise media servers is fantastic,” he added, praising the crew.

“It’s powerful having someone like [Video Director] Ellie Clement and [Lighting Designer/ Director] Pyrderi Baskerville at FOH, playing off the band’s energy with their hands on the sliders. The crew are amazing. The way they drive the show is impressive, and the fact everything is live is fantastic.”’

‘CALM LEADERSHIP AND CREATIVITY’

The show’s video element relied on realtime generative content, mapped in multiple

configurations to accommodate the shifting geometry of the moving screens. Each look combined busked responses to the band’s performance with software-driven sequences, all manually triggered and controlled via MA Lighting grandMA3 consoles.

One of the earliest sequences Evans designed was All I Need, drawing on In Rainbows and layering RGB colour. He also highlighted the opening of Planet Telex, the fan-out moment during Karma Police, and the piano-mounted camera in You and Whose Army? “There’s a lot of taking live loops of the band and overlaying them on themselves. It looks like a subtle prerecord, but it’s all live,” he said.

“T he video effects rely heavily on how the band and arena are lit,” added Video Director Ellie Clement. “Pryderi has a real skill for balancing what the video needs without compromising the mood he creates.” She also credited Camera Director, Drew Mercadante: “Drew has been brilliant cutting cameras and tweaking effects as the show has evolved.”

Mercadante of SUPERVOID.tv joined the conversation: “I grew up listening to the band, so being involved is surreal. The set list is open, so the brief was to build a giant toolkit of looks rather than tie ideas to specific songs. The directive was: ’90s VHS – textured, glitchy.”

Not every look was complex. Simple grain overlays via an Edge Dictator could create trail-

heavy or trickling effects, while other moments leaned into abstract visuals, pin-art-style imagery, and CD-era distortions. “The whole show is in Notch – no pre-renders – everything real-time,” Mercadante explained. “It makes for an exciting show, and Radiohead being Radiohead, means we can experiment.”

He detailed the system’s flexibility: “There are three MEs on one song. We use the multiview as an input, send two screens to Disguise, and within Notch we clone and noise-cycle through camera feeds we’ve preselected. We can ‘park’ the noise on whichever feed fits the tempo. The band have always loved that CCTV vibe, so we wanted to honour it.”

Mercadante also praised the Blackmagic Designer switcher at his fingertips. “It does everything we need and more. We use the Supersource to build four-way multiviews for backline techs. The macro capability saves us 20 seconds of routing each time. This is my first time working with Universal Pixels and it’s been great. Ellie thought through the whole system. Every time they play How to Disappear Completely – a song that got me through a lot – I get to watch it from the best seat in the house.”

The video system centred on 24 cameras: 17 mini cameras and seven PTZs, all required to be available on screen simultaneously. “Each camera had its rigging optimised to reduce vibration from the stage, which has worked

Left page: KINETIC LIGHTS Crew Chief, Lutz Rennart; Some members of the video crew; Lighting Crew Chief, Blaine Dracup with Lighting Designer/Director, Pyrderi Baskerville; Automation Crew Chief, Programmer and Operator, Chris Sabelleck. Right page: Production Manager, John Lafferty; Monitor Engineer, Daniel Scheiman with FOH Engineer, Simon Hodge; Tour Accountant, James ‘JB’ Bullock and Tour Manager Sarah-Jane Pearson with Assistant Tour Manager/Physical Therapist, Shannon McEwen and Tour Manager, ‘Ade’ Bullock; Camera Director, Drew Mercadante.

incredibly well,” Clement said. Blackmagic Micro Studio Camera 4K G2 minicams were selected for their flexible lensing and tactile controls. “With the BMD infrastructure we can remotely rack them with familiar CCPs and adjust zoom and focus as needed,” she noted.

Panasonic PTZ cameras were used by backline for monitoring and were adjusted by operators when required. A Polecam Autopod/ Waterbird system was specified for its compact footprint and ability to form a custom curved track around the stage.

Video Engineer Owen Evans oversaw the 24 stage-level cameras. “Everything comes back to us over fibre in UHD 4K,” he said, speaking from ‘video world’ at The O2. “We’re shading a lot of cameras, so we’ve developed tricks – traditional RCPs for the PTZs and moving heads, with companion apps tying the static cameras together. Backline techs see our feeds via multiviews and under-stage monitors. Pryderi has his own monitor and router panel for automation and the bird’s-eye camera.”

Fellow Video Engineer Piotr Klimczyk said this was his first in-the-round arena show. “I thought it would be spatially challenging, but it’s been smooth. There are 24 camera looms plus monitors, backline gear and audio and lighting infrastructure piled on the stage. More bandwidth is needed at this quality, but it’s the operators who have the tough job.”

Camera Supervisor and Operator, Dan English; Tracking Camera Technician, Harri Selby; Lead LED Technician, Jens Couckuijt;

LED Technician, Tyler Hilton and LED Technician and Camera Operators, Danny Sheldon and Kieran Yates made up the video crew. “Owen and Piotr are masters at juggling the camera-control science project. Dan English, who’s worked on The Smile and Thom Yorke’s solo shows, has been essential in leading the camera team. Tyler, Danny and Harri’s operating expertise brings real energy – they’ve captured some magic moments with perfect timing,” Clement said.

The system expanded into a “beast” of a full-UHD setup, integrating MIDI triggers, PSN tracking, Art-Net and sACN.

Both the ROE Visual V8T screens and ROE Strips were driven by Disguise GX 3 servers and Brompton Technology SX40 processing. “Control of the ROE Strips passes between video and lighting,” Clement explained. “We map content to them like any LED product but also treat them as metre-long RGB DMX fixtures. There’s not much else you could throw at a media server that we’re not already doing.”

Custom ROE Strip attachments for the V8T panels were designed by Wonder Works. “The Universal Pixels team has been incredible,” Clement added. “Custom camera connection units, power supplies to reduce cable spaghetti, custom camera-control software for the minicams, and a bespoke PPU – they’ve gone above and beyond.”

Universal Pixels Project Manager Hamanshu ‘Hammy’ Patel commented: “This is the most technically complex project we’ve done – 24 12G cameras, automated LEDs constantly moving,

and our first investment in automated and tracking cameras. We’ve enjoyed working with John Lafferty, Ade Bullock, Jeremy Lloyd, Sean Evans, Ellie Clement and Pryderi Baskerville.”

Video Crew Chief Bob Aitkenhead said: “It’s a lovely camp to be in. Most of the control is IPbased, racked backstage. Early on the cameras struggled with command latency, so Universal Pixels built custom elements to solve it.”