MUN 100 SPECIAL RESEARCH REPORT 2025

MUN 100 SPECIAL RESEARCH REPORT 2025

$801,000 $759,073 $1,020,000

STEVE BUTT WITH PARTNERS —Novamera Inc. NSERC Alliance Grant: Surgical Mining for Massive Sulfide Deposits

YAN ZHANG, KELLY HAWBOLDT, AHMED ELRUBY, SHEGUFTA SHETRANJIWALLA WITH PARTNERS

E-Tech Resources Inc. and Torrent Capital Ltd. NSERC Alliance Missions Grant: Characterization and Solvent Extraction of Rare Earth Elements

JONATHAN ANDERSON WITH PARTNERS National Cybersecurity Commission: Securing Critical Marine Systems

$585,400

OCTAVIA DOBRE WITH PARTNERS —Transforming Climate Action: Next Generation Technologies for Transforming Ocean Observation (OCTOPUS)

$250,000

BING CHEN —New Frontier in Research Fund Global Grant: ArctSolution: Arctic Pollution in a One Health Perspective - from Complex Challenges to Sustainable Solutions. Addition to €6M ArcSolution EU Horizon Europe program

MAJOR RESEARCH HIGHLIGHTS

MESSAGE FROM DEAN AND ASSOCIATE DEAN OF RESEARCH

DEPARTMENTAL RESEARCH HIGHLIGHTS

OUR FACULTY

A LOOK BACK: FEAS THROUGH THE YEARS

RESEARCH STORIES

ANNUAL RESEARCH DAY

INDUSTRY ENGAGEMENT DAY

FEAS-C-CORE PARTNERSHIP

FEAS-NRC

RESEARCH

I AM PROUD OF THE MOMENTUM WE’VE BUILT AND THE DIRECTION WE ARE HEADED.

As Memorial University marks a century of excellence in higher education, the Faculty of Engineering and Applied Science (FEAS) reflects on its legacy of growth and milestones-stepping confidently into a new era defined by innovation, intelligence, collaboration and impact at local, national, and global levels. Over the past 56 years, FEAS has flourished into a global leader in engineering education and applied research, driving innovation and addressing complex global challenges with purpose and distinction.

Rooted in exceptional research expertise and capabilities, FEAS has consistently advanced the frontiers of knowledge and technology, making far-reaching contributions and transformative impact across multiple disciplines of civil engineering, computer engineering, electrical engineering, mechanical engineering, mechatronic engineering, ocean and naval architectural engineering, and process engineering.

In 2024, our researchers have sustained a strong trajectory of innovation and excellence, securing over $24.6 million in funding through 203 grants and contracts and setting a record in the history. This year highlights the depth and impact of our scholarly contributions and research leadership in many challenging fields, from climate change and renewable energy to cybersecurity and artificial intelligence. Notable grant successes this year include multimillion-dollar collaborations supported by the NSERC Alliance and Alliance Missions grants, the New Frontiers in Research Fund (partnering with Horizon Europe Program), and the Canada First Research Excellence FundTransforming Climate Action program. These initiatives advance sustainable and critical mineral processing, Arctic pollution mitigation, marine systems security, and nextgeneration ocean observation.

Across departments, our faculty achieved significant milestones. In Civil Engineering, grants were secured for projects on thermoplastic water pipes exposed to ground movements, marine oil spill response, and biochar production from dairy manure. Electrical and Computer Engineering researchers advanced ocean remote sensing technologies, smart grid systems, and robotic swarm manipulation. In Mechanical Engineering, teams explored space surface modelling, advanced alloy coatings, and additive manufacturing. Ocean and Naval Architectural

Engineering researchers focused on autonomous shipping, marine safety, and impact modelling, while Process Engineering faculty worked on clean energy storage, biopolymeric and carbonaceous composite materials, and direct air capture technology.

Over the past year, our researchers and their trainees have produced 444 technical publications, including 147 openaccess articles. Many of these works have appeared in high-impact venues within their respective fields, with some receiving recognition through best paper awards. We also have 15 faculty members who have received institutional, national and international awards such as the Memorial President’s Award for Outstanding Research, fellowship of the Royal Society of Canada and the Engineering Institute of Canada, University of Regina Alumni Crowning Achievement, recognition of Top 2% Scientist in the World by Stanford University, etc. Our members have actively assumed leadership roles in scholarly and professional service, contributing to scientific committees, industrial and governmental advisory boards, journal editorial boards, and community organizations nationwide and worldwide.

Student research and experiential learning remain central to our academic culture. With a steadfast commitment, FEAS continuously strives to cultivate and enhance a stimulating, equitable, inclusive, and diverse training environment, supported by state-of-the-art research facilities, experiential learning opportunities, and robust supervision and mentorship frameworks. Our students and postdoctoral fellows have significantly contributed to advancing knowledge and technological innovation through highquality research outputs, including technical publications, conference presentations, and active engagement in professional communities. Their excellence is reflected in around 30 awards and honours, ranging from NSERC Banting Postdoctoral Fellowship and KEGS foundation scholarships to best paper and presentation awards and recognitions by professional associations.

Our Engineering Research Office (ERO) has continued to support the FEAS by offering development opportunities that enhance the quality and competitiveness of research applications and the training opportunities for highly qualified personnel (HQP), while actively promoting collaboration with other faculties and partners. Some of the events include Lunch & Learn sessions, NSERC and CFI application workshops, Research Poster Day, and Industry Engagement Day.

Our local and global partnerships remain key to our success. A testament to enduring collaboration, our long-standing partners also celebrate a shared legacy with FEAS—exemplified by C-CORE, marking five decades of joint contributions to ice engineering, remote sensing, and geotechnical engineering, and by the National Research Council of Canada (NRC) in St. John’s, reflecting over 40 years of collaborative advancement in ship design and vessel performance in harsh ocean environments. Our strong partnership with Professional Engineers and Geoscientist Newfoundland and Labrador (PEGNL) further reinforces our commitment to professional excellence and the advancement of engineering practice in the province.

These accomplishments underscore our interdisciplinary strengths and unwavering commitment to tackling complex, real-world challenges. FEAS remains dedicated to nurturing a creative, diverse, and inclusive research and academic environment where equity and collaboration are fundamental to advancing technology and training of next-generation researchers and professionals for the future.

As we celebrate a century of excellence at Memorial and 56 years of engineering achievement, I am proud of the momentum we’ve built and the direction we are headed. The Faculty of Engineering and Applied Science remains dedicated to nurturing a vibrant research culture that fuels discovery, supports students and faculty, and addresses the most pressing challenges of our time. We thank all our partners, funders, and collaborators who make our work possible and look forward to continued progress in the years ahead.

PHD, P.ENG., F.CAE, F.EIC, F.CSCE, M.EASA

Interim Dean and Professor, Faculty of Engineering and Applied Science

TOGETHER WITH OUR STUDENTS, RESEARCHERS, AND PARTNERS, WE ARE NOT JUST PREPARING FOR THE FUTURE—WE ARE WORKING TOGETHER TO CREATE IT

As Memorial University celebrates 100 years of impact, and our Faculty marks 50 years since the graduation of our first engineering class, we reflect with pride on the extraordinary progress that has brought us to this moment. In this MUN 100th Special Edition of our annual research report, in addition to reflecting on the our own history within FEAS, we proudly celebrate the 50th anniversary of C-CORE and reflect on nearly four decades of collaboration with the National Research Council (NRC). Our longstanding partnerships have been instrumental in positioning our Faculty—and Newfoundland and Labrador—as a global leader in cold oceans engineering. Our shared history is one of bold ideas, pioneering research, and a deep commitment to serving the needs of our province, our country, and the world. From founding the first co-operative engineering program in Atlantic Canada to leading global advances in cold oceans and harsh environment technologies, our faculty’s legacy is one of meaningful innovation and impact.

Today, our research community continues to rise to meet the challenges of our time. From cybersecurity and AI to the energy transition, quantum computing and

communications, green shipping, and sustainable infrastructure, our faculty is creating the knowledge, technologies, and partnerships that will shape the next 100 years.

This year’s Research Report reflects that momentum. In 2024, we secured over $24.6 million in funding, published 444+ peer-reviewed papers, and celebrated major successes in national and international grant programs. These achievements reflect both the diversity and depth of innovation across our faculty. Our students and postdoctoral fellows showcased their work at Research Day, and our strong ties with partners across industry, government, and Indigenous communities continued to grow through our Annual Industry Engagement Day and collaborative initiatives.

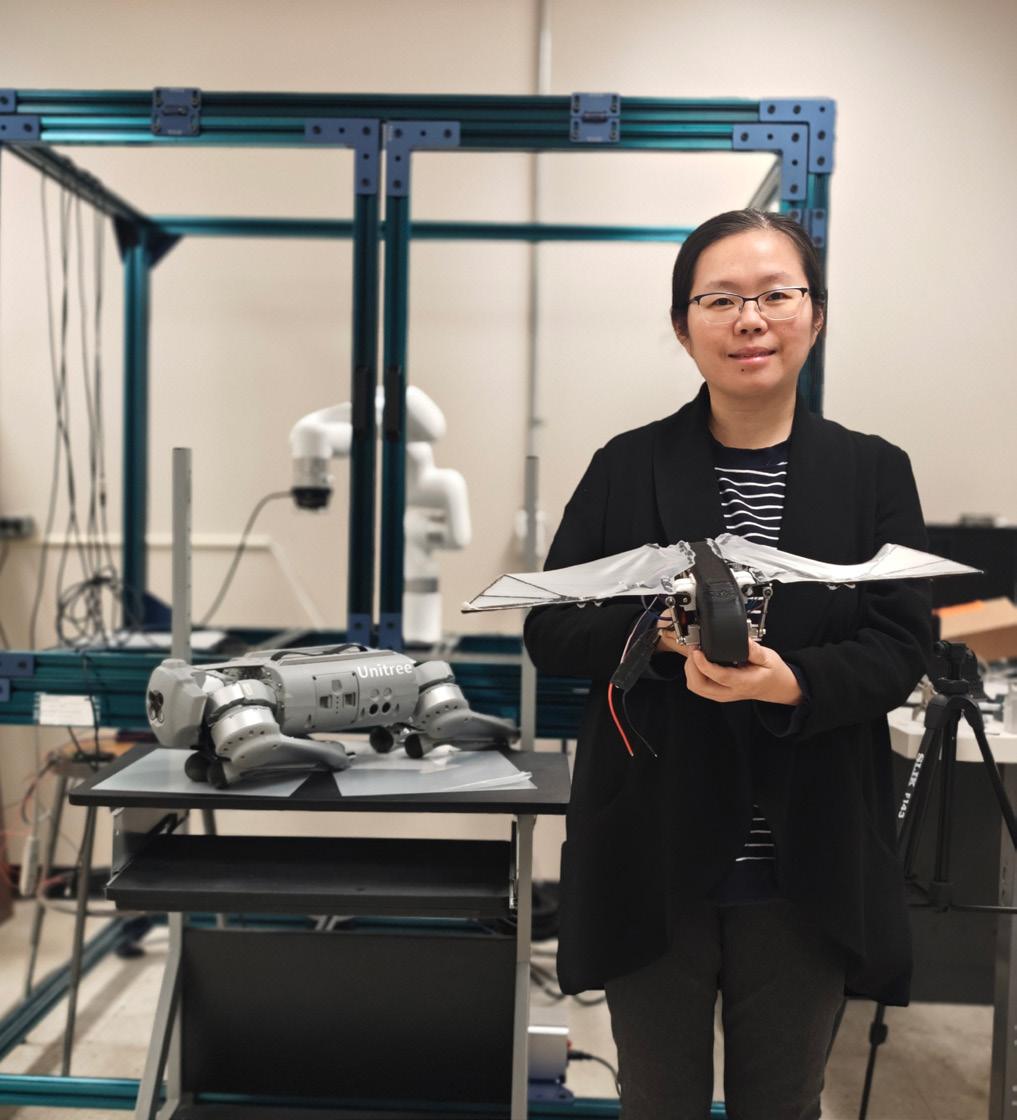

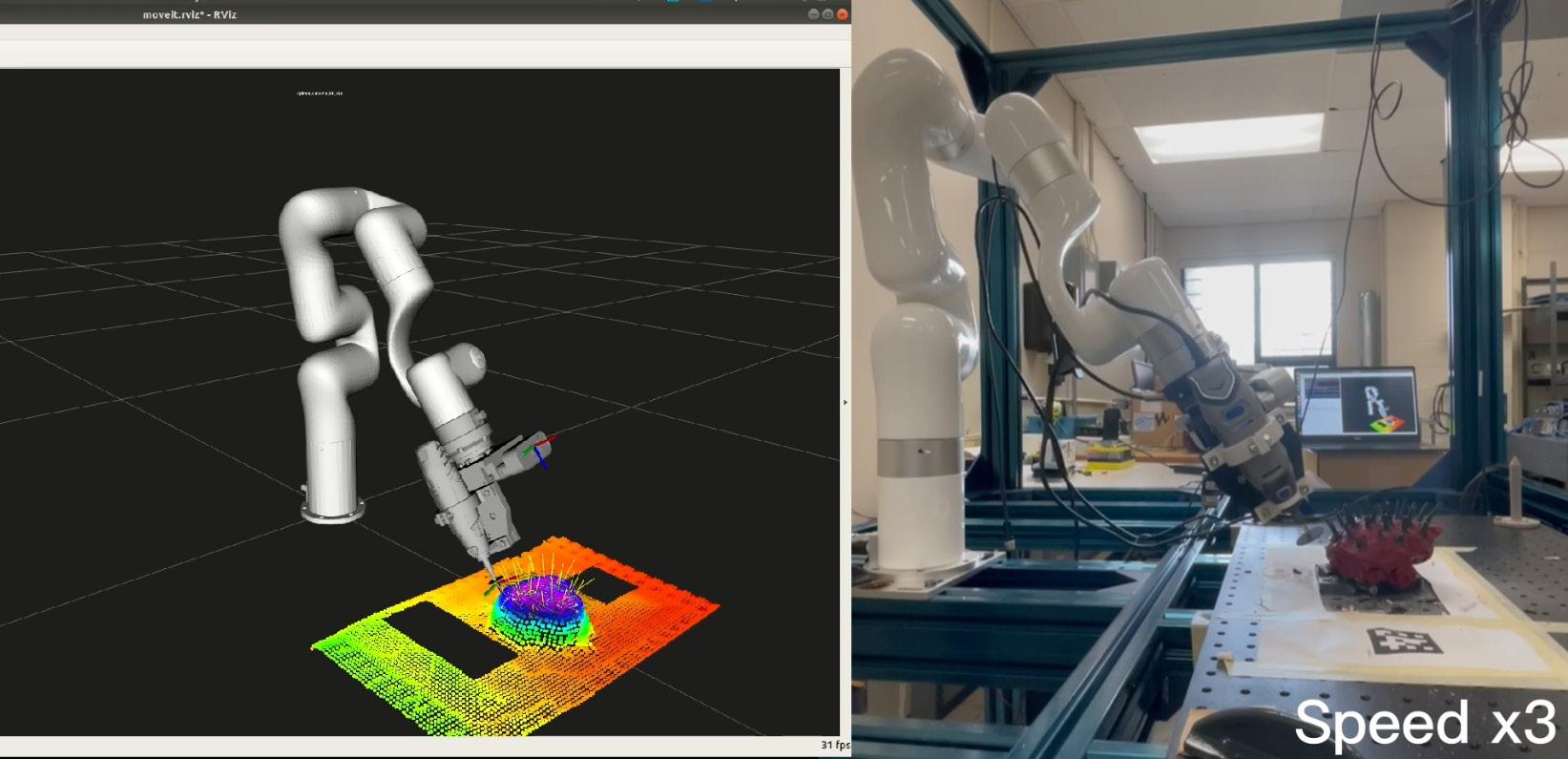

You will read about many of these efforts in this report— from Dr. Adam Noel’s pioneering work in molecular communication systems to Dr. Bing Chen’s international leadership on persistent organic pollutants in northern regions. Dr. David Molyneux is advancing safety and search and rescue in remote regions, while Dr. Hodjat Shiri is using

