COMPANY REPORT

Joseph Délano

Director | Délano Schmidt & Kranz

Joseph Délano

Director | Délano Schmidt & Kranz

Q: What problems does Délano Schmidt & Kranz solve in the mining sector and what new innovations is it offering the market?

A: We provide the mining sector with exceptional German vehicles and solutions. We have detected that there are great opportunities to improve the efficiency of mines in Mexico, especially in the area of production through the use of vehicles that are well adapted to mines and through the implementation of high technology such as software and telecommunications that allow the vehicles to be connected to a mine’s operations center. We offer a solution under GHH rocks and Nerospec SK. This solution allows access to the telecommunications infrastructure that already exists in mines. It offers a complete solution to the mining industry that also reduces costs.

Q: How does the company ensure high-quality services?

A: Our clients prefer a local presence that provides a more personalized service. For this reason, the company offers products, technicians and spare parts. This has allowed us to guarantee that our clients have the company’s support at all times. This year we have a full service workshop and our next step is an assembly line, which will become one of our biggest differentiators in the mining market. In addition, this allows us not only to have greater coverage in Mexico but also in the US, Canada and Central America.

Q: What does the company think about doing business in Mexico?

A: Mexico is an important mining country and having a presence in this jurisdiction is essential if you work in mining. However, among the obstacles is the lack of certainty and reliability, which has serious consequences for international investment. Mexico is a country that is continuously growing and is highly attractive for investments due to the benefits it offers, especially when compared to other countries in South America. However, there is a risk factor that currently is affecting the credibility and guarantees for long-term investing in the country. This is one of the biggest challenges in the industry and I believe that the government and the sector must work together to create a more appealing image, both nationally and internationally.

Q: What products and services does the company offer?

A: The company’s experience in the sector allows us to identify the needs and understand the problems miners face. We offer a wide range of services and products for the mining industry, including 20-ton trucks such as the GHH Dump Truk MK-20, which is easy to use and maintain. We also have a line of resinous products that provide the formwork and robustness for mine tunnels to avoid gaps and water leaks. Through the implementation of high technology, we provide a less expensive solution compared to other similar services on the market.

We also provide products that do not have high levels of electronics, which can be very difficult to repair if the mine site does not have a sophisticated workshop. We offer

products with high-quality engines. Our components are mostly of well-known brands that have several workshops that ensure prompt repair or service. The company knows that selling products is not the real business. It is the service we provide after the sale that is important, so we really make sure our customers know they can count on us.

In addition, there are many products that can increase the productivity and safety of a mine. An example is when a mine needs to conduct an explosion and has to evacuate all its personnel. Their return can be delayed due to many factors. However, an automated SK vehicle can enter the mine and remove products without wasting time or risking personnel.

Q: What alliances does the company want to make and what are the benefits companies obtain when working with Délano Schmidt & Kranz?

A: This year, we are working strongly on our marketing efforts to show the market place our products and values. We have a couple of projects with the mining clusters who have been very open and helpful to support our initiatives. We also want to increase our presence in the contractor market. We want them to understand the benefits that our services and products provide, especially our vehicles, which will be seen as a new alternative in mining.

The main added value we offer our partners is a reliable technology and product. The company offers a high availability of its products and an excellent knowledge of how to use them efficiently in mining operations. We also have great knowledge of the market and technologies oriented toward digital marketing, which has allowed us to provide our partners with an important marketing tool.

Q: What goals does Délano Schmidt & Kranz want to achieve and what are its strategies to achieve them?

A: Our goals imply 100 percent sales growth compared to last year. As part of our strategy, we intend to invest in digital marketing, hire new resources, include new brands in our portfolio, get closer to the digital and face-to-face market, continue with innovation and look for new business platforms.

We also have a strong interest in clean energies and innovation; for instance, hydrogen products that we want to promote in the Mexican market. Therefore, this year we want to participate in energy forums and communicate to our potential customers of the benefits of hydrogen and its use in mining and other industries.

Jan Petzold

CEO | GHH Group

Q: What solutions does GHH offer?

