Leo Surach

PORTFOLIO METAMORPHOSES

Leo Surach

Monsuntorn Surach

Production Management / Technical Direction

(203) 627 3856

leo.surach@yale.edu

leo.surach@outlook.com

ABOUT ME

Graduated from Department of Dramatic Arts, Faculty of Arts, Chulalongkorn University and M.F.A. in Technical Design and Production from David Geffen School of Drama at Yale University. He is technical manager and designer, also co-founder of Circle Theatre.

Data driven and enthusiastic theater problem solver with four years of experience as a technical manager for small and medium theaters. He strongly believe in making sustainability and equality both on stage and backstage.

SKILLS

DOCUMENTATION

MICROSOFT OFFICES

GOOGLE SUITE

DRAFTING

AUTODESK AUTOCAD

AUTODESK INVENTOR

AUTODESK FUSION360 SKETCH UP

CNC: MACH4 AND ASPIRE 3D PRINTING: 3D CARBIDE

REFERENCES

SHAMINDA AMARAKOON

CHAIR OF TD&P DEPARTMENT

DAVID GEFFEN SCHOOL OF DRAMA AT YALE UNIVERSITY

SHAMINDA.AMARAKOON@YALE.EDU

JENNIFER McCLURE

CO-CHAIR OF TD&P DEPARTMENT

DAVID GEFFEN SCHOOL OF DRAMA AT YALE UNIVERSITY

JENNIFER.MCCLURE@YALE.EDU

SELECTED TECHNICAL WORKS

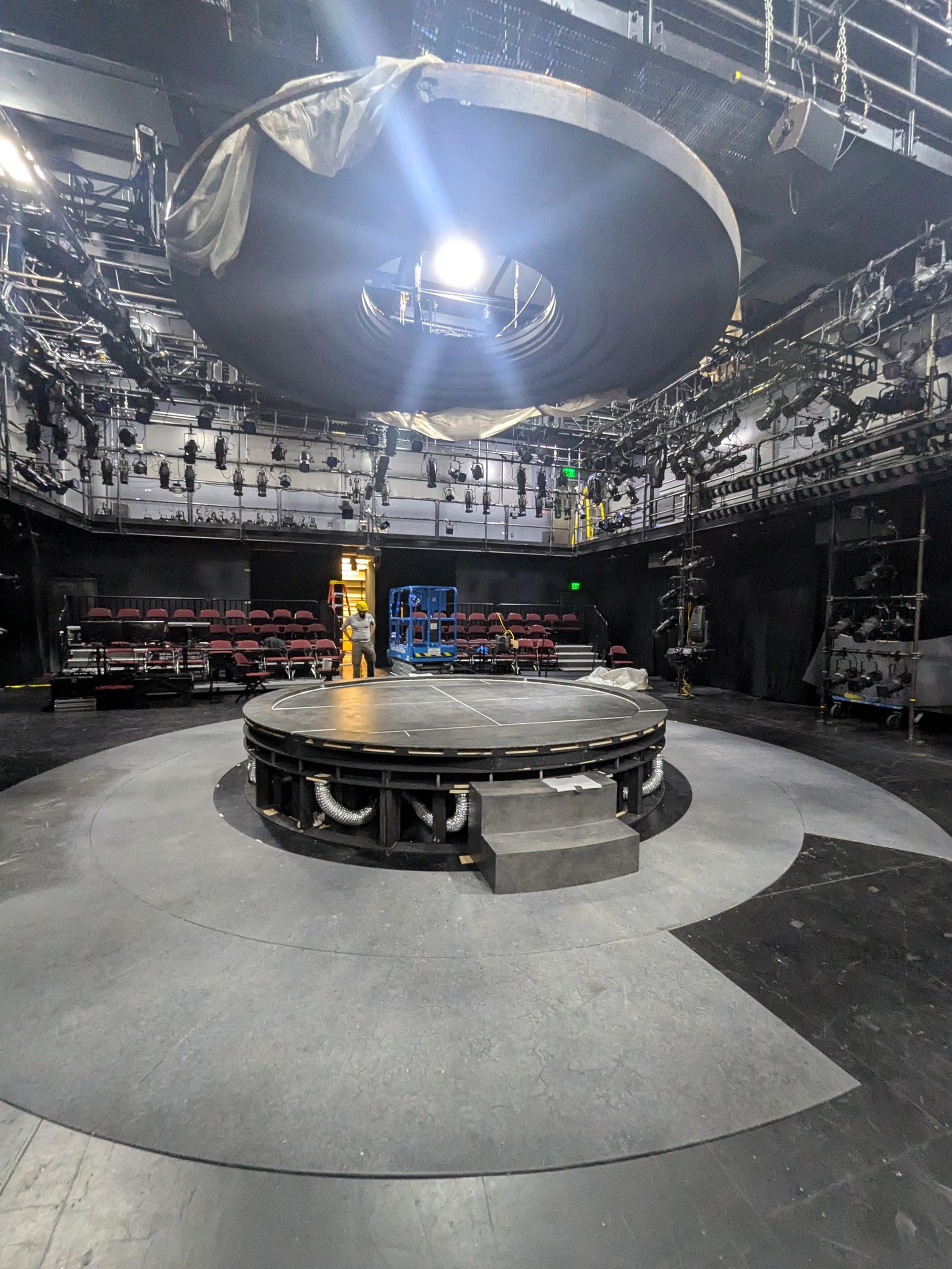

TECHNICAL DIRECTOR,

“METAMORPHOSES” AT ISEMAN THEATRE

SEP 2024 - DEC 2024 : NEW HAVEN, CT

TECHNICAL DIRECTOR,

“YOU SEE WHAT YOU SEE” AT KONDOLEON STUDIO

JAN 2024 - FEB 2024 : NEW HAVEN, CT

ASSISTANT TECHNICAL DIRECTOR, “MARY SEACOLE” AT YALE REPERTORY THEATRE

OCT 2022 - JAN 2023 : NEW HAVEN, CT

SELECTED PRODUCTION MANAGEMENT WORKS

FABRICATION

CARPENTRY: SCENIC & PROPS

WELDING: MIG

RIGGING: GRID / FLY SYSTEMS

CHAIN MOTOR INSTALL BASIC UPHOLSTERY

JONATHAN REED

ADADEMIC ADVISOR / PM SUPERVISOR

DAVID GEFFEN SCHOOL OF DRAMA AT YALE UNIVERSITY

JONATHAN.REED@YALE.EDU

LATIANA “LT” GOURZONG

TECHNICAL DIRECTION SUPERVISOR

DAVID GEFFEN SCHOOL OF DRAMA AT YALE UNIVERSITY

LATIANA.GOURZONG@YALE.EDU

PRODUCTION MANAGER,

“YALE CABARET SEASON 55” AT YALE CABARET

DEC 2023 - MAY 2023 : NEW HAVEN, CT

ASSISTANT PRODUCTION MANAGER,

“WISH YOU WERE HERE” AT YALE REPERTORY THEATRE

“FUCKING A” AT UNIVERSITY THEATRE

JUL 2023 - DEC 2023 : NEW HAVEN, CT

INTERNSHIP: SCENIC PROJECT MANAGEMENT

PRODUCTION RESOURCE GROUP, PRG SCENIC TECHNOLOGY

MAY 2024 - AUG 2024 : LAS VEGAS, NV

SELECTED PROPS MANAGEMENT WORKS

CO-PROPS MANAGER, “ESCAPE ALONE” AT YALE REPERTORY THEATRE

DEC 2023 - MAR 2024 : NEW HAVEN, CT

ASSISTANT PROPS MANAGER,

“WHO’S AFRAID OF VIRGINIA WOOLF” AT YALE REPERTORY THEATRE

JUL 2022 - OCT 2022 : NEW HAVEN, CT

Table of Content.

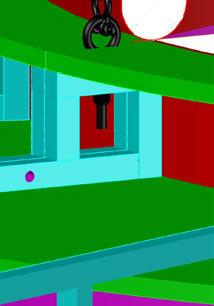

METAMORPHOSES

Based on The Myths of Ovid

Written and originally directed by

Mary Zimmerman

Directed by Alexis Kulani Woodard

Scenic Designer

Jessie Baldinger

Costume Designer

Lyle Laize Qin

Lighting Designer

Gib Gibney

Technical Director

Leo Surach

Assistant Technical Director

Lilliana Gonzalez

Aaron Frongillo

Production Manager

Timothy “TJ” Wildow

Stage Carpenter

Steven Blasberg

Lead Carpenter

Kat McCarthey

Doug Kester

Sharon Reinhart

Photo Credit: Doaa Ouf

LEO SURACH

PROJECT OVERVIEW: METAMORPHOSES

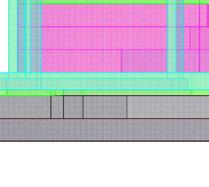

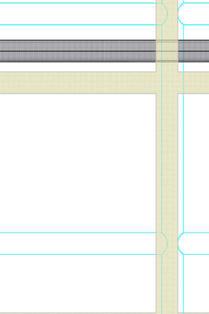

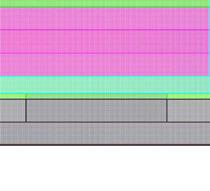

PRODUCTION CHART

LABOR DISTRIBUTION CHART

PROJECT SUMMARY

A. 11.56% over budget on Material

B. 1.8% under budget on Labor

C. Delivered all scenery on time.

PROJECT TIMELINE

Budgeting: Sep 8th - 18th

Planning & Drafting: Sep 19th - 28th (week#12-13)

Build: Sep 29th - Oct 26th (week#14-17)

Load-in: Oct 27th - Nov 5th (week#18-19)

Strike: Nov 23rd

LABOR SHORTAGE IN LOAD-IN

After Budgeting, we found out that we hadn’t have enough labor in the load-in. So, we start the build period one week earlier, and start our load-in week 16th - 17th. Which the green and blue line were 1050% higher than budgeting plan.

Although, the actual hours came close to the budgeting number. With many challenge and testing time we provided to the production. The total hours was close to the budget even we had about 20% contingency.

LINE CHART FOR TEAM COMMUNICATION

This chart was used to communicate with team to discuss about our following day /or week. We also using this to communicate with Artistic team to show them our availability and our production capacity.

