JOIN THE WAITLIST NOW

Introducing SB1 (Sensi Boost 1) — Advanced Nutrients’ 8th-Generation Breakthrough Brix, Resin & Terpene

Enhancer

Supercharge your grow with SB1 for massive, sugar-coated, resin-saturated buds exploding with flavor and aroma.

After 25+ years of research, we’ve cracked the code on crafting the sweetest, gooiest, most terpene-rich flower possible.

NanoCarb : Breakthrough nanotechnology enables direct sugar uptake, maximizing brix levels for unsurpassed resin production and terpene enhancement. Unlike conventional products with oversized sugar molecules that only feed substrate microbes, NanoCarb’s nanosized carbohydrates are absorbed directly into your plants, fueling rapid growth, significantly enriching flavor profiles, and intensifying the nose.

Phyto-Sacchara : Advanced Nutrients’ exclusive compound derived from fermented sugarcane extracts. This powerful biostimulant unlocks your flower’s fullest potential , enhancing flavor, quality, and bag appeal like nothing else on the market.

Maximize terpene production for an unforgettable aroma

Amplify bud weight and yield

Increase brix content for rich flavors Push trichome development into overdrive for unparalleled crop value

With over 25 years of science-backed innovation, Advanced Nutrients delivers solutions that growers in over 120 countries trust to maximize crop value. Don’t waste your time and money on subpar carbohydrates your plants can’t absorb. Harness SB1’s cutting-edge technology and experience heavier harvests of the frostiest, most mouthwatering flower you’ve ever produced.

STORY

From puff studies to performance standards, vaping is getting a high-tech makeover. Here’s how scientists, engineers, and brands are working together to create safer, smoother, more satisfying experiences.

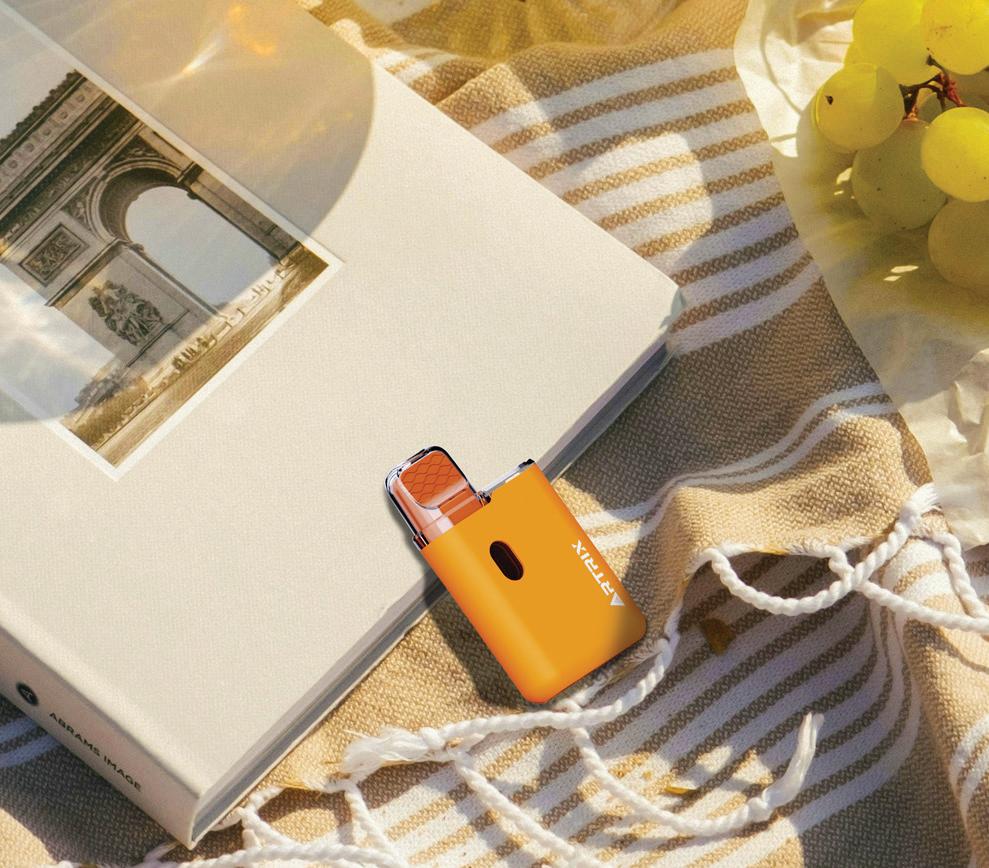

Trends: Next-Gen Vapes

From smart ceramics to glass pods and robotic filling systems, next-gen vape tech is reshaping the user experience from the inside out.

News, data, trends, and other tidbits for the well-informed professional.

Retailing: Spa Vibes

Alta blends family legacy, femininity, and hands-on design into a serene, high-touch sanctuary.

Guest Column:

Rapid Evolution

From cobbled e-cig hacks to sleek status symbols, vapes have come a long way in a short time.

Opinion: Quality In, Quality Out

Premium ingredients and attention to detail give brands an edge in a commodified market.

Manufacturing: Formulation Magic 46

Nano-emulsions change the game for edibles with faster, stronger, and more reliable effects.

Technology: Rise of the Machines 48

Manual labor can’t compete with machines built for speed and scale.

CAKE SHE HITS DIFFERENT’S DESIGNER DISTILLATE ALL-IN-ONE IS AMONG THE VANGUARD IN A NEW ERA OF CLEANER VAPES.

—THOMAS HARDY

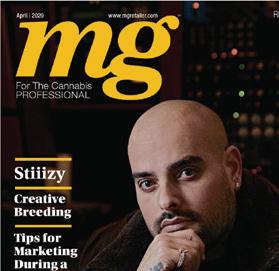

When mg Magazine examined the vaporizer sector for the first time, the consumption method was just beginning to hint at the consumer favorite it would become. A twenty-page special section published in the January 2017 issue (our eighteenth) revealed sales in the category during the previous year topped $146 million in the three states BDSA tracked: Colorado, Oregon, and Washington. The figure represented a 132-percent year-over-year increase.

Since then, the market has changed dramatically. A 2025 Grand View Research report pegged cannabis vape revenue across all United States markets at $1.73 billion in 2024. Part of the explosion was due to market expansion, of course, as more states legalized medical or adult use or both, but we can’t discount the role played by increasingly sophisticated technology, a wider selection of e-liquids, and growing consumer demand for discreet consumption methods.

Undoubtedly, technology has been a primary driver of consumer uptake. Each year brings new advances that address safety, portability, and suitability for emerging concentrate types. In the early days, most cannabis vape hardware was based on e-cigarette technology, modified

to address the challenges posed by thicker oils. Today, vapes are designed for cannabis extracts from the get-go, with the understanding vaping is becoming part of the zeitgeist. Contemporary devices incorporate an extraordinary number of features that improve the consumer experience by protecting flavor, enhancing effects, and adding a little fun.

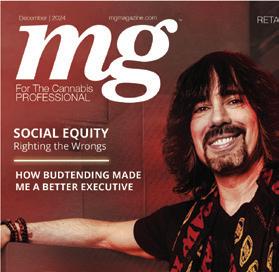

Vapes will continue to evolve. mg Magazine is still evolving, too. Since publishing our first issue in August 2015, we’ve endeavored to reflect a dynamic, sometimes chaotic, but always fascinating industry that is redefining commerce and the notion of personal choice. We’ve watched empires rise and fall, stood with advocates for social justice, mourned the loss of icons, and analyzed legislation, regulation, market shifts, and the vagaries of public policy to help the industry adapt.

Ten years, 120 issues, and more than 10,000 pages after mg Magazine debuted, all of us on staff are profoundly grateful for the readers, advertisers, celebrities, experts, and icons who’ve joined us on this journey. We look forward to discovering what the next ten years will bring.

Kathee Brewer Editorial Director

A writer, editor, and professor who splits her time between Southern California and North Carolina, Evan Senn also serves as senior project manager for Zen Brands. Founded in 2019, Zen remains privately owned and operated. The company’s cannabis and hemp products are available in several U.S. states and more than twenty European countries. zencannabis.com

For Corey Keller, business is a family affair. Co-founded and co-owned by brothers Corey and Conlan Keller, Bonanza Cannabis Company crafts and markets cartridges and gummies in Arizona, Colorado, Nevada, New Mexico, and New York. (Products vary by state.)

bonanzacannabis.com

As a NASA Jet Propulsion Laboratory engineer, Nohtal Partansky helped develop and launch the MOXIE project, which is generating oxygen from the Martian atmosphere. Now a serial entrepreneur, he and Cassio Dos Santos Jr. co-founded Sorting Robotics, which creates cuttingedge automation technology for the cannabis industry. sortingrobotics.com

A native of Oahu, Hawaii, Chloe KSL grew up steeped in the rich rhythms of live music and aloha energy. The synergies between her career as a disc jockey and music producer and her Hawaiian heritage inspired her to launch CAKE She Hits Different in 2019. The brand bridges the gap between music, festivals, and cannabis culture. shehitsdifferent.com

Editorial Director Kathee Brewer

Creative Director Angela Derasmo

Digital Strategist Dexter Nelson

Contributing Writers Alyson Jaen Esq., Anthony Coniglio, Brendan McKee, Chloe KSL, Christian Wolfgram Esq., Corey Keller, Danny Reed, Ellen Holland, Evan Senn, Jeff Adams, Justin M. Brandt Esq., Kim Prince, Laura A. Bianchi Esq., Leah Eisenberg Esq.,Marc Beginin Esq., Michael Mejer, Nohtal Partansky, Pam Chmiel, Paul Rivard Esq., Rachel Gillette Esq., Rachel Permut, Richard Proud, Robert T. Hoban Esq., Ruth Rauls Esq., Scott Thomas, Shane Johnson MD, Shawna Seldon McGregor, Sue Dehnam, Tara Coomans, Taylor Engle, Will Read

Artists/Photographers Mike Rosati, Christine Bishop, Unsplash

ADVERTISING SALES & CLIENT SERVICES

BRANDI MESTA Senior Account Executive

Brandi@inc-media.com (424) 703-3198

BUSINESS OFFICES

Managing Member & CEO

Darren Roberts

Circulation Manager

Faith Roberts

CRM Manager

Travis Abeyta

Accounting Brittany Gambrell

Diane Sarmiento

Subscriptions subscribe.mgmagazine.com

Back Issues store.mgmagazine.com

Mailing Address

Inc Media | mg Magazine 23055 Sherman Way, Box 5069 West Hills, CA 91308 (310) 421-1860

BRYCE MCDONALD Account Manager

Bryce@inc-media.com (559) 350-2477

Vol.11, No.8 | August 2025 Printed in U.S.A.

mg Magazine (ISSN 2379-1659) is published monthly by Incunabulum LLC. Periodical Postage Paid at Las Vegas Post Office and additional mailing locations. POSTMASTER: Send all UAA to CFS. NON-POSTAL AND MILITARY FACILITIES corrections to: PO Box 5069, West Hills CA 91308.

mg Magazine® is a registered trademark (USPTO #5999685). © 2025 Incunabulum LLC. All rights reserved. No part of this publication may be reproduced, distributed, or transmitted in any form or by any means without prior written permission from the publisher.

