Q: What have been the most important changes surrounding safety in the oil and gas industry?

A: The list of global safety and security requirements has continued to grow throughout the last decade. These requirements have been focused on concrete actions that have a tangible impact on decreasing fatalities. Safety requirements in regard to coatings have become robust. Mexico is an industry leader in Latin America in terms of these requirements. Fireproofing requirements from PEMEX, for example, require that all products be certified by at least two global testing protocols. These include the UL1709 Standards in Refineries and Chemical Plants, among them the ASTM E1529 Standard Test Methods for Determining Effects of Large Hydrocarbon Pool Fires on Structural Members and Assemblies. They also include certifications, such as the ISO 22899, which determines the resistance to jet fires of passive fire protection materials. PEMEX demands the fulfillment of these requirements and more for any coating and fireproofing products used in its facilities. This guarantees a window of time in which employees can evacuate those facilities safely in the event of a fire. During this window, these products will certify that the structure will not collapse.

I have been in the oil and gas industry for 20 years and in the coatings market for 11 years. I have been certified as a Level One coatings inspector by SSPC in Mexico and as a fireproofing inspector by the National Fireproofing Contractors Association (NFCA) in the US. Throughout my career I have seen enormous changes but also faced great challenges.

Dos Bocas is undoubtedly the most important challenge of my professional career so far due the project’s unprecedented dimension, even for us as a company this is the biggest project in the world. If I were a professional athlete, I would compare Dos Bocas to the challenge of winning a gold medal at the Olympics. However, I am ready; I survived COVID-19 and beat the virus after 12 days of intubation, so I always say: whatever does not beat you makes you stronger, and I returned from the ashes of that battle to bring to the company’s Protective & Marine Coatings (PMC) division its biggest project in Mexico in over 50 years.

Q: How does PPG design and develop its fireproofing and coating products?

A: We develop technologies for the oil and gas sector based on structural analysis. This industry works on the basis of steel structures, so we need to work with the physical and chemical properties of all structural elements that are common to this material. We test different thicknesses of coating products to determine how much of our product is necessary to protect these structures. These and other calculations are related to something we call the massivity factor, which is a measure of the ratio of the heated perimeter to the area or mass of the cross-section. Those calculations along with measurements of time determine how long these protections last. Each testing protocol has its own laboratory with its own testing oven, so we send our products out to be tested at each one. These ovens test our products at over 1,000 ℃ (1832 °F) to simulate fires at hydrocarbon facilities, whether upstream or downstream.

These products are designed to be tumescent, meaning they expand under these high-temperature conditions. A coating thickness of 10mm will grow several increments of that size to create a carbon shield for the structural material. This is to prevent the metal underneath from reaching the 500 ℃ to 550 ℃ (932°F to 1022°F) range, at which point this steel reaches a state of structural failure. These tests are done under a variety of conditions. The steel structures in question are subject to increasing load weights and to elevated temperatures to make sure no unexpected reactions will take place in hydrocarbon worksites. The average protection time that Mexican operators are hoping to achieve is two hours but it can go up to four.

This process gives us the advantage of generating products that are applicable in all segments of the oil and gas value chain, from upstream to midstream to downstream. This is the case with our Pitt-Char® NX Protection product line. The latest generation of these products is incredibly versatile, which makes us extremely competitive because our competitors manage completely different product lines for different segments of the industry’s value chain, which logistically and in terms of cost puts them at a disadvantage in the market. Pitt-Char® NX also works as an anti-corrosion coating system, so no additional products are necessary to fulfill that function.

Q: What are some of the ways in which PPG’s coating and fireproofing solutions have supported the development of the Dos Bocas refinery project?

A: Our product has already made a significant contribution to making sure that the refinery is as safe as any other facility of its kind in the world. Our coating products can be applied in much thinner thicknesses to be effective, as much as 15 percent thinner, so less bulk of the product needs to be purchased without losing any quality. Our coatings are also much more flexible in terms of their plasticity after being applied.

This means that you can coat a section with our product in a workshop or in an external facility and then transport that section to your site without the coating being damaged, cracked or fractured, which is what tends to happen with the products that our competitors offer. If your fireproof coating cracks during construction or installation, you will need to repair and reapply it for it to be effective, which means an additional expense of time and money. In the case of a project with an accelerated time frame, such as Dos Bocas, this is unacceptable. This aspect of our product has been particularly beneficial at Dos Bocas because the project has depended on prefabricated assemblage; after all, the Dos Bocas location is already extremely busy with the Dos Bocas port being not only active but in a state of growth, so most of the coating work is done in off-site fabrication yards and silos.