PROJECT OVERVIEW: METAMORPHOSES

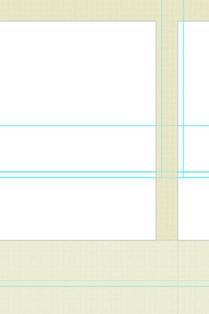

MATERIAL EXPENSE CHART

MATERIAL EXPENSE

When we first budgeted, we planned to keep a huge contingency: We needed $7499, but we budgeted about $8500 to cover unknown factors like a plastic sheet (cut later), sand (the ratio of vermiculite and the amount of sand was still unknown at that time), and the rain system. As the production went through, many factors drove the actual number up.

DRIVE FACTORS

1. Change Order from Clients on Oculus

1.1 After budgeting, $826.29 added to the Oculus in order to fulfill the design.

2. Soft Masking

2.1 Decided to change to hard masking to save load-in time ($331 added)

3. Minor Factor

3.1 Over purchased on Back-up Material

3.2 Sample

PROJECT OVERVIEW: METAMORPHOSES

HOUR TRACKING SHEET

Surach

L lliana Gonzalez

Aaron Frongi lo

Ryleigh

Tom M nucci

Steven Blasburg

Matteo L

Cian Jaspar Freem

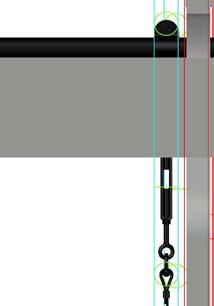

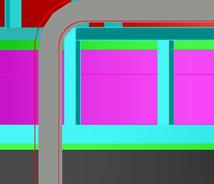

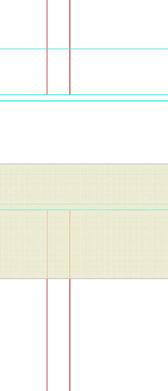

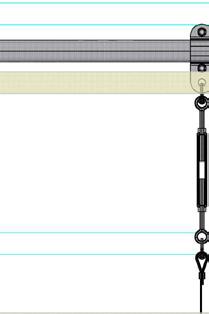

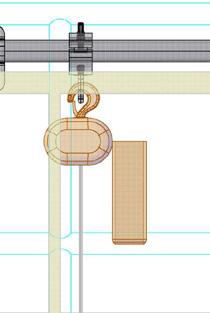

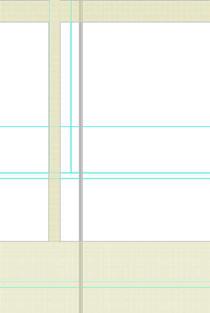

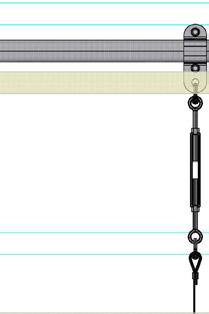

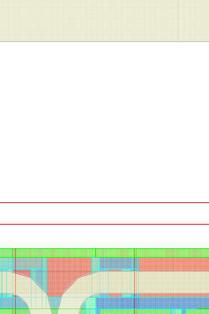

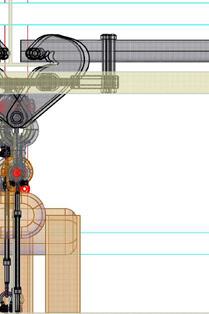

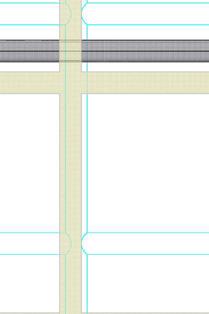

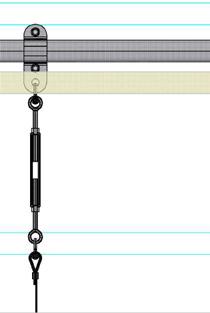

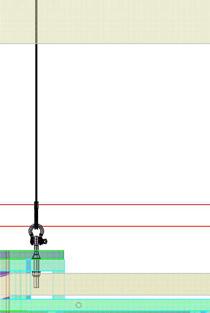

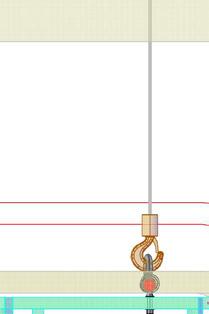

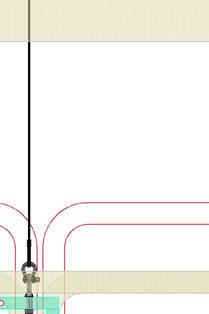

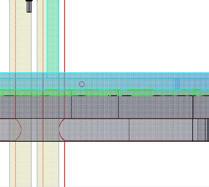

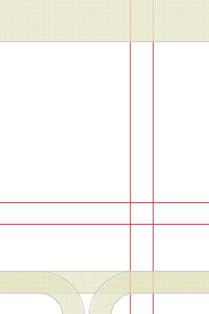

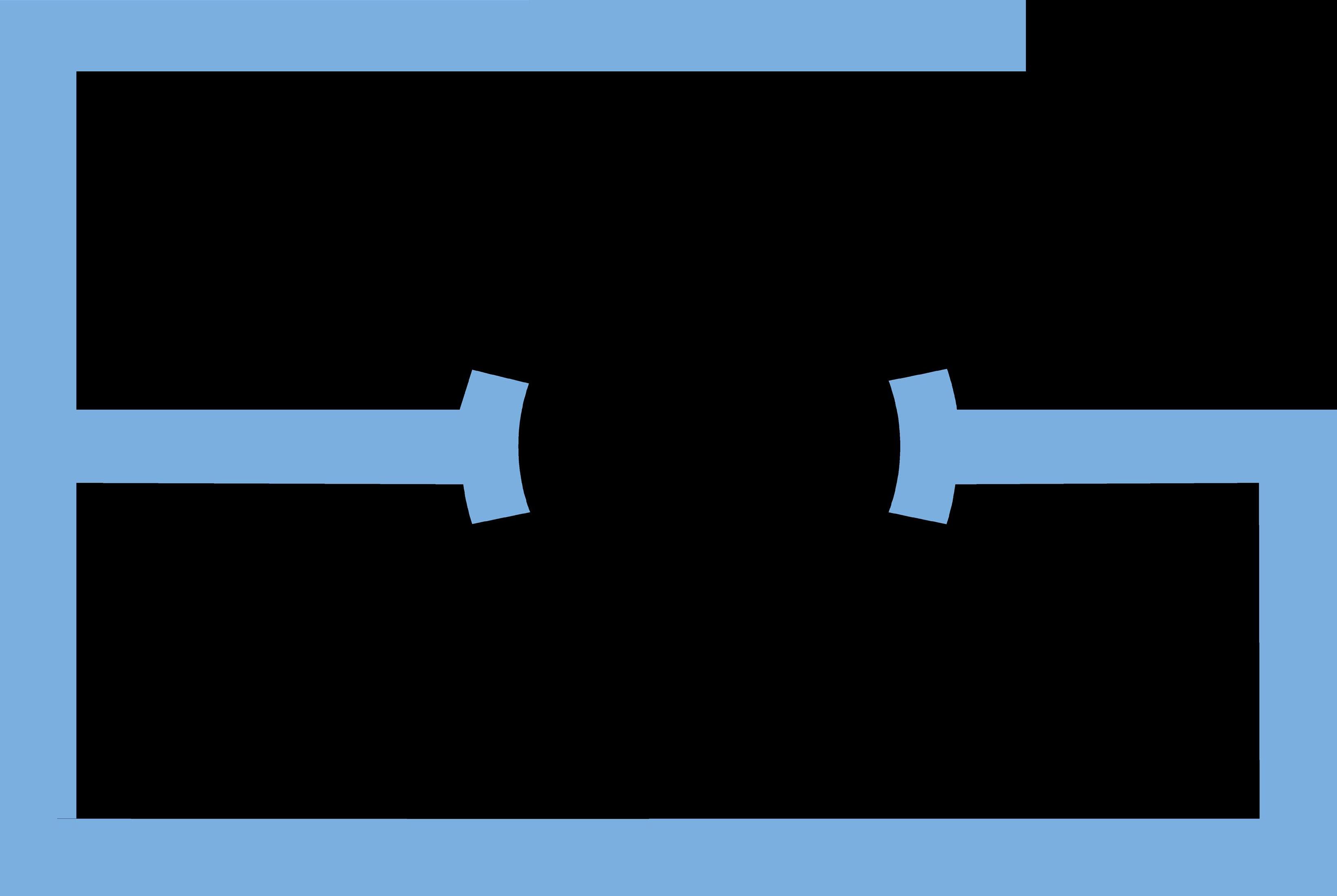

Drafted by Leo Surach SECTION PLAN

RIGGING DRAWING

Drafted by Leo Surach (SAMPLE)

(Top Left)

Showed rigging in the catwalk area. (Top Right)

Showed some revision note. (Bottom)

Showed center pipe rigging.