While mg Magazine’s editorial team considers its sources reliable, inaccuracies may occur. Readers should independently verify all information before taking any action. Neither Incunabulum LLC nor its employees, consultants, or vendors assume responsibility for errors, omissions, or the views expressed by contributors.

All letters and other submissions to the editorial department are considered unconditionally assigned for publication and copyright purposes. Submissions may be edited, commented upon, and used in any format or medium, including print, digital, online, and promotional materials.

mg Magazine is not responsible for the content of external websites or advertisements. Opinions expressed by contributors do not necessarily reflect those of the publisher.

WASHINGTON – The campaign to reclassify cannabis to a less-restrictive schedule under the Controlled Substances Act (CSA) may face new hurdles as both houses of Congress recently made moves that could block the initiative.

The Senate confirmed President Donald Trump’s pick to lead the Drug Enforcement Administration. New Administrator Terrence Cole is a former DEA field agent and a longtime critic of marijuana legalization. During confirmation hearings in May, Cole repeatedly sidestepped questions about whether he would allow the rescheduling process begun under the Biden administration to continue.

Ultimately, Cole’s hands may be tied if a House budget bill makes it to the president’s desk. In July, the House Appropriations Subcommittee on Commerce, Justice, Science, and Related Agencies advanced legislation containing language that prohibits the Department of Justice from spending appropriated funds to reschedule marijuana. DEA is a Justice Department sub-agency. The same bill continues protections from federal interference for state-legal medical cannabis programs, albeit with increased penalties for businesses located within 1,000 feet of schools, universities, playgrounds, or public housing. A corresponding Senate bill omitted both the spending prohibition and enhanced location penalties.

In May 2024, the Department of Health and Human Services recommended reclassifying cannabis from Schedule I to Schedule III under the CSA. Rescheduling represents several potential benefits for cannabis businesses, including relaxation of banking and federal tax laws. In January 2025, after activists accused the former DEA administrator of skewing the list of federal hearing participants toward anti-cannabis perspectives, the administrative law judge overseeing the hearings put the process on indefinite hold pending appointment of a new administrator.

A sweeping analysis of products sold at dispensaries across Colorado discovered inaccurate labels on nearly half of cannabis flower, with most labels claiming products contained more THC than they actually did. Funded by the Institute of Cannabis Research and published in Scientific Reports, the study also found labels on concentrates like oils and waxes were more accurate, with 96 percent matching the product.

More than one quarter of New York consumers (28 percent) say price is the leading factor in their purchasing decisions, according to a survey by extraction company Jaunty. When it comes to products, the state bucks national trends with 40 percent of consumers reporting a preference for edibles, followed by vapes (21.8 percent) and flower (17 percent).

WASHINGTON – A federal ban on intoxicating hemp is inching toward reality as bipartisan measures in both houses of Congress seek to close a 2018 Farm Bill loophole that allowed unregulated hemp-derived cannabinoids to proliferate.

Ironically, the Senate effort is led by former majority leader Mitch McConnell (R-Ky.), who championed hemp legalization in the 2018 bill. Today, he said, “malicious actors” exploit the farm bill’s plain language to develop “dangerous [cannabinoid] products” that “contain even higher THC levels than marijuana itself.” Too often, he added, those products are marketed in ways that appeal to children.

To address the issue, McConnell and Senator Jeff Merkley (D-Ore.) introduced a new definition of hemp in the 2026 Agriculture Appropriations Bill, which unanimously passed the Senate Appropriations Committee in July. The new bill separates industrial hemp from hemp-derived cannabinoids, leaving legality in place for hemp grown for fiber, food, and other commercial uses as long as the total THC concentration, including THCA, is 0.3 percent or less. Cannabinoid derivatives and synthesized cannabinoids including delta-8, -9, and -10 THC would be prohibited outright under the proposed legislation.

In the House, the Appropriations Committee advanced the Agriculture, Rural Development, Food and Drug Administration, and Related Agencies Appropriations Bill, which also rewrites the rules for hemp. Championed by Representative Andy Harris (R-Md.), a physician, the bill defines industrial hemp in much the same way as the Senate bill—with one important difference. Instead of setting a ceiling of 0.3 percent THC, the House bill bans all plants and products, including seeds, with any “quantifiable amount” of THC or THCA. All synthesized cannabinoids also would be prohibited if the legislation becomes law.

According to the U.S. Hemp Roundtable, either bill would ban 90 percent of all consumable hemp products in the United States.

“ Cannabis will one day be seen as a wonder drug, as was penicillin in the 1940s.”

—Dr. Lester Grinspoon

The youngest legal adults have definite ideas about their stash.

prefer cannabis to alcohol

The University of Mississippi’s fifty-seven-year run as the sole provider of cannabis for federally approved research may become a victim of the Department of Government Efficiency’s (DOGE) budget ax. Ole Miss’s contract with the National Institute on Drug Abuse has been suspended pending review, the university revealed in July.

Two bipartisan bills filed days apart may bring adult-use legalization to Pennsylvania. Both bills—one in the state House and one in the state Senate—include “incentives” to encourage women, minorities, and veterans to open dispensaries. Democratic Governor Josh Shapiro’s 202526 budget proposal predicts $536.5 million in state revenue from recreational sales within the first year.

Grön’s signature Pearls and MEGAs got a craft-rosin-infused makeover in Missouri thanks to award-winning local producer Head Change. The 10mg-perpiece rosin Pearls are available in Orange Yuzu, Electric Honeydew, and Dragon Punch varieties, while the 100mg-per-piece rosin MEGAs pack a punch in Baja Blaze, Peach Mango, and Cherry Cola. All are crafted with real fruit and natural colors.

Real Housewives of Potomac star Stacey Rusch partnered with Jushi Holdings to launch the infused wellness brand Shayo (a Nigerian term meaning “to be happy”). The brand’s first release, Vibes, comprises a line of rosin-infused chews designed to promote energy (THC and CBG) or relaxation (THC and CBN). Available in Virginia.

Digital natives vastly prefer e-commerce.

look up the brand/product on a search engine 52% 34% 32% 26%

look up the brand/product on a retailer’s website or app

visit the brand’s website or app visit a physical store to check out the product/ brand

If there’s a need in the marketplace and you do something right, people will find out about it.

— Toby Skard, Futurola “

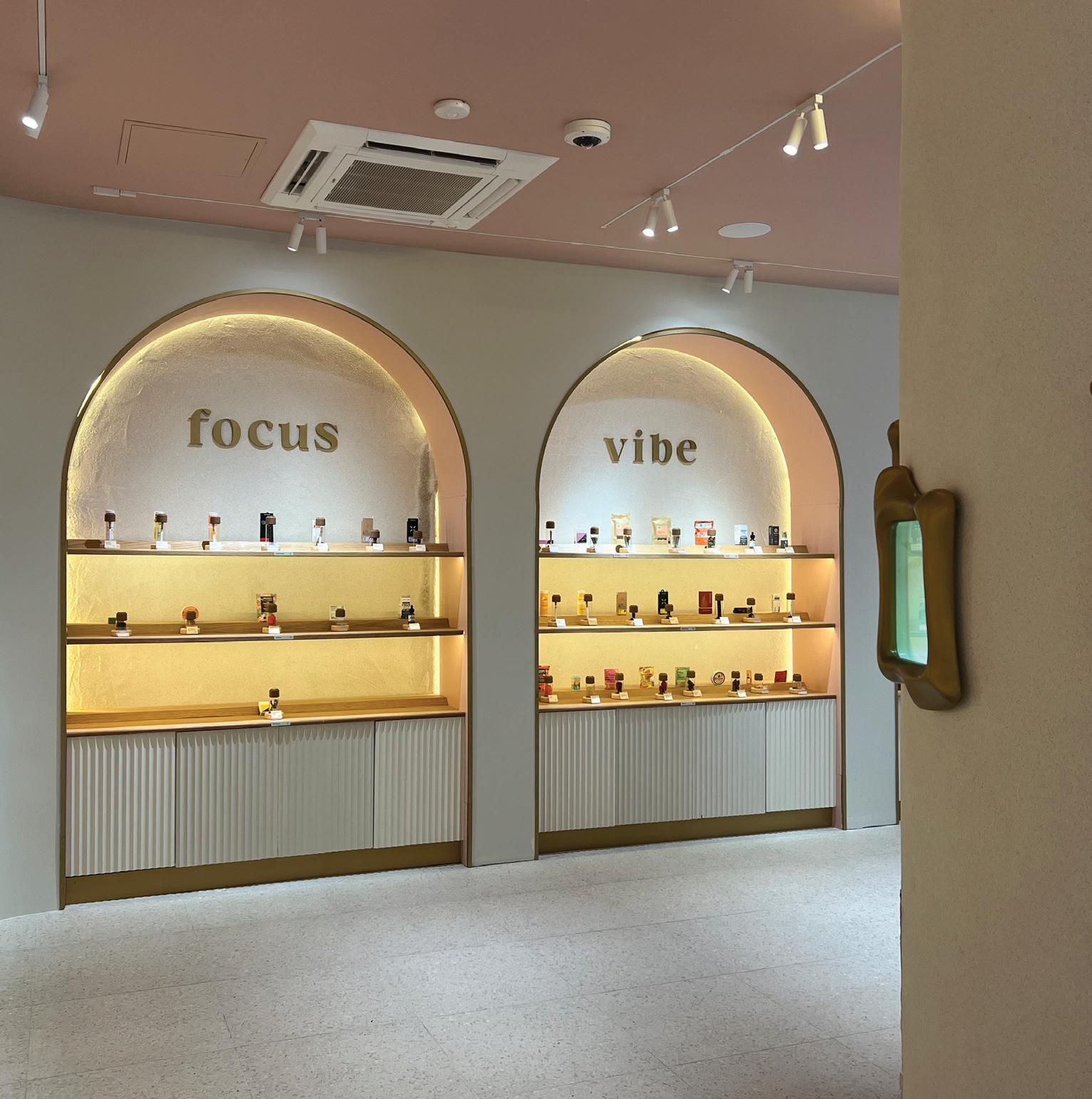

Alta is a tribute to an immigrant family’s journey, one woman’s vision, and the power of building something beautiful by hand.

BY TAYLOR ENGLE

Alta opened in 2021, but its origin story traces back to the 1970s— and the story is not at all what one might expect. Tucked into a corner of Manhattan’s Nolita-Chinatown neighborhood, the serene, spa-like dispensary was once a safe haven for an immigrant family that had just fled political unrest. Decades later, after multiple business incarnations, the building now houses a retail experience unlike any other in New York, built on family legacy, resilience, and a distinctly feminine approach to wellness.