digital twins to enable smarter, more resilient infrastructure. Dr. Jonathon Anderson is helping to secure marine industry technologies against emerging cybersecurity threats, and Dr. Kelly Hawboldt continues to lead in transforming industrial waste into valuable bioproducts to support circular economies in northern and remote communities. You will also read about Dr. Liam Morrissey’s atomic modeling of space weathering, Dr. Ting Zou’s bio-inspired robotics, Dr. Wei Qiu’s work on reducing propeller noise, and Dr. Yahui Zhang’s work on using resins to efficiently separate metals from water and waste

As we reflect on this milestone at Memorial, it is not only a time of celebration, but a time of transformation. As our faculty continues to evolve, adapt, and lead, we do so with a shared sense of purpose. Together with our students, researchers, and partners, we are not just preparing for the future—we are working together to create it.

I invite you to explore this report, connect with our researchers, and celebrate what we have achieved together and the exciting path ahead.

Rocky S. Taylor PHD, P.ENG, MBA

Interim Associate Dean (Research) Professor

ASHUTOSH DHAR — NSERC Alliance International Collaboration Grant: Thermoplastic Water Pipes Exposed to Ground Movements

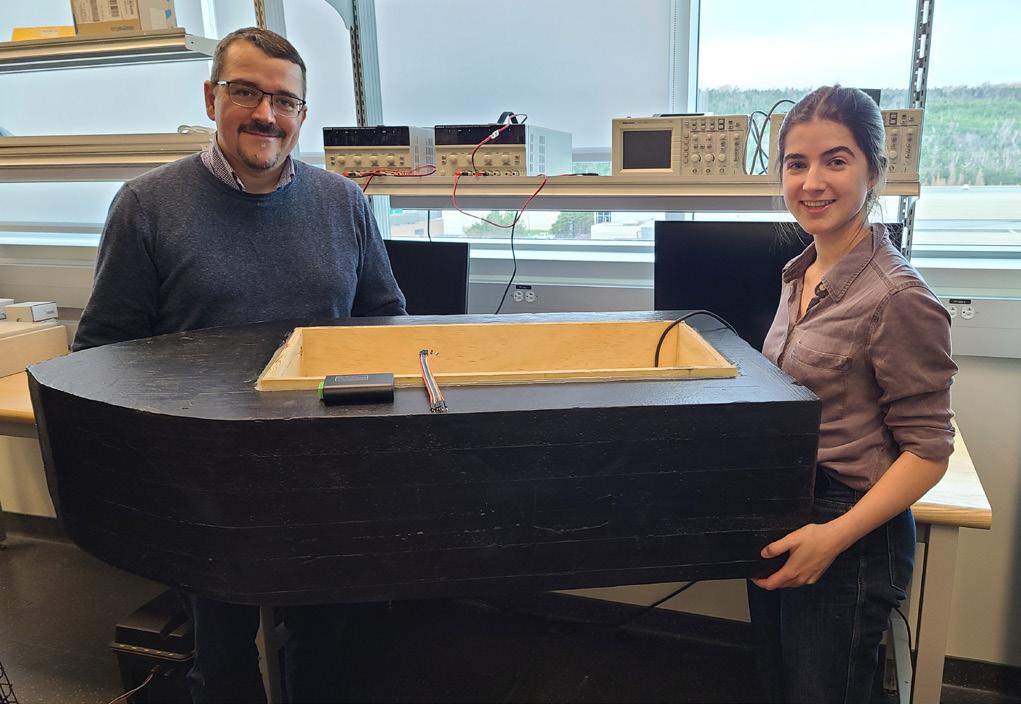

BING CHEN AND HELEN ZHANG — NSERC Research Tools and Instruments (RTI) Grant: Multi-Functional Wave Tank Platform for Marine Oil Pollution and Spill Response Research and Training (Wave-POL)

NOORI SAADY — Government of Newfoundland and Labrador: Investigating Manufacturing of Biochar from Dairy Manure and Studying its Effects on Biogas from Dairy Manure

WEIMIN HUANG — NSERC Discovery Grant: Ocean Remote Sensing Using Highfrequency and Microwave Radars: Theoretical Models and Application Algorithms

ANDREW VARDY — NSERC Discovery Grant: Multi-Object Manipulation by Robot Swarms

MOHSIN JAMIL — NSERC Discovery Grant: Innovative Power Electronics Technologies for Power Quality Improvements in Smart Grids

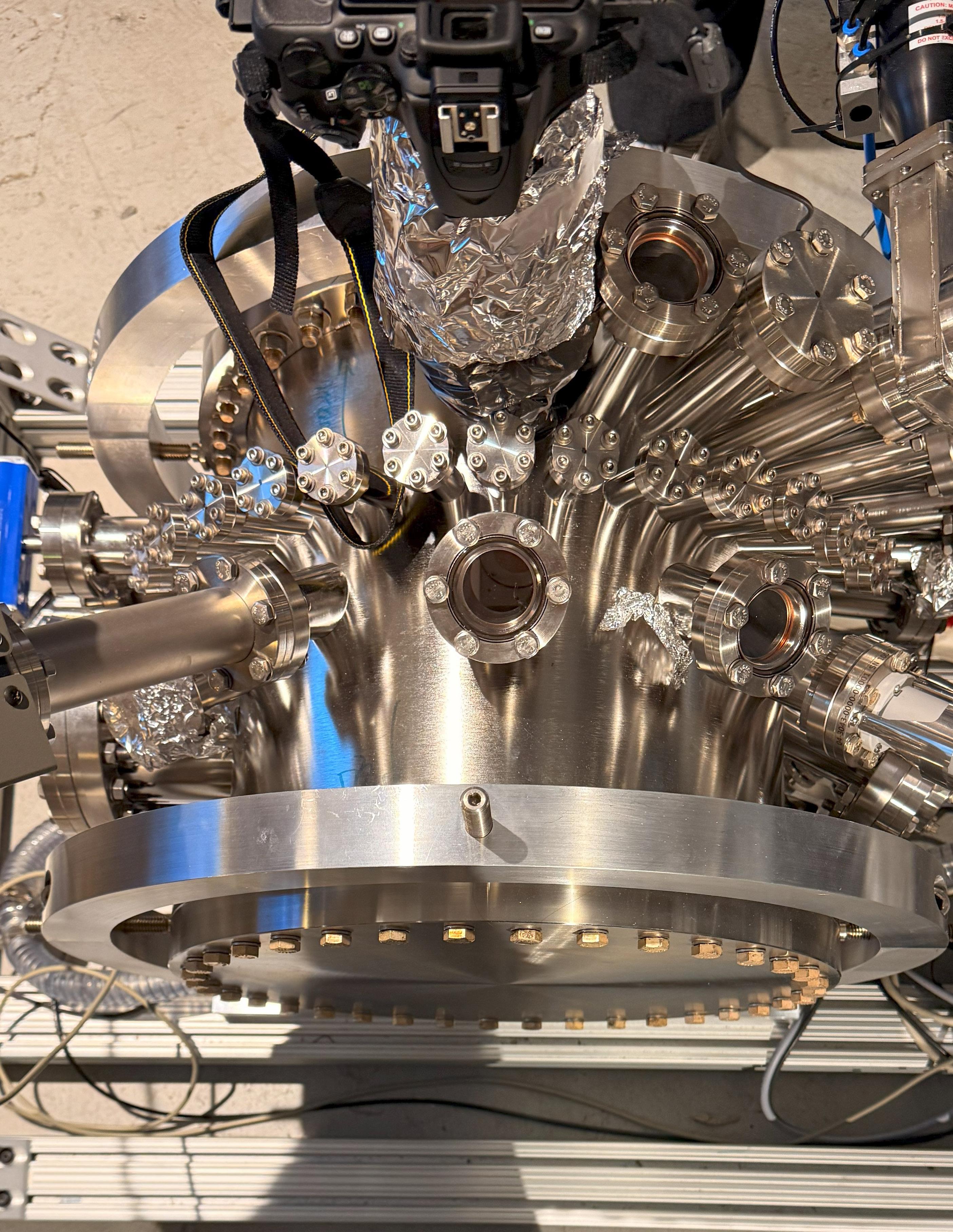

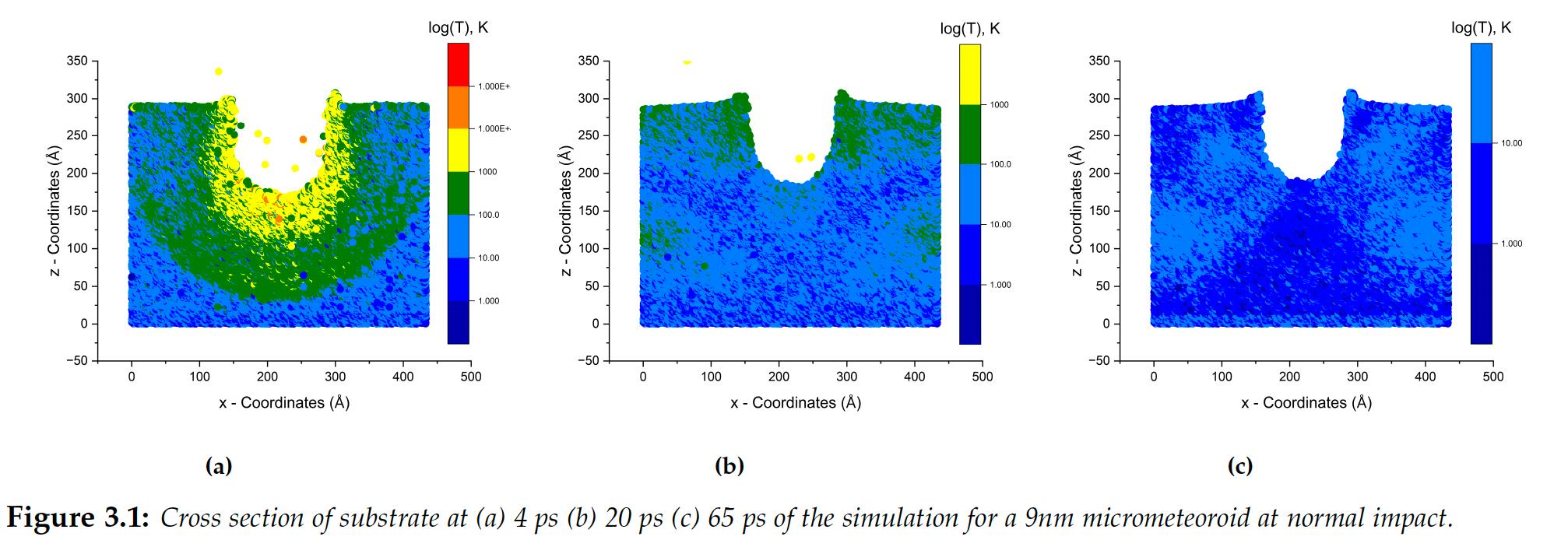

LIAM MORRISSEY AND KRIS PODUSKA WITH PARTNERS — Canadian Space Agency: From Surface Atom to Exposure: Theoretical multidimensional modelling of Surface Processes on the Moon and Mercury and Their Effects on Predicted Exposures

SIMA ALIDOKHT — NSERC Discovery Grant: Enhanced Surface Engineering of MultiPrincipal Element Alloys Tribological Coatings through Utilization of Third-Bodies Analysis Insights for Harsh Environment Applications

AHMED ELRUBY — NSERC Discovery Grant: The Effect of Microstructural Defects on the Elastoplastic Behavior of Additively Manufactured Multi-metallic Parts

WEI QIU — Natural Resources Canada: Opportunities and Gaps for the Canadian Maritime Autonomous Surface Ships (MASS) Sector

BRUCE QUINTON WITH PARTNERS — Femto Engineering: MoD Large Pendulum Impacts

BRIAN VEITCH WITH PARTNERS — Virtual Marine Technology Inc. Mitacs Accelerate: Adaptive Instructional System for Safe Marine Operations in Icy Waters

YAN ZHANG — NSERC Discovery Grant: Water and Wastewater Treatment by Porous Biopolymeric and Carbonaceous Composite Materials

LESLEY JAMES — NSERC Discovery Grant: Hybrid Data-Driven Molecular to Macro Upscaling for Clean Energy Storage

SOHRAB ZENDEHBOUDI — NSERC Discovery Grant: Assessment of Arctic Carbon Capture with Direct Air Capture (DAC) Technology

Interim Dean

Chen, B.

PhD, P.Eng., FCSCE, FEIC, FCAE, MEASA; Professor, Civil Engineering

Acting Associate Dean (Graduate Studies)

Hawlader, B.P.

