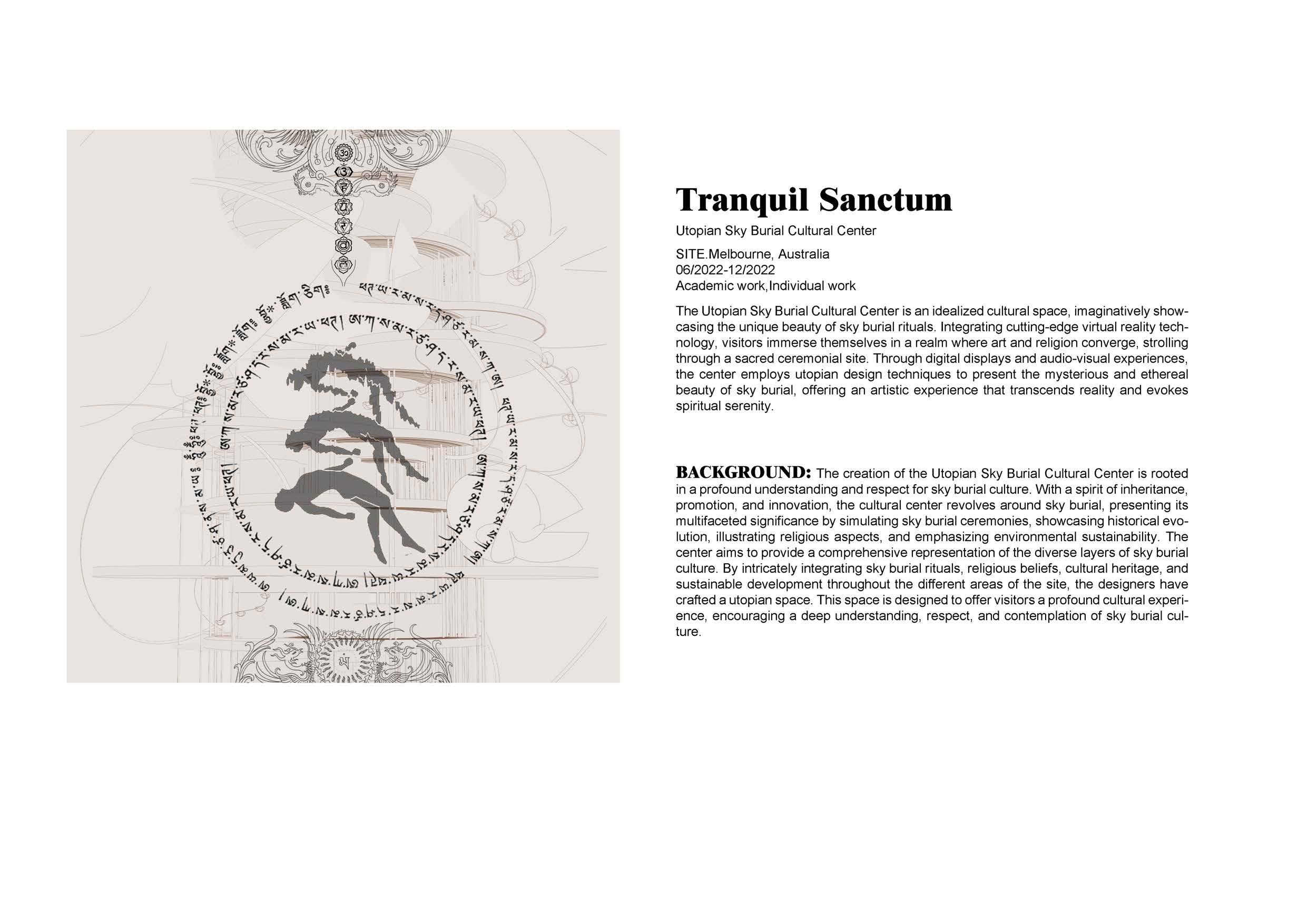

Tranquil Sanctum

Site: Tibet, China

Date: 06/2022 - 12/2022 Academic work,lndividual wo「k

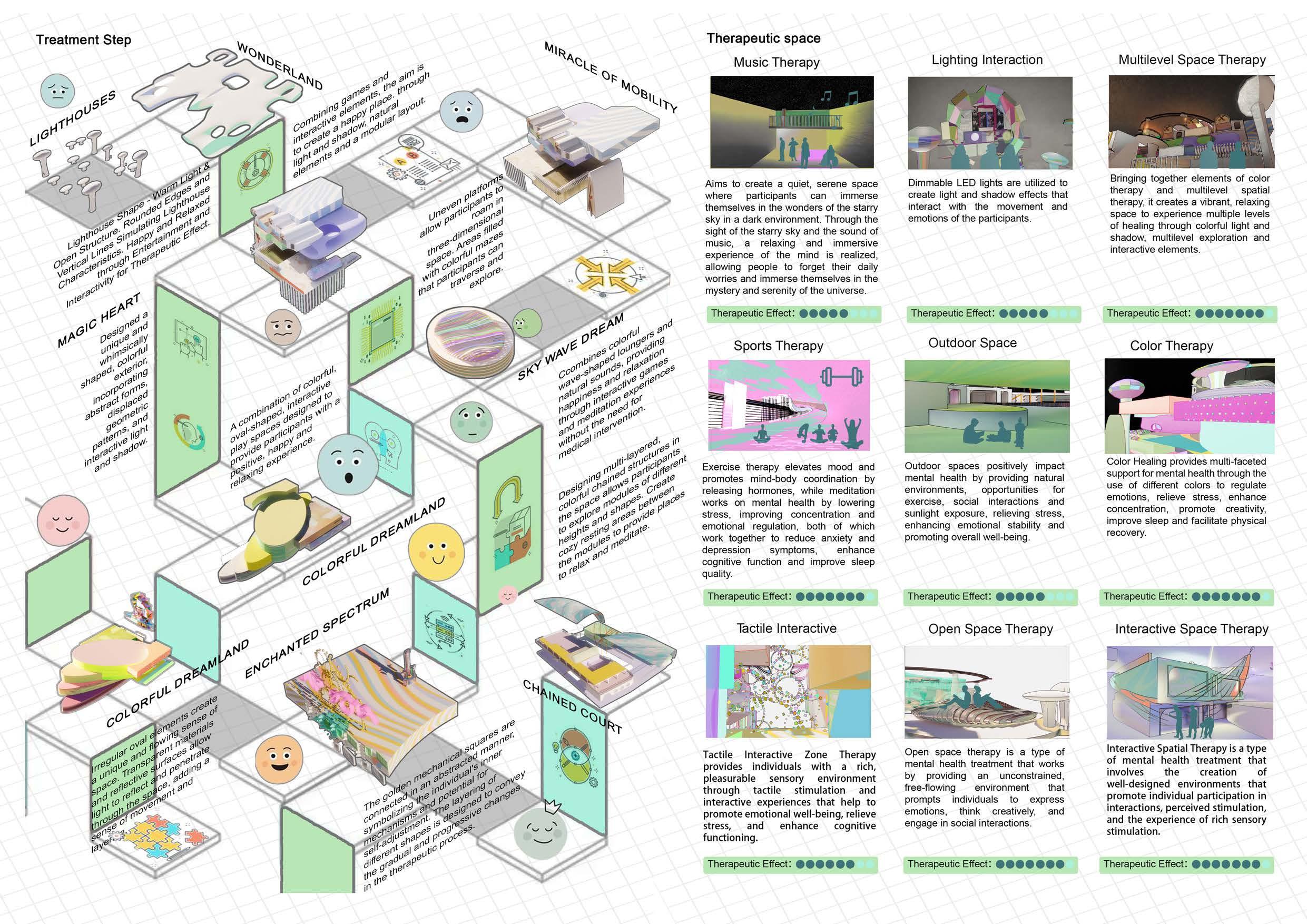

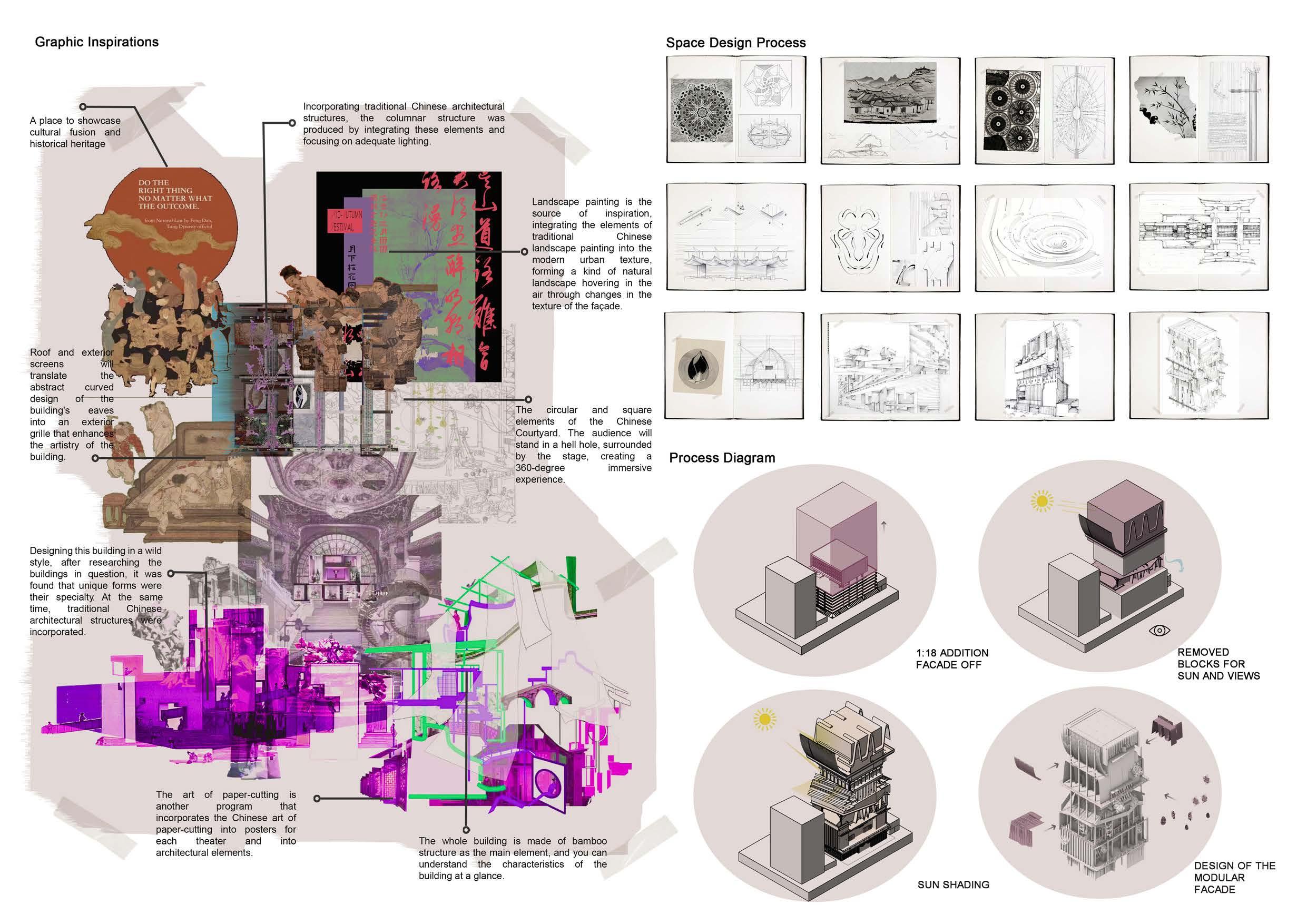

02 DreamSoul Haven

Site: Melbourne.Aust「alia Date: 03/2022 - 09/2022 Academic work,lndividual work