“Women are the fastest-growing consumers of cannabis, and to be able to capture that in the beginnings of the New York City market really resonates with me,” said founder Vanessa YeeChan. “Being women-owned and exploring the plant myself, this was a great way to express myself and have this store to show that women can consume and it doesn’t have to be so discreet anymore. It can be out in the open. It can even be expected.”

From the soft arches and soothing scents to the clear educational touchpoints and warm, welcoming

energy, every inch of Alta reflects Yee-Chan’s intention to create a space where people—and women, in particular—can explore the plant at their own pace. This is a passion-project-turnedneighborhood-gem, shaped by Yee-Chan’s creativity, resourcefulness, and the helping hands of her family.

“Back in the day, my grandparents were refugees from Mozambique who had immigrated here because of a military coup that was taking place,” Yee-Chan said. “They picked up what they had and fled in the middle of the night because the country was turning communist and people were getting shot. Because my grandmother dealt with the government in a sort of underground currency exchange, they were able to acquire a lot of cash. They pretended they were going on vacation, and they left everything behind.”

The building Alta occupies was the first building Yee-Chan’s grandparents bought after arriving in the United States in 1976. Eventually her father took over management, and Yee-Chan was next in line. After being raised in a building where the tenants literally watched her grow up, it’s now her turn to preserve the legacy.

“I don’t have a background in cannabis, but I was an adamant user on the wellness side,” she said. “I found it in my thirties as a means to go to sleep, relieve anxiety, and unwind, so I merged my interests. My intention was to use the property to build something on the wellness side—fitting for microdosers, but attractive to connoisseurs as well.”

Alta came together as the product of a true family effort. Yee-Chan’s brother owns Arcanna Metals in the nearby Brooklyn neighborhood of Williamsburg, where he does custom architecture and fabrication work. Yee-Chan pitched her idea: a space that was calming, stylish, and mood-based, with arches, essential oils, and warm mauve tones. From there, the siblings got creative.

“I wanted to create something that I’d feel comfortable going to myself,” she said. “And I

wanted visitors to feel like they could come in and interact with the products. I decided to arrange the store with five different arches, each representing [a different mood state]: sleep, chill, relief, focus, and vibe. I arranged products in indicas, hybrids, and sativas to really guide [the experience]. That way, people can come in and the flow just really clicks for them.”

At the same time, she noticed many brands launching effects-based products, which flowed right into her goal of dividing the shop into sections based on desired experience.

“I wanted arches, because that’s the trend right now. I wasn’t crazy about the pink at first, but as I developed [the plan], I said, ‘You know what? Let’s just go for it wholeheartedly,’” she said. “And I’m glad I did, because it has real customer appeal. They love the spa, the breathwork, the sound baths, the

meditation sessions we host. And despite the pink, we have tons of men coming in. I think some men appreciate it, actually, because they come in and they’re like, ‘Ah, it smells like a spa in here!’ For me, weed is like my glass of wine at the end of a long day, and I just wanted to share that calming experience with others.”

Yee-Chan self-funded Alta, so instead of hiring an expensive team of consultants, she and her family worked with what they had. She sourced materials herself, experimented, and figured out what worked, like DIY-ing some water-activated fiber resin that gave the walls a beautiful stone-like texture—and cost just $1,500 to cover all the walls in the store.

“I wanted everything to be interactive, too. I wanted every product I sold in my store to have a space on the shelf,” she said. “So, I designed custom, interactive jar displays so every product could be seen and touched. We made movable display pucks out of Corian using my brother’s plasma cutter. Even my kids helped fan them dry over the summer. My dad, who now lives in Portugal, came back to help with final touches, and my sister helped with branding. The whole thing truly came together as a family.”

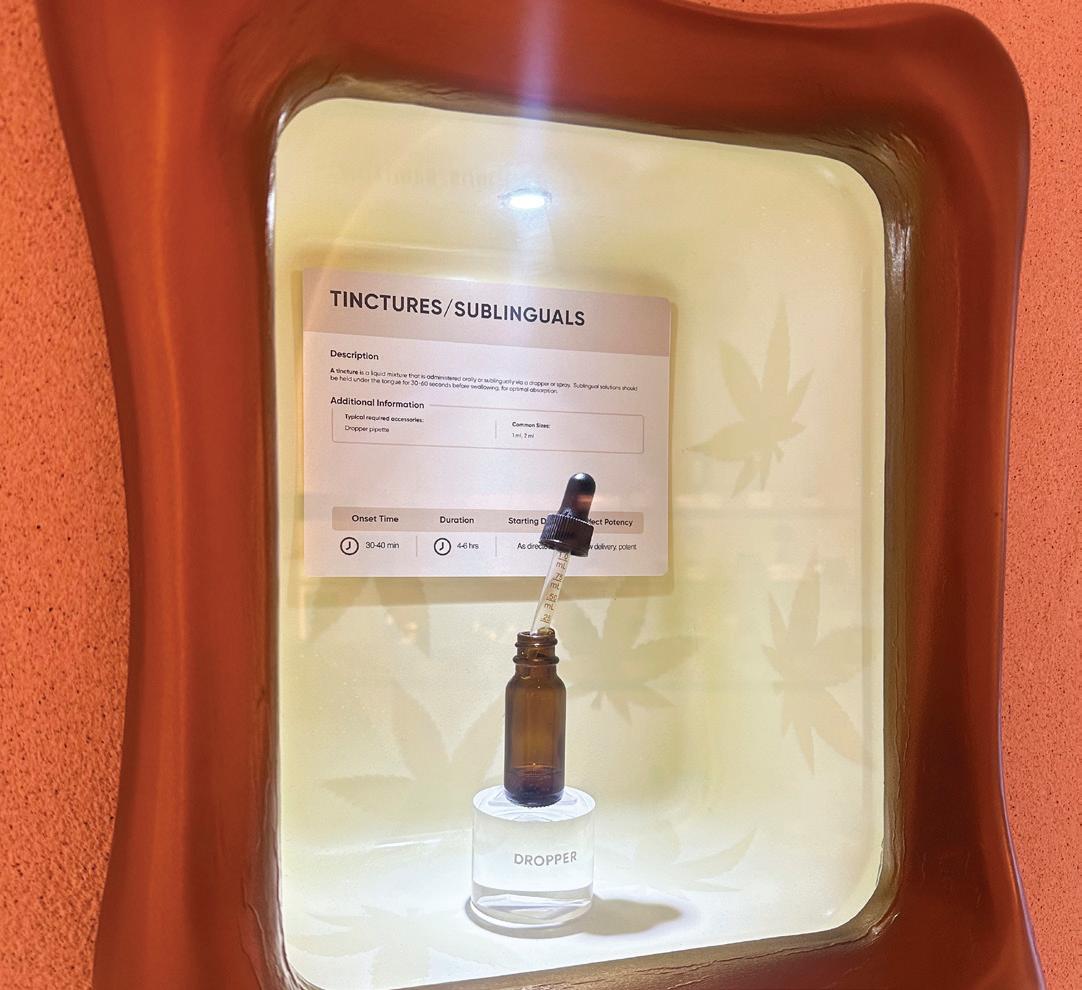

Consumer education is a pillar of the Alta experience, and Yee-Chan made sure to infuse every corner of the store with learning opportunities.

“Inside, we built an educational touchpoint right into the structure,” she said. “We have panels that explain different ways to consume cannabis—vapes, tinctures, edibles, dabs, even suppositories—and we label everything, because some people are completely new. Even I don’t really know how to roll a joint.”

Regulations always play a major role in dispensary design, and many owners or designers see this as a frustrating limitation. For Yee-Chan, it was another opportunity to get creative.

“Because of the regulations, I had to cover my windows, but I didn’t want to use frosting; I wanted clear glass,” she said. “One day, I saw these mesh metal curtains on display in a boutique in SoHo, and I was like, ‘This is really cool. How can I do this?’ When the curtain is folded and the lighting is changed, it creates this barrier where you can’t see inside, and it did the trick. So I got samples, found a supplier, and got it imported.”

Yet again, she and her family installed the material themselves, piecing it together and making decisions

on-site in real time. “I even stood there with an angle grinder to custom-cut the arch,” she said. “That DIY energy is part of the soul of this place.”

From the gentle playlist to the soft lighting and even the curved wall behind the checkout register, every detail was chosen to avoid harsh lines and create a sense of flow. Even behind the scenes, Yee-Chan and her family found ways to make the mundane magical. The access point to the fulfillment room is hidden behind a wall of custom wood veneer on which her brother cut large leaves for a subtle cannabis pattern. On the backs of educational displays, the team spraypainted tone-on-tone weed leaves, creating texture without flash.

“People tend to overspend because they don’t know where to start,” she said. “But if you get creative, you can achieve a lot. It doesn’t have to be that serious.”

She recalled the time she and her father wandered into a restaurant supply store in the Bowery, where they saw $10 metal pans typically used for food prep and repurposed them into softly-lit display cases. “We drilled a hole, spray-painted them, and it worked,” Yee-Chan said. “Sometimes you just have to walk around, get inspired, and let the ideas come.

“Now, we’ve been doing community events like mahjong night, which is a really cool way to bring my Chinese culture into things,” she said. “That’s been a real hit among the community. We also do high yoga, breathwork, meditation, and blazed bingo. We’ve partnered with Miss Grass, and for Pride, we threw a drag dim sum event in partnership with Stone Road, an LGBTQ-owned brand.”

For Yee-Chan, Alta isn’t just a dispensary: It’s an homage to her grandmother, her family, and the strength of small-business owners. The team built more than a retail store; they’re building community.

“I’m always trying to help people. I’m partnering with brands, working on retail alliances, and working with lobbyists to influence regulation,” she said. “I also volunteer a lot, putting on events for banking or insurance webinars for operators. As I was learning these things, I also got to host, lead, and moderate. It was to educate myself, so I figured why not educate others along the way?”

Thanks to one family’s resourcefulness and one woman’s vision, New York has gained not just another dispensary but a destination for community, healing, and joy.

BY CHLOE KSL

Vaporizer technology has come a long way from its humble beginnings. What once felt fringe has evolved into a refined, user-centric experience grounded in precision, safety, and thoughtful design. Today’s vapes are sleek, reliable, and engineered to deliver clean, consistent hits—no lighter, no smoke, no smell. Far from a passing trend, vapes are among the most widely used product formats in cannabis, thanks to major innovations in hardware, materials, and the overall user experience.

Let’s rewind to a previous era—before proprietary hardware, ceramic coils, and dual-chamber systems. Where did vapes originate?

Believe it or not, the very first patent for a vaporizer was filed in 1927. It kind of makes sense that in the Roaring Twenties Joseph Robinson envisioned a device that could heat medicinal compounds gently without burning them. Cannabis probably wasn’t the medicinal compound Robinson had in mind, as other medications were more popular during the era. While Robinson may not have built a working prototype in his lifetime, he is credited as the first person to conceptualize electronic vaporization, decades before the modern cannabis industry existed.

Fast-forward nearly eighty years to the late 2000s, when cannabis vapes began to enter the market. Those early devices were rough, consisting of e-cigarette parts poorly repurposed for weed: plastic tanks, fabric wicks, and off-the-shelf mods cobbled together with limited understanding of how cannabis oil behaved under heat.

