International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Sonet D Cleetus1 , Manish Jose2

1 Student, Dept. of Civil Engineering, St. Joseph’s College of Engineering & Technology, Kerala, India

2 Assistant professor, Dept. of Civil Engineering, St. Joseph’s College of Engineering & Technology, Kerala, India ***

Abstract - Most residential buildings are constructed of shallow footing. If soil shows low bearing capacity, deep foundations are adopted. But it is uneconomical to construct a deep foundation for residential purpose. So, in order to reduce the construction cost and strengthen the soil, soil reinforcement methods are adopted. Geocell reinforcement is one of the effective ways to reduce the soil settlement. In this paper, the possibility and effects of providing geocell reinforcement on conical shell footing, isolated footing and strip footing are determined. A comparison on single and multilayer geocell reinforcement on these foundations are analyzed. Also, the effect of varying cohesion value of soil and friction angle value of soil on these foundations reinforced with geocell is determined.

Key Words: Geocell, Conical shell footing, Isolated footing, Strip footing, Settlement, Bearing capacity

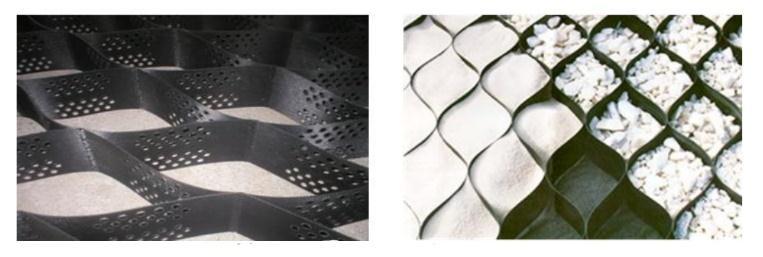

Soil reinforcement techniques is the means of giving strength to the soil. If the soil is having low bearing capacity and high settlement, the only way to reduce this conditionissoilreinforcement.Severalsoilreinforcement methodsareavailablenowadays.Inthebeginning,thesoil isreinforcedusing bamboos,straws,reedsetc.Butdue to the innovations in construction field and difference in construction techniques, the natural reinforcement method was unable to take heavy loads and cause higher settlement. So, the natural reinforcement technique is replaced with modern technique. One of the most commonly adopted reinforcement methods nowadays is geocell reinforcement. Geocell is a three-dimensional polymermembraneusedto strengthentheweak soil.Itis ameshlikestructure,thepocketsorcelllikeshapeisfilled with locally available soil. Mostly they are used for enhancing the strength of road, embankments, protection of slope etc. The fig below shows the geocell filled with soil.

Themainaimandobjectiveofthisprojectistoanalyzethe settlement behavior and bearing capacity of conical shell footingreinforcedwithsingleandmultiplegeocell.Andto compare these footing with isolated footing and strip footing. A parametric study on varying the cohesion and frictionanglehasbeenconductedtofindtheeffectofthese footings on different soil and to determine their settlementandbearingcapacity.

Geocell reinforcement is one of the soil reinforcement techniques used to strengthen the weak soil. Several reinforcement methods are available nowadays. But this technique is unique is because theyare very cost effective andcanevenbeusedforfoundationpurpose.Geocellsare three-dimensional in shape and cells or the pockets of geocell are filled with sand, gravel or locally available materials.Due toits meshlike, the pockets encasethesoil and provide enrich support to weak soil. This will help in spreading the vertical forces to a much wider area. Thisis developed by U. S. Army to strengthen the weak soil material. Providing multilayers of geocell give additional strengthtothesoil.Providing multilayers ofgeocell tothe soilgiveadditionalstrengthtothesoil.