SCENERY DELIVERED TO PAINT SHOP

Photo by Leo Surach

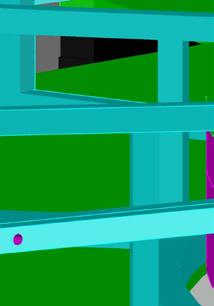

LOAD-IN PROGRESS: TESTING FOG

Photo by Leo Surach

LOAD-IN PROGRESS: TESTING FOG

Photo by Leo Surach

shc40 1-1 2" P pe

( n4) Z ( n3 wt(p f) D( nch) Tdes ( nch A( n2) E(ps ) 0 293 0 421 2 72 1 9 0 135 0 749 29000000

( ft Cat ( nch) Cat P ( bs) Fy (ps )

assume ha the p ck ng po n n at center do Case formu a 2

Ca ula ion Max

Vmax p/2 100 bs Mmax pl 4 200 t bs

P ^3/48EI 0 05423090503 nch

Ca ula ion a /240 0 2 nch

M a l Z(Fy) Ωb 7562 874251 nlbs 630 239521 ft bs

V a l 0 3FyA/Ωy 4036 526946 bs

Compar son

Max A l Pass/Fai

V 100 4036 526946 Pass

M 200 630 239521 Pass

0 05423090503 0 2 Pass

*Assume the one point pass, then two d s ributed po nt load should pass

Case Formu ar 3

Ca cu a on Max

a<b) Vmax Pb/ 126 0504202 bs Mmax Pab/ 346 6386555 t bs

[Pab(a+2b)sqr 3a(a+2b)] 27E

Pab 415800 a+2b 159

sqrt3a(a+2b) 36 2180894

Top sum 2394457570

Low sum 22941900000

0 1043704998 nch

Ca ula ion Al

/240 0 4166666667 nch

M a l Z(Fy) Ωb 7562 874251 nlbs 630 239521 ft bs

V a l 0 3FyA/Ωy 4036 526946 bs

Compar son

Max A l Pass/Fai

V 126 0504202 4036 526946 Pass

M 346 6386555 630 239521 Pass

0 1043704998 0 4166666667 Pass

*Assume the one point pass, then two d s ributed po nt load should pass

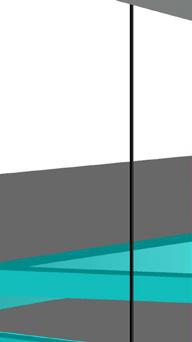

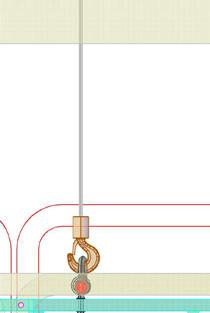

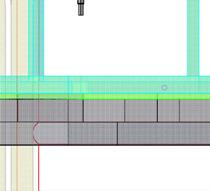

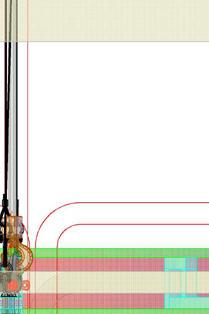

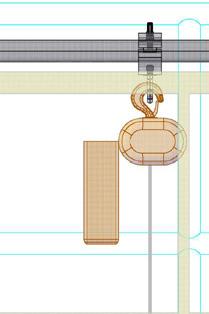

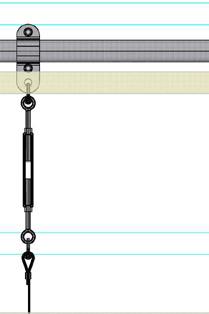

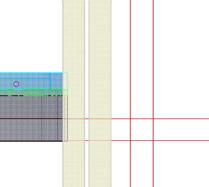

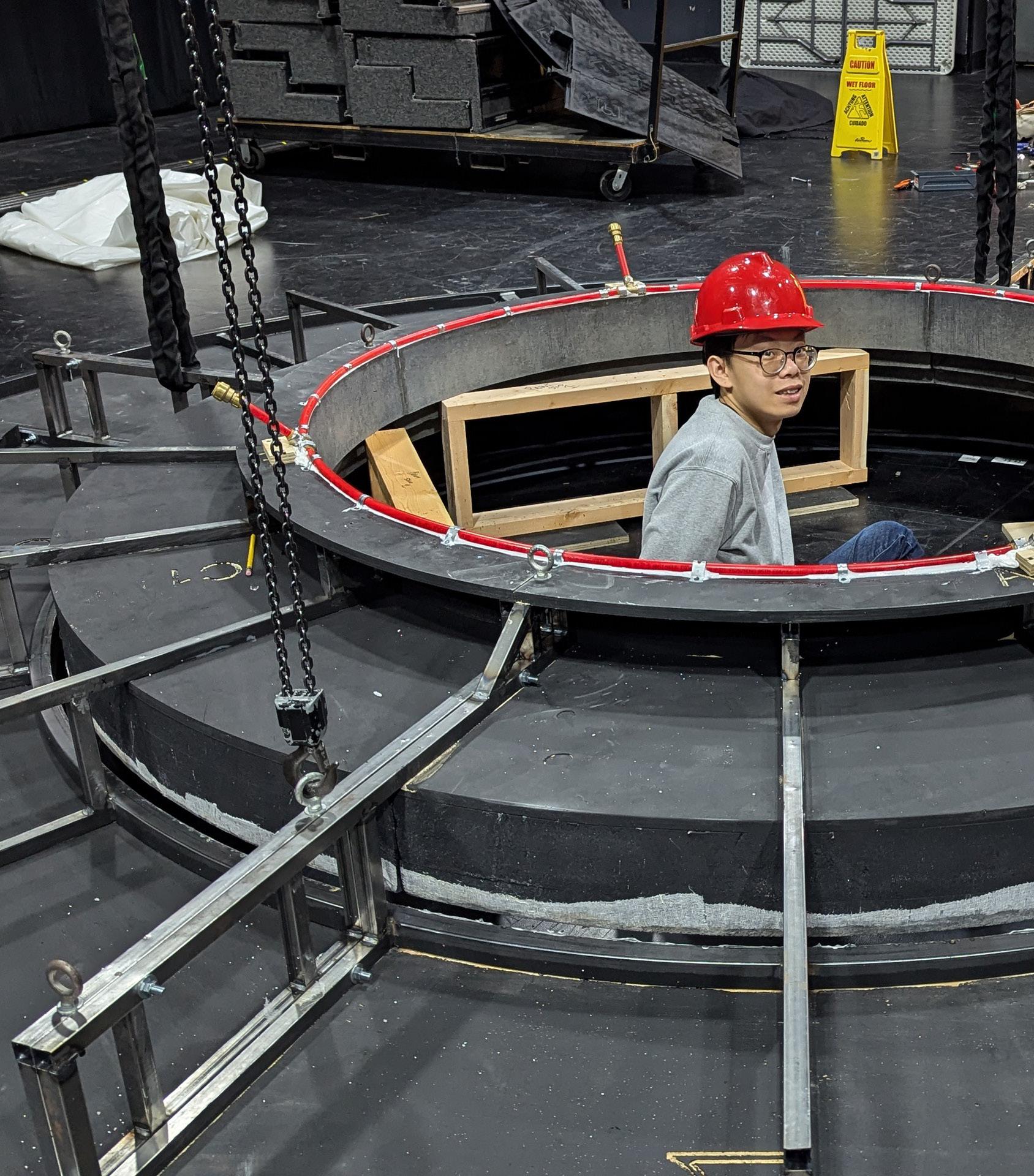

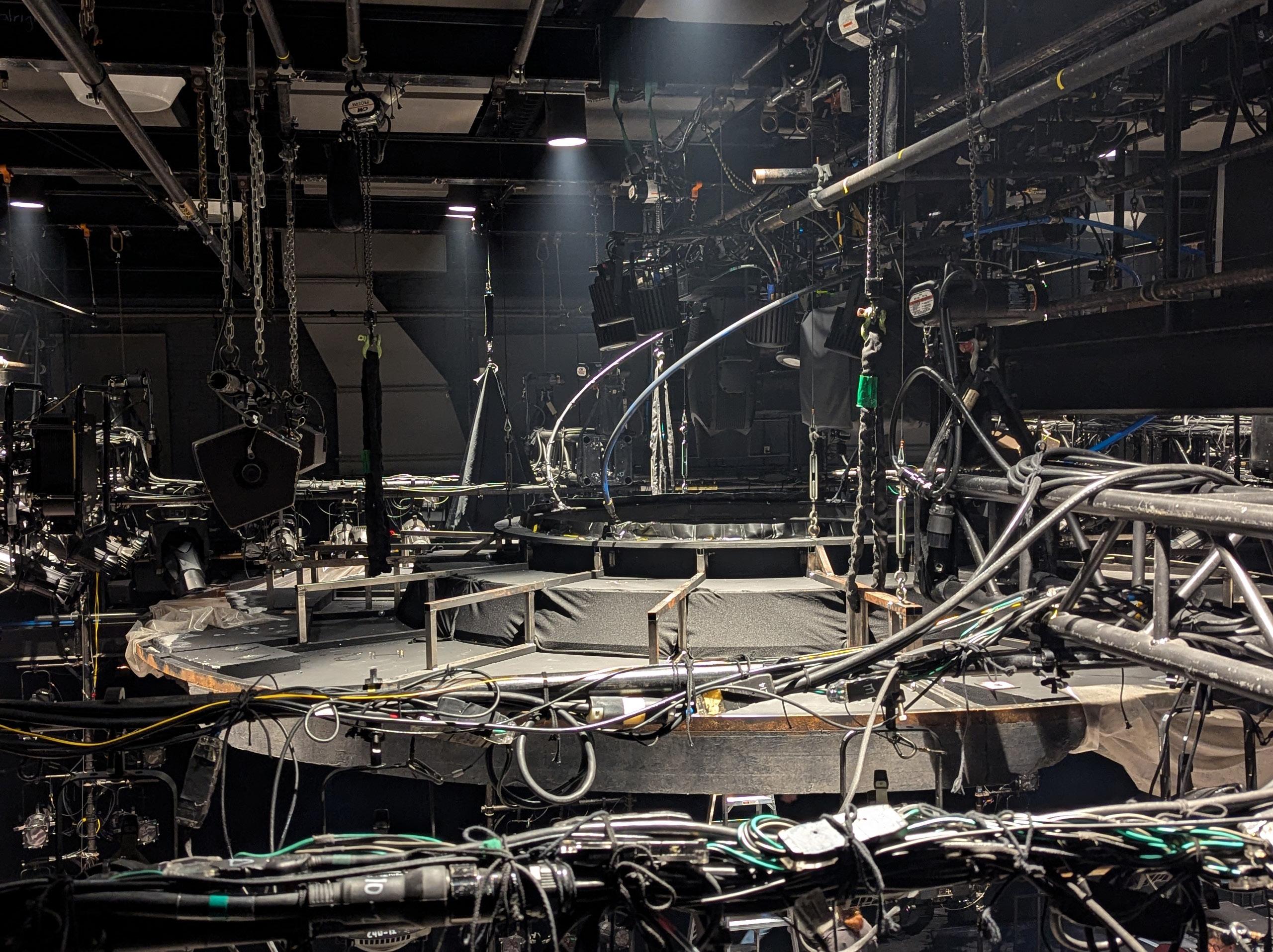

RIGGING: TOP VIEW INFRASTRUCTURE CALCULATION

Oculus divided into four pieces, the heaviest part was 187 lbs. we rigged this unit with four chain motor, so each chain motor took about 200 lbs per lifting point.

Then when this unit came up to the curtain height, we attach eight GAC lines (estimated max 100 lbs per point).

As a Technical Director, I provided two set of calculation on the structure of the Oculus (shown next page) and infrastructure capacity (next table).