PhD, P.Eng., Professor, Civil Engineering

Interim Associate Dean (Research)

Taylor R.S.

PhD, P.Eng., MBA; Associate Professor, Mechanical and Mechatronics Engineering

Acting Associate Dean (Undergraduate Studies)

Ahmed, S.

PhD, P.Eng.; Professor, Process Engineering

Director, First Year Engineering

Peng, H.

PhD, P.Eng.; Associate Professor, Ocean and Naval Architectural Engineering

Director, Ocean Engineering Research Centre Molyneux, D.

PhD, P.Eng.; Associate Professor, Ocean and Naval Architectural Engineering

Director, Centre for Artificial Intelligence Czarnuch, S.M.

PhD, P.Eng.; Associate Professor, Electrical and Computer Engineering

Director, Office of Industrial Outreach

Bruneau, S.E.

PhD, P.Eng.; Associate Professor, Civil Engineering

Senior Administrative Officer

Lewis, S.

BBA, B.Ed., MER

Acting Department Head

Dhar, A.S.

PhD, P.Eng.; Professor

Specialization: Geotechnical engineering; pipe testing; numerical modelling

Acting Deputy Head

Daraio, J.

PhD, P.Eng.; Associate Professor

Specialization: Climate change, infrastructure, storm water management, coastal flooding, flood risk

Professors

Chen, B.

PhD, PEng, FCAE, FEIC, FCSCE, MEASA, UArctic Research Chair in Marine and Coastal Environmental Engineering

Specialization: Marine & inland oil/HNS spill response; emerging contaminants under climate change; water & wastewater treatment and reuse

Hassan, A.A.A.

PhD, P.Eng.

Specialization: Development; durability; corrosion and service life prediction of concrete structures

Hawlader, B.P.

PhD, P.Eng.

Specialization: Finite element modelling; soil-structure interaction; geotechnical engineering

Zhang, B.

PhD, P.Eng., FCSCE, FEIC, Canada

Research Chair in Coastal Environmental Engineering

Specialization: Coastal Environmental Engineering, Environmental Biotechnologies, Emerging Contaminants

Associate Professors Adluri, S.

PhD

Specialization: Research mobilization; entrepreneurship; numerical methods

Bruneau, S.E.

PhD, P.Eng.

Specialization: Arctic ships and structures; energy; marine structural design and analysis

Hussein, A.

PhD, P.Eng., FCSCE

Specialization: Advanced composite materials as reinforcement for concrete structures; testing of concrete under generalized stress conditions; constitutive modelling of concrete structures

Saady, N.

PhD, P.Eng.

Specialization: Bioenergy; hydrogen energy; carbon capture

Shiri, H.

PhD, P.Eng.

Specialization: Offshore Geotechnics, Arctic and Harsh Environment Engineering, Sustainable Infrastructures

Professors Emeriti Jordaan, I.J.

PhD, P.Eng., C.Eng., FICE, FCSCE, FEIC, FRSC

Lye, L.M.

PhD, P.Eng., FCE, FCSCE, FEIC, FCAE

Deputy Head

Masek, V.

PhD, P.Eng.; Associate Professor

Specialization: Instrumentation and control; smart sensors and robotics

Professors

Dobre, O.A.

PhD, P. Eng, FRSC, FIEEE, FEIC, FCAE

Research Chair in Ubiquitous Connectivity

Specialization: Wireless communications and networking; underwater communications; optical communications

Duong, T.Q.

PhD, FIEEE, FEIC, FAAIA

Canada Excellence Research Chair in Next

Generation Communication Technology

Specialization: Wireless communications; quantum machine learning; quantum optimization

Gosine, R.G.

PhD, P.Eng., FCAE, FEC

Specialization: Telerobotics; machine vision; pattern recognition

Huang, W.

PhD, P.Eng.

Specialization: Remote sensing; ocean radar; machine learning

Iqbal, M.T.

PhD, P.Eng.

Specialization: Hybrid power systems; renewable energy systems; passive Houses; electronics and control systems

O’Young, S.D.

PhD, P.Eng.

Specialization: Unmanned aircraft; instrumentation; controls and automation; robotics

Department Head

Zhang, L.

PhD, P.Eng.; Professor

Specialization: Very large-scale integration; design automation; microelectromechanical system

Peters, D.K.

PhD, P.Eng., FEC, SMIEEE

Specialization: Software design and specification; high performance computing; machine learning

Vardy, A.

PhD, P.Eng., Joint appointment (Computer Science)

Specialization: Swarm robotics

Associate Professors Anderson, J.

PhD, P.Eng.

Specialization: Cybersecurity; operating systems; privacy

Czarnuch, S.M.

PhD, P.Eng., Joint appointment (Faculty of Medicine)

Specialization: Image processing; computer vision; machine learning

George, G.H.

PhD, CertEd, FRAS, FIMA

Specialization: Calculus; probability

Power, S.

PhD, P.Eng., Joint appointment (Faculty of Medicine)

Specialization: Biomedical engineering; brain-computer interfacing

Jamil, M.

PhD, P.Eng.

Specialization: Renewable energy systems; controls and power electronics, AI and machine earning.

Noel, A.

PhD

Specialization: Molecular communication; biophysical communication engineering

Assistant Professors Al-Nahhal, I

PhD

Specialization: Wireless communication; machine Learning

Khan, A.

PhD

Specialization: Power electronics; electric vehicles; energy systems

Shahidi, R.

PhD, SMIEEE

Specialization: Remote sensing; machine Learning, FPGA development

Wanasinghe, T.R. PhD, P.Eng.

Specialization: Autonomous robotics systems; applied AI and machine learning; digitalization & its socio-economic impact

Honorary Research Professor Moloney, C PhD

Professor Emeriti Gill, E.W. PhD, P.Eng.

Quaicoe, J.E. PhD, P.Eng., FEC

Venkatesan, R. PhD, P.Eng.

MECHANICAL AND MECHATRONICS ENGINEERING

Department Head

Rideout, D.G.

PhD, P.Eng.; Professor

Specialization: Modeling and simulation; vibrations; dynamics

Deputy Heads Mann, G.K.I. PhD, P.Eng.; Professor

Specialization: Robot trajectory control; multi-robotic systems; robotic mapping

Duan, X.

PhD, P.Eng.; Associate Professor

Specialization: Heat transfer; multiphase flow; energy

Professors Muzychka, Y.S.

PhD, P.Eng., FCSME, FASME, FEIC, AFAIAA; University Research Professor

Specialization: Fluid dynamics; heat transfer; multiphase flow

Nakhla, S.

PhD, P.Eng.

Specialization: Computer aided design; finite element modelling; structural health monitoring (metal corrosion and composites)

Pope, K.

PhD, P.Eng.

Specialization: Sustainable energy systems; wind energy; clean hydrogen production; ocean Energy

Sharan, A.

PhD, P.Eng.

Specialization: Energy and environment; robotics; artificial intelligence

Yang, J.

PhD, P.Eng.

Specialization: machine design; vibration analysis; wind turbine dynamics

Associate Professors

De Silva, B.M.O.

PhD, P.Eng.

Specialization: Navigation systems; robotics, artificial intelligence

Taylor, R.S.

PhD, P.Eng., MBA

Specialization: Ice-load estimation for the design of offshore structures; mechanics of compressive ice failure

Zou, T.

PhD, P.Eng.

Specialization: Robotics; machine learning; mechanism design and control

Assistant Professors

Alidokht, S.A.

PhD, P.Eng.

Specialization: Surface engineering; additive manufacturing; materials characterization

Elruby, A.Y.

PhD, P.Eng.

Specialization: numerical modeling; mechanical characterization, additive manufacturing; plasticity, failure predictions

Morrissey, L

PhD, P.Eng.

Specialization: Multiscale harsh environment modelling; mechanical properties of nanostructures

Said, M. W. M. E

PhD, P.Eng.

Specialization: Controls; robotics; mechatronics

Teaching Professors Rosales, J.

PhD

Teaching Assistant Professors Etminan, A PhD, EIT

Department Head

Qiu, W.

PhD, P.Eng., FSNAME, FRINA, FCAE; Professor

Specialization: Ship and offshore hydrodynamics; wave and body interaction; seakeeping; marine propulsion; CFD for marine applications

Deputy Head

Quinton, B W. T.

PhD, P.Eng.; Associate Professor

Specialization: Extreme and accidentals loads; ice impact; structural resilience

Professors Bose, N.

PhD, FCAE

Specialization: Autonomous underwater vehicles; marine propulsion; ocean environmental monitoring

Daley, C.G.

Dr.Tech., P.Eng., FEC, FSNAME, FCAE

Specialization: Arctic ships and structures; marine structural design and analysis; materials and mechanics; offshore and marine safety; safety and risk; simulation; structures and materials

Veitch, B.J.

PhD, P.Eng., FSNAME, FCAE

Specialization: Offshore and marine safety

Associate Professors Moro, L.

PhD

Specialization: Ship noise and vibration

Molyneux, D.

PhD, P.Eng.

Specialization: Ocean engineering; marine safety

Peng, H.

PhD, P.Eng.

Specialization: Marine hydrodynamics; numerical modelling; wave - body interaction

Walker, D.

PhD, P.Eng.

Specialization: Fishing vessel safety and design

Assistant Professors Smith, D.

PhD, P.Eng.

Specialization: Complex systems; organizational safety; functional modelling

Professors Emeritus

Haddara, M.R.

PhD, P.Eng., C.Eng.

Department Head

Imtiaz, S. A.

PhD, P.Eng.; Professor

Specialization: Process control; fault detection and diagnosis; nonlinear model predictive control; machine learning

Deputy Head

James, L.A.

PhD, P.Eng.; Professor

Specialization: CCUS; enhanced oil recovery; reservoir management; fluid-fluid and fluid-rock interactions; digitalization

Professors Ahmed, S.

PhD, P.Eng.

Specialization: Process safety and control; alarm system design; system identification

Butt, S.D.

PhD, P.Eng., University Research Professor

Specialization: Natural resources engineering and geology; drilling and mining technology development.

Hawboldt, K.A.

PhD, P.Eng., University Research Professor

Specialization: Chemical engineering; bioprocessing

Zendehboudi, S.

PhD, P.Eng.

Specialization: Energy and environment; Process systems engineering; transport phenomena

Zhang, Y.

PhD, P.Eng.

Specialization: Chemical and process engineering

Associate Professors Zhang, Y.

PhD, P.Eng.

Specialization: Mineral processing; extractive metallurgy; wastewater treatment

Assistant Professor Lin, C.

PhD, P.Eng.

Specialization: Automation in mine geomechanics; underground design; numerical modelling

Teaching Associate Professors Aborig, A. PhD

Teaching Assistant Professor Mamudu, A PhD

Lecturer

Azargohar, R.

PhD, P.Eng.

FEAS THROUGH THE YEARS MEMORIAL TURNS 100 AND FEAS CELEBRATES 56 YEARS

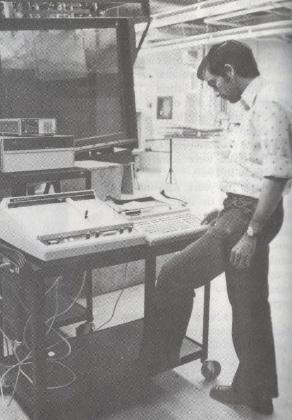

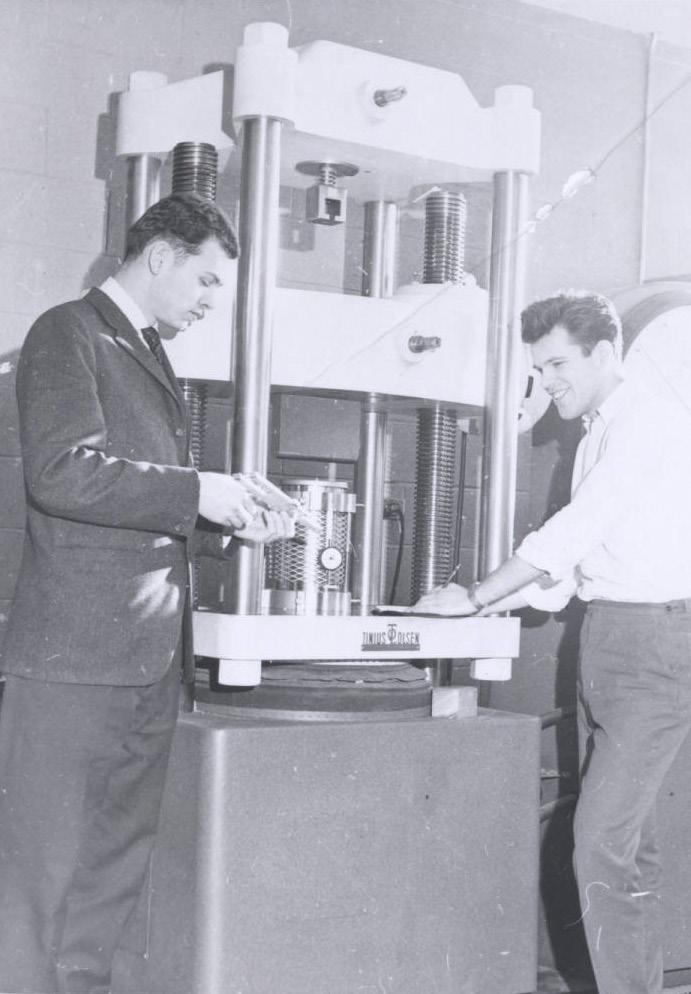

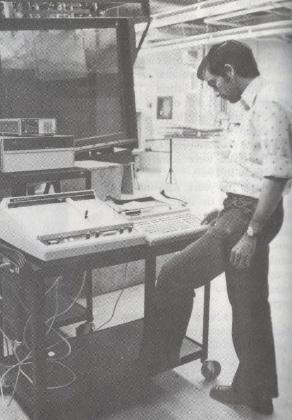

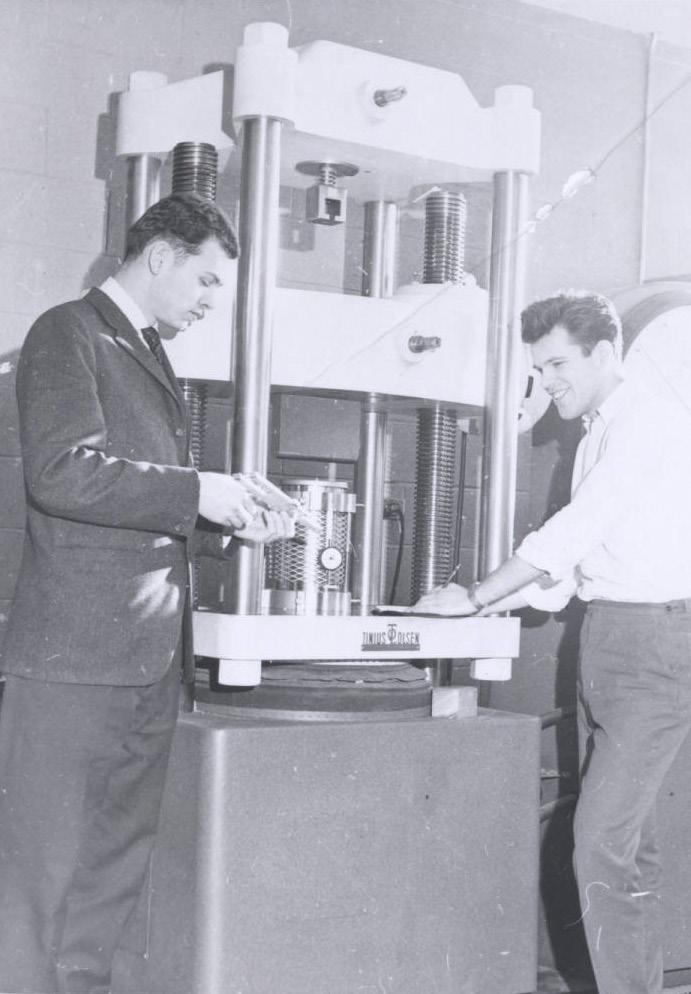

As Memorial celebrates 100 years, the Engineering Research Office (ERO) reflects on the evolution, milestones, collaborations, and transformative impact of the Faculty of Engineering and Applied Science (FEAS) during its first fifty-six years.