Most, if not all, of the early devices leaked, burned the oil, and delivered inconsistent hits.

Despite their flaws, the devices offered something revolutionary: a portable, discreet, smoke-free way to consume the plant. And that changed everything.

As more people tried vapes, the category quickly moved from novelty to necessity. Everyone from medical patients and working parents to ravers, travelers, and creatives had their own reasons for embracing the convenience of vapor.

What started as a tool for stealthy seshes evolved into a cultural phenomenon. Vapes offered measured dosing, minimal odor, and smooth, clean inhales that made flower feel old-school. But consumers soon wanted more than just convenience. They also wanted control. They wanted purity. And they no longer tolerated oils, plastics, or metals that compromised their health— especially in the wake of the e-cigarette or vaping product use-associated lung injury (EVALI) crisis that erupted during the summer of 2019.

The demand for safety, consistency, and aesthetic quality forced brands to level up fast.

Today, we’re living in the golden age of vape innovation. Hardware that once looked like DIY science projects now resembles luxury electronics: sleek, smart, and built with purpose.

Today’s best-in-class devices are engineered with non-reactive materials like zirconia ceramic, medicalgrade stainless steel, and lab-tested borosilicate (Pyrex) glass. These components don’t just look clean; they

are clean. They minimize the risk of heavy-metal contamination, plastic off-gassing, and flavor distortion. What consumers taste is the terpene profile the extractor intended, not something altered by the hardware.

Another major leap we made as an industry? Precise temperature control.

Temperature matters because every cannabinoid and terpene has its own combustion point. If oil is overheated, users risk not only ruining the flavor and quality of the product but also inhaling harmful byproducts. To solve the overheating problem, modern vape devices allow optimized temperature delivery: the right heat at the right speed in the right amount. That means better taste, more potent effects, and a safer inhale every time.

Some brands take technology a step farther, calibrating their hardware and heating specifications to each unique oil formulation, fine-tuning every detail for the smoothest, cleanest pull possible. What once were considered premium standards now are the bare minimum to survive in today’s saturated and highly competitive vape market. The days of one-size-fits-all cartridges are over.

One of the most significant recent shifts is the explosion of all-in-one vapes. These self-contained systems—ready to use because the battery and cartridge are combined into one unit—offer a streamlined, elevated experience. No buttons, no charging cords, no fumbling with thread compatibility. Just pick up, puff, and go. Originally designed for entry-level consumers, all-in-ones quickly became the go-to format for a large cross-section of customers, from casual weekend tokers to daily macrodosers.

With their growing appeal across demographics, vape devices have transcended pure utility. Today, they’re as much a marker of taste and identity as they are a method of consumption. That means design matters. Brands that understand this have leaned into fashion-forward aesthetics, building devices that look like high-end tech or minimalist art pieces.

Vapes are no longer just a delivery system. They’re part of individuals’ personal brand.

In the future, expect even more personalization. Features like adaptive heating profiles, interactive screens, postless tanks, and larger oil volumes are on the horizon. Expect cleaner, more exclusive inputs like solventless oils, limited-edition small-batch

runs, and full-spectrum extracts that celebrate the plant’s complexity, not just its THC content. Expect sustainability, including hardware that’s recyclable, refillable, or—dare I say it?—engineered with biodegradable components.

Most of all, expect the fusion of culture, tech, and selfexpression to continue. As cannabis steps deeper into lifestyle, consumers are demanding products that don’t merely function but also align with their values, routines, and personal style.

Brands will realize success if they develop products that genuinely resonate with the next generation of consumers who want to feel good, look good, and know exactly what they’re putting into their bodies

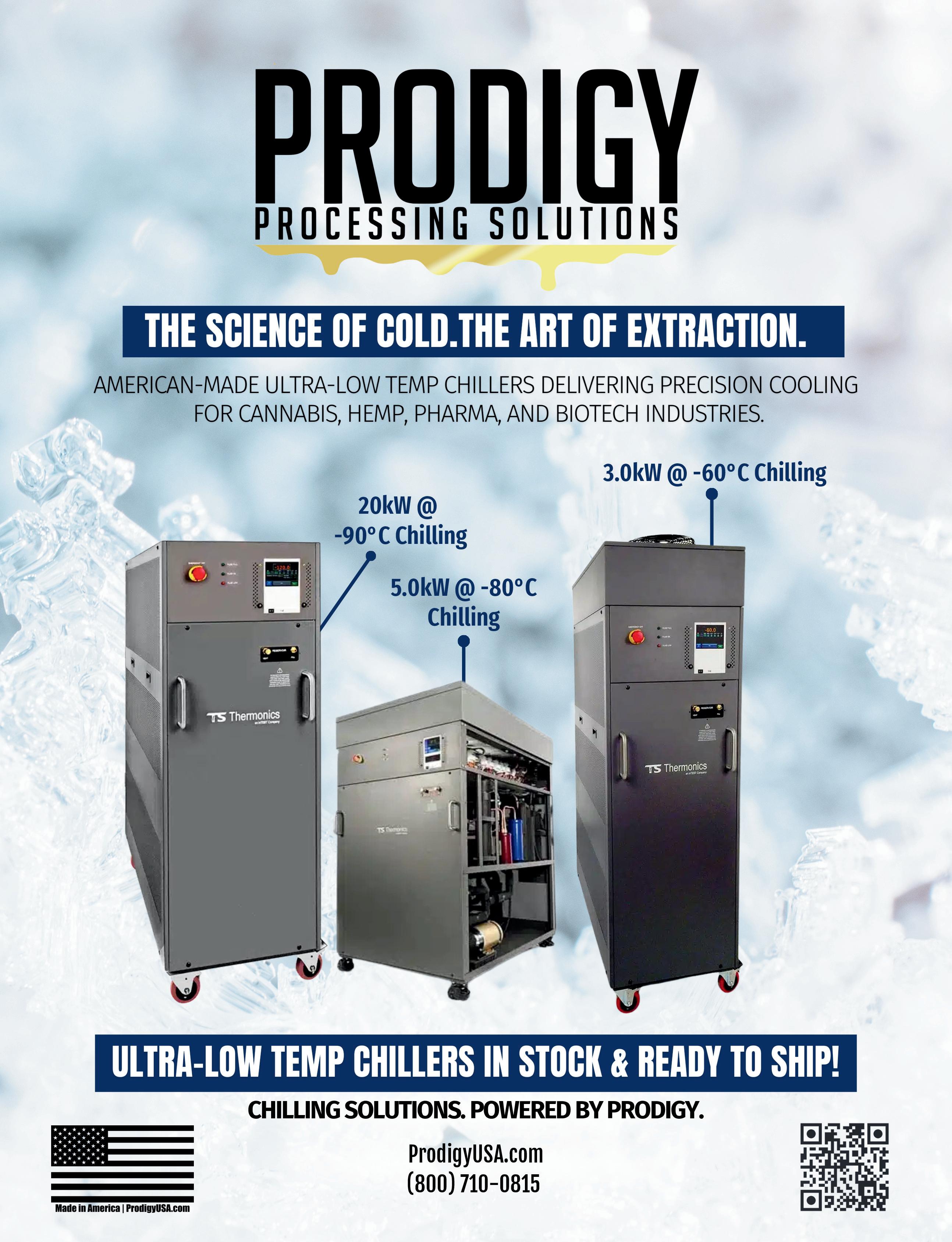

Four brands that are driving the next evolutionary phase in vaporizer technology.

Founded 2016 – Toronto, Canada

Focus: Chip-based oil vape hardware using microfluidics

Quantum Vape™: Metal- and ceramic-free chip heating

Coldstream™: Vapor up to 52% cooler than ceramic coils

GT Series: Custom cartridges and disposables for brand partners

CCELL

Founded 2016 – Shenzhen, China

Focus: Disposable and atomizer designs with postless tanks

CCELL 3.0: Biomimetic cotton-free heating at lower temps

MixJoy: Dual-oil disposable with blend control

Rosin Bar: Engineered for solventless oil with flavor integrity

Founded 2014 – Ontario, California

Focus: High-performance ceramic vaporizers and disposables

Lilcube Pro: High-conductivity ceramic AIO with display

DabGo™: World’s first disposable dab pen for concentrates

ArtrixDemo™: Micro-size trial vape for sample economy

Founded 2009 – Shenzhen, China

Focus: Ceramic tech and OEM/ODM vape systems

Reoregin™: Mesh ceramic core for cleaner, terpene-rich vapor

Glist Bar1: Portable disposable with elevated taste delivery

ELEV Box7: All-in-one with transparent tank and AutoTemp™

BY COREY KELLER

The cannabis industry has faced a dilemma in recent years as increased competition, uncertain economic conditions, and market expansion have conspired to create lower prices for consumers, but often with a steep decline in quality. As other industries have discovered in the past, rapid growth and competition can lead to product commodification and quality decline, and we see evidence of that today with the rise of “value” brands and discounted flower products. However, the current environment also can lead to innovation in processes, product formats, ingredients, and formulations.

Rather than go the dirt-cheap route, some brands and operators battle for market share by taking the high road, doubling down on quality sourcing, rigid processes, and stringent manufacturing conditions. While many businesses pursue the race to the bottom and drag consumers along with them, the high-road companies have found a way to elevate the consumer experience while still building a profitable enterprise. Although it sounds simplistic, achieving greater quality is very often a matter of going back to basics.

“Quality in, quality out,” is the old mantra so often repeated among business leaders. Companies focused on value will produce value-shelf products. But businesses focused on quality will create brands with value—and consumers increasingly are able to detect the difference. It’s no secret that quality sourcing is what sets these brands apart.

The quality of ingredients plays a larger role than anything else in determining the quality of the finished product. When sourcing plant inputs, a dedication to natural cultivation practices, a focus on quality genetics, and attention to terpene profiles, potency, and consistency are important criteria for creating quality. In addition, the integrity of sourced material plays a crucial role, particularly for manufactured products like edibles, vape cartridges, and tinctures. Plants grown cleanly without the use of harmful additives or contaminants will create quality even novice consumers can discern.

While mass-production operators have prioritized quantity over all else, brands focused on quality embrace small-batch craftsmanship, limited production runs, and personal oversight of every step in the process. This hands-on approach helps

preserve flavors and ensure consistency across products in addition to allowing periodic spot checks for purity, color, texture, and other identifying markers of quality. Smaller batches, smaller grows, and smaller production runs equate to big accountability that makes a real difference in the final product.

In addition, adhering to manufacturing best practices allows strict quality control and greater consistency across batches. In the cannabis industry, this also ensures an even stronger adherence to mandatory regulation standards through rigid contaminant screening, potency verification, and residual solvent checks conducted by independent labs. As consumers become more sophisticated, these often-unnoticed practices play a larger role in buying decisions.