Using Google Suite for accessibiliry of team to see the calculation in the shop or in the theatre space.

From the table above, there are two calculation on the 4ft added pipe and 8.25ft added pipe.

All of those location using sch40 1.5” black pipe, and they all passed shear, moment, and deflection test,

Pb/ 116 5644172 bs Mmax Pab/ 165 1329243 t bs

[Pab(a+2b)sqr 3a a+2b)]

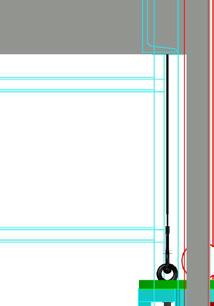

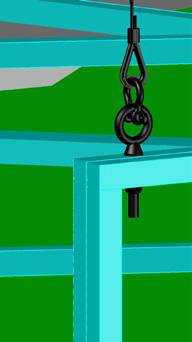

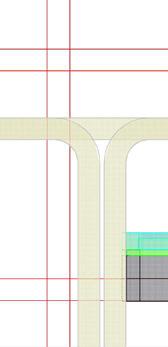

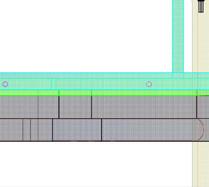

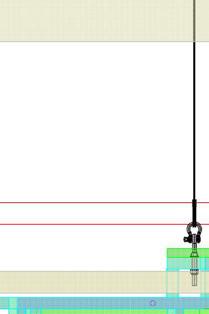

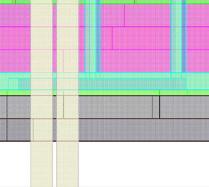

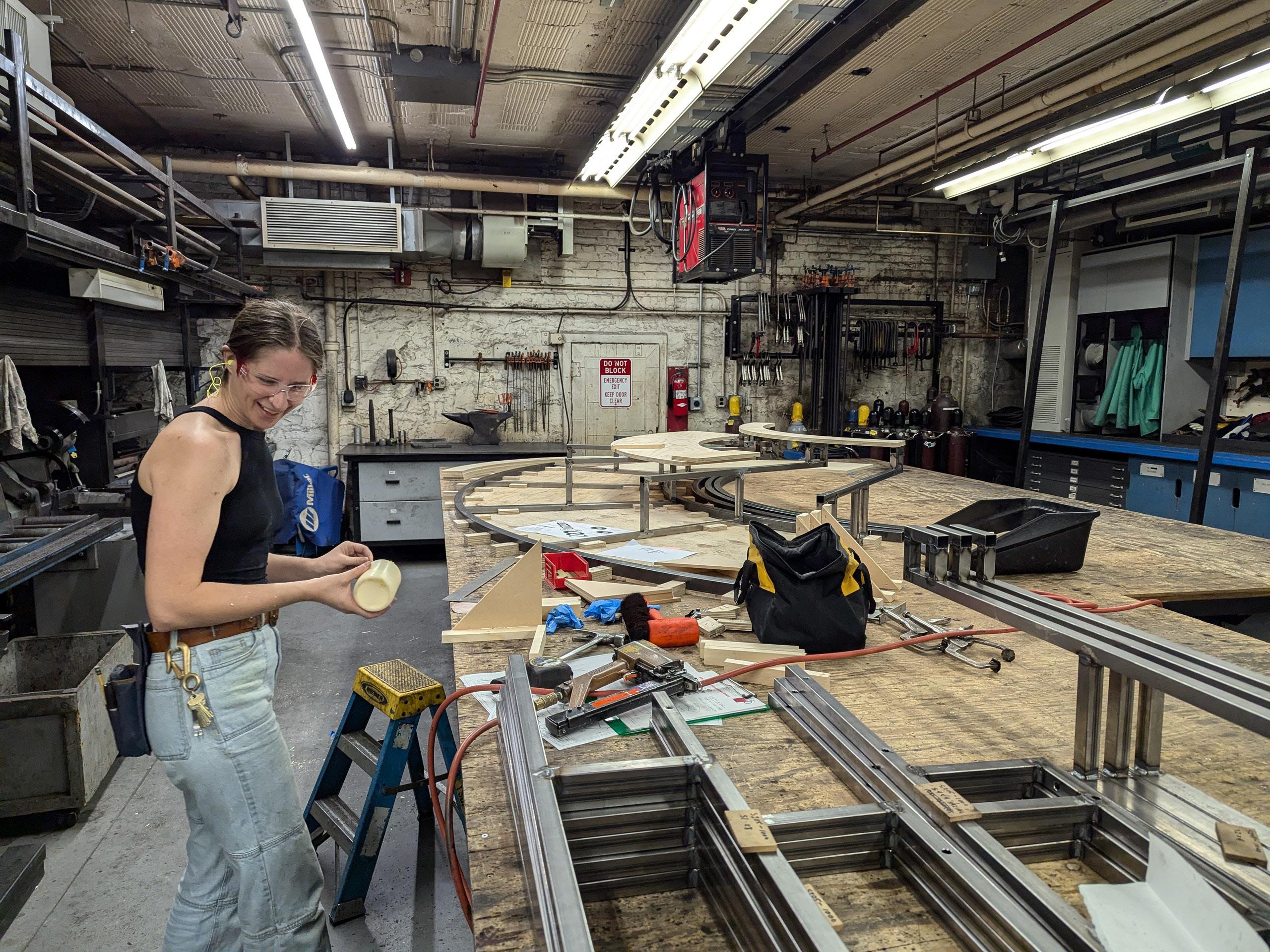

RIGGING: TOP VIEW - OCULUS STRCUTURE

Oculus consisted of framing member called “ spider leg”.

Our ATD, Lilliana Gonzalez and I working closely to select the right materials which make fabrication easier and also serve all the structural suppport. Lilliana offer 1” box tube 0.49ga. which cost and weight suit our show. I did the calculation and found out that our rigging points / lifting point needed to add some structure. (two red circle on the picture above.

976048 bs

Compar son Max A Pass/Fai

V 116 5644172 1051 976048 Pass M 165 1329243 86 22754491 Fa led 0 3467480694 0 1697916667 Fa led at 3 5" f om the p ck ng po n 1" Box ube 0 49ga

Ca cu at on Max Vmax p/2 100 bs Mmax p /4 29 16666667 t bs P ^3/48E 0 001825244785 nch

Ca u a on A l /240 0 02916666667 nch

M a Z Fy) Ωb 1034 730539 n bs

V a 0 3FyA/Ωy 1051 976048 bs

Compar son Max A Pass/Fai V 100 1051 976048 Pass M 29 16666667 86 22754491 Pass 0 02916666667 Pass 0 001825244785

OCULUS STRUCTURE CALCULATION

Using Google Suite for accessibiliry of team to see the calculation in the shop or in the theatre space.

From the table above, the calculation on the chain motor rigging point shown that those location fail moment and deflection test. The solution is simple, we added two structural member to each leg that fuction as a lifting members.