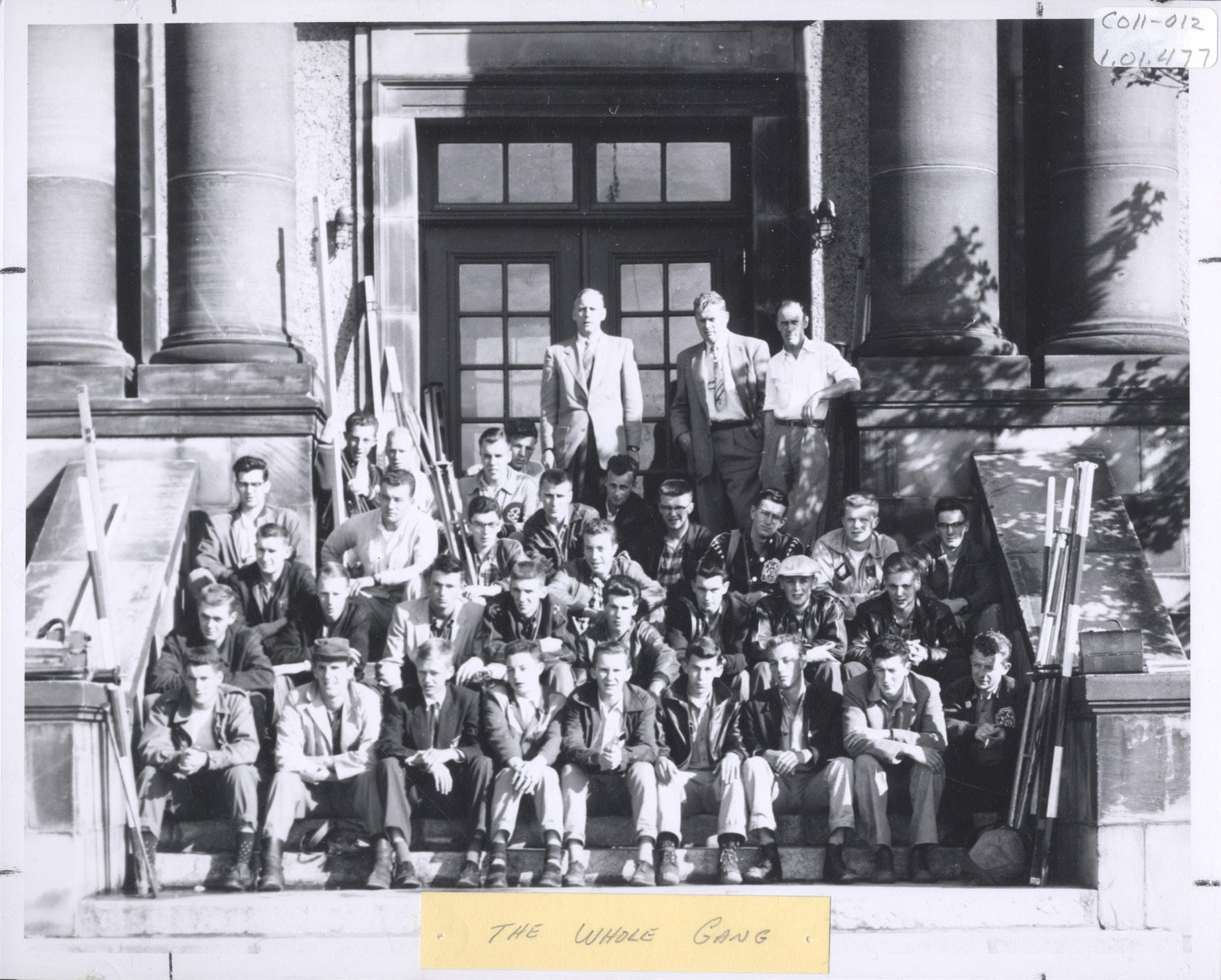

In 1930, five years after Memorial University College opened on Parade Street, a three-year engineering diploma program was introduced with Dr. Thomas Winter supervising the first thirteen students.

In 1949 Memorial University College became Memorial University of Newfoundland, a degree-granting institution. One year later in 1950, the Engineering Department was renamed the Faculty of Applied Science with Dr. Stanley James Carew, who hailed from Bell Island, as its first dean (1950-1968).

FACULTY OF ENGINEERING DEAN YEARS

Prof. Stanley J. Carew

(dean of Faculty of Applied Science before it became a degree-granting program)

Dr. Angus Bruneau (founding dean of the new Faculty of Engineering and Applied Science)

Dr. Robert Dempster

Dr. Colin D. DiCenzo

Dr. G. Ross Peters

1950–1968

1969–1974

1974–1980

1980–1982

1982–1992

Dr. Rangaswamy Seshadri 1993–2002

Dr. Mahmoud Haddara 2002–2003

Dr. Raymond G. Gosine

Dr. John E. Quaicoe

2003–2008

2008–2011

Dr. Ramachandran Venkatesan 2011–2012

Dr. Greg F. Naterer

(Dr. Dennis Peters acting dean from June 2021–July 2022)

Dr. Octavia A. Dobre

(First female dean (interim) of the faculty. Appointed as dean beginning January 1, 2026)

Dr. Bing Chen (Interim dean)

2012–2022

Opposite page: Engineering students and staff (back row S.J Carew, John MC Facey and A.O Nemec) on the steps of the Parade Street Campus. (Source: S.J. Carew Photograph Collection. MUN DAI)

In 1968, the engineering diploma program expanded into a full-degree program so students would no longer have to leave the province to get their B.Eng., and Dr. Angus Bruneau, a young professor from the University of Waterloo, became dean of the newly named Faculty of Engineering and Applied Science, which offered undergraduate degree programs in three disciplines: civil, mechanical and electrical engineering - as well as a new master’s degree (M.Eng.) in ocean engineering.

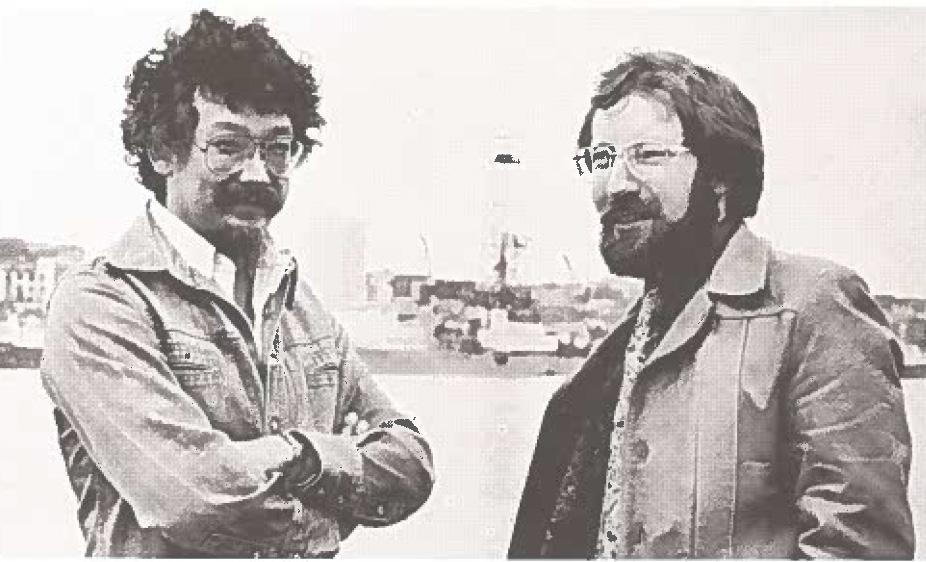

From the very beginning, Dean Bruneau decided that Memorial’s Faculty of Engineering and Applied Science would become a hub for cold ocean and harsh environment research. Understanding that offshore oil & gas fields would be developed in the near future, Dean Bruneau, along with Dr. Robert Dempster, who became the Faculty’s second dean, launched the first iceberg classification and towing expeditions in 1971, establishing a link between resource development and the academic community and leading to funding from both the oil & gas industry and the National Research Council (NRC).

2022–2024

2025

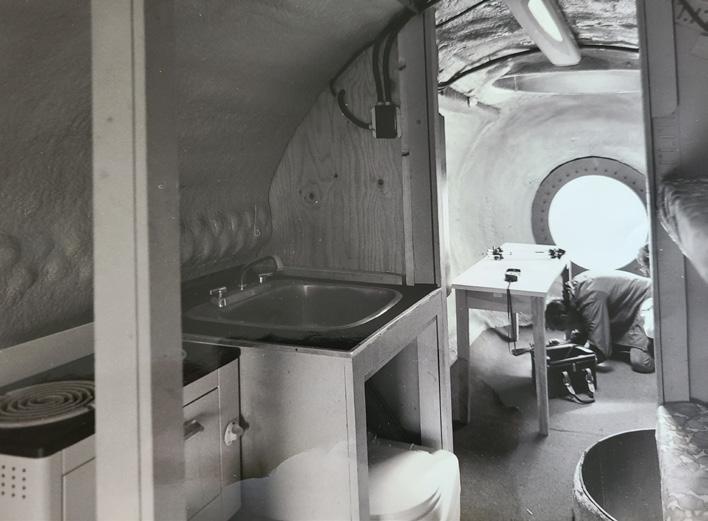

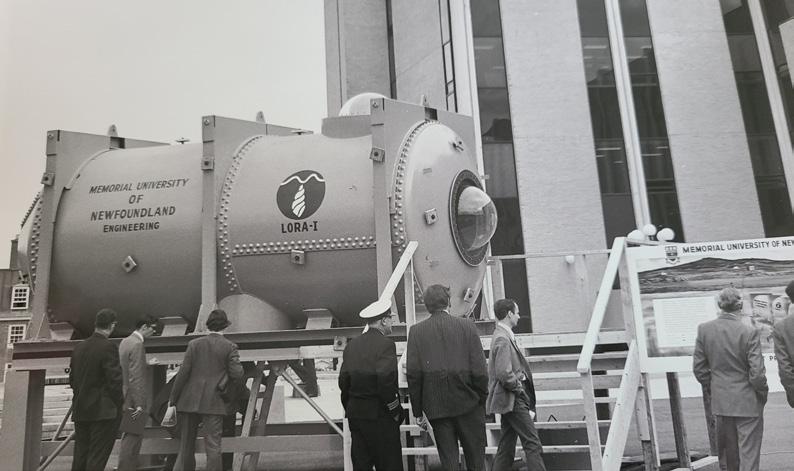

Another major project in 1971 was the development of an underwater laboratory called LORA-1 (Low Temperature Ocean Research Activity), which was built from scavenged parts and anchored to the ocean floor in Conception Bay.

The sixteen-foot-long cylindrical laboratory weighed eleven tons and could house students underwater for weeks at a time to study corrosion and metals behaviour, underwater pipelines and sediment movement and the dispersion of pollutants in coastal waters.

In 1974, leadership of the Faculty transferred to Dr. Robert Dempster who had the honour, along with Professors John Molgaard and John Allen, of overseeing the graduation of Memorial’s first electrical, mechanical and civil engineers.

David Rees was a member of that first graduating class, a cohort of seventy-six bachelor students. “Studying engineering at Memorial was wonderful; I enjoyed every minute of it,” he said. “The profs… were at the top of their game in their fields. It was great for us to be trained by them,” said David.

1975 was another pivotal year for the Engineering Faculty. Hilary Dawson became the first female engineering graduate at Memorial, and the civil, electrical and mechanical disciplines

achieved accreditation by the Professional Engineers and Geoscientists Newfoundland and Labrador (PEGNL). In November that same year, the Faculty moved to the new S.J. Carew Building which housed the Ocean Engineering Research Centre (OERC) with a fifty-eight-metre tow tank and a hydraulically-actuated wave board to test standard ship resistance, self propulsion and propellers.

The Centre for Cold Ocean Resource Engineering or C-CORE also opened in 1975 specializing in remote sensing, ice engineering and geotechnical engineering. Harold Snyder was the first director. “C-CORE would not exist if we hadn’t started those field studies in 1971,” said Dr. Dempster. “We started aerial photography using a single-engine plane which allowed us to calculate iceberg mass above the water and determine the portion underneath the surface.”

In 1980, Dr. Dempster introduced a new shipbuilding program with only two students and three faculty members, Bill Milne, Dr. Charles Hsiung and Dag Friis.