Finally, packaging and materials play an important role in conveying a company’s commitment to quality— maybe even as important a role as the inputs from which the products were crafted. Packaging that feels thoughtful and intentional—whether through childproofing features, sustainable materials, or other attributes—is a reflection of the product it contains. Quality hardware and smart product design also signal a product has been planned and developed with care.

When consumers base buying decisions on price alone, they are easily swayed by the next good offer to come along.

But buyers who choose quality will stand by a brand so long as the promise of quality is maintained and reinforced. When executed correctly, an approach focused on quality will drive repeat purchases, encourage word-of-mouth recommendations, and build goodwill for a company. There is literally no downside for a business that does this right.

Legal products are no longer novelties, and today’s customers have the same expectations they have of any other retail purchase. The brands that understand this reality reject the race to the bottom in favor of creating a vibrant marketplace.

3.0

Vapes are more popular than ever, but behind every consumer favorite lies a complex dance of science, engineering, and evolving safety standards.

BY PAM CHMIEL

Vapes remain the second most popular cannabis consumption method in the United States (behind smoking), and demand for the devices shows no sign of slowing. Nevertheless, success for brands isn’t guaranteed. In fact, creating and maintaining a vape brand is far more complex than it initially might appear. Not only can consumers be notoriously fickle, but also recent research has identified multiple pathways of potential harm associated with both hardware and oils. According to data collected by industry analysts at BDSA, distillate vapes currently command a market share of about 60 percent. If trending data is any indication, they won’t rule the landscape forever, though. Mature markets have seen increased demand for resin and rosin vapes over the past few years as consumers become more educated about concentrates and more aware of the potential for richer plant profiles in rosin and resin. As a result, hardware companies are being challenged to innovate

and adapt their technology to accommodate more complex concentrates that behave very differently from distillates when vaporized.

Vaporizing rosin and resin extracts is challenging due to their whole-plant profiles, which often include lipids, fats, and waxes that can clog hardware and disrupt oil viscosity. Controlling viscosity is important not only for the vaping experience but also for safety. If the extract is too thick, it may not saturate the atomizer properly, leading to “dry hits” and the formation of harmful emissions. On the other hand, overly thin oils can leak, damaging hardware components. Other factors including cannabinoid and terpene profiles and additives like thickeners or reducers also influence viscosity, making hardware and formulations key factors in product development. It takes a village of scientists, hardware engineers, extractors, formulators, manufacturers, and regulators, all working together, to establish standards and build a safe, innovative, and thriving vaping sector.

Established industries have set standards to ensure product safety and consistency. Ninety industries—including tobacco, beverage alcohol, and prescription drugs—adhere to standards developed by ASTM International, a 125-yearold organization that develops and publishes worldwide voluntary consensus technical standards. By adopting ASTM Standards, the cannabis industry could demonstrate its commitment to safety, helping build trust with regulators and the public alike. The sooner the cannabis industry embraces these standards, the better prepared companies will be when federal agencies like the U.S. Food & Drug Administration, U.S. Department of Agriculture, and others begin drafting federal guidelines.

Darwin Millard, technical director at Cannabis Safety and Quality (CSQ), a certification program for cannabinoid products that is accredited by the American National Standards Institute, is leading efforts within ASTM’s D37 Committee to create performance standards for cannabis vape formulations and hardware. He emphasized the need for hardware-specific standards in cannabis, rather than relying on the well-established standards for nicotine e-cigarettes. Cannabis oils differ significantly from nicotine e-liquids in character and composition, he said, making hardware designed for vaping nicotine products less than ideal for cannabis. Inconsistent or subpar components can lead to hazardous emissions, device malfunctions, and contamination from dissolved plastics or corroded metal parts. Furthermore, he added, “the lack of standards means variable components from batch to batch.”

To address these concerns, the ASTM D37 Vape Device Safety & Testing Initiative is working to define five key indicators that cannabis devices are reliable and fit for their intended use.

• Material specifications for metal wires and ceramics, designed to identify restricted substances and manufacturing tolerances.

• Power and voltage limits to reduce the risk of overheating, a major source of harmful emissions.

• Aerosol and emissions characterization to better understand what consumers inhale.

• Disassembly guidelines to ensure the safe disposal of all-in-one devices.

• Puff topography protocols tailored to cannabis extracts’ unique performance profiles.

Millard also warned that extracts high in acids, like live resin and rosin, can corrode hardware while they sit in the device. “Cannabinoids themselves are solvents, so they can dissolve plastics and other components, leading to contamination,” he said. “Elemental impurities are a real risk, and because they’re present at trace levels, they’re difficult to detect with standard testing methods.”

The ASTM vape device safety group is working to produce thirty-five to forty standards. As standards are finalized, CSQ will incorporate them into its accredited certification programs, allowing operators to become certified as adhering to the ASTM standards that best fit their use cases. “This is a challenge in itself to define, but we’re making progress, and collaborating with formulation and hardware manufacturers is crucial to achieving the safe, consistent products that cannabis consumers deserve,” Millard said.

Puff topography research examines how people use vaping devices by analyzing their puffing behaviors to determine device performance and safety considerations. While nicotine vapes have well-established puffing standards, cannabis vapes lack similar data-driven guidelines.

ACTIVE recently conducted the first large-scale human puff topography study specifically focused on cannabis vaporizers. Among the findings: Cannabis users typically take longer puffs (around five to six seconds), inhale larger volumes (110–220 milliliters), and have shorter inter-puff intervals (seven to ten seconds) compared to nicotine vapers.

The study’s results have significant implications for both safety and cannabinoid delivery. For instance, longer, deeper inhalations can increase not only the amount of THC and other cannabinoids reaching the lungs but also may spur the formation of potentially harmful thermal degradation byproducts. The research suggests development of cannabisspecific puffing standards is crucial for consumer safety and continued industry growth.

Hardware manufacturers like Canada’s Greentank are using data from studies like this, combined with their own internal research, to develop safer devices. As the only cannabis vape hardware company to hold a Canadian federal research license, Greentank investigates the interplay between extracts and equipment. “We have a licensed lab in our headquarters to do in-house oil-to-coil testing for hardware compatibility studies with cannabis oils,” said

Derek Champoux, head of marketing for the company. “Our lab team ensures every new formulation meets performance and safety thresholds.”

Moreover, the team works directly with brands to create devices tailored to the specific viscosity and composition of their novel extracts. “Brands might come to us with a new liquid diamonds formulation, and we’ll help design a vape product that perfectly matches it,” Champoux said. “There are many levers to pull— reservoir size, intake hole size, resistance levels—all of which we can tweak to match the brand’s formulation.”

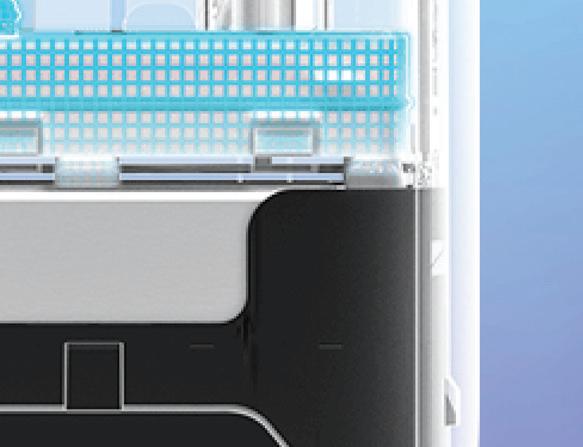

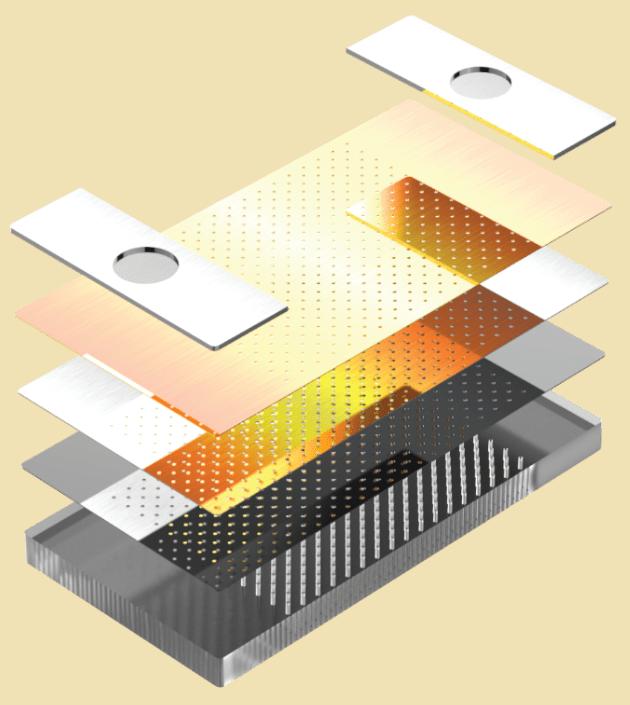

Champoux said his company is tackling emerging challenges with a new generation of heating technology. Greentank’s proprietary Quantum Chip™ is a step up from traditional ceramic heating elements—long the industry’s workhorse. Acting like a sponge that absorbs and re-releases oil through repeated thermal cycling,

when repeatedly heated, the Quantum Chip is made from 100-percent heavy-metal-free materials. “No ceramic particles or heavy metals like lead—virtually zero emissions of those chemicals,” Champoux said. He pointed to laboratory data backing up his claim, including a recent report from Virginia-based McKinney Specialty Labs confirming the chip’s emissions are “virtually zero.”

Greentank’s testing also discovered devices outfitted with Quantum Chips produce aerosol temperatures that are up to 52-percent cooler than the output from conventional ceramic-based hardware. “[The vapor is] a lot smoother and cooler,” said Champoux. “You get a more satisfying vapor, with better flavor and less harshness. That’s especially important, since hotter vapor can irritate the throat and lungs.”

Of the twenty best-selling disposable products during 2024’s first quarter, nine featured fruit-forward or blended cannabis flavors.

ceramic has inherent limitations. “That thermal cycling of the core being heated and cooled hundreds of times degrades flavor, performance, and safety,” Champoux said. “Consumers notice the flavor drop after fifty to 100 puffs. We wanted to eliminate that.”

Inspired by semiconductor nanofabrication, the Quantum Chip features thousands of microscopic holes that do not absorb oil. Instead, the chip channels oil through the micro-channels, where it is vaporized instantly upon contact with the heating layer. “There’s no thermal cycling of the oil,” Champoux said. “It only gets heated once, so you get a fresh puff every single time from the first to the last.”

The technology also addresses concerns about emissions and heavy metals. Unlike ceramic, which can contain and release heavy metals or other particles

In vape manufacturing, every detail matters. Achieving a safe, high-quality product requires an in-depth understanding of the chemical interactions between extracts, additives, and hardware components as well as significant knowledge of formulation science and engineering best practices. Dr. Robert M. Strongin, a professor of organic chemistry at Portland State University, is one of the foremost researchers investigating the toxicological risks associated with cannabis vaping products. His work has made significant contributions to understanding the chemical safety concerns associated with devices and extracts, particularly in the areas of thermal degradation, adulterants, and harmful emissions that can damage consumers’ health.