Our coatings are also easier to apply, contributing to the project’s efficiency. Our competitors offer products that require multiple turns for application because one half of the coating’s thickness needs to be applied, then it must be allowed to dry off, which takes between eight and 12 hours, before the second half can be applied. The two halves of our coating’s thickness can be applied in the same eight-hour shift.

Epoxy coatings are not a one-size-fits-all solution. When it comes to the oil and gas sector, choosing the best protection for various infrastructure requires a great deal of experience. PPG has been doing this for 138 years and provides an in-depth look at the unique chemical characteristics that make up its products.

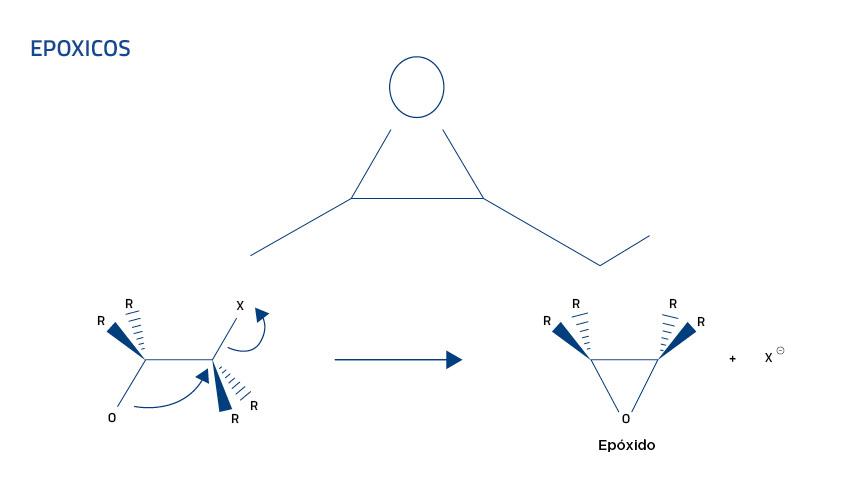

In organic chemistry, an epoxide is a cyclic ether formed by an oxygen atom bonded to two carbon atoms that are then bonded to each other through a single covalent bond. Generally, they are liquid, colorless and soluble in alcohol, ether and benzene.

They are named by adding the prefix “epoxi-” to the hydrocarbon that shares the same number of carbon atoms and indicating the carbons bonded to the oxygen.

Epoxide, or epoxy, materials have diverse uses in the industry. In the field of paintings and coatings, they are particularly useful in the elaboration of anticorrosive systems, along with protecting wood and floors.

Epoxy coatings are extremely versatile and capable of meeting high working standards, such as high mechanical and chemical resistance. This is why they are used in substantially tough environments, such as industrial facilities, vessels, offshore platforms, wind turbines, pipelines and other common structures that require constant protection against environmental degradation.

To create an epoxy coating that fulfills these requirements, it is fundamental to find the perfect combination of resin and curing agent, which provide characteristics specific to each formulation.

In all industrial segments in Mexico and in other countries, which include all marine and oil and gas activities, market trends indicate that the two most valued characteristics in epoxy coatings are the following:

This is a trend that has been developing for some time; nevertheless, today, this characteristic tends to be obligatory due to national and regional environmental regulations, which include lowering VOC emissions.

PPG offers a range of products that satisfy the needs of these projects, including PPG-Amerlock 2, PPG-Sigmashield 880 and PPG Sigmashield 1200.

This trend is also reinforced by environmental needs, not just lower VOC emissions but also less odor and a reduction in the use of solvents for cleaning. The product can be used beyond the industrial sector, with applications in the healthcare and commercial industries, among others.

The design of the product’s formulation involves a series of parameters that require care. It is also good to know their basic reactions.

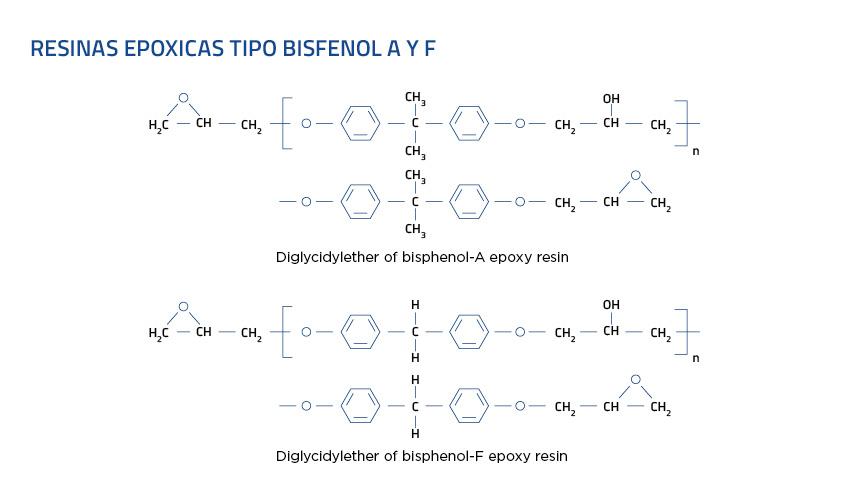

The process through which epoxy resins are manufactured is an example of the product’s versatility, benefits and varied characteristics. These include the classic formulation that mixes bisphenol A with Epichlorohydrin, along with other possible functionalities within that same structure.