03 Time Journey

Site: Melbourne,Australia Date: 07/2023 - 11/2023 Academic work,lndividual work

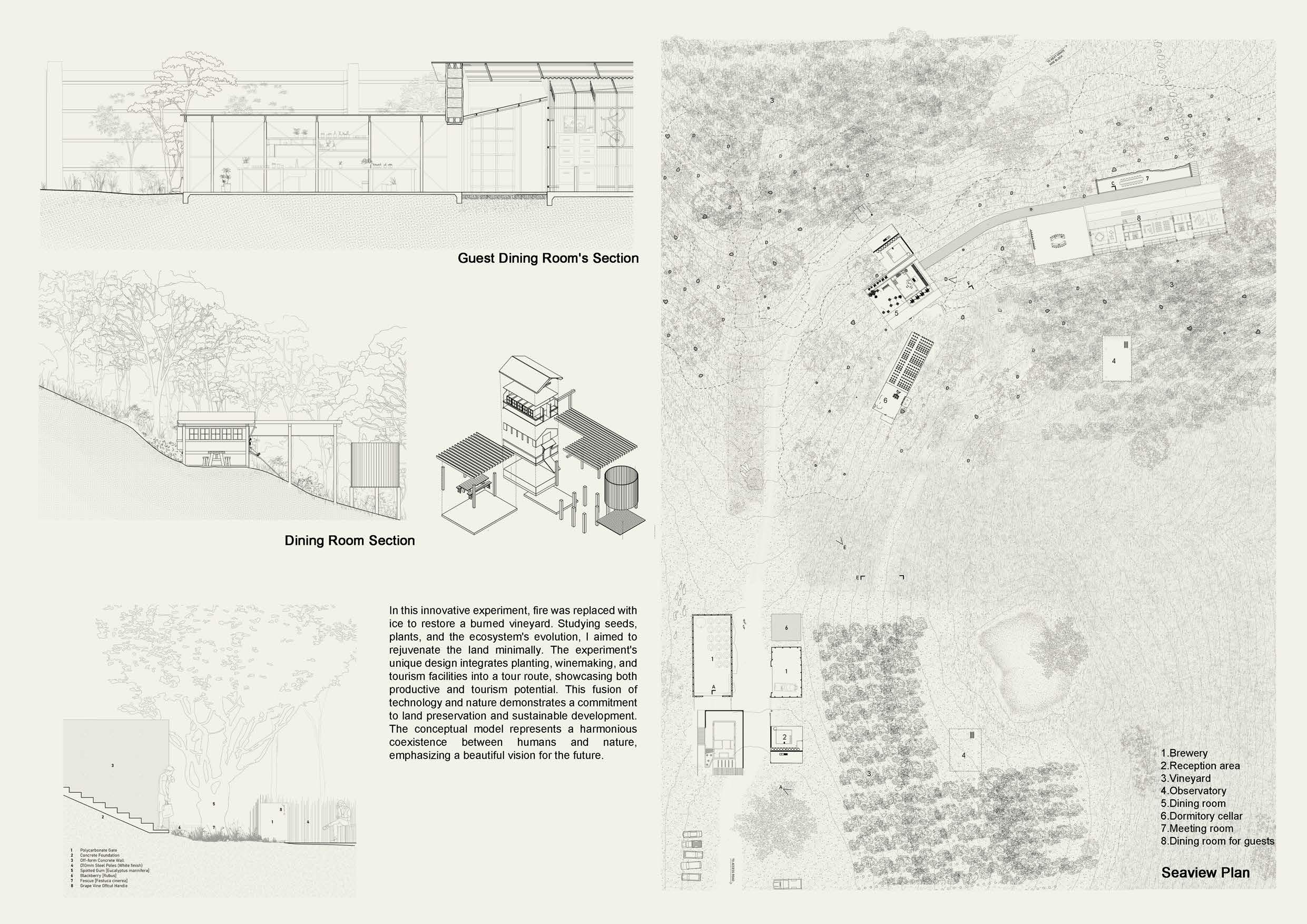

04 Minimal Intervention

Site: Melbourne,Aust「alia Date: 02/2023 - 07/2023 Academic work.Individual work

05 Inflatable Formwork for Concrete Casting

Site: HONGKONG

Date: 05/2024 - 06/2025 Academic work.Group work

Inflatable Formwork for Concrete Casting

The University of Hong Kong MAAD6103 Design Research Studio III Documentation Group

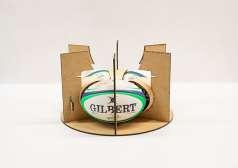

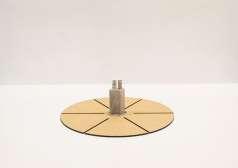

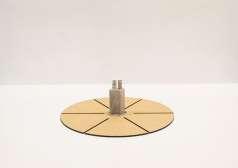

The first mockup model is complete, symmetrical and stable, which proves that the whole design process is successful and reasonable. The concrete surface clearly records the outline of the mold, and the columns are slightly distorted due to the high compression of the concrete.