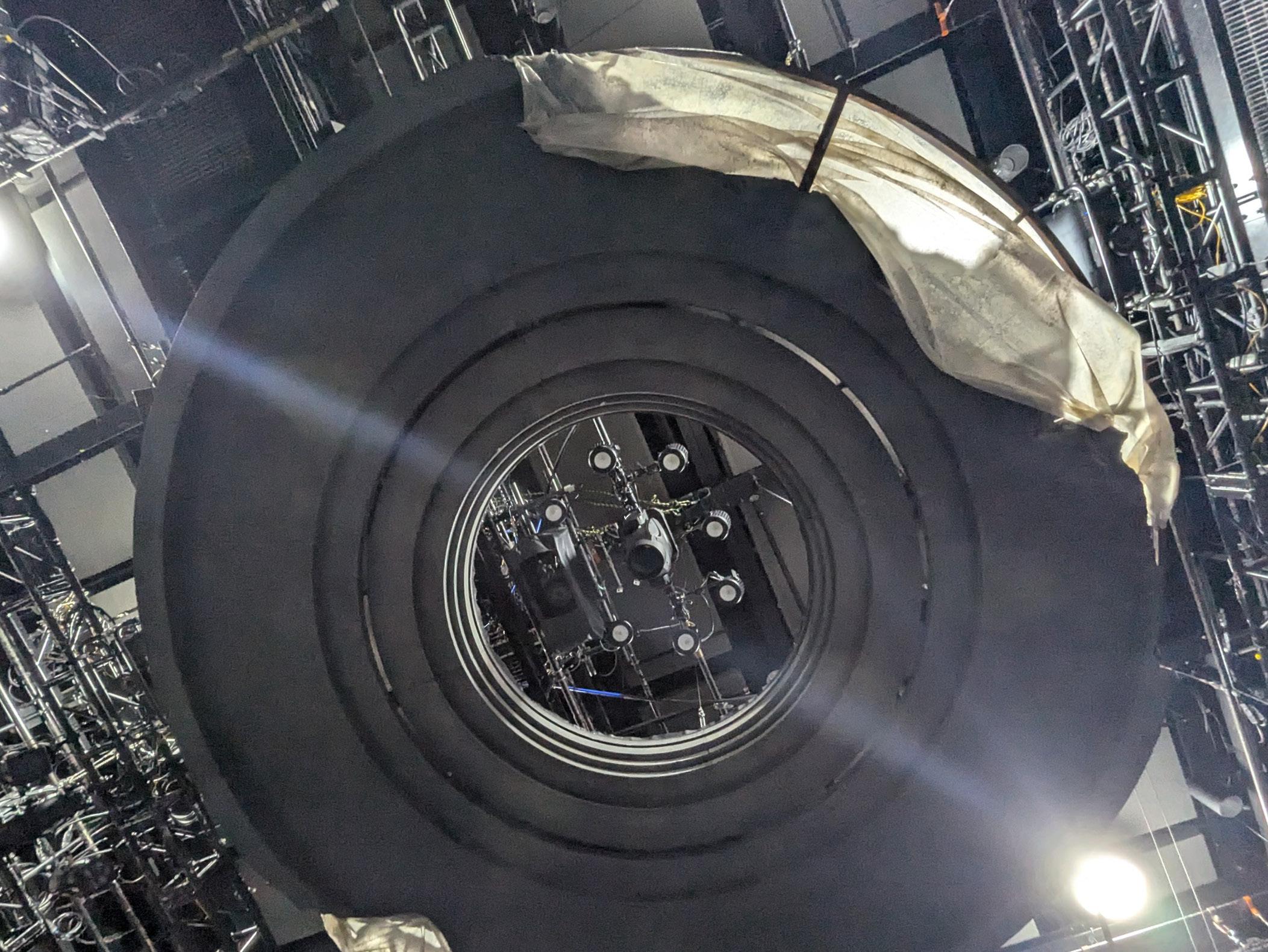

TOP OF THE OCULUS

Photo by Leo Surach

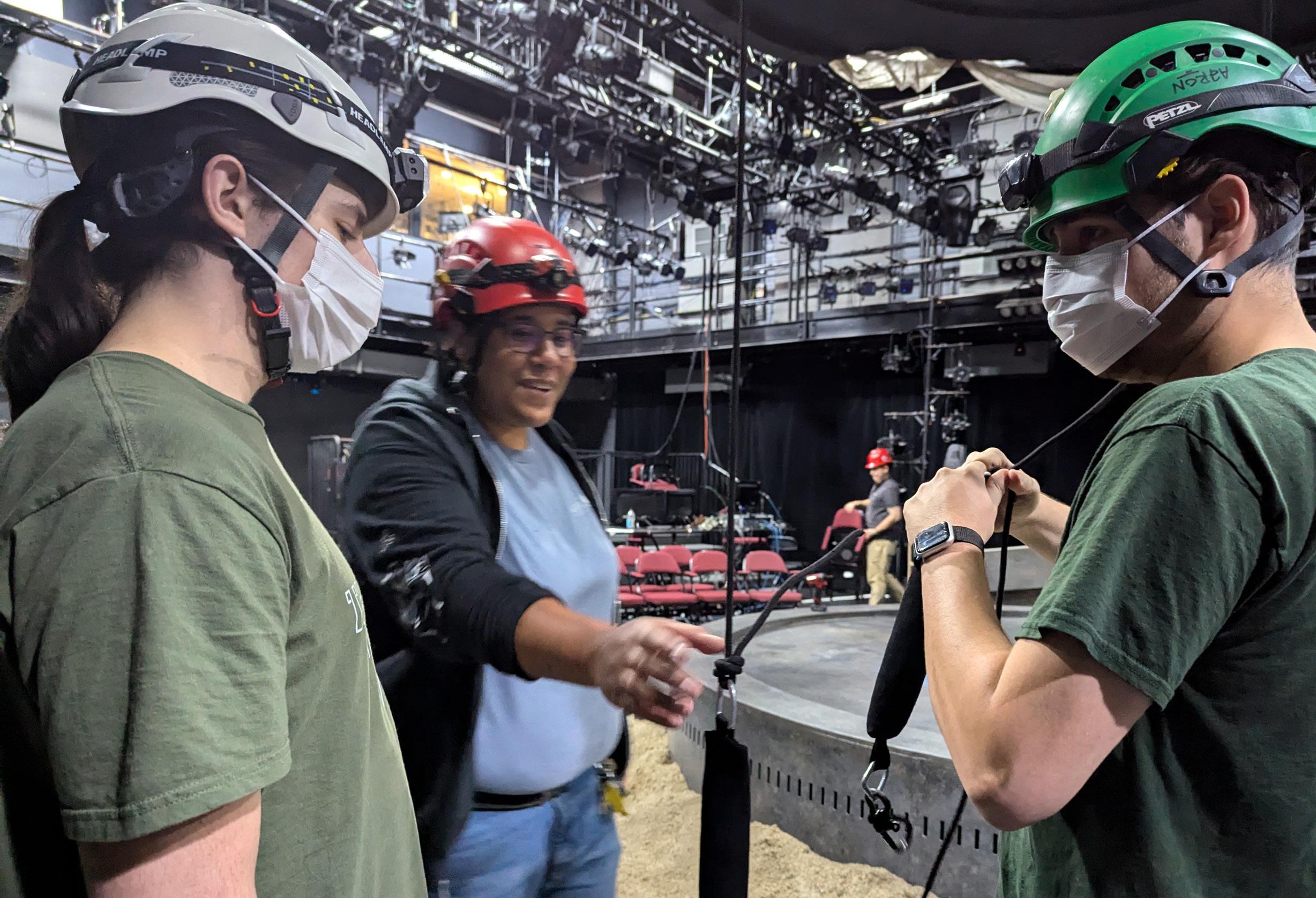

TECHNICAL REHEARSAL

Photo by Leo Surach

2.3 Disease

So, to find the right water temperature, Andrew’s mention about the Legionnaires’ Disease which the bacteria can grow in 77F-122F then he suggests.

“We should heat our water to 140F then mixed with cold water.”

But the water that come through the sink is fresh and clean, so we might not need to worry about the 140 degrees as worried about the Actor preference of warm water.

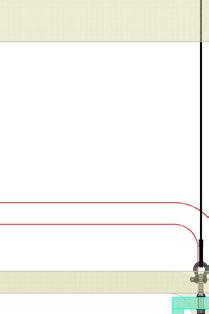

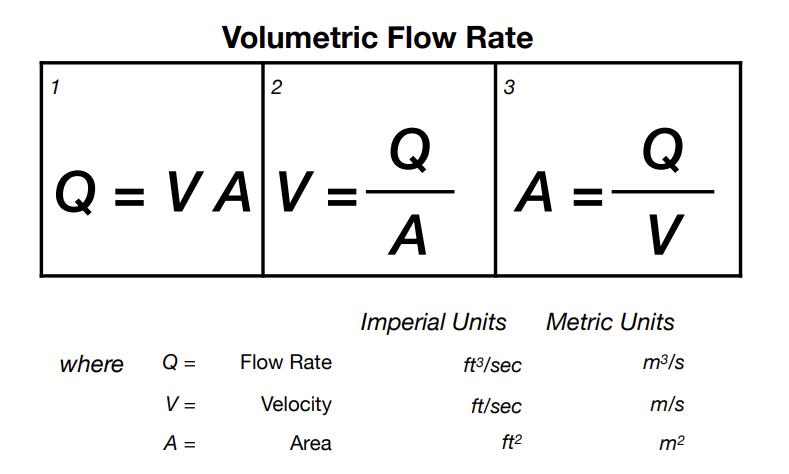

3. Calculation

3.1 Q, Flow Rate Conversion Table

It’s shown the friction loss in every 106’-9” ft; so we have 3-12 GPM / 15-40psi /1.5-4 ft/s with about 100’ travel distance. So please see the details below.

X gal/min (0.0022) = x cu.ft/sec

Min: 3 gpm (0.0022) = 0.0066 cu.ft/sec

Max: 12 gpm (0.0022) = 0.0264 cu.ft/sec

3.2 Capture Capacity

How much water we need on the deck? With 12’ dia and 2” wall

- Volume = (3.14) (6^2) (0.166667) = 18 ft^3

With the wall height that we have by now is 2” let say.

“Our rain limit is 1-1/2” – 1-3/4” of rain. So, the amount of total water we use in the system is 103-138 gal. (13.8-18.4 cu. ft)”

*I added 3”-5” height of rain in case they would like to have more rain in the future.

3.3 Run the Math

Case 1: Share the PSI from sink into both rain ring and the solenoid center given

“We have 3-6 GPM and 15-40psi to play with” (assume 1.5-4ft/s)

“Our rain limit is 1-1/2” – 1-3/4” of rain. So, the amount of total water we use in the system is 103-138 gal. (13.8-18.4 cu. fT

How long it takes to fill out the deck from the sink directly?

