An architectural practice which is based in Mysore and Mangalore, 2PKM Architects has a team of young, motivated architects and engineers who strive to deliver projects of different typologies and scale. As an intern, the firm assisted me in improving various software skills as well as artistic and creative skills with daily and weekly activities. The office also provides exposure to the system of running a firm, communication with the vendors, meeting with clients, and the technical aspects of a drawing that has to be sent to the site with never-ending deadlines and a few sleepless nights, the firm helped me take one step closer to confidence.

The design boasts sleek, utilitarian, curved features and pastel tones, creating a modern and sophisticated aesthetic. The curved features add a soft, organic touch to the otherwise clean lines of the home, while the pastel tones adds a touch of playfulness to the space, making it feel welcoming and approachable. Overall, these features gives this home a unique look.

WORKED ON: 3D CORRECTIONS AND RENDERINGS

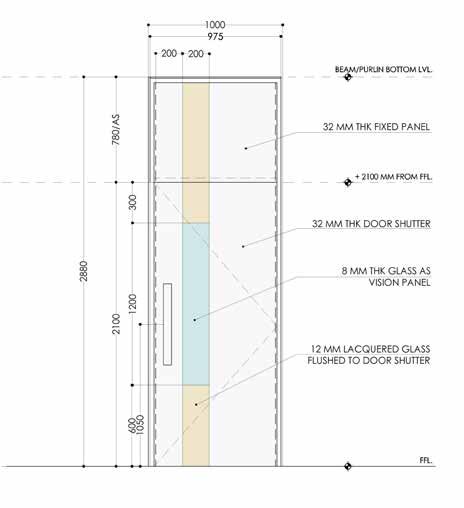

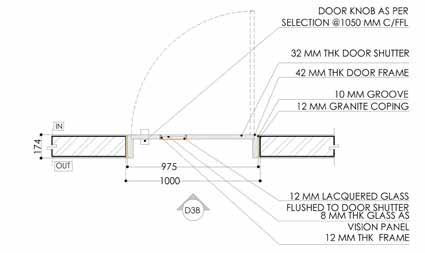

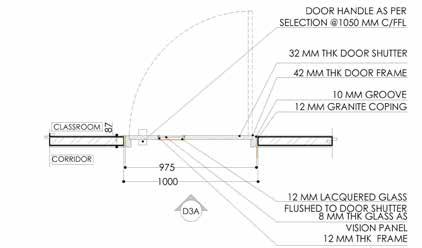

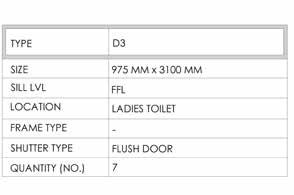

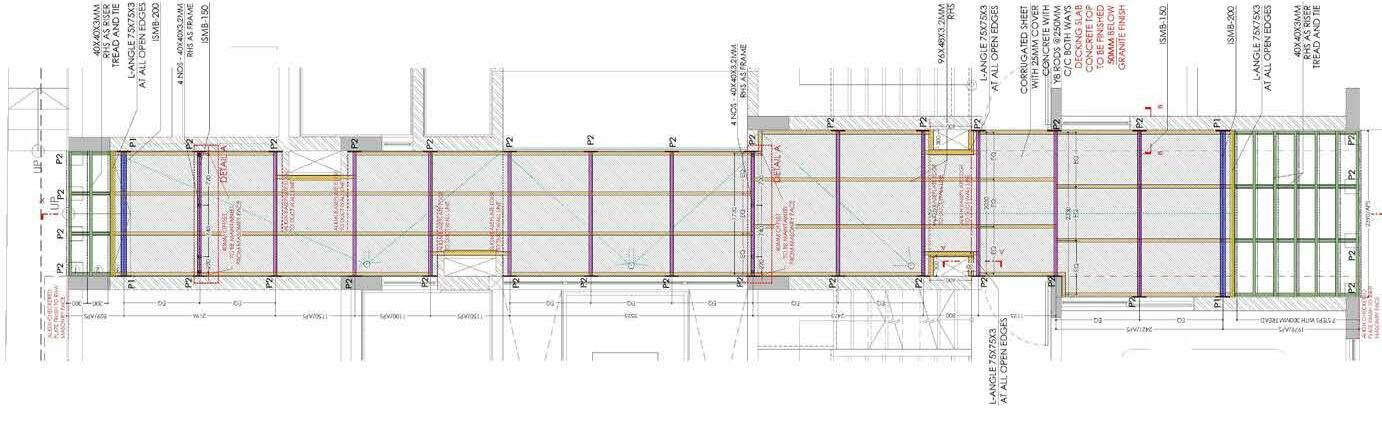

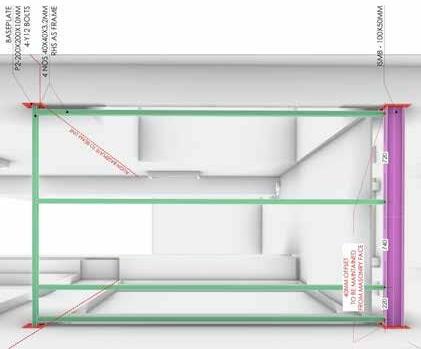

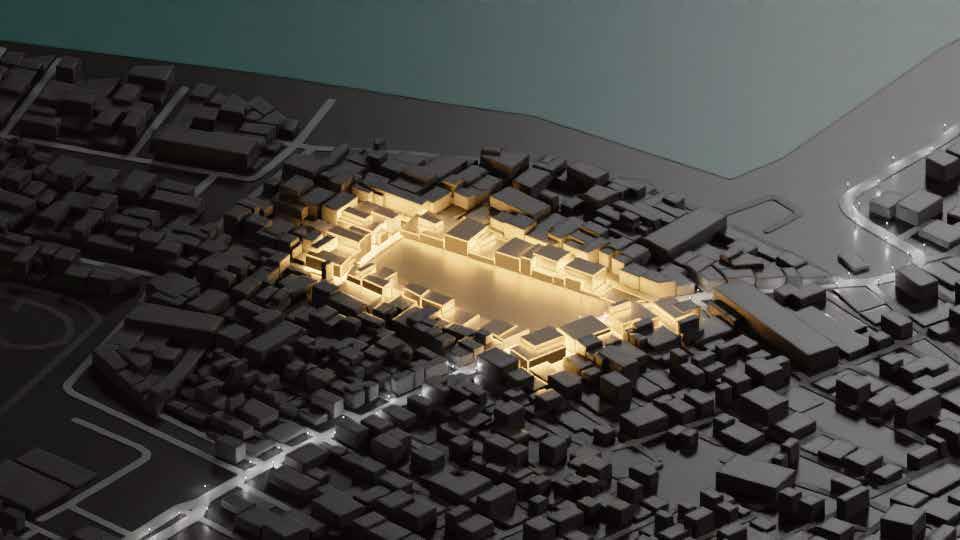

Located in Bangalore, ISBR is a 30,000 square foot institutional complex. For both long span classrooms and accelerating construction, steel is the primary building material employed. The usage of lighting along the arrangement of the false ceiling profile is an intresting component of the project.