MOCKUP TRIALS

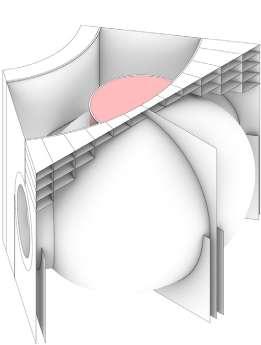

The 1:1 MOCK-UP project presents a large-scale concrete prototype that reexamines the column-to-slab structural archetype by investigating alternative materials for formwork design, emphasizing environmental sustainability, economic viability, and responsiveness to the casting process. The primary objective of this project is to analyze the structural dynamics of the plate column while aiming to create a sculptural form akin to an umbrella, achieved by inverting a membrane under the pressure exerted by an inflated balloon.

MOCKUP TRIALS

Prior to the official pour, we conducted a 1:15 mock-up, a 1:10 mock up and worked with the factory to complete the construction drawings for a 1:1 prototype. This approach not only helps to optimise the current design, but also enhances our understanding of the manufacturing process and builds up more practical knowledge for next semester’s construction at the site.

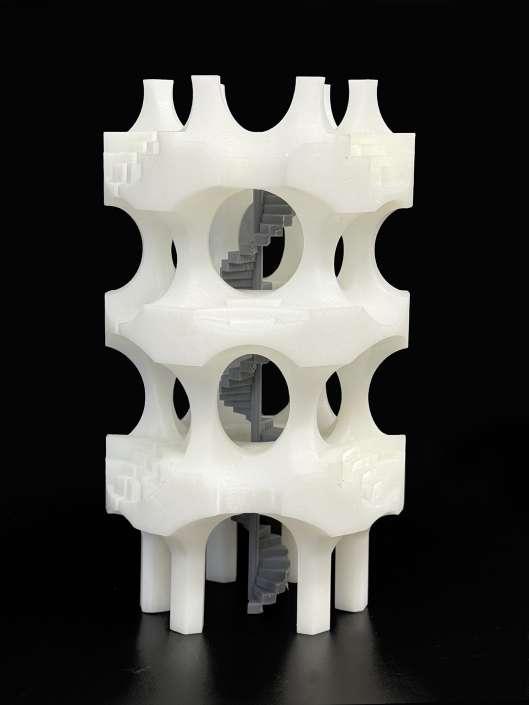

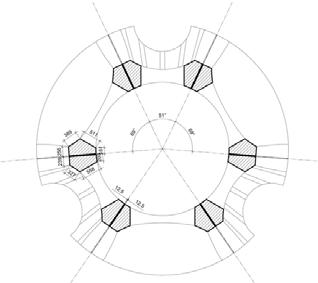

The construction methodology for this design involves the integration of elliptical elements with a diameter of 4 meters and spherical elements of equal size, forming the fundamental building blocks of the structure(Figure 5). The first layer is supported by prefabricated hexagonal columns, which create an arched arrangement that enhances both the visual aesthetics and structural stability of the design. These hexagonal columns, approximately 1.43 meters tall, are complemented by arches reaching a height of 2 meters, which collectively support the platform for the second layer.