Strongin has evaluated a wide range of devices and formulations. He confirmed poor temperature control and faulty hardware components can dramatically increase the formation of toxins in aerosols. “The wicking feature in vapes is one of the biggest failure points,” he explained. “When it doesn’t perform well, the oil can reach dangerous temperatures, creating carcinogens that are harmful for the lungs.” Even a slight temperature shift can have an outsized impact. “Ten degrees can change the rate of a reaction by a lot,” Strongin said. His work spotlights the urgency of rigorous hardware testing and formulation science for consumer safety.

While Strongin acknowledged steady improvements in hardware safety, he remains concerned about the additives used in formulations. “Just because an additive is safe to eat does not mean it’s safe to inhale,” he said. “The lungs are much more sensitive than the digestive system and lack the stomach’s ability to break down potentially harmful compounds. Many vape ingredients, especially flavorings, have never been tested for inhalation safety, which creates serious health risks.” A wild-west approach to vape formulation, he warned, could spark health crises reminiscent of previous vaping-related outbreaks if harmful or untested additives are used.

Perhaps the most notorious cannabis-vaporizer-related health crisis occurred in 2019, when an outbreak of severe lung illness and rapid respiratory failure left sixty-eight people dead and more than 2,800 hospitalized across the U.S. Some of those who recovered suffered irreversible lung damage. The cause of the syndrome, eventually dubbed EVALI (for e-cigarette or vaping product use-associated lung injury), never was isolated definitively, but vitamin E acetate was the primary suspect. Vitamin E acetate may provide antioxidant benefits when used in dietary supplements, but it can damage lung tissue when inhaled. Prior to the emergence of EVALI, the substance was used as a thickening agent for THC distillates, primarily in the illicit market.

Even some natural components of the plant itself can be problematic in vaping liquids, according to Strongin. He pointed out terpenes can present risks when heated. “Terpenes are composed of isoprene units, and when inhaled in large amounts, they can exceed safety thresholds,” he explained. He stressed the need for informed formulation. “Some terpenes are going to be more toxic than others or degrade more readily,” he said. “We’ve just started to scratch the surface of this research, and brands need to be aware of

these differences when mixing and heating [vape liquids].”

Terpenes generally are preferred over synthetic flavorings, but although the natural aromas and flavors of these organic compounds can be appealing, Strongin urged caution when incorporating them into vape-bound extracts. Even seemingly benign organic flavorings can degrade and create harmful emissions when exposed to high temperatures in poorly controlled hardware systems, he said.

Beyond formulation concerns, the physical materials in hardware present another safety hazard. Research from the American Chemical Society revealed the metal components in vape cartridges, responsible for heating the oil, can leach harmful elemental metals into the oil even before the product is used. These contaminants also can end up in the aerosol consumers inhale, posing serious health risks.

While most state regulations mandate vape testing for just four heavy metals (lead, cadmium, arsenic, and mercury), researchers and some manufacturers in the industry suggest hardware makers should strive for pharmaceuticalgrade standards that cover a broader range of twenty-four elemental impurities.

Despite the inherent formulation risks, consumer data from BDSA suggests flavor can have a significant impact on a vape product’s success. Of the twenty best-selling disposable products during 2024’s first quarter, nine featured fruitforward or blended cannabis flavors. Meanwhile, nearly all top-selling cartridges were strain-specific products.

As vice president of research and development (R&D) at terpene-based flavor solutions provider Abstrax Tech, TJ Martin is hyper-aware of safety issues attached to aerosolized extract enhancers. For that reason, hardware compatibility is among the primary issues he and his team evaluate when helping clients develop safe and enjoyable vaping products. “The first thing I ask is what hardware they are using, because that plays a huge role in the performance of a product,” he said, adding he recommends clients “don’t cheap out on the hardware.”

Martin’s team primarily works with distillates containing a THC base that can be layered with terpenes to create unique, custom flavor profiles or recreate specific strain experiences (since the distillation process typically removes terpenes). Formulating customized vape liquids is one of the easiest ways to scale a brand across state lines or internationally, he said, since it allows companies to

maintain product consistency while working with different regional cultivators and hardware manufacturers. “Flavors will be the same regardless of where a consumer buys the product,” Martin said.

In contrast, rosin and resin concentrates, which are crafted from whole-plant extracts, are inherently more variable. Their taste profiles can shift from batch to batch because brands must source their inputs from multiple cultivation and extraction facilities, which makes guaranteeing consistent flavor or potency challenging. However, Martin sees this as an opportunity, not a drawback. “The craft beer world is full of small-batch options like hazy IPAs and West Coast pilsners with taste profiles that can vary, and that’s part of the appeal,” he said. Similarly, in the world of live resin and rosin vapes, subtle variations are part of the allure many connoisseurs enjoy exploring.

market demand and avoid costly missteps that lead to warehouses full of unsold products. While not every cannabis brand has access to a fully trained sensory panel, even small-scale consumer feedback can offer invaluable insights into flavor preferences and guide formulation adjustments. Abstrax developed Sensei, a software platform that standardizes sensory evaluation during cannabis vape R&D. Sensei uses a dynamic cannabis aroma lexicon to train sensory panelists and aggregate data about consumers’ flavor and aroma preferences.

For example, panelists using Sensei might describe a vape liquid’s flavor as “cherry, berry, and gassy” or note an unexpected pineapple hint in a strain meant to evoke OG Kush. Such nuanced feedback helps product teams fine-tune formulations and better align the final product with consumer tastes.

Formulating customized vape liquids is one of the easiest ways to scale a brand across state lines or internationally.

Martin also highlighted how brands can harness distillate formulations for creative collaborative products. “I’ve recently seen some cannabis brands doing collaborations with breweries, recreating popular craft beer flavors like Simcoe® hops in vape products for co-branded opportunities,” he said.

Of course, the targeted consumer base makes a big difference in the flavor profiles a brand offers. Martin pointed out canna-curious consumers in their forties or fifties tend to actively avoid the gassy, dank, skunky taste more experienced consumers sometimes seek. Instead, novices in certain adult demographics lean toward fruity-tasting products with strawberry, blueberry, or fruit punch notes.

In traditional consumer packaged goods sectors, sensory science is a cornerstone of R&D, helping brands match

Martin emphasized the importance of sensory evaluation for industry standardization, because the flavor landscape is constantly evolving. “[Plant] breeders in this industry are putting in a lot of work to find what’s new and different and push it to the limits,” he said. “Every year, we see new cultivars you’ve never seen before. If we looked at the sensory wheel from 2002, it wouldn’t have included things like Gelato, Zkittlez, or Runtz, or the more tropical strains like Tangie. It’s an evolving world, and staying in tune with those changes is critical to building a winning vape brand.”

As cannabis vapes continue to evolve, so too must the standards that govern them. Innovation is essential, but without science-backed safeguards and consistent regulation, the risks remain real. The brands that thrive won’t just chase trends; they’ll engineer trust, one puff at a time.

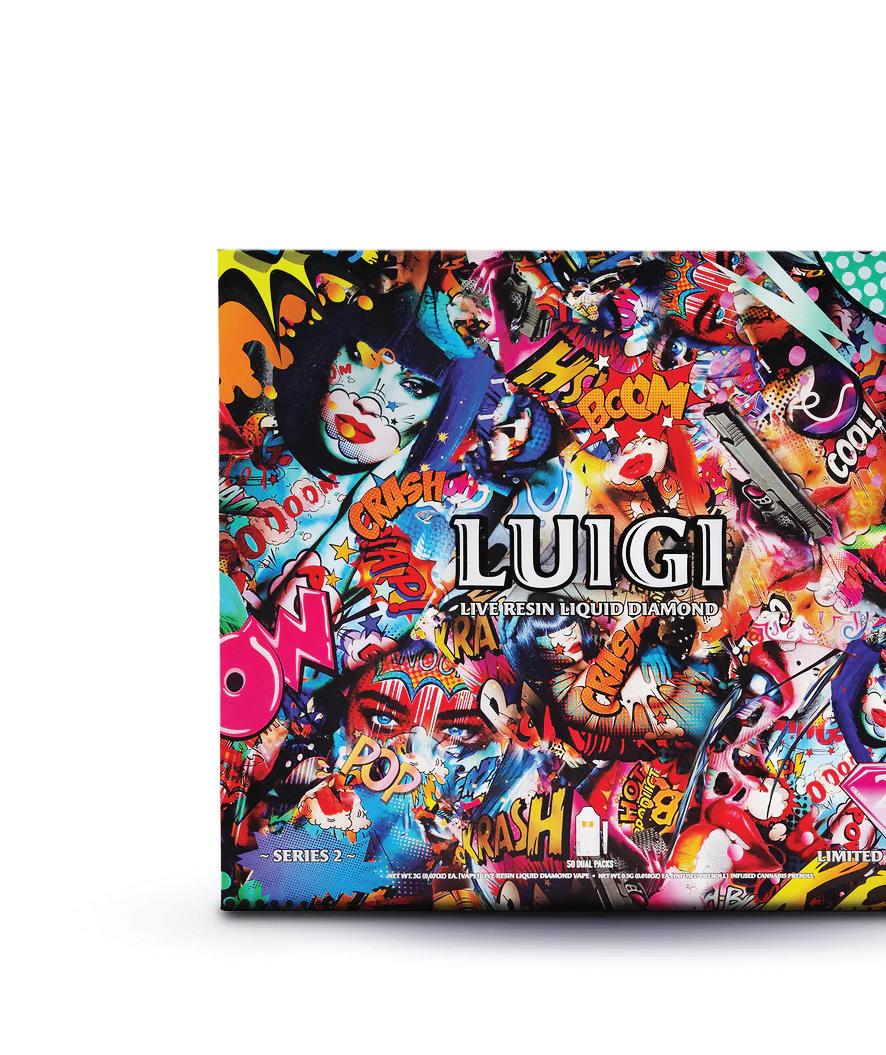

Even in an industry sector teeming with product variety, ample room for innovation remains. Luigi Oil intends to be a leader in bringing new ideas to market.

Founder and Chief Executive Officer Hovik Sudzhyan segued into the industry following a history of successes in another notoriously competitive space. He’s not unaware of the challenges facing startups.

“Before Luigi, I built a successful career in the clothing manufacturing industry, where I learned firsthand how critical it is to blend quality, efficiency, and scalability,” he said. “I transitioned into cannabis because I saw a huge gap: A lot of brands were either accessible but lacked quality, premium but overpriced, or operated without real integrity. I wanted to build a brand where consumers didn’t have to choose, so I made a promise that Luigi would be premium, accessible, and consistent.”

Sudzhyan believes every consumer product should provide an experience that transcends simple functionality. That perspective often is missing in the cannabis industry, he believes. “At Luigi, we approach everything through the lens of hospitality,” he said. “How does this product make you feel? How easy is it to use? How proud are you to share it with friends?”