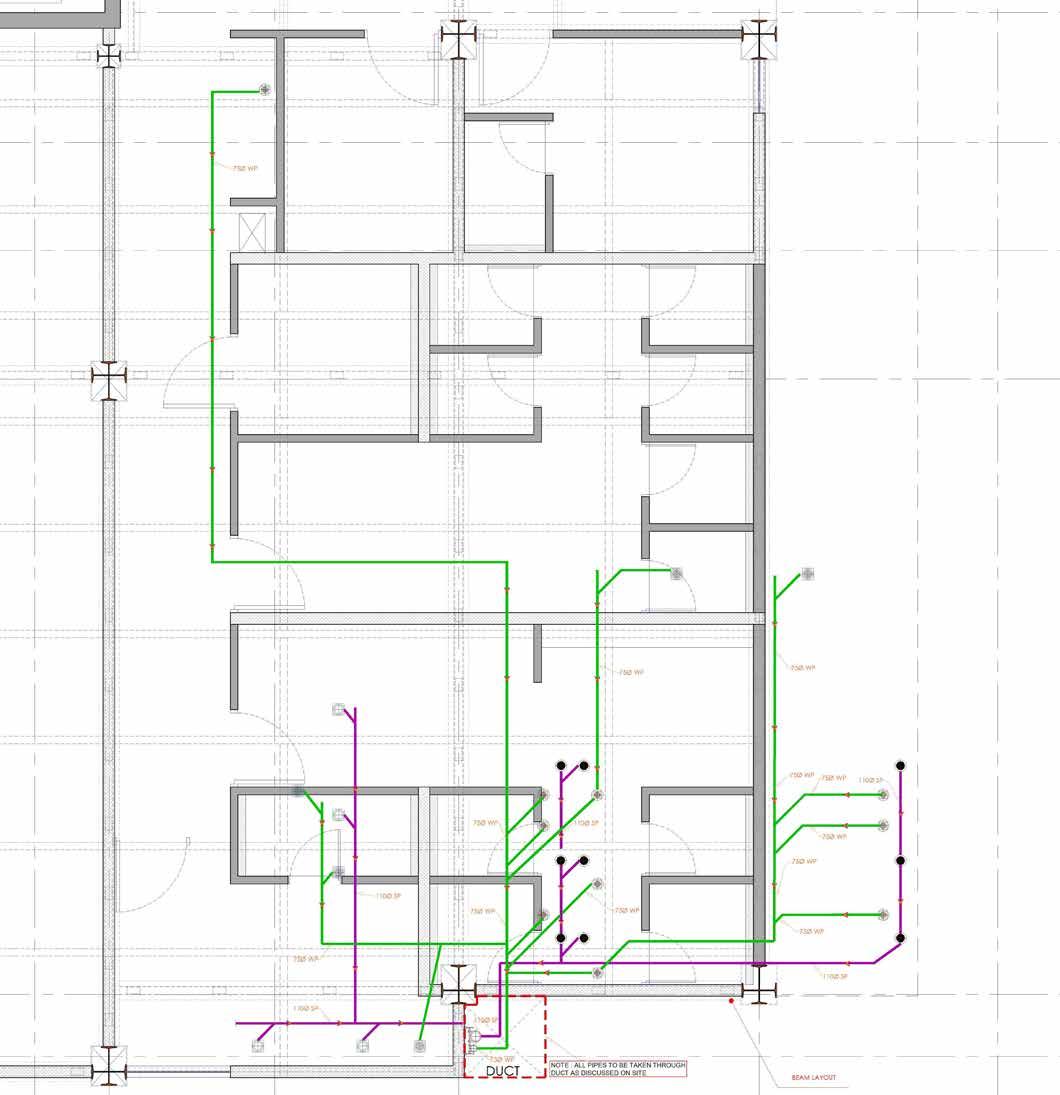

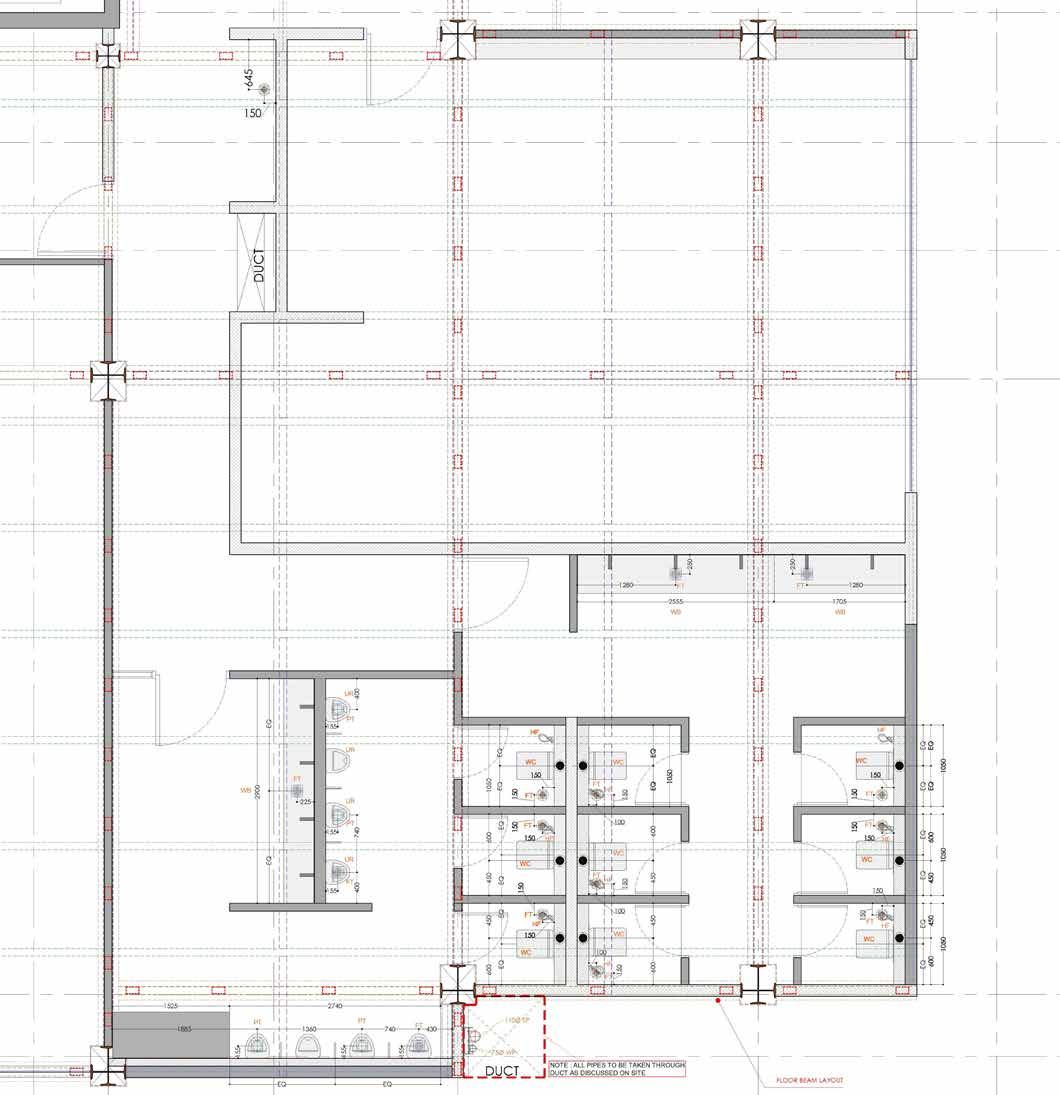

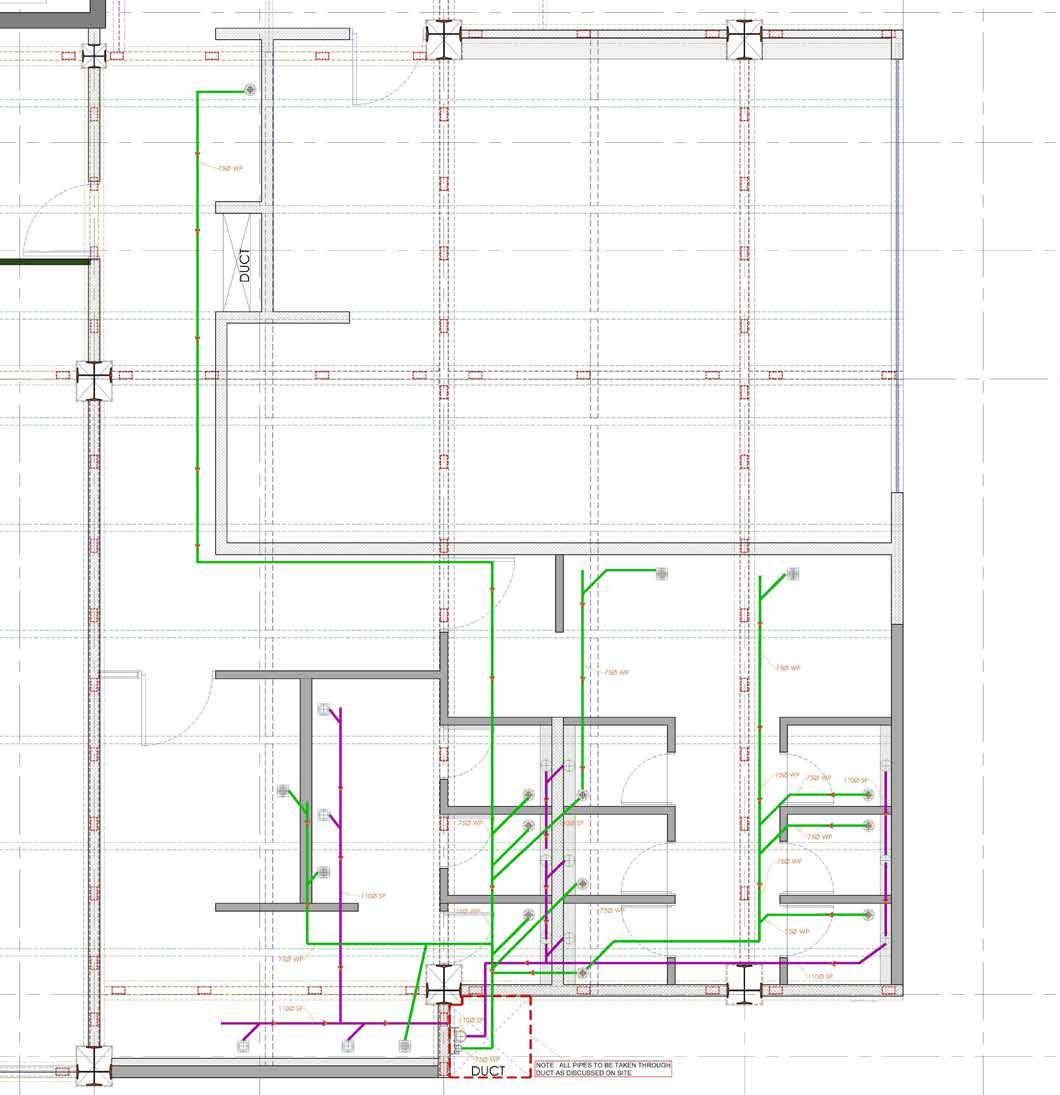

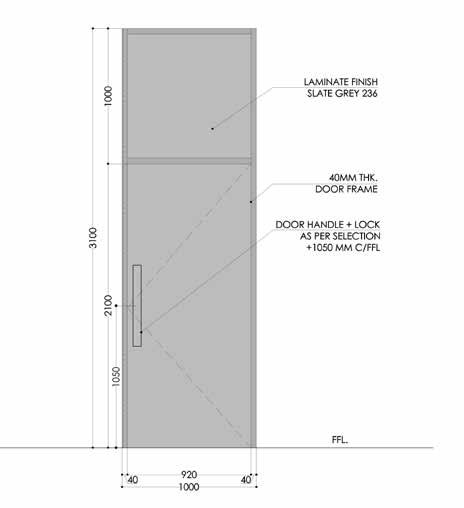

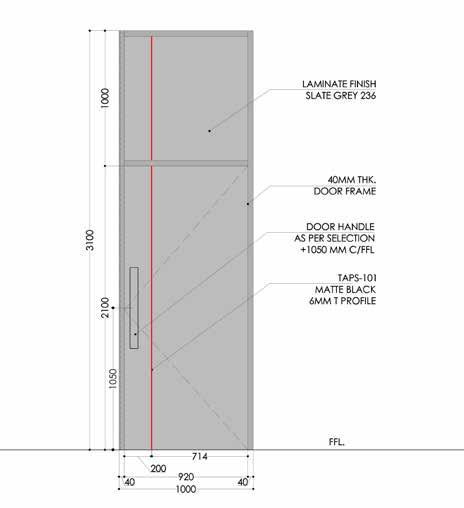

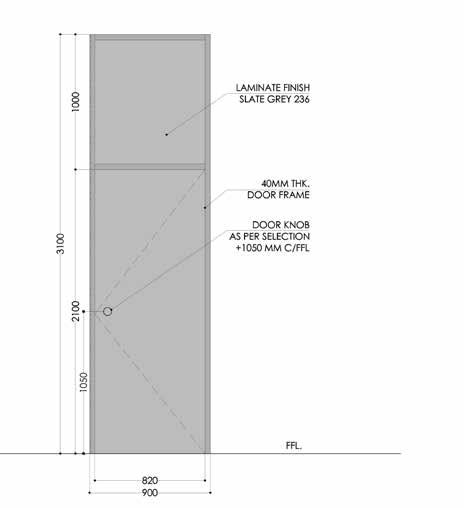

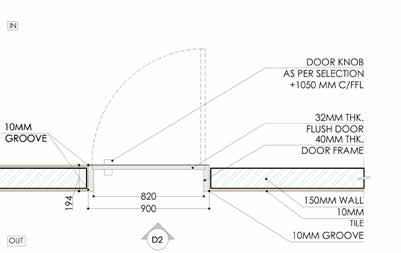

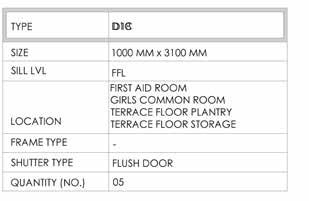

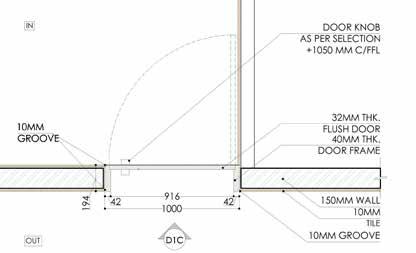

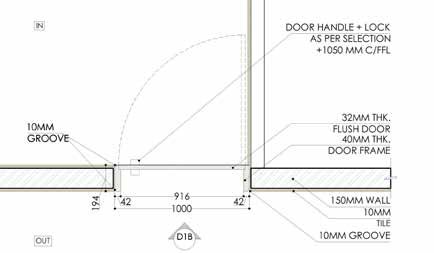

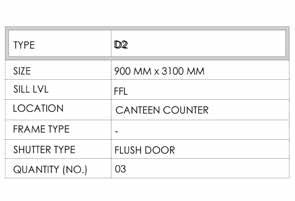

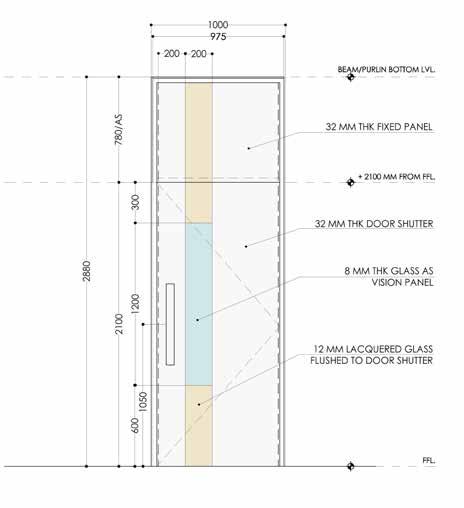

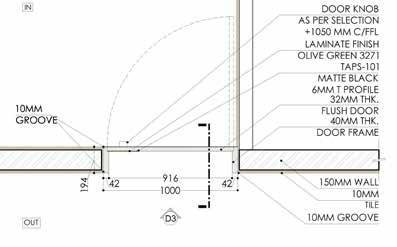