DESIGN PITCH

模板设计 FORMWORK

模板设计 FORMWORK

模板设计 FORMWORK

模板设计 FORMWORK

预制构件A1 PRECAST COMPONENT A1

Precast Concrete Components

预制构件A1 PRECAST COMPONENT A1

Component A1

SIZE(L*W*H)=3.94M*1.97M*3.29M 体积=4.97立方米

普通混凝土重量=11.93吨

普通混凝土重量=11.93吨

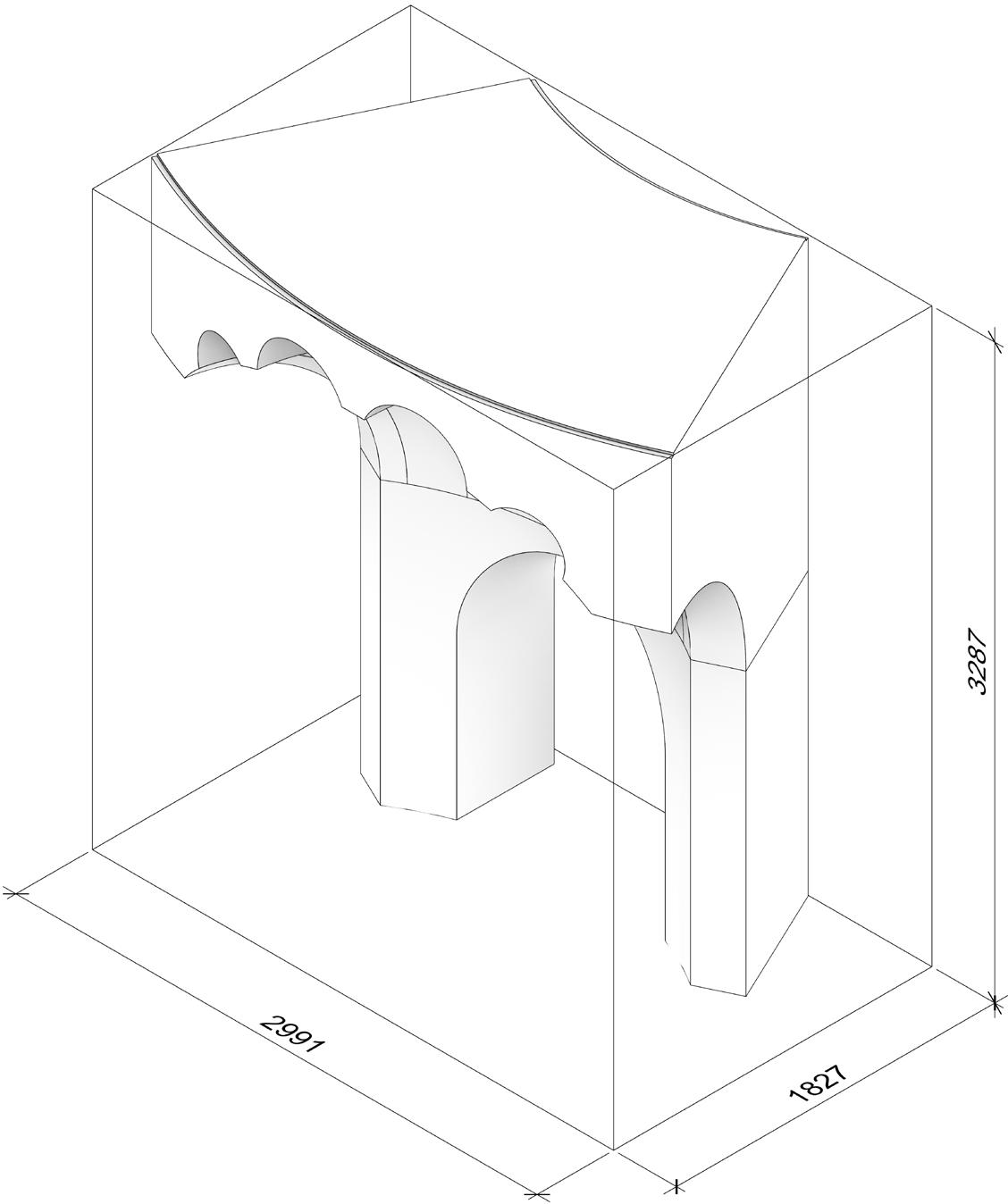

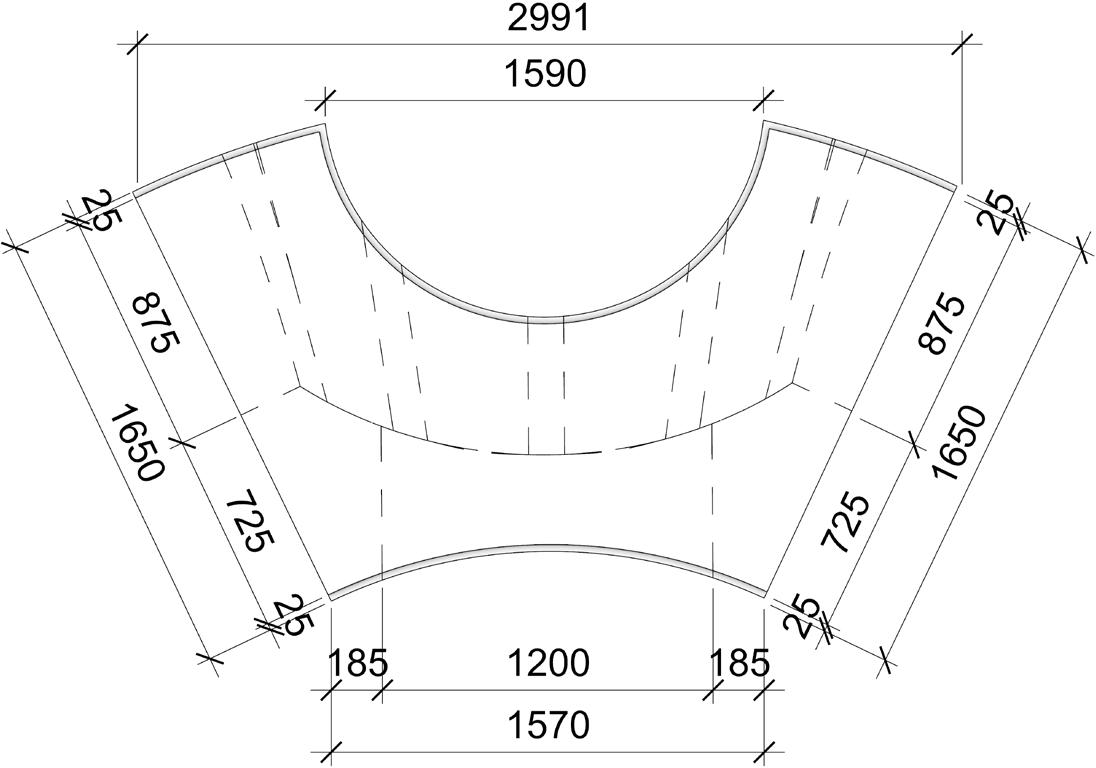

Component A2

SIZE(L*W*H)=3.94M*1.97M*3.29M VOLUME=4.94M³ NORMAL CONCRETE WEIGHT=11.93T

SIZE(L*W*H)=3.94M*1.97M*3.29M SIZE(L*W*H)=3.94M*1.97M*3.29M 体积=4.97立方米

PRECAST COMPONENT B1

预制构件B1 PRECAST COMPONENT B1

Precast Concrete Components

Component B1

Size(L*W*H)=3.94M*1.97M*3.29M Volume=4.97㎡ Normal Concrete Weight=11.93t Top View