Bisphenol A, usually abbreviated as BPA, is an essential chemical that has been researched substantially. It is primarily used in the fabrication of durable epoxy resins, along with transparent and resistant polycarbonate plastics.

In the last few years, a great deal of attention has been given to bisphenol A due to its use in the fabrication of materials that are in contact with food, requiring the approval of the FDA.

Bisphenol A is an organic compound with two functional groups of phenol. It is a difunctional block of many important plastics and plastic additives.

+ Formula: C15H16O2

+ IUPAC: 4,4’-(propane-2,2-diyl) diphenol

+ Molar mass: 228.29 g/mol

+ Fusion point: 158 °C

+ Soluble in: Ethanol, Base

Epichlorohydrin is an organochlorine compound and an epoxide. It is a colorless liquid with a spicy smell similar to that of garlic. It is moderately water soluble but miscible with most polar organic solvents.

+ Formula: C3H5ClO

+ Molar mass: 92.52 g/mol

+ Density: 1.18 g/cm³

+ Boiling point: 117.9 °C

+ Fusion point: -25.6 °C

On the other hand, we have bisphenol F, which is a small, organic, aromatic compound with the empirical formula ₂CH ₂. It is related to bisphenol A through its basic structure, since they both belong to the bisphenol category of molecules characterized by two phenolic groups connected by a bonding group.

+ Formula: C13H12O2

+ PubChem CID: 12111

+ Molar mass: 200.237 g·mol−1

The chemical nature of industry epoxides allows the understanding of part of the characteristics that each formulation provides; for example:

Epoxides with this characteristic are the most sought after by clients who require that maintenance on their facilities take place

in the shortest amount of time possible to ensure their productivity remains unaffected.

While fast-drying and rapid-curing epoxides have always existed, they were usually made on the basis of solid resins with a high molecular weight, along with modified amines and accelerators. Nowadays, the same characteristic is achieved through adducts in slow-cured amines, which are generated by the coating manufacturing process itself.

The use of phenalkamines is an option for fast-curing coatings with high molecular weight that can also have other characteristics, such as cold curing, curing in high humidity conditions and curing on surfaces that have not been adequately prepared.

Throughout its 138 years of history in the global industry, PPG has maintained several development processes that combine all of these types of chemistry to achieve products with the characteristics that the market needs. Examples of these products include Sigmafast 278, Sigmacover 350 and Amercoat 240.

The advantages of making adducts in epoxide curing agents are as follows:

+ The reaction with the epoxide resin is initiated, leading to a faster curing process.

+ The amine’s molecular weight increases, reducing its volatility and absorption time, thus making it healthier to use.

+ 100 percent solids translate into greater anti-corrosion protection, chemical resistance and use in concrete floors.

+ Low odors and VOC emissions when applied at high thicknesses.

+ Like other trends previously mentioned, it has become more common to comply with new regulations and its use has become extensive in confined spaces, interior rooms and low ventilation locations.

+ Resins with 100 percent solids are also of low viscosity to minimize or entirely avoid the use of diluents that affect the coating’s final performance. Hybrid resigns can also provide the product with specific characteristics.

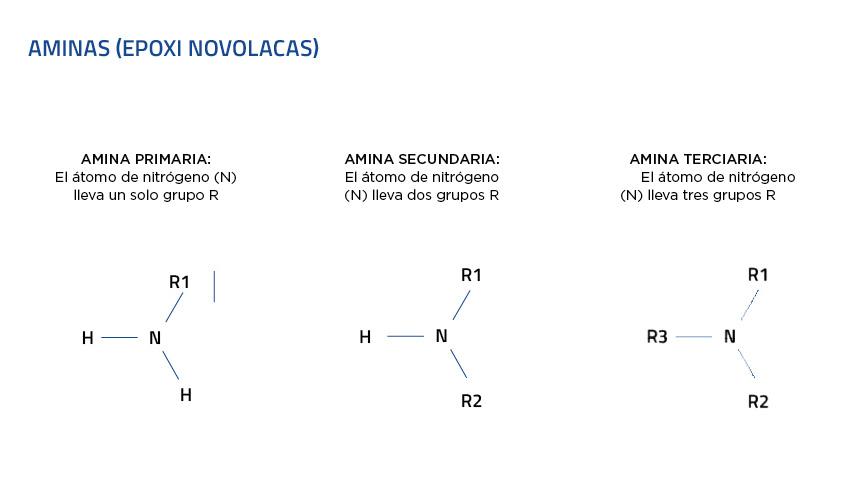

Amines are compounds that result from the substitution of one or more hydrogen atoms in ammonia for alkyl radicals (aliphatics) or aryl radicals (aromatics).