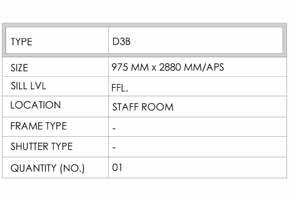

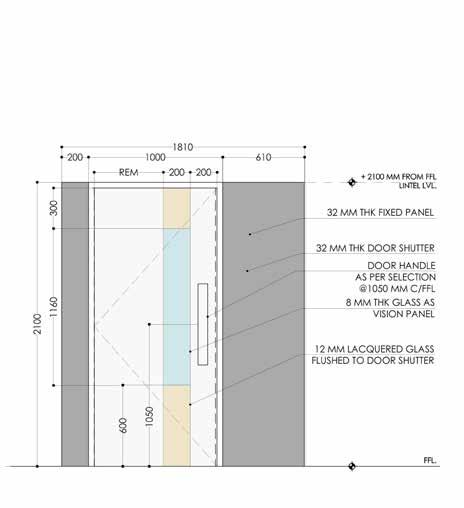

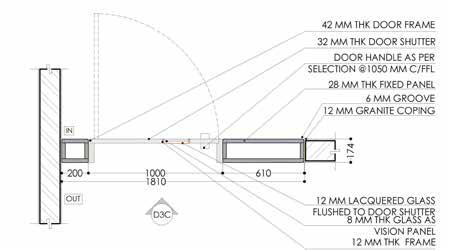

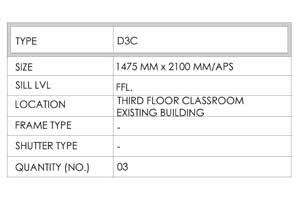

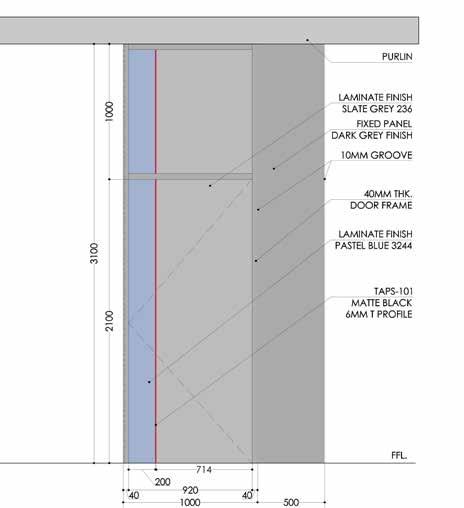

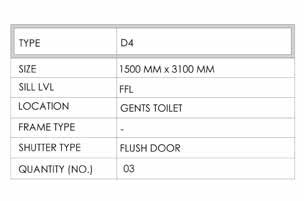

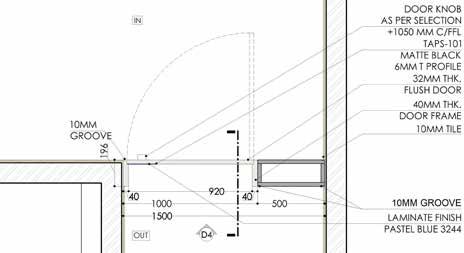

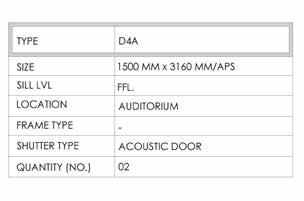

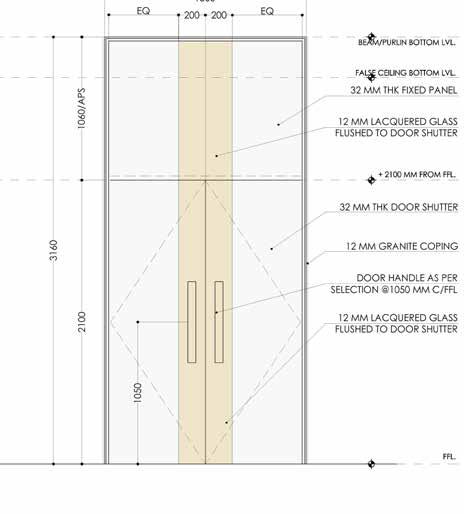

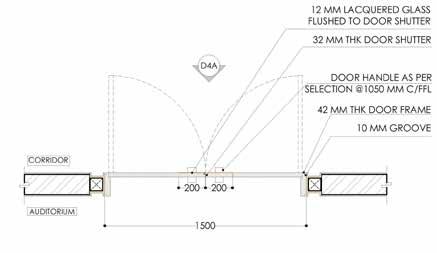

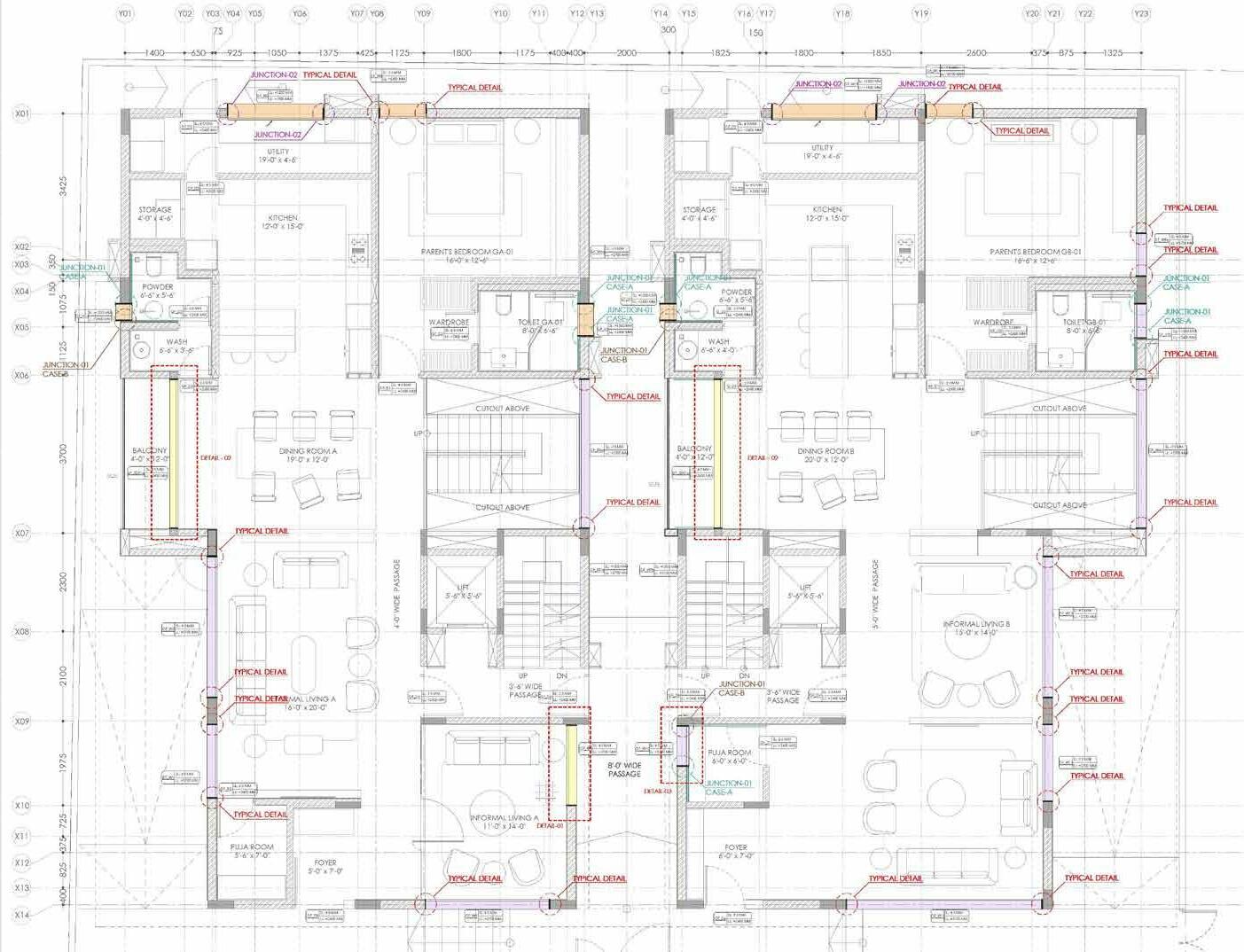

WORKED ON: DRAINAGE LAYOUT AND DOOR DRAWINGS