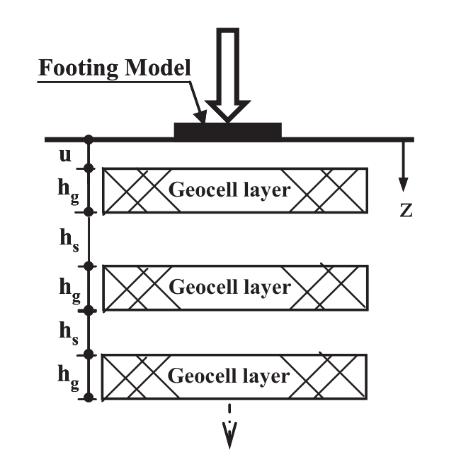

Where u is the height of the soil from the footing base to thetopofthegeocell,hg istheheightofthegeocellandhs is the height of the soil layer between the geocells. Multilayers of geocells helps in reducing the stress developed inside the soil to a great extent. Therefore, the settlementorthedeformationtherebyreduces.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

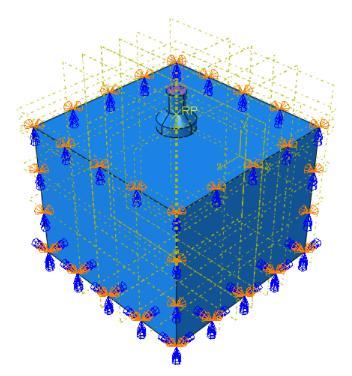

Non-linear analysis of conical shell footing, isolated footing and strip footing reinforced with single and multilayers of geocell is done using ABAQUS CAE 2018 software.

Detailed dimensions and material properties of conical shell footing reinforced with single and multilayer geocell arediscussedintable1below.

-

Properties Soilbed Coresoil Footing Geocell

Young’s modulus,E (kN/m2)

11000 11000 1.61× 1010 275000 Poissons ratio,ν 0.3 0.3 0.25 0.45

Cohesion,c (kPa) 0.35 0.35Friction angle,ϕ(◦ ) 37 37 - 30 Unit weight,γ (kN/m3)

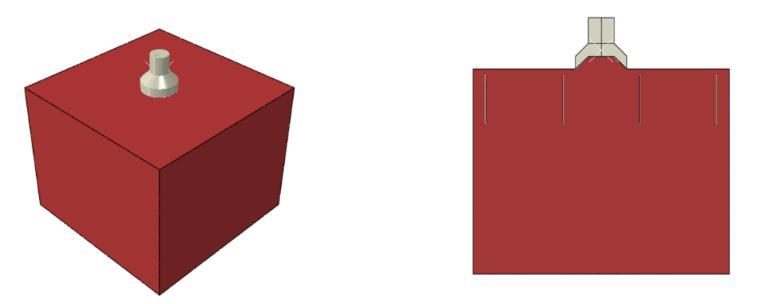

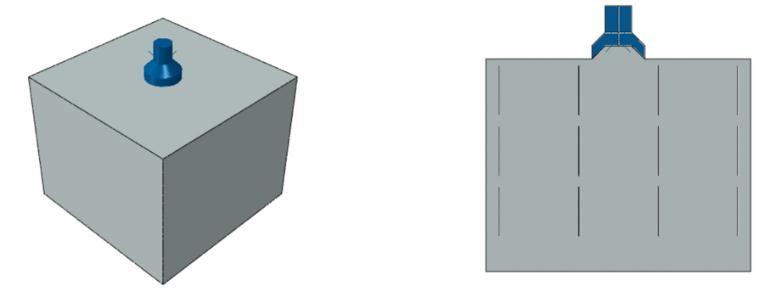

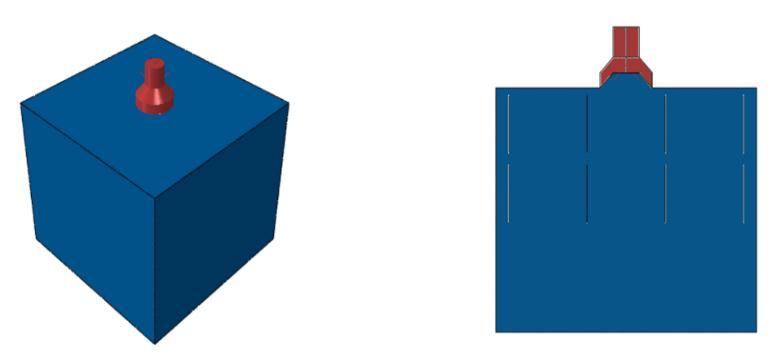