The functional group that characterizes amines is known as amino and is represented as (-NH2).

The general formula of an amine is R-NH2 if it is aliphatic and AR-NH2 if it is aromatic.

For example, in methylamine, a methyl group substitutes a hydrogen atom in ammonia. The bonding of two methyl groups produces dimethylamine and the three methyl groups in trimethylamine substitute all the hydrogen atoms in ammonia.

Through methods such as these, PPG takes the best chemical characteristics and combinations and uses them to fulfill the objective of consolidating the development of products that help find the best technological solution its clients require. PPG can find these solutions for a tank, a platform, a pipeline or any kind of industrial plant or facility in the world.

Through the success of its new professional division Pintawil del Bajío, PPG Comex is continuing to expand its role as a key supplier of PMC (Protective & Marine Coatings) products and technologies at the Dos Bocas Refinery.

“Professional division Pintawil del Bajío was established in 2019 with the goal of obtaining 30 percent of the available industrial market share in Mexico by 2024,” said Feliciano Solís, Director of the company’s professional division. Since its creation, Pintawil del Bajío has followed a path of success, “currently amassing a portfolio of 150 clients, each with distinctive projects across a range of industries,” said Solís. In addition, the company is participating in the Dos Bocas Refinery through a number of its clients. One of these clients is Sisttemex, a Mexican company that manufactures steel towers and structures and is in charge of important sections of the Dos Bocas facilities.

Another of its clients that is working on the Dos Bocas Refinery is Tecnología Aplicada de Servicios y Suministros (TEASSA), a Mexican construction company based in Queretaro that specializes in building storage tanks that will play a fundamental role in the refinery’s daily operations. These tanks will store amines, fuel, crude oil, feedstocks and

Read the complete article

More about this topic

water throughout its treatment stages. Pintawil del Bajío is playing an advisory role in the construction process of these tanks, as well as supplying PMC products that will cover the inside and outside surfaces of the tanks.

The tank’s internal surfaces are being covered with NOVAGUARD™ 890, a two-component, solvent-free, aminecured novolac phenolic epoxy coating. The system works with only one coat, and it is chemically resistant to a wide range of products and solvents, including crude oil at temperatures of up to 120°C (250°F). It is suitable for the storage of unleaded fuels with up to 100 percent of ethanol-mixed content. It is also suitable for the storage of EN14214-standard biodiesel. NOVAGUARD™ 890 significantly reduces fire and explosion risk while also having excellent pit filling capabilities.

It has good visibility, thanks to its light color, it is easy to clean and it can be applied by a heavy-duty, single-feed and airless spray equipment. It meets all of the requirements of the EI1541 2.2 standard for coating systems for aviation, fuel storage tanks and pipes, according to the company.

The external surfaces of the tanks will be covered first with RP-22, a zinc rich epoxy primer with extraordinary adherence and chemically resistant properties. It meets all the requirements for PEMEX’s NRF 053 2006 standard. This primer will also function as a sacrificial, or galvanic, anode, increasing the steel’s protection and resistance against corrosion. Once this primer is applied on all tanks, a second product can be applied on top of it depending on the tank’s specific use or application.

These can include the RA-28 system, for a polyurethane finish, or the RA-35 system, for a polysiloxane finish. These and other possible combinations yield great results when resisting different kinds of corrosive and high humidity environments, such as those found in the coasts of Tabasco, where the refinery is being constructed. The systems are ultimately chosen through a careful and methodical collaboration between client and supplier, reported the company.

It took Pintawil del Bajío over a year to prove the unique advantages of its products to TEASSA. “It was thanks to the quality of our service that we went from supplying a fraction of TEASSA’s work at Dos Bocas to 100 percent,” said Solís. Pintawil del Bajío aims to increase its development by an additional 30 percent in 2022 through the oil and gas sector, as well as through its significant involvement in the industrial, logistics, automotive and manufacturing sectors in Mexico’s Bajio region.

The company is working on the marketing and application of a diverse portfolio of products and solutions that include fire retardants, such as the Pitt-Char and Steelguard product lines, and structural or workshop primers, such as AIP 72 and Xtiren® DG, with companies that include Celaya-based automotive manufacturer Grupo CIE, tire manufacturer Pirelli and retail giant Suburbia. These products are also making their way to other segments of Mexico’s refining infrastructure, such as the recent revamping and modernization of PEMEX’s Ing. Antonio M. Amor refinery, located near the city of Salamanca, Guanajuato.