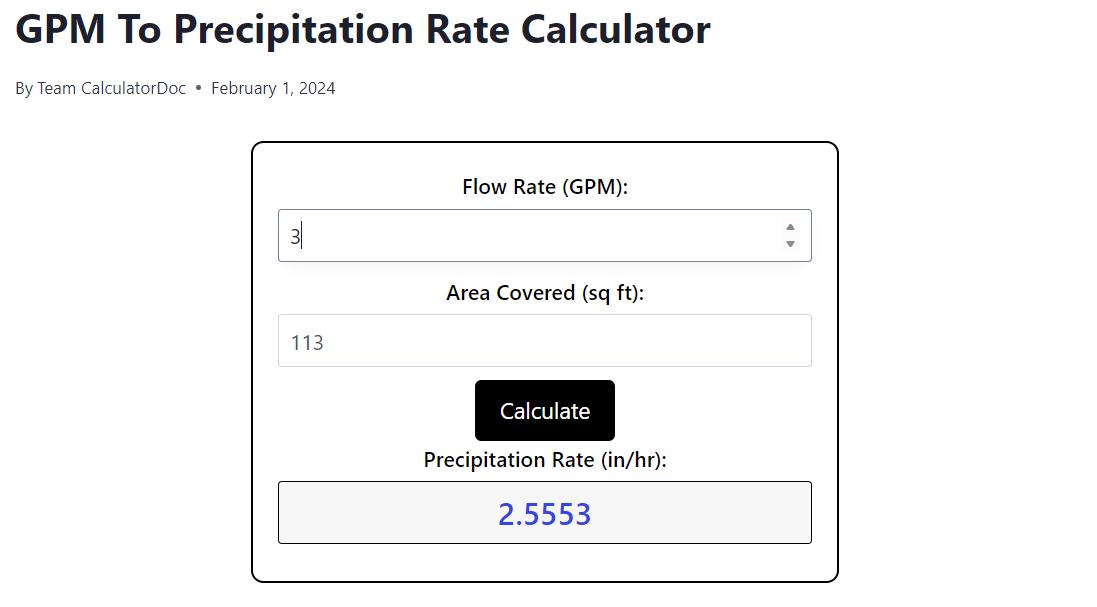

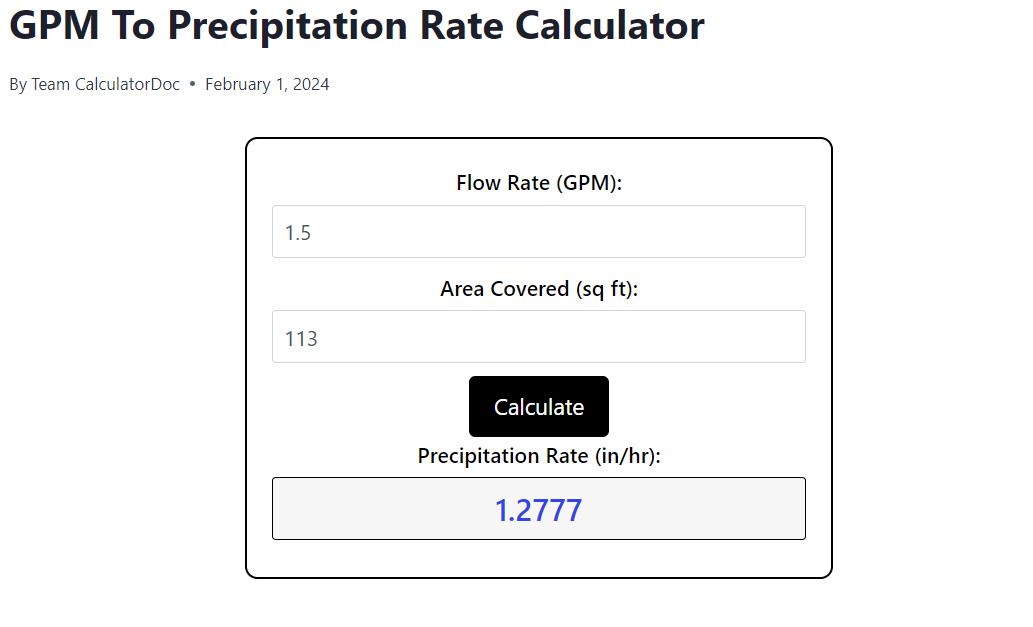

Calculator the Precipitation Rate of Rain to Compare to the visual reference

GPM To Precipitation Rate Calculator - Calculator Doc with 3gpm, we can fill the stage with 2.5 in/hr in 113sq.ft which If I am not wrong, its very good heavy rain.

*in this case as we share the pressure into two system, then the GPM per system might drop to 1.5 each (3/2) then it could look like 1in/hr Rain

Rain Rate Visualizer (weather.gov)

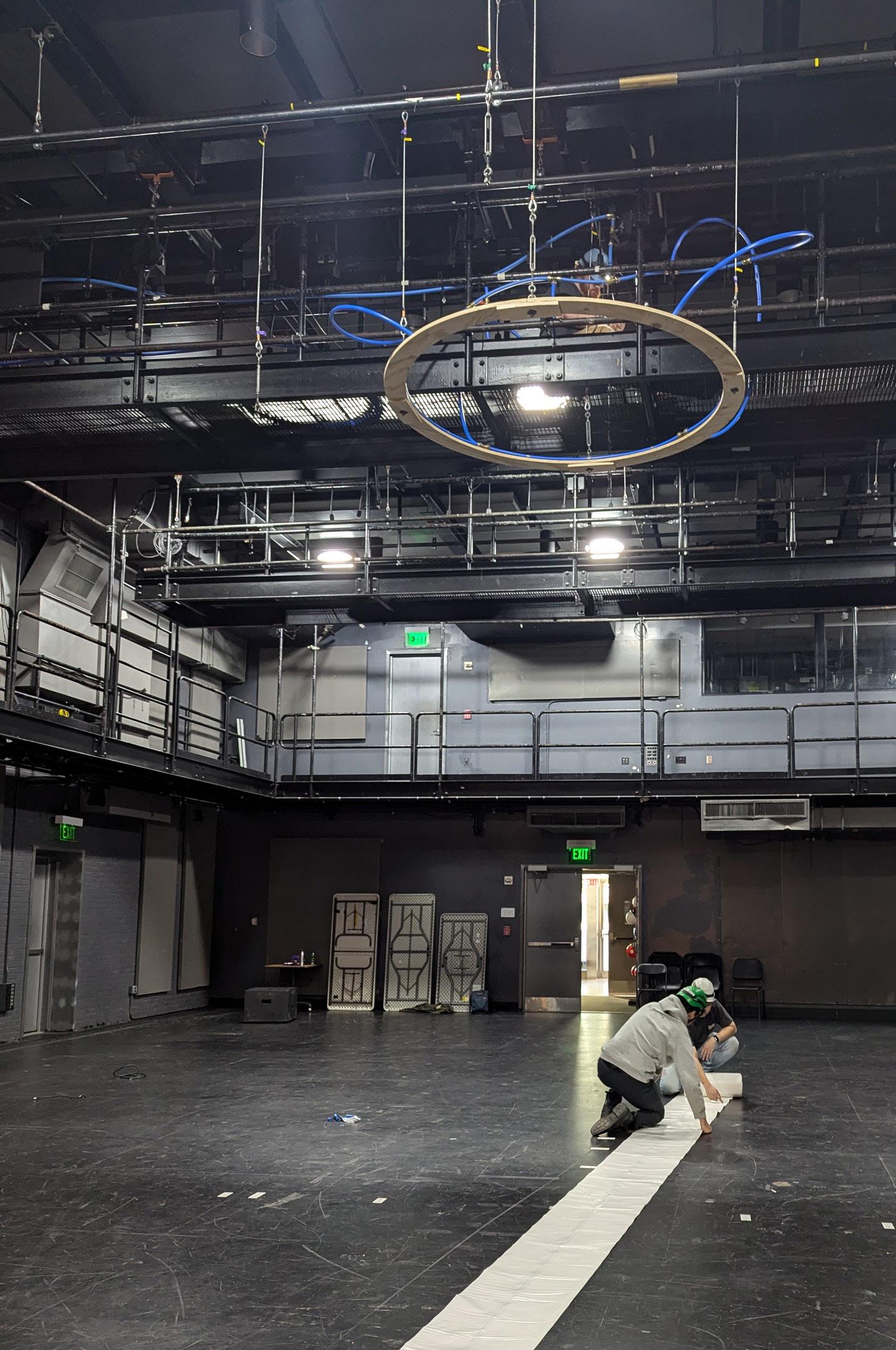

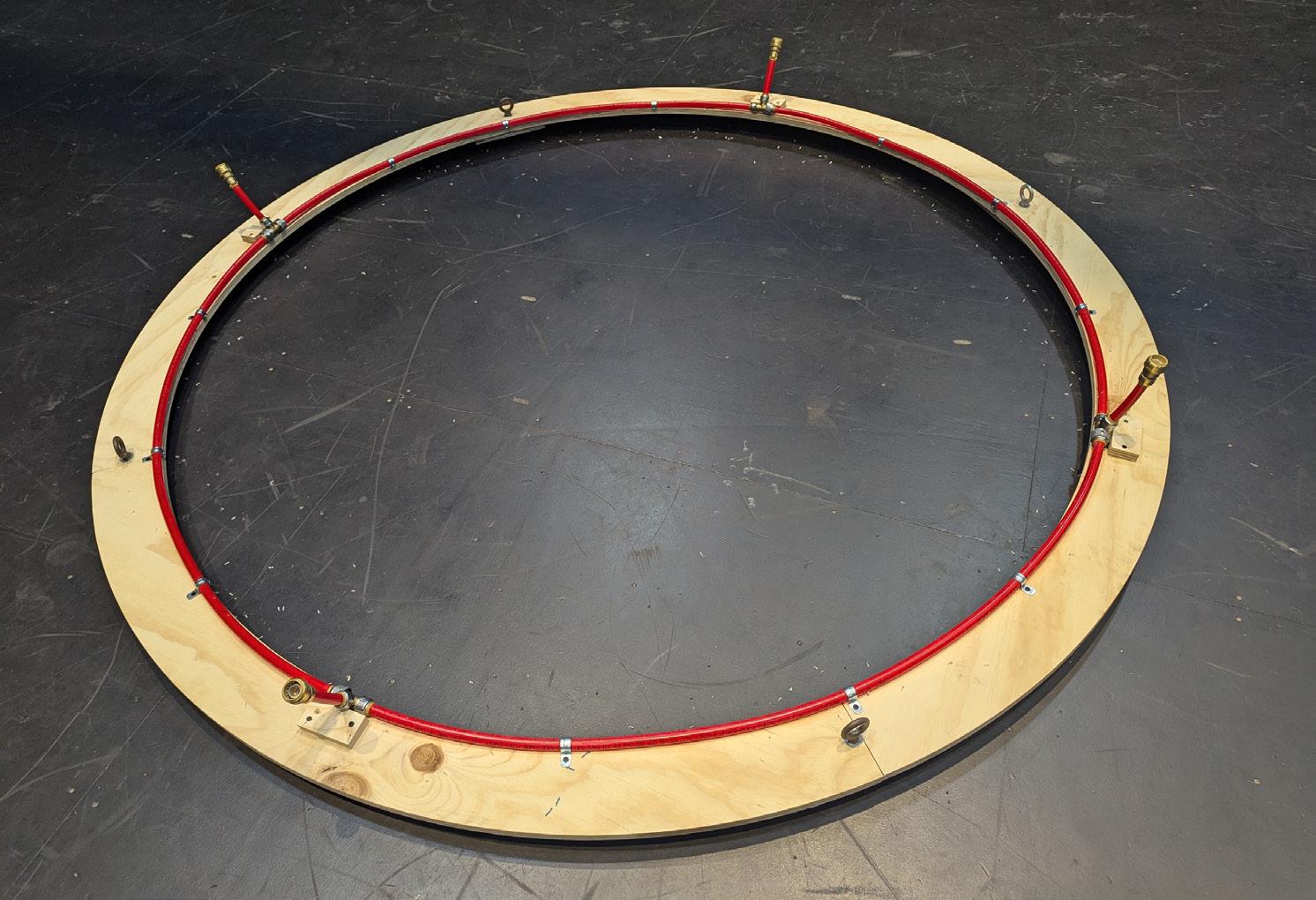

PRELOAD-IN: RAIN TESTING

(Left) Aaron Frongillo and I preped a plastic turf for the rain testing. The one shown in this photo called “baby

Oculus”. Lilliana Gonzalez lead this unit. After first couple testing, Lilliana decided to try with a smaller pipe to increase

more pressure flow in the ring (bottom right).

RING AND TANKLESS SYSTEM

We connected this system with the faucet in the shop behind the theatre. After my research on the GPM, we decided that shop faucet had enough pressure for this system. Regards of the dicease, if the water stay in the system less than 24 hours, there is no chance of Legionaire dicease. One heater to the system was enough to provide proper temperature for the actors.

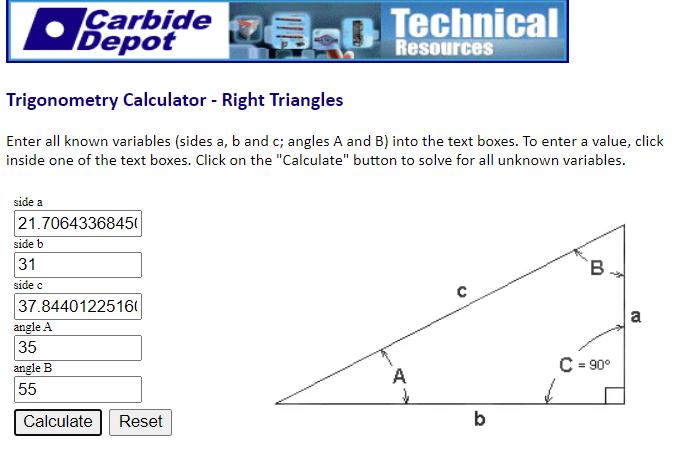

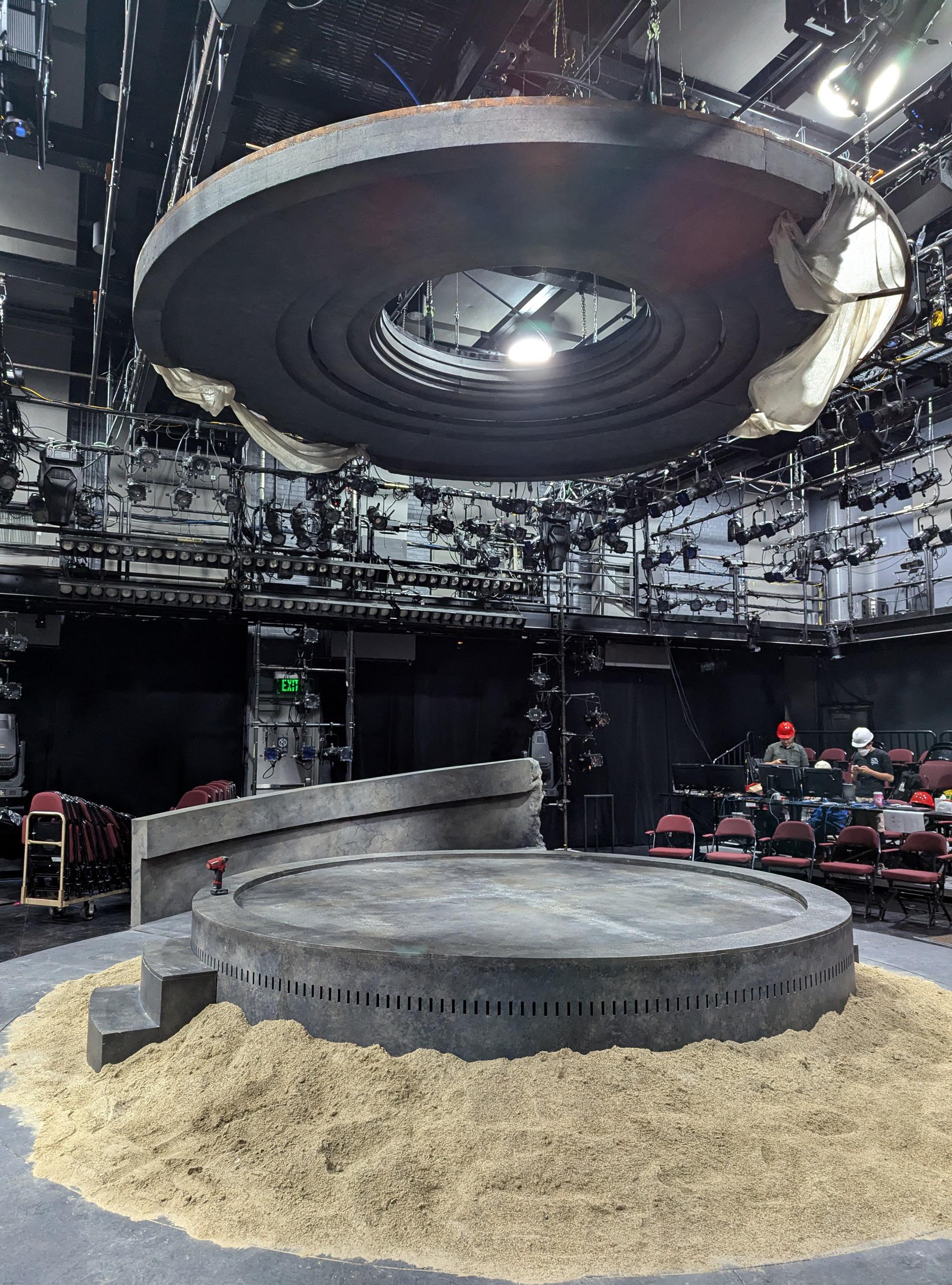

Introduction

As this show contains a pile of sand around the center deck area. I calculated the height of the pile of the sand on each side based on the angle of repose of the dry sand.

*The angle of repose is the highest angle before the pile of sand will collapse.

The angle of repose of the sand

‣ Sand (dry) 34°

‣ Sand (water filled) 15–30°

‣ Sand (wet) 45°

In DGSD2, we mixed the dry play sand wit the vermiculite, so the density of the sand will be reduced, the angle of repose will be reduced accordingly. So, with the estimation, the angle for the sand would be 30° - 35°

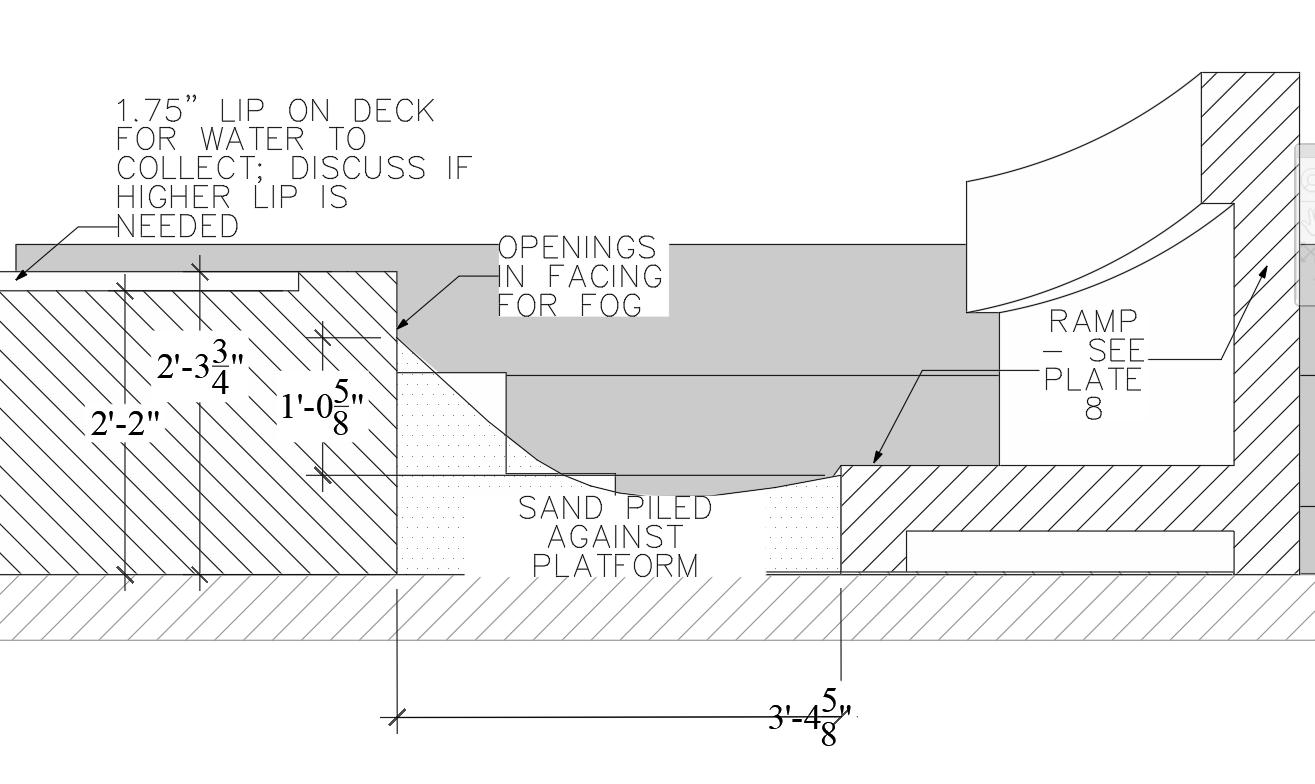

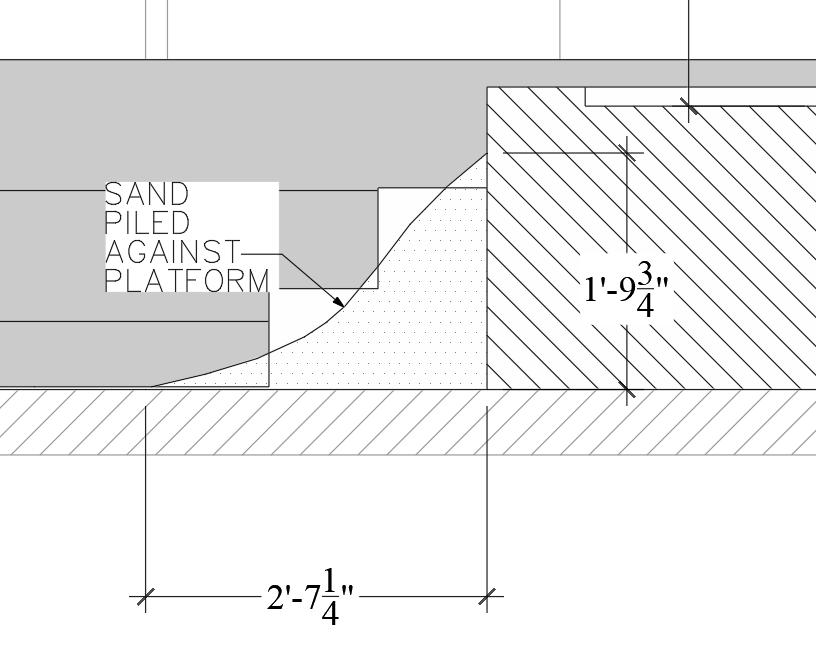

Below, There are two type of pile in the theatres

‣ The sand on the curved ramp side.

‣ The sand in other areas.

‣ The sand on the curved ramp side.

‣ With fixed angle (A) = 35° at peak and fixed distance (b) = 41” at maximum.

‣ The height of the sand in that area will be 28.7” about 2’ – 4 “which more than the drawings

The sand on the other side without the curved ramp support

‣ With fixed angle (A) = 35° at peak and fixed distance (b) = 37.8” at maximum.

‣ The height of the sand in that area will be 21.7” which is about 1’-9” which less than the drawings.

[PART OF SAND RESEARCH DURING THE BUDGETING PROCESS

Worked with Aaron Frongillo (ATD) on this unit, I provide this information about the height of the sand when we in stalled. Using basic trigomity to communicate the number with team and designer was pretty efficient.

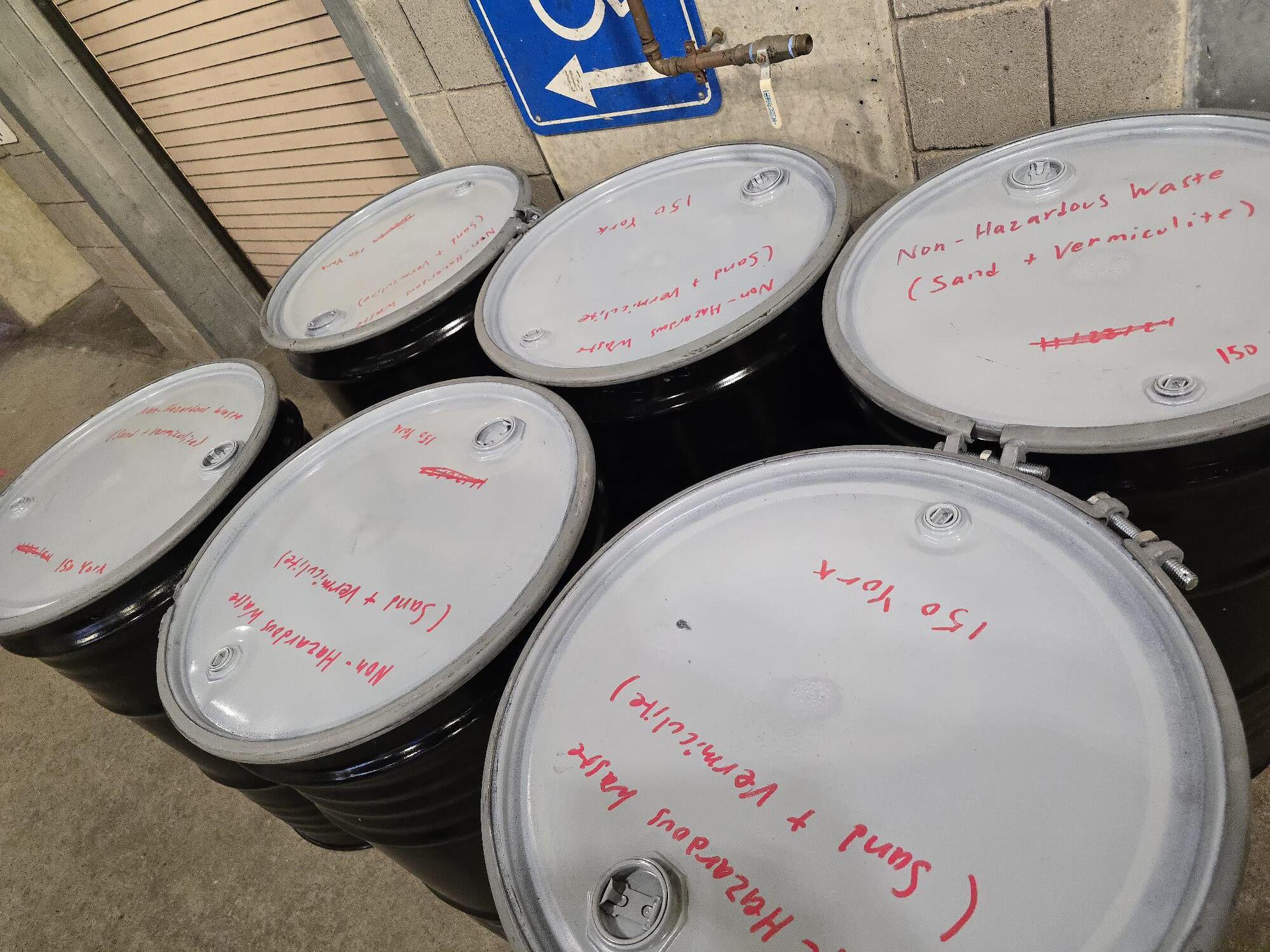

SAND MANGEMENT

(Top Left) Lilliana mixed playground sand with Vermiculite, which could help the mixture maintain the moisture longer to reduce the dust in the theatre. (top center) Aaron and I watered the sand during pre-show / pre-tech rehearsal. Also stage carpenter with crew did the watered routine with hand pump spray (water + vodka) to reduce the smell.

We used sand without silica, and send the sample to the rehearsal, so the actor could made themselve comfortable with this materials. Although we checked the SDS sheet and else. Allergy could happend at anytime.

As a Technical director of this show, I made a plan with ATDs to remove the sand if needed. We prep the plastic bags and pallet for disposal if there was any emergency case.

SAND DISPOSAL

(Bottom Left) We coordinated with Yale EHS - Yale Environmental Health & Safety to disposal this mixture safety. Eventhough , this is not a pure sand as we mixed with Vermiculite, but also not a hazardous substance, Yale EHS prefer us to drop this into sealable 50gal. drum

TESTING FOG DURING TECHNICAL REHEARSAL

Photo by Leo Surach

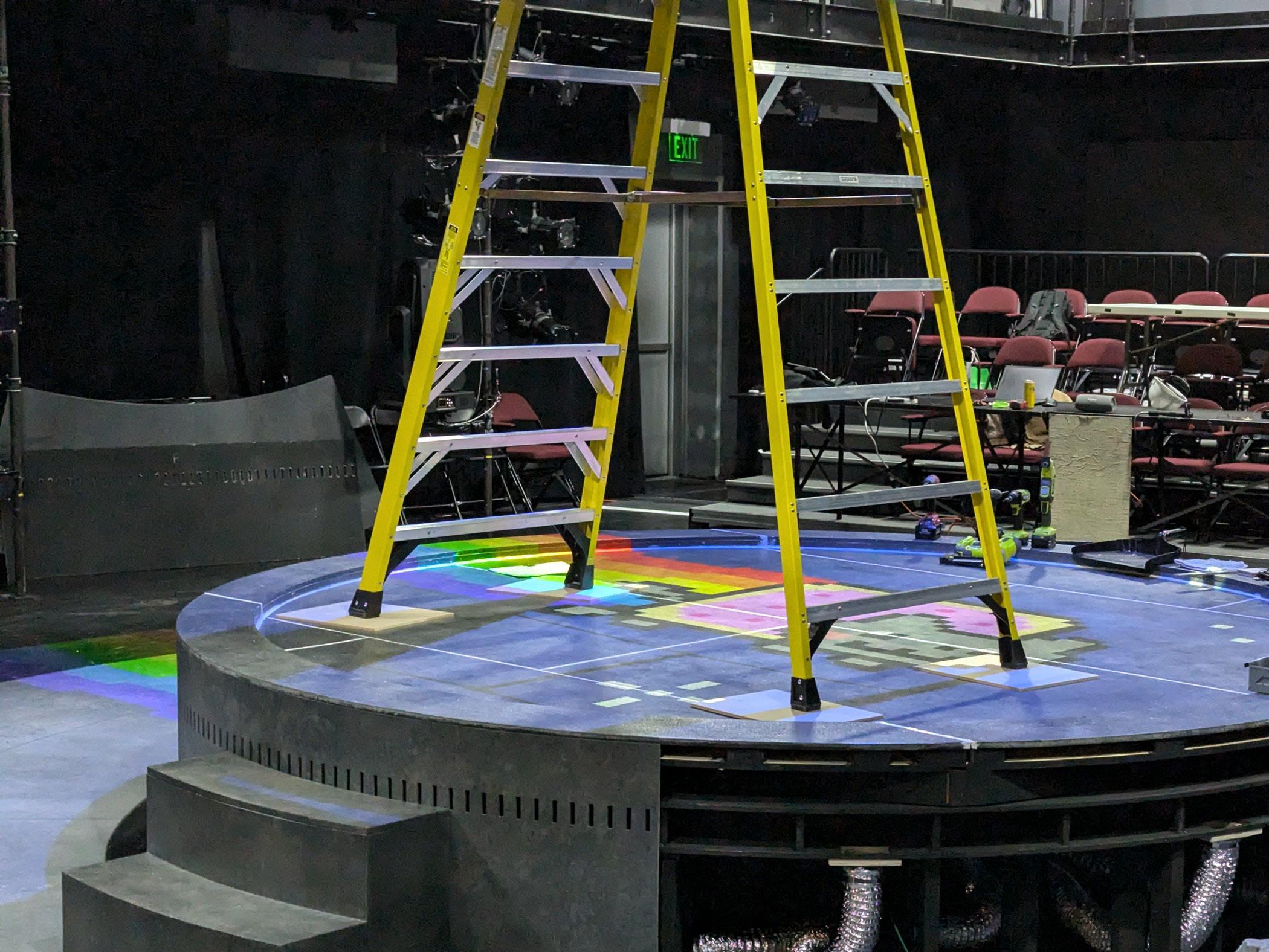

(TOP LEFT) HOW WE FOCUS THE LIGHT INSIDE OF THE OCULUS

Photo by Leo Surach

(TOP RIGHT) INSIDE THE OCULUS

Photo by Leo Surach

(BOTTOM LEFT) HOW WE SEAL THE DECK

Photo by Leo Surach

TECHNICAL TEAM / DREAM TEAM

(Top Left) Kat McCarthy (Bottom Left) Latiana “LT” Gourzong / TJ Wildow and Aaron Frongillo (Top right) Kino Alvarez (Bottom Right) Ryleight Rivas / Sean Blues / Cian Freeman / Leo Surach

TECHNICAL TEAM / DREAM TEAM

The best collaborator : Lilliana Gonzalez & Aaron Frongillo.