But those are just the surface features. Beneath them lies a foundation of rigorous research and development. “Having a leading flavor scientist on our team is absolutely critical,” Sudzhyan said. “It ensures we aren’t just creating products that taste great, but ones that are made with exceptional purity, consistency, and effectiveness. Science is at the core of our integrity promise. It’s what allows us to confidently say we’re delivering a premium product every single time.”

Luigi produces its own distillates at a downtown Los Angeles manufacturing and production facility. There, the team tests its vaporizers and oils for safety, flavor consistency, performance, and durability. Sudzhyan said providing an elevated experience can be expensive, but such is the cost of properly building a brand that will live up to his—and consumers’—expectations.

“Instead of focusing on short-term corporate profit, we’re focused on long-term retail and consumer adoration and obsession with the Luigi brand and products,” he said. “We will happily pass the ultimate experience on to our partners and consumers rather than ourselves. Currently, every penny of profit goes back into strengthening our product and the consumer experience. By funneling the majority of revenue back into the operation, Luigi keeps prices competitive with the rest of the market while maintaining a standard of quality that is typically not achievable at this price point.”

Much of Luigi’s product research comes from customer interaction. For example, consumer response to the free pre-roll delivered with every vape purchase encouraged the company to expand into new product lines. The company soon will launch Fattones, which are multismoke packs including infused blunts, pre-rolls, and gummies, “all for what consumers are used to paying for a six-pack of pre-rolls from most other brands,” Sudzhyan said. Consumer response will determine whether the edibles get their own line.

Testing new products as free tagalongs with existing customer favorites allows Sudzhyan to plumb another of his core beliefs: that consumers crave variety. He said experience has taught him brands should anchor their business with a quality product line, but customers can become bored if the lineup never changes. Like Starbucks, Luigi is committed to seasonal releases that generate excitement and anticipation.

“Our seasonal flavor releases like Blue Razz Lime and Cherry Pie are scientifically designed to keep things fresh and fun for our customers while staying true to our high standards,” Sudzhyan said. “We focus on creating limited editions that celebrate the vibe of the season, whether that’s something lighter and fruitier for summer or richer for fall. Every seasonal drop is carefully crafted, never rushed, and designed to give our customers a little extra something to look forward to.”

That attitude extends even to packaging. Luigi’s boxes, pouches, and pre-roll tubes are works of art. The “pop surrealism meets neo-pop comic” style of the imagery

blends hints of Roy Lichtenstein’s signature comic-strip aesthetic with the energetic use of color and graphic disruption that defines street art to create packages as cravable as the products inside.

“We see every touchpoint as an opportunity to connect with the customer—and that includes the joint tube,” Sudzhyan said. “Instead of treating it like an afterthought, we design ours to reflect the same quality and style that’s in the product itself. It’s vibrant, intentional, and something you’d actually want to keep around—a subtle but powerful way to reinforce the Luigi experience.”

Launched in 2024, Luigi met the market with an aggressive plan to give consumers something different. Already, the company’s products are available in more than seventy California dispensaries; Luigi plans to expand into more states by 2026. In addition, Sudzhyan is seeking farmland so the brand can cultivate its own plants. That will allow Sudzhyan and his team to expand their meticulous oversight to every step in the seed-to-sale life cycle and help him keep the vow he made when he founded the company.

“At the end of the day, Luigi isn’t just a cannabis brand,” Sudzhyan said. “It’s a promise—a promise that customers don’t have to choose between premium quality, fair pricing, and brand integrity. In an industry that’s still finding its footing, we’re proud to be building something that feels good, tastes good, and does good—and we’re just getting started.”

luigioil.com

According to Smithsonian Magazine, cannabis vaping can be traced back to 440 B.C., when the Scythians used red-hot stones to heat hemp seeds so they could inhale the smoke. Not nearly as long ago, in 1927, Joseph Robinson filed a patent for a medical device he called a “mechanical butane ignition vaporiser.” The Scythians and Robinson were high-tech innovators for their day.

The vaping landscape has changed a lot since then. According to market data firm Headset, vaporizers represented 23 percent of all sales on April 20, 2025—better known in the industry as cannabis’s high holy day, 4/20. The reasons for the devices’ popularity are legion. They’re convenient. They’re discreet. Like combustible flower, vaping produces immediate effects, but unlike joints, vapes aren’t rendered irritating during a wind gust. Vapes also mostly dispense with the telltale “weed smell.”

Vaping’s momentum seems poised to grow. MarketResearch.com reported the market for cannabis vaporizers was worth $6.3 billion in the United States during 2024. That figure is expected to swell to almost $15 billion by 2030. Analysts attribute much of the predicted surge to technological advances including increased battery life, customizable temperature settings, and Bluetooth connectivity.

Equipment manufacturers already are hard at work on the innovations that will define the next phase in vaping’s evolution. Here are some brands out in front of the trends.

By Danny Reed

Founded in 2016 by brothers Corey and Dustin Koffler, Greentank Technologies is the only cannabis vape company with a Canadian federal research license allowing “oil-to-coil” testing on-site. “What distinguishes us in the industry is our ability to calibrate our products using actual cannabis extracts,” Chief Executive Officer Corey Koffler said. One of the fruits of Green Tank’s sophisticated end-to-end testing and research is the Quantum Chip™, a revolutionary heating technology that eschews traditional ceramic cores. Instead, the product uses thousands of microscopic holes to channel oil toward a heating layer, which instantly vaporizes the liquid. “Quantum Chip technology harnesses microfl uidics and capillary action,” Koffl er said. “Think of an ultra-modern pump that smoothly draws cannabis oil through the chip to a heating layer where it is converted into vapor.”

Because the oil is heated only once rather than repeatedly cycling through a ceramic core, every puff tastes as fresh as the first, he added. More importantly, because the oil never touches ceramic or metal—both of which can degrade over time and leach particles into the vaping liquid—the potential for contamination is virtually eliminated.

The technology was developed inhouse by Greentank’s team of more than 100 engineers, designers, scientists, and product specialists.

“We stepped back to rethink the very core of vape technology,” Koffler said. “Rather than iterating on outdated ceramic systems, we reengineered the ‘engine’ itself. Inspired by advancements in semiconductors and nanofabrication, it delivers cleaner vapor, richer flavor, and more consistent performance.”

The Quantum Chip forms the foundation for Greentank’s Quantum Vape™, which Koffler said produces smaller aerosolized particles that are

more easily and efficiently absorbed by the body. Also of note: The Quantum Vape produces vapor that is up to 52-percent cooler than traditional vapes. Quantum products are just the beginning of Greentank’s plans to make vaping safer, cleaner, and more fun for consumers. “Looking ahead, we’re also seeing strong momentum toward larger-capacity devices and smart features like LED indicators for oil levels, temperature control, and charging status,” Koffler said.

Instead of abandoning traditional architecture entirely, Artrix Innovation turned its attention to developing a next-generation system it calls highconductivity ceramic heating cores. The technology overcomes many of the shortcomings associated with using traditional technology to vaporize evolving extracts.

“Live rosin is rapidly emerging as a premium choice in the high-end cannabis market,” according to Sylph Wu, Artrix’s digital marketing director. “Its solventless extraction process and rich terpene profile offer unmatched purity and flavor—qualities that discerning consumers increasingly seek. Yet, most vaporizers on the market are still optimized for distillates, not for the nuanced chemistry of live rosin.”

The mismatch results in uneven vaporization and significant loss of flavor, Wu said. “As consumer demand shifts from ‘high potency’ to ‘high fidelity,’ the hardware industry must evolve,” she said. “Live rosin users aren’t just chasing effects. They’re chasing experience: flavor, smoothness, authenticity. Premium extracts deserve premium hardware.”

Lilcube, a disposable all-in-one (AIO) designed for use with both traditional distillates and thicker extracts, is the company’s latest release to address the consumer-preferences shift. Every element of the device—from oil pathways to heating curves and material selection—has been reimagined with one goal: to unlock the full sensory potential of solventless oils. “Instead of compromising for broad compatibility, Lilcube delivers a tailored experience that enhances flavor consistency, vapor smoothness, and overall enjoyment for

live rosin consumers,” Wu said. She cited key features that are tailored specifically for the distinct needs of liverosin vaping:

• High-conductivity ceramic heating element provides fast and even thermal distribution.

• Crucible-style chamber with an embedded coil enhances oil absorption and minimizes the risk of dry hits.

• Center-tube-free architecture reduces contact with metal in the heating zone, preventing unwanted chemical reactions and preserving terpene integrity.

“Traditional ceramics often suffer from low thermal conductivity, which can create hotspots that degrade terpenes and alter flavor,” Wu explained. “Lilcube redefines ceramic performance through high-conductivity materials, delivering instantaneous heat response to preserve delicate terpene compounds; uniform thermal diffusion for consistent, clean vapor; and cotton-free oil delivery, which minimizes carbon residue and extends hardware longevity.

“These are not theoretical claims,” she added. “In extensive field testing, Lilcube consistently outperformed conventional cartridges in terms of vapor quality, flavor retention, and overall user satisfaction when used with live rosin.”

Like others leading the development of next-generation vaporizers, O2VAPE founder and CEO Dana E. Shoched believes vapes must evolve to meet the market. Since 2013, the company consistently has pushed technology toward more portable, easier to use, and safer designs that address a growing consumer demand for thicker, more complex extracts.

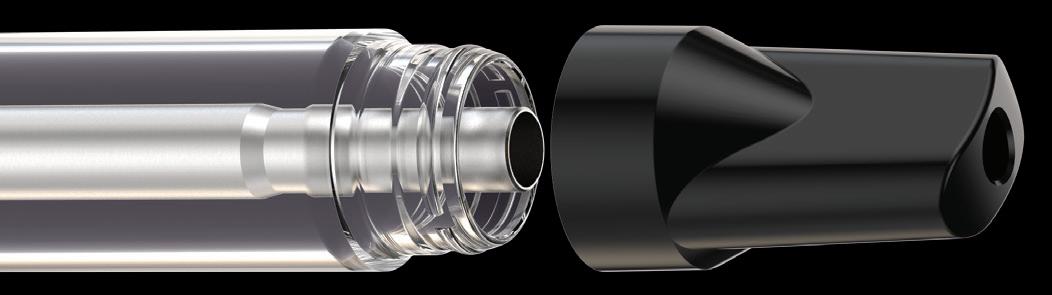

O2VAPE’s most recent introductions rely on all-glass components to meet those objectives. “We engineered both the new Traveler Extreme All Glass Bucket AIO and new postless Glass Nano Pod Kits to vastly improve the vaping experience,” Shoched said. “Currently, many vape devices have components or settings that interfere with the oil. Metal, plastic, and high heat can all impact flavor, stability, and composition, especially with live resin or rosin. So, we eliminated all of that.”

