Welcome to TAMSEN MARITIM

Our crew today

preservation of value maritime tradition since 1850

Dear customers, crews and friends, let us introduce to you the TAMSEN MARITIM shipyard in Rostock, Germany. Since 1994 we have had more than twelve hundred dockings as one of the most well-known refit yards in Germany. Today our company is more successful than ever, with its diversification into the three main fields of ship repair, shipbuilding and the building of large composite structures. The right investments in state-of-theart facilities and in highly skilled employees as well as the constant pursuit of strategic aims have led to this success. 1.200 repairs and modernisations of all types of ships and boats, the application of the latest composite technologies for various industries as well as the further development of newbuilds from 40´ boats to 200` ships and special vessels comprise the current portfolio. For the surging need of supplying patrol boats for our authorities, we consistently apply lightweight and proven technologies to products which will be demanded by our unique and challenging customers. Success comes from the experience over the last 30 years in which many vessels of all kinds have been serviced by us. From this we draw the energy to fulfil your expectation professionally - in terms of quality - on time and budget.

Bound by tradition Christian Schmoll made in Germany

A very warm welcome to TAMSEN MARITIM

Repair Naval Vessels

Composite Systems

Repair Authority Vessels

Newbuild

Modernizations & Conversions

Repair Commercial Ships

Repair Naval Vessels

Composite Systems

Repair Authority Vessels

Newbuild

Modernizations & Conversions

Repair Commercial Ships

YARD AREA: 54.000 sqm

COVERED FACILITY: 25.000 sqm

10 WORKSHOPS: 28 m – 81 m length

4 X ACCOMMODATION BERTH: up to 90 m length

5-AXIS CNC MILLING MACHINE: 70 m x 13 m x 7 m

SHIP LIFT SYSTEM: 65 m x 20 m, 1,500 t

PIER LENGTH: 300 m

WATER DEPTH: 7 – 10 m

→ central location on the Baltic Sea coast

→ 20 min from Rostock Airport

→ close to Hamburg and Berlin

→ only 5 nm from the open sea

→ tide free water

→ local university and institutes

OUR HISTORY | ROSTOCK / GERMANY

1850 → Founding of the Neptun shipyard in Rostock

1994 → A & R Neptun Werft founded by Abeking & Rasmussen and Meyer Werft

since 1994 → Maintenance and repair work on more than 1,200 boats and ships as well as on ships of the German Navy and German authorities

1995 – 1996 → First expansion phase: Over € 23 million is invested to convert

the shipyard into one of the most modern in Europe, including construction of a ship lift with a capacity of up to 1,500 t.

2003 – 2006 → Second expansion phase:

• Total investment of € 38 million

• Production hall area increased to 25,000 m2 (total property area: 54,000 m2)

• One of the world‘s largest 5-axis CNC milling centers is installed

• Certification of the shipyard by all relevant licensing and environmental authorities

October 2009 → The shipyard gets acquired by entrepreneur Heiner Tamsen:

• Shipyard starts to operate under the name TAMSEN MARITIM

• Increased focus on governmental clients and building special vessels

• Continuous growth of turnover and the team of craftsmen and engineers

LOCATION BENEFITSFACTS

Repair Naval Vessels

The TAMSEN MARITIM team combines many years of experience, knowledge-based professionalism and the highest level of commitment when it comes to realizing our customers‘ orders. Our own high-performance targets, excellent knowhow and state-of-the-art production facilities form the basis for meeting the highest requirements of customers such as the German Navy.

High quality, great flexibility and fast decision-making processes in the company ensure that even complex repair orders can be accepted and carried out reliably.

To date, more than 1.200 ships of various types and sizes have been serviced and repaired at our location. Including a wide range of naval vessels, ranging from patrol boats to training and minehunting vessels up to corvettes.

With our expertise and experience in the field of naval ship repair, the fundament has been created to consistently continue the success of TAMSEN MARITIM and to advance our development in other business areas such as the technologically highly sophisticated conversion and new construction of naval ships.

54 m German Mine Hunting Vessel 30 m Harbor Tugboat 54 m Minesweepers Navy Vessel Upgrade 57 m Fast Patrol Boat 90 m Corvette 56 m Multi-Purpose Navy Vessel

Repair Authority Vessels

→ Structural work on hull and superstructure

→ Maintenance on all ship operating systems

→ Change of main engines and propulsion systems

→ Upgrades of navigation and communication systems

→ System modification and update to the latest technology standards

→ Working with all materials from wood to non-magnetic steel, aluminum and even carbon sandwich

→ Quality corresponds to the standards of the German Navy and classification societies

→ Diagnostic analysis of onboard systems

→ Professional sweeping and painting

28 m SAR Boat

43 m Survey Vessel

46 m SAR and OPV Vessel28

m Fire-fighting Boat20

28 m SAR Boat

43 m Survey Vessel

46 m SAR and OPV Vessel28

m Fire-fighting Boat20

65 m OPV German Boarder Police 57 m Research Vessel

28 m Customs Cruiser

Repair Commercial Ships

We repair (almost) everything that floats:

→ water surveillance and oil recovery ships

→ marine pollution control vessels

→ crew transfer vessels (CTV)

→ offshore supply vessels (OSV)

→ small waterplane area twin hulls (SWATH)

→ passenger vessels

→ ferries

→ firefighting ships

→ seismic research vessels

→ solar boats

→ submarines

→ fishery vessels

→ yachts of all kinds

→ restaurant boats

→ pleasure crafts

→ residential ships

→ work boats

→ survey vessels

→ multi-purpose vessels

→ funeral ships

→ cogs

→ drones

→ barges (hopper)

→ tugs

→ historic vessels

→ cable layers

→ sailboats

11

Traditional

27 m Habor Tugboat 28 m Oceangoing Tugboat 24 m Fast Crew Transfer Vessel

27 m

Passenger Ship

24 m Offshore Catamaran

Propulsion System Refit23 m Seagoing Passenger

60 m Hopper Barge

Vessel

35 m Luxury Sailing Yacht

Newbuild

The construction of new ships is one of TAMSEN MARITIM‘s rapidly developing business areas. Our own construction department works according to the latest technical standards and is able to process even very special projects. While in the past the focus was primarily on yachts with a length of 24 to 41 meters, the range of projects now extends to ships of all types and with a length of 10 to 70 meters. Our design engineers convince with independent innovative solutions and the aspiration of the best possible engineering into the products on behalf of our customers.

TAMSEN MARITIM is currently offering a line of new construction projects. Our company can proudly assure our customers that it builds new ships in accordance with our maxim for engineering efficiency and quality „Made in Germany“ and that it supplies high-tech products of long-term value.

We invite you to have a closer look into our newbuild department of SAR, special and patrol vessels.

23 m Fast Lightweight Hull (under construction) 17 m Fast

Aluminum welding and construction 20 m Navy Vessel Steelwork (under construction) 20 m Special Navy Vessel (2 vessels; contract signed) 23 m Patrol Boat 3D-Design

In-house Design

Patrol Boat (contract signed)

/

Department

Today TAMSEN MARITIM has established itself as the high-quality builder for workboats of highest demands. We are proud to serve for the German Maritime Search and Rescue Service with a series of 12 special emergency SAR boats so far. The German customs has ordered two 23 m patrol boats for operation in shallow waters.

These vessels have a high noise and vibration standard, a really efficient boat shape and the latest technology of an exhaust treatment system.

For the “parent” German Navy we have been contracted to build two safety vessels. These are about 20 m long steel boats operating as assistant vessels during the exercises of the German Navy frigates in the Baltic Sea.

The patrol boat family of TAMSEN MARITIM has with its new 17 m fast patrol boat another high-performance member dedicated for policing and fishery protection, customs and also SAR duties. These programs will be continued soon.

16

Engine installation

17 m Ultra

Fast Interceptor

23 m Patrol Boat for Coast Guard and Customs Duties

34 m Coast Guard study

25 m Fast Motor Yacht

10 m SAR Boat at the Baltic Sea

during training

11 m SAR Aluminum

productionCraftsmen

Design, Research & Development

With our own design department, the engineers are creating our family of vessels from the first sketch to the tested and ready-to-use boat including integrated logistics support (ILS).

The research and development team is dedicated to analyze new technologies and trends and support the team of inhouse designers with their scientific research results.

Proven concepts are discussed in an open way to find room for improvements like carbon free energy solutions for the propulsion systems.

The team is also focusing on low resistance, lightweight, slender hull shapes with foil support for future generations of human transport vessels using the latest technologies.

As a leading member of a research association for the development of emission-free electric mobility, we develop innovative solutions for future transport in urban sea areas.

of

3D Engine Room

Patrol Boat3D Bridge Design High Performance Propulsion Systems

34 m Patrol Boat Design

3D Hull Shape

CFD Analysis Hull

R & D Team Meeting

Composite Systems

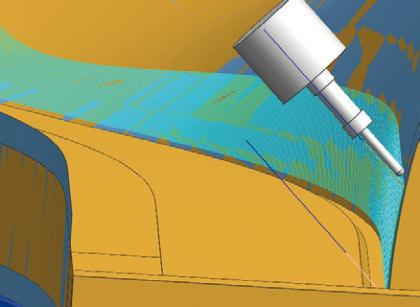

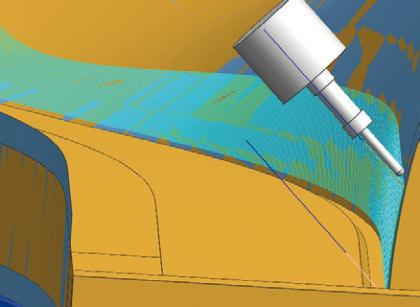

TAMSEN MARITIM’s broad portfolio of productions includes the treatment and processing of composite materials. In order to be able to implement even the most demanding projects in terms of design and dimensions, Europe‘s largest 5-axis CNC milling center is available in our company. In addition to maritime products such as ship hulls, in particular components for the wind industry are created by us, including master models, molds and composite parts with a length of up to 85 meters.

The 5-axis CNC milling center and other modern processing facilities ensure high product quality, great precision, short delivery times, and compliance with applicable standards. Together with our customers, our engineers develop specific production methods and quality parameters. They bring many years of experience, the latest knowledge and innovative materials to the table and thus ensure the successful completion of every project to the satisfaction of our customers.

48 m Direct Motor Yacht Mould70 m x 13 m x 7 m Working Area Plug and Mould of a 60 m + Rotor Blade

transport

m Hull Demoulding

Process

Special tasks and special people

5-Axis CNC Milling Machine

Product

25

Milling head details Lamination

Milling program model

DEPARTMENTS: Refit & Repair, Modifications, Conversions, Newbuild, Composite, CNC milling / plug manufacturing, Training & Offshore Service ANNUAL TURNOVER 2009 – 2022: increase by 500 % PERSONNEL: 140 employees, 30 engineers SPECIALS FEATURES: in-house design department, research & development department, service department The Shipyard WORKSHOPS: LBHCRANE CAPACITY HEATING MMMSYSTEM 0 81 (89)23164 x 6.3 tyes 1 74 (87)24252 x 16 tyes 2 53 (68)14152 x 10 tyes 4.1 60 (67)15.516.58 x 16 tyes 4.2 60 (67)15.516.58 x 16 tyes 4.3 28 (35)1716.54 x 6.3 tyes 4.4 3220121 x 2 tyes 5.0 7020184 x 25 tyes Outdoor I 100201 x 20 t Outdoor II 7030 4.40124.14.24.35.0 Outdoor II Outdoor I

TAMSEN MARITIM GmbH

Maritimstraße 1 | 18147 Rostock, Germany

Phone: +49 (0) 381 65 81 0 | Fax: +49 (0) 381 65 81 104

info@tamsen-maritim.de

For more information please visit our websites: www.tamsen-maritim.de

•

•

•

•

•

•

•

•

•

•

www.tamsen.com The world of TAMSEN MARITIM´s customer countries … … to be continued Australia • Turkey • Sweden • Morocco • United Kingdom • United Arab Emirates • Spain • Denmark

Japan

China

Germany

USA

France

Singapore

South Africa

Austria

Switzerland

Italy

Repair Naval Vessels

Composite Systems

Repair Authority Vessels

Newbuild

Modernizations & Conversions

Repair Commercial Ships

Repair Naval Vessels

Composite Systems

Repair Authority Vessels

Newbuild

Modernizations & Conversions

Repair Commercial Ships

28 m SAR Boat

43 m Survey Vessel

46 m SAR and OPV Vessel28

m Fire-fighting Boat20

28 m SAR Boat

43 m Survey Vessel

46 m SAR and OPV Vessel28

m Fire-fighting Boat20

32 m Buoy Layer and Ice Breaker

44 m Offshore Patrol Vessel

32 m Buoy Layer and Ice Breaker

44 m Offshore Patrol Vessel