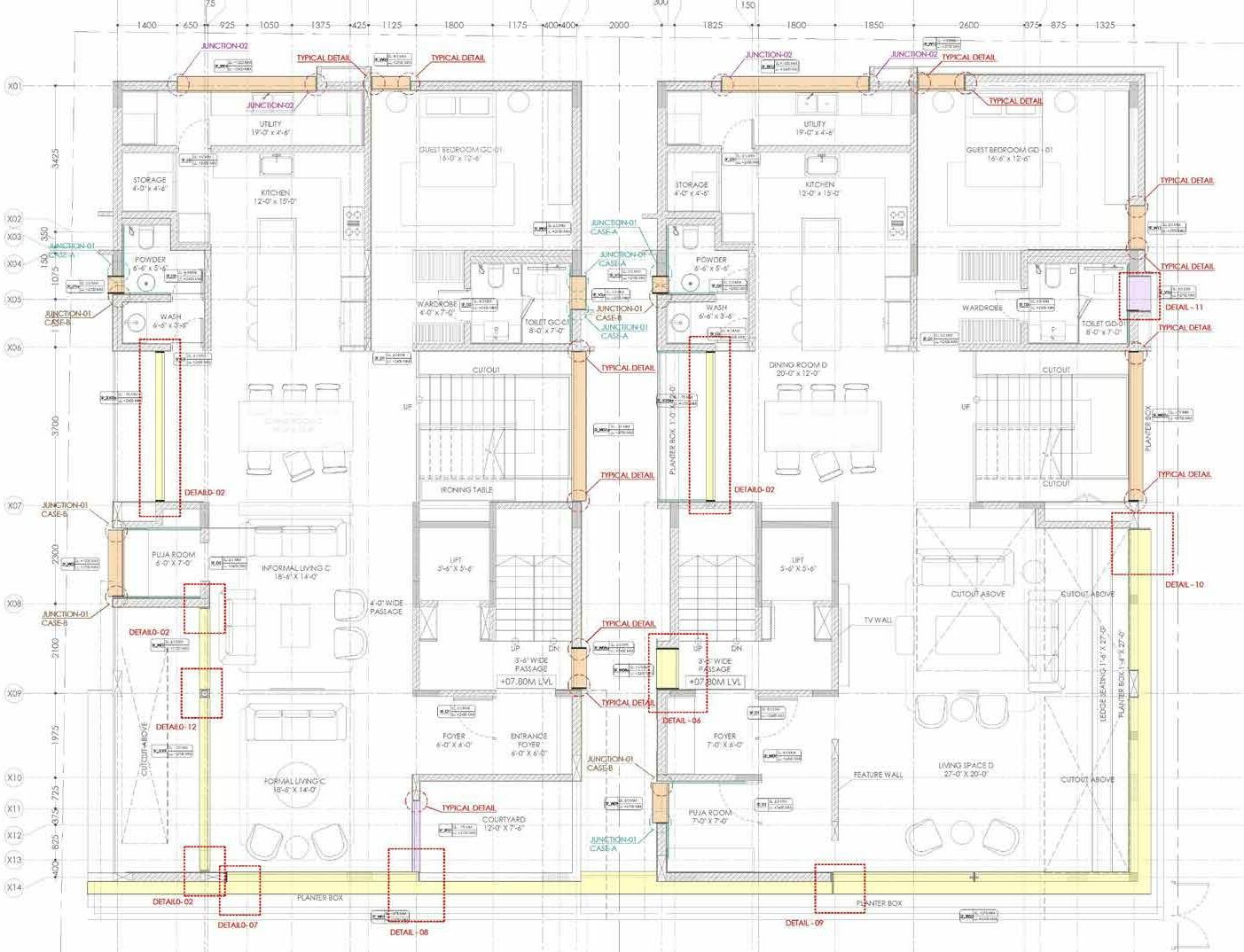

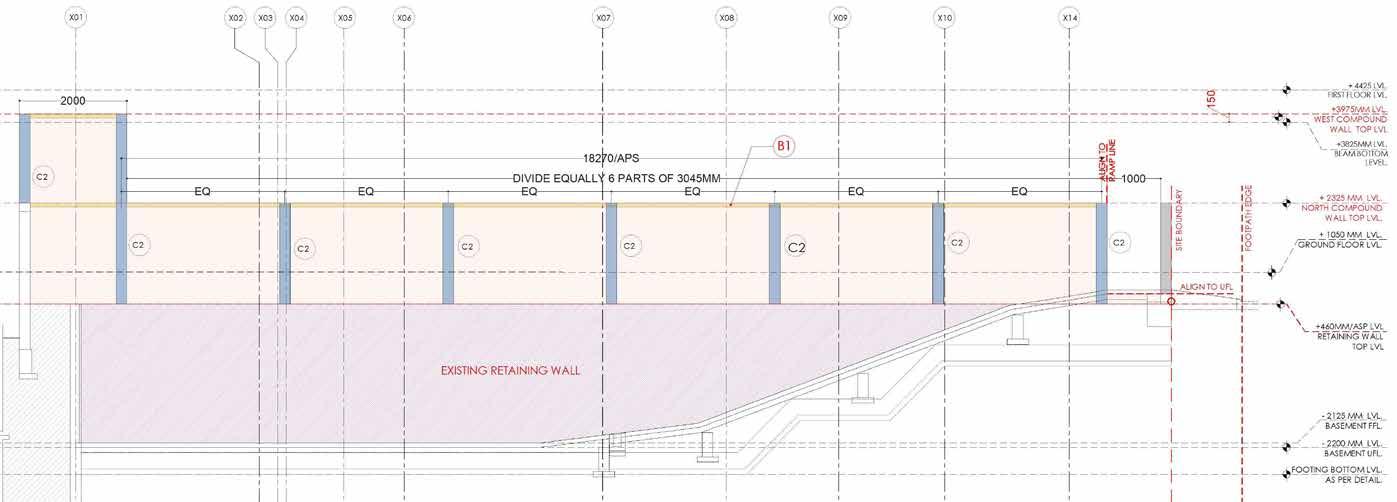

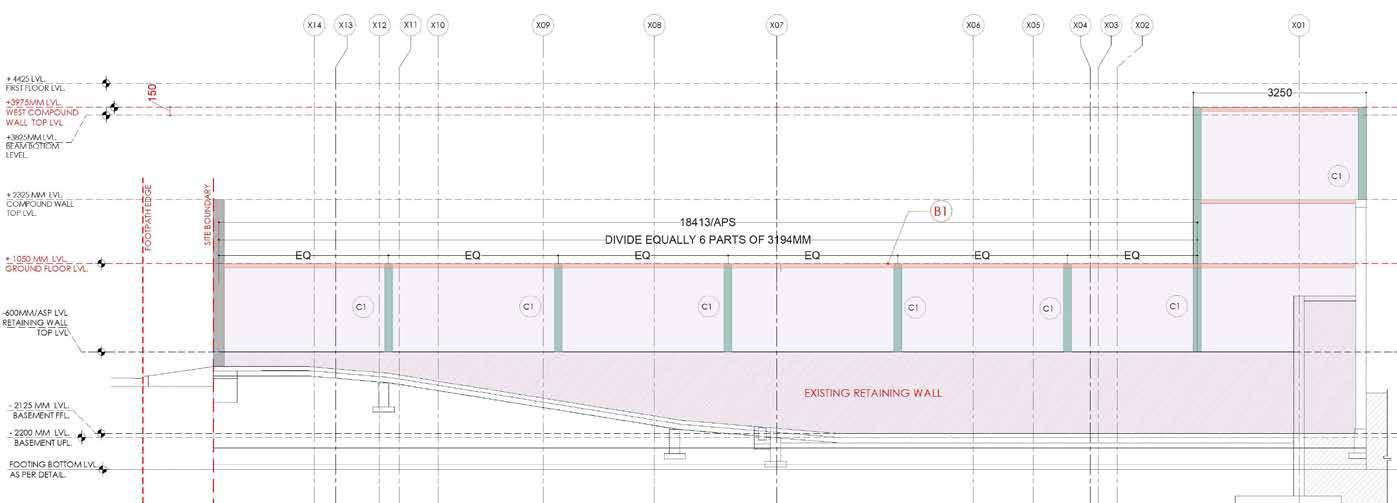

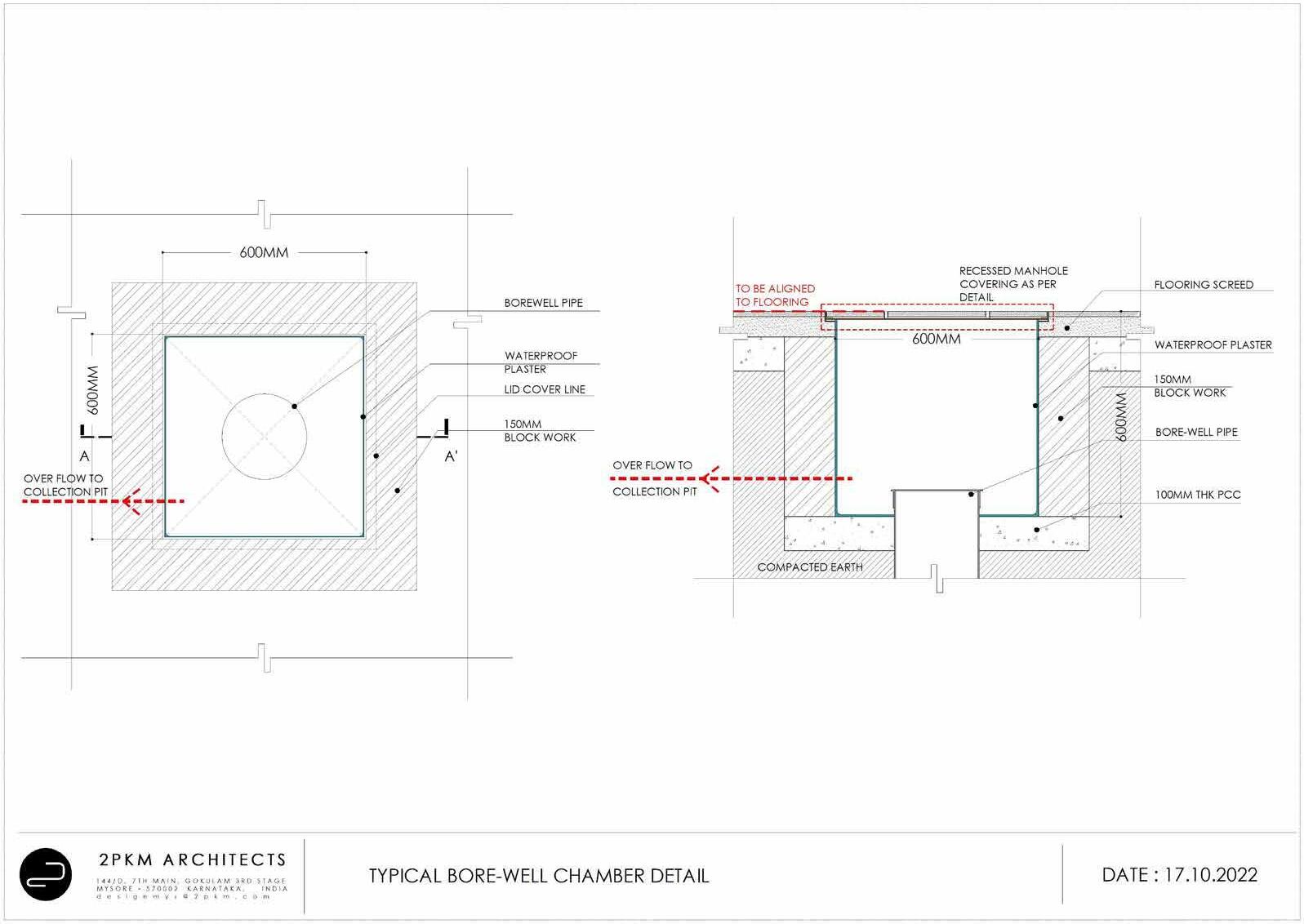

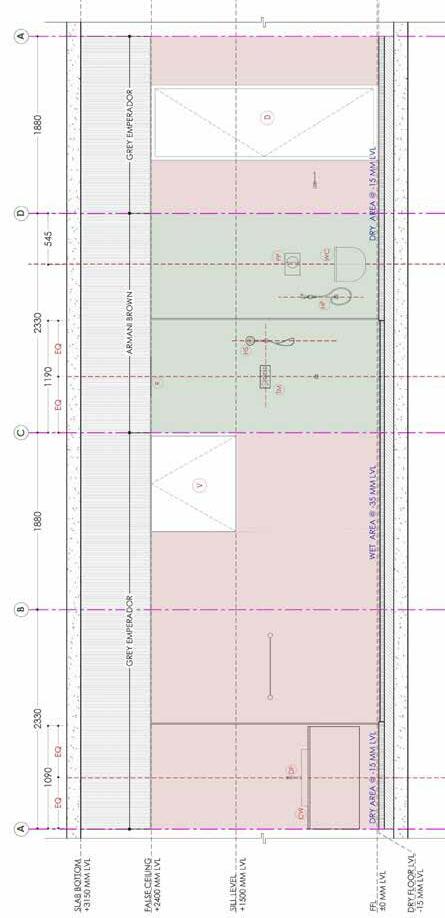

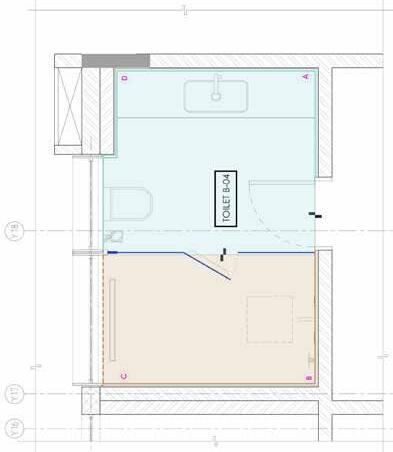

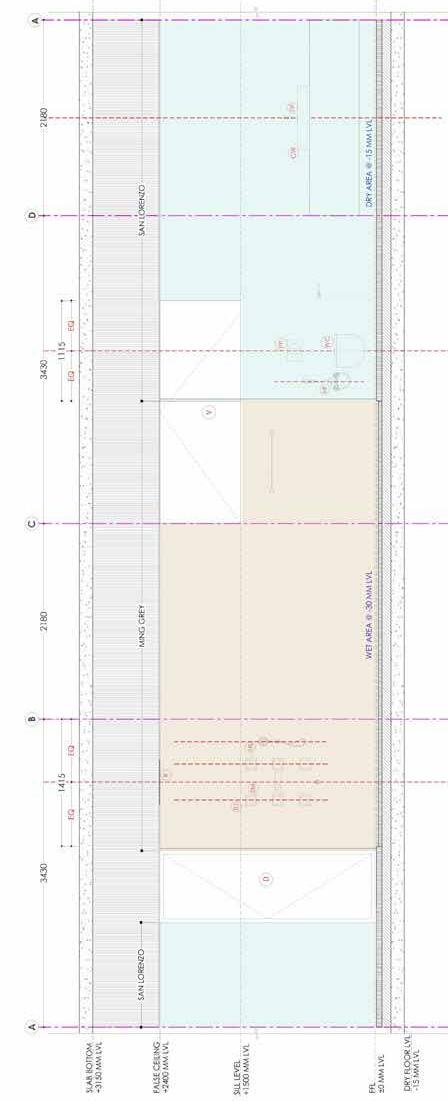

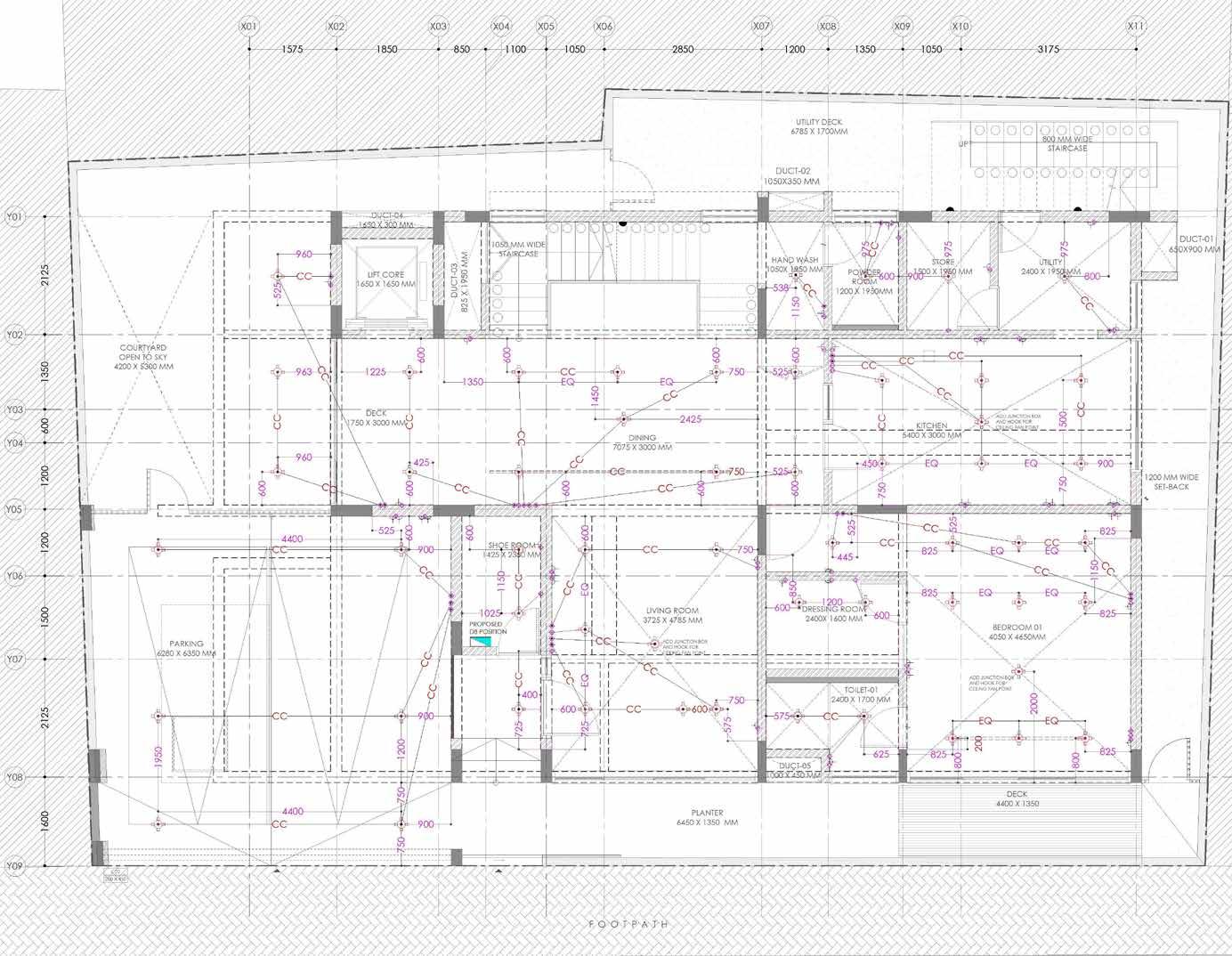

Volumen is a 20000 sq ft residential project located in Bangalore. The project seeks to achieve the ideal of togetherness with added privacy. The building is a perfect example of simplicity and elegance.