VIEW @1:50

预制构件B2

PRECAST COMPONENT B2

Size(L*W*H)=2.99M*7.83M*3.29M Volume=4.63㎡

Normal Concrete Weight=11.11t

预制构件A2 PRECAST COMPONENT A2 TOP VIEW

预制构件A2 PRECAST COMPONENT A2 TOP VIEW @1:50

Size(L*W*H)=3.94M*1.88M*3.29M Volume=4.74㎡ Normal Concrete Weight=11.38t Top View

预制构件B2 PRECAST COMPONENT B2

Component B2

SIZE(L*W*H)=2.99M*1.83M*3.29M

体积=4.63立方米

普通混凝土重量=11.11吨

SIZE(L*W*H)=2.99M*1.83M*3.29M 体积=4.63立方米

普通混凝土重量=11.11吨

SIZE(L*W*H)=2.99M*1.83M*3.29M VOLUME=4.63M³ NORMAL CONCRETE WEIGHT=11.11T

SIZE(L*W*H)=2.99M*1.83M*3.29M VOLUME=4.63M³ NORMAL CONCRETE WEIGHT=11.11T

SIZE(L*W*H)=2.99M*1.75WM*3.29M

体积=4.27W立方米

普通混凝土重量=10.25吨

SIZE(L*W*H)=2.99M*1.75WM*3.29M