Today what is known as the Ocean and Naval Architectural Engineering allows students to gain experience in construction, management, marine engineering, marine hydrodynamics, ship structures, seakeeping and manoeuvrability, submersibles and small craft design.

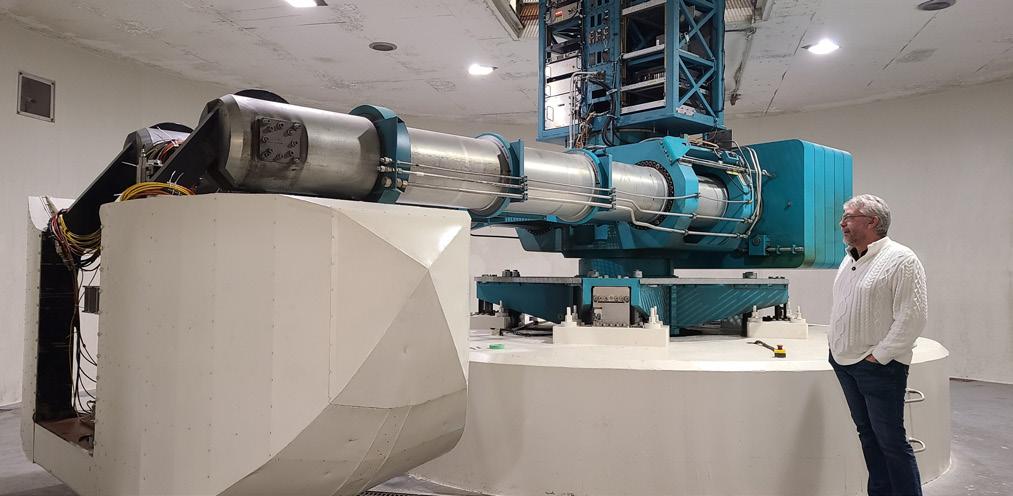

Four years after the debut of the shipbuilding program, the National Research Council (NRC) set up on Memorial campus. The NRC’s 200-metre towing tank and ninety-metre ice tank, one of the largest in the world, allow for ice modelling and scale-model testing of ships.

The Faculty was led by several deans over these years including Drs. Colin DiCenzo, Ross Peters, Rangaswamy Seshadri, Mahmoud Haddara, Ray Gosine and John Quaicoe.

During Dr. Colin DiCenzo’s short tenure as dean, the Faculty employed seven professors, twenty-seven associate professors, nine assistant professors and two forestry professors. For his contributions to engineering and science education, he was appointed as a Member of Order of Canada in 1972.

Dr. Ross Peters led the Ocean Engineering Research Group, served as chair of PEGNL’s board and received the Order of Canada for his work on the Canadian Engineering Accreditation Board.

Dr. Rangaswamy Seshadri established new industry partnerships, started the Office of Industrial Outreach and worked to attract the first Canada Research Chairs to the Faculty.

In 2002, long before he became dean, Dr. John Quaicoe played a leading role in introducing transition and fast-track programs to allow high school students direct entry into the Faculty.

In 2004, recognizing the demand for a course-based postgraduate education in computer engineering, a Master of Applied Science in Computer Engineering (MASCE) was developed by Dr. Venkatesan, who had become associate dean of graduate studies and research and Dr. Ray Gosine, who was then dean. These programs were developed in response to both opportunities and challenges that had been identified by Dr. Mahmoud Haddara,

previous associate dean of graduate studies and research and interim Dean.

Then between 2003 and 2008 the Faculty, under the leadership of Dean Ray Gosine, redesigned the undergraduate engineering curriculum to reduce the length of the bachelor’s degree program from six to five years. Dr. Gosine, who also served as chair of PEGNL, was instrumental in mentoring several start-ups such as Intrignia Solutions and Verafin, which was acquired by Nasdaq in 2020 for $2.75 billion USD.

In response to the need for engineering solutions to oil & gas industry challenges, programs in process engineering and a master’s in oil & gas engineering were introduced, and in 2013, the Hibernia Enhanced Oil Recovery (EOR) Laboratory opened in the Bruneau Centre.

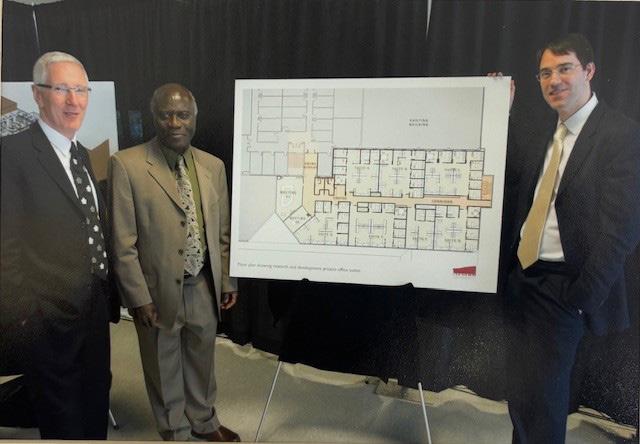

In 2008, the position of associate dean of graduate studies and research was split into two positions with Dr. Brian Veitch becoming the first associate dean of research. Dr. Veitch with Dean John Quaicoe solicited support from industry to finance the 2014 Suncor Energy Offshore R&D Centre, the 14,200-squarefoot expansion of the S.J. Carew Building which enabled the university to take on large offshore engineering research projects in collaboration with industry partners.

In 2014, the Faculty launched the Memorial Centre for Entrepreneurship (MCE) in partnership with the Faculty of Business,

which has led to the creation of companies like CoLab Software, BreatheSuite and Mysa Smart Thermostats. The Faculty also houses the Student Design Hub (SDH), which provides hands-on space and resources for students to collaborate, develop prototypes and innovate through engineering design projects and competitions.

From 2008-22, under the leadership of deans John Quaicoe and Ramchandran Venkatesan, the number of international students in the Faculty continued to increase to the point that today the Faculty has graduate students from more than thirty countries.

During the ten years Dr. Greg Naterer was dean (2012-22), undergraduate enrollment increased by over twenty per cent and graduate enrolment approximately doubled.

In 2022 Dr. Octavia Dobre became the Faculty’s first female dean (interim). “Solving problems to enhance the community and the country continues to be the main focus of the Faculty,” she said. “From its humble beginnings in 1930 with thirteen students and one professor, we have grown to thirty-degree programs across seven disciplines – twenty-three graduate and seven undergraduate. From one female student in the class of 1975, today Memorial is a leader of student diversity and women in engineering. For the past two years, Newfoundland and Labrador has had a significantly high percentage of female undergraduate engineering students nationally, at over 29 per cent.”

Dr. Bing Chen now leads the faculty as the interim dean. Since the first engineering students graduated in 1974, the Faculty has grown to 1,300 undergraduate students, 925 graduate students, roughly 1,000 co-op work term placements per year. External research support has also grown from under $2 million in the mid-1990s to nearly $25 million in 2024, reflecting the faculty’s expanding role in research and innovation. Over the past three decades, the faculty has secured more than 4,440 external research grants, totaling over $266 million.

Today, in addition to its concentration on ocean technology; the Faculty of Engineering and Applied Science has become a research centre for information and communication technology and is home to the Canada Research Chair on Ubiquitous Connectivity, the Canada Excellence Research Chair in Next Generation Communication, the Centre for Artificial Intelligence (AI), as well as the Quantum Communications and Computing Centre.

From iceberg tracking and classification to designing and building communication satellites, the only way for the Faculty to go is up.

A full-length version of the Faculty of Engineering and Applied Science’s history is availble on our website.

$25,000,000

$20,000,000

$15,000,000

$10,000,000

$5,000,000

(Source: MUN fact sheet)

Can you imagine a future in which humans have implants to help regulate their metabolism? Or, how about a fleet of tiny robots working together to destroy cancer cells?

Dr. Adam Noel, associate professor of electrical and computer engineering, certainly can.

“It all comes down to being able to manipulate how cells communicate - if we can strengthen certain signals or weaken those that are harmful, we can then target diseases and conditions where there’s a breakdown of communication,” said Dr. Noel, who came to Memorial in 2024 from the University of Warwick in Coventry, UK, where he spent six years doing research into what is known as molecular communication engineering.

“Molecular communication engineering is a collaboration between engineering, chemistry, biology and medicine that can lead to devices that listen and talk to cells. Cancer and bacterial infections, for example, tell the body to reproduce undesirable cells too quickly whereas in the case of neurodegenerative disease, cells become less efficient at sending signals. Being able to manipulate cell communication would be a gamechanger for helping those suffering from diseases such as Multiple Sclerosis or Parkinsons where cell communication is damaged.”

Futuristic? Yes. Doable? Also, yes.

But let’s back up a bit and explain how Dr. Noel became one of the most renowned researchers in this field.

When Dr. Noel first began his studies in communication engineering, he was immersed in the more traditional communications fields involving wired (fibre-optic cables or Ethernet) or wireless (WiFi, Bluetooth or 5G) communications;

the latter based on transmitting electromagnetic waves. In these more well-known fields, many devices can be connected in a web, like the Internet; or one device can communicate directly with another without going through a hub - think walkie talkies which use a transmitter and receiver. Currently, Dr. Noel shares this engineering knowledge with Memorial students through courses on random process and digital signal processing (DSP). He is also supporting the new mechatronics program that is shared with the Department of Mechanical and Mechatronics Engineering with a course on microprocessors and digital logic.

When Dr. Noel began his PhD, however, his research ventured beyond the systems we currently use to explore communication between human cells. Communication at a molecular level is a whole new ballgame for communications models, with millions of cells transmitting chemical molecules.

“The attempt to understand how specific cells and organisms use molecules to communicate is what interests me,” said Dr. Noel. “Once we understand this, perhaps the day will come when scientists can manipulate cells to strengthen signals or weaken those that are harmful. Designing and analyzing communications systems in which the signalling - transmitters and receiversrely on molecule propagation is the definition of molecular communication engineering.”

The first step is to study the environment where the molecular communication takes place. A mathematical model is made to represent these molecular communications systems, then a hypothesis can be formed as to how the transmitting and receiving cells act under various conditions, including how they react to changes like cell growth and increases in temperature. Hypotheses can then be tested from the model itself (e.g., numeric evaluation) and from computer simulations. This is the focus of the research

in the newly established Biophysical Communication Engineering Lab in the Core Science Facility at the St. John’s campus.

“We are looking for experimental validation in the lab; we want to run a model and make predictions on how actual biology works,” said Dr. Noel. “Biological processes are complicated; we want to replicate them in a lab setting. Is the model accurate enough to make predictions? We will make progress through different iterations, by engaging with collaborators over an extended period.”

Of course, the long-term success of this research requires collaboration outside of the Faculty of Engineering and Applied Science, for which Dr. Noel is well-positioned at Memorial with the Department of Electrical and Computer Engineering’s new home in the Core Science Facility. The building also hosts the Department of Biology and Department of Biochemistry, which makes interdisciplinary engagement much easier. Even though engineers and biologists can have very different perspectives and be interested in different research questions, collaboration can produce mutually beneficial results, as Dr. Noel has already demonstrated in England.

“All of my Ph.D. students in the UK had a co-supervisor or collaborators from a different discipline,” said Dr. Noel. “This is necessary for us to do impactful work in molecular communication.”

And the big question - how exactly does one mimic molecular communication or achieve the ability to communicate with molecules in a lab setting?

In one approach, Dr. Noel and his team model lab-on-a-chip technology, which are miniature-scale lab benches. A lab-on-achip can be about the size of a deck of cards and include multiple interconnected compartments. Pumps can push fluids through the chip to mimic processes like human metabolism.

During his years in England, Dr. Noel was principal investigator on a project funded by the Engineering and Physical Sciences Research Council (EPSRC), the equivalent of Natural Sciences and Engineering Research Council (NSERC) in Canada. The research looked at different ways in which communication engineering tools could be applied to understanding microbiology.

ENGINEERING IS A COLLABORATION

BETWEEN ENGINEERING, CHEMISTRY, BIOLOGY AND MEDICINE THAT CAN LEAD TO DEVICES THAT LISTEN AND TALK TO CELLS.

While there are clear connections with Dr. Noel’s research and the life sciences, his link with mechanical engineering through the new mechatronics program might be unexpected. However, understanding molecule diffusion and other types of transport within the body relies on a good understanding of fluid dynamics - a fundamental mechanical engineering topic.

— Dr. Adam Noel

Of course, theory doesn’t tell the full story - prediction and control of biophysical systems at a microscopic level is not child’s play. So much can happen in a practical lab bench setting. Has there been contamination? Are the cells too young or too old? Where is the sweet spot in terms of environmental conditions in which the cells are grown?

The study was also supported by AstraZeneca Sweden, who were doing a lot of R&D in the lab-on-a-chip space with the goal to replace animal testing in drug trials with lab-on-achip products. AstraZeneca supported Dr. Noel with expertise they were developing and data they were generating in their lab-on-a-chip projects. The benefit to AstraZeneca was new insights to understand their platforms at a microscale level and design future experiments.

“We had a focus on metabolism; they were interested in glucose regulation for diabetics,” Dr. Noel explained. “On their labson-a-chip, each compartment represents an organ like the liver or pancreas. Tubes fed into the chip to drive a pump. The compartments, each about half a centimetre in diameter, are filled with liquid and contain clusters of cells, liver cells for example, with each cluster about half a millimetre in diameter. It is these large clusters of cells operating together, known as spheroids, that we are interested in. We can model spheroids as receivers and transmitters and how signals might pass between them over time.”

“The mathematics involved are quite interesting. We look at the mathematical modelling to study how waves of molecules dissipate, get amplified, or how they react when passing through a spheroid,” he said, explaining that the concept of diffusion has been studied for more than a century; Einstein himself wrote a paper on it in 1905 (https://einsteinpapers.press.princeton.edu/ vol2-trans/137). Diffusion can describe how molecules spread when inside a fluid. For example, if you add food colouring to water, the dye initially spreads through the water like a cloud. If you were to zoom in more than on what the naked eye could see, then you would notice that the dye molecules move in random patterns; they don’t spread out evenly.

“What I’m interested in is the random processes - these could be in how the molecules move around, or how they bind to receptors on the surfaces of cells. The randomness is actually very important; I didn’t appreciate this until I engaged with people from a life sciences background.”

It was during Dr. Noel’s time in the UK when he realized that one exciting application of his work on spheroids was for modelling cancer cells and tumour progression, in part because spheroids themselves are grown from cancer cells.

