Whether consumers realize it or not, they’re taking part in the circular economy every day. When a used beverage container goes in a blue box or is dropped off at a retailer or a depot, it enters a circular economy that transforms the material into new products and packaging.

With more than 50 years of successfully operating beverage container recycling programs, high consumer adoption and the move to extended producer responsibility (EPR), several Canadian provinces are global leaders in enabling a circular economy for packaging. EPR requires producers take full or partial financial and operational responsibility for collecting and recycling their products and packaging.

The widespread adoption of deposit return systems (DRSs) and public policy initiatives to drive up recycling rates in Canada are proven examples of recycling leadership in action. In a DRS, consumers are incentivized to return their beverage containers with a modest deposit — typically 10 cents. Provinces with established DRSs achieve high recovery rates for non-alcoholic beverage containers, with programs in Alberta and Saskatchewan recovering over 80 per cent of all containers. Inconsistency across the regulatory landscape in provincial recycling regulations, notably Ontario’s lack of a DRS program for non-alcoholic beverage containers, has limited the national beverage container recovery rate.

A framework to improve beverage container recovery rates

Through partnerships like the Canada Plastics Pact, beverage companies are collaborating to improve pack-

aging recyclability and meet recycled content targets. But without a stable domestic supply of recycled content, beverage producers cannot source the required volume of recycled material from domestic end markets alone.

The solution is bringing a national focus to the circular economy with a national recycling framework. Common definitions, data and reporting standards, and a shared understanding of system design would transform the recycling landscape in Canada. This would harmonize recycling policy across provinces and territories, reducing trade barriers and aligning EPR principles to enable economies of scale and minimize disruption for Canadian beverage companies.

A collaborative approach built around shared principles would have the added benefit of fostering resilience and much-needed business certainty for a sector still facing increased system costs due to tariffs. It would also keep provinces in control of program design while Canadians benefit from the sharing of enhanced design principles, building on best practices for convenient and effective beverage container recycling.

Canada’s beverage sector has already shown that the circular economy is not an abstract idea — it is a practical system that Canadians participate in every day. By working together on shared principles and proven solutions, we can reduce waste, strengthen our economy, and give Canadians the modern recycling system they expect and deserve. The path forward is clear: it’s time to close the loop, together.

Executive General Manager

American

Canada is chasing big ambitions in critical minerals, and momentum is building nationwide. But while much public attention focuses on new mines and battery plants, the midstream — the smelters and refineries, and the recyclers that feed them, that transform ore and manufacturing scrap into usable metals — is just as vital.

How well Canada strengthens this part of the supply chain will determine how much value stays at home.

That’s where Glencore — one of the world’s largest global diversified resource companies and a major player in Canada’s economy — sees a clear opportunity to bolster Canada’s critical minerals pipeline.

Glencore is one of the world’s largest diversified resource companies, producing and marketing more than 60 responsibly sourced commodities. With about 150 sites worldwide, its operations support supply chains across metals, minerals, energy and agriculture.

Global Scale, Local Impact

With nine mines and five processing facilities in Canada, employing about 12,000 people, Glencore is a pillar of Canada’s critical minerals economy. Its operations stretch from nickel mines in Sudbury and Raglan Mine to Quebec’s Horne Smelter, the only copper smelter still operating in the country. The company recently acquired Li-Cycle, now branded Glencore Battery Recycling, adding lithium, nickel and cobalt recovery to its portfolio.

Glencore’s footprint is broad: it is Canada’s largest producer of refined copper, second-largest producer of nickel and zinc, and a leading producer of steelmaking coal. Its Canadian copper business alone contributed more than $850 million to the economy in 2023 and supported over 3,200 jobs. Recycling and circular practices are central to its growth strategy, from processing electronic scrap at Horne to closing the loop on battery metals.

Federal and provincial support is critical. Midstream often gets overlooked, but it’s the link that turns mined or recycled material into refined metal. Longterm investment is essential to keep it viable.

Recycling and circular practices keep materials in circulation, rather than always starting from scratch. The company continuously invests in ways to recover more metals and return them to the supply chain.

Q&A: Inside Glencore’s Approach

Vincent Plante, Executive General Manager for Glencore’s North American Copper Value Stream, and Ajay Kochhar, Head of Glencore Battery Recycling, discuss how circular practices, policy support, and new capacity can shape Canada’s role in the critical minerals economy.

Recycling is central to your business. What does that look like in practice?

Vincent Plante: “Recycling has been part of our DNA since 1984, when we built the recycling circuit at the Horne Smelter, which is North America’s largest processor of electronic material. Back then, it was about keeping the smelter running after nearby mines closed. Today, it’s about meeting future demand. Copper demand is

expected to more than double, and it’s already the third most used metal in the world.

These materials are everywhere: in cars, hospitals, data centers, and clean technologies. Producing them here, while continuing to invest in recycling streams, reduces reliance on new mining, lowers environmental impact, and invests directly in Canada’s future.”

Ajay Kochhar: “As for batteries, people often think battery recycling means only end-of-life batteries, but manufacturing scrap is just as important. In Ontario, two new gigafactories will generate material that needs to be recycled, and our feedstock, whether scrap or used batteries, is already highly refined. That lets us produce the same amount of metal with less processing and a smaller footprint, while keeping value in Canada.

The phrase ‘responsibly sourced’ gets thrown around a lot. Can you give concrete examples of what that looks like at Glencore?

VP: “At the Horne Smelter, our copper production has one of the lowest greenhouse gas profiles in the world. Since 2022, we’ve cut arsenic levels at the nearest monitoring station by nearly 47 per cent. Continuous improvement is part of our mission. We keep investing to raise environmental performance while expanding recycling.”

With recycling, you get traceability and a smaller footprint. Using refined scrap means starting with material that’s already been through the supply chain.

AK: “With recycling, you get traceability and a smaller footprint. Using refined scrap means starting with material that’s already been through the supply chain. You can make new units with less energy, less water, and fewer emissions than mining alone. That’s what responsible sourcing looks like in practice: looping materials back instead of starting from scratch.”

Looking ahead, what do you see as most important for Canada to succeed in this space?

VP: “Federal and provincial support is critical. Midstream often gets overlooked, but it’s the link that turns mined or recycled material into refined metal. Long-term investment is essential to keep it viable.”

AK: “It’s encouraging to see critical minerals recognized as strategic, even tied to national security. The challenge now is to turn that recognition into action by building the midstream capacity that lets Canada capture the value of its own resources and keep materials in circulation.”

Alberta’s leading beverage container recycling system demonstrates the role community and entrepreneurism play in building a healthy circular economy.

Sonya Friesen

Since 1997, Beverage Container Management Board (BCMB) has ensured Albertans have convenient access to reliable recycling for used beverage containers. The Government of Alberta delegated the non-profit organization to regulate the province’s deposit return system, keeping empty beverage containers from polluting the environment.

Canada’s leading system collects 18 different types of containers, including liquor bottles, bi-metal drink cans, and even drink pouches. Success is rooted in BCMB’s oversight, a robust network of independently owned bottle depots, across 160 communities and a strong culture of entrepreneurialism. Many depots have become buzzing community hubs that support local charities, sports teams, and provide a subset of Albertans with an income they may not otherwise have.

The path to 100 per cent BCMB’s work has supported economic diversification and a stronger circular economy, where resources are reused instead of discarded. Beverage container recycling has created primary and secondary jobs, and Albertans have benefited from a cleaner environment. The province boasts an impressive collection rate, but there is more to be collected.

As BCMB President & CEO Mark Emsden explains, “While Alberta's population has grown, access to depots for some groups is becoming more limited and difficult. We are exploring different, modern collection options to improve the accessibility, convenience, and efficiency of our system, benefiting everyone.”

With around 15 per cent more containers to collect, BCMB is exploring solutions to reach hard-to-service areas and encouraging younger demographics to recycle. With new technologies, community participation, and Alberta’s trademark ingenuity, the goal of collecting 100 per cent of beverage containers sold seems well within reach.

By reimagining materials once destined for landfill, Multy Home is driving Canada’s circular economy and creating products for homes worldwide.

Chantal Simard, Sustainability leader at Multy Home

Thirty years ago, we witnessed a fi re of 14 million used car tires, which ultimately tipped this country toward a circular economy of weird wastes. The 1990 Hagersville Tire Fire triggered solutions for recycling programs beyond glass bottles. Today, car tires are still considered a “Weird Waste,” a term used by Multy Home, a Canadian company that transforms recycled materials into sustainable home and garden products, to describe materials that, while ineligible for municipal recycling programs, nonetheless hold worth within the circularity of materials in Canadian value chains.

When Multy Home was challenged to incorporate rubber from used tires to make new products, the curiosity and creativity of company founders were set ablaze. They re-invented existing products historically made from virgin raw materials, converted them into recycled rubber, and then partnered with major retailers to put the new consumer-ready products on shelves.

Today, Multy continues to manufacture new products such as planters and garage flooring from recycled rubber diverted from Canadian landfi lls. Multy has since diverted 27 million tires from landfills and produced products for millions of homes across the planet.

Shaping a sustainable future

“At Multy, we think Weird Waste is beautiful. There are many types of waste, especially plastics, that still lack curbside recycling solutions today,” says Multy’s Vice-President of Marketing and Sustainability Chantal Simard. “REDU Materials is what we’ve named our process of transforming Waste into Wonders.”

“Multy now has many formulations using mixed wastes in our various manufacturing locations in the Toronto area and in Cowansville, Que. Our Quebec facility’s expertise is in sheet extrusion. We produce flexible matting made of recycled rubber and plastics to support tiered manufacturing in the automotive sector, vehicle conversions, commercial mats, and even residential applications,” says Multy’s Chief Operating Officer Rod Anderson, proving that Multy’s reach with recycling solutions continues to drive circularity solutions in Canada.

Why Every Beverage Container Counts in Alberta’s Recycling System

With the right knowledge, new and long-time Albertans alike can keep beverage containers in the loop, ensuring they’re properly recycled.

Jamie Zachary

Recycling beverage containers in Alberta is more than waste reduction — it’s an economic driver that keeps materials in circulation while returning money to residents.

Alberta leads Canada with an 85 per cent recovery rate, collecting over two billion containers annually. Yet millions still end up in landfills, leaving an estimated $40 million in unclaimed deposits each year, according to the Alberta Beverage Container Recycling Corporation (ABCRC).

ABCRC president and CEO Guy West notes that many newcomers to the province, along with residents lacking convenient access to depots, may be missing opportunities. “Alberta has built a strong culture of recycling,” says West. “Yet for those new to the province, this system might not be second nature. The opportunity lies in education — helping more people understand how easy it is to return their containers and why even the less obvious ones, such as milk cartons and juice pouches, make a difference.”

Addressing often-missed container types

While cans and bottles are widely recognized as refundable, recovery rates for other materials lag. In 2023, only 57 per cent of the 14.8 million drink pouches sold were returned. Small plastic bottles under one litre, poly-coat cartons like protein shakes, and bi-metal cans such as tomato juice also see lower recovery. “Other containers are just as valuable,” West emphasizes.

Supporting a circular economy

Every non-refillable beverage container sold in Alberta carries a deposit, refundable at nearly 220 independently owned depots.

“It’s a simple way for Albertans to put money back in their pockets and keep millions of containers out of landfills,” says West. “The more we can educate people — whether they’ve been recycling here for years or are still getting used to the system — the better we can ensure every container stays in the circular economy.”

RCC RETAIL SUSTAINABILITY CONFERENCE 2025: Turning Strategy into Action for Retail, CPG & QSR Leaders

Retail Council of Canada (RCC)’s Retail Sustainability Conference returns October 29–30, 2025, at the Toronto Congress Centre, convening senior leaders from retail, CPG, and QSR alongside Canadian

innovators, and global brands.

Experts defining tomorrow’s sustainability strategies

Discussions will span scope 3 emissions, greenwashing, circular design and recyclability, and feature a line-up of global sustainability thought leaders, among them:

• Sheri Flies, Senior Vice President, Global Sustainability and Compliance, Costco Wholesale

• Jim Andrew, Executive Vice President, Chief Sustainability Officer, PepsiCo

• Kristina Friedman, Head of Sustainability for North America, Unilever

• Ashley Fill, Director, Global Sustainability Communications, Procter and Gamble

Workshops driving real-world impact

New this year, an expanded program with half-day workshops designed to tackle the operational realities that senior executives face, offering solution-oriented discussions and clear actions to move forward.

Producer and Regulator Perspectives on EPR Transitions brings together producer and regulator perspectives on Extended Producer Responsibility (EPR), focusing on cost pressures, compliance, and oversight.

Enabling Zero-Emission Delivery, led by IKEA Canada and PowerON, will dig into fleet transition strategies, charging infrastructure, and the funding incentives available to help businesses accelerate adoption at scale.

“In Canada and around the world, regulators are advancing sustainability regulations, consumers are demanding greater transparency, and supply chains are being reshaped by circularity, climate resilience, and more responsible sourcing. In this environment of economic uncertainty and trade pressures, our role is clear: to keep pushing the needle forward through collaboration and shared goals. This conference is where leaders align strategy with innovation and partnerships that drive impact,” says Michael Zabaneh the Vice President, Sustainability at Retail Council of Canada.

RCC’s Retail Sustainability Conference is where Canada’s retail ecosystem and global leaders come together come together to advance sustainability objectives—for today and the future.

Lucid Corp’s innovative plastic meat tray eliminates the problem of non-recyclable soaker pads and diverts tons of plastic from the landfill.

If you think those empty plastic meat trays you toss into your Blue Box get recycled, think again.

“Tens of billions of plastic and Styrofoam trays with soaker pads are dumped into landfills each year,” says Salman Ebrahim, President & Co-Founder of Lucid Corp, a Toronto-based firm specializing in food packaging solutions.

The soaker pad or “diaper” in the tray is there to absorb the fluids, or purge, that come from proteins like chicken, beef, and seafood. While the plastic tray itself is recyclable, the pad attached to the tray isn’t. “People toss the whole thing into the recycling bin with good intentions, but by not removing the soaker pad, that tray is now non-recyclable and will be rejected at the sorting plant and sent to the landfill,” says Edmund Chin, Managing Director and Co-Founder, Lucid Corp.

Innovative solution

People toss the whole thing into the recycling bin with good intentions, but it will be rejected at the sorting plant and sent to the landfill.

Lucid Corp has developed a solution to this global challenge. “Once we grasped the gravity of the problem, we knew we had to act,” says Ebrahim. In 2020, he and Chin founded Lucid Corp with the goal of becoming the most sustainable food packaging company in the world. Their determination, coupled with a worldclass engineering team, led to the invention of the Lucid Infinity TM tray. The Infinity tray is made from 100 per cent recyclable polyethylene terephthalate (PET) and is the first commercially padless tray available at scale. “By prioritizing efficiency through automation and process, we’ve engineered a solution that makes the soaker pad totally obsolete. Our patented 2-piece design provides a sophisticated built-in reservoir, cleanly separating meat fluids from the product,” says Chin.

Pad-less trays make it easy for consumers

That’s good news for both consumers and the environment.

“Being pad-less, consumers don’t have to handle or smell the bacteria-laced soaker pad. They can simply place the Lucid Infi nity tray into the recycling bin and feel confident that they’re helping to divert tens of billions of trays with soaker pads from the landfill,”

Anne Papmehl

says Chin, “It’s the world’s largest problem in sustainable food packaging.”

The tray’s leak-resistant design and customizable reservoir make it a versatile product choice for commercial retailers. “Our tray delivers premium quality, and is engineered for sustainability and circularity, but priced to compete head-to-head with standard meat trays with soaker pads,” says Ebrahim.

Rising pressure to address plastic pollution Leaders are recognizing the negative impact of the plastic pollution crisis on human health and the environment. While the recent fifth around of negotiations for a UN Global Plastics Treaty to eliminate plastic pollution failed to reach an agreement, a majority of countries have expressed support for it. “With consumers demanding sustainable choices, companies racing to hit ESG goals, and industry groups enforcing the Golden Design Rules that our tray already meets, the shift to sustainable is inevitable,” says Ebrahim.

Choose recyclable plastics

Consumers can help accelerate this shift through the choices they make every single day. By advocating for sustainable food packaging, such as the Lucid Infinity tray, retailers and consumers can help drive a powerful push towards a more sustainable and regenerative economy. “The Lucid Infi nity tray has set the gold standard in food packaging. When you offer your consumers our 100 per cent PET packaging options, you’re sending a clear message about your commitment to sustainability,” says Ebrahim. “All Lucid Infinity packaging is 100 per cent recyclable, helping to meet ambitious environmental goals,” he says.

More sustainable options

In addition to making conscious choices, there are plenty of advocacy activities consumers and retailers can partake in. They may consider writing to sustainability leaders or directors of major grocery chains encouraging them to phase out the use of soaker pads. They can also advocate during grocery store visits by asking the manager if they plan to adopt a pad-less tray. Chances are, they don’t even know about it, so here’s your chance to educate.

Grocery chain leaders can bring this solution to the table for consideration. Not only is it helping to solve a global environmental waste problem, but the Lucid Infinity tray also makes for a positive consumer experience at a competitive price—no mess, no fuss, and no more guesswork on where it should go. And in-store, it’s designed to highlight freshness and offer customizable designs for sleek, streamlined merchandising.

The chasing arrows symbol on packaging doesn’t always mean it will be recycled. The number inside is a code for what kind of plastic was used.

PET (polyethylene terephthalate) is the most recycled plastic in the world. Its code is “1.”

One plastic tray with a soaker pad will stay in a landfill for centuries; tens of billions of trays with soaker pads are sent to landfills every year.

People have unknowingly or accidentally cooked their meat with the pad still stuck on.

Nearly 40 per cent of all plastic waste is attributed to packaging.

Sometimes soaker pads tear and can seep onto your food.

Wish-cycling is a term used when someone puts an item into the recycling bin hoping or assuming it’s recyclable, which often results in it being rejected by local recycling programs and sent to landfills.

Danielle Holly, Executive Lead, North America, at the Ellen MacArthur Foundation, on why this is a critical time for a circular economy in Canada.