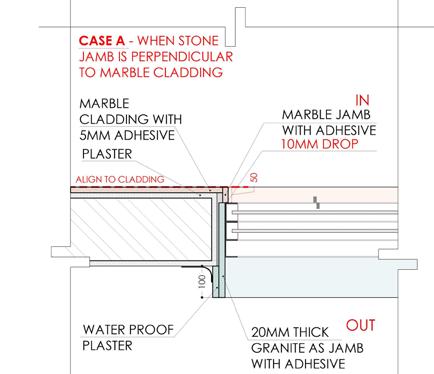

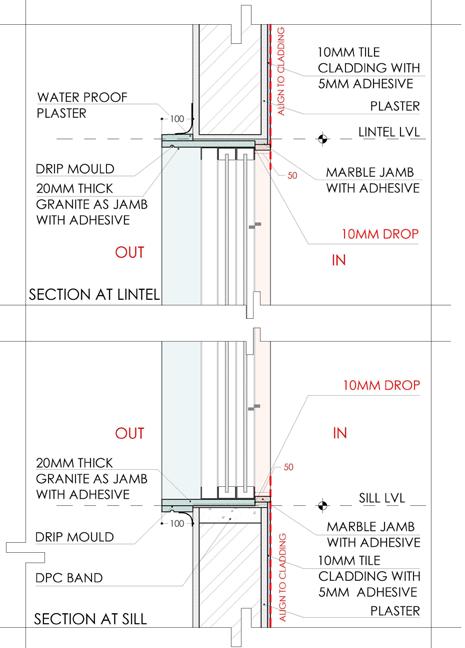

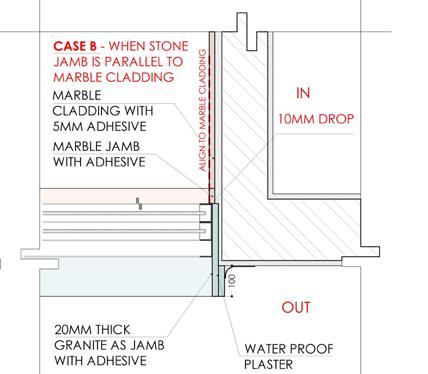

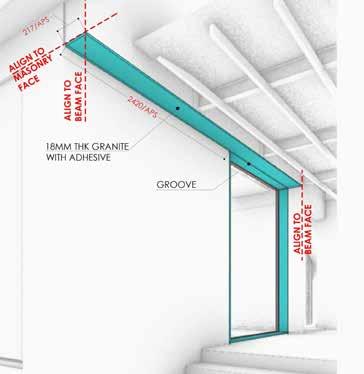

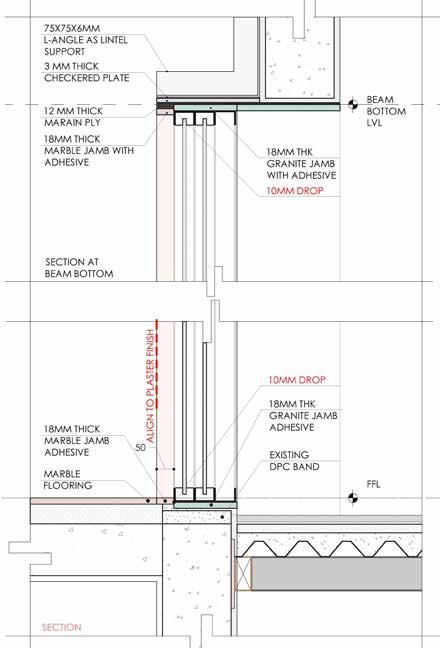

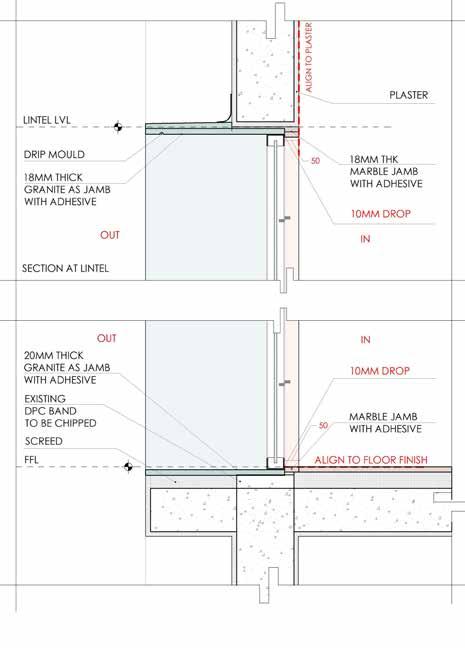

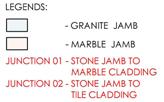

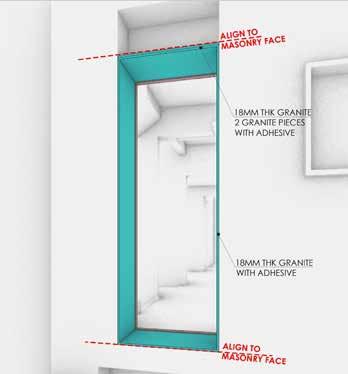

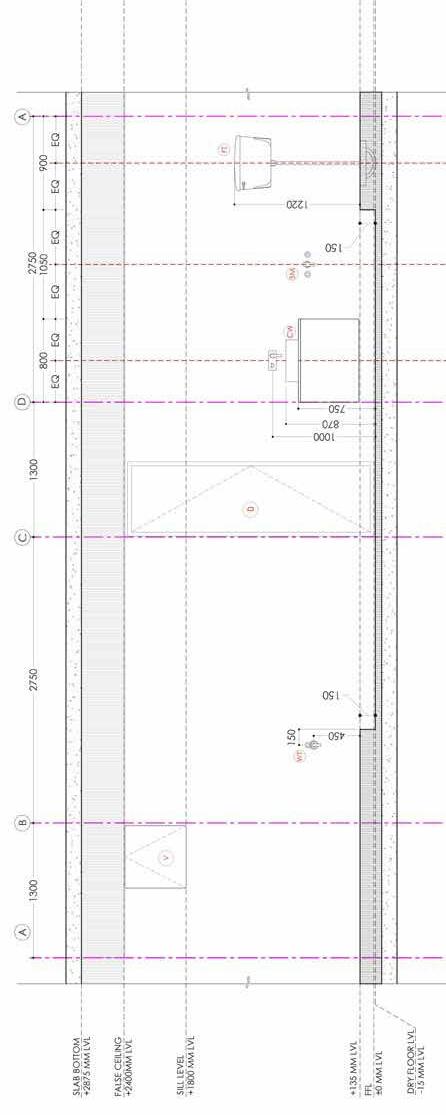

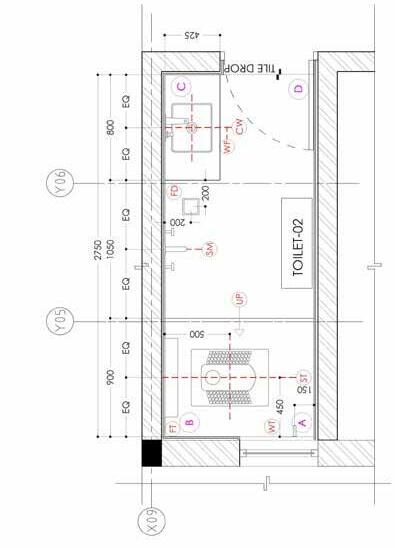

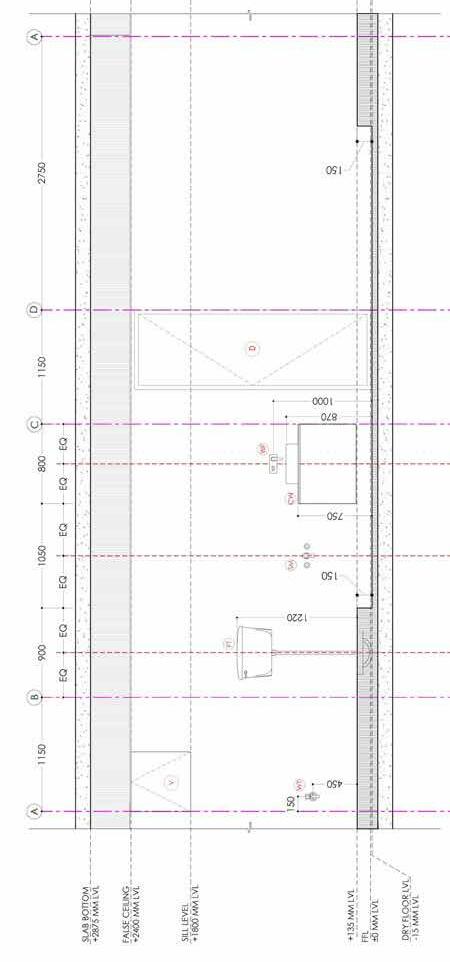

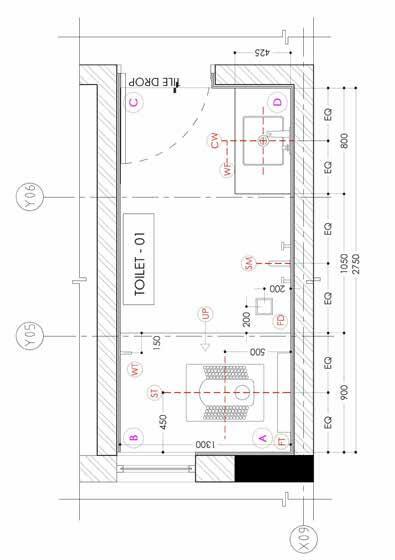

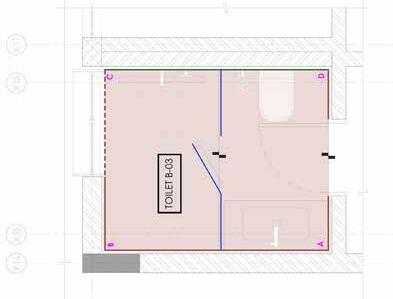

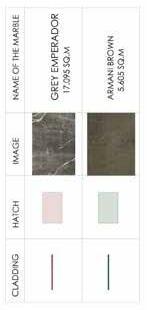

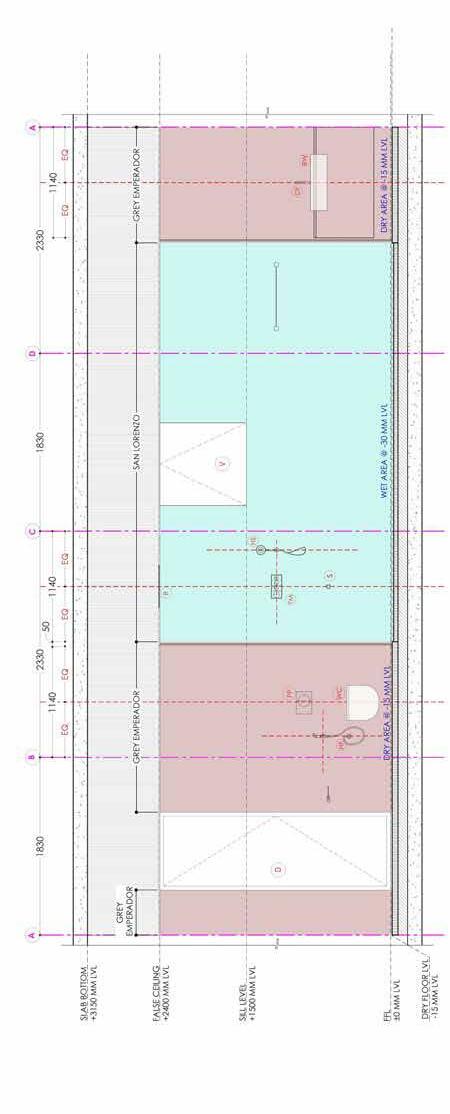

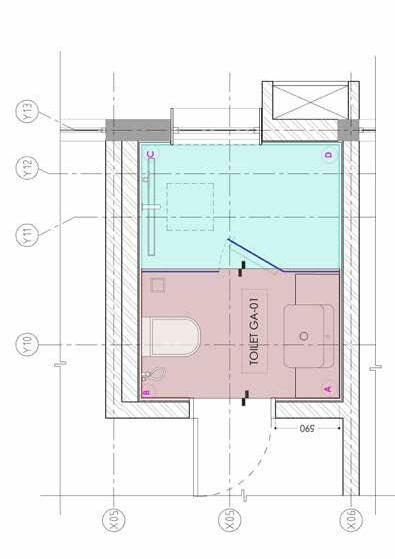

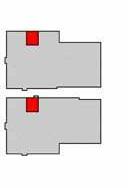

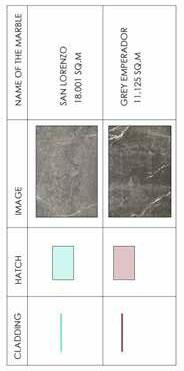

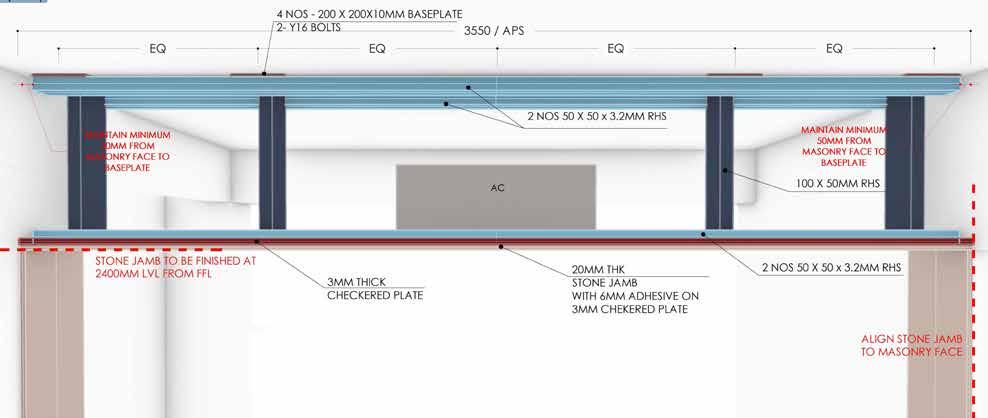

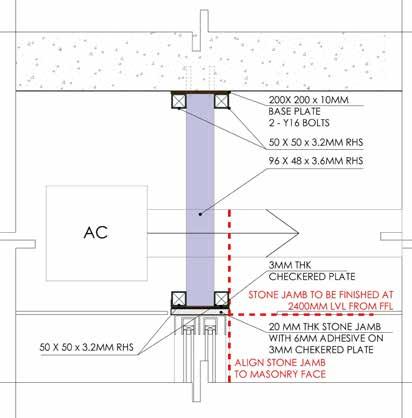

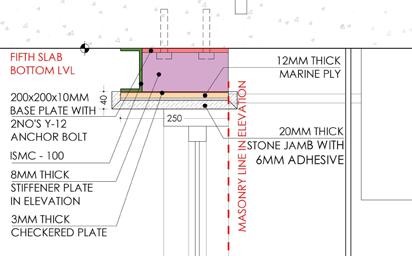

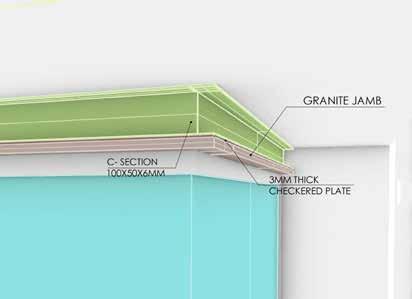

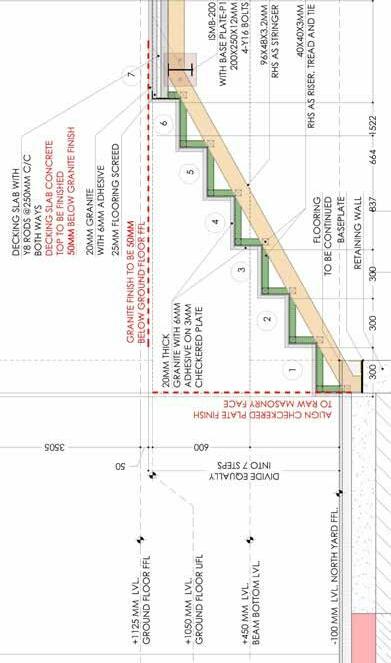

WORKED ON: FLOORING DRAWINGS, WINDOW DRAWINGS, STONE JAMB DETAILS, WALL PANELING LAYOUT, BORE WELL PIT DETAILS, TOILET DETAILS, COMPOUND WALL DETAILS,FABRICATION DRAWING, WORKING 3D, RENDERINGS AND BOQ.