Just like organs and artificial mini-organs such as spheroids, tumours are not homogenous. As tumours grow, there are cells inside with different properties, and they can develop layers with different thicknesses. Denser layers can slow down propagation which can prevent effective drug delivery to a tumour. The questions Dr. Noel is concerned with include whether drugs can penetrate a tumour or whether some of the drugs will stay outside the tumour and damage healthy tissue.

One method proposed to improve drug penetration is to engineer miniature drug carriers packed with drugs for targeted drug delivery. So, in the case of a tumour, a carrier should only release the drugs once inside the tumour, thus delivering a more potent payload with less damage to healthy cells outside.

“The ultimate goal would be to develop technologies that can communicate with cells in our bodies,” said Dr. Noel. “Geneticallymodified cells or robots using biochemical components could potentially monitor cell communications within the human body, detect where and when they are not performing or communicating optimally, and trigger a response to fix these problems. This is the killer app that we hope to create.”

Electrical and Computer Engineering Faculty of Engineering and Applied Science Memorial University of Newfoundland

Dr. Adam Noel is an associate professor of electrical and computer engineering at Memorial, where he obtained a bachelor’s degree in electrical engineering in 2009. He received his master’s in electrical engineering in 2011 and PhD in electrical and computer engineering in 2015, both from the University of British Columbia.

While completing his PhD, Dr. Noel did a stint as a visiting scientist at the Institute for Digital Communication at FriedrichAlexander-University in Erlangen, Germany. Following his PhD, he worked as a postdoctoral fellow at the University of Ottawa and the University of Montreal (2016-2018).

In 2018 Dr. Noel took a job at the School of Engineering at the University of Warwick in Coventry, UK, where he spent six years before returning to his home province to establish the Biophysical Communication Engineering Lab at Memorial.

His research interests include the prediction and control of biophysical systems at a microscopic level, biophysical communication engineering; molecular communication; and reaction-diffusion processes.

...WE WANT TO PROTECT PEOPLE AND MANAGE THE ENVIRONMENT IN A SUSTAINABLE WAY.

— Dr. Bing Chen

In today’s world, flame retardants are incorporated into a wide range of products—curtains, furniture, electronics, vehicles and building materials, to reduce fire hazards. A key class of these chemicals, polybrominated diphenyl ethers (PBDEs), can leach from discarded items into soils and water bodies, posing risks to human health and the environment. They have been widely recognized as a typical compound of the persistent, emerging and organic pollutants (PEOPs).

It has been reported that PBDEs are detected in Canadian drinking water supplies and across northern communities, from human breast milk to polar bears, seals and fish. Their multiple brominated aromatic rings confer environmental half-lives of years to decades. Toxicological studies have linked PBDE exposure to endocrine disruption, neurodevelopmental deficits and immune alterations. Once released into the environment, these compounds bioaccumulate in lipid-rich tissues and resist natural degradation.

“In Canada, the production of PBDEs is banned, and commercial mixtures of penta-, octa- and deca-BDE are prohibited,” says Dr. Bing Chen, Professor and UArctic Chair of Marine and Coastal Environmental Engineering in the Faculty of Engineering and Applied Science. “Yet imported goods containing these mixtures continue to enter the market. We urgently need comprehensive monitoring and mitigation strategies for all congeners and their existence in soils and waters to understand and reduce their negative impact.” Canada has banned some commercial PBDE mixtures, including penta-, octa- and deca-BDE, but routine monitoring programs seldom include the full suite of lowerbrominated congeners. The contamination status in northern regions remains largely unclear, leading to challenges in developing/ improving suitable regulatory programs and management practices.

NRPOP Lab

Dr. Chen’s Northern Region Persistent Organic Pollution Control Laboratory (NRPOP Lab) was established with support from the

Canada Foundation for Innovation (CFI) and the Newfoundland and Labrador Industrial Research and Innovation Fund (IRIF)

See Facility Spotlight in the 2023 Annual Research Report, p. 50. https://issuu.com/memorialu/docs/rr_2023_web?fr=xKAE9_zU1NQ

“For a large number of PEOPs, we don’t know if they are in drinking water because many compounds are not regulated and thus not included in routine monitoring programs,” says Dr. Bing Chen, explaining that analyses are infrequent and expensive. “All chemicals can be toxic at high enough doses—the dose makes the poison,” he adds. While there are existing and new treatment technologies that can remove some PEOPs, more in-depth R&D, pilot testing and field validation are much desired.

To develop methods for analyzing and removing PEOPs from soil and water (including freshwater and saltwater) in harsh environmental conditions and under climate change, Dr. Chen’s NRPOP Lab has partnered with many collaborators and partners from the Arctic and Sub-Arctic regions in Canada and globally. For example, he has recently conducted a project funded by the Northern Contaminants Program (NCP) through collaborating with the North Slave Métis Alliance (NSMA), representing Indigenous Métis communities in the North Slave region. Dr. Chen’s team, which includes master’s student Hongjie Wang and postdoctoral researcher Dr. Xing Song, has completed four sampling campaigns in Yellowknife and sounding the Great Slave Lakes, targeting both surface soils, permafrost and water. For soil, stratified cores are collected every five centimetres to depths of 1.5–2 metres; permafrost samples require a heavy-duty auger. Local community members have been trained by the team and have worked closely with the team on the project. The team has also gained unique opportunities in learning traditional knowledge and incorporating it into research.

“We have 36 sampling sites and over 300 soil and water samples from areas near landfills, remote locations, and multiple points surrounding Great Slave Lake and adjacent ponds,” reports Dr.

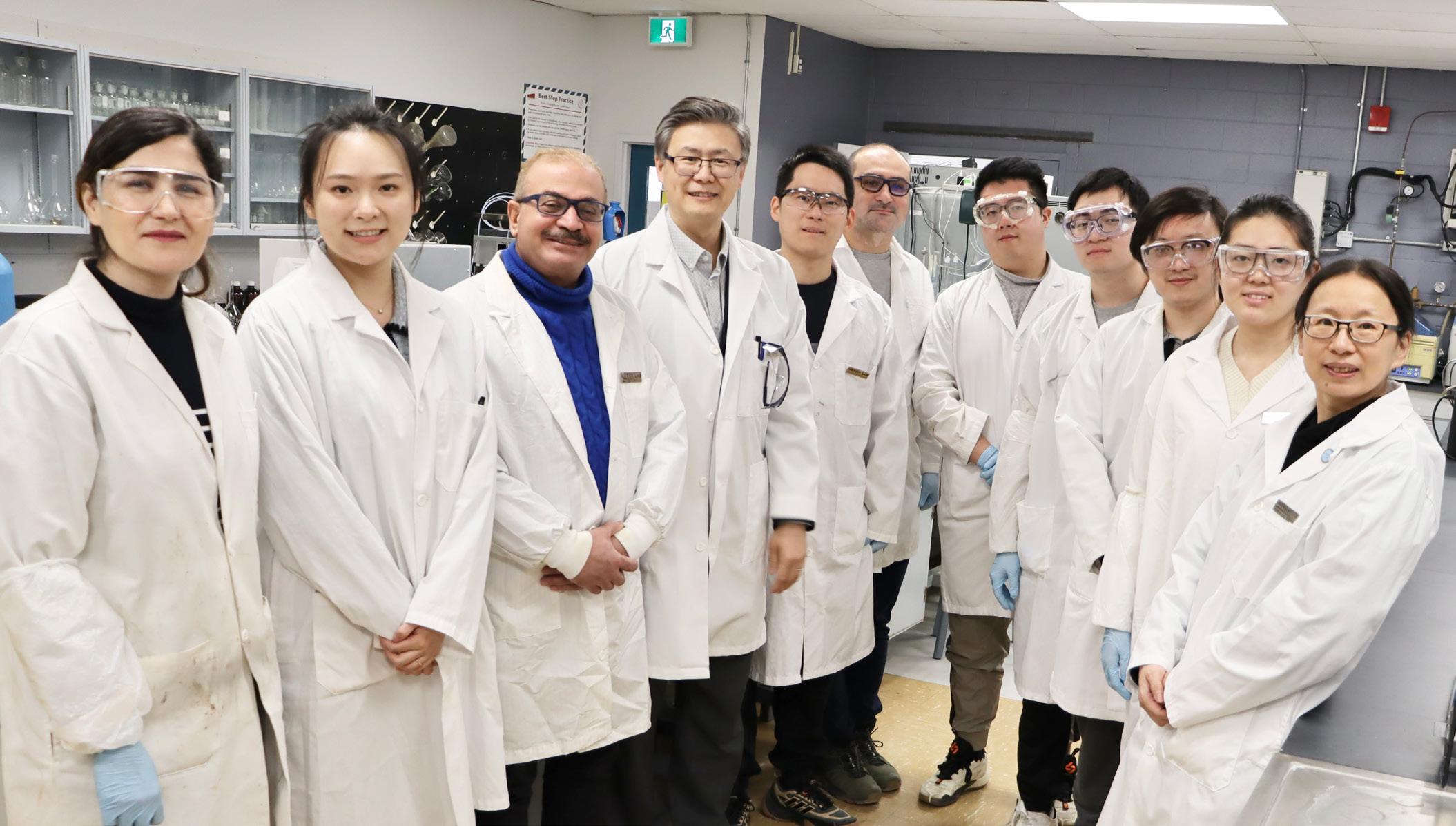

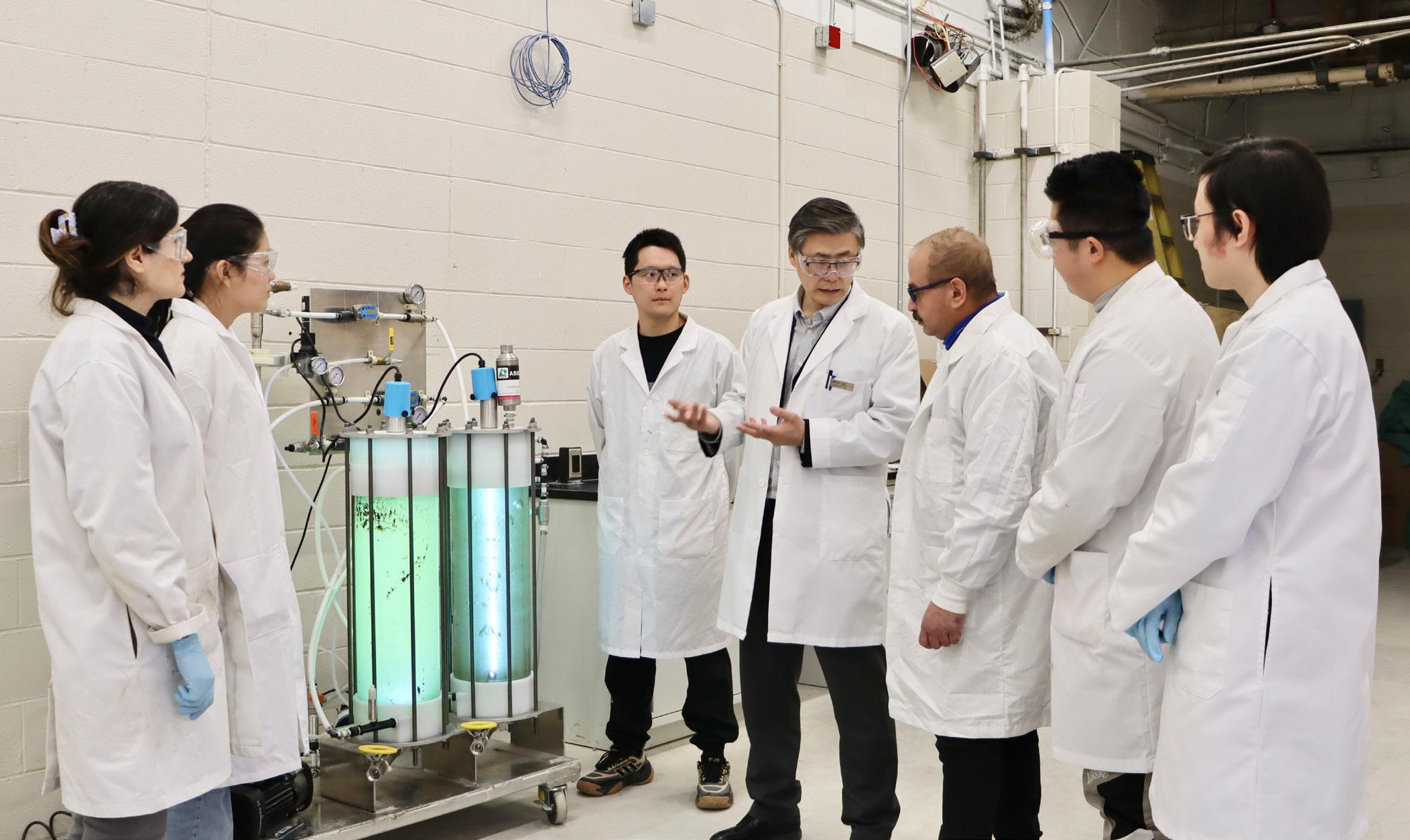

Members of the NRPOP Lab (L-r)Masoumeh Bavadi (PhD), Anran Wang (BSc), Moein Shahwan, Dr. Bing Chen, Runbo Yuan (PhD), Mojtaba Zarea (BSc), Hongyi Li (PhD), Hao Wu (BSc), Hongjie Wang (PhD), Xueyan Xu (PhD), Lidan Tao

Discussion on a mesoscale separation, demusification, and enhanced oxidation system for oil water emulsion (L-r) Masoumeh Bavadi (PhD), Xueyan Xu (PhD), Runbo Yuan (PhD), Dr. Bing Chen, Moein Shahwan, Hongyi Li (PhD), Hongjie Wang (PhD)

Chen. “PBDEs have been detected in approximately two-thirds of the 300 samples tested so far.”

The team has also studied the potential sources of the PBDEs which may originate from nearby landfills, industrial activities, or be transported long distances through rivers and surface runoff and deposition from the atmosphere via rain and snow.

Testing poses significant challenges. “The process requires extensive pretreatment,” explains Dr. Chen. “We separate solids from water, extract analytes, and analyze samples by an advanced analytical technique, gas chromatography with tandem mass spectrometry (GC-MS/MS), for separating and identifying chemical compounds.” The NRPOP Lab is equipped with state-of-the-art advanced instruments for PEOP analysis.