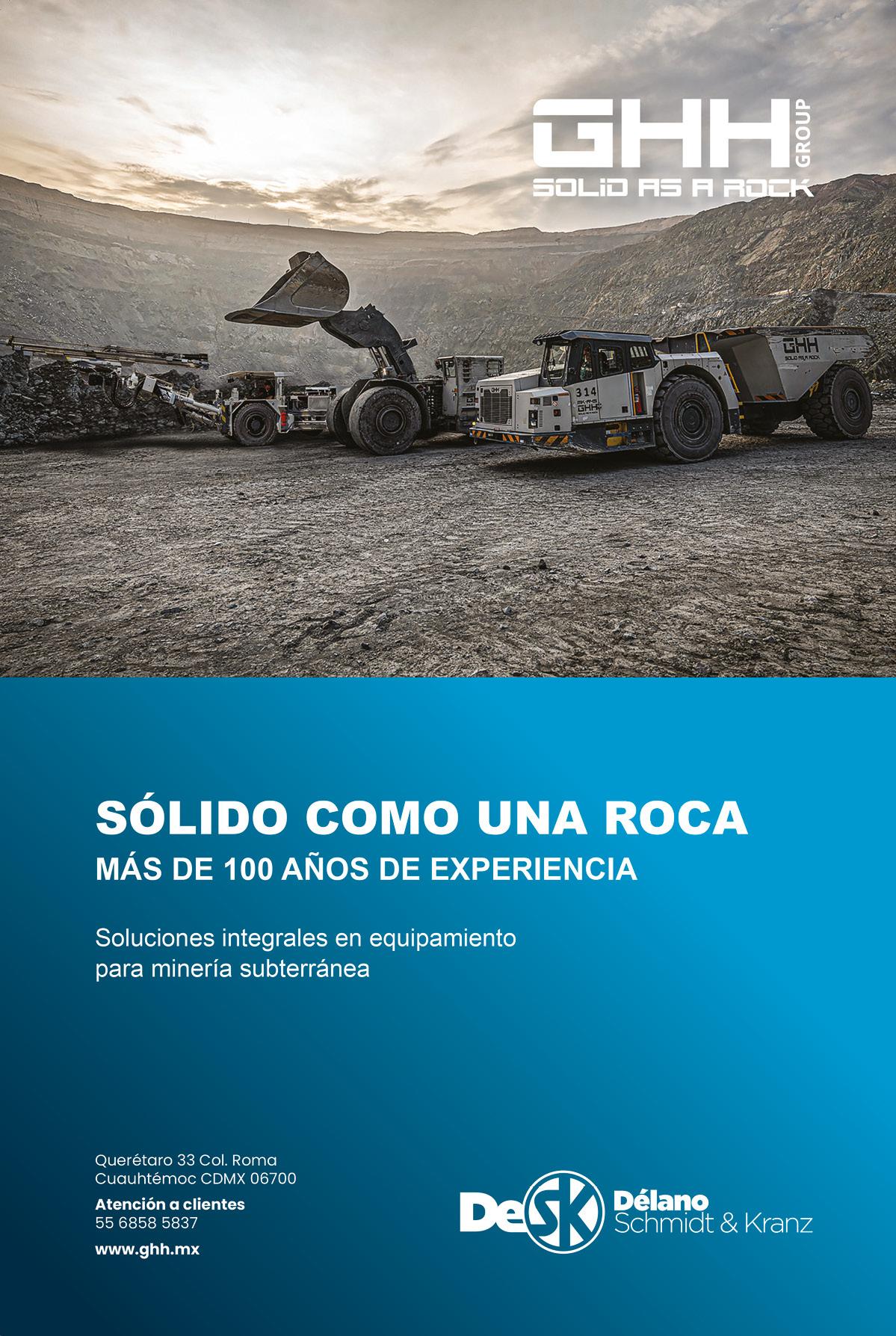

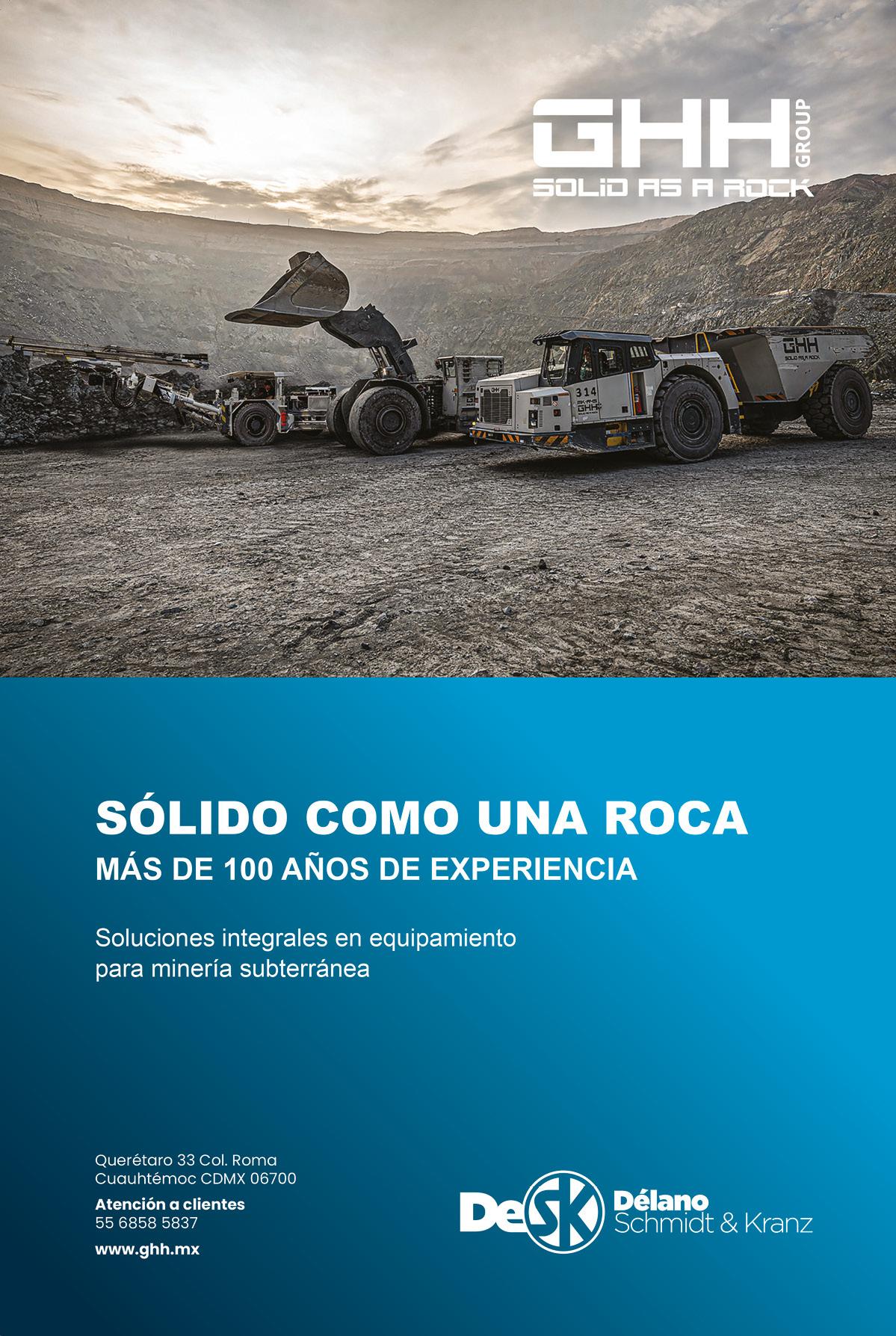

A: GHH Group is an integral solutions provider with production facilities in Germany, Poland and South Africa. We have assembly facilities in countries such as Chile and other strategic partners around the world. GHH’s offering includes loaders, trucks, drills, bolters, long-hole production drills and various utility vehicles for both the Hardrock and Softrock mining and construction industries. GHH is proud to provide customers with tailor-made solutions, while being able to deliver fit-for-purpose machines to the industry. The ability to adapt and have the flexibility to deliver custom solutions in short “time-to-market” timelines is key to GHH’s success.

Q: How has GHH evolved its position in the Mexican mining market?

A: GHH has been in the Mexican market for a while, and we are providing our 20-ton dump trucks and LHDs up to 10 tons. Our alliance with DeSK, which is our dealer in the Mexican mining market, has given GHH boots on the ground.

DeSk has a good footprint with key customers and has the experience to provide frontline services when required. DeSK is in constant contact with the mining industry, while we, as a mediumsized entity, have the advantage of having rapid decision-making processes, which allows us to jointly identify the needs of the end customer and provide our clients with appropriate solutions.