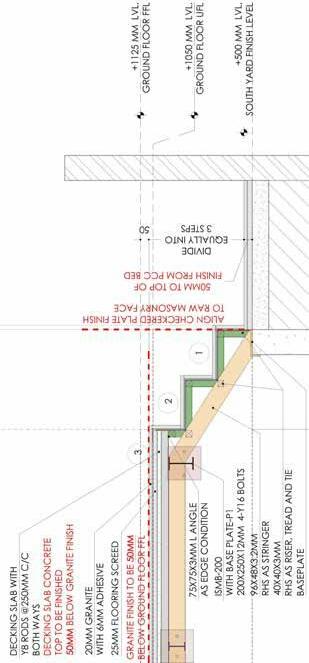

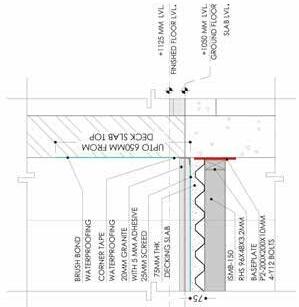

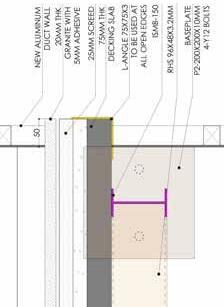

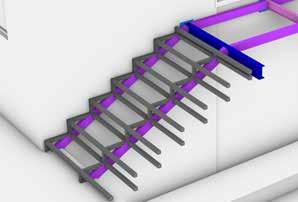

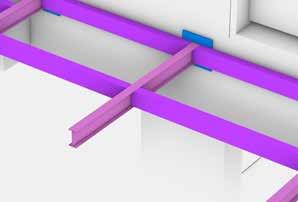

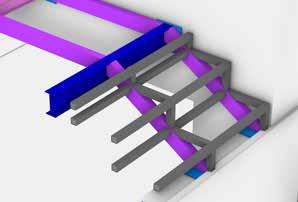

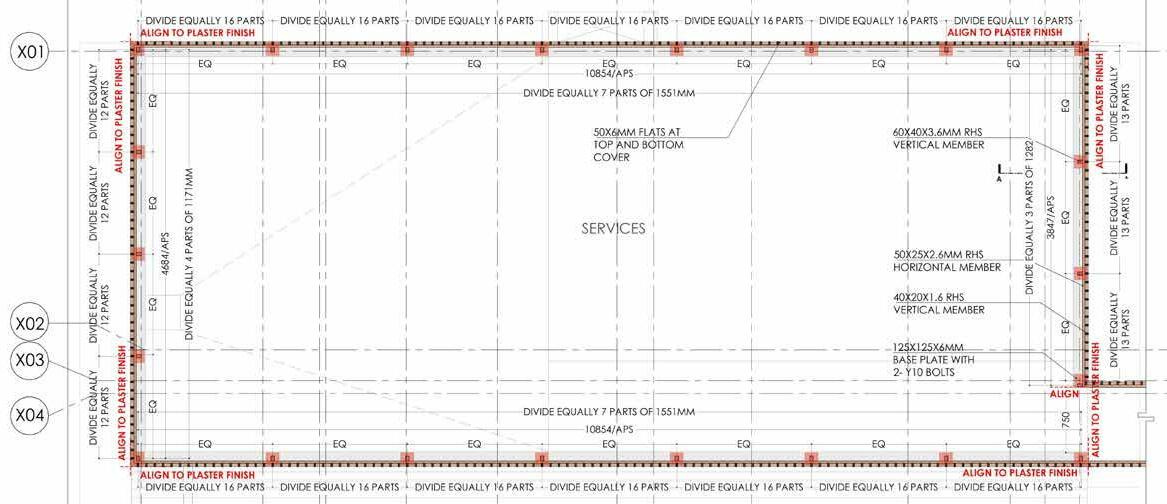

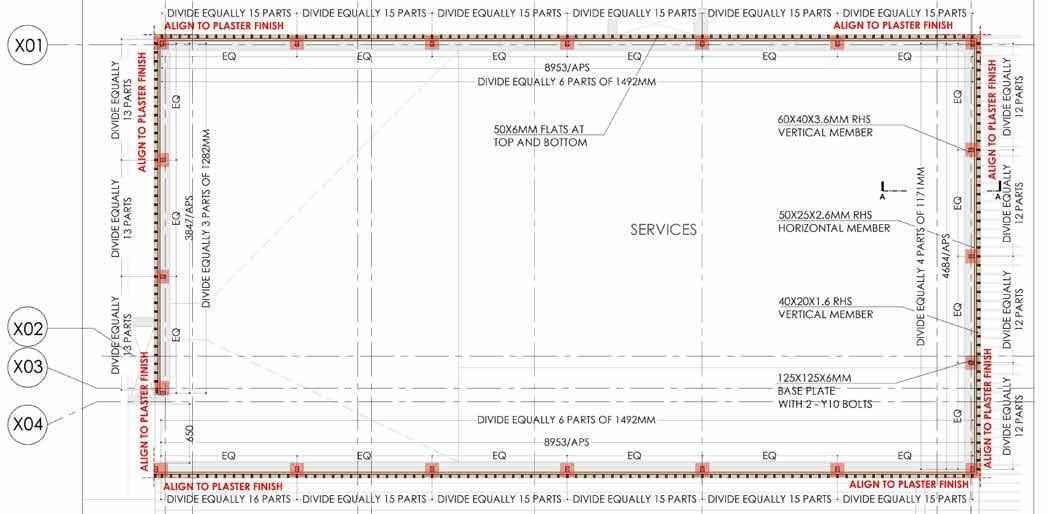

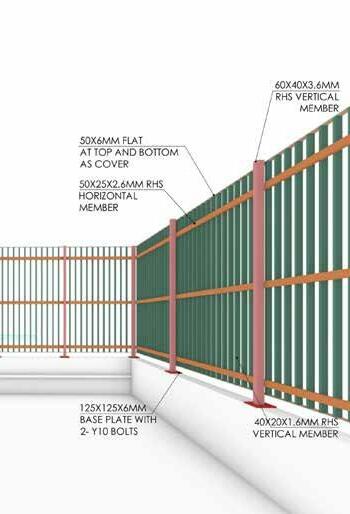

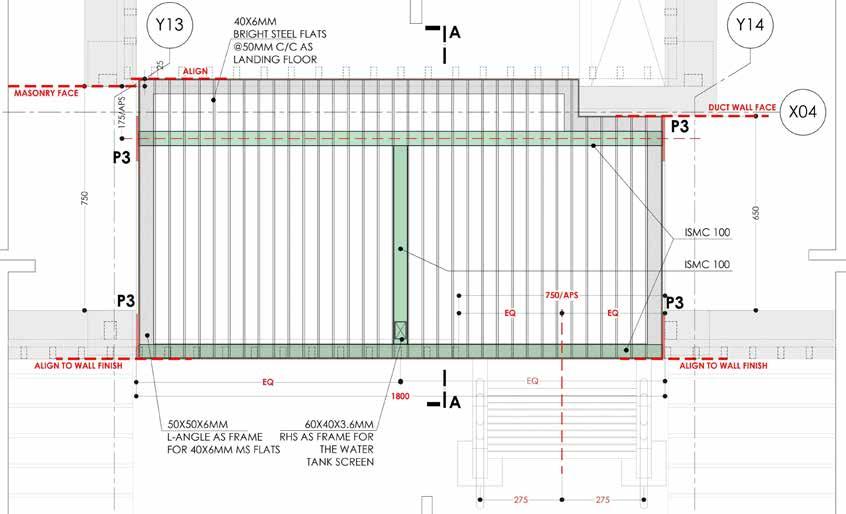

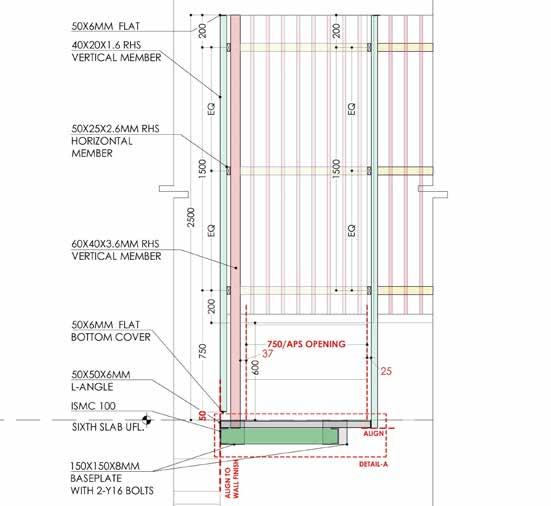

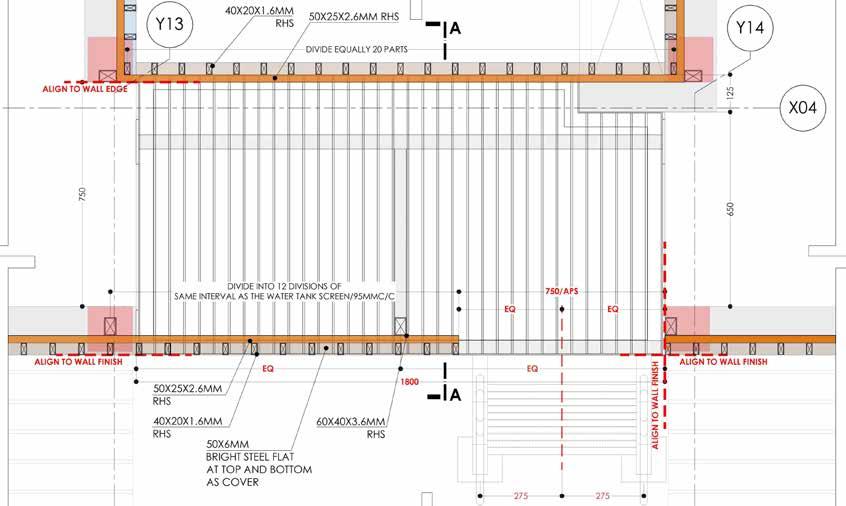

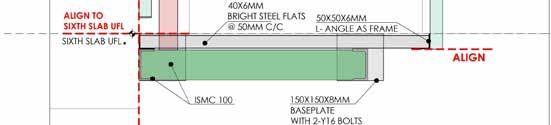

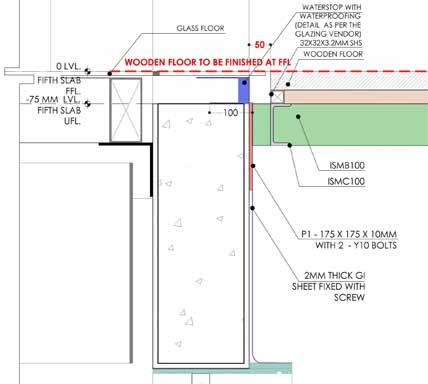

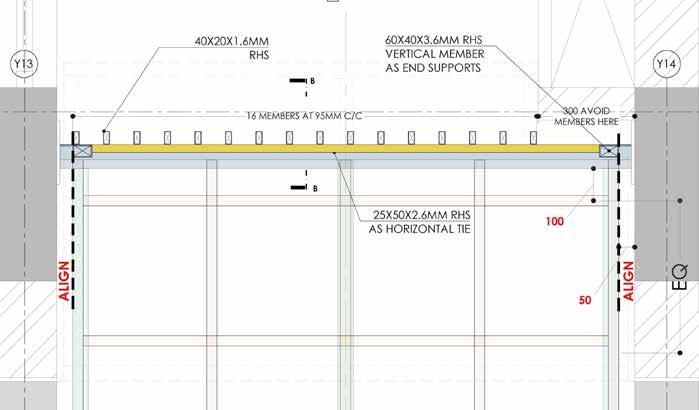

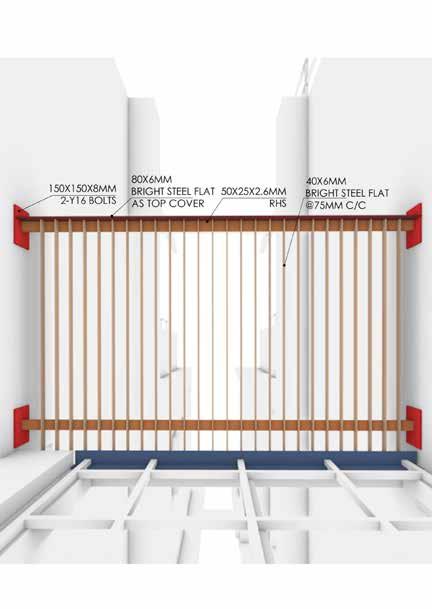

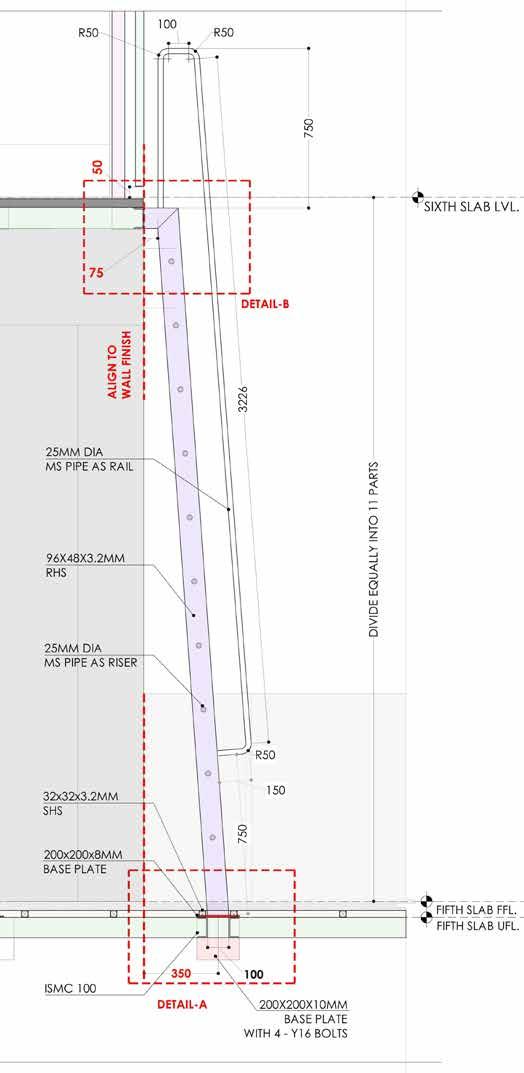

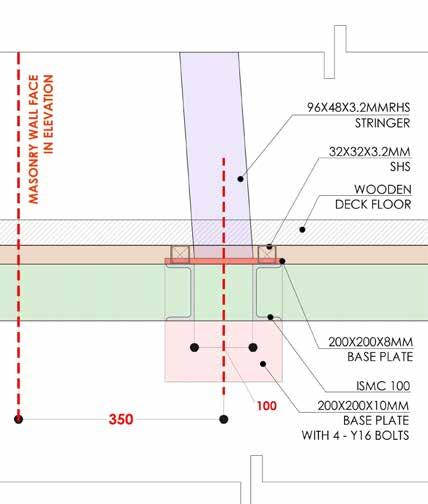

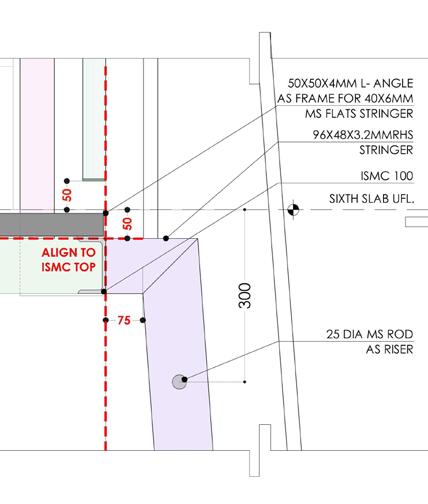

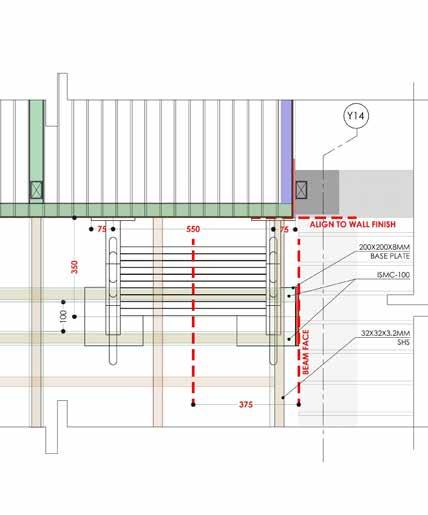

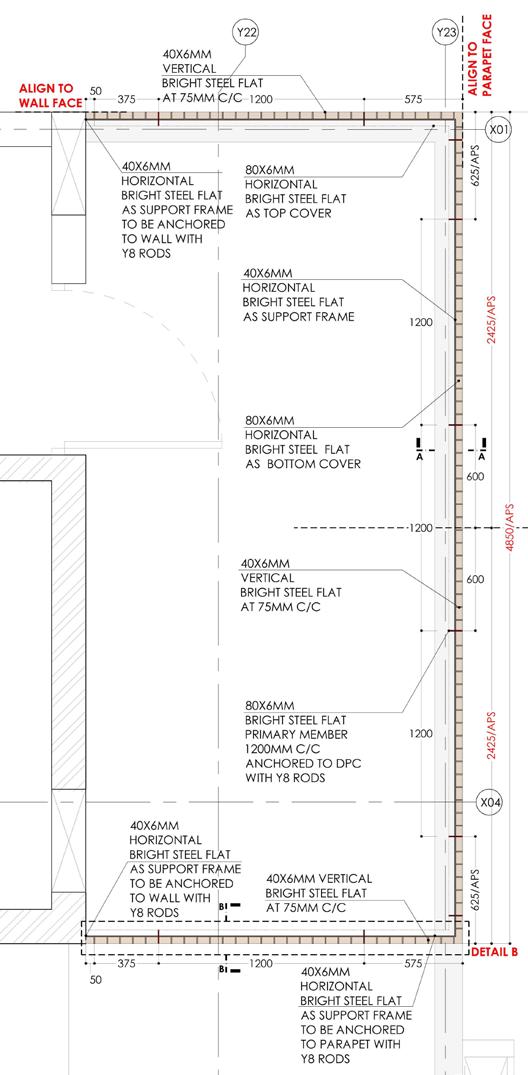

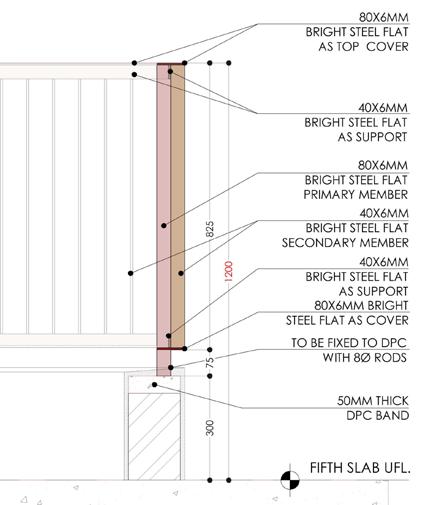

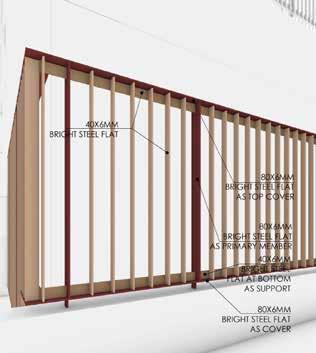

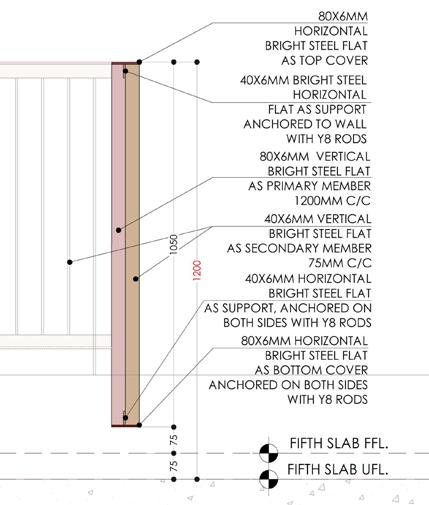

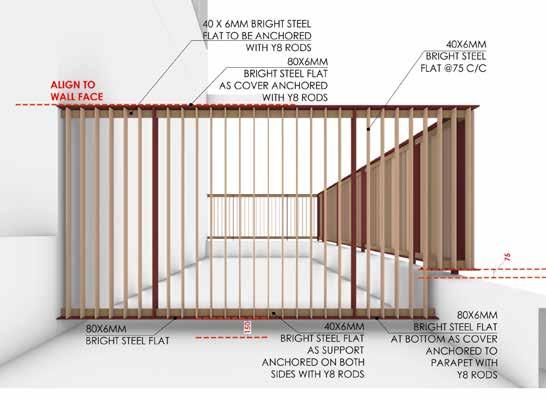

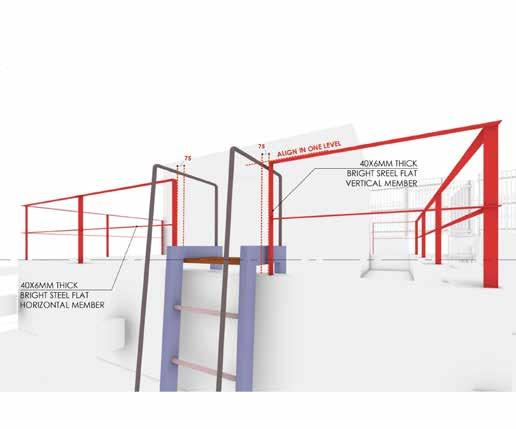

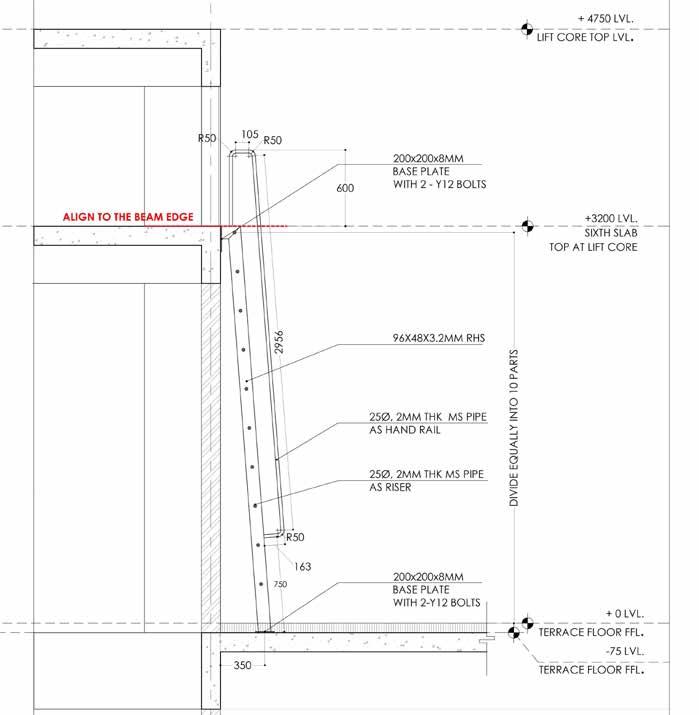

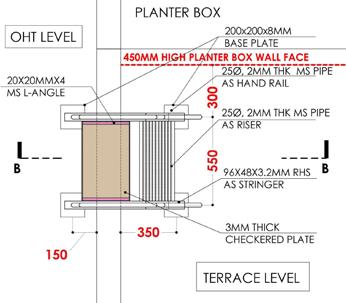

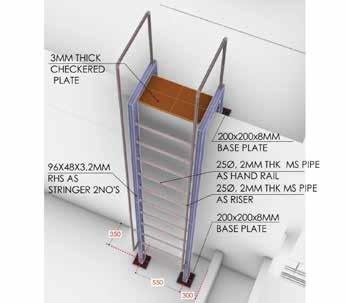

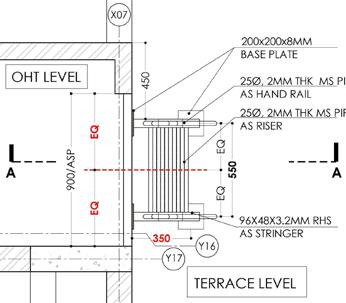

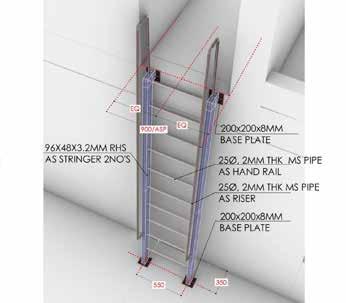

WORKING 3D FOR DECKING SHEET SLAB AND UTILITY GRILL FABRICATION

WORKING 3D FOR DECKING SHEET SLAB AND UTILITY GRILL FABRICATION

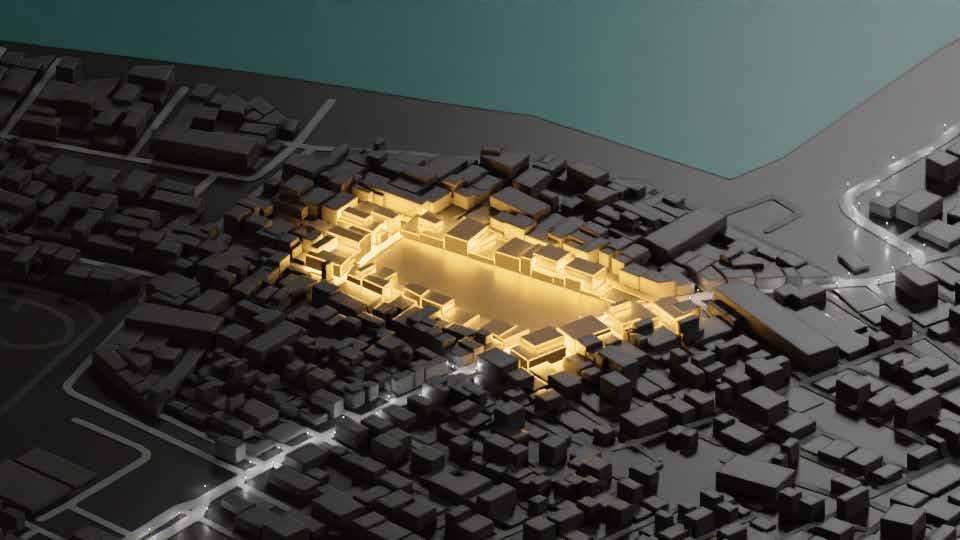

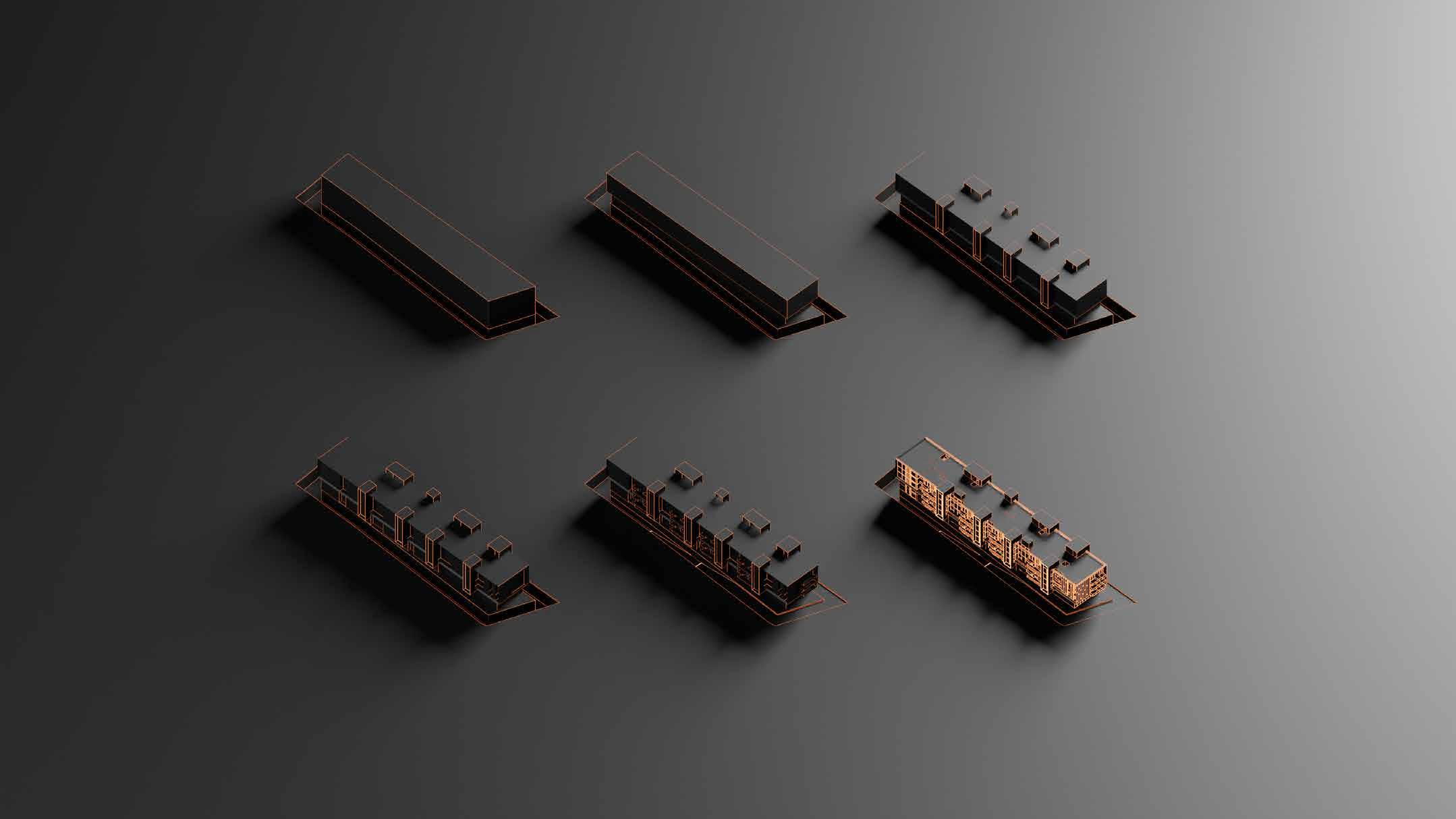

A residential apartment building project with a simple design approach would focus on creating a minimalist and modern aesthetic. This would involve using clean, geometric lines and a neutral color palette. The interior spaces would be designed to maximize natural light and create a sense of openness and airiness. The use of materials, such as glass and aluminium panel, would be emphasized to create a connection with the surrounding environment. Simplicity would be key elements of the design, with an emphasis on creating comfortable and practical living spaces.

WORKED ON: ILLUSTRATIONS OF MASSING, FACADE OPTIONS AND CONTEXT

The intention of the design was to create a habitate with the no compromise on space. Within limited spread of land. In this endeavour explored the voids and volumes to accomodate as to make it intresting. The minimalistic shell of the residence hides a surprising diversity of spaces inside.

Volumen is a 20000 sq ft residential project located in Bangalore. The project seeks to achieve the ideal of togetherness with added privacy. The building is a perfect example of simplicity and elegance.

Project Name : DRB

Project Location : BANGALORE

Date : 26 10 2022

PERSONS PRESENT:

1 Mr Dil p Nahar (cl ent)

2 Ar Sabir Baputty (Arch tect - 2PKM)

3. Ar Nithya Surabh B A (Architect - 2PKM)

4. Mr. Ranjeet (window vendor)

5 K rankumar K Bandi (Intern - 2PKM)

6 Mr Jagadish (Marble layer)

SITE PROGRESS:

SITE PHOTOGRAPHS

TILL: 26 / 10 / 2022

DESCRIPTION

CLINTES QUERRIES AND INPUTS:

Basement f oor:

1 The cl ent has requested to el minate the door for the ut l ty area next to the l ft lobby