Dr. Chen notes that the high cost of comprehensive testing presents one of the key challenges of large-scale monitoring. The other challenges are also associated with the technical and financial limitations in mitigation and management practices.

“PBDEs are just the tip of the iceberg considering the persistent, emerging and organic pollutants. We have a long way to go for our regulatory programs to include the key PEOPs. It requires comprehensive and interdisciplinary research and development effort and continuing, significant investment in monitoring, assessment, treatment, management and policymaking.”

Still, Dr. Chen hopes his research will not only enhance understanding of pollution mechanisms but also help governments and industries improve mitigation practices for PEOP-related environmental problems, yielding both short- and long-term ecological, economic, and social benefits. His research also helps inform our northern communities, including Indigenous people, with scientific understanding and support for their capacity building and proactive participation in environmental management and policy making. Complementing the NRPOP Lab’s work, Dr. Chen leads several major initiatives that investigate the fate, transport and impacts of PEOPs (including oil spills, microplastics, PBDEs, and PFAS) and develop new treatment techniques for the Arctic and Sub-Arctic regions and waters, such as the recent ArcSolution project funded by the New Frontiers in Research Fund and the European Union Horizon Program with collaboration with more than ten other institutions from the countries around the Arctic.

“We want to provide scientific evidence to support our government in regulatory improvement and our industry in sustainable development, and we want to protect our northern communities and the environment from those persistent, emerging and organic pollutants.”

Dr. Bing Chen (B.Eng. (Jilin), M.Sc. (Peking), PhD (Regina), P.Eng.) obtained his B.Eng. and M.Sc. from Jilin and Peking Universities in China, respectively, and his PhD from the University of Regina, Saskatchewan. He worked as an NSERC Postdoctoral Fellow at the University of British Columbia and conducted visiting research with Environment Canada before joining Memorial University in 2006. He is currently the interim Dean of the Faculty of Engineering and Applied Science, a professor and UArctic research chair in the Department of Civil Engineering and director of the Northern Region Persistent Organic Pollution Control Laboratory (NRPOP Lab). He is also the founding director of a pan-Canadian and global Network of Persistent, Emerging, and Organic PoLlution in the Environment (PEOPLE Network or NSERC PEOPLE CREATE Program).

Dr. Chen has developed novel engineering and managerial solutions by integrating environmental engineering with nano-/ bio-technologies and advancing physical and numerical modelling methods. He has acted as PI or Co-PI in over 60 research projects and contracts. He has authored or co-authored more than 560 technical publications, including over 190 refereed journal papers and three books, and has eight patents/disclosures. He has supervised or co-supervised more than 100 thesis-based graduate students and postdoctoral research fellows, who have received awards and are well placed in the field of their training locally, nationally and internationally.

Dr. Chen is a fellow of the Fellow of the Canadian Academy of Engineering (CAE), the Engineering Institute of Canada (EIC), the Canadian Society for Civil Engineering (CSCE), a member of the European Academy of Sciences and Arts (EASA), and a former member of the Royal Society of Canada (RSC) College. He also serves as Editor-in-Chief of Environmental Systems Research, President (2024-25) of CSCE, and Vice-President of the Canadian Association on Water Quality (CAWQ). As a registered P.Eng., he provides advice to governments, industries, NGOs, and communities in Canada and worldwide.

It is a common fact that commercial fishing is one of the world’s most dangerous professions. In July 2024, seven Newfoundland fishermen were forced to abandon their fifteen-metre fishing vessel after a fire in the galley caused it to sink.

The seven men, only five in immersion suits, spent two days at sea in a life raft that had no communications equipment to alert rescuers to their location. Their plight was further hampered by a dense fog which prevented the four Coast Guard vessels, Cormorant helicopter and Hercules military aircraft that had been dispatched by the Joint Rescue Coordination Centre (JRCC) in Halifax from finding them. PAL Airlines also sent out aircraft

equipped with sensors to try to locate the vessel, while other inshore fishing vessels in the area searched on water.

But for two days, no one could find any trace of the life raft, despite using drift charts which help calculate where a vessel may have ended up.

The SAR helicopter passed low enough that the fishermen could hear it, but they could not see each other due to the thick blanket of fog.

Finally, two days after they abandoned their vessel, the fishermen were successful in alerting a rescue helicopter to their location using a handheld rocket flare.

This story had a happy ending when the fishermen were brought on board a Coast Guard vessel, warmed up, given food and water and brought home. The fact this happened in the summer contributed to their survival.

Because incidents like this are so common, researchers at four universities have teamed up to attempt to increase mariners’ odds of survival at sea.

“If you are adrift in a lifeboat in a heavy traffic area, you have a good chance of being found or rescued by one of the four main elements of the Canadian SAR system: helicopter, fixed-wing aircraft, dedicated Coast Guard vessel or by a ship of opportunity, which just happens to be in the area,” said Dr. David Molyneux, associate professor of ocean and naval architectural engineering (ONAE) and director of the Ocean Engineering Research Centre. “But what about if you go missing in late fall or in a less frequented area? What if you are drifting off the coast of Labrador where

fewer vessels pass through and which has no dedicated Search and Rescue lifeboat station?”

If you map lifeboat distribution, there’s really good coverage in the Gulf of St. Lawrence and around the Atlantic provinces until you get to the tip of the Northern Peninsula and the coast of Labrador. Right now, if you run into trouble offshore in the Labrador Sea, a responding helicopter might have to make several stops to refuel. A fixed-wing aircraft could respond more quickly and has the ability to drop a pump if water is coming in or even drop off a SAR technician who can board the vessel and stay with crew until help arrives. But with no Coast Guard lifeboat stations along the Labrador coast, what would more likely happen is Coast Guard would task either a ship of opportunity or another Coast Guard vessel, not necessarily a SAR lifeboat, to respond.

Would things improve if there was a seasonal lifeboat station up there?

That is just one of the questions Dr. Molyneux and his collaborator, Dr. Rob Brown, senior research scientist in the School of Maritime Studies at the Marine Institute, hope to answer in a project called Future Ocean and Coastal Infrastructures (FOCI) sponsored by Ocean Frontier Institute (OFI). The part of the research they are involved in, called Search and Rescue in Remote Coastal Regions, also includes Drs. Ron Pelot and Floris Goerlandt at Dalhousie University, Dr. Peter Kikkert at St. Francis Xavier University and Dr. Whitney Lackenbauer at Trent University.

“If there’s more activity in the north with more shipping, at what point is it reasonable to introduce rescue services in areas that are not currently covered?” asked Dr. Molyneux. “That’s what we’re looking at in the FOCI project. Part of sustainable coastal infrastructure is the ability to help people when they get into trouble offshore.”

ULTIMATELY, WE THINK THIS WORK WILL IMPROVE SAFETY FOR PEOPLE LIVING AND WORKING IN COASTAL REGIONS.

— Dr. David Molyneux

“The goal of the overall project is to improve our understanding of the main factors that affect search and rescue performance, with the hope that future decisions on equipment procurement and positioning can be informed by our models,” said Dr. Brown. “Ultimately, we think this work will improve safety for people living and working in coastal regions.”

Indeed, this research comes at an opportune time as the Canadian Air Force is in the process of changing their SAR aircraft from Hercules to Kingfishers, which are smaller with a shorter range.

“Although the Kingfishers are smaller with a shorter range, they have a much higher probability of detecting someone or something in the water because of the instrumentation on board. What we’re looking at is how the response time changes as a result of switching out planes,” said Dr. Molyneux.

The research team consists of five engineering co-op students and three graduate students at Memorial (two at the Marine Institute and one in the faculty of engineering) plus five master’s students at Dalhousie who are funded through linked projects.

Three Memorial engineering co-op students include Aya Ibrahim (Process Engineering), who carried-out a literature review and summarized existing research in the field in the early stages of the project, while Mohannad Alrefai (ONAE) and Samia Nusrat (Computer and Electrical) have analysed traffic patterns using a free open-source website called Global Traffic. With a year’s worth of ship density data downloaded, they can look at ship hours per month in one-kilometre grid squares. Mr. Alrefai has also analysed the role of life boats.

“This gives us a realistic distribution of ship positions and helps determine if our modelling works,” said Dr. Molyneux, adding that the group has had funding from the American Bureau of Shipping (ABS) and continues to share research results with them.

The fourth co-op student, Lucas Frampton (Mechanical), has analysed Transportation Safety Board data looking at the location and types of shipping accidents and collated this data into a single database while the fifth MUN Engineering co-op student, Mohammad Awad (Mechanical), is continuing this work this semester, to help ensure datasets are ready for the Master’s students to use in their models.

Three graduate students also worked or are working on the project. Mohammad Zarrin Mehr completed his Master’s of Science (Maritime Studies) at the Marine Institute and now works for Hatch while Evan Lane is currently researching ships of opportunity and CCG lifeboats for his Master’s of Engineering and Yang Ji is investigating and modelling fixed-wing aircraft at the Marine Institute for his Master’s of Science (Maritime Studies).

“It is because of these talented students, coupled with the efforts of the master’s students supervised by our co-investigators, Dr. Ron Pelot and Dr. Floris Goerlandt at Dalhousie, that the modelling work has come as far as it has,” said Dr. Brown. “We are excited to see how far we can take this research and what impact it has on SAR planning and preparedness in the long term.”

Although funding from the Ocean Frontier Institute wraps up in the summer of 2025, Dr. Molyneux hopes the research will continue.

“This is a long-term planning tool. We hope the Coast Guard and the JRCC will pay attention to our results. It is a challenge to turn decision-making and planning into rules and computer code,” said Dr. Molyneux. “And the biggest challenge is making sure the study is realistic; if it doesn’t reflect what happens in the real world, it’s useless. Every situation is different but if we can come up with the average time and extreme time, our research will be a success.”

Ocean and Naval Architectural Engineering

Faculty of Engineering and Applied Science

Memorial University of Newfoundland

DR. DAVID MOLYNEUX

Dr. David Molyneux arrived at Memorial in 2015 after a career in research and consulting in both public and private sectors. He worked at the National Research Council (NRC) in St. John’s from 1985 until 2008 carrying out research into marine safety, hydrodynamics and performance of ships and offshore structures in ice. In 2008 he moved to Oceanic Consulting Corporation to manage the development and acquisition of computer codes for predicting the performance of ships and offshore structures in harsh environments.

Dr. Molyneux’s research highlights include numerical and experimental predictions of ice loads on ships and offshore structures; the safety of RO-RO Ferries against flooding and capsize, after damage; particle image velocimetry measurements of flow around ships with yaw angle; the performance prediction of escort tugs at large yaw angles; and the safety of fishing vessels against capsizing.

Dr. Molyneux completed his B.Sc. (Newcastle-Upon-Tyne), M.Sc. (University of British Columbia), and PhD (Memorial). He is a professional engineer in Newfoundland and Labrador.

DR. HODJAT SHIRI

Wouldn’t it be nice to know in advance when your roof shingles are going to fail? Or your hot water boiler? Or heating system? Imagine if you had a digital replica of your house right down to the thermostats that could help you keep on top of maintenance. That would save time, money and a lot of headache. The idea of a digital twin of your private home may be a little way off, but you’d be surprised at how many companies are turning to digital twins to help make corporate life easier.

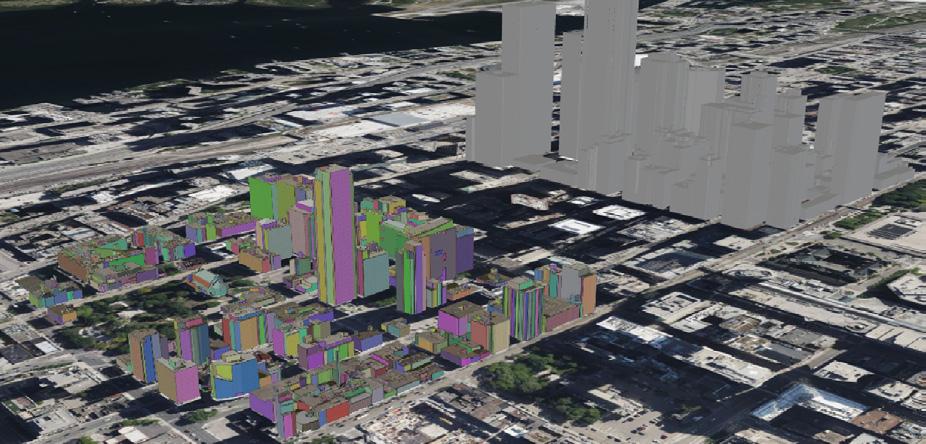

“Using digital twins in industry is progressing at a scorching pace,” said Dr. Hodjat Shiri, associate professor of civil engineering at Memorial. “The fast advancements in building information modeling (BIM), artificial intelligence (AI), internet of things (IoT), and cloud computation have significantly expanded the power of digital twins. There is a huge demand for developments in this area and more and more companies and industries are adopting digital twins in their daily operations.”

What exactly is a digital twin?

Most people think of a digital twin as a virtual model of a physical object that can be used to simulate what happens to the object in real life. Using Artificial Intelligence (AI), a digital twin receives data sent from sensors to simulate behaviours, monitor operations, analyse performance and predict future behaviours. On a production line, for example, a company can use a digital twin to monitor temperature, pressure and environmental conditions to detect if something is off balance. Or a digital twin of a ship engine can be modeled in order to test, monitor, predict failures and determine when preventive maintenance is required. Or an electric vehicle can send real-time operational data on things like battery life and motor function allowing the manufacturer to update software and predict maintenance for the vehicle’s entire life cycle.

Here in Newfoundland and Labrador’s offshore oil fields, the Hibernia Platform uses a digital twin of its power generation system and through simulations, electrical loads can be adjusted to ensure optimal power use and reduce greenhouse gas emissions.

Where did the idea of digital twins come from?

Although the term digital twin was not used until 1997, the concept was introduced by NASA after Apollo 13 made an emergency landing in the Pacific Ocean in 1970 and simulators were used to evaluate the failure of Apollo’s oxygen tanks. Today digital twin applications can be found everywhere, not just in manufacturing and operation of equipment, but in complicated infrastructure like transportation systems including bridges and tunnels, mines, hydro plants, refineries and renewable energy sites, offshore platforms, marine ports and airports. NASA even has a digital twin of the Earth System.

The continuous and targeted observations provided by digital twins allow people to build more sustainable infrastructure, and it is this idea of infrastructure sustainability that most interests Dr. Shiri.

“Digitalization can be used for design, construction and operation monitoring of infrastructure, but sustainability is something more. You may have an infrastructure that has been designed and constructed in a way that has not considered the socio-economic effects; that has been designed only for the current generation, not for the future; that is not going to be sustaining and resilient against climate change effects over time. Digital twins integrated with BIM can effectively help resolve all of these issues.”

“Achieving this is not possible with conventional tools,” Dr. Shiri explained. “But digital twins are an excellent solution because they allow you to make a virtual but interactive copy of the physical infrastructure that can run numerous simulations and update the input data, and then use AI to predict the future performance of the infrastructure for potential corrections. The integration of digital twins with BIM creates an extremely powerful tool that enables virtual interaction with the infrastructure during the initial concept and design, continuous monitoring, fault detection, maintenance planning, and testing new ideas or what-if scenarios.”

“In simple terms, our infrastructure shall be designed, built and operated in a manner to not only have positive socio-economic impacts, but also be environmentally sustainable,” said Dr. Shiri. “Our goal is to preserve the natural environment and conserve resources for the well-being of both present and future generations.”

Dr. Shiri’s journey towards digital twin research has been at least fifteen years in the making; he spent about two decades in infrastructural construction, maintenance, and operation industries in the early part of his career. Once he joined Memorial as a faculty member and Wood Group Chair in Arctic and Harsh Environment

Engineering in 2015, his research journey evolved from conventional geotechnics to using AI algorithms to investigate the effects of soil interaction on the structural performance of onshore and offshore pipelines and risers and his current work in sustainable infrastructure.

“Moving from industry to academia in 2015, I was always trying to find the best way to implement my industry experience into my research projects,” said Dr. Shiri. “I did this partly by establishing courses with more practical industry-oriented contents. Although it was quickly acknowledged by Canada pipeline industries, it was not enough. It wasn’t until 2019 that we began discussing the idea of setting up a program in Sustainable Infrastructure at the Department of Civil Engineering at MUN. This led me to the idea of working on digital twins, which had become more popular in industry, to develop more sustainable infrastructures.”

The following year, 2020, the Department of Civil Engineering initiated the Sustainable Infrastructures Program, and in 2024, thanks to a sabbatical, Dr. Shiri established a modern drone lab with a range of sensors, facilities, and a high-performance computation cluster to facilitate developing digital twins for airborne-assisted real-time monitoring of sustainable infrastructures.

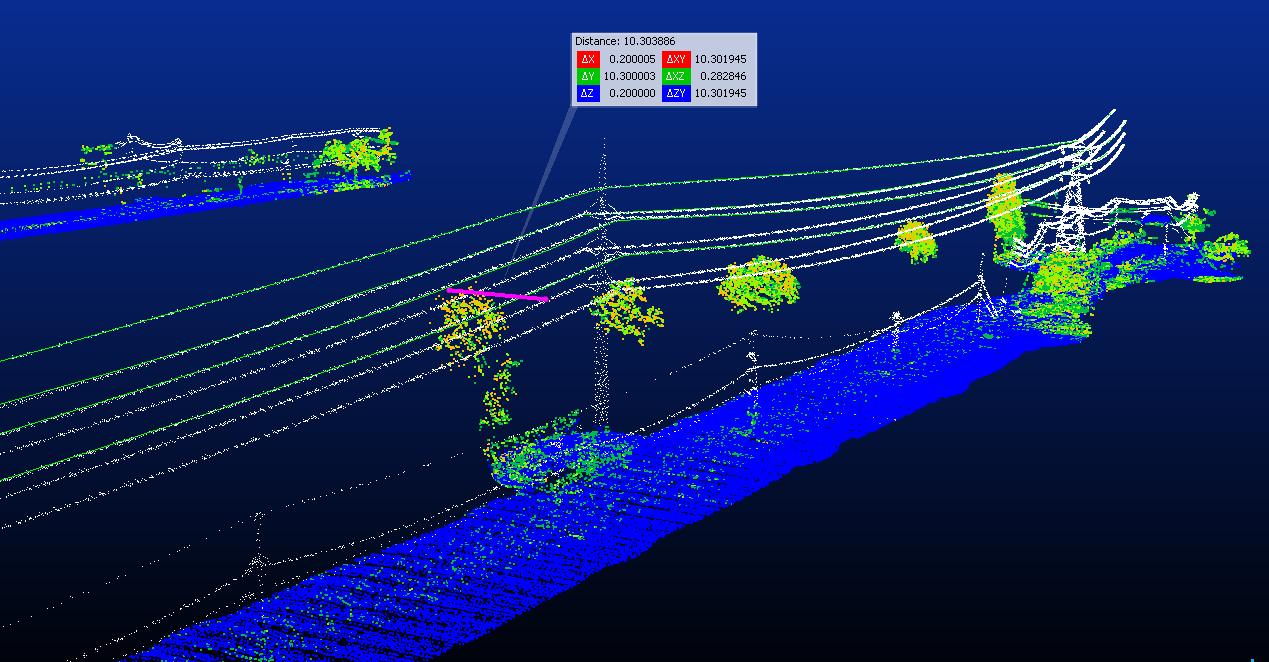

“Over the past five years, trying to stay aligned with trending technologies, we started using AI and Computer Vision (CV) algorithms for airborne and satellite-assisted monitoring and assessment of some infrastructural challenges,” said Dr. Shiri. These challenges include iceberg damage to subsea infrastructure,

cold-region roads and pothole detection, ground movements, and climate change-induced environmental geohazards.

“To develop a digital twin of an existing infrastructure, first we create a 3D virtual interactive copy of the infrastructure by using cameras and LiDAR sensors mounted on drones, as well as terrestrial and hand-held instruments. These 3D models along with other semantic and operational data, for example from internet of things (IoT) sensors, are then introduced into digital twin platforms for further analyses,” said Dr. Shiri.

Using powerful AI algorithms and the results of simulations, the lifecycle performance of the infrastructure can also be predicted. These predictions can assist in decision-making and improve the performance of infrastructure over time to achieve sustainability targets.

What this means is they loop the virtual observations with the real infrastructure to attain the desired performance. For example, a digital twin of a smart building can simulate energy consumption patterns based on weather forecasts. Using these simulations, building managers can optimize heating, ventilation, and air conditioning (HVAC) systems to reduce energy consumption while maintaining occupant comfort. Another example is geotechnical engineering, where digital twins can have a huge impact on the planning, design, construction, monitoring and maintenance of

large-scale projects involving complicated geotechnical aspects including deep excavations, slope stabilities, ground movements, liquefaction, and settlements.

Dr. Shiri and his team have had both financial and technological support from industry as well as funding from the provincial Department of Industry, Energy and Technology (IET), Natural Sciences and Engineering Research Council of Canada (NSERC), Mitacs, and Memorial University.

Currently, Dr. Shiri’s team working on AI-assisted assessment and monitoring of infrastructures, includes two Postdoctoral researchers, three PhD and three master’s students. He also has other students working on conventional geotechnical research projects.

These students and others who follow them will be trained by Dr. Shiri to help develop digital twins in the province, country and worldwide for a variety of infrastructure sustainability projects including urban planning, traffic optimization, port management, structural health monitoring of bridges, dams, tunnels, buildings, power plants, wind turbines and other renewable energy systems, forestry and aquaculture, archeological sites, building performance, smart cities and waste management.

Dr. Hodjat Shiri, associate professor of civil engineering, completed his BSc degree in civil engineering (Urmia University, Urmia, Iran, 1996), his M.Sc. in geotechnical engineering (Shahid Chamran University, Ahvaz, Iran, 1999), and his PhD in offshore geotechnics (University of Western Australia, Perth, Australia, 2010). During his PhD, he worked at the Centre for Offshore Foundation Systems (COFS)) with Professor Mark Randolph, the world’s renowned geotechnical scientist, on fatigue performance of Steel Catenary Risers (SCR). After his studies he worked on some of the world’s largest offshore oil and gas projects as design engineer, offshore installation engineer, project engineer, project manager, offshore installation manager, and project director.

Dr. Shiri joined Memorial in 2015. Since then, he has supervised more than forty students including post-docs, PhDs, master’s and undergrads. In 2022, he received the Dean’s Award for Excellence in supervision of graduate students. These research works have resulted in about 150 journal and conference papers.

From 2015 to 2020, Dr. Shiri was Wood Group Chair in Arctic and Harsh Environment Engineering. In 2024, he was recognized among the world’s top 2% most cited scientists by Standford University. He also obtained a certificate of expertise from Harvard University in launching tech ventures to further support students’ entrepreneurship after graduation and several of his students have established their own start-up companies.

Newfoundlanders and Labradorians would be hard pressed if supplies couldn’t arrive by ship. Any type of disruption in shipping would send ripple effects through every supply chain. And not just in this province; throughout the world, it’s estimated that eighty to ninety per cent of cargo is transported by ocean-going vessels.

One of the biggest threats to global shipping is cyber attacks. Things can go sideways pretty quickly if marine systems are hacked with malicious intent.

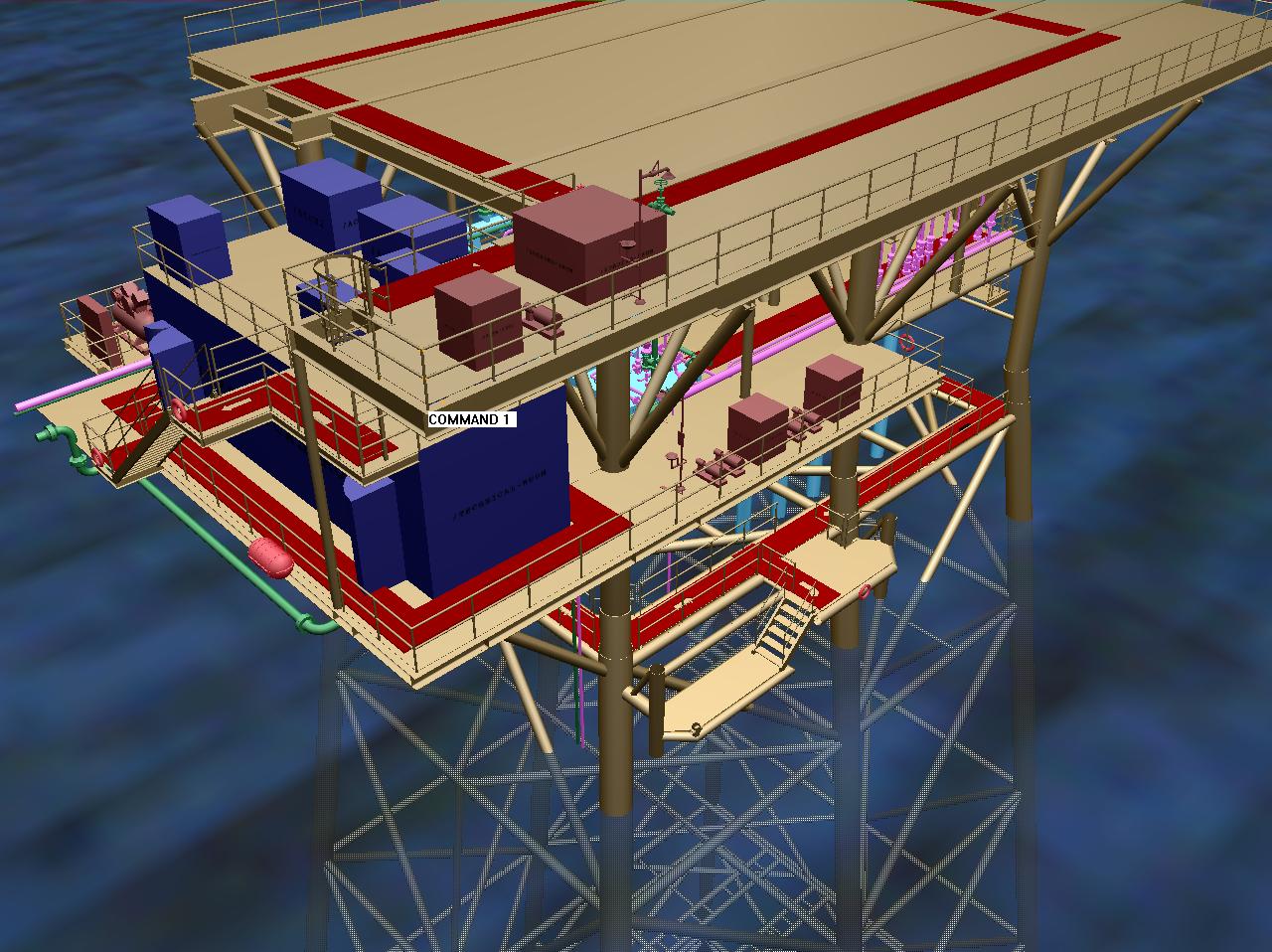

But have no fear. Dr. Jonathan Anderson (PhD, P.Eng.), associate professor of computer engineering at Memorial, is determined to improve marine cybersecurity and has received $1.8M in funding from the National Cybersecurity Consortium to make it happen.

“The supply chain is important; we take it seriously,” said Dr. Anderson, explaining the first thing he and his research team want to do is make ships and seafarers safer and more secure from attack.

“We need to beef up security against cyber warfare,” he said, explaining the two main research projects he’s involved in. The first project is called Securing Critical Marine Systems (SCMS) and it’s in conjunction with the Marine Institute as well as Dalhousie’s Department of Computer Science.

A second project, Marine Cybersecurity Training (MCT), is also in partnership with the Marine Institute and Thales Canada, an aerospace and defence firm, and will teach mariners how to recognize and respond to cyber attacks.

The training curriculum they develop will give mariners and organizational leaders the tools they need to deal with cybersecurity incidents onboard ships, with the aim of keeping

everyone in the marine industry safe, as well as the environment and the ships themselves.

“Our team is fantastic,” said Dr. Anderson. “At the Marine Institute we have Dr. Steven Mallam; Capt. Christopher Hearn, director of the Marine Institute’s Centre for Marine Simulation; and Maria Halfyard, manager of business development, research and strategic partnerships. Here at Memorial, there will be researchers involved from the Department of Electrical and Computer Engineering, and at Dalhousie we have Drs. Srini Sampalli and Nur Zincir-Heywood from the Faculty of Computer Science.