LIQUN MA

Bartlett School of Achitecture

HIGH-RISE ALLOTMENT GARDEN

A residential project for remote workers

Naples, Italy

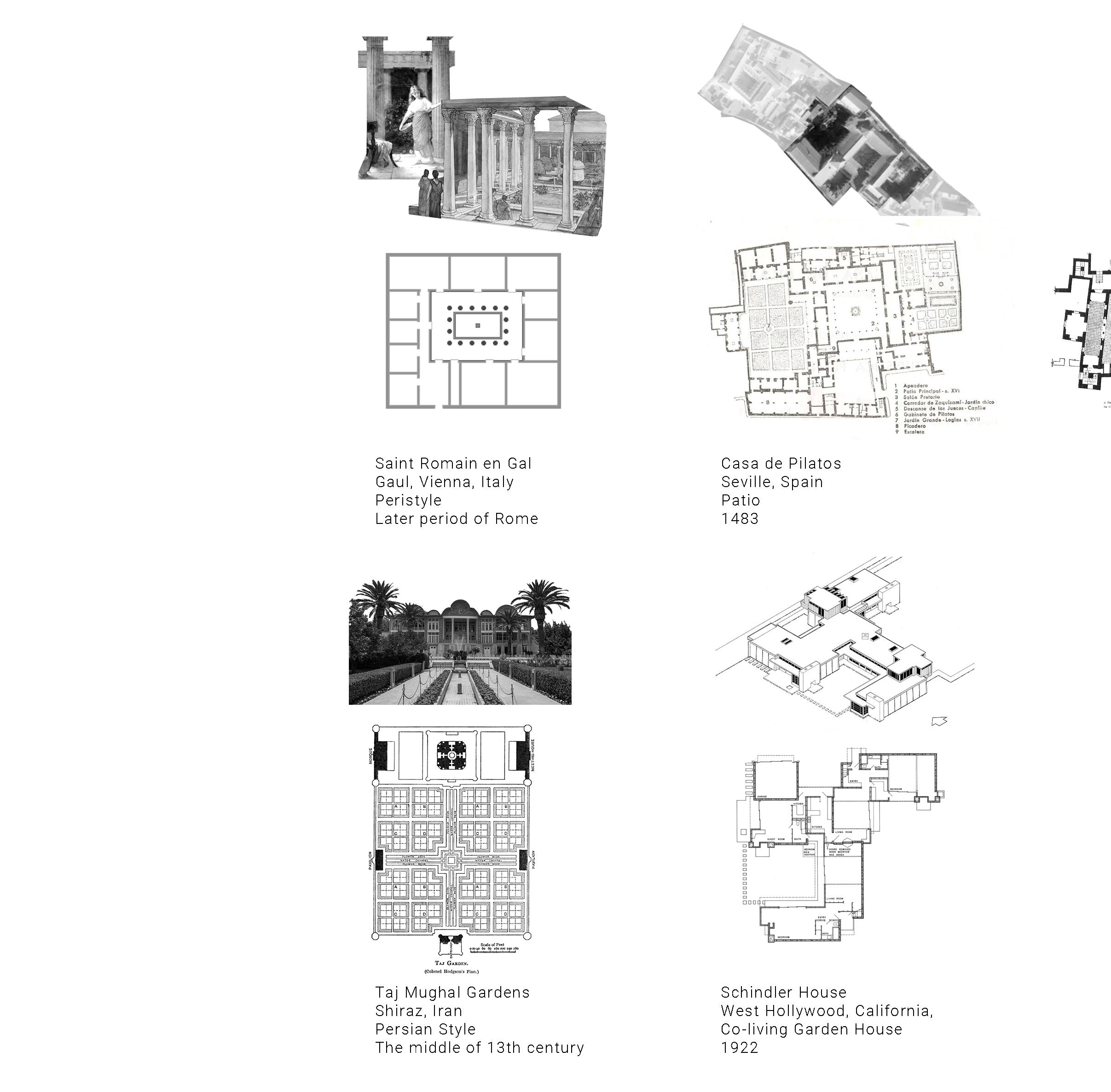

REMOTE WORK

From the industrial revolution to the advent of digital technology, labor and communication remain the critical elements of sustaining the local economy. Remote work began in the 1970s and was coined by Jack Niles to describe a decentralized business framework as a solution to the increasing urban sprawl. This proposal was made possible because of Infrastructure and Communication Technology (ITC). Although it comes with different terminologies such as "telework", "virtual work", "work from home", or "flexible working", remote work is referred to as the concept of carrying the "work" in any locations acceptable by the employer, whether at home or shared office space through digital technology. The earliest report on economic and social implications of telework was done in 1996 by the UK-based Institute for Employment Studies, where they differentiated telemediated work into three main categories:

1. Individualized teleworking (i.e., homeworking, mobile working, or other forms carried out by individuals in isolation away from traditional office environment);

2. Teleworking involving the relocation of entire functions or group of workers to a remote site within national boundaries (i.e., satellite offices, telecenters, and call centers);

3. Cross-border teleworking (i.e., work outside national boundaries, whether outsourced or carried out internally by a transnational corporation).

A recent report by the Joint Research Centre of the European Commission and Eurofound(see Figure 2) showed the percentage of actual teleworkers in Europe in 2018 compared to potential teleworking future utilization. The divide between a white-collar job and a blue-collar job also represents the teleworkability between the two. Data showed only 5% opted to work from home even though the job is teleworkable before the pandemic. The feasibility of teleworking across different occupations depended on the company's organization, labor distribution, and job hierarchy.

Remote work offers oppurtunities such as mobility, higher autonomy, lower stress, life choice fleibility, reduced commuting cost and time and less work-family conflict. Others are facing some challenges such as mental health issues, isolation and loniliness, work-life boundaries and difficulty connecting to network.

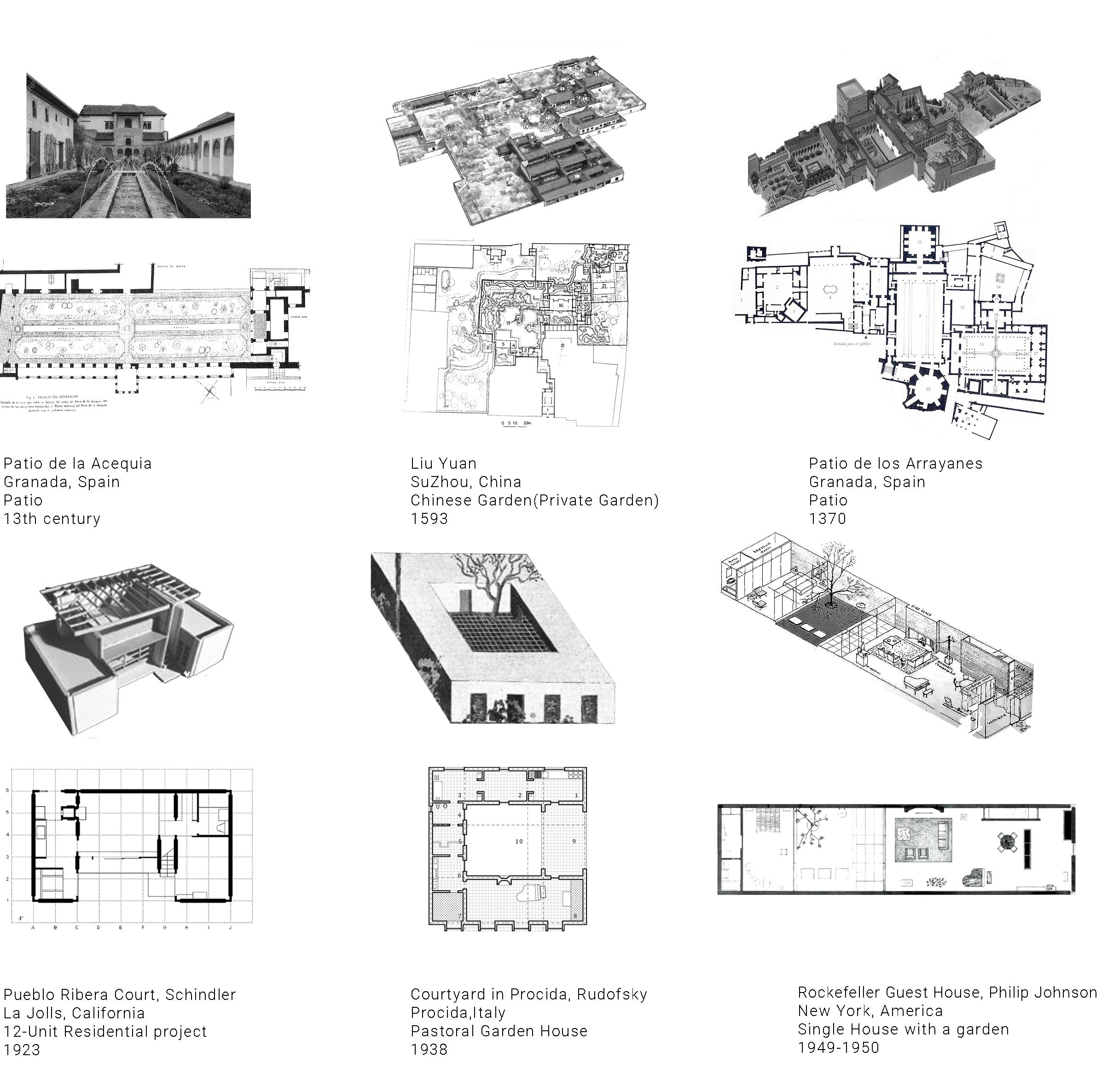

PROJECT OVERVIEW

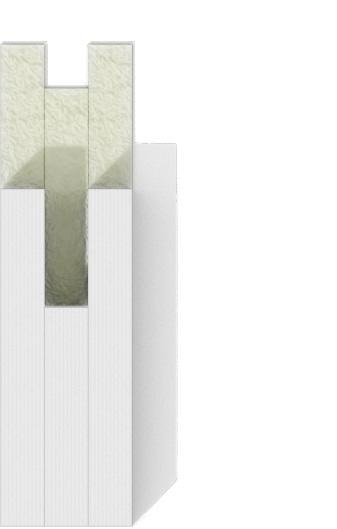

High-Rise Allotment Garden is a housing project for about 800 people working remotely from home. Our aim is to integrate living and working spaces of different sizes and proportions into a single building envelope.

RESEARCH CLUSTER 0 | STUDIO MEDITERRANEO GROUP 3 | HIGH-RISE ALLOTMENT GARDEN

Design Tutor | Alessandro Bava | Tobias Jewson

Theory Tutor | Julian Siravo

Cengyi Wang | Jiaxi Zhang | Liqun Ma | Mark Trance

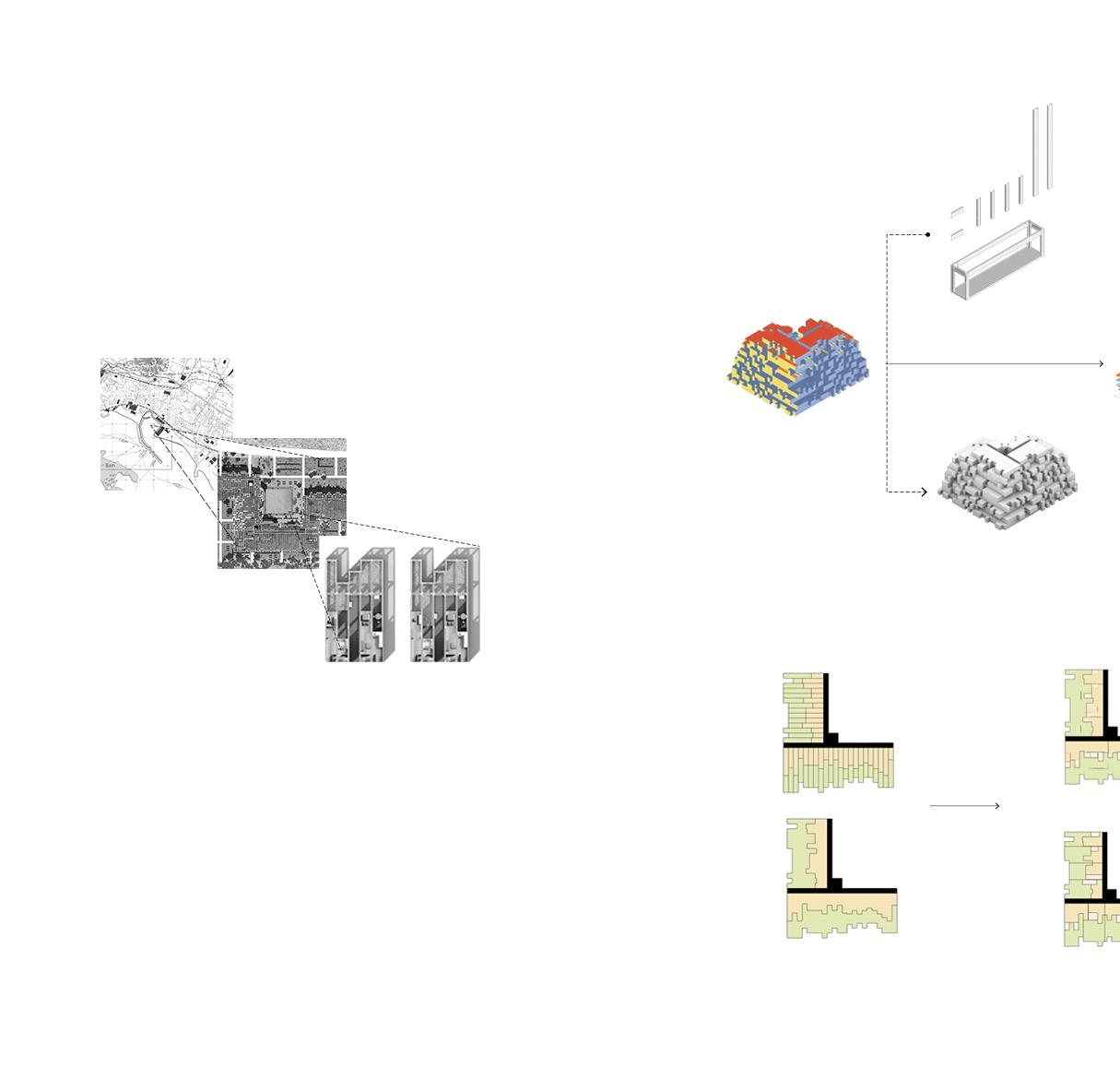

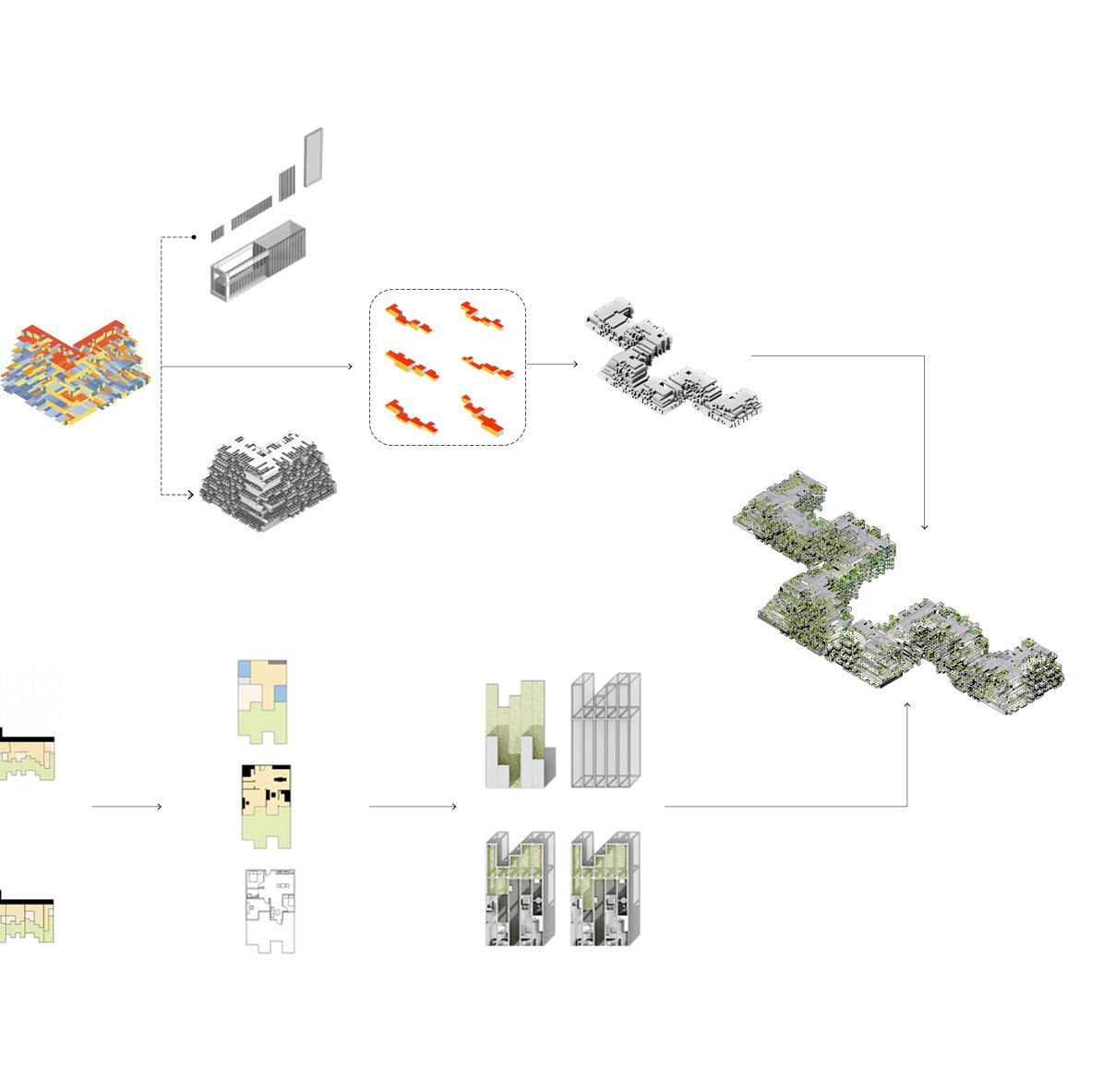

Project Workflow

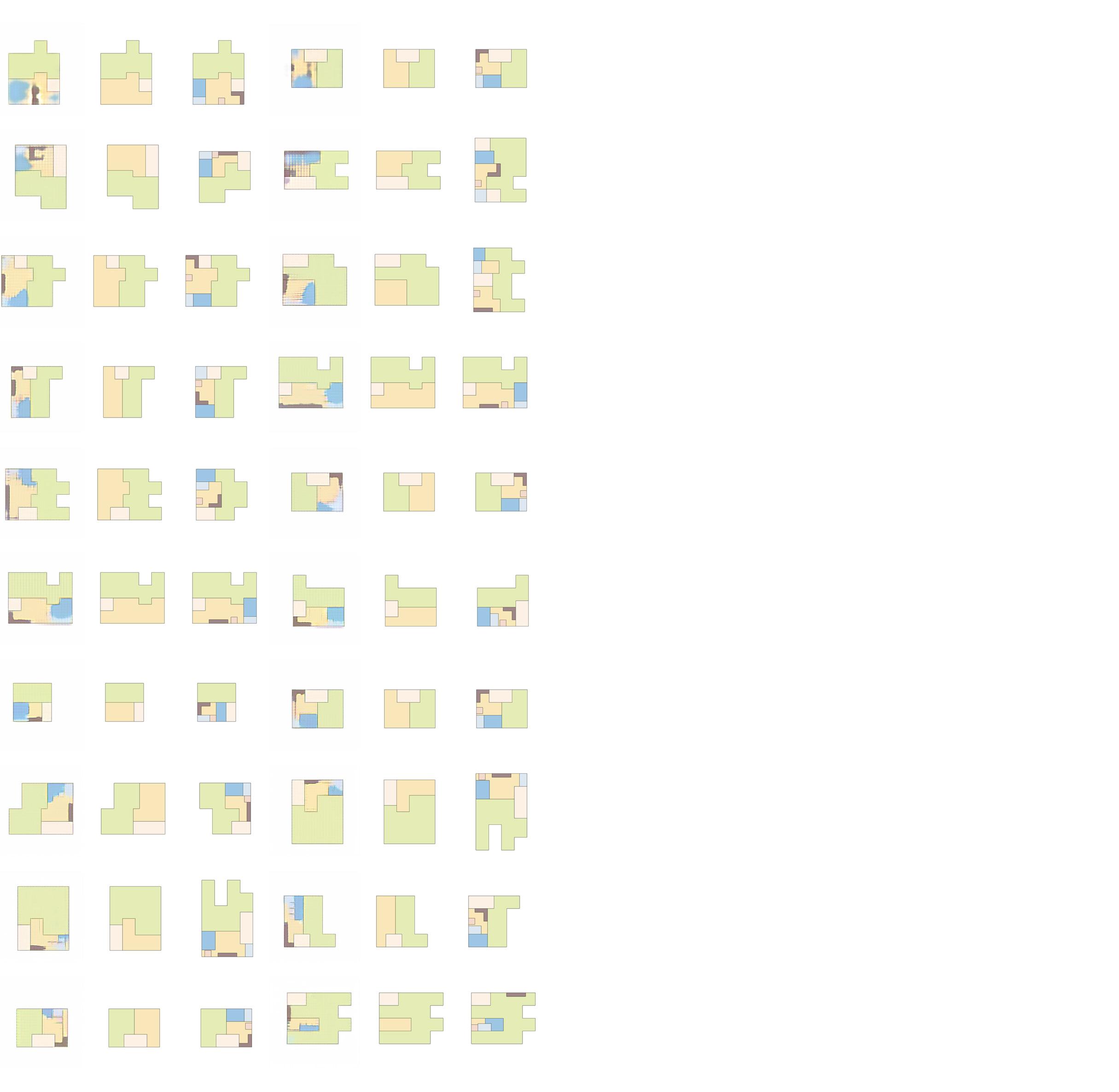

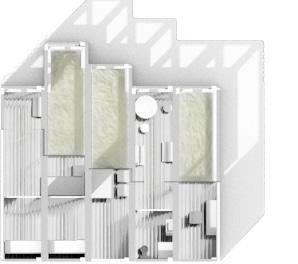

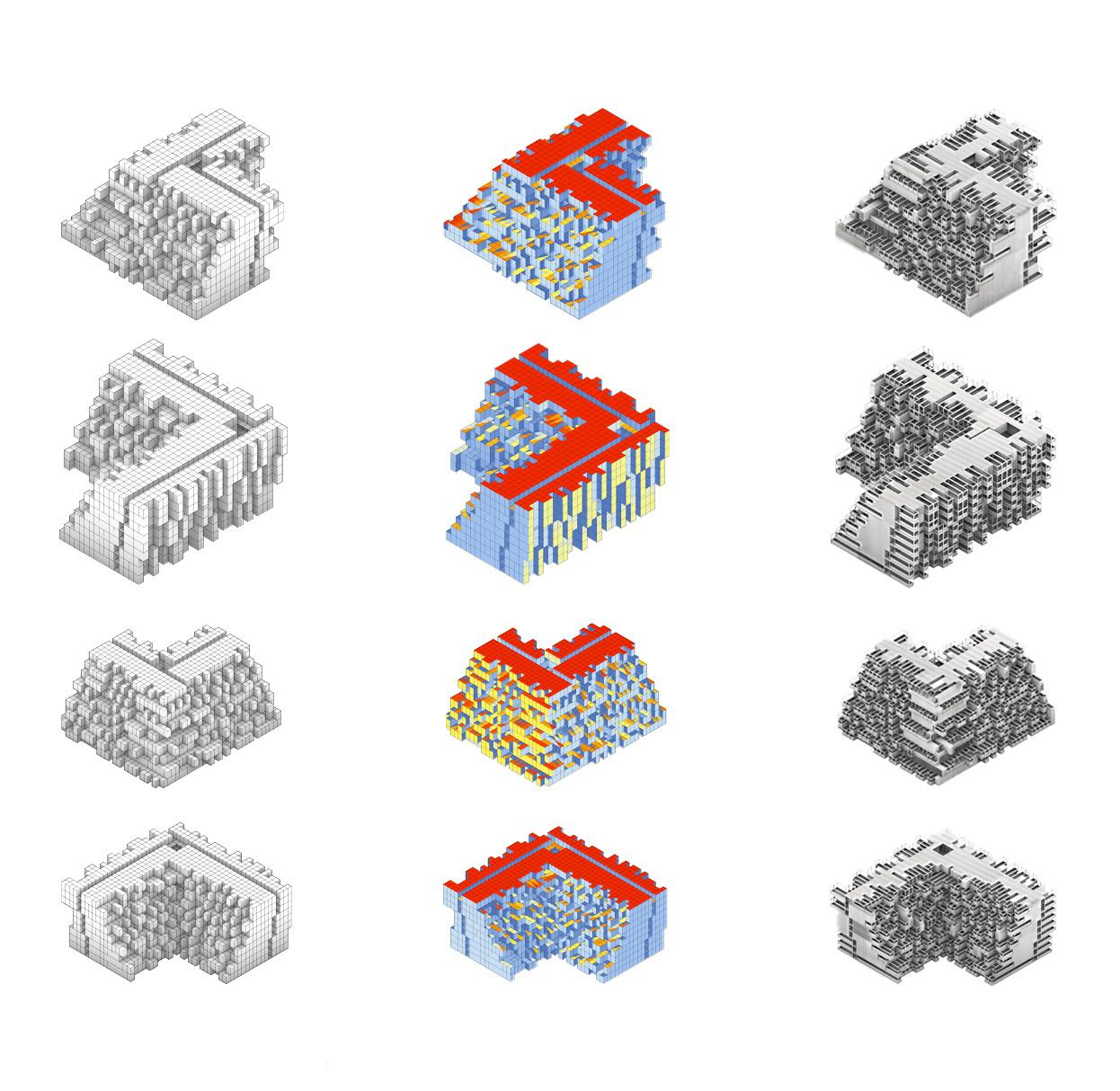

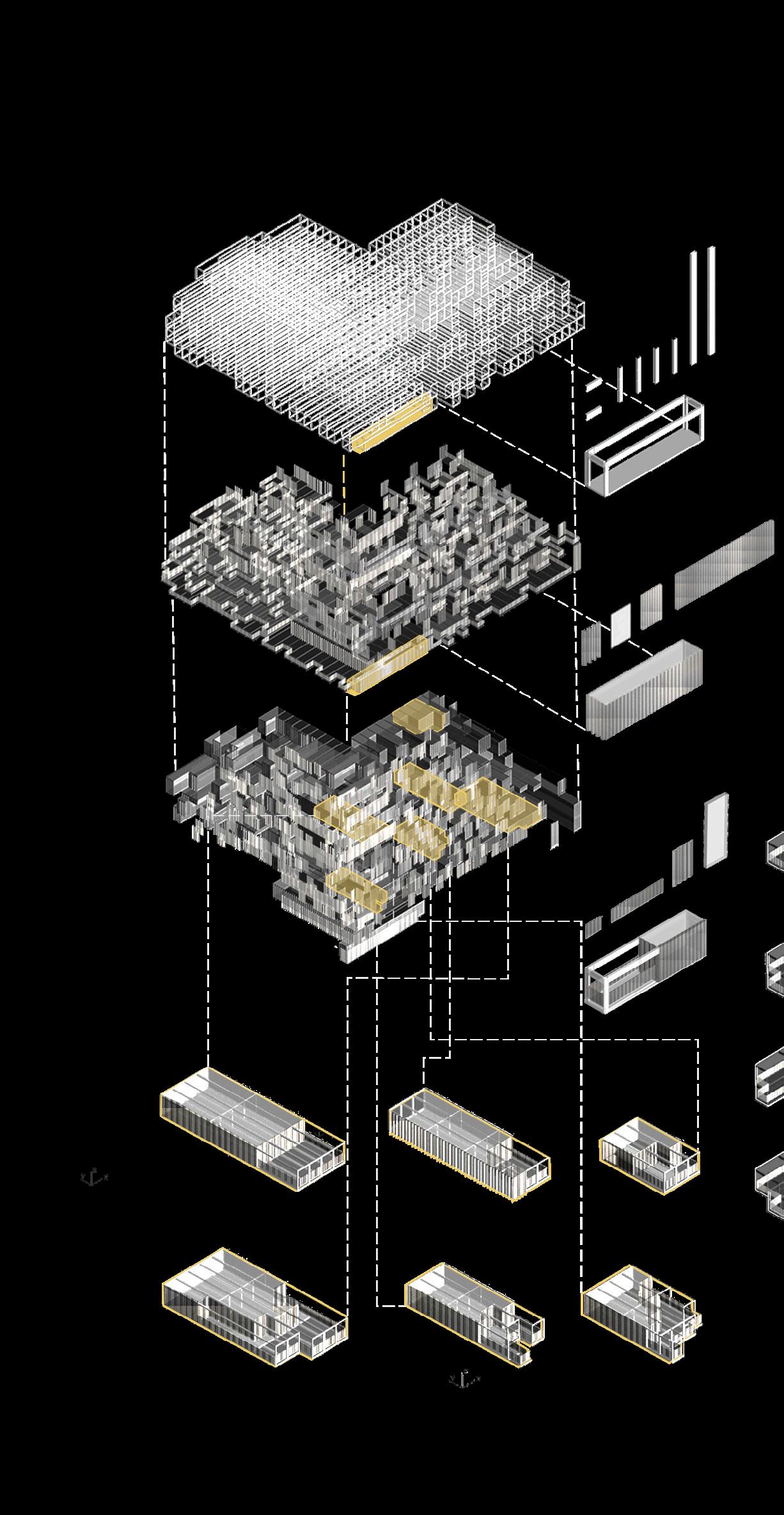

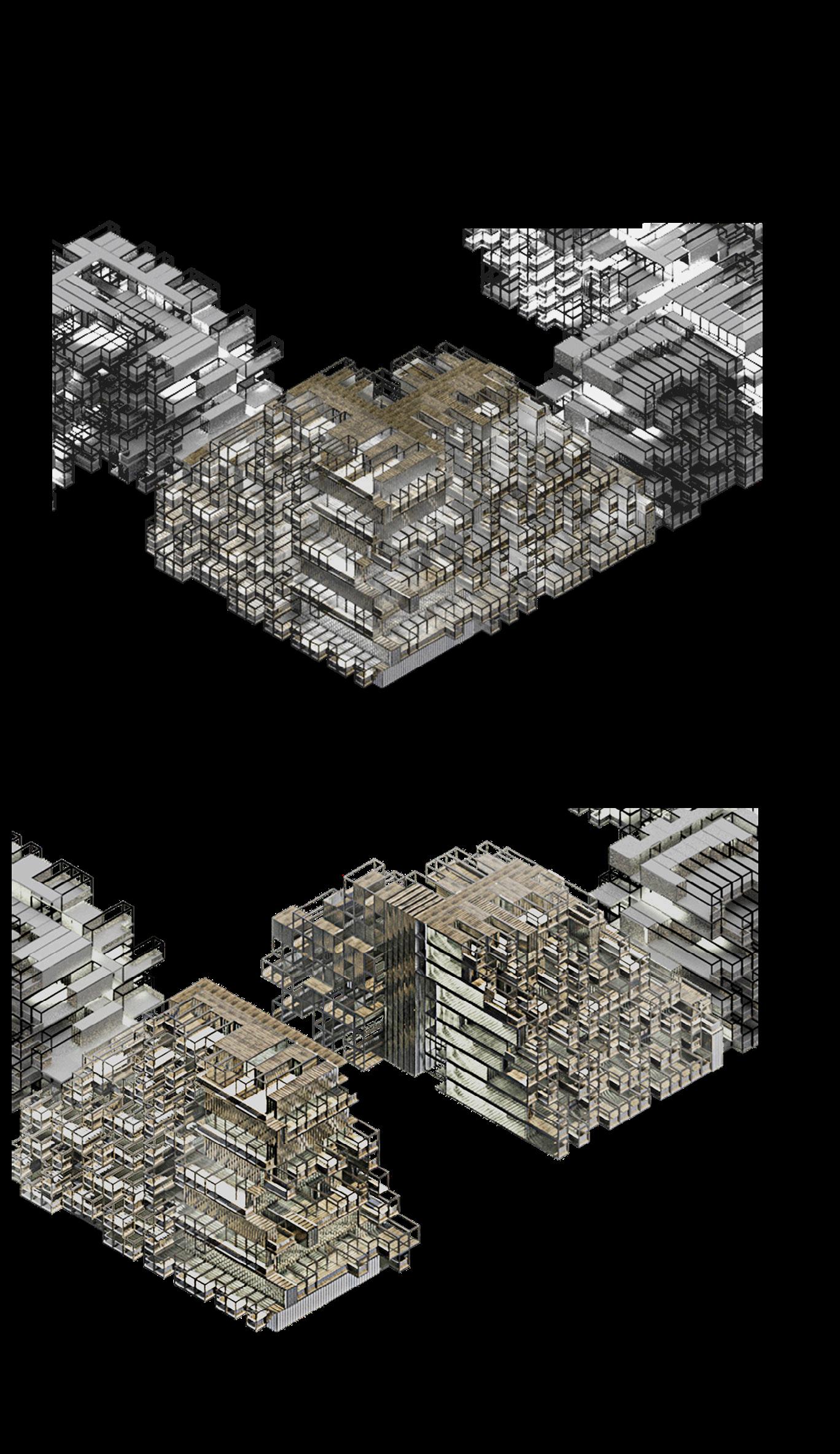

STEP1 Module

The prefab construction in b-core slab material defines the sizes of modules and building envelope.

Project Objective

The housing project aims to combine green space and living space in a non-rhetorical way.

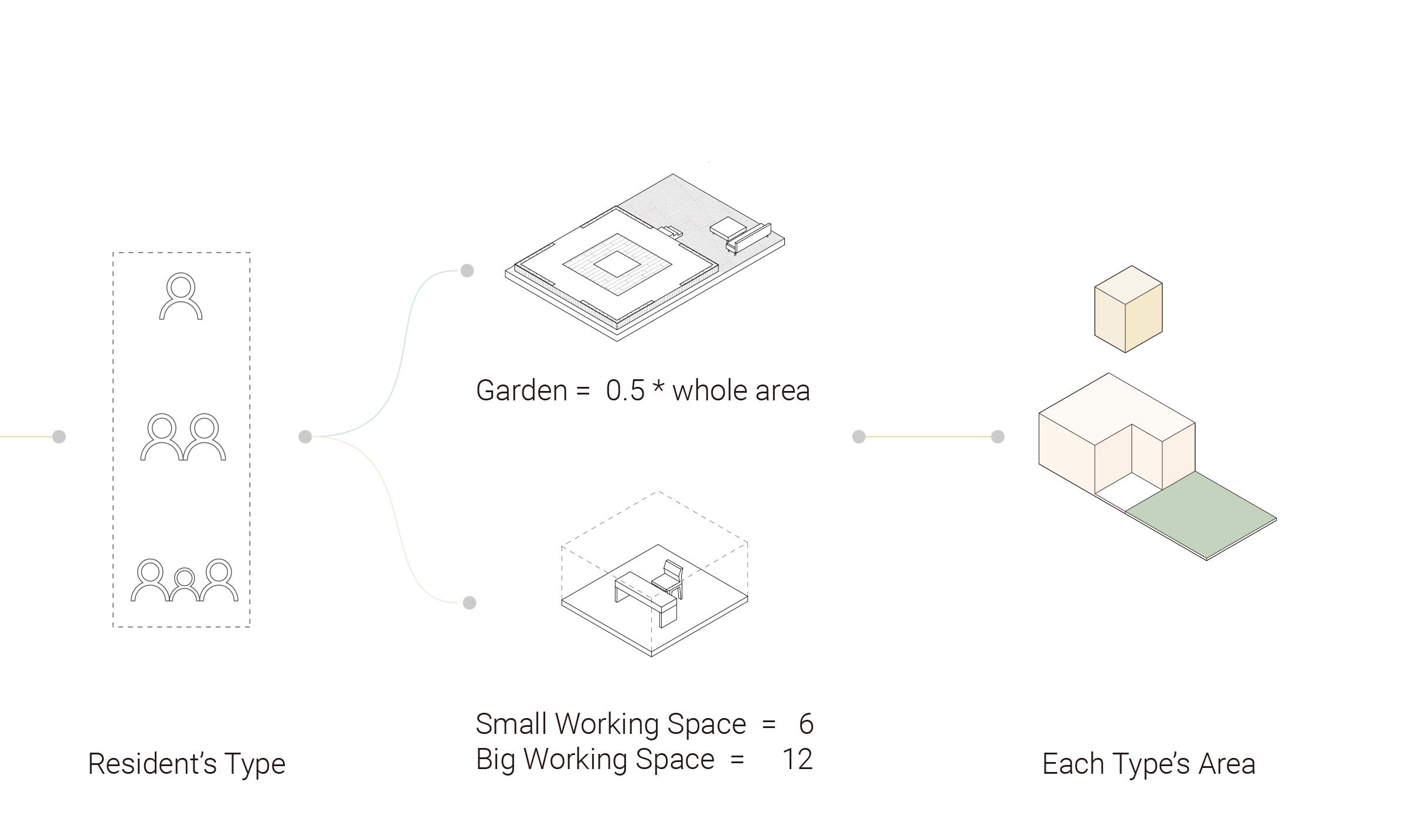

ML1 Footprint

The outdoor space decides the location of private work space.

ML2 Family

The distribution decides the combination

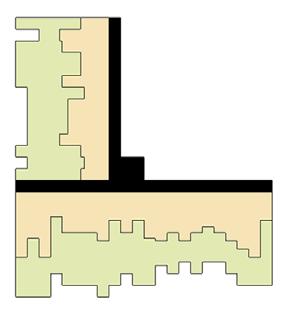

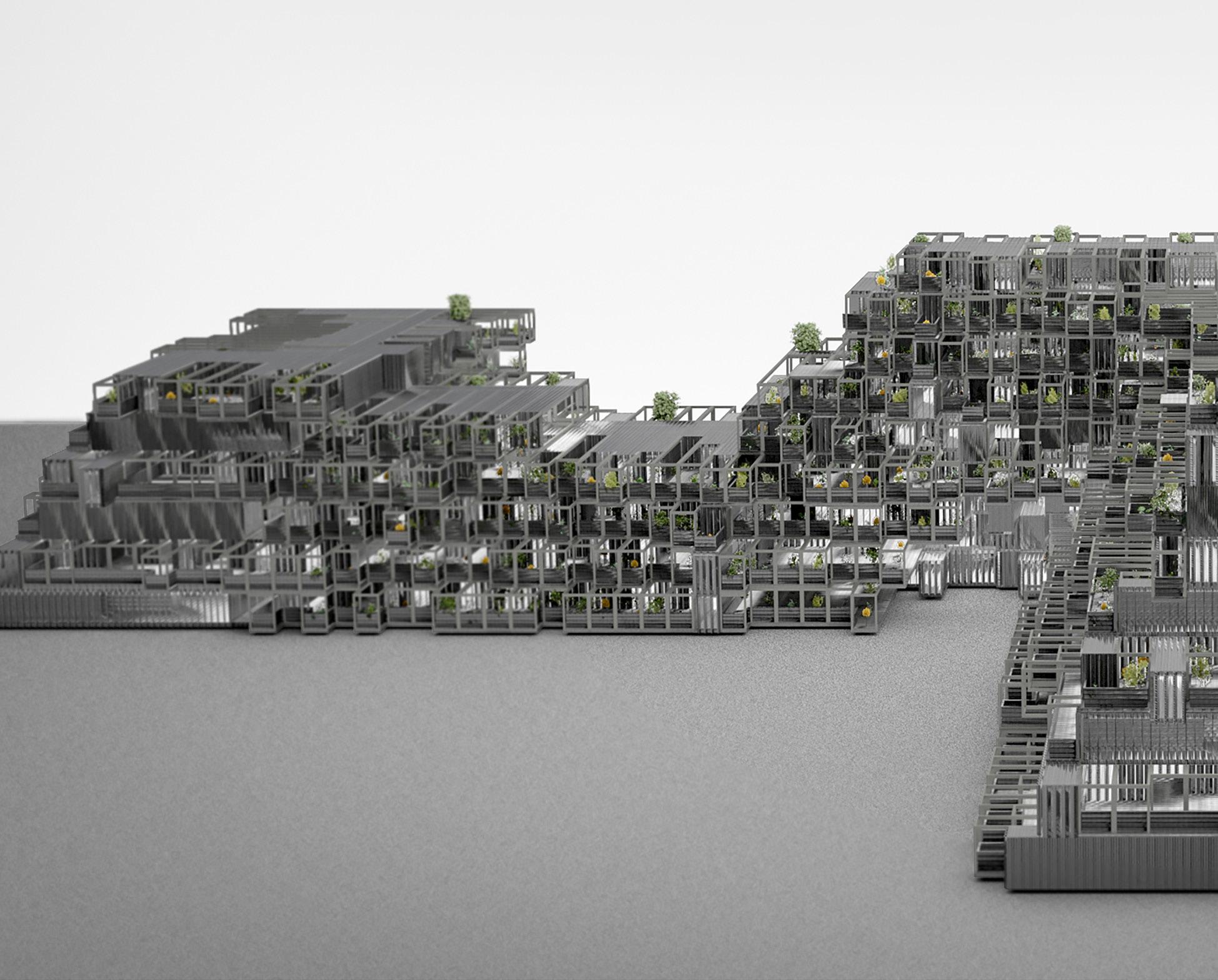

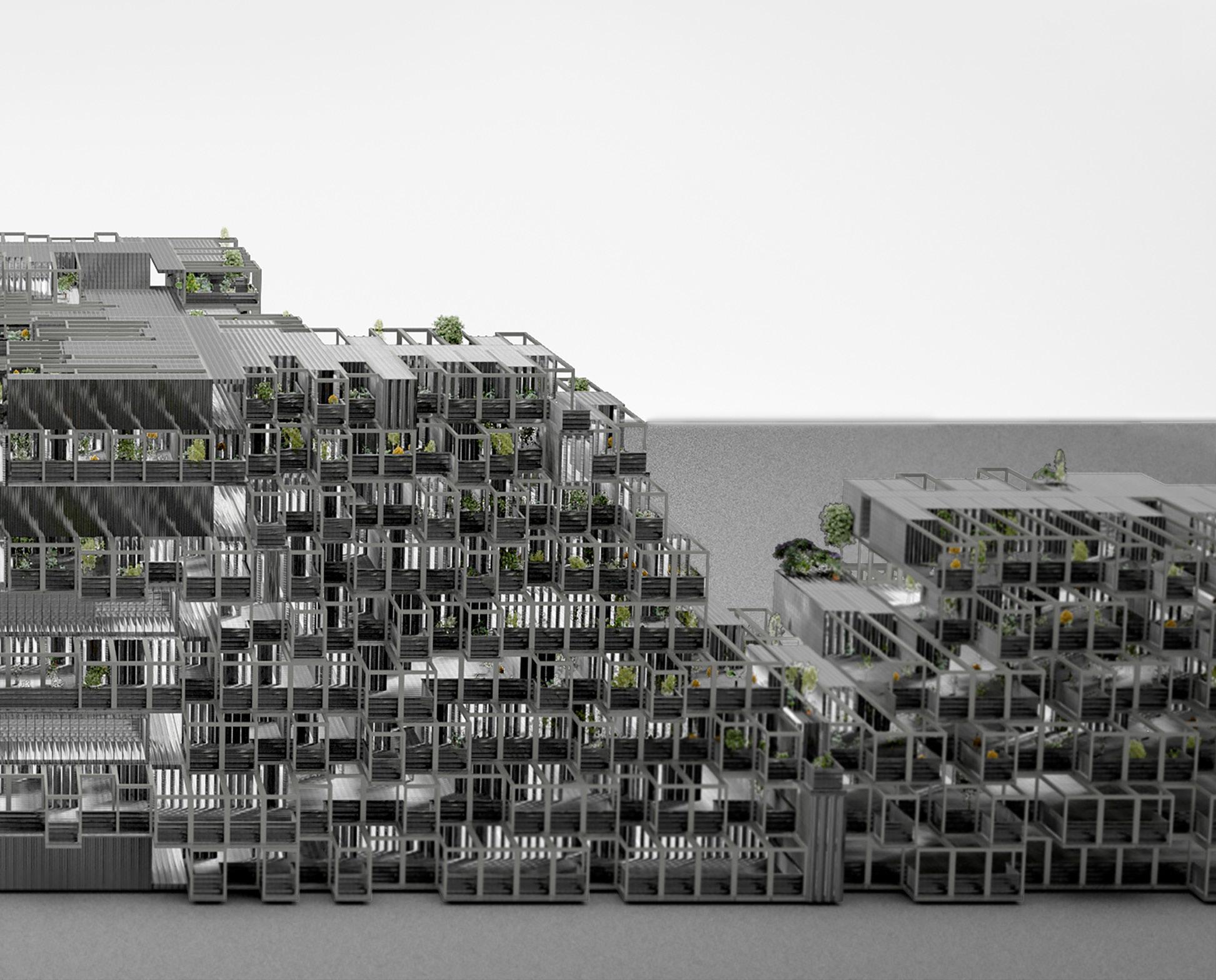

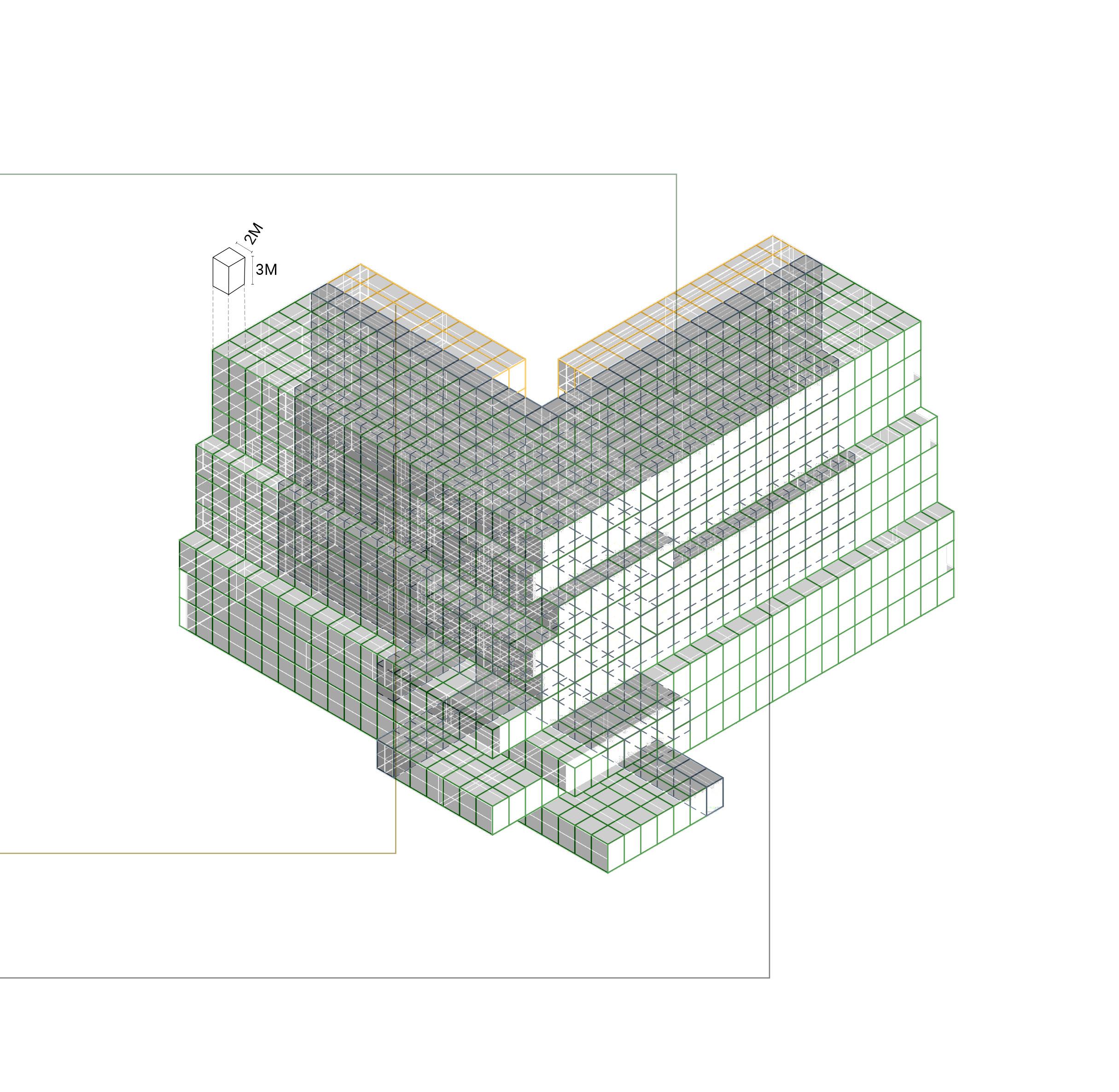

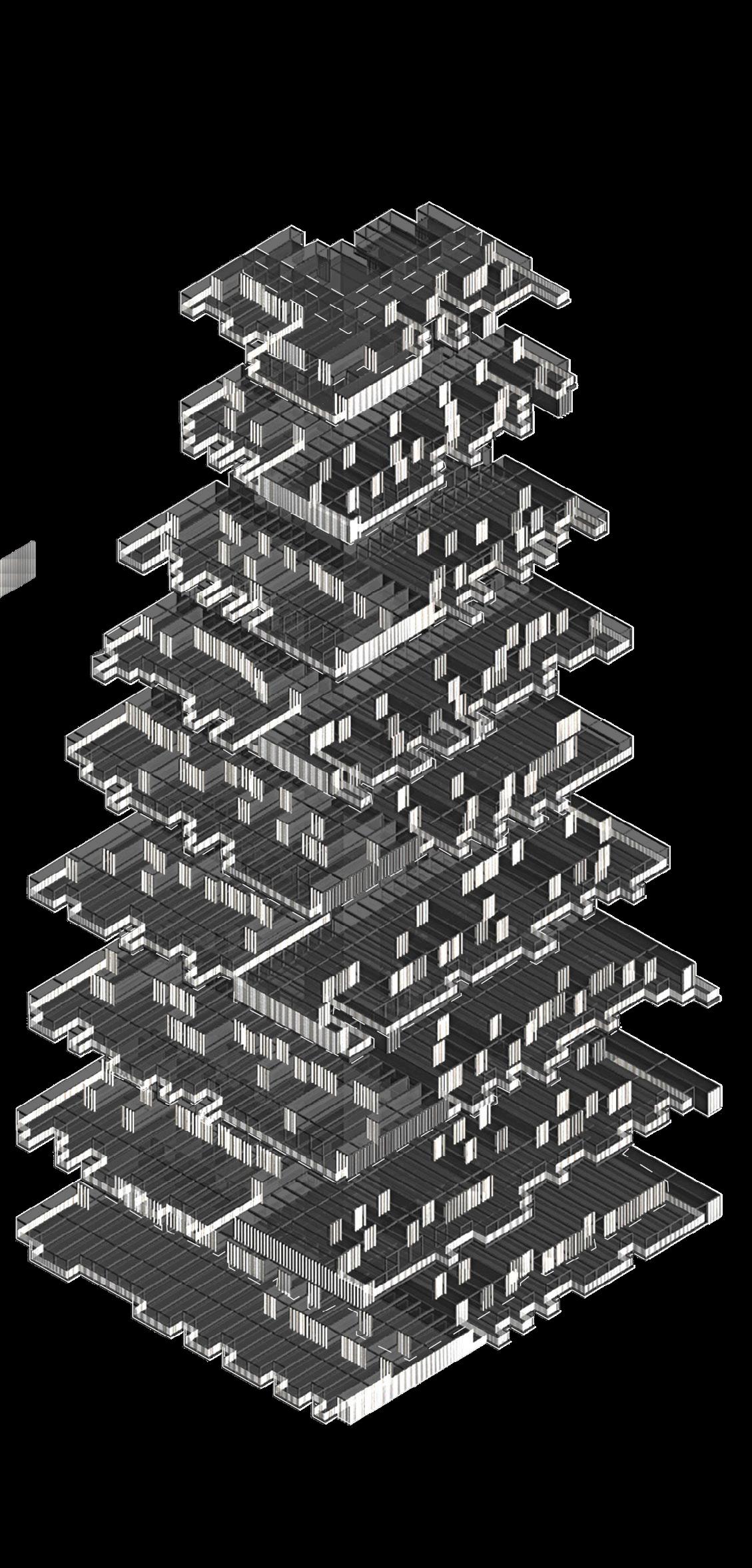

Step2 Cluster

The module aggregation results and the division of outdoor and indoor space are adjusted by the radiation model

Step3 Building Envelope

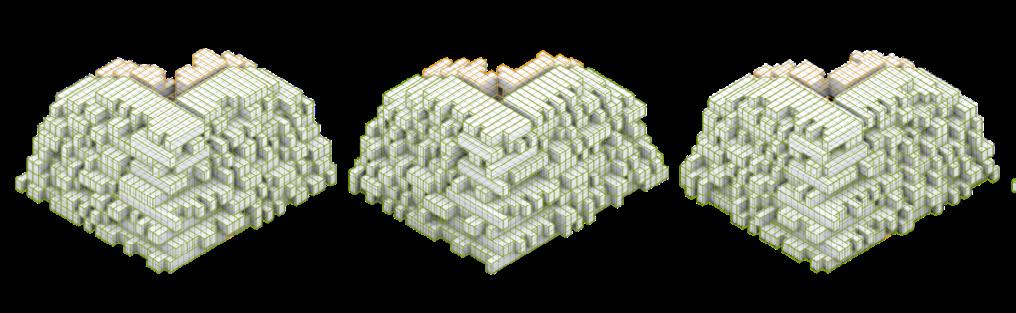

The clusters are combined into a building envelope formed by radiation analysis.

modules.

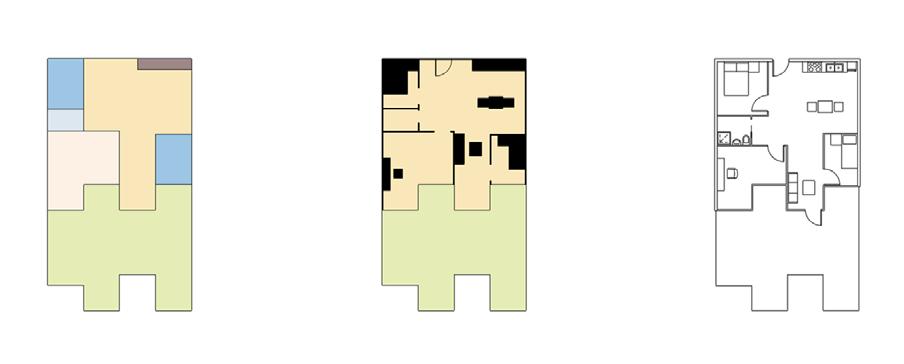

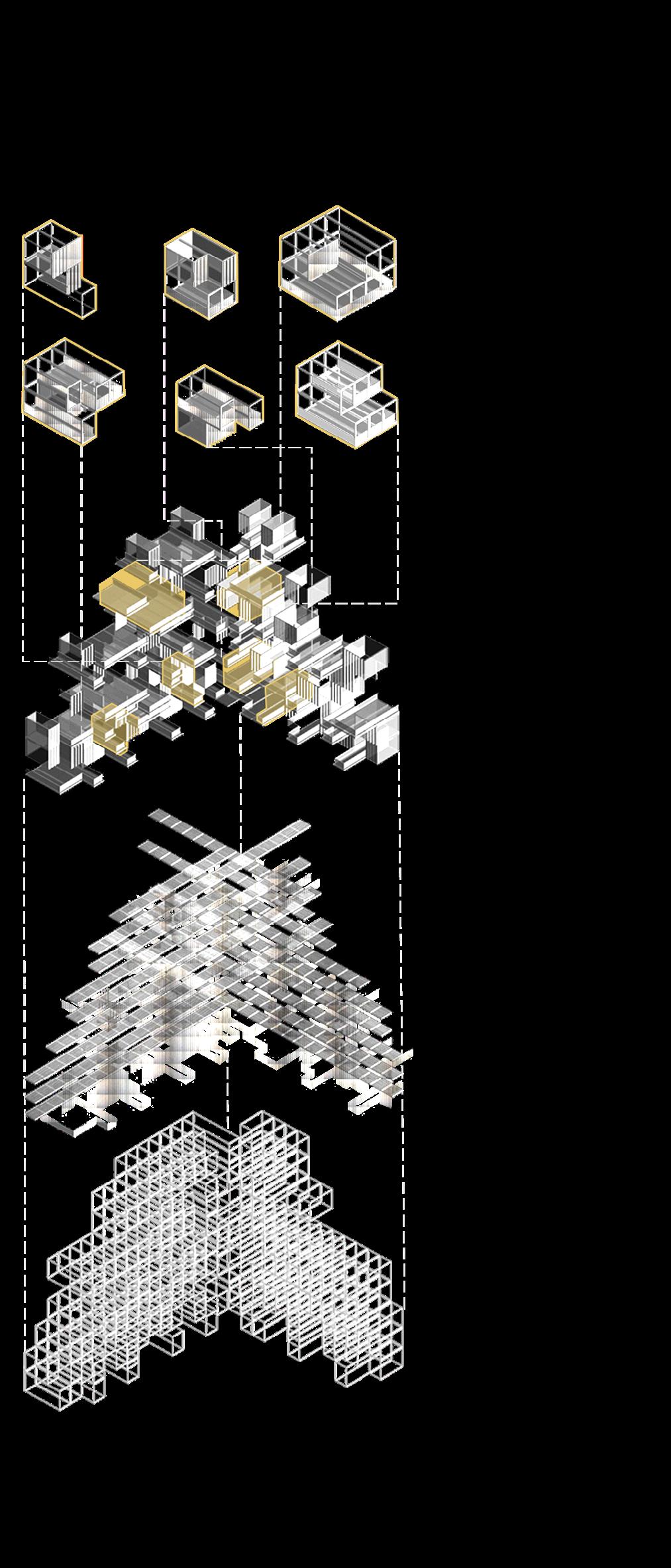

ML3 Interior Design

The furniture sets are alloted in each family unit.

ML4 Floor Plan

The floor plan is completed with the family units and shared space units.

BCORE SLAB (CORE TUBULAR STEEL)

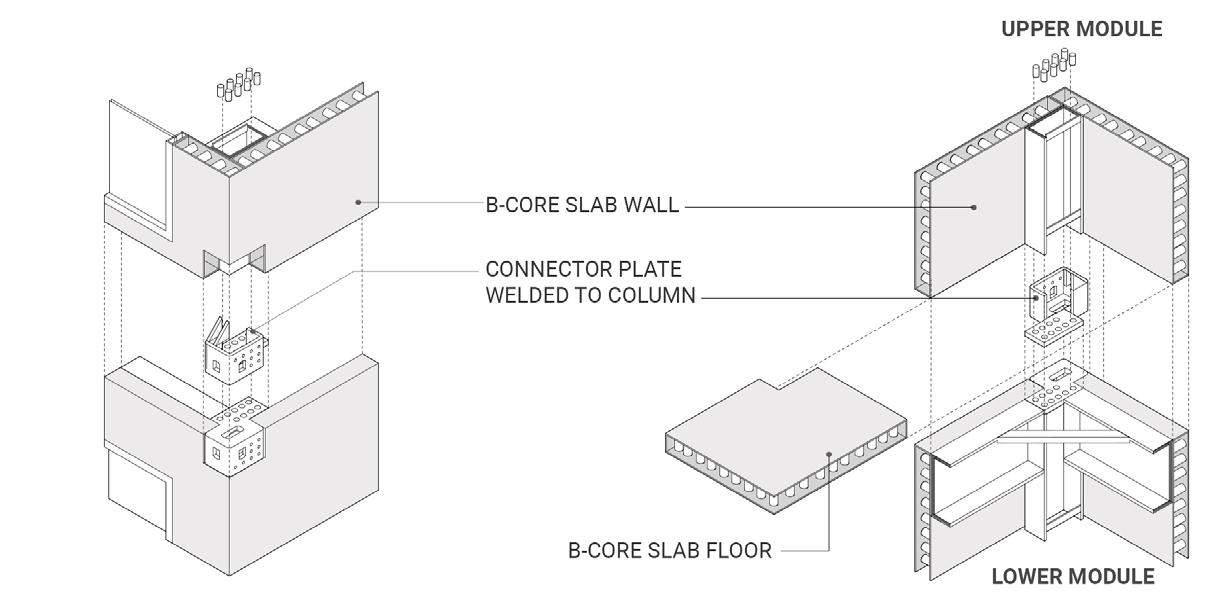

BCORE slab are thin-walled core tubes sandwiched between top and bottom plates. The slab components are made-up of stainless steels, titanium and alloy steel. Each slab comes in a standard size of 12m long, 2 m wide, and 0.15m thick. They are manufactured into panels that made up the modular units through basic steel framing. BCORE system is a proprietary product made by Broad Group company based in Changsha, China.

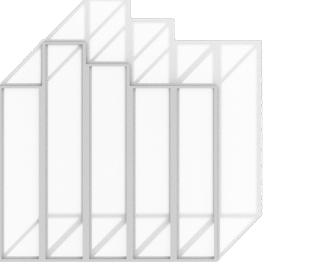

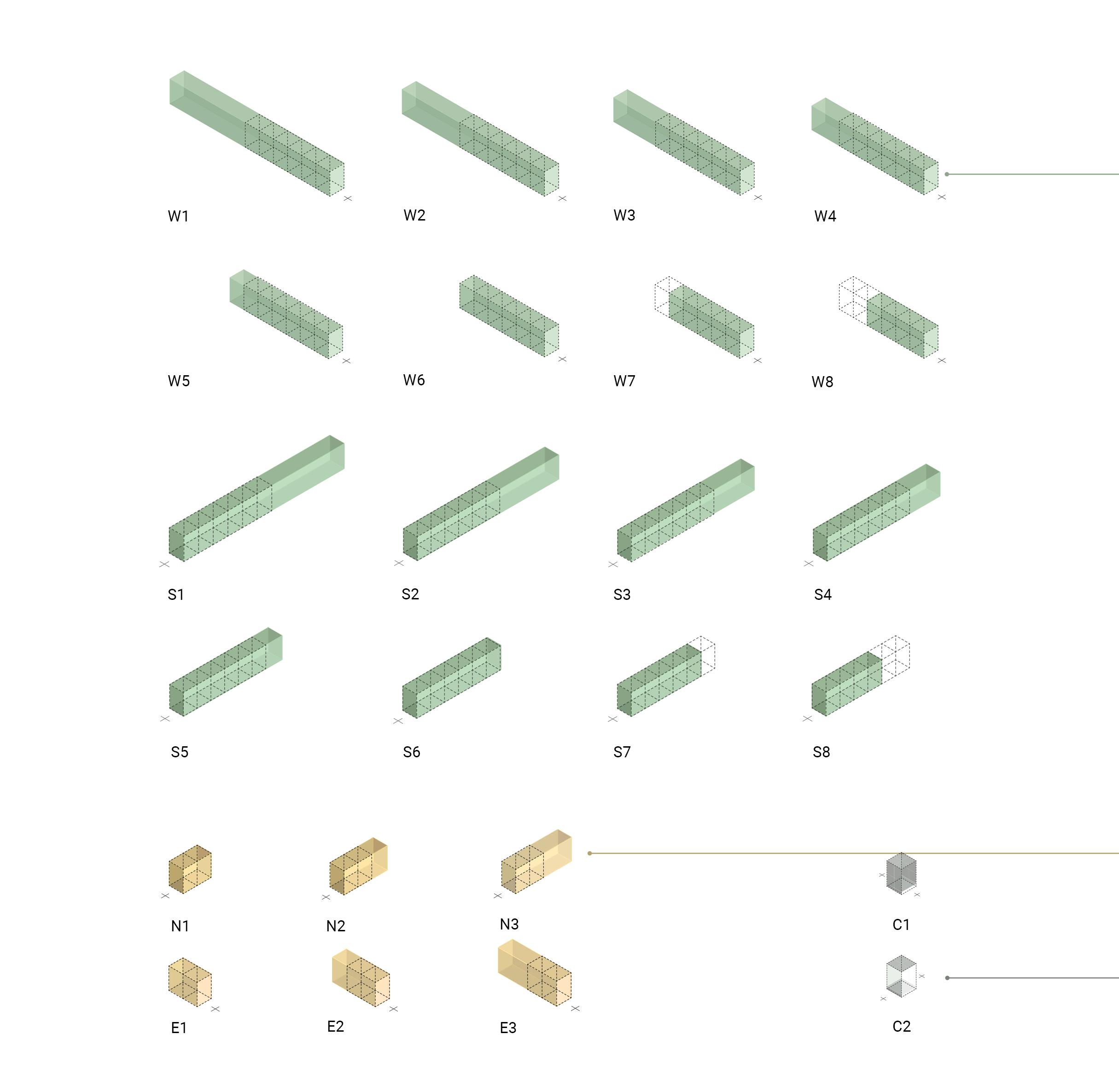

MODULAR SYSTEM

The modular building is an integrated application form of BCORE system. BCORE modular system starts at a +/- 2m (w) x12m (l) x3m (h) transportation dimension. On site, the inner wall is deployed, making the dwelling area doubled in size. In post-installation phase, modules are connected according to designated unit type. The production cycle range from 1-6 months per building size configuration. Exterior walls, interior walls, doors, windows, floors, roofs, balconies, stairs and elevatiors are 100% factory-made.

ADVANTAGES

These units offer several advantages:

• TRANSPORTATION- - all components are shipped in containers

• CONSTRUCTION - less labor and lower cost (one room per worker per day), short construction period (1F/day)

• SUSTAINABILITY - recyclable, reusable, removable

• LIFE CYCLE DESIGN - 100x more resistant than carbon steel, service lfe can reach 10,000 years

• RESILIENCY - 10x lighter than concrete and can effectively resist earthquake and land subsidence

• EFFICIENCY - High insulation performance, multi-layered window glass, fresh-air heat recovery

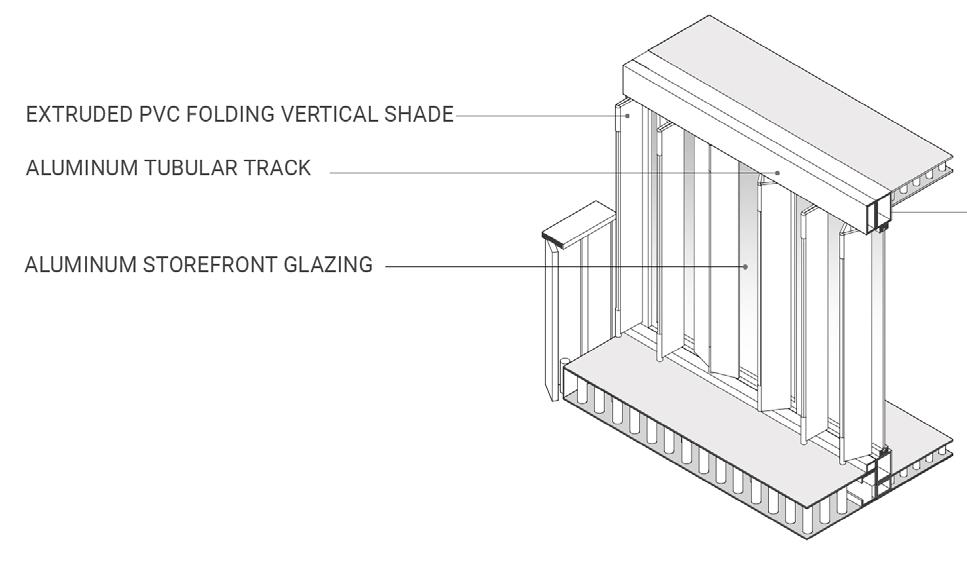

DETAILS

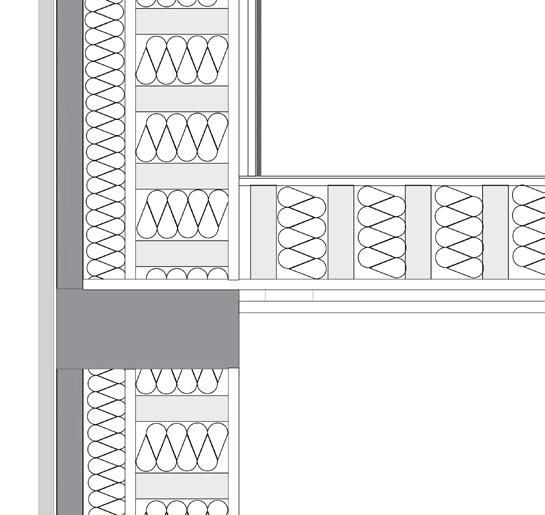

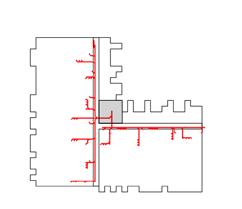

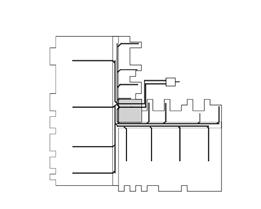

EXTERIOR WALL-TO-FLOOR CONNECTION INTERIOR WALL-TO-FLOOR/CEILING CONNECTION

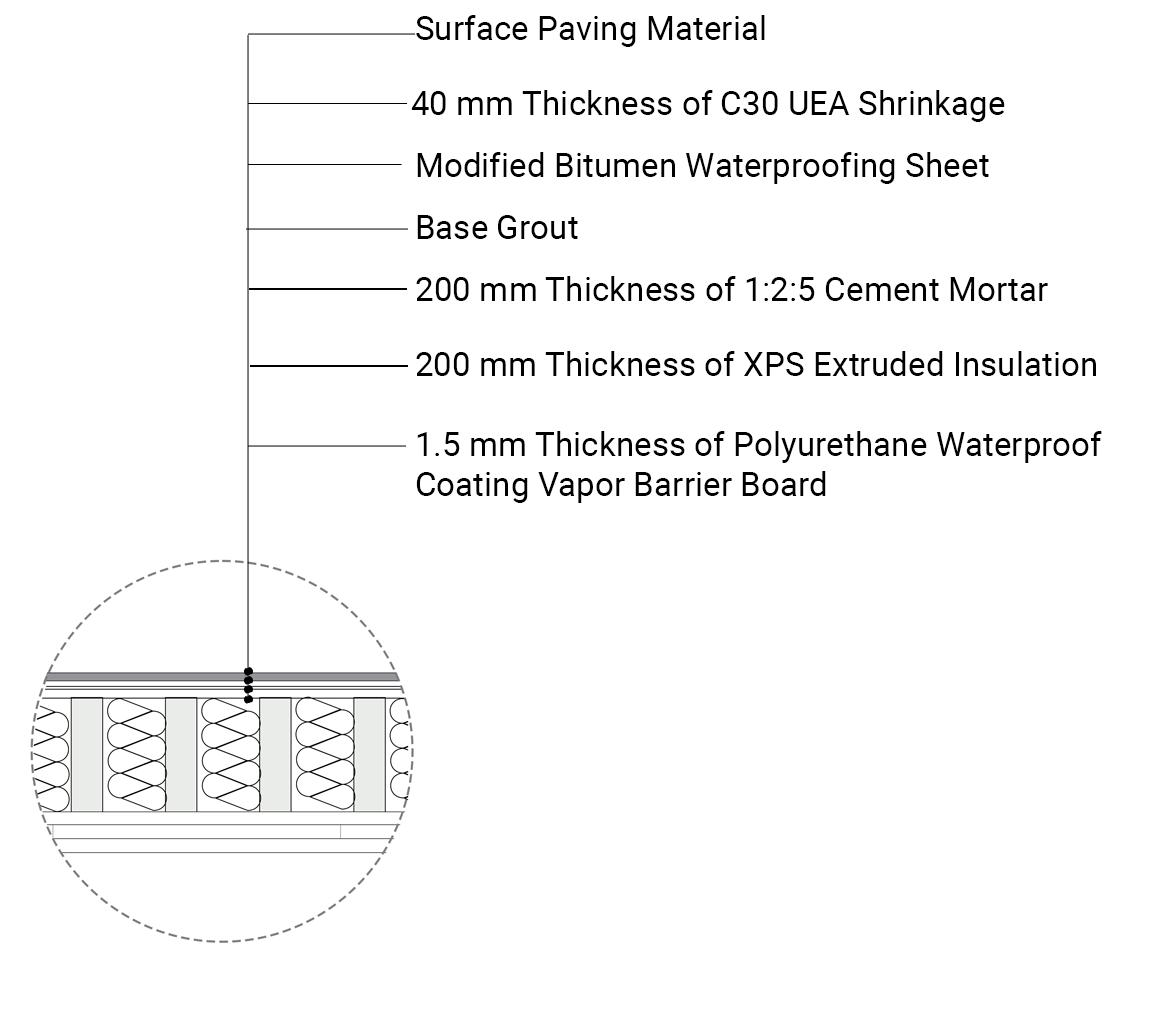

WATERPROOFING PROFILE OF ACCESSIBLE ROOF / BALCONY (SOURCE: BCORE SKYCITY )

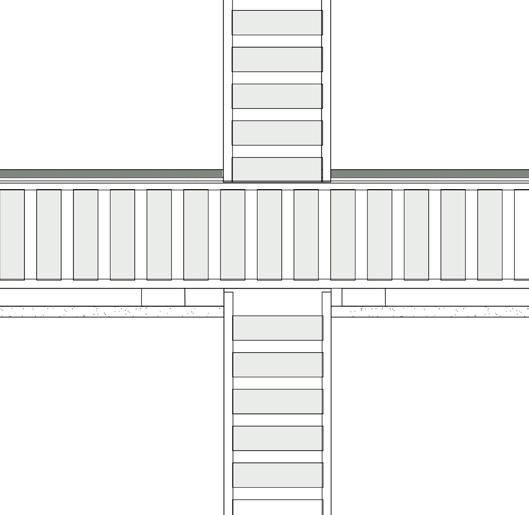

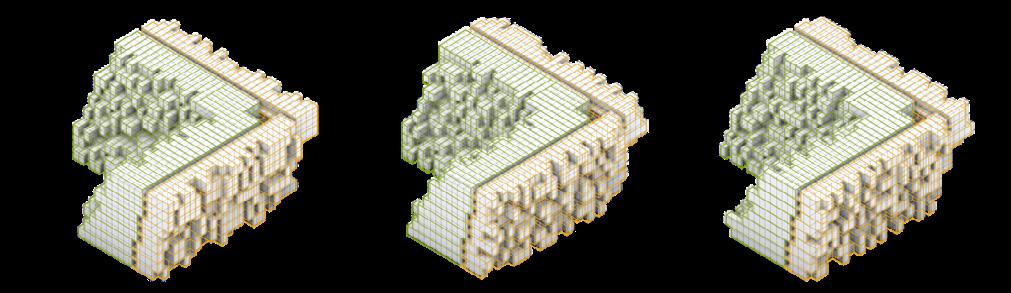

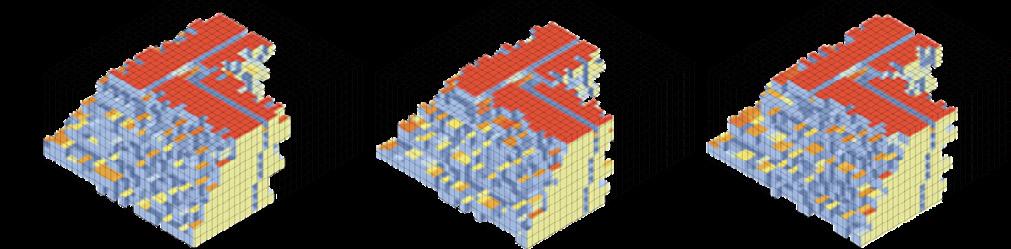

Modules Construction in Slots

Modules for Dwellings

Modules Distribution in Slots Boundary

Front Modules for Dwellings

Back Modules for Shared Space

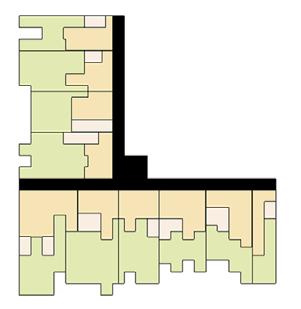

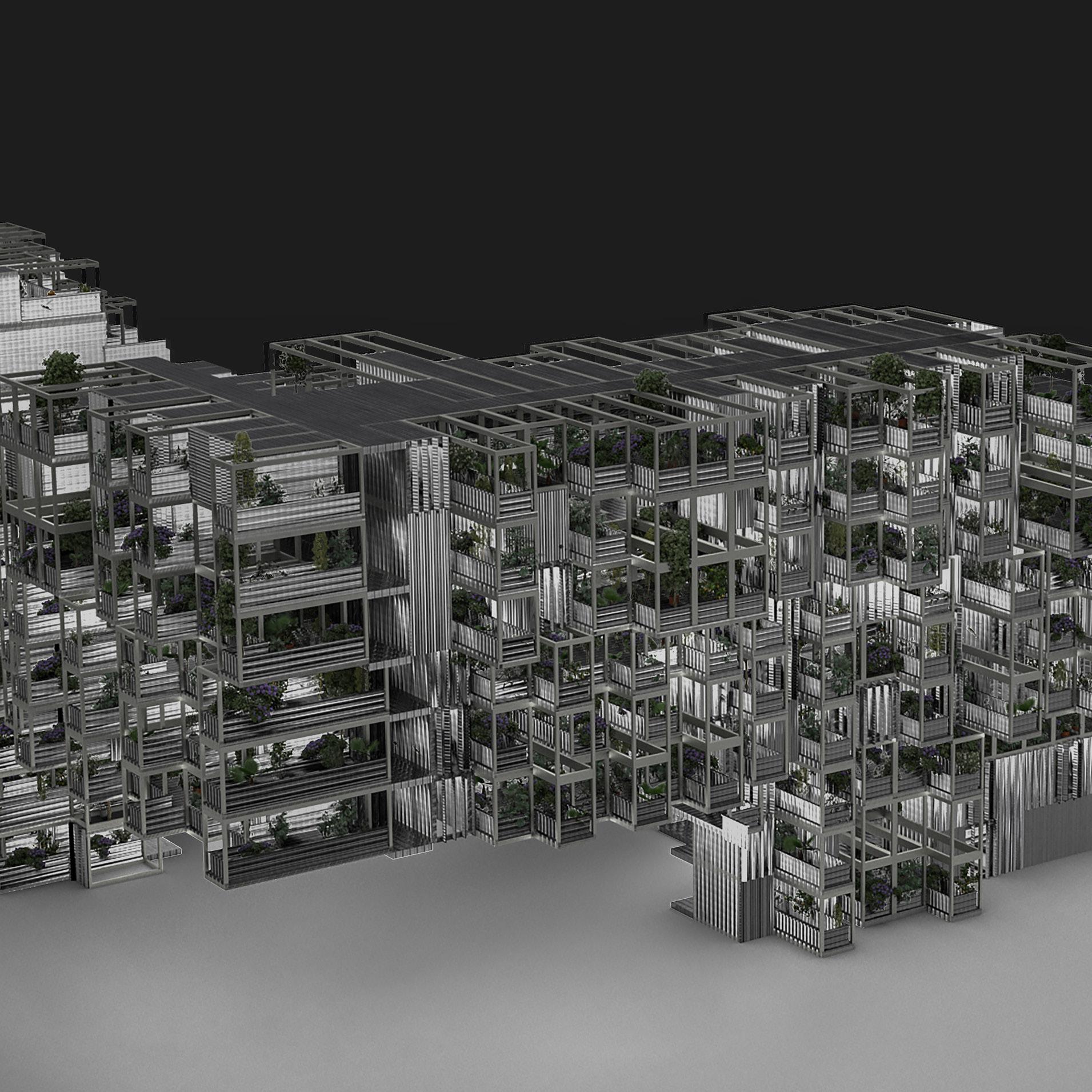

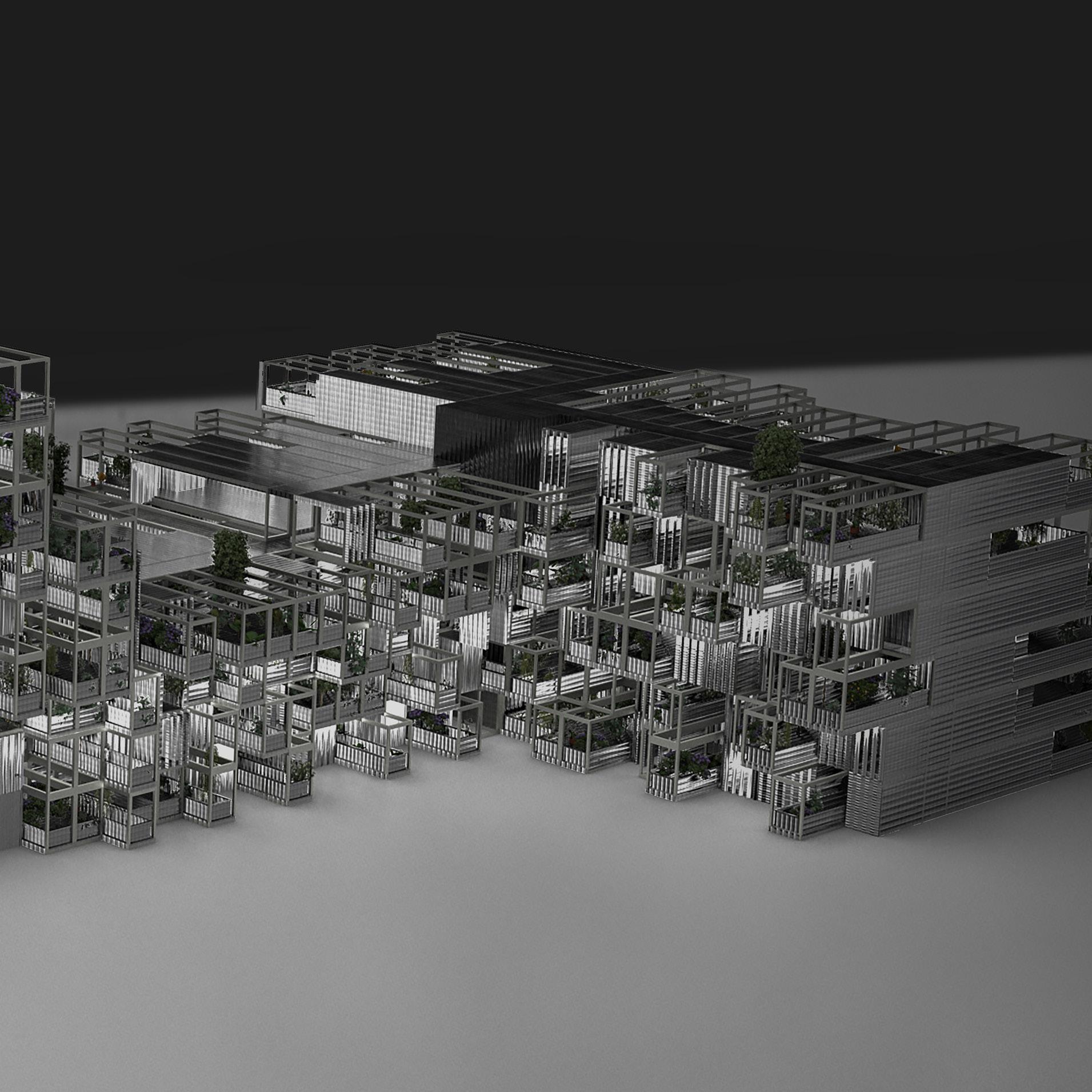

Aggregation Method

Middle Modules for Corridors

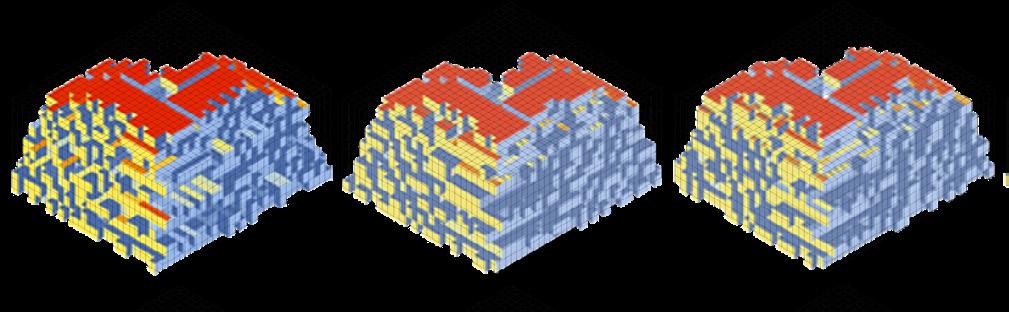

The a computational method is to stack the floors within a building envelope.The slots organize the circulation by locating certain modules.Their shapes can be adjusted at each floor to fit the different sizes of modules.The housing modules and shared space modules are assigned to the two sides of the corridors with connectors.

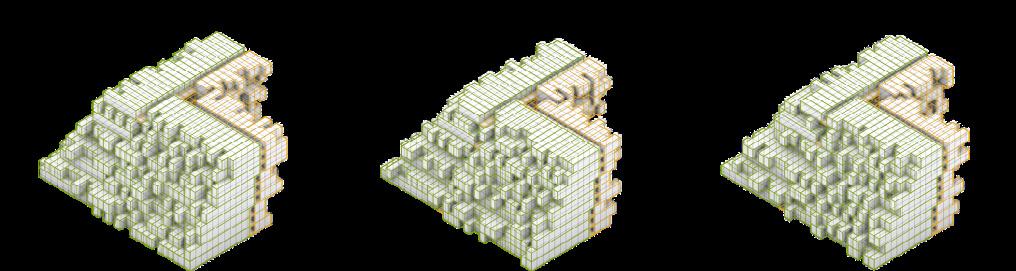

South-East Seeds

South-West Seeds

North-East Seeds

North-West Seeds

South-East Seeds

South-West Seeds

North-East Seeds

{0;40} 0. 810.0633

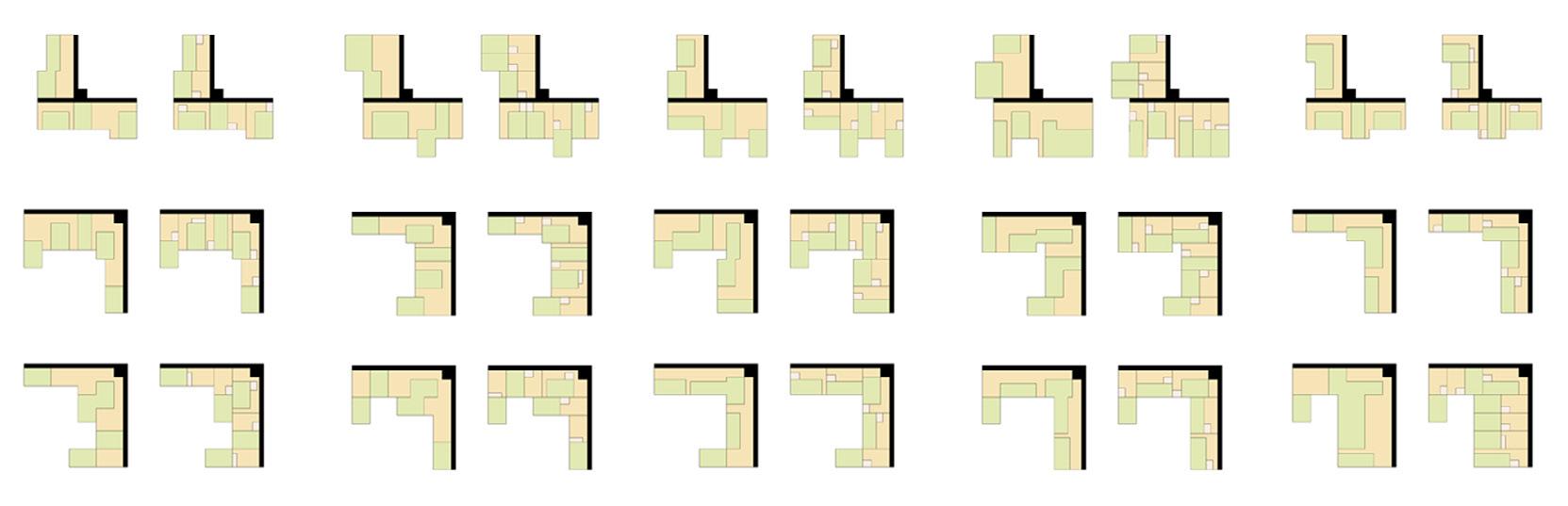

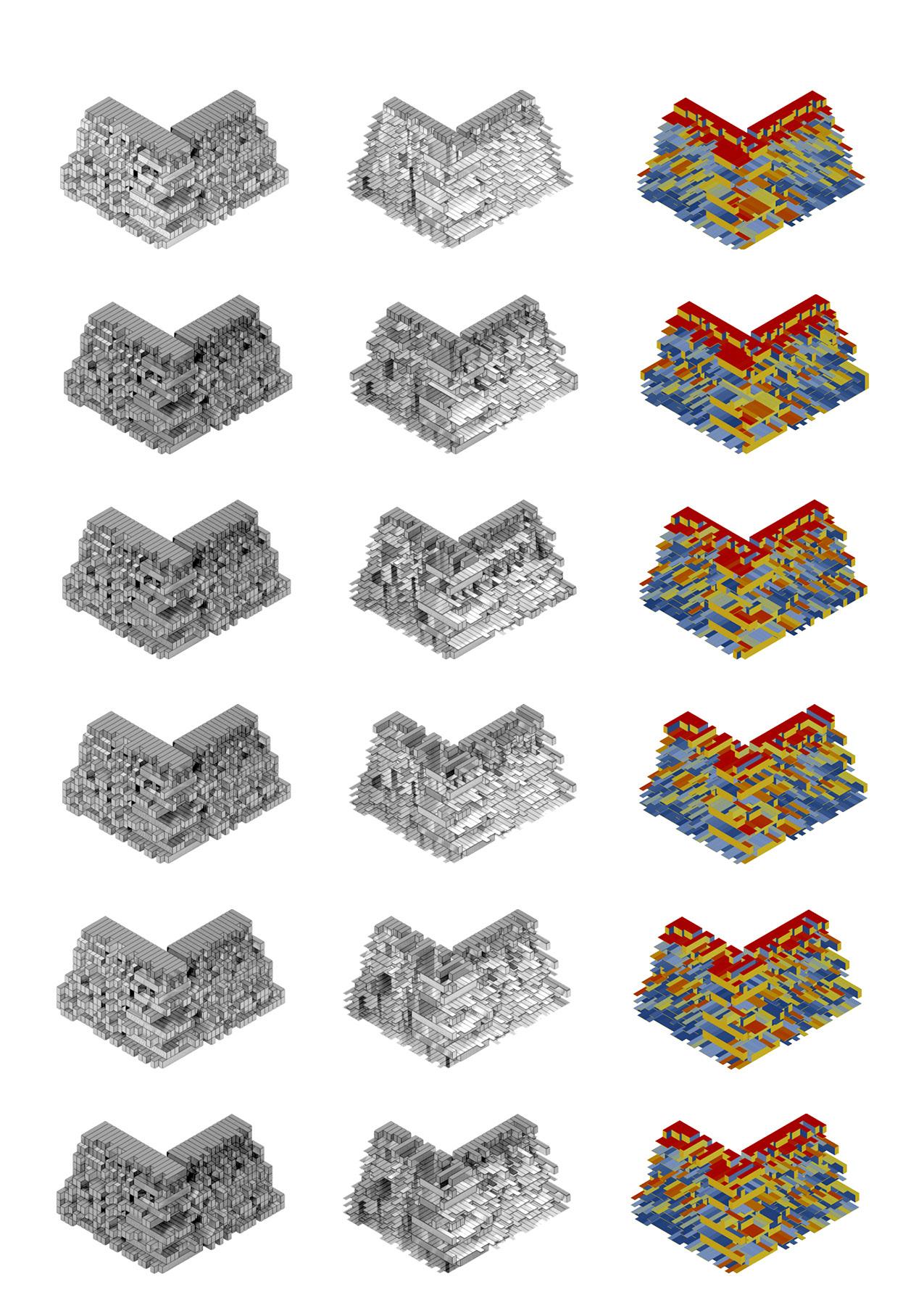

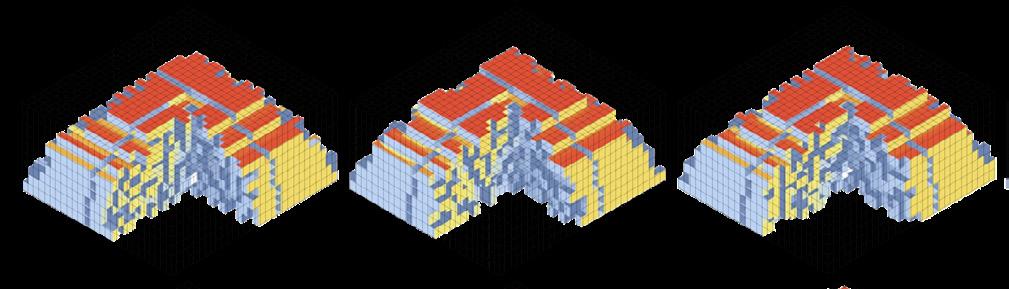

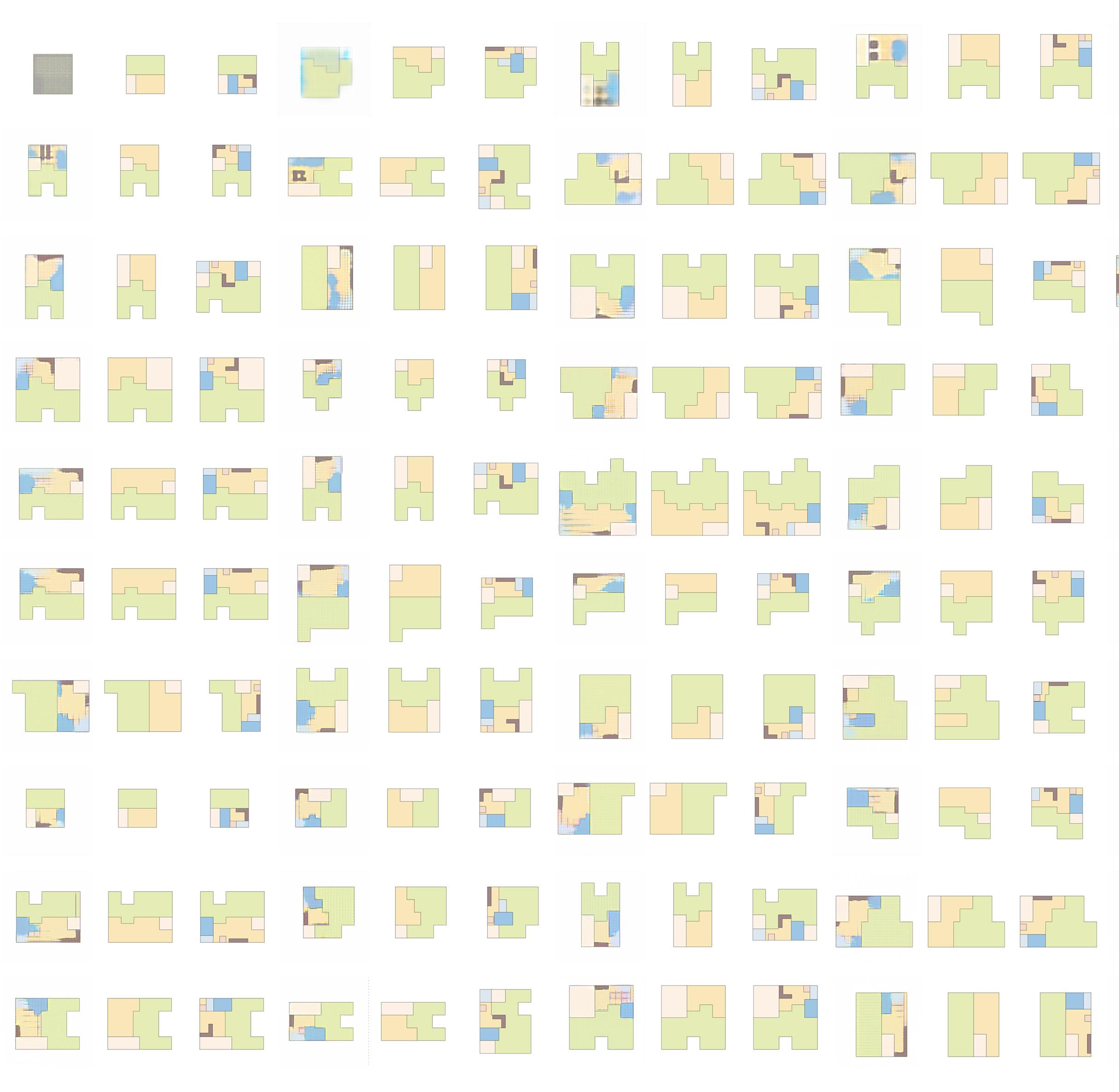

The computational method is to stack the floors within a building envelope. The housing modules and shared space modules are assigned to the two sides of the corridors. The outdoor space for gardens and indoor space for living is divided in each housing module. On the basis of maintenance of the garden ratio as 0.5, the results are selected by 3 fitness objectives: minimizing the degree of structural exposure; minimizing garden fragmentation and maximizing radiation in the garden.

North-West Seeds Module Aggregation and Evolution

Module Seeds

Radiation Seeds

Garden Seeds

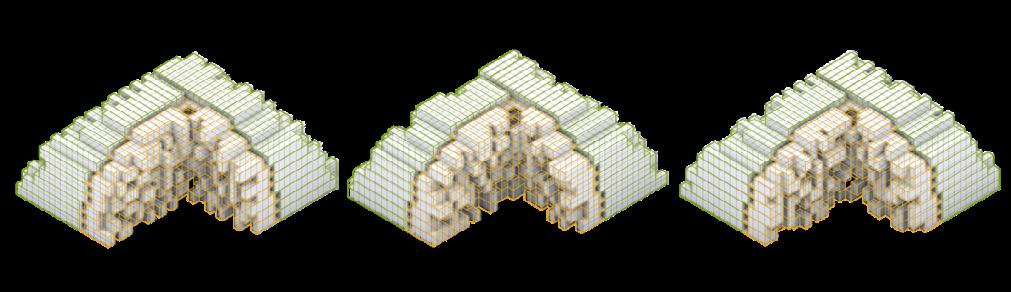

L-shape Cluster Compostion

Structure Layer

Outdoor Layer

Indoor Layer

Housing Units

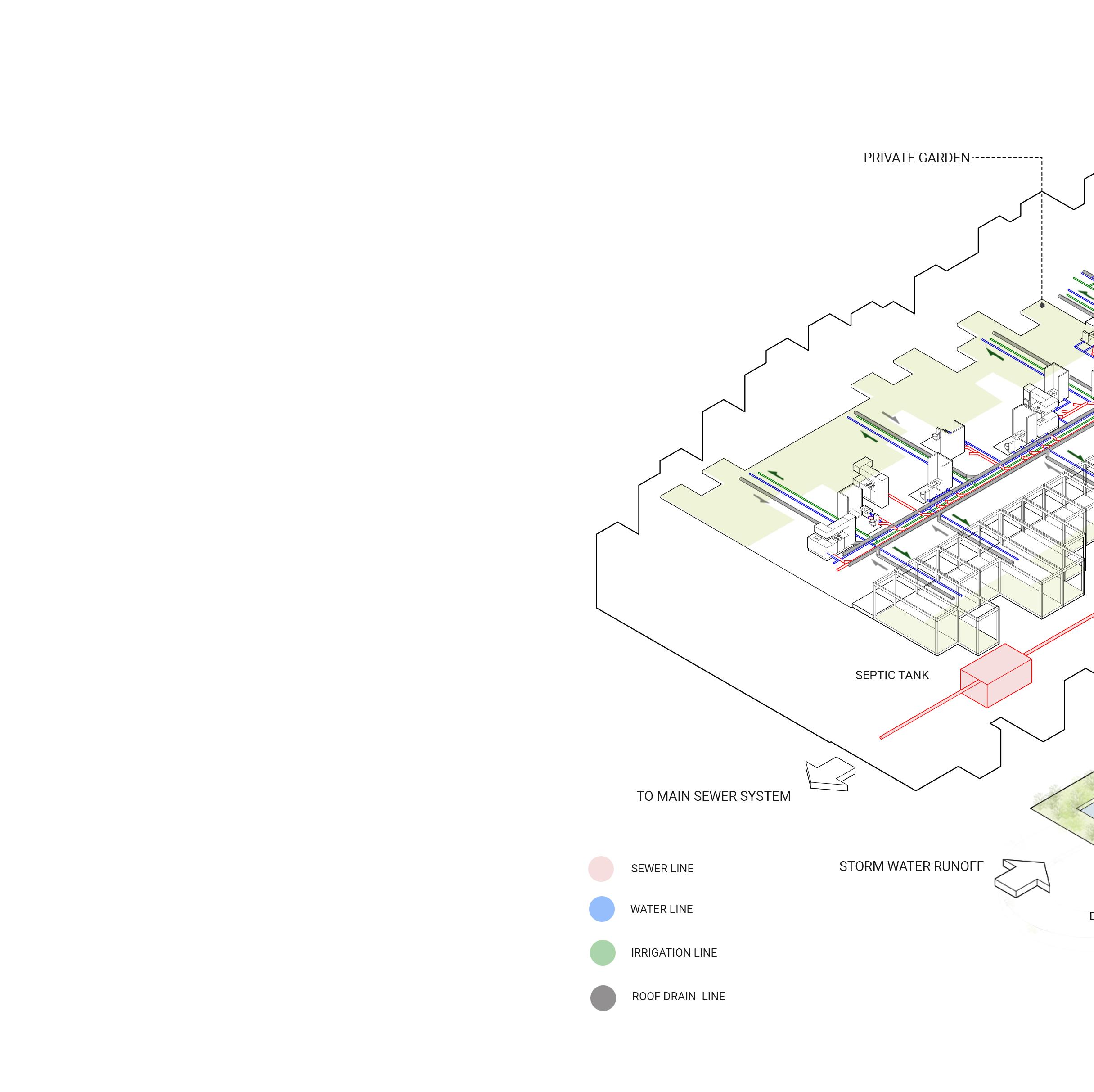

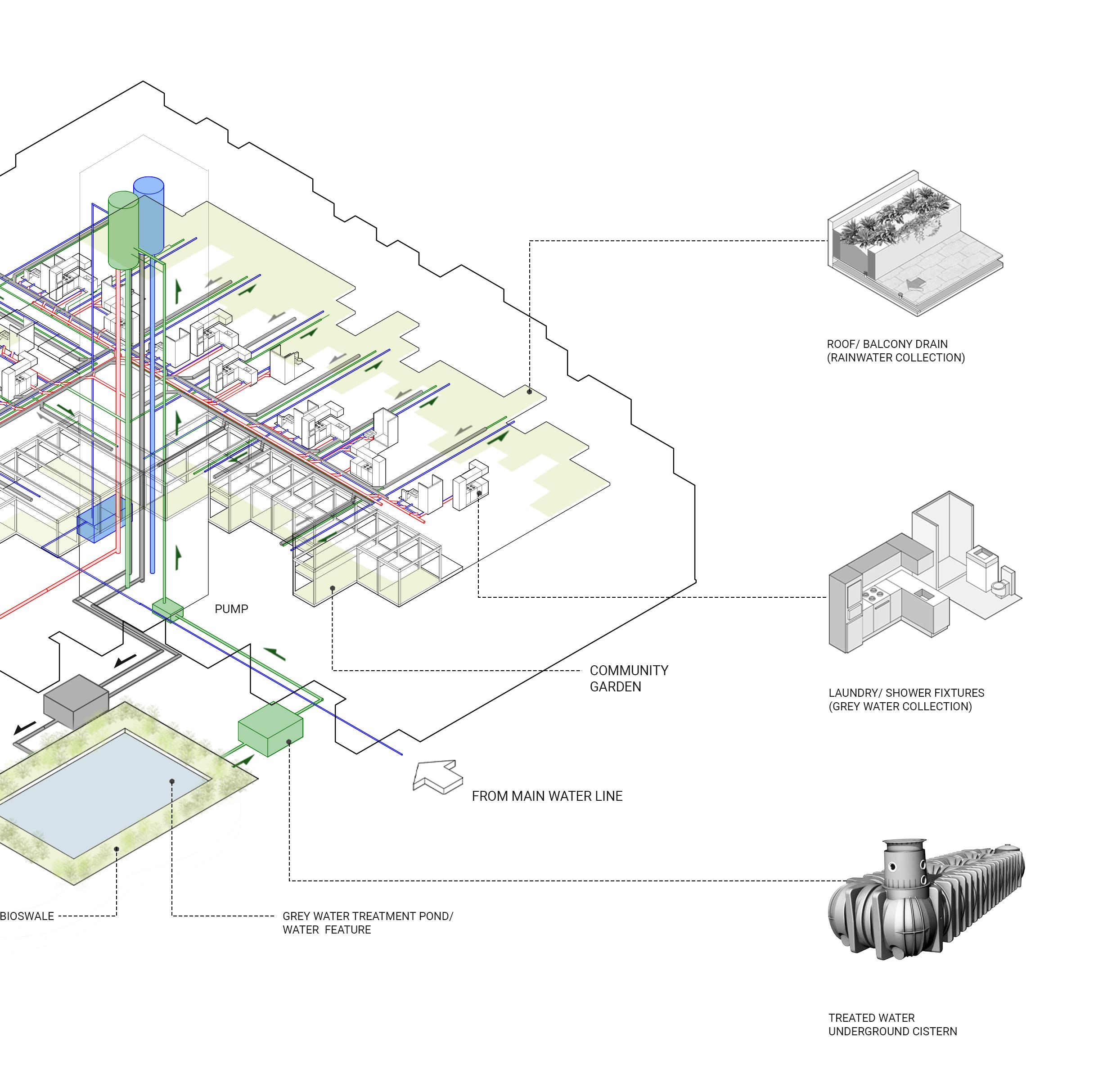

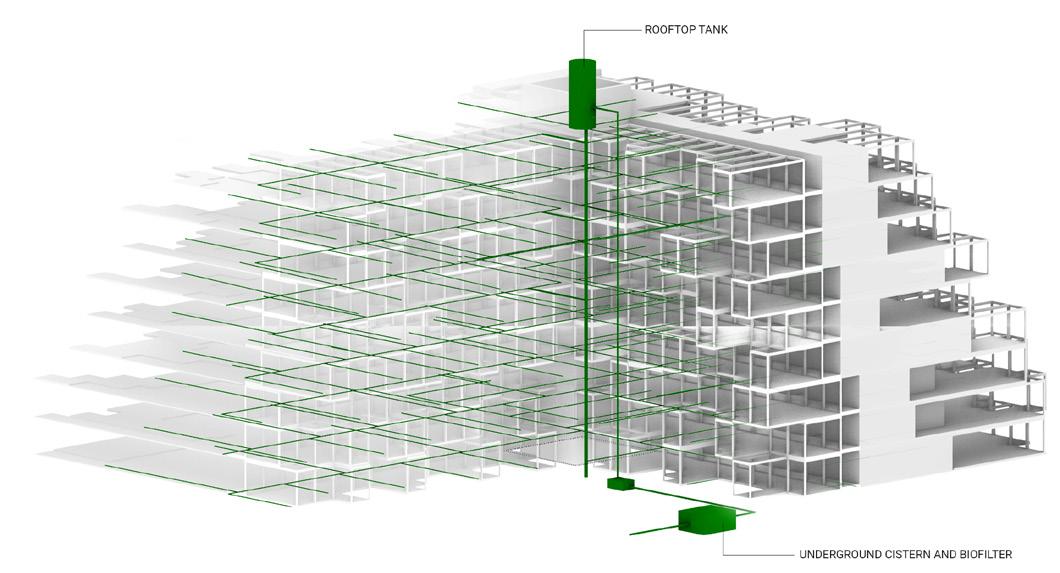

Plumbing and Irrigation

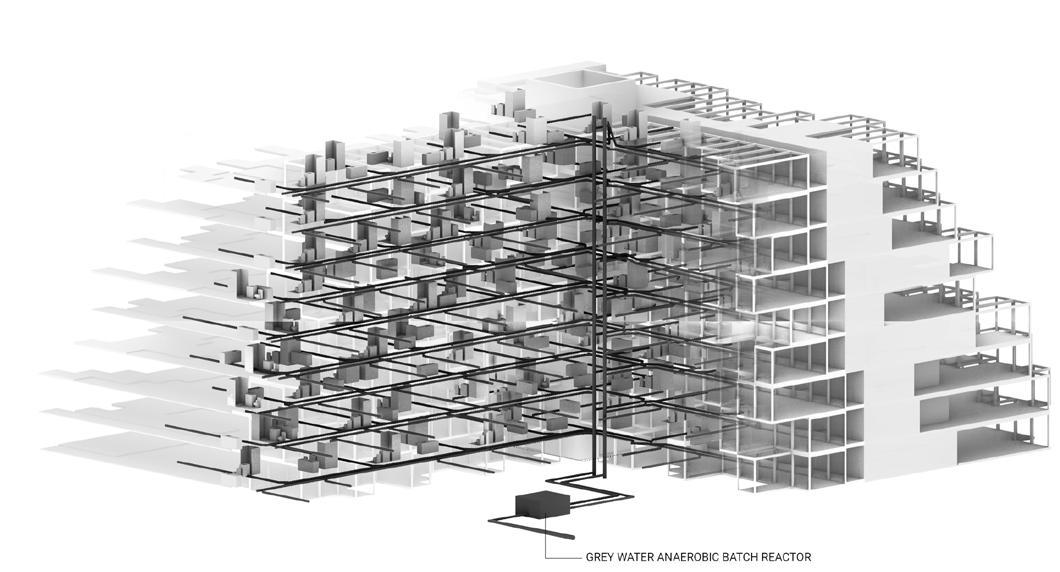

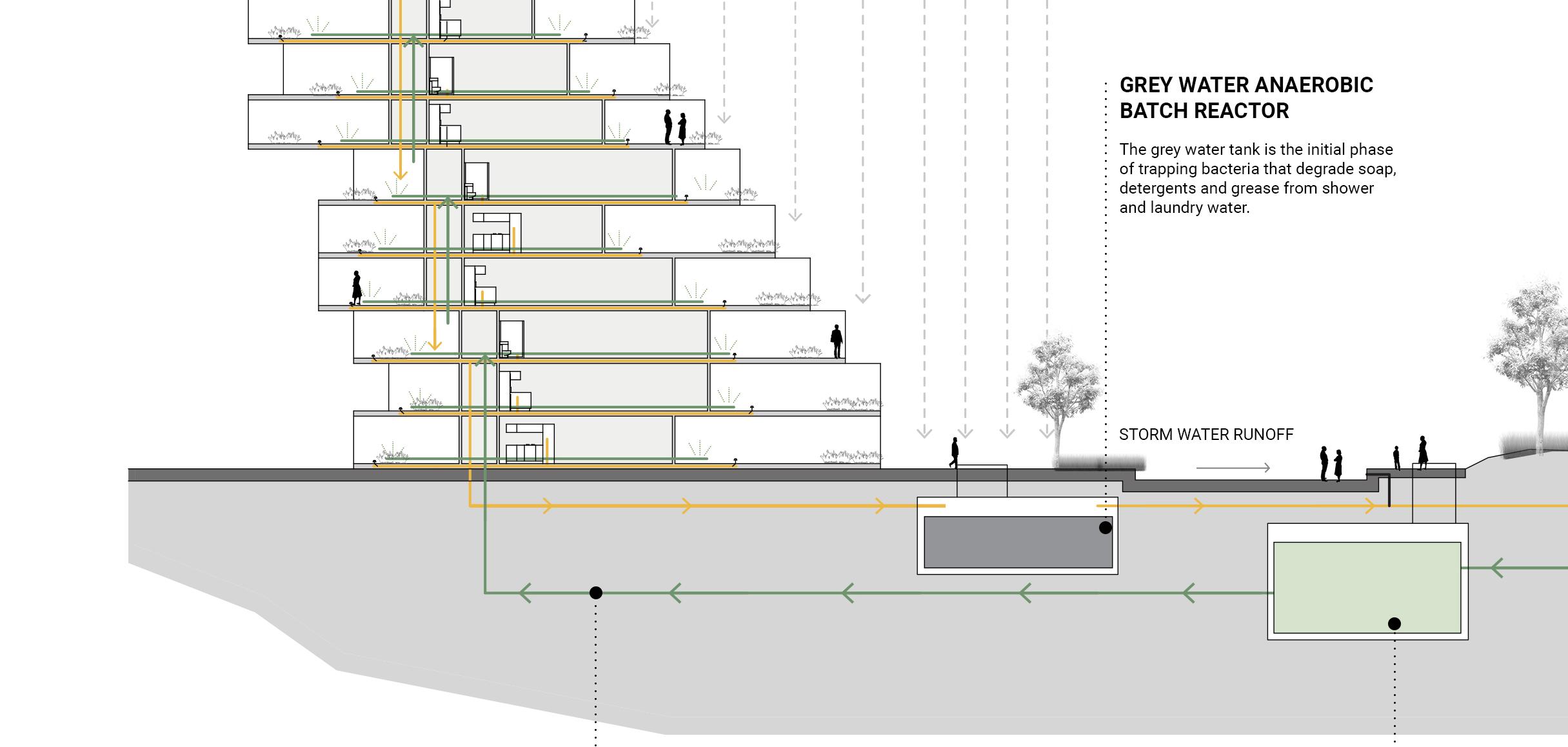

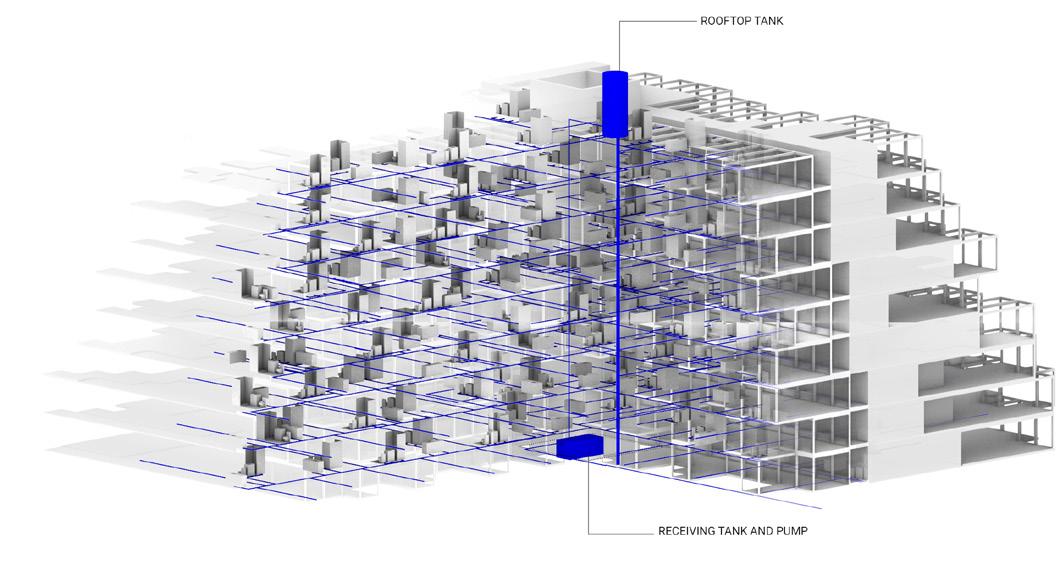

Wasteline and Water Piping diagram

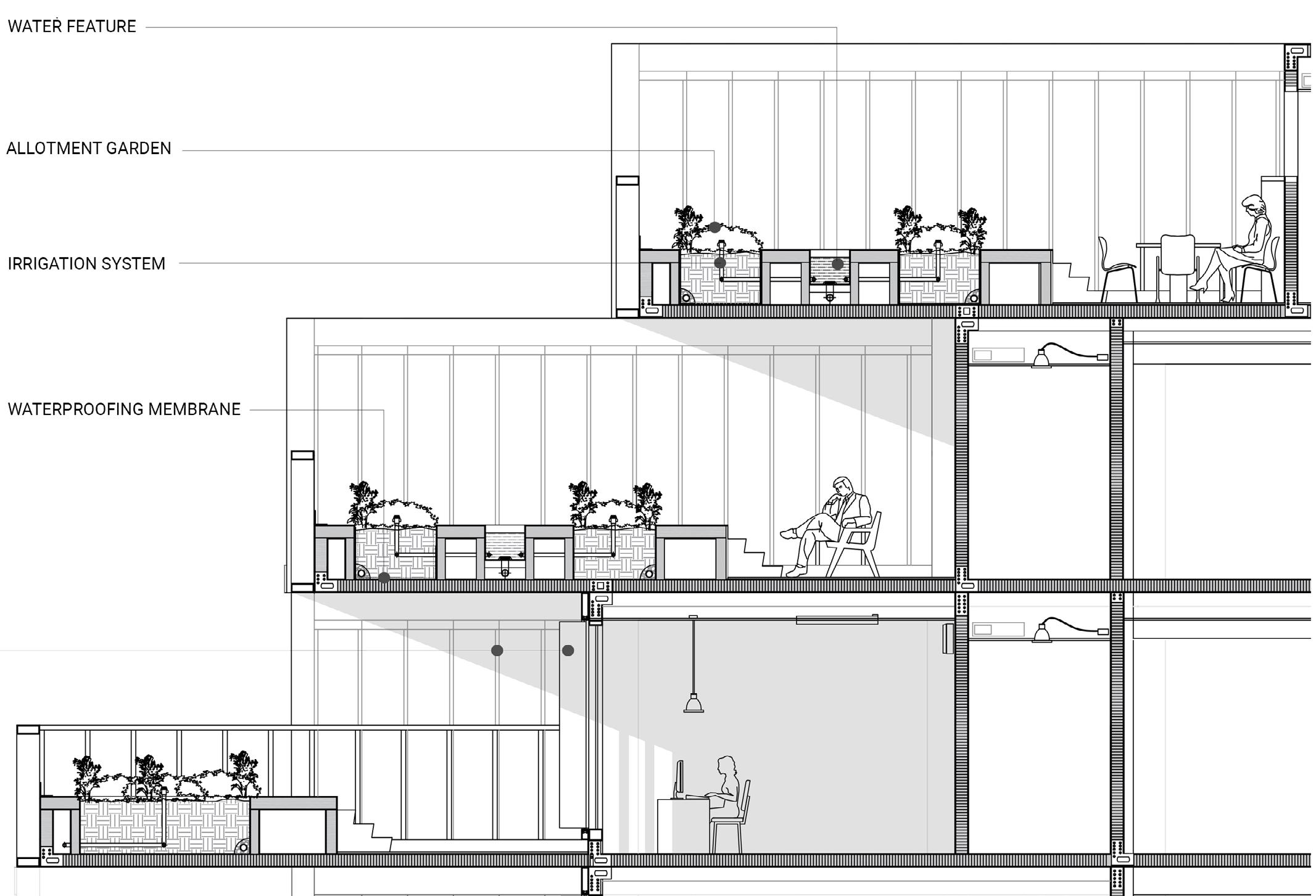

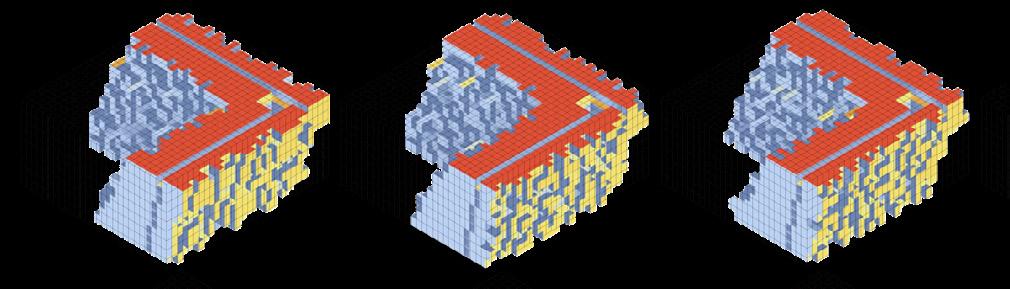

High Rise Allotment Gardens' primary challenge is the building systems due to its customized units and the sloping building topography. The modular B-Core slab system also adds constraints in running most typical building components, particularly the plumbing and irrigation systems. Since assigning a chase is a challenge on a volumetric modular unit, we run our plumbing system under the floor.

For the WASTE piping system, all toilets and kitchen waste run under the floor towards the corridor. Once outside the units, waste pipes converge in the core of the L-cluster building and connects to a central vertical line that collects all waste on every floor. The main waste pipe is then connected to the local cluster building septic tank and later dispose of wastewater to drain field or city sewer system.

All fixtures supplied by local water first enter the main building through the cluster meter for the WATER piping system. Receiving tanks hold the water until it is ready to pump into the rooftop tank. Due to the high elevation of the building, we opted to use a rooftop tank and use gravity to provide adequate water pressure for each unit.

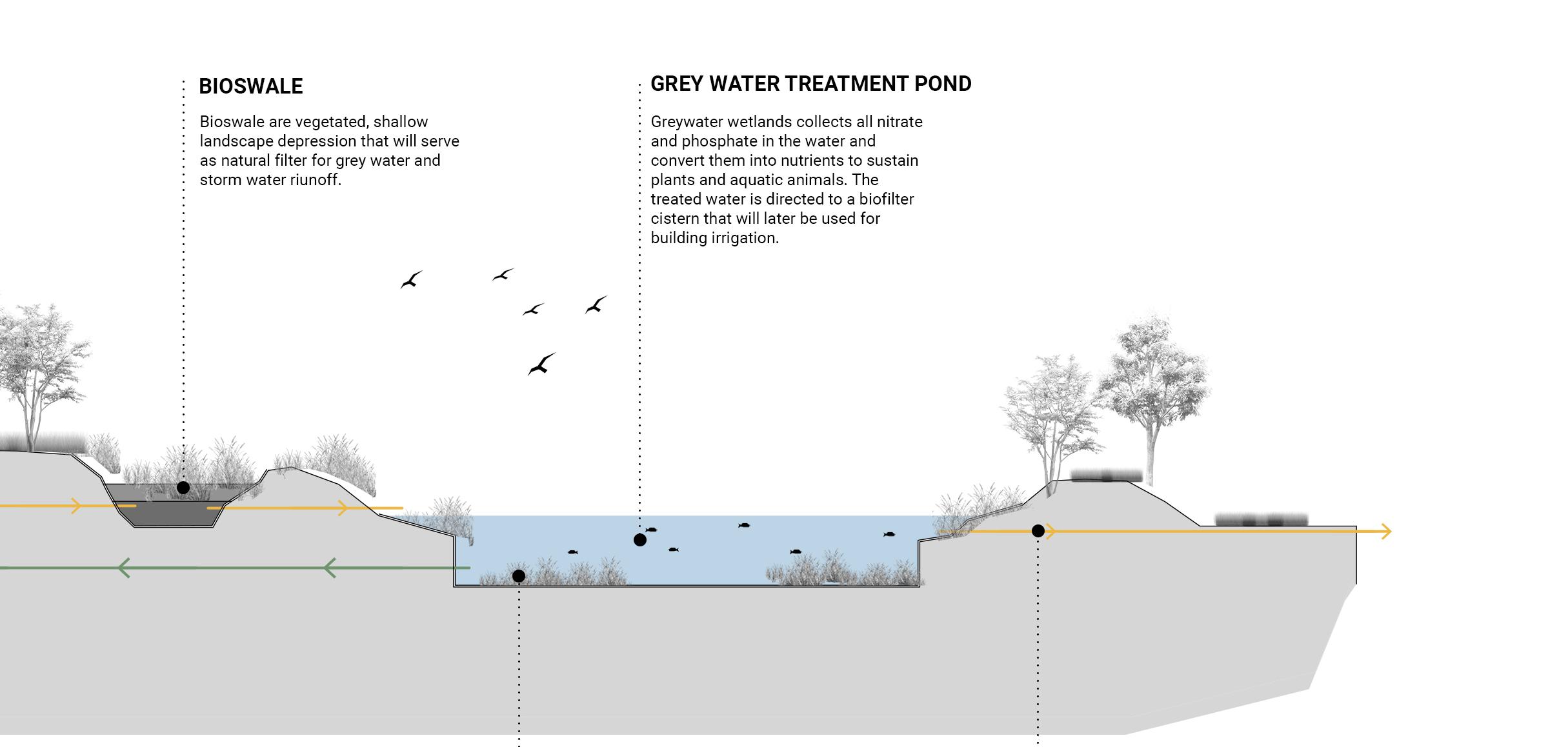

To save water for irrigation, we decided to use greywater and reuse it in conjunction with storm water to supply irrigation for private and public gardens. For the GREY water piping, all wastewater from showers, baths, and sinks is separated from the unit waste system. These pipes also converge into the core of the cluster building, where it is transitioned into three phases of artificial and natural filters. First, it is stored in an anaerobic batch reactor tank until the bacteria is removed. Then it is transferred to a bioswale where it is mixed with stormwater runoff and filtered by sand, stones, and plants. The final filter of the greywater takes place in the pond. Like in the natural wetland ecosystem, this pond comprises aquatic plants and animals that feed on contaminants such as nitrate and phosphorus. In return, the pond's nitrogen-rich water is delivered back to the building via an underground cistern with a biofilter. The cistern will be connected to the network of the building irrigation.

MACHINE LEARNING FOR FLOOR PLANS AND INTERIOR LAYOUTS