To reduce carbon emissions and contribute to the decarbonization of maritime operations, PPG has embarked on a mission to provide solutions that prolong the life of coatings using antivector technologies. Sailadvance and Sigmaglide are among the technologies to this end.

Sailadvance contains a load of biocides that gradually releases patented oils that promote the smoothness of the surface and better prevents the adhesion of marine fauna to the hull of a boat. Sailadvance not only generates up to 5 percent fuel savings during navigation, it also protects vessels with an idle time tolerance up to 30 days.

Sigmaglide is considered among the most advanced technologies because it is a 100 percent silicone technology that does not require biocides. It works as a repellent to the adhesion of the shell. It is easy to clean (if required) and because of its elastic properties, it regenerates naturally to some extent. Fuel savings of up to 10 percent are possible, plus it provides up to 60 days of protection for unattended boats.

“These are two of the sector’s most complete technologies, contributing to regulatory compliance at a relatively low cost compared to other solutions. Sailadvance and Sigmaglide are available not only in Latin America but across the world and are considered great allies in the fight for environmental justice,” says Cristobal Gómez, Marine Key Account manager Sr. México PPG Industries.

In a race against time and considering that the International Maritime Organization (IMO) seeks the decarbonization of its operations, PPG aims to introduce these technologies and contribute to this process in a timely fashion. The regulatory process will start this year and to expedite this process, shipping companies and other actors in the maritime sector have already established short, medium and long-term plans to achieve their environmental goals.

For instance, the IMO has set a goal of reducing transportationrelated emissions by 40 percent by 2030 and 70 percent by 2050, in comparison with the emissions recorded in 2008. Likewise, the reduction of other greenhouse gases in international maritime transfer is stipulated at 50 percent by 2050.

The indexes used to determine these measurements are EEXI (Energy Existing Ship Index) and CII (Carbon Intensity Indicator).

The EEXI is an index that is similar to its predecessor, the EEDI (Energy Efficient Design Index). It will apply to existing vessels that are not regulated by it. It will act on vessels over 400 GT that are under Annex VI Marpol, which limits the number of pollutants emitted through flue gases, such as sulfur oxides (Sox) and nitrogen oxides (Nox).

To define CO2 emissions standards in EEXI, practically the same methodology is used as in EEDI. Emissions are accounted for per ton of cargo and per mile, which are linked to the installed engine power, transportation capacity and speed of the vessel. Standard emissions take place as a function of fuel consumption, the capacity of the main engine, as well as auxiliary engines and a conversion factor between the fuel and the mass of CO2 produced.

In the case of the IIC, it is aapplicable to vessels over 5,000 GT, which must report and quantify the carbon emissions

generated. This regulation provides shipping companies with a factor of CO2 emissions that must be reduced annually to ensure continuous improvement and compliance with the regulation.

The IIC should be implemented in the Energy Efficiency Management by the Ship Operator (SEEMP) Policy. The SEEMP is a specific, mandatory document for each vessel that details the plan to improve energy efficiency in an economically sustainable and viable way over time.

To comply with the two parameters, there are several measures that shipping companies and boat owners can take, such as:

1. Use of clean fuels such as LNG (liquified natural gas) or hybrid fuels.

2. Use of additional propulsion systems through the wind by means of sails.

3. Use of batteries.

4. Slow steaming.

These alternatives are costly since reconversions, change of equipment and redesign of vital parts of the boat are required.

The simplest of these options is linked to periodic maintenance work that any type of boat must perform to preserve its class: hull protection with antivegetative coatings.

Depending on the technology for the anti-vegetative coating, a smoother surface is applied to the hull of the boat, prompting a better displacement while decreasing the amount of additional weight that can be embedded in the hull during unattended periods. Doing this saves fuel and reduces environmental emissions.

However, while they are a great solution, there are problems regarding anti-genetics as they do not all work in the same way. Traditional anti-vectors tend to deteriorate faster than state-of-the-art technologies, gradually losing the smoothness of the surface and its protection. As a result, fuel consumption increases due to the additional weight of barnacles and attached chamfer.

Fernando Muzquiz

National Account Manager | PPG

It is very common to hear about coating failures. Examples include fallen coatings, rust on the surface, premature coating failures, such as blistering or delaminations, and the coating not lasting long enough, forcing earlier-than-expected maintenance.

Throughout my career I have had to listen to these and other complaints related to coatings; however, I have rarely heard questions like the following:

+ How was the surface prepared?

+ What were the environmental conditions at the time of the surface preparation?

+ Was the substrate cleaned previously with a solvent? What kind?

+ Were anchor profiles measured?

+ Were the soluble salts in the substrate measured?

+ How much time passed between surface preparation and coating application?

Surface preparation is the first step toward a successful performance of an anticorrosive system; that is, more than 80 percent of the success of an anticorrosive system in the long term will depend on the surface preparation for a new construction or having had the proper maintenance work completed.

Depending on the substrate, its conditions and whether it is a new construction or maintenance, we can analyze the elements that make up the surface preparation, as well as its function for anticorrosive protection.

In the field of anticorrosive coatings, surface preparation can be defined as the cleaning of a substrate prior to receiving protection treatment. Surface preparation can be done using solvents, chemicals, abrasives, applying pressure or water at high or ultra-pressure.

The objective of surface preparation is to remove any type of visible and non-visible contaminant that may intervene in the adhesion of a coating, causing a short- or long-term failure, including the low performance of the final system applied.

The most common contaminants that can be removed by surface preparation are:

+ Rolling husk or calamine (steel)

+ Oil

+ Grease

+ Chlorides

+ Sulfates

+ Oxides

+ Dirt

+ Poorly adhered paint/coatings

Some of the basic factors for a surface preparation to be successful and those that we have to pay close attention to, depending on the system to be applied and the environment housing the structure, are the following:

+ Environment temperature (between 8°C and 40°C).

+ Substrate temperature (between 8°C and 40°C).

+ Relative humidity (RH) percentage (depending on the coating technology, usually not exceeding 85 percent RH).

+ Dew temperature (the difference between surface temperature and dew temperature should be higher than 3°C)

Another factor that must be taken into account when performing a surface preparation by abrasive jet to a metal, is to know the type of steel to be prepared. Basically, there are four degrees that are the most common:

+ Corrosion Grade A

+ Corrosion Grade B

+ Corrosion Grade C

+ Corrosion Grade D

There may be some cases where it is necessary to prepare a surface with D+ grades but in these cases, steel stability studies generally are required. If an abrasive jet cleaning is feasible, then other types of coatings will have to be used with greater thickness, greater hardness and flexibility in order to support the steel and keep it stable.

The purpose of surface preparation is to ensure maximum bonding force for adhesion at the interface between the substrate and the coating, these types of adhesions can be chemical, polar or mechanical.

In this article, I will only address the mechanical adhesion between substrate and coating.

The mechanical adhesion of a substrate following a surface preparation or surface cleaning by abrasive jet is associated with the roughness of the surface or anchor profile.

The anchor profile is the roughness of the surface formed by the peaks and valleys of the substrate, which can vary in ranges of height and depth; however, of importance for coatings is the number of peaks and valleys, which will increase adhesion in the surface area and in the current roughness.

Due to their chemical nature, some coatings have relatively poor adhesion or they need a deeper anchor profile, which requires greater roughness or a higher anchor profile to obtain adequate adhesion.

Most high-performance coatings can obtain adequate adhesion with an anchor profile at least 1-2 mils of an inch thousandths deep.

The anchor profile will depend on the angle of the abrasive jet, the speed of the particle, the size of the abrasive and the hardness of the surface.

Abrasives are divided into two large groups:

+ Non-metallic abrasives: silica sand, quartz, garnet, zirconium, walnut shell, eggshell, silicon carbide, dry ice, among others.

+ Metal abrasives: shot and steel pellet

Within the metal abrasives that are mostly used in the industry for their durability, recycling and practicality, their shape and size must be considered since the pattern and depth that the anchor profile will have after cleaning with an abrasive jet will depend on them.

The cleaning or preparation of a surface by abrasive jet is a technique to remove lamination husk, rust, adhered or poorly adhered paints, as well as any foreign material that may be on the surface. As a result, it is important to know what type of cleaning we will perform for the required work. This will be provided to us by a specification according to the quality and performance the work requires. This is why surface preparation has been classified into the following types of cleaning, according to Nace (National Association of Corrosion Engineers) and SSPC (Structural Steel Paint Council). Today, both associations have come together to create the AMPP (Association for Protective and Performance Materials), while still retaining their independent names. We can also reference other important committees, such as the Swiss standards (SIS) and the British standards (BIS); however, the most used are NACE, SSPC and SIS. Here are the most used:

Here are those that are most used in the industry:

By

According to NACE and SSPC, white metal cleaning is the highest degree of cleaning recognized in the industry for a metal, given its level of protection and maintenance. Using sp5 or NACE#1, the clean metal must be free of oils, grease, dust, dirt, rolling husk, rust, poorly adhered coatings, corrosion products, paint and other elements outside the metal itself.

According to AMPP, the almost white metal cleaning must be free of oils, grease, dust, dirt, rolling husk, rust, poorly adhered coatings, corrosive products, paint and other elements outside the metal itself, except for some stains that must be limited to no more than 5 percent of the surface. These may consist of light shadows, slight streaks or small discolorations caused by rust commands, or bark husk commands.

This is considered a degree of practical surface preparation.

Abrasive Jet Cleaning at Commercial Level(SSPC SP6 / NACE #3)

The surface must be free of oils, grease, dust, grime, rolling husk, rust, coatings, corrosive products, and other elements of the metal itself except for staining that must be limited to no more than 33 percent of the surface area and this may consist of light shadows, slight streaks or minor discolorations caused by rust stains, lamination shell stains or stains produced by previously applied coatings.

Manual Mechanical Cleaning(SSPC SP3)

This is defined as cleaning with manual-mechanical elements that must remove the loose rolling shell, loose rust, loose paint and other elements outside the metal. This procedure does not remove the entire peel of lamination, rust and well-adhered paint.

This method leaves many more contaminants on the surface than the methods earlier mentioned; however, the use of cleaning by

mechanical manual equipment is necessary because no other possible method can be used.

We could include others, such as Wet Abrasive Jet Cleaning and Non-Ferrous Metal Cleaning. Nevertheless, the quality and degree of cleanliness will be provided by the client’s climate specification, what function it will perform and how it should be protected, depending on the coating system selected.

TYPES OF CLEANING

Solvent

Manual

Mechanical Manual

White Metal

Metal Almost White

Commercial Level

Light Level

Chemical

High Pressure Water / Watterjetting

Bare Metal Mechanical Cleaning

Concrete Cleaning

Industrial Cleaning

Manual Cleaning with Mechanical Tools

SSPC NACE

SSPC SP-1

SSPC SP-2

SSPC SP-3

SSPC SP-5 NACE #1

SSPC SP-10 NACE #2

SSPC SP-6 NACE #3

SSPC SP-7 NACE #4

SSPC SP-8

SSPC SP-12 NACE #5

SSPC SP-11

SSPC SP-13 NACE #6

SPC SP-14 NACE #8

SPC SP-15

Cleaning Non-Ferrous Metals SPC SP-16

Finally, it is important to note that before moving to the application of the coating after a surface preparation by abrasive jet, the client may require the elimination of non-visible contaminants (salts). These are classified as follows:

+ NV-1: surface free of soluble contaminants verified by field analysis or using reproducible testing methods.

+ NV-2: surfaces with less than 7 μ g/cm2 chlorides, less than 10 μ g/cm2 nitrates or less than 17 μ g/cm2 sulfates verified by field analysis or using reproducible testing methods.

+ NV-3: surfaces with less than 50 μ g/cm2 of chlorides, sulfates or nitrates verified by field analysis or using reproducible testing methods.

In addition to the verification of non-visible contaminants, close attention should be paid to the time a piece is left either outdoors or indoors. Due to environmental conditions, a phenomenon called Rapid Oxidation (flash rust) can occur.

This phenomenon cannot be removed with sandpaper; therefore, the surface will need to be prepared again by an abrasive jet to comply with the level of cleaning requested by the client, causing an increase in the use of labor force, as well as the amount of abrasive material originally required, which could affect the total time of a project.

I hope that with these fundamentals of surface preparation, our reader can have a better vision of how to prepare a metal surface, what grade you will need according to the life span you want the anticorrosive system to have as well as the factors that can affect it by highlighting early failures of anticorrosive coatings. Read the complete article

In the B2B Industrial Division of PPG Comex, we have a great deal of experience working with the oil and gas, mining, energy, traffic and infrastructure industries. These industries undoubtedly faced difficult challenges due to raw material shortages, prolonged delivery times and the viability of starting projects despite the limitations and impact resulting from the pandemic.

PPG Comex has an extensive product portfolio to cover the needs of the industrial segment according to the degree of protection, weather conditions, lifetime expectancy, resistance to different substances, temperature, location, the substrate to cover, required aesthetics, and more. The company takes into account these variables to recommend the most adequate system supply according to each case, creating a tailored solution for the projects of our commercial allies.

Moreover, we have a large network of 600 dealerships and 5,000 Comex stores nationally to care for our clients everywhere, always providing on-site attention and looking to have more localized materials and highly qualified staff for service on site.

With the best infrastructure, experts in every sector and technologically innovative products, PPG will continue working to cover the necessities of all of its clients, maintaining a focus on the client, providing a valuable relationship-based service and seeking to innovate to be able to protect their activities with the best attention and delivering the best product according to their needs.

One of the big success cases for PPG in the industrial segment is a commercial alliance with one of the biggest companies in the country according to market capitalization. This account has national and global operations in the mining, railway, oil, construction, energy, highway, fuel and engineering segments.

We have worked together with this company to find the best possible way to cover all its needs in product, assessment, training, recommendations and specifications, collaboration in projects, including contractors, detecting needs, and with contacts and personalized attention in every locality. We started working for this group more than 20 years ago in the mining sector. It was through a network of contacts, knowledge and investigation of its needs, deep understanding of the client, the market and its particular needs in every sector that we have been able to reach all of its divisions and users to offer the best value proposal for every single one of the group’s projects, either for construction or for maintenance.

Today, we are not only their product supplier but a partner and commercial ally to most of the company’s divisions, increasing our participation and commercial agreements thanks to the service and attention we provide, which speaks for itself and allows us to be near our client, understanding and serving its business.

We have many similar stories to tell. We serve industrial projects with experts, professional attention, technical

guidance, trained and certified staff to comply with all norms and we are always looking for new challenges that ensure we remain recognized as the best brand for construction tools and industrial coatings.

PPG seeks continuous improvement through training and technological innovation, working hand in hand with our clients, which allows us to grow our participation with all of them, becoming their commercial partners, learning from all of them and generating long-term business relationships that allow us to be present in their upcoming projects.

Currently, we are facing countless opportunities in all of our industrial segments, from the increase in fuel demand to mineral exploitation, new construction projects, railway construction and equipment and maintenance of land routes. We will continue preparing ourselves to always offer the best alternatives in our role as protection coatings providers to protect our clients’ assets.

PPG always looks for the best way to solve the needs of its clients, generating value and supporting them in their particular needs and making possible the protection of their assets with the best technology, on-site specialized attention and added-value service, with our PPG WAY as our pillar: We partner with customers to create mutual value

Account Manager | PPG

At PPG Comex División Profesional, we are passionate about strengthening relationships with all of our clients to make things happen.

We work hand in hand with our commercial partners to offer personalized attention and customized solutions for each project we are involved in. As a result, we have been able to generate alliances and increase our presence in big projects, contributing to our clients’ successes. Thanks to the trust our commercial partners have in us and the excellent quality of our materials, PPG Comex is proud to have participated in the most representative investment projects in Mexico in the past 50 years. These include, the new Olmec Refinery in Dos Bocas, Paraiso, Tabasco, and the clean fuel project at the refinery in Tula, Hidalgo.

One of PPG Comex’s success stories involves a strategic and commercial alliance with one of the largest EPCs, which is a leader in the development and implementation of projects. This company is present in Mexico, Central America and the Caribbean and focuses on the development of construction projects and industrial plants for both governmental and private sectors. As one of the main EPCs, it addresses projects in the industries of oil and gas, refinement, chemistry and petrochemistry, energy, mining and metals, automotive and manufacturing, concrete, telecommunications and maritime platforms, among others.

We are fortunate to participate and collaborate with this company through our innovative and technological solutions. Thanks to our partnership, communication and teamwork, we have been able to understand and fulfill their needs regarding pressing times, consultancy and product performance. In addition, we presented them with our Pitt-Char® NX Protection line of products, known for its easy application, in addition to being safe, resistant and lightweight. This product was designed to protect against all risks related to onshore and offshore fuel fires. It is an innovative product that is lighter than any alternative system produced under UL1709 and ISO 22899 (pillars of the NFR-065). It has a thickness of only 7.98mm for a pool fire, providing 120 minutes of fire resistance and for a jet fire it offers 120 minutes with 9.33mm of thickness. Thanks to the application of thick layers and its short curing time, the whole system can be applied in a single day, offering significant time savings, improving productivity and reducing construction times and application costs both on site or at the workshop. This convinced our client this was the solution they were looking for. It was implemented in record time with excellent quality and safety.

As a result, we have increased our participation and commercial agreements with this client for the short, medium and long term. We have leveraged opportunities and generated integral solutions for applicable coverings that have given this company the confidence to continue being our commercial partner for each of their businesses. We have accomplished this by using different technologies that have transformed the world of coverings and have been implemented in projects as a differentiator of our brand. The great teamwork that we have provided them has allowed us to have a deep understanding of their main needs, consultancy

and to provide orientation with technical recommendations, specifications, sample application, training and, most importantly, personalized attention from our distribution force, which has been key to ensure proper execution and service. We have had a great deal of success in delivering an unforgettable product experience from the very start.

PPG Comex is a global painting and coverings company with a robust and innovative portfolio, and, therefore, we can recommend proven solutions to clients abroad. This has allowed us to be a technical reference that provides personalized attention, while looking to continuously improve technology and to innovate in sustainability and color. We provide our clients with sustainable solutions and offer the support of a team of experts that aims to facilitate projects while implementing the best services, cost-benefit balance, efficiency, quality and technology.

At PPG Comex, we aim to strengthen the relationship with our clients to generate mutual value as long-term commercial partners, always working under the principles of PPG. Our goal is to make things happen, providing exemplary results while protecting and beautifying the world.