Q: How does GHH’s technology benefit the Mexican mining sector and what differentiates its solutions?

A: We have more than 900 people working with us internationally, including more than 150 mining engineers. Since we are engineers and mining engineers, we have a clear understanding of the market’s needs, the application of our products and the mining methods used by our customers. As a result, GHH offers rock-solid products: simple, robust, reliable, long-lasting, easy to maintain and with size classes of up to 45 tons in dump truck and 21 tons in LHDs. We believe that the sizes of the products we are providing are an advantage in the market, since they are particularly made for the geology where the client is operating. In addition, if customers want intelligent machines with digital analytics, GHH can also provide customized solutions to suit their specific needs.

Q: Why should companies incorporate GHH’s new product LF-7 and how does it increase safety and productivity in operations?

A: The LF-7 is a versatile middle-class loader that meets the demands of both large, narrow vein and small-mass mining operations. At approximately 18 tons of operating weight, the LF-7 is powered by a 164kW Cummings diesel, making it the best in its class. It complies with Tier 3 and Tier 4, as well as with EU and US Stage 5 emissions standards, so this is one of the cleanest vehicles around when it comes to safety. From an operational standpoint, the LF-7 easily copes with gradients of up to 28 percent and reaches speeds of up to 27 km/h.

The ergonomic cab is ROPS/FOPS certified and offers a high level of safety and ergonomics with a comfortable t-back seat, low whole-body vibration and noise levels, as well as ride control and great visibility.

Read the complete article

More about this company

More about this topic

We have one of the largest cabins on the market, for this size class loader, since we place a great deal of importance on the comfort of our operators. In addition, the new product allows the operation of 18 tons with an up to 25 percent incline, which is a huge advantage compared to other products that only allow operations on less angles and inclines.

Q: What is GHH approach to technology development regarding electric battery equipment?

A: Industry discussions are taking place regarding batteries and alternative diesel energy sources. The question is whether everyone will be using it or will it only be used in markets where the government is providing funds or forcing the industry to use alternative batteries. GHH has decided to focus on a combined technology, a hybrid that combines batteries and cables.

GHH has designed and developed the LF-19EB, a tethered battery specifically for the potassium industry. We are also developing other products in this technology range. The benefits of a battery to tram between working panels removes the need for towing facilities or a generator, which is a huge advantage for any operation. With this product, clients can provide a constant flow of power to the off-grid system in the mine and they do not have to recharge the battery, as is required with battery-powered equipment. A normal battery-powered machine will not last more than three hours but our equipment allows it to operate within a radius of 500 meters with constant power supply and no interruptions.

Q: What are the benefits of 100 percent electric light vehicles?

A: We are offering 100 percent battery-driven light-duty vehicles in cooperation with the Dutch company Tembo. Light vehicles are visionary cars that reduce the heat and emissions in mines. These are fast vehicles and we believe that this type of car is well suited for the Mexican market. We are offering 72kw hours of battery power under normal driving conditions. The battery can be charged at stations that can be located at any point in the mine.

Most people worry that the more electric a mine is, the less work there will be for people; however, this narrative must change. These cars represent a new opportunity for infrastructure. In addition, there are weighted calculations of CAPEX versus OPEX in the implementation of light electric vehicles.

Q: What is GHH inSiTE and how does it maximize the value of data to improve mining operations?

A: The term GHH inSiTE is meant to demonstrate extensive on-site operations alluded to by the implied word “insight.” It provides digital performance and condition monitoring, as well as the baseline for the future of digitally optimized mining operations. It provides improved operational safety and cost control, without requiring a substantial effort on the part of the user. In the simplest format, GHH inSiTE measures data related to the equipment’s performance, which allows clients to have data analytics and visualization.

GHH inSiTE is not only for GHH equipment. Our system can also operate with other OEM machines.

CEO | Nerospec SK

Q: What problems and issues does your technology solve and what are some of the advantages it brings to your clients?

EP: In regard to the digitalization and modern technology challenges we see in mines around the globe, as well as in Mexico, what we need is to get data communication into underground mines. We provide dedicated underground communication technology all the way from traditional levels of Leaky Feeder UHF communication, enhanced with localization of people inside machines up to modern, broadband WiFi booster connections with outstanding range results not achieved anywhere in the world, as far as we know. This allows for seamless data logging and analytics for productivity, measurement and tracking, as well as for maintenance usage. Automation is another main focus for us. Automation is a great safety feature because in mining, people need to go to dangerous places. The core benefit of all of these things is increased safety, especially with moving vehicles. These are the tangible benefits for our customers.