The company believes the Glass Nano Pod Kit is the world’s first patented all-glass nano pod system, bringing the performance of O2VAPE’s popular glass

pens to a pod format that allows users to change flavors and oils on the move without changing batteries. The Traveler Extreme features a fully transparent design with all-glass components—tank, center post, and mouthpiece—in halfmilliliter and one-milliliter capacities. Neither the pods nor the AIO need a cotton barrier between the oil and heating elements, leaving glass and ceramic as the only points of contact for vaping liquid. Shoched said the glass components slow oxidation, which contributes to the degradation of extracts over time. Consumers usually notice oxidation as altered flavor. Because O2VAPE’s glass components minimize oxidation, they also may extend products’ shelf life.

“It took us months to perfect the designs, but the result is a smoother, more consistent vape that preserves the formulation’s integrity,” Shoched said. “For years, we’ve been rethinking how a vape should work from the ground up, and these two new products are testament to our ongoing drive for product innovation.”

An independent operating unit of Shenzhen, China-based Smoore Technology Co. Ltd., CCELL is part of a global giant specializing in electronic cigarette research, development, and production. Since 2016, the company has maintained a significant presence in the cannabis vape market and operates a research facility in the U.S.

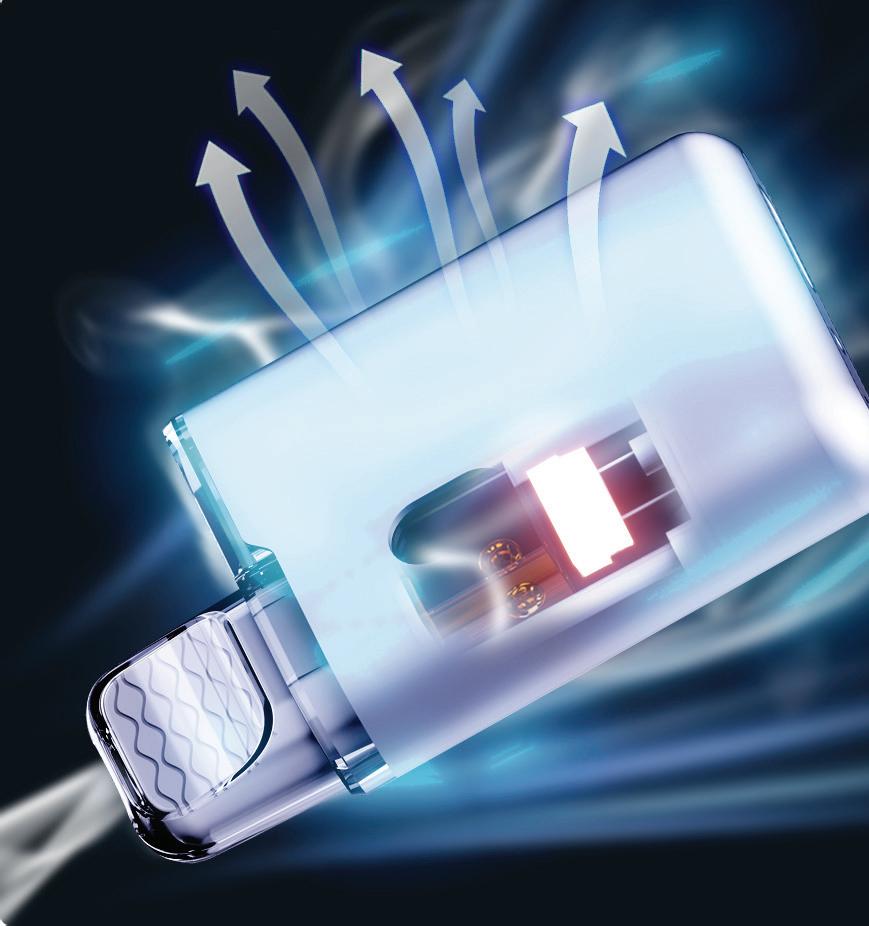

The company’s most recent innovation, introduced earlier this year, employs a postless tank and a cottonless “bio-heating” system that produces temperatures up to 30 percent lower than many competing products. Lower heat can help preserve terpenes—the flavor and aroma components that are increasingly important to devoted vapers and connoisseurs seeking an experience beyond the high.

MixJoy, which can contain two strains at once thanks to its twin-tank design, was the first hardware to debut with the 3.0 system. Users may enjoy each strain individually or combine the two using a switch on the bottom of the device.

“Our latest advancements include enhanced vapor cloud production and cutting-edge digital and Bluetooth capabilities,” said Corporate Relations Director Nicholas Kovacevich.

“We’re particularly excited about our breakthroughs in flavor performance, driven by two key technologies: our Smart Temperature Control, which operates 100°C cooler than traditional vaporizers to prevent flavor distortion from excessive heat, and our Stable Flavor Delivery, which automatically adjusts power to maintain perfect temperature consistency whether a user takes a five-second puff or a thirtysecond draw.”

CCELL 3.0 technology also reduces leaks and clogs, Kovacevich said,

adding the 100-percent-cotton-free core prevents burnt flavors associated with traditional cores. The postless tank creates a direct path for vapor to travel to the mouthpiece, meaning consumers can experience denser, more flavorful clouds than they may be accustomed to with traditional tanks.

What does the future hold for CCELL? According to Kovacevich, larger tank volumes and new all-in-one formats, both aimed at providing more robust, tailored experiences, are on the drawing table.

Although portable, discreet all-in-one (AIO) vapes are gaining in popularity with consumers across the spectrum, battery-and-cartridge models remain an industry mainstay. In addition to minimizing sustainability issues often associated with disposable AIOs, cartridges allow consumers to switch between concentrates easily as the mood strikes, and many are affordable compared to the recurring costs of AIO replacement.

To meet consumer demand, extractors, brands, and even some dispensaries find themselves filling an ever-greater number of carts with their best-selling oils. Compounding the issue, new strains, new formulations, and new consumer preferences make keeping up with demand challenging.

Thank goodness for technology. Automation has revolutionized cart-filling, turning what once was a tedious, time-consuming, and messy process into a quick and profitable operation. Two automated systems are particularly noteworthy.

Billed as “the world’s fastest vape cart filling machine,” Xylem Robotics’ X4 allows operations to increase speed, scale, and quality by completely automating cartridge filling and capping.

According to Xylem, one X4 machine can replace as many as twenty workers, performing inline filling and capping at a rate of as many as 1,650 units per hour. Precision ceramic pumps, combined with inert gas overlay to prevent oxidation, result in finished carts with leak-resistant vacuum locks and visually higher fill lines with the same gram of oil.

“When people look at a vape produced by our machines, they often want to know why our cartridges look fuller,” said founder and Technical Director Jeff Wu. “It’s because we cap fast and we do it at the lowest temperature possible, and we can deposit the oil at a specific location inside the cart. By [keeping the oil where it belongs], the vape looks full.”

The X4’s low operating temperature also preserves terpenes and decreases product degradation. Consumers notice a clearer, more vibrant extract color and experience more trueto-the-plant aromas, flavors, and effects.

Operating the robotic machines requires human oversight, but the human tasks are quick and easy to perform. Simply load the caps and carts into the X4’s hopper (no trays required), use the large touchscreen to enter custom or preset parameters for cart specifications and concentrate temperature, and push a button. The machine does the rest. Xylem provides training and support on-site or via video chat.

By reducing the cost per unit to manufacture cartridges and allowing staff reallocation instead of hiring more team members, the X4 can exert a powerful influence on an operation’s bottom line. In fact, according to Wu, “most operators generate a return on investment in as little as two months.”

The latest evolution of Vape-Jet’s fully automatic platform eliminates inefficiencies and reduces labor costs while preserving terpenes and overall oil quality. Hand-built in Oregon using American-made parts, the Vape-Jet 4.0 Top Load, designed for larger batches and high-volume SKU production, can fill between 5,000 and 10,000 cartridges or AIO devices per shift.

The innovative top-loading feature streamlines processes and reduces downtime. Instead of removing and replacing a physical tank, operators pour oil directly into the top of the machine. Machines can be configured with a two-reservoir stack, doubling oil capacity to two liters.

“Loading extract from the top allows for more rapid changeover of batches,” said Chief Executive Officer Tim Marsh. “We stepped back and thought about how our machine not only does its job but also fits into the broader operational workflow. We realized batch changes were more

of a constraint than tray runtime, slowing how many vapes could realistically be filled per day.

“Now, rather than loading and swapping reservoirs, the machine can essentially be filled directly with pre-heated extract,” he continued. “We eliminated complicated steps and unnecessary [standard operating procedures] to help our customers streamline their operations. This maximizes uptime of the machine to drive lab throughput.

“There are also further benefits like a shorter fluid path for even more minimal product loss, less maintenance, and less to clean,” he said. “And most importantly, operators and managers have been loving the new experience.”

Three individual heat zones and a nitrogen-pressurized fluid path help protect product integrity by reducing degradation, evaporation, and oxidation. A pharmaceutical pump and software-based guided calibration procedures help operators consistently hit the desired fill volume.

Training, rapid-response support, and process consultation that includes data analysis and proactive guidance are part of the package.

When cannabinoids go nano, onset times shrink, potency grows, and greater consistency becomes possible.

BY EVAN SENN

Why does one edible kick in after thirty minutes and another take two hours—if it hits at all?

The answer can be found not in the dosage, but in the delivery. As cannabis consumption evolves from smoke, vape, and flower to drinks, gummies, and tinctures, one scientific breakthrough is taking center stage: nanoemulsion. This technology is changing the way cannabinoids behave in the body, making them faster, more effective, and more predictable than ever before.

In basic terms, an emulsion is a mixture of oil and water stabilized by a surfactant (a substance that stabilizes mixtures of liquids that otherwise would separate). Think salad dressing that you don’t have to shake. In cannabis, emulsions allow cannabinoids—which are naturally oil-loving and water-fearing—to become water soluble, meaning they can be incorporated into water-based products like sodas and gels.

A nano-emulsion takes this one step farther. It breaks down oil droplets into tiny fragments—typically less than 200 nanometers in diameter. (That’s super small.) At this size, the droplets behave differently: They stay suspended longer, absorb faster, and become more predictable in the way they behave in the body. They can’t be seen with the naked eye, but the body feels the difference. In the real world, “nano-emulsion” often is called “fast-acting.” Overthe-counter nonsteroidal anti-inflammatory medications long have called their products “fast-acting,” indicating they are nano products.

Cannabinoids like THC and CBD are lipophilic: They dissolve in fat but not water. In traditional edibles, they must pass through the digestive system and liver before reaching the bloodstream, where they start producing effects. The process can take hours and substantially reduce potency in the process.

Nano-emulsified cannabinoids sidestep many of these hurdles. Their itty-bitty size increases surface area and makes them more readily absorbed by mucous membranes and intestinal walls. That means faster onset—often ten to twenty minutes instead of one to two hours—and greater bioavailability. More of the compound actually gets into the user’s system, resulting in stronger effects.

This leap in absorption efficiency is why nano-emulsions are becoming the go-to method for manufacturers and consumers alike (both medical and recreational).

Creating a real nano-emulsion is more complicated than just blending oil and water, though. The process requires sophisticated equipment and precise formulations.

Three main methods commonly are used in cannabis nano-emulsion production: