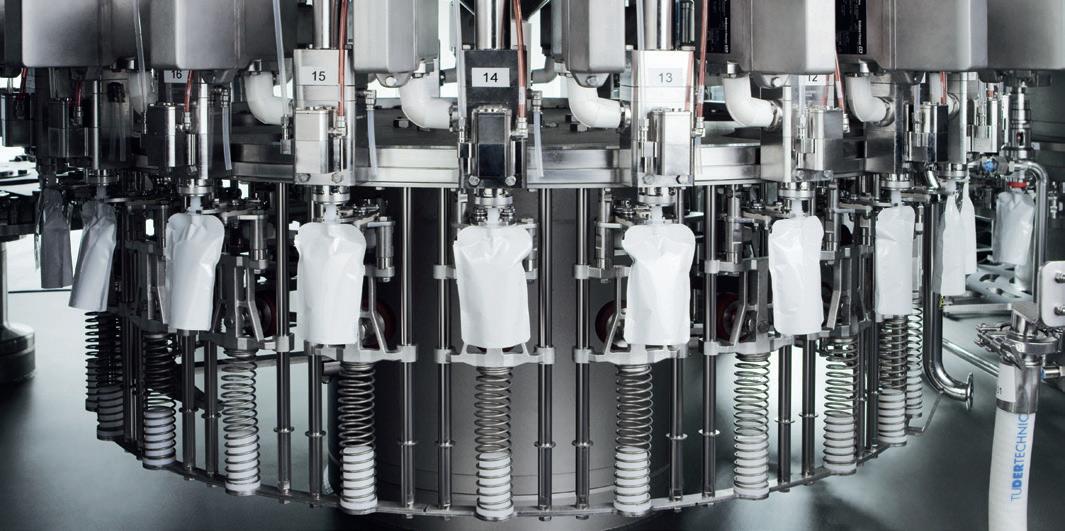

IMA serves the international dairy and dairy alternative industries with the best platforms and machines, consistently providing tailored technologies for the packaging of cheese, butter, margarine, yoghurt, desserts, UHT milk and more.

From stand-alone machines to fully-integrated solutions, our advanced technologies and expert consultancy ensure tailored support for every need, from primary to end of line packaging solutions.

Make the most, with us.

Visit us at GULFOOD MANUFACTURING

Dubai, UAE - Shk Saeed Hall 3 - Booth S3-D52

dairyfood@ima.it

ima.it/foodanddairy

Associate

Assistant

Raseena

Contributors

Dr.

Neville

one of the UAE’s leading FMCG distributors, and Food Tech Valley, Dubai’s governmentbacked hub for food innovation, have announced a landmark partnership to establish a state-of-the-art food logistics and facility within Food Tech Valley.

The signing ceremony took place at the Future Food Forum 2025, held at Le Méridien Dubai, and under the patronage of the Ministry of Economy and Tourism, underlining the UAE’s commitment to creating a

resilient, sustainable and self-sufficient food ecosystem.

The first initiative under this partnership will be the design and construction of a cutting-edge logistics facility at Food Tech Valley, built to prioritize speed, scalability and agility. This hub will initially focus on streamlining food distribution across the UAE, with future plans to expand product categories and nurture the growth of locally owned brands, strengthening the country’s food production ecosystem.

Once operational, this facility will

Get to know a wide range of high quality bakery ingredients ready for all your needs from small treats to grand indulgence.

• Carefully selected ingredients, perfect processing properties and maximum reliability make for excellent results

• From ingredients for American baked goods such as Brownies and Cookies to our colourful Schokobella range - dicsover pure delight in every bite

Contact us for more innovative ideas and information: Alexander Misiewicz

Export Manager & Technical Adviser

Tel.: + 49 511 4107-367

Mail to: a.misiewicz@martinbraun.de

become a cornerstone of the UAE’s Food Security Strategy 2051, redefining how food is sourced, stored and distributed. By integrating advanced ambient and cold chain systems, it will enhance efficiency, reduce waste and ensure consumers have greater access to safe, high-quality food at optimal prices. Beyond logistics, the facility will create jobs, develop skills and generate value for the local economy, reinforcing the UAE’s position as a leader in sustainable food systems.

Martin Braun KG Tillystraße 17–21

30459 Hannover, Germany

+49 (0)511 4107-0

www.martinbraun.com

Al Ain Farms Group (AAFG), the UAE’s national food champion, and Khalifa University Enterprises Company (KUEC), the commercial arm of Khalifa University, have signed a landmark Memorandum of Understanding at the Abu Dhabi International Food Exhibition. This strategic agreement advances research, innovation, and sustainable practices across the UAE’s food sector, reinforcing the nation’s leadership in food security and science-driven industry growth. It also lays the foundation for talent incubation, with AAFG offering

students access to real-world facilities and potential pathways to scale promising research ideas.

AAFG, which brings together five of the UAE’s most trusted legacy brands—Al Ain Farms, Marmum Dairy, Al Ajban Chicken, Al Jazira Poultry’s Golden Eggs, and Saha Arabian Farms—plays a central role in delivering highquality, locally produced foods. With a vertically integrated model spanning feed production, hatcheries, processing, packaging, and logistics, AAFG is wellpositioned to support the UAE’s

food security agenda.

This alliance redefines the region’s food innovation landscape across three key areas: the Camel Milk Revolution, Sustainable Poultry Feed, and Talent, Science, and Real-World Solutions.

The strategic partnership will advance flagship pilot projects in camel milk and sustainable poultry feed, with rapid validation and scaling. It also includes co-ownership and management of technology and intellectual property, ensuring UAE-based breakthroughs remain nationally significant.

RAW Coffee Company, the UAE’s leading specialty coffee roaster, has partnered with JAR Premium Foods to launch the RAW x MILKLAB Barista Training Centre, which opened on September 25th, 2025, at RAW’s roastery and café in Al Quoz, Dubai.

The centre represents a first-of-its-kind collaboration in the UAE, bringing together RAW’s internationally recognised specialty coffee expertise and MILKLAB’s barista-grade plant-based milk portfolio. Together, the two brands aim to raise barista standards, support cafés in meeting growing demand for plant-based alternatives,

and strengthen the local coffee community through accessible, professional education.

“Specialty coffee is evolving, and so are the preferences of café customers,” said Kim Thompson, Founder and Director of Culture & Brand at RAW Coffee Company.

“We’re seeing a generational shift toward cold brews and plant-based alternatives, and baristas need the knowledge and confidence to deliver consistent quality in this new landscape. This training centre is about equipping them with the skills, techniques, and product knowledge to do just that.”

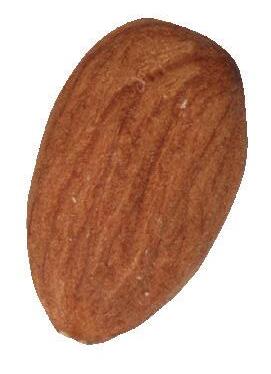

“MILKLAB identified the rise of

plant-based coffee culture early, launching our barista milk range in Australia in 2015 with almond as the category game-changer, followed by coconut, oat, and macadamia,” said Murad Janakat, CEO at JAR Premium Foods, exclusive distributor for MILKLAB since 2017.

“Eight years on, we are proud to serve specialty coffee shops across GCC and Levant. With the UAE’s vibrant café scene, this training centre with RAW Coffee Company reflects our commitment to raising industry standards, ensuring baristas are equipped to consistently deliver the quality and creativity today’s consumers expect.”

From design to consultation, service to optimisation, let us support you in achieving your business goals, as the single-source partner to the food industry.

Following a year of remarkable success since opening its doors in June of 2024, bkry has quickly become a cult favourite, blowing up across the UAE as the go-to spot for baked perfection. Drawing loyal guests who travel all the way from Abu Dhabi, Al Ain, Ras Al Khaimah, and other cities just to enjoy their favourites, the homegrown brand is now setting the stage for the next chapter of its journey with a series of exciting openings across the UAE and beyond.

Since its inception, bkry has quickly established itself as one of

Dubai’s most talked-about concepts. Guests have lined up for hours to experience its inventive breads, croissants and chocolates, making it a must-visit destination in the city’s dining scene. In its debut year, bkry was honoured with two major awards, securing industry-wide recognition.

For the bakery’s first plan of expansion in Q4 of this year, bkry will make its international debut in New Cairo’s Fifth Settlement at the Waterway Branded Residences. With its bustling food scene, diverse population, and passion for artisanal

craftsmanship, Cairo emerged as the perfect destination for bkry to start growing.

The space will reflect the same inviting, industrial-chic aesthetic that has defined the Dubai flagship, with an open design encouraging transparency and connection with its visitors. The menu will feature signature bkry creations alongside exclusive new items crafted specifically for the Egyptian market, incorporating locally sourced ingredients and flavours inspired by the country’s rich heritage.

The Abu Dhabi Quality and Conformity Council (ADQCC), in collaboration with TAMM, the digital platform under the Department of Government Enablement, has launched a new smart feature to enhance the “Nutri-Mark” initiative.

The feature, available through the TAMM app, allows users to scan food product labels and instantly receive a nutritional classification ranging from Grade A (highest nutritional value) to Grade E (lowest).

Showcased by ADQCC during GITEX 2025, the Nutritional Label was developed in cooperation with the Abu Dhabi Public Health Centre. It evaluates products based on their nutritional content, such as fats, sugars, fibres, proteins, and more, thus enabling consumers to make informed choices at a glance.

Diriyah Company has announced the launch of Jabal AlQurain Avenue, a pioneering new area designed as a multidisciplinary incubator for visionary Saudi and regional entrepreneurs and emerging talent in the retail and F&B

Jabal AlQurain Avenue will provide flexible spaces for emerging and established businesses, offering a dynamic platform for creative Saudi entrepreneurs to nurture and develop innovative brands that will appeal to Diriyah residents and visitors. It will also form a significant part of the much larger Qurain Cultural District that was announced in 2024.

In addition to its Saudi-focused retail and F&B offer, the new avenue will also feature a dynamic mix of arts, retail, offices, and residences—inviting people to live, work, explore local brands, and enjoy authentic dining experiences. A place that is designed to become a vibrant hub where culture and modern urban living come together.

The fully pedestrianized avenue and surrounding areas will also be home to residential units and offices alongside a range of cultural academies and institutes.

More efficient. More flexible. Higher performance. Consistent results. Designing

At Nothum, we specialize in predust, batter, breading, and frying equipment designed to enhance the value of your convenience food products. Our machines are built to deliver maximum line flexibility while ensuring consistent high-quality results.

Saudia Dairy and Foodstuff Company (SADAFCO), a leading producer of high-quality dairy and food products in the Kingdom, announced the signing of a strategic agreement with Tetra Pak to install the cutting-edge Tetra Pak E3/Speed Hyper line, the fastest filling machine in aseptic carton manufacturing for food and beverage products.

Equipped with eBeam sterilization, the technology behind the Tetra Pak E3/ Speed Hyper line delivers

important sustainability benefits by reducing operational costs and minimizing water, energy, and chemical consumption compared to conventional food and beverage filling machines.

The agreement was signed by Patrick Stillhart, CEO of SADAFCO, and Konstantin Kolesnik, Managing Director of Tetra Pak Arabia Area, marking a new milestone in the long-standing partnership between the two companies that spans more than 40 years during which both companies have collaborated

to transform the food and beverage industry in the Kingdom of Saudi Arabia.

Patrick Stillhart, CEO of SADAFCO, said: “At SADAFCO, we continue to invest in advanced technologies that enhance efficiency, ensure the highest quality for our consumers, and reduce our environmental footprint. The deployment of the Tetra Pak® E3/Speed Hyper line represents an important step in strengthening our Saudia Milk portfolio and advancing our sustainability commitments.”

Nestlé UAE has signed a strategic Memorandum of Understanding (MoU) with Emirates Foundation to support ne’ma, the UAE’s national initiative to reduce food loss and waste by 50% by 2030. The signing ceremony took place in the presence of His Excellency Abdulla bin Touq Al Marri, UAE Minister of Economy and Tourism, during the Future Food Forum 2025. This collaboration supports the UAE’s National Food Security Strategy 2051 and contributes

to achieving UN Sustainable Development Goal 12.3 to halve food loss and waste by the end of the decade.

The MoU formalizes Nestlé’s contribution to the UAE Food Loss and Waste Baseline Study, led by Emirates Foundation under the ne’ma initiative. Nestlé will provide operational data, industry insights, and collaborative support to help establish national indicators and drive systemic change across the food value chain, including through ne’ma’s Zero Food

Waste Framework.

This partnership builds on Nestlé’s long-standing commitment to sustainability and its economic and social impact in the UAE. Nestlé’s collaboration with Emirates Foundation under ne’ma will also support public awareness campaigns, youth engagement programs, seasonal food rescue efforts such as those during Ramadan, and the development of scalable solutions to reduce food waste in manufacturing and distribution.

From burgers and sausages to sliced cheese - however you choose to process or pack your plant-based products, our team of specialists are on hand to provide expert advice.

MULTIVAC supports producers along the entire processing and packaging chain: with advanced machine technology and comprehensive line know-how, sustainable packaging development and innovative digitalization solutions.

· Portioning · Loading · Packaging · Marking · Inspection · Cartoning

Visit us at GULFOOD Manufacturing, our website about alternative proteins, or contact us directly to learn more.

dsm-firmenich, a leading innovator in nutrition, health, and beauty, announces a breakthrough in dairy cultures that aims to transform fermentation performance across the food industry. In collaboration with APC Microbiome Ireland, a world-leading Research Ireland Center at University College Cork,

and the French National Research Institute for Agriculture, Food and Environment (INRAE), dsm-firmenich has uncovered how bacteria used in dairy fermentations employ and activate defense systems against bacteriophages. Otherwise known as phages, these bacterial viruses can impact the production of cheese,

yogurt, and other fermented dairy products and therefore require strict and costly management. Published in the Proceedings of the National Academy of Sciences (PNAS), the findings unlock new opportunities to design more resilient, highperforming cultures for large-scale food production.

A global leader in yeast-based ingredients and culinary powders, is set to participate in Fi Europe 2025, the leading global food ingredients event, from 2–4 December at Paris Expo Porte de Versailles.

Visitors can find Ohly at Booth 40A40, where the team will demonstrate how their fermentation-based ingredients and Precision Extraction® techniques deliver consistent, multifunctional solutions that bring satisfying savoury complexity and umami.

Daria Pashkova, Product and Marketing Manager at Ohly, says, “Since 1836 our experts have been passionate about delivering multifunctional fermentationbased ingredients using our state-of-the-art fermentation and Precision Extraction® techniques. Whether liquid, paste, or powdered — our commitment remains the same: to deliver the highest quality yeast specialities. We ensure exceptional consistency and functionality in every batch.”

Zelo, a leading digital financing platform, and Watermelon Ecosystem, the UAE’s premier F&B platform, announced a strategic partnership that will revolutionize cash flow management for food and beverage suppliers. The collaboration provides instant liquidity by financing invoices

within 24-48 hours, eliminating the traditional 60–90-day payment wait times that constrain supplier growth.

The partnership directly addresses the F&B industry’s most persistent challenge: suppliers waiting months for payment while needing immediate cash for operations, inventory, and growth. Through Zelo’s automated

invoice financing platform, suppliers in Watermelon’s network of over 1,000 F&B outlets can now convert unpaid invoices into working capital in just one business day.

“Cash flow is the lifeblood of any F&B supplier,” said Dhanush Arjun, co-founder and CEO of Zelo.

“Our partnership with Watermelon ensures suppliers never have to choose between taking on new business and maintaining healthy cash flow. They can now say ‘yes’ to larger orders and invest in growth opportunities immediately.”

NORMA, a chain of discount grocery stores in Germany, France, the Czech Republic, and Austria, has recently taken an important step towards greater sustainability: Effective immediately, select convenience products from its private label will be packed in a remarkably innovative and recyclable paper product made by Koehler Paper: “Koehler NexPlus® Advanced.” This product is heatsealable, features an oxygen and oil barrier, and is greaseresistant, ensuring that it can reliably protect the products inside it while remaining highly recyclable. In fact, the paper’s recyclability has been verified in conformity with the Cepi standard, confirming its value as an environmentally friendly alternative to conventional plastic packaging. The products were manufactured by Frießinger Mühle.

Delivering the ultimate in Namkeen processing with flexibility and quality

Delivering the ultimate in Namkeen processing with flexibility and quality

We transform the raw recipe into the extruded, pulse, and legume snacks consumers know and love. We provide solutions to create cheese balls, cheese puffs, namkeen, and green peas.

We transform the raw recipe into the extruded, pulse, and legume snacks consumers know and love. We provide solutions to create cheese balls, cheese puffs, namkeen, and green peas.

• Preparation + Processing

• Frying + Oil Management

• Preparation + Processing

• Coating + Seasoning

• Frying + Oil Management

• Drying + Roasting

• Coating + Seasoning

• Product Handling

• Drying + Roasting

• Product Handling

SINCE 1950

info@heatandcontrol.com I heatandcontrol.com

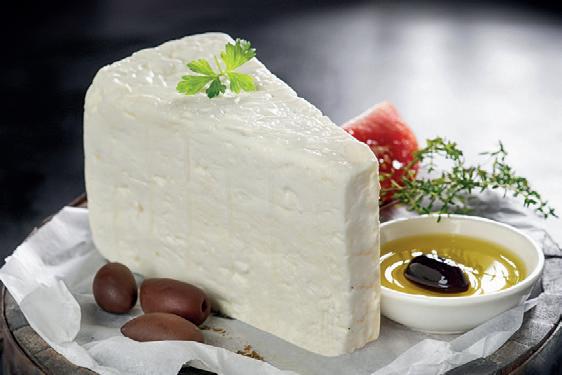

In a market where consumers are increasingly moving towards more responsible food choices, DalterFood Group – a leader in the international dairy sector – reaffirms its commitment to providing high-quality cheeses for those who follow specific dietary preferences.

Among the products in its extensive portfolio, there is a complete range of vegetarian-friendly cheeses, designed to respond effectively to emerging trends and offer professionals in retail, the food industry and food service high-quality, versatile and tasty products. At the heart of the range are Italian mature cheeses made with microbial coagulants – meaning they are not derived from

animals – such as Vegeterian Pecorino, with its strong, long-lasting flavour, and Spinoro, with its delicate, enveloping aroma, ideal for blending perfectly with other ingredients.

Selected by trusted partners and available in a wide variety of cuts, such as flakes, cubes and fillets, they are perfectly suited to production and service requirements. The range is completed by vegetarian grated cheese blends, designed to guarantee excellent performance in terms of seasoning, gratinating, stringiness and browning.

For the food industry, DalterFood Group is a valuable partner in developing new recipes or reformulating ready meals with a vegetarian twist, while staying true

to traditional Italian cuisine and flavor. Grated cheese blends, for example, are ideal for evenly melting between the layers of a lasagna and browning the top layer, while grated Vegetarian Pecorino is perfect for adding character to ready-to-serve sauces inspired also by Italian classics – such as Cacio e Pepe – reimagined in a vegetarian version. To enhance convenience and reduce waste, ready-to-eat soups and salads can be paired with single-serving sachets of Spinoro fillets, flakes, or nuggets, packaged in practical singleserving cushion packs made 100% by recyclable plastic.

CJ BIO, a global leader in fermentation-based bio products and taste solutions, will return to Gulfood Manufacturing 2025 in Dubai with an expanded presence in a new pavilion hall, offering visitors a diverse and interactive experience of its taste solutions portfolio.

Backed by over 200 R&D experts and more than 70 years of food and biotechnology

expertise from its parent company, CJ CheilJedang, CJ BIO has established global leadership in the savory ingredients category through flagship brands such as CJ TIDE™ (Nucleotides), and TasteNrich® (Premium Taste Solutions Brand).

• TasteNrich® delivers authentic, clean taste through advanced microbial fermentation technology, developed with a commitment to natural ingredients and no

additives. Within the TasteNrich® portfolio are specialized lines such as BASIC, SOLUTION, VMEET, HYBIND, and INNO, each designed to meet diverse customer needs.

• CJ TIDE™ is the world’s leading umami flavor enhancer, leveraging 40 years of dedicated R&D and advanced production technology to surpass competitors worldwide.

Together, these brands empower food manufacturers with solutions that balance authentic flavor, functionality, and cost efficiency. This year, under the theme “Your Choice of Taste Experience, From Foundation to Edge”, CJ BIO presents its vision as a Total Taste Solution Provider, covering everything from foundational savory ingredients to advanced taste innovations.

The U.S. Soybean Export Council (USSEC) announced updates to its regional structure designed to maximize efficiency, align talent, and continue delivering trusted, impactful programs to international customers on behalf of U.S. Soy farmers and USSEC members.

As part of the reorganization, Kevin Roepke has been appointed Executive Director – Middle East, North Africa, and South Asia (MENASA), effective October 1. In this role, Roepke will lead USSEC’s efforts to build trust, grow relationships, and strengthen market

access for U.S. Soy across the region for the mutual benefit of U.S. Soy farmers and international customers.

The regional structure updates will ensure USSEC is well-positioned to achieve its strategic goals amid evolving global market dynamics. The updated model realigns regional boundaries for U.S. Soy export markets, streamlines program administration, and strengthens USSEC’s ability to support global priorities and deliver value to customers worldwide.

“Guided by our core values and commitment to continuous

improvement on behalf of U.S. soybean farmers, USSEC regularly assesses its effectiveness and efficiency,” said Jim Sutter, USSEC CEO. “The new structure strengthens USSEC’s focus on strategic priorities, vital relationships, and ensures U.S. Soy remains the trusted partner of choice for customers around the world. We are confident that Kevin will provide strong leadership across MENA and South Asia and look forward to the impact he will make in advancing U.S. Soy’s presence and partnerships in the region.”

The leading global trade fair

Anuga broke all previous records with its 2025 edition: Over 8,000 exhibitors from 110 countries exhibited in Cologne from 4 to 8 October – more than ever before. More than 145,000 trade visitors from over 190 nations took advantage of the opportunity to discover

innovations, experience trends and establish international business contacts. The trade audience was especially strongly represented from Great Britain, Italy, the Netherlands and Spain. Outside Europe, Brazil, China, Japan, Canada and the USA were among the top nations. With a 94 percent share of foreign exhibitors and 80 percent share of visitors from abroad and with its ten trade shows, Anuga impressively reinforced their position as the undisputed global platform

for the F&B industry. The visits of Alois Rainer, the German Minister of Agriculture, Food and Regional Identity, and Miryung Song, Minister of Agriculture, Food and Rural Affairs from the Republic of Korea as well as many international delegations also underlined the high level of political interest in the trade fair.

"Anuga impressively demonstrates the central role it plays for the international food industry: It is a showcase for the success of an entire sector and a key driver of billions in sales. The global food industry is one of the most important growth drivers worldwide. This strength becomes tangible at Anuga, it underscores the innovative power and international significance of the sector," explained Gerald Böse, President and Chief Executive Officer of Koelnmesse GmbH.

The stage is set for the Africa Food Show Morocco 2025 (AFS Morocco), the continent’s premier platform dedicated to driving innovation, sustainability, and trade in the agri-food industry. Taking place from 19–21 November 2025 at La Foire Internationale de Casablanca, this influential event will unite global food producers, buyers, innovators, and policymakers under one roof to shape the future of Africa’s food value chain.

Now in its third edition, AFS Morocco has become a key meeting point for agribusiness professionals seeking to explore emerging markets, connect with

high-level decision-makers, and unlock cross-border opportunities. The show is part of a wider pan-African series with successful editions in Kenya and Côte d’Ivoire, cementing its position as a catalyst for growth and collaboration across the continent.

AFS Morocco 2025 will feature over 150 exhibitors and 3,500 visitors from 20 countries, hosting more than 500 B2B meetings and 10 high-impact conferences. Exhibitors will present over 100 innovative products across key sectors, including:

• Food Ingredients & Specialty Products

• Food Processing, Manufacturing, Supply Chain & Logistics

• Beverages & Functional Drinks

• Sustainable Food Packaging & Labeling

• Plant-Based & Alternative Proteins

• Food Safety & Quality Assurance

• Smart Agriculture & Farming

The Africa Food Show Morocco empowers Moroccan and African producers, promotes sustainable practices, and bridges global partnerships. From cutting-edge farming technologies to advanced processing and packaging solutions, the event serves as a gateway for businesses aiming to expand in Africa’s booming food and beverage market.

Fruit Attraction 2025 has generated an economic impact of €407 million in Madrid and contributed to sustaining 3,066 jobs in the region. These figures represent a 6% increase in economic terms compared to 2024, and 5% more in employment, further consolidating Fruit Attraction’s role as a catalyst for the economic and social development of the Community of Madrid.

At its closing, the fair – organized by IFEMA MADRID and FEPEX – welcomed more than 120,000 professionals from 150 countries, a historic milestone that reflects its strong international reach.

According to estimates from this edition, Fruit Attraction will have brought together 2,460 exhibiting companies from 64 countries, representing growth

of 8.4% over last year, and will have occupied 78,000 m² of exhibition space, up 10% from 2024. This expansion has had a direct impact on Madrid’s economy, while consolidating its leadership and confirming the city’s growing relevance as a global hub for the fruit and vegetable business.

Of the 2,460 exhibitors,

national participation accounted for 52% of the fair. The presence of all Spain’s fruit and vegetable producing regions underscores the country’s strength as a global leader in the horticultural market and confirms Fruit Attraction’s importance as a benchmark platform to showcase Spain’s productive and export capacity on the international stage.

FoodTech startup SOLVEAT, announces it has sealed an investment-based joint development and commercial agreement with The Central Bottling Company, Ltd. (CBC Group), a leading multinational beverages company.

The new, long-term collaboration will focus on the development of functional beverages infused with SOLVEAT’s patented natural herbal formulations.

Under the new partnership, SOLVEAT and CBC’s juice concentrates and fruit-based solutions subsidiary Gat Foods, will create a new line of soft drinks that target a range of health and wellness categories, including metabolic support, blood sugar control, and

more leveraging SOLVEAT’s naturally derived botanical compositions. CBC will play a key role in manufacturing and commercializing the branded products, granting SOLVEAT access to Gat Foods’ global customer network.

R&D will be carried out in SOLVEAT facilities, in collaboration with the CORE—CBC Group’s Open Innovation Center and in conjunction with clinicians from the world leading Sheba Medical Center.

“As a leading beverage provider with decades of industry experience, we’re committed to pioneering innovative products that align with modern trends and consumers’ wellness priorities,” states Yoram Sagy, CBC’s

president. “We’re delighted to partner with SOLVEAT to elevate soft drinks into functional beverages that are not only refreshing but also a daily source of wellbeing and vitality.”

SOLVEAT developed a pioneering approach to nutritional supplementation by supercharging everyday foods with science-backed botanical ingredients. The startup utilizes a proprietary phyto-delivery platform that enables the integration of its clinically validated herbal compositions into ordinary foods, such as snack bars, cereals, chocolates, soft drinks and more without altering the sensory joy of indulging.

ISM Middle East 2025 has reaffirmed its status as the region’s definitive platform for global growth in sweets and snacks, uniting global buyers, retailers and distributors at a time when Asia-Pacific, Middle East, and Africa (APMEA) is driving the sector’s fastest expansion, powering a $1.1 trillion market by

2029 at a CAGR of 5.7%.

The strategic weight of APMEA in the global sweets and snacks trade was underscored by the 2025 edition’s participation of 725 exhibitors from 66 countries, as brands like Caffarel (Lindt & Sprüngli Group), Amos, Walker’s Nonsuch Toffees, Chickles Gum, Trolli, Powermints, Maison Du Chocolat Café, Mrs. Bector’s, Sucralliance, The Belgian Chocolate Group, Katrina Sweets and Yupi Indo Jelly Gum sought to expand distribution networks and capture growth across these dynamic trade routes.

This year’s show drew an exceptional roster of industry powerhouses, with attendance climbing 30% to 25,033; attendees included

Big Basket, Carrefour, Dubai Duty Free, Dunkin’, Emirates Airlines, Marriott International, Nestlé, Noon, Panda, Reliance Retail, Tim Hortons, Nesto Group, Yandex and West Zone, reflecting the show’s pivotal role as a bridge between international buyers and fast-growing regional markets.

The three-day event brought together an exceptional roster of new market entrants, high-calibre buyers and sourcing leaders from around the world, who leveraged the platform to connect, spark new conversations and stay ahead of emerging trends as the Middle East was cited as the epicentre for fast-moving global trends amid the accelerating demand for sweets and snacks.

Akorn Technology, Inc. announced it has been awarded a prestigious National Science Foundation (NSF) Phase IIB Small Business Innovation Research (SBIR) grant to advance groundbreaking plant-based edible coatings for fresh produce. This next-generation solution will enable the first commercial post-harvest application of essential oils combined with other natural plant extracts to control devastating plant pathogens without synthetic fungicides.

By combining natural antimicrobial agents with proprietary upcycled plant protein technology, Akorn will deliver a safe, sustainable, and highly effective solution that extends

shelf life, reduces food waste, and improves food safety. The technology has broad applicability for many high-value crops including mangos, avocados, sweet potatoes, citrus, and other produce affected by common diseases such as anthracnose, stem end rot, and blue and green mold.

Common chemical fungicides frequently lead to the development of resistant strains of pathogens, forcing growers to use higher doses or switch to new chemicals. This vicious circle frequently ends with producers getting shut out of major markets due to poor quality or Maximum Residual Limit (MRL) breeches. Akorn’s formulation, by contrast, contains a broad range

of plant-derived active compounds that work in synergy, making it far more difficult for resistance to develop and helping break this costly and unsustainable cycle.

“Our mission has always been to tackle the global challenge of food waste with sustainable, science-based solutions,” said Anthony Zografos, CEO of Akorn Technology. “This NSF award is both a recognition of our progress and a critical boost to our efforts to replace harmful synthetic fungicides with safe, natural alternatives. We’re bringing together the best of nature and science to protect fresh fruits and vegetables from farm to table.”

Palsgaard will highlight the costcutting and sustainability potential of its emulsifiers for pistachio chocolate and more at Gulfood Manufacturing 2025 (4–6 November, Dubai).

The company’s emulsifiers and stabilisers are used worldwide to enhance sensory qualities and shelf life while optimising cost-in-use. They can replicate key functional qualities provided by other ingredients, helping manufacturers address resource challenges such as the ongoing cocoa shortage.

At Gulfood Manufacturing, Palsgaard (Hall 6, Stand C6-4) will present concepts including pistachio chocolate made with Palsgaard® AMP. The emulsifier enables producers to cut cocoa butter – the most expensive ingredient in chocolate

production – while maintaining sensory qualities and flow properties. AMP is significantly more efficient than lecithin, allowing for greater cocoa butter reductions, substantial cost savings and more sustainable use of scarce raw materials.

In the bakery segment, Palsgaard will highlight how its sustainably produced emulsifiers help industrial bakers reduce food waste, extend shelf life and lower energy use in production. This combination of performance and sustainability allows manufacturers to meet consumer expectations for indulgent baked goods while also improving efficiency and ESG performance.

In the dairy sector, the company will offer a canned breakfast cream

formulated with Palsgaard® Creamer. This emulsifier-stabiliser blend improves mouthfeel while reducing fat and extending shelf life.

Herbal Isolates, a global leader in value-added food ingredients and part of the Synthite Group, has announced the launch of its new sub-brand Savouron™, dedicated to its growing range of flavour enhancing solutions. This marks a strategic milestone in the company’s journey to strengthen its position as a forward-looking innovator in the global food ingredients space.

For decades, Herbal Isolates has been known for pioneering leadership in green pepper products and hydrolysed vegetable proteins (HVPs). With Savouron™, the company is consolidating

its expanding portfolio of flavour enhancers under a single identityoffering customers a comprehensive suite of solutions that balance indulgent taste, functionality, and cleanlabel needs.

“Consumers today demand more from foodcleaner labels, bolder flavours, and responsible sourcing. Savouron™ is our answer to this global shift, enabling brands to create products that are not only delicious but also aligned with evolving consumer expectations,” said Jacob Ninan, Managing Director, Herbal Isolates.

DEAL Holdings, one of the UAE’s most forwardlooking investment and development firms, has launched The Food & Beverage Group (The FAB Group) — a new hospitality powerhouse set to redefine how the Middle East experiences dining, culture, and community.

The FAB Group brings together world-class culinary talent, global partnerships, and

homegrown creativity to develop a new generation of restaurants, bakery concepts, and lifestyle destinations across the region.

As part of its launch, DEAL Holdings has appointed awardwinning chef Colin Clague as Global Culinary Director and Partner, marking a significant step forward in the Group’s mission to elevate the region’s culinary standards.

Whether with honey, nuts, or flatbread, thanks to Hydrosol, low-fat breakfast cream stays creamy and spreadable, just like consumers want.

• Perfect gelling

• The flexible answer to raw material variety

• Much lower fat content

• Creamy consistency

Symrise announces the launch of new chicken powders that it will produce at its Berric site in France. The new spray-drying tower, operational from mid-2026, will expand Symrise’s production capacity and portfolio. The company already offers a complete range of chicken solutions for taste, texture, mouthfeel and nutritional benefits, from food ingredients to high-impact flavor creations. This expansion will further enhance the versatility and breadth of its chicken offering to meet key

customer needs.

The industrial expansion responds to the growing global demand for chicken, one of the most preferred ingredients worldwide. It strengthens Symrise’s chicken portfolio and ensures reliable supply for customers across regions. While Symrise already produces these powders in the United States, these new French powders open access to the Europe, Africa and Middle East market, increase capacity for Asia Pacific and Latin America, and reinforce supply

security with dual sourcing options for global accounts.

Also, the new powders allow Symrise to respond to the growing demand for convenient, cost-efficient, and indulgent natural chicken solutions, widely used in noodles, bouillons, and soups. They combine sustainable sourcing with consistent quality and allow for clean labels.

This helps food manufacturers differentiate their products in competitive markets. Customers can already obtain early samples for evaluation.

Global Food Week (GFW) 2025 has set a new benchmark for international collaboration and culinary innovation in the food and beverage sector. This year’s edition, hosted at ADNEC Centre Abu Dhabi, has drawn thousands of participants from 75 countries around the world, including 18 first-time attendees. This excellent participation underscores the event’s prestigious reputation and expanding global influence.

GFW 2025 has brought together an array of global corporations, manufacturers, farmers and

renowned chefs, all under one roof. Combined with several countries eager to showcase their products and innovations, the event is a meeting point for international buyers, producers and innovators in a rapidly growing sector. It underscores Abu Dhabi’s position as a cosmopolitan city and its reputation as a global crossroads.

This year’s exhibition features countries from across five continents, representing a celebration of cultural diversity. The Italian Pavilion, led by Executive Director of Global Marketing Donato Cinelli, features over 20 companies and a dedicated hall for live cooking demonstrations by esteemed chef Luca Martino, who presents authentic Italian cuisine.

Mexico is well represented too, featuring eight sections

dedicated to corn, peppers and cocoa. In the Global Gourmet Hall, international chefs conduct live demonstrations, shining the spotlight on dishes such as tacos, fajitas and hot sauces. Meanwhile, European pavilions such as Denmark and Poland are showcasing all that the continent has to offer, such dairy and meat along with numerous organic and natural products.

Japan, South Korea and China have made a strong impression at this year’s exhibition, with large pavilions spotlighting advances in food processing and transport. Japan has impressed with sushi, ramen, and smart agriculture while South Korea has showcased a range of kimchi, teas and natural ingredients. Meanwhile China has focused on plant-based foods and cutting-edge preservation.

Eco-driven Skeppsbro Bakery in Stockholm’s historic Old Town has become the first bakery in Sweden to ensure its bread is completely free from PFAS “forever chemicals.” The waterfront bakery, already known for milling its own organic flour on-site, is now also purifying the water used in its baking to remove PFAS, lead, and microplastics thanks to proprietary Swedish purification technology developed by Bluewater, a world-leading clean water and beverage innovator.

“Using the best organic ingredients has always been at the heart of our craft,” said Fredrik Ekman, CEO of Skeppsbro Bakery. “Now we’ve taken the natural next step by making sure the water we use meets the same standard. Just as organic food has become the obvious choice for many,

I believe it will soon be just as natural to ask if the water in your bread or coffee has been purified from harmful chemicals.”

PFAS, a group of nearly 5,000 man-made chemicals, are used in everything from firefighting foam to cosmetics. They persist in the environment and have been linked to health risks, including elevated cholesterol, a weakened immune response, and liver damage. PFAS chemicals, which do not break down naturally, are found in tap and bottled water worldwide.

In Stockholm, drinking water is drawn from Lake Mälaren, where PFAS levels in some areas have been found to exceed recommended thresholds. Tests conducted by Eurofins on behalf of Bluewater found PFAS levels in Stockholm tap water

at approximately 3.5 ng/L – close to the forthcoming EU limit of 4 ng/L. Bluewater’s second-generation proprietary reverse osmosis technology, SuperiorOsmosis, has been demonstrated to effectively remove both PFAS and microplastic particles from tap water. By partnering with Bluewater, Skeppsbro Bakery is showing that it is possible to produce food entirely free from hidden waterborne contaminants. “We believe more restaurant owners should ensure the tap water they use is free of PFAS and other toxic chemicals. It’s an investment in both human and planetary health,” said Bluewater founder and CEO Bengt Rittri, a well-known Swedish ecopreneur who earlier launched indoor air purification pioneer Blueair, acquired by Unilever in 2016.

A leading global provider of ingredient solutions to the food and beverage manufacturing industry, will showcase its latest innovation in sugar reduction at Gulfood Manufacturing 2025 in Dubai. The company will introduce DULCENT Sweetener Solutions, a new sugar reduction solution designed to help manufacturers balance taste, affordability and consumer appeal. Developed specifically for beverage and dairy applications, DULCENT Solutions combines Ingredion’s advanced sugar reduction technologies with its proprietary Reb M varietal. The result is a convenient, cost-effective solution that allows manufacturers to achieve high levels of sugar reduction without compromising taste performance.

Sue Bancroft, director of healthful solutions EMEA at Ingredion, said: “Manufacturers are increasingly under pressure to reduce sugar while keeping their products enjoyable and affordable. We created DULCENT to meet that challenge by providing a sugar reduction solution that delivers the taste experience that consumers prefer and gives brands the benefit of reduced sugar labelling and attractive cost-in-use.”

“The new solution offers a taste experience closer to sugar-sweetened products compared to commonly used artificial sweeteners like aspartame and acesulfame K. It also enables a greater reduction in sugar than stevia alone,

making it easier for manufacturers to develop reduced or no-addedsugar recipes.”

Castle Ingredients® helps manufacturers protect margins without losing quality.

Castle Chocolate and Castle Black replace up to 50% cocoa while holding colour and flavour.

Castle Egg 4.0 secures binding, emulsification and browning with a clean-label profile. For artisanal bakeries we supply diastatic and roasted malt flours plus wheat, spelt, rye, special, and technical flours.

Keep production steady with FSSC 22000 certification, heat treatment, precise packing and secure storage.

Grandiose, a premier quality food and grocery retailer in the UAE with nearly 50 stores and part of the Ghassan Aboud Holding, supported by Microsoft technology, announced the launch of GrandChef, an AI-powered chef designed to help customers build their carts smarter based on recipes, dietary preferences, and cooking inspirations.

Currently rolling out in the newest versions of the Grandiose Android and iOS apps, this pilot marks Grandiose’s first AI-powered initiative and a defining milestone in its digital transformation journey.

With GrandChef, Grandiose continues to push the boundaries of

www.castle-group.eu

2 production plants powered entirely by solar energy Find all our products and services in one place.

Learn more about what makes Castle Ingredients the best partnerfor your business.

retail innovation, blending world-class technology with its commitment to putting shoppers at the heart of the experience. Whether planning a weeknight meal or preparing for a special occasion, shoppers can now enjoy a seamless and personalized shopping experience tailored to their kitchen needs.

“At Grandiose, our mission has always been to delight shoppers with fresh ideas, premium experiences, and a touch of innovation,” said Mussaab Aboud, CEO of Grandiose. “GrandChef embodies this promise, bringing the best of technology and a peoplefocused approach into the hands of

our shoppers. It also aligns with the UAE’s vision under the National Artificial Intelligence Strategy 2031 to drive smarter and more sustainable living.”

“By combining Microsoft’s AI capabilities with our retail expertise, we’re unlocking a new era of intelligent shopping, driven by innovation, applying technology to put customers first, and moving with the agility to exceed expectations,” added Marcin Piekarczyk, Director of Technology at Grandiose. “GrandChef exemplifies putting customers first through technology, delivering smarter, personalized shopping experiences that evolve with feedback.”

Brenntag, the global market leader in chemicals and ingredients distribution, announced the begin of operations of its new Innovation & Application Center in Leeds, UK.

The facility will focus on research and development for Food & Nutrition applications and provide services for customer projects related to ingredient selection, formulation guidance and applications. Dedicated Brenntag experts will serve customers and suppliers

with concepts and prototype development, customized formulation support, technical solutions and stability studies for a broad range of applications.

“Brenntag acts as an important link with our customers and suppliers to bring innovation closer to the marketplace. The new Center is a great addition to the strong network of now already 31 Food & Nutrition Innovation &

Application Centres globally and 13 in the EMEA region,” said Jerzy Jasinski, Global President Nutrition and President Brenntag Specialties EMEA.

SternVitamin, a global supplier of micronutrient premixes, will present two innovations and an expanded product portfolio at Gulfood Manufacturing from November 4 to 6, 2025, in Dubai (Hall 8, Booth G843). This underlines SternVitamin’s expertise in a wide range of applications for functional foods and beverages, as well as its trend-based development of premix solutions.

The Clear Proteinshake, which has been developed based on pea protein hydrolysate by the sister company SternLife, contains the premix solution SternActive from

SternVitamin. Thus, it offers a high protein source of 68g per 100g of powder. To support hydration during or after exercise, calcium, magnesium, and sodium are included, which restore electrolyte balance.

Vitamin C, D3, iron, zinc, and selenium also support the immune system, while vitamins B2, B6, and B12 provide energy and reduce tiredness and fatigue. Sugar-free and with a refreshing, tropical taste, the Clear Proteinshake supports physical performance.

According to the market research institute Innova, one of the top trends in 2025 in the beverage and food sector is the topic of “mental health”. Sleep and stress are particularly important: Worldwide, 34% said they wanted to improve their sleep through food or drinks, and 30% said they consume foods at least

once a month to relax and reduce stress. With the SternDe-Stress & Relax Premix, SternVitamin is responding to exactly this trend: B vitamins, vitamin D, zinc, magnesium, and selenium support a strong nervous system and counter act stress-related changes in the immune system. The lemon balm leaf extract also has a relaxing effect.

A wide variety of applications are suitable for the SternDeStress & Relax premix, including juice drinks. Due to the warm climate and the local variety of fruits, these are in high demand in the Middle East/Africa region. For example, juices and smoothies are the most popular drinks there, and they are even ahead of water or coffee. 36% of consumers in the region also say that the claim “enriched with vitamins and minerals” influences their decision to buy juices.

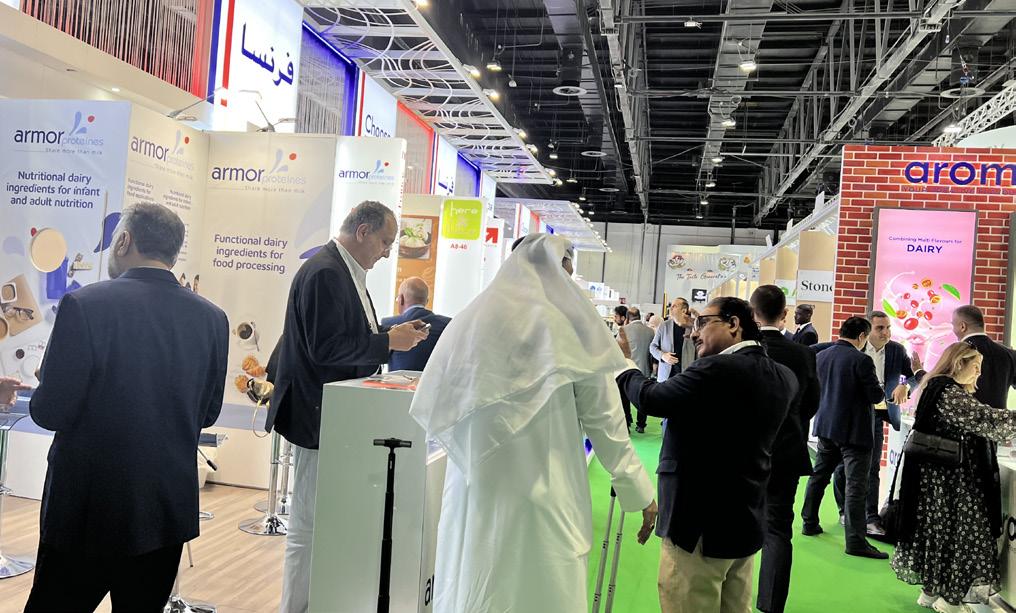

Industry Leaders such as Cargill, GEA Middle East, Givaudan Suisse SA, Novonesis and Tetra Pak Converge in Dubai as Increasing Number of Companies Shift Supply Chains to Free-Trade Ecosystem

The Middle East has become a magnet for investment, talent and technology as it redefines the geography of global food production. As supply chains recalibrate in the wake of geopolitical and economic shifts, manufacturers are moving operations closer to the UAE and wider GCC, drawn by its unmatched

logistics infrastructure, open trade routes and advanced industrial policies.

With Dubai ranked the world’s number 1 destination for global foreign investment projects, Gulfood Manufacturing stands at the crossroads of this economic shift, catalysing the next wave of food manufacturing growth across MENA, South Asia and Africa. Fuelling this transformation is the region’s leadership in artificial intelligence adoption, growing at an impressive rate of 43.65% CAGR through 2033, MENA is fast becoming the engine room of AI-driven industrialisation.

With record-breaking 32% show growth from 2024, Gulfood Manufacturing 2025 returns to the Dubai World Trade Centre from 4–6 November, marking its

largest and most globally diverse edition to date. Driven by surging international demand and the rapid evolution of manufacturing technologies, the event unites 2,500 exhibitors from 79 countries across 21 halls, encompassing the full spectrum of the production value chain — Ingredients, Processing, Packaging, Supply Chain Solutions and Control & Automation.

Anchored by 90% participation from the world’s leading food manufacturing brands including Chocolake, IMCD, Multivac Middle East FZE and SIG and complemented by a wave of bold new innovators, the show embodies Dubai’s rise as the global epicentre of food innovation, investment and industrial transformation. This rapid expansion mirrors the region’s investment momentum: across the GCC, governments have pledged over $3.8 billion into food technology and agri-innovation to fortify local processing and food

security, while the global food processing machinery market is set to grow by $21.69 billion by 2029, driven by AI-powered automation and APAC investment flows.

Commenting on the show’s significance, Mark Napier, Vice President Exhibitions Department, Dubai World Trade Centre said, “Dubai stands at the perfect inflection point for global industrial transformation. Under Operation 300bn and the UAE leading AI adoption in manufacturing, the nation is powering a new wave of advanced, intelligent production. As the world’s industries realign toward technology-driven efficiency and sustainability, Dubai’s strategic position, infrastructure and policy vision make it the natural focal point for change. Gulfood Manufacturing sits at the heart of this evolution, its exponential growth reflects the region’s role as the hub of AI-driven industrialisation.”

Global industry leaders consistently choose Gulfood Manufacturing as the stage to unveil their most

significant, industry-defining innovations, a testament to the show’s scale and influence.

In the ingredients sector, powerhouse names including ADM International, Brenntag, dsm-firmenich, FSL, Ingredion, Kerry MENAT DMCC, Robertet Middle East, Symrise and Tate & Lyle are propelling exponential growth at Gulfood Manufacturing 2025. The 11th edition will unveil a treasure trove of trends such as, breakthroughs in biotech-derived actives, precision fermentation, AI-powered flavour mapping and next-generation stabiliser systems, marking the global shift toward health-conscious, sustainable consumption.

Across processing and packaging, pioneers such as Heat & Control, Husky, Ishida, KHS, Krones AG, Middleby Middle East FZE, Rieckermann GmbH, Sidel and TNA Solutions are redefining smart manufacturing. Expect breakthroughs in IoT-enabled sensors, AI vision systems reducing waste by up to 25%, modular machinery, and eco-engineered packaging

solutions that bring efficiency, intelligence, and sustainability to every layer of production.

Sean Sims, Global Vice President, Automation and Solutions, Tetra Pak said “Gulfood Manufacturing is a cornerstone event for us — it’s where we connect with the industry’s most forward-thinking partners and showcase how Tetra Pak is shaping the future of food manufacturing. This year, we’re proud to launch our new global portfolio of advanced automation and digital solutions that accelerate AI readiness in smart factories. These innovations will help producers across the Middle East and beyond digitalise operations, optimise resources, and drive sustainable growth.”

At the heart of this year’s agenda, the FoodTech Summit will host a 50% increase in new speakers including Mars, Titan Capital, Unilever and Hive Capital, alongside other visionary futurists, technologists, policymakers, and innovators exploring the next frontier of industrial food. Discussions will span tech for cold chain integrity in emerging markets, the future of food-tech funding, and whether alternate proteins truly represent the next evolution in global nutrition.

Renowned digital futurist, Mark Minevich, will explore how intelligent, self-adapting systems are transforming production including living supply chains, superhuman safety, zero-waste efficiency and AI-driven food sovereignty. Together, these sessions cement the Summit’s position as the ultimate global think tank, combining connections and knowledge to pave the way for the next wave of industrial revolution.

• 56 French companies to exhibit at Gulfood Manufacturing 2025 (Dubai November 4-6), including 35 equipment & packaging manufacturers and 21 ingredient specialists

• A showcase of high-quality French innovations aligned with the fast-evolving needs of the UAE and GCC food manufacturing market

From November 4 to 6, 2025, 56 French companies will showcase their solutions at the French Pavilion at Gulfood Manufacturing, held at the Dubai World Trade Centre. The delegation will be located in two key halls: 35 manufacturers of equipment and packaging technologies at Sheikh Saeed Hall 1 (Booth S1-C28) and 21 ingredient specialists at Sheikh Rashid Hall (Booth R-J19). Their collective offering will reflect France’s commitment to innovation in support of sustainability, food security, and industrial transformation across the UAE and broader GCC region.

French Innovation Aligned with Gulfood Manufacturing 2025 Themes

This year’s Gulfood Manufacturing places a strong focus on four priorities shaping the global food industry: sustainable sourcing, advanced automation, digitalization, and next-generation food safety. The French Pavilion reflects these priorities through a comprehensive offer that ranges from plant-based proteins, reformulated ingredients for healthier diets, and ecofriendly packaging supporting the UAE’s food security and net-zero ambitions, to robotics, precision engineering, and integrated processing systems that enhance efficiency and reduce operational costs. French exhibitors also bring advanced traceability, hygienic processing, and monitoring technologies that guarantee compliance with the highest international standards. By combining innovation with regional collaboration, the Pavilion illustrates France’s commitment to co-developing solutions that support the UAE’s Vision 2030 and strengthen the wider region’s food manufacturing ecosystem.

Inside the French Pavilion: From Ingredients to Processing Solutions

The Pavilion will feature a diverse portfolio of high-value ingredients, including dairy and egg derivatives, flavorings, freezedried components, and pastry solutions. These innovations respond to multiple needs in food manufacturing, from enhancing taste and nutritional value to extending shelf life and improving processing performance. They highlight France’s long-standing expertise in delivering quality, traceability, and cutting-edge technologies to international markets.

Alongside ingredients, 35 French exhibitors will showcase advanced equipment and packaging solutions. Their offer spans silicone molds, piping systems, and labeling machines, as well as next-generation packaging technologies. Engineered to optimize efficiency, ensure food safety, and support sustainable production, these solutions reinforce France’s position as a trusted global supplier of industrial equipment for the agri-food sector.

The UAE food industry is undergoing rapid transformation, with a projected 6.9% CAGR growth from 2022 to 2028.

French ingredient suppliers are ideally positioned to support this momentum with sustainable and functional solutions that directly address local needs. With 568 food and beverage factories registered in the UAE as of 2023, the market is increasingly demanding ingredients that are both innovative and aligned with food security goals.

France ranked as the 11th largest supplier to the UAE in 2021, underscoring a strong foundation for collaboration. Emirati industry professionals emphasize innovation as central to future food systems: “Collaborating with French companies provides us with the tools to address marketspecific challenges like sustainable packaging and innovative product formulations,” said a UAE-based food manufacturer.

With over 2,000 companies in its food manufacturing sector and nearly 60% of them exporting regularly, France continues to be a valued and forward-looking partner to the Middle East’s evolving food landscape.

“The strength of the French Pavilions lies in its diversity. By bringing together ingredient creators and technology providers under one roof, we demonstrate how France can offer integrated solutions that respond to every stage of the food value chain. This synergy is what makes our participation at Gulfood Manufacturing unique and positions France as a trusted partner for building efficient, safe, and sustainable food industries worldwide.” Stated Axel Baroux, Business France Near & Middle East Director.

Italy leads gelato, the Italian artisanal frozen dessert fresh made by a gelato chef, consumption in Europe, representing - together with France and Spain - 68% of portions sold in the top 5 markets. Within a summer growth whose value in Italy stood at +3% compared to 2024, a period in which at least 70% of the sector's estimated 3-billion-euro Italian turnover is concentrated. These are the positive data

with which the entire artisanal gelato supply chain will present itself at SIGEP World - The World Expo for Foodservice Excellence, organized by Italian Exhibition Group (IEG) at Rimini Expo Centre, in Italy, from 16th to 20th January 2026. Now at its 47th edition, the event confirms its role as the international showcase with the very best of industrial gelato, pastry, chocolate, coffee, bread and pizza supply chains. A record-breaking edition is forecast, with 1,300 exhibiting brands from

over 30 countries, distributed across 30 halls, and an estimated number of visiting professional operators from over 150 nations.

THE WORLD’S MOST IMPORTANT ARTISANAL GELATO SHOWCASE

The artisanal gelato offer will be the most complete on a worldwide scale, covering the entire value chain. Technology and equipment (from the latest generation machines to refrigerated display cases), raw materials, ingredients

and semi-finished products, design and furnishings, and the most innovative digital solutions for every foodservice business model: from independent gelato parlours to organized chains, quick service restaurants, fine dining venues and luxury hospitality.

SIGEP World intensifies its initiatives aimed at expanding the presence of Italian artisanal gelato in key markets. Starting with the 'Sigepland' project for Germany, the second world market in terms of number of gelato parlours after Italy. The initiative includes personalized guided tours for thousands of German professionals, also facilitated by the direct MunichRimini flight during the days of the Show, to favour networking and encourage them to explore the exhibition offer. A programme brimming with amiable moments designed to offer an immersive experience. SIGEP World’s Guest Country at the 47th edition will be India: a choice that proves the considerable expansion

and enormous potential of the Asian market for the Italian hospitality and gelato industry. The delegation of Indian operators arriving at SIGEP will have the chance to closely explore the potential of traditional Italian artisanal gelato. Lastly, the digital “What is Gelato?” campaign, which aims to educate foreign investors and operators on the culture, quality and innovative applications of gelato, the Italian frozen desert, in foodservice. The initiative, in collaboration with Acomag (National Association of Gelato Machinery, Furnishing and Equipment Manufacturers) and Unione Italiana Food – Gelato Product Group, will put the Italian supply chain into contact with major players in global catering through workshops and masterclasses.

The SIGEP World arena will be hosting the highly anticipated Gelato World Cup, the biennial international competition in which teams of gelato professionals will be battling it out. The eleventh edition will see Italy, holder of the 2024 title, competing against 11 other top nations: France, Belgium,

Poland, Japan, Singapore, Indonesia, China, Argentina, Mexico, Peru, Ecuador. The teams will take part in eight spectacular tests that combine technical rigour, taste and artistic ability.

Circana's CREST data underline the centrality of Italy in the EU market: «Despite a few uncertainties linked to unfavourable climatic conditions, summer is a gelato consumption driver in Italy, France and Spain, which together represent 68% of portions served in the top 5 European countries,» explained Matteo Figura, executive director of Foodservice Italia at Circana. «Gelato confirms its status within the small accessible luxury category that consumers are not willing to relinquish.»

While according to AIG (Italian Gelato Makers’ Association), the summer confirmed consumption forecasts. In value terms, growth stood at +3% compared to 2024: driving the sector was above all central Italy (+5%) thanks to cities of art, and the south (+4%), while the north showed minimal growth, mainly due to bad weather.

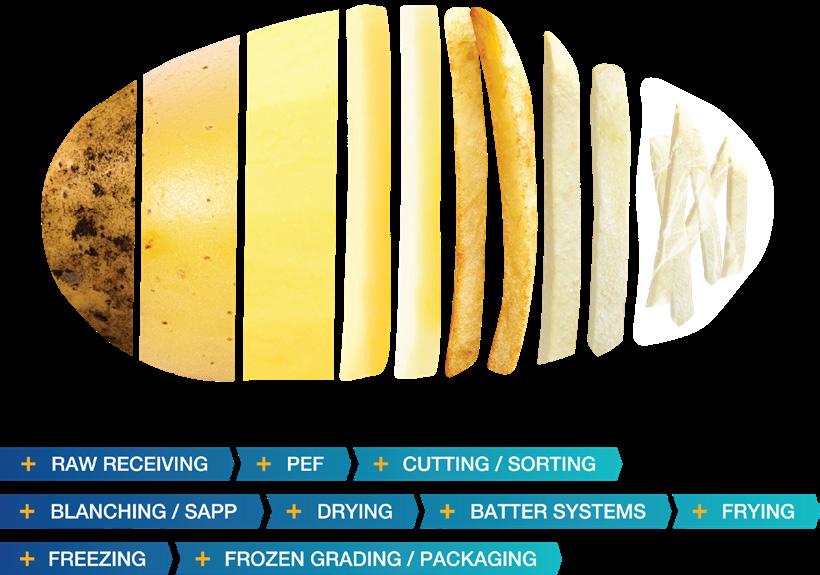

Sanitation in MEA: A Growing Priority

Across the Middle East and Africa (MEA), the demand for processed potato products is rising fast—driven by urbanization, population growth, and evolving consumer diets. As processors expand capacity to meet this demand, they face mounting pressure to uphold international food safety standards while contending with regional realities: high temperatures, fluctuating humidity, and limited access to clean water.

In these conditions, sanitation is more than a compliance exercise—it’s essential to maintaining food safety, brand integrity, and equipment uptime. Achieving consistent hygiene while reducing water and chemical use has become one of the region’s most pressing operational challenges. At FPS, we recognize this balance as central to sustainable growth. Our mission is to help processors in MEA and worldwide adopt hygienic design and sanitation

technologies that safeguard food quality while optimizing efficiency.

From Then to Now: The Changing Face of Hygiene

Not long ago, potato processing factories operated only 10 to 16 hours a day, five days a week. Production followed the harvest cycle—starting in August and wrapping up in June—and cleaning was straightforward: fire hoses, plenty of water, and few chemicals. Back then, water alone solved most hygiene challenges.

Four decades later, the industry looks entirely different. Modern factories run continuously for 21 days or more before pausing for sanitation. Cleaning and maintenance teams now have as little as 12 to 24 hours to complete full cleaning and system checks before production restarts.

Efficiency and uptime have become the new priorities, reshaping how hygiene is managed in today’s potato plants.

Extended production runs are

here to stay. The question facing food processors is no longer how to clean better, but how to stay clean while running.

To remain competitive, factories must achieve stringent food safety standards while minimizing downtime, water usage, and energy consumption—all without compromising product quality. At the same time, global concerns over resource conservation and sustainability are influencing how every facility operates.

Hygiene, once viewed as a maintenance task, has become a strategic business function— central to uptime, safety, and total cost efficiency.

At FPS, we believe equipment design holds the key to achieving these new hygiene standards. Our hygienic engineering philosophy is built on three guiding principles: 1.Stay clean in operation –Equipment must minimize contamination risks with smooth surfaces, open layouts, and easy-

access points for inspection.

2.Self-clean effectively –Integrated Clean-in-Place (CIP) and pasteurization systems must allow sanitation without halting production.

3.Use fewer resources – Smart cleaning systems should reduce water, chemical, and energy use while maintaining high sanitation performance.

Our proprietary cleaning and sanitation systems are engineered to help processors extend production safely, control microbial growth, and reduce total cost of ownership. These innovations form the backbone of the next generation of hygienic processing lines—built for high performance, reliability, and global compliance.

What succeeds in a temperate factory in Europe or North America may not perform as well in tropical or arid environments. In MEA, high humidity and heat can accelerate microbial growth, while water scarcity demands more efficient cleaning strategies.

To ensure consistency across climates, FPS designs equipment tailored to local conditions—whether that means optimizing airflow in humid

environments or integrating efficient CIP systems that reduce water dependency. By adapting hygienic design to regional challenges, we help processors maintain safety and uptime in any environment.

True food safety cannot be achieved in isolation. Equipment suppliers, processors, and regulators must work together to align on shared goals of safety, uptime, and sustainability.

Processors who focus solely on purchase price risk overlooking the broader advantages of hygienic design—improved uptime, lower

maintenance, brand protection, and longterm savings. The true measure of value lies in total cost of ownership, not the initial investment.

When hygiene is compromised, the hidden costs—product loss, recalls, and damage to consumer trust—can be far greater than any upfront savings. By fostering collaboration and transparency, the industry can co-develop solutions that strengthen global food safety and operational resilience.

FPS is proud to support processors in MEA and around the world as they embrace these challenges. Our goal is to be the partner of choice for those who share our vision of hygienic excellence and sustainable operation.

Food safety is not just a requirement— it’s a shared responsibility. By advancing hygienic design, investing in smart sanitation systems, and building strong partnerships, we can redefine hygiene not as a cost, but as the cornerstone of a safer, smarter, and more sustainable food future.

For more information, visit www.fpscorp.ca

Two new studies add to growing evidence that a mother’s diet during pregnancy has lasting implications for her child’s brain development and decisionmaking skills- extending well beyond infancy into the teen years.

In a population-based cohort study published in The American Journal of Clinical Nutrition, researchers found that higher maternal consumption of nuts and seafood during pregnancy was associated with improved neuropsychological function in children from ages 4 to 15. A complementary study published in European Child & Adolescent

Psychiatry reported that maternal intake of nuts and fish was linked to reduced risky decision-making behaviors in children at age 11.

The study evaluated a sample of more than 1,700 mother-child pairs from four Spanish regions was analyzed. Maternal diet was analyzed using a food frequency questionnaire, while the children's neuropsychological function was assessed through standardized tests measuring reaction time and variability (attention), working memory, and fluid intelligence.

While neither study focused exclusively on walnuts, both contribute to the broader evidence supporting the role of including nutrient-dense foods,

such as nuts, as part of a healthy prenatal diet.

Key takeaways:

• Children whose mothers consumed more nuts and seafood during pregnancy scored higher on measures of attention, working memory, and executive function throughout childhood and adolescence.

• These children were also less likely to make impulsive, high-risk decisions in early adolescence.

• Omega-3 fatty acids- abundant in walnuts and fatty fish- were identified as a key nutrient associated with these benefits. Walnuts are the only tree nut that is an excellent source of the plantbased omega-3 fatty acid ALA (2.7 grams/ounce).

Food for Thought:

These findings could inform further studies or maternal nutrition programs in the Middle East and North Africa, given the existing neurological health burden. Wider epidemiological data for the Middle East shows ADHD prevalence among children ranges from 7.8–11% in Arab countries and up to 17% in Iran. Additionally, a 2021 Global Burden of Disease study reported that neurological conditions such as epilepsy and migraines are significant contributors to disability in youth across the broader North Africa and Middle East region.

For more information on the role of walnuts in brain health or recipe ideas, please visit www.californiawalnuts.ae.

WS Warmsener Spezialitäten GmbH, a member of the dairy Uelzena Group, will once again exhibit at Gulfood Manufacturing in Dubai as part of the German pavilion. The company is one of the largest manufacturers of sweetened condensed milk in Europe and offers a wide range of different recipes and packaging options suitable for industrial use. This includes products according to halal, kosher and Fairtrade certification as well as blends of sweetened condensed milk with vegetable oils. All sweetened condensed milk products have a nice smooth texture, a clean taste without any ‘cooked’ flavour, and are technologically resilient to further processing.

Sweetened condensed milk is one of the most important milkbased ingredients for the food and confectionery industry, alongside milk powder and anhydrous milk fat and mainly used in the production of highquality caramel fillings, chocolate bars, pralines, toffees, dessert sauces or ice cream. It not only provides the typical caramel taste, but also influences the consistency and mouthfeel of the finished product.

“When turning market trends into business opportunities, speed from idea to launch is key. That’s why Valio created the Valio Fast Track™ powder solution, enabling brands to take the fast lane to launching new value adding products”

High protein is the clearest growth driver in dairy, cutting across family staples and performance-focused choices alike. Consumers are asking for more from everyday products: more nutrition, more relevance to their routines, and more reasons to choose a brand again. For manufacturers, the question is not whether to act, but how to enter the high protein category quickly and confidently without long development cycles or heavy investments. To meet this demand, Valio has created the Fast Track™ solution for high protein milk.

To ensure commercial viability, the new product concept was tested in both the UK and Saudi Arabia, revealing strong consumer appeal across markets. The nutritious, great-tasting milk stood out for combining health and flavour, offering an easy way to meet daily protein and calcium needs while supporting a balanced lifestyle and digestive comfort. The lactose free, high protein concept resonated especially well with families with children and consumers

seeking lactose free options, showing the highest purchase intent within these groups. In Saudi Arabia, the product performed exceptionally well across commercial KPIs, as an impressive 83% of consumers reported willingness to buy. Notably, performance was also very strong among plant-based drink consumers indicating commercial potential across very different segments.

The concept clearly connects to two durable demand drivers: high protein and digestive wellness. Protein resonates with families seeking smarter everyday nutrition, active consumers looking for convenient recovery options, and older demographics valuing protein for wellbeing. Consumer testing showed that the product was especially attractive to households with children and health-conscious consumers thanks to its lactose free formula and high protein and calcium content served with a fresh milk taste. This powerful combination allows brands to create added value that retailers recognize and consumers adopt easily, supporting a premium price point while keeping the product positioned as an everyday milk rather than a niche offering. When turning market trends into business opportunities, speed from idea to launch is key. That’s why Valio created the Valio Fast Track™ powder solution, enabling brands to take the fast lane to

launching new value adding products. Rather than starting from scratch, you begin with a proven base and specifications already translated into practical manufacturing considerations. Valio experts streamline product development so your R&D team can focus on where it creates value instead of managing avoidable rework. In parallel, Valio’s team helps optimize manufacturing processes for your context, helping you identify the most efficient way to produce high protein milk at scale while maintaining the taste and texture consumers expect. The aim is simple: shorten time to market, protect throughput, and avoid costly detours.

The Fast Track™ solution is not just a technology – it’s a launch pathway to commercial success. Valio provides go-to-market guidance, helping you define your proposition, choose messages that are both compelling and compliant, and plan the activation details that

make a difference on the shelf. Because the base concept is already consumer-proven, your sales and marketing teams can focus on brand-specific elements like packaging, partnerships, and retail strategy rather than debating fundamentals.

All of this is designed to keep capital outlay under control. By building on a validated base and an implementation plan tuned to your plant, Valio Fast Track™ helps you avoid heavy upfront investments. The partnership model is hands-on and practical: Valio supports your team through key milestones such as pilot runs, industrial trials, and preparation for commercial scale-up, providing clear specifications and knowledge transfer to keep taste consistent and processes efficient. The objective is to de-risk decisions, maintain momentum, and give you the confidence to move from first batches to stable supply and distribution.

In short, Valio Fast Track™ gives you a way to move decisively where demand is growing. You launch a high protein milk consumers already understand and want. You keep the fresh milk taste that drives repeat purchases. You streamline product development, optimize manufacturing for your context, and enter the market with a confident commercial story. You do it with lean CapEx and a timeline that matches today’s market pace.

Read more and see how the concept adapts to your market at Valio.com

In an era defined by innovation, agility, and responsible growth, Millenium has established itself as one of the GCC’s leading names in the food and specialty chemicals industry. Headquartered in Dubai and led by Hareeish Kumar, the group has expanded its footprint across Saudi Arabia, Oman, Qatar, and Kuwait, setting new benchmarks in quality, reliability, and sustainability.

Over the past decade, Millenium has evolved from a trading company into a comprehensive regional enterprise—integrating global expertise, technical knowledge, and ethical business practices. Its operations span multiple sectors, including food ingredients, personal care, water treatment, and industrial solutions, each built on a foundation of trust and professionalism.

A key milestone in the group’s growth was its expansion into Saudi Arabia, where fully operational bases in Riyadh, Jeddah, and Dammam serve major food manufacturers and industrial clients.

“Our strength lies not only in what we supply, but how we support,” notes Kumar. “Speed, reliability, and service define who we are.”

Within the food and beverage sector, Millenium provides end-to-end ingredient solutions across categories such as dairy, meat, bakery, beverages, and HORECA, supported by alliances with global leaders including Kerry (UK), BASF (Germany),

Hareeish Kumar CEO at Millenium Chemical Trading

and

Through Milleniums food division, the company serves multinational brands such as McDonald’s, KFC, Unilever, and Nestlé, offering functional and clean-label ingredient systems designed to meet global standards.

Beyond food, Millenium’s specialty chemicals division supplies high-performance materials for cosmetics, pharmaceuticals, water treatment, and construction, ensuring product quality, compliance, and sustainability.