Q: What are the advantages of implementing Level-9 technology?

EP: We have successfully developed this technology for more than six years in South Africa. Approximately 2,000 underground machines benefit from our machine interface and control technology. This enables any Proximity Detection Vendor to fit their Proximity Detection System to any mining machine to achieve intervention control (level 9) in response to the detection of threats picked up by their system. With basic detectionlevel solutions there is a screen in the cabin that indicates that something is getting dangerously close to you, leaving the system still reliant on the operator to react. Level-9 means that there is not only a creation of awareness but also what is industry termed as “machine intervention”, meaning that the Nerospec SK controller intervenes in the control of the machine and two actions happen: the machine is slowed to a crawl and then it is stopped by applying the brakes. This is the definition of Level-9 and in South Africa it is becoming a standard requirement in the mining sector to avoid people getting harmed.

Q: What is Nerospec SK’s vision in Mexico regarding underground wireless communications solutions, data logging and analytics and machine automation?

EP: Our technology can benefit the Mexican market in the categories of safety and automation, while enabling very efficient underground communications and data visualization systems. Our vision is that the new generation of miners expect mobile phones to become regular tools to obtain data, and they expect this to work like a coffee machine or like your regular mobile phone. Today in underground, we are still a long way from reaching this point but there is no question that future generations will expect the technology to work very naturally, also underground. Especially autonomous solutions are defining this vision and setting the requirements, defining the underground workspace to be highly connected and safe. In the future, people will not want to go underground because it is time consuming, it is dangerous and you need to be prepared for it. I envision a future in which there are vehicles capable of autonomous operations everywhere.

Q: Délano Schmidt & Kranz distributes your technology in Mexico. What is your working relationship and how has this relationship evolved regarding delivery times, safety and logistics?

EP: We have had a very long-term relationship with DeSK. There is a whole breadth of products coming from the Schmidt & Kranz group and companies that are distributed via the DeSK organization. This has been essential for our success in Mexico, especially having the footprint in place with the language, the culture, the proximity, the readiness to go and have a meeting wherever. All of this has been very valuable for us and has helped us to develop the GHH business. Regarding Nerospec SK, we now have a whole sequence of business opportunities in Mexico that are very active and vibrantly engaged.

Q: What do you bring to the table in terms of the implementation of certain safety measures?

EP: Our sweet spot is what you call the PDI proximity detection interface. This PDI is the controller that connects to the vehicle, meaning that we control the vehicle functions and whatever needs to be done. What we provide the Mexican market and elsewhere is the ability to retrofit traditional classic machines that are the installed everywhere. These are electro hydraulically controlled machines, not the newest generation, but the hundreds of machines that are out there. For these machines, there are no retro fit solutions, except the solutions that we provide. We are absolutely ready to put data collection and machine control solutions on your old-school machines. Our simple solutions can be applied to old-style machines. I also want to point out that we will integrate our products and services into any specific mine. That is the value offer and benefit we provide. We integrate across the whole fleetof vehicles such as Caterpillar, Sandvik, Epiroc, GHH as well as Toyota trucks and other utility vehicles, like cements trucks, people movers and others.

Q: How has your partnership with Neurospec evolved in Mexico?

JD: Délano Schmidt & Kranz started its partnership with Nerospec SK sometime in the middle of last year. We have been very straightforward with our presentation. Eric is a very open and direct executive who has a strong knowledge of the solutions that can be applied and he also has a strong background regarding Nerospec SK partners. They have many years of experience, mainly in the South African market, and have introduced many applications in other countries.

An additional point that DeSK brings to the table with our Nerospec SK relationship is that we have a strong experience in telecommunications, which is also part of the solution. This means the ability to talk to miners and present them with solutions.

An example is to present them with the opportunity to have excellent quality cellphone conversations. To understand that part of digitalization that we are leading in the telecommunications arena and bring it to the underground mine creates a strong liaison for the product we want to introduce. So that also is part of the wealth we bring to the table and part of this wonderful relationship with Nerospec SK that we are developing. We are working on a couple of projects and we know there are many more on the way. Read the complete article