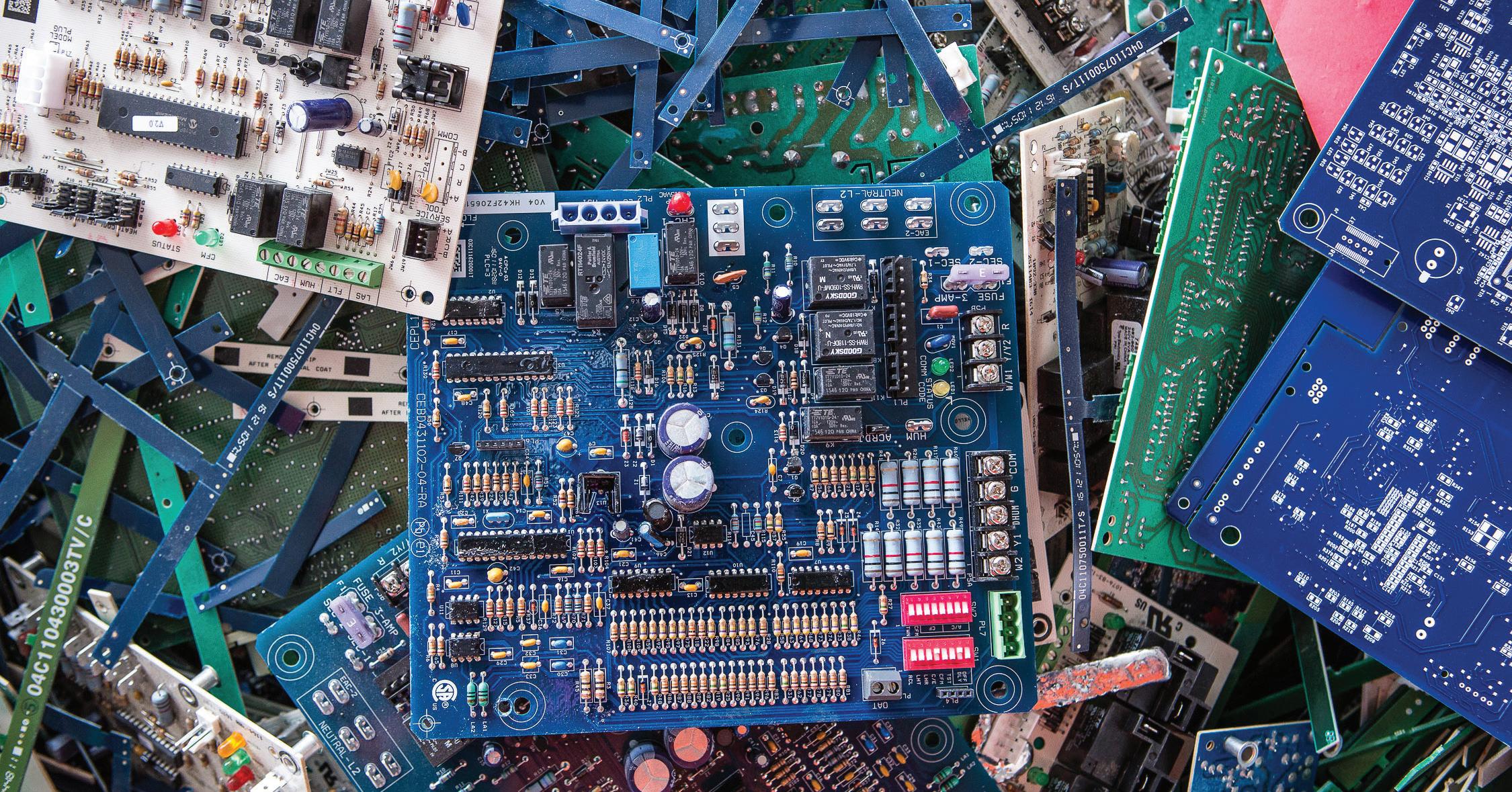

The global demand for critical minerals is set to double by 2040. As the world shifts away from fuel-based technologies and toward electric alternatives, critical minerals – such as lithium, cobalt, and nickel – are vital to power the clean energy and digital transitions.

Canada’s economy is well positioned to benefit from the race to secure the critical minerals needed for the new electric economy. But instead of relying solely on mining and extracting these key resources, there’s a timely opportunity for Canada to lead the way in creating a more circular economy for critical minerals.

Mining the waste Opening a new mine can take up to 16 years and is both

financially and environmentally costly. Consider this. From one ton of mined gold ore, you typically get just 10 grams of gold –about the size of a wedding band. But with the right recycling and collection systems in place, a single ton of discarded smartphones could yield up to 350 grams of gold.

By recirculating materials already extracted and built into our electronics and digital infrastructure, Canada can help meet the global demand for these valuable materials, build resilient supply chains, and unlock significant economic benefits.

Canada’s economy is well positioned to benefit from the race to secure the critical minerals needed for the new electric economy.

That future is within reach. With the right policies, infrastructure, and tracking of materials, let’s turn this vision into reality.

Explore how the circular economy can help meet the growing demand for critical minerals . Visit ellenmacarthurfoundation.org

Dedicated researchers at Carleton are making strides toward a low-carbon or net-zero economy. As a research-intensive interdisciplinary university, you will fi nd skilled people in many fields, working on projects that complement a shared goal: furthering knowledge and discovery through co-creation — on campus and in the local community.

Reorienting energy policy

At Carleton, our researchers are advancing knowledge and discovery for a lowcarbon economy through interdisciplinary cocreation on campus and in the local community.

One of these researchers is Daniel Rosenbloom, Assistant Professor in the Faculty of Public and Global Affairs, who holds the Rosamond Ivey Research Chair in Sustainability Transitions. The chair was established in 2024 and is funded by the Ivey Foundation, a community partner. It’s the first chair that’s explicitly dedicated to deepening scholarship and practice surrounding the growing field of sustainability transition in Canada. Rosenbloom’s goal is to develop a world-class hub for research and policy around sustainability transitions. In June, he partnered with the Energy Modelling Hub to convene the Net Zero Meets Trade Disruption workshop, bringing together a diverse group of leading voices from government, academia, and industry. During the intensive day-long event, participants identified trade-disruption scenarios and modelled

how to handle them effectively using relevant data, policy, and tools.

Reducing industrial carbon and costs Also on campus, you’ll find the Energy and Particle Technology Laboratory led by Reza Kholghy, Associate Professor in the Faculty of Engineering and Design and Canada Research Chair (CRC) in Industrial Decarbonization. “My research investigates technologies that could significantly reduce the carbon footprint and cost of manufacturing processes by heavy industries in Ontario,” he explains. One of the technologies is a novel process to produce high purity alumina from recycled aluminum and cogenerate hydrogen as a byproduct. Alumina is a metal oxide with applications in display glass (for phones and laptops) and batteries and the process developed by Kholghy and his team significantly reduces the carbon footprint of its manufacturing; a target that is required from suppliers of Apple for its iPhones and Macbooks.

Kholghy’s research is a prime example of successfully working across academic, governmental, and industrial lines. He received an Early Researcher Award from the Ontario government, which helps fund his work. He also works with international industry and key government partners, including the National Research Council Canada and Natural Resources Canada.

Creating viable, feasible change

Another example of the interdisciplinary work being done at Carleton is at the APEX (Alternative Pathways for the Energy Transition) lab, led by Faculty of Engineering and Design Associate Professors Ahmed Abdulla and Kristen Schell, who also holds a CRC in Uncertainty-informed Net Zero Energy

System Modelling. There, they’re working to develop decarbonization pathways that are both “techno-economically viable” and “socio-politically feasible.” Their work is a concentrated response to the century-defi ning challenge of climate change. At the lab, researchers are investigating improved wind and hydropower forecasting, novel carbon removal technologies, and optimizing the integration of electric transportation and heating systems into the power grid.

Carleton: advancing low-carbon knowledge and practice

The wide range of disciplines and partners involved demonstrates Carleton’s far-reaching commitment to approaching sustainability issues from every angle, and not just within the bounds of the university. It shows in its participation in the Net Zero Challenge. Carleton is a bronze-tier participant and the only university involved in the Government of Canada initiative. The commitment is also evident at Efficiency Canada, an organization that’s housed in Carleton’s Sustainable Energy Research Centre. The centre brings together academic researchers, industry, and governments to advocate for public policies that move us toward a more energy-efficient future.