Ground floor:

Cl ent has requested for seating at house-02 ba cony

First floor:

Cl ent has requested for updated nter or renders for house 2 kid’s bed rooms and iv ng room

Second floor

Cl ent has conf rmed fixed skyl ght nstead of open-ab e skyl ght at second floor Water out to be addressed

Terrace floor:

1 Glass door at home theatre to be addressed for acoust cs

2 Mode of Transportat on of VRF un ts to OHT level was nquired Same to be addressed

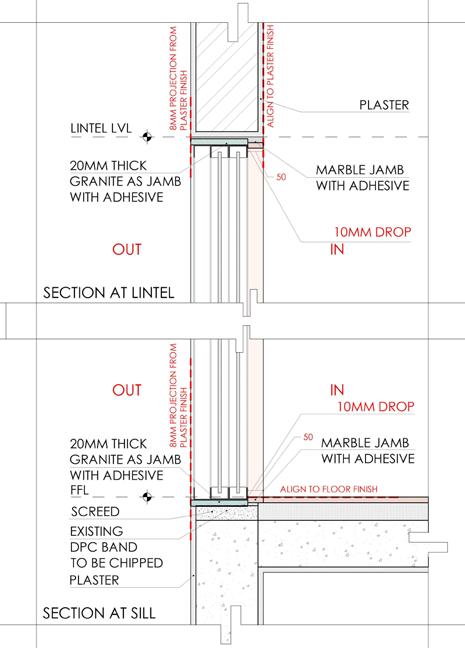

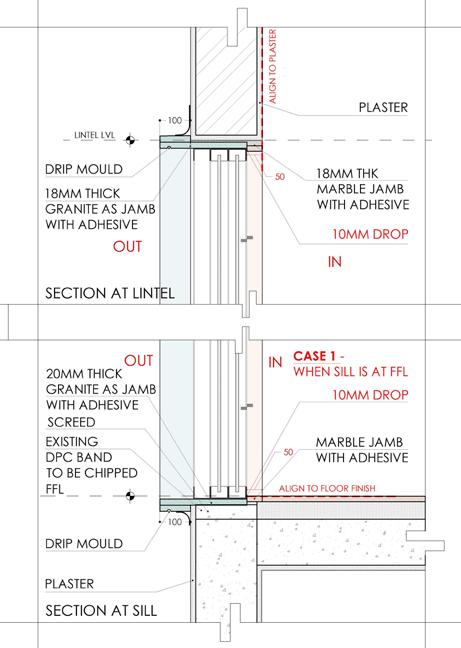

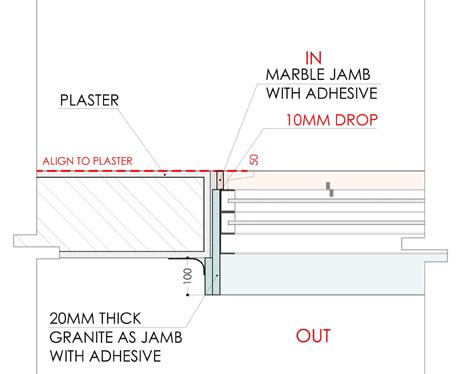

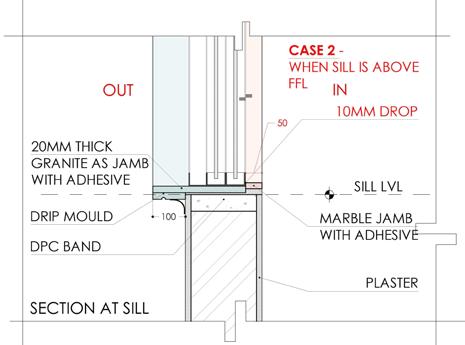

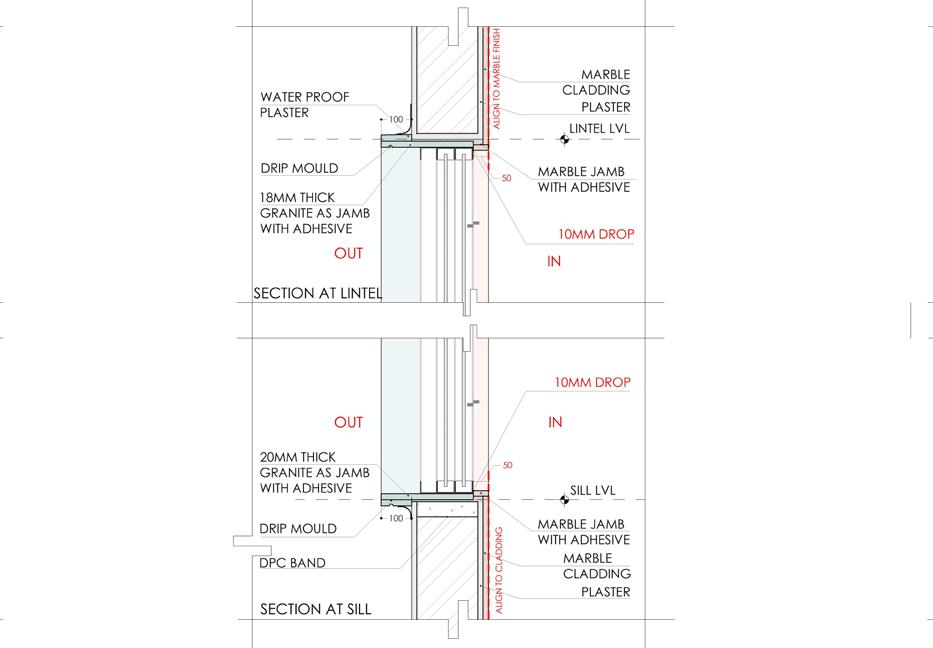

STONE JAMB AND WINDOW DISCUSSIONS WITH THE CORTIZO VENDOR MR RANJEET:

1 Note: Fo owing are the c ear depth requ red for the cort zo w ndow systems:

- COR v sion - 44mm

- COR v sion p us - 80mm -

2 COR v s on p us w indow systems w ere not feas b e for our current f ooring depth. Same to be addressed

2. The cl ent requested for parapet nstead of ful he ght w al s at l ft core of basement Gr ls w ere requested on top of it

3. 4mm s ope for the stone amb w as agreed by Mr Ran eet

4 10mm drop w as agreed for COR

vis on w indow system, t has to be dec ded f the level difference has to be cont nued on the other 3 s des.

5 t w as noted that since the w ndow SF W10 at second f oor has a fabricated s l and ntel, the f x ng of the w ndow systems w ou d be d fferent.

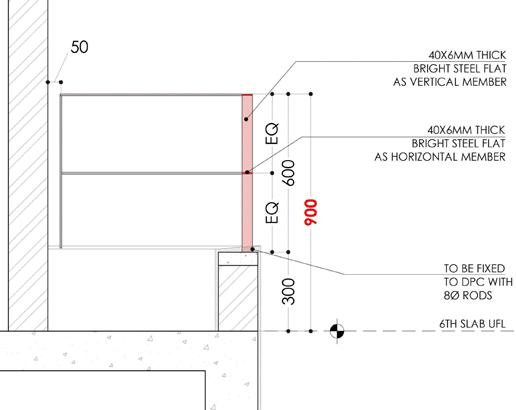

1 t w as noted that the p anter box edge w a l w as ow er than the fabricated s l of w ndow SF W10 at house 4

2 t w as noted that the si l of w ndow SF W11 and W12 w ere f nished at 450mm because of the DPC band

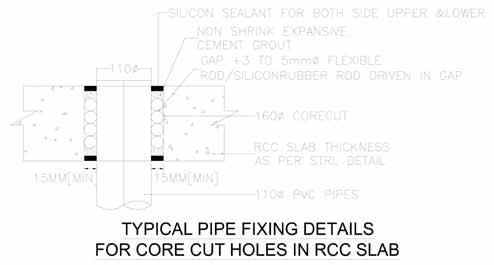

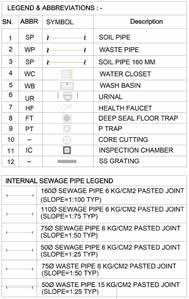

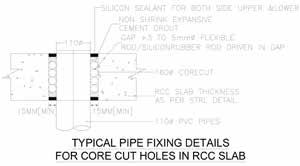

OBSERVATIONS IN PLUMBING

1 t w as not ced that beam core cutt ng w as done for the beams of to et B03 and DO2 for WC out pipes

Later w as nquired from Kumar, that the re nforcements w ere not cut

3 Clos ng of Ducts needs to be addressed at balconies

2 t w as observed that the w ash bas n out ets w ere not provided at site yet

Later w as nquired from Kumar that the out ets wou d be prov ded on top of the w aterproofing ayer

3 t w as noted that plumb ng ine in the ground f oor k tchen w as taken on the top of w a .

4 Automat on condu ts w ere observed at un t 1 l ft core w here adder pos t on w as conf rmed at terrace f oor.

5 SCB blockwork on top of the retaining wal was observed to be not done on site yet

SUMMARY:

1 A l the points mentioned above to be discussed and rectified

2 In case of any changes or discrepancies as per site in the given deta ls, the same to be brought into the notice of design team

The essence and intent of the design reflects in its materiality and aesthetics. The design is transparent. Most of the jewellery exhibits are intended to be gleaming, hence the room is flooded with lights. Here rather, they have instrumentalised materials and lighting to bring about subtleness to the ambience not overthrowing the lights, but giving the required attention to the displayed products.

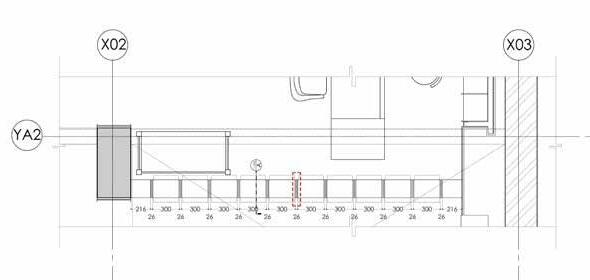

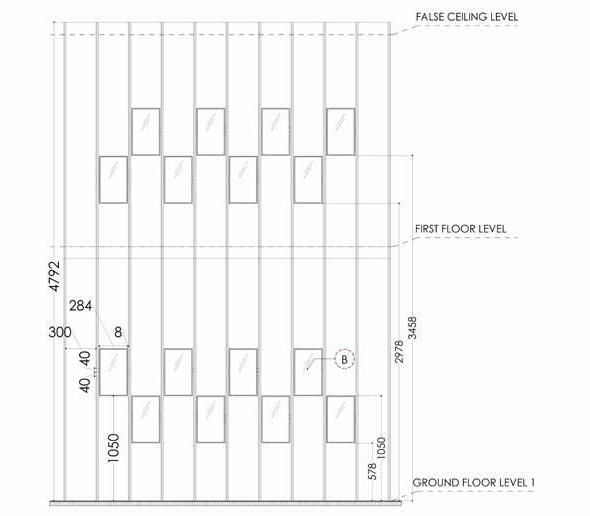

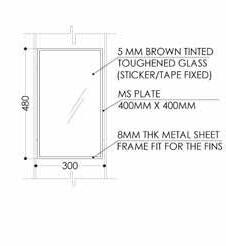

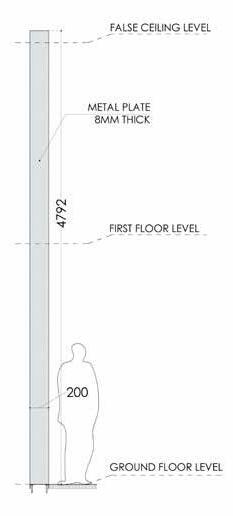

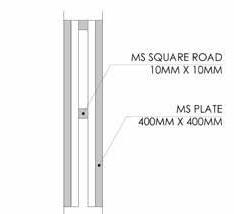

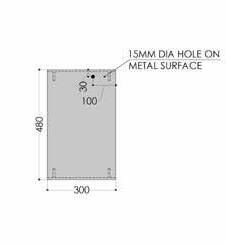

The façade proposed for Jewel Mandir is a combination of glass and metal plates to achieve simple and elegant appearance. Light plays a key role in the design with an attempt to highlight the jewellery by keeping the background subtle. The contrast between the glass and the metal plates in the façade makes the structure attractive, where the glass gives glimpse of the interiors and metal plates gives feeling of solidarity. A similar language is kept up between the exterior and interior of Jewel Mandir by following the same architectural grid.

Jewel Mandir is situated in one of the prime streets of Mysuru; Devraj Urs Road .

Devraj Urs Road

Jewel Mandir is situated in one of the prime streets of Mysuru; Devraj Urs Road .

Devraj Urs Road

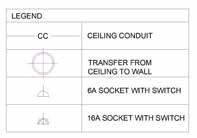

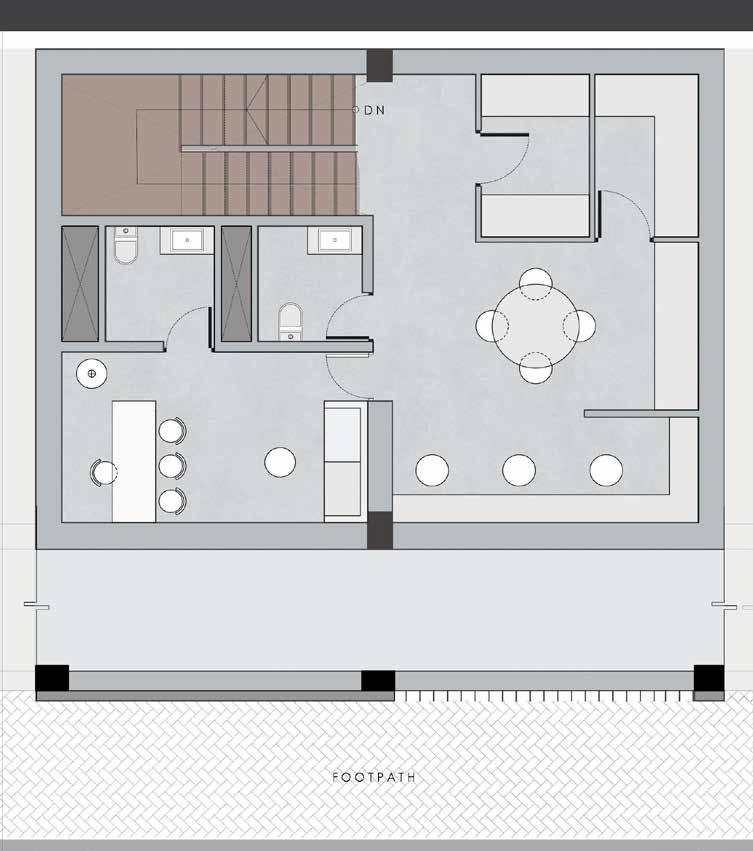

GROUND FLOOR PLAN

1 - ENTRY

2 - PREMIUM DISPLAY 1

3 - CASH COUNTER

4 - OUTDOOR DISPAY

5 - BUYING COUNTER 1

6 - DISPLAY 1

7 - PREMIUM DISPLAY 2

8 - LAUNGE

9 - BUYING COUNTER 2

10 - DISPLAY 2

11 - PREMIUM DISPLAY 3

CARPET AREA- 76.61 SQM

PLINTH AREA- 87.02 SQM

FIRST FLOOR PLAN

1 - PREMIUM DISPLAY 3

2 - BUYING COUNTER 3

3 - DISPLAY 3

4 - BUYING COUNTER 4

5 - DISPLAY 4

6 - STRONG ROOM

7 - PREMIUM DISPLAY 4

8 - CUTOUT SEEN BELOW

CARPET AREA- 64.72 SQM

PLINTH AREA- 76.46 SQM

SECOND FLOOR PLAN

1 - SERVICE AND ACCOUNTS

2 - STORAGE

3 - PANTRY

4 - STAFF STORAGE

5 - WORK TABLE

6 - ADMIN ROOM

7 - ADMIN TOILET

8 - STAFF TOILET

CARPET AREA- 56.2 SQM

PLINTH AREA- 87.02 SQM

GLASS FOR DISPLAY UNITS

BLACK MARBLE FOR COUNTER DISPLAY UNITS

MATERIAL PALETTE

GLASS FOR DISPLAY UNITS

BLACK MARBLE FOR COUNTER DISPLAY UNITS

MATERIAL PALETTE

THE BOARDS ARE BROADLY CLASSIFIED AS PLYBOARD, BLOCK BOARD, PARTICAL BOARD AND MDF BOARD. HDHMR BOARD IS A TYPE OF MDF BOARD.

HOW IS THIS MADE ? – AN HDHMR BOARD IS MADE USING A HOMOGENOUS MANUFACTURING PROCESS THAT COMBINES FIBRE CHIPS AND FOREST WOOD WASTE. THE FIBRE CHIPS ARE PRESSED TOGEHER TO FORM A SINGLE LAYER, AFTER WHICH SMALL AMOUNTS OF WOOD ARE REMOVED TO CREATE A MORE STURDY BOARD WITH HIGHER DENSITY.

THE FIRST MAIN ATTRACTIVE THING ABOUT HDHMR BOARD WE WANT TO FOCUS IS, WATER RESISTANCE. AS YOU CAN SEE IN THE NAME THE TERM, HIGH DENSITY IS ACHIEVED THROUGH THE COMBINATION OF THE HARD WOOD PARTICLE BOARD ALONG WITH THE SPECIAL GLUE PRESSING TECHNIQUE. THESE HARDWOOD PARTICLES WHEN PRESSED THROUGH THE GLUE, THEY FORM A UNIQUE WATER RESISTANCE LAYER THROUGH THE BOARD. DUE TO THIS FEATURE, THESE BOARDS WILL TAKE OVER PLYWOOD IN KITCHEN FURNITURE SOON AND CAN BE USED AS LAMINATED FLOORING.

DUE TO PRESSING TECHNIQUE SMALL UNUSABLE PARTICLE GET REMOVED FROM THESE BOARDS, WHICH MAKES THEM TERMITE FREE TOO. IN PLYWOOD MAKING PROCESS SOME CONTENT OF WOOD GET STUCK, WHICH PROVIDE EASY ACCESS TO TERMITES IN TERMS OF FOOD; BUT IF YOU ARE USING HDHMR BOARD THAN THERE IS NO NEED TO WORRY ABOUT TERMITES. DUE TO PRESSING TECHNIQUE OF HDHMR BOARD, SEVERAL SMALL FIBERS OF WOOD COMBINES TILL THE TIME IT REQUIRED DENSITY IS NOT ACHIEVED.

PROPERTIES

1. HIGH – DENSITY (850 KG/M3)

2. TOUGHER THAN PLYWOOD

3. NOMINAL COST

4. HIGHLY WATER RESISTANCE

5. BORER RESISTANCE

6. MULTI DIMENSIONAL BONDING TECHNOLOGY

7. HIGHER SCREW HOLDING STRENGTH IN CORE

8. ZERO BUBBLE FINISH

9. TRUTH CALIBRATED PANEL

10. ENVIRONMENT FRIENDLY

11. NO SPLINTERS/CHIPING

12. IDEAL ROUTABLE SUBSTRATE

LIFE SPAN

DRY CONDITION – LIFE UPTO 15YEARS WITH LAMINATION – LIFE UPTO 17-20YEAR

DISADVANTAGE

AFTER LONG-TERM USE, SOME HDHMR BOARDS MIGHT BEND AND LOSE SHAPE.

MARKET AVAILABLITY AND RATES

• 3MM THIK 8’X4’ - 20RS PER SQ.FT

• 5.5MM THIK 8’X4’ - 35RS PER SQ.FT

• 8MM THIK 8’X4’ - 50RS PER SQ.FT

• 12MM THIK 8’X4’ - 75RS PER SQ.FT

• 16MM THIK 8’X4’ - 100RS PER SQ.FT

• 16.75MM THIK 8’X4’ - 105RS PER SQ.FT

• 18MM THIK 8’X4’ - 115RS PER SQ.FT

THE KEY APPLICATION AREAS OF HDHMR

•KITCHEN SHUTTERS •FURNITURE WHERE RISK OF MOISTURE EXIST •DOORSHUTTERS •PACKING INDUSTRY •SHOE HEEL• PARTITIONS •OUTDOOR FIXTURES LIKE ELECTION CUTOUTS OR SIMILAR APPLICATIONS •WALL PANELING.

PLYWOOD

1.PLYWOOD IS MADE WITH WOOD VENEERS WHICH ARE LAID IN SUCH A MANNER THAT GRAINS OF ADJACENT LAYERS ARE IN PERPENDICULAR DIRECTION TO EACH OTHER.

2. PLYWOOD USES VENEERS PEALED FROM THE TRUNK OF MATURE HARD WOOD TREES ONLY. HENCE 50% OF THE TREE REMAINS UNUSED OR WASTED.

3. SINCE MADE FROM VENEERS, DISADVANTAGES OF WOOD LIKE TERMITE/BORER ATTACK AND UNCONTROLLED EXPANSION/CONTRACTION REMAINS THERE.

4. TRUE THICKNESS IS NOT AVAILABLE AS CORE & FACE THICKNESS VARY WITH THE PEELING & THE CAN BE CONTROLLED ONLY TO A CERTAIN EXTENT.

5. OVER THE PASSAGE OF TIME, PLYWOOD LAYERS TENDS TO PEEL OFF FROM THE EDGES

6.PLYWOOD & BLOCK BOARD TEND TO HAVE DENSITY VARIATION DUE THE VARIABLE GRAIN DENSITY, HENCE HAS VARIED PHYSICAL & MECHANICAL PROPERTIES. HAS CORE GAPS.

7.PLYWOOD HAS A SURFACE THAT NEEDS TO BE FINISHED/PREPARED LIKE SANDING AND PUTTY FILLING BEFORE PAINTING/ POLISHING OR OTHER FINISHING PROCESSES .

8.DUE TO UNCONTROLLED THICKNESS VARIATION ACROSS THE BOARD AND ROUGH SURFACE, PRELAMINATION OF RESIN IMPREGNATED PAPER IS NOT POSSIBLE

9.PLYWOOD CANNOT BE CARVED OR ROUTED OR PROFILED

10.DENSITY LIES IN NORMAL MEDIUM DENSITY I.E AROUND 750 KG/M3

1.HDHMR IS MADE WITH WOOD FIBRE/WOOD CHIPS AND SYNTHETIC THERMOSETTING RESIN IN A HOMOGENEOUSLY SPREAD MAT & PRESSED IN TEMPERATURE AND PRESSURE CONTROLLED PRESS.

2. HDHMR IS MADE FROM WOOD FIBRES/CHIPS THAT IS PRODUCED FROM PLANTATION WOOD, AGRICULTURAL WASTE OR FROM THE FOREST WOOD WASTE & USES 95% OF THE TREE. HENCE SAVES THE ENVIRONMENT.

3. MADE FROM FIBRES OF LIGNOCELLULOSIC MATERIALS, DURING PROCESS OF MAKING FIBRES THE WOOD CHIPS ARE STEAM COOKED RESULTING IN REMOVAL OF ALL FOOD CONTENT THEREBY MAKING IT TERMITE/BORER RESISTANT, AS THESE INSECTS ATTACK THE WOOD IN SEARCH OF FOOD ONLY.

4. TRUE THICKNESS IS AVAILABLE AS PRESSING PARAMETERS ARE PERFECT. PRECISE UNIFORMS THICKNESS CAN BE MANUFACTURED.

5. HDHMR HAS A MULTI-DIMENSIONAL BOND BETWEEN FIBRE WHICH IS STRONGER WITH HIGHER BONDING SURFACE BETWEEN FIBRES.

6.HDHMR HOMOGENEOUSLY CONSTRUCTED WITH UNIFORM SPREAD OF FIBRE/CHIPS, HENCE HAS UNIFORM PHYSICAL & MECHANICAL PROPERTIES.

7.IN HDHMR/MDF THERE’S PAINT/POLISH READY SURFACE. PASTING OF VENEER/HPL IS EASIER RESULTING SMOOTH FINISH WITHOUT ANY UNDULATION UNLIKE PLYWOOD OR BLOCK BOARD.

8.DUE TO UNIFORM THICKNESS AND SMOOTH SURFACE, PRE-LAMINATION ON HDHMR WITH RESIN IMPREGNATED PAPER GIVES A PERFECT FINISH

9.HDHMR DUE TO ITS FIBROUS HOMOGENEOUS CONSTRUCTION CAN BE PROFILED, CARVED, MOULDED, ROUTED

10DENSITY MORE THEN 850 KG/M 3 RESULTING IN BETTER COMPACTNESS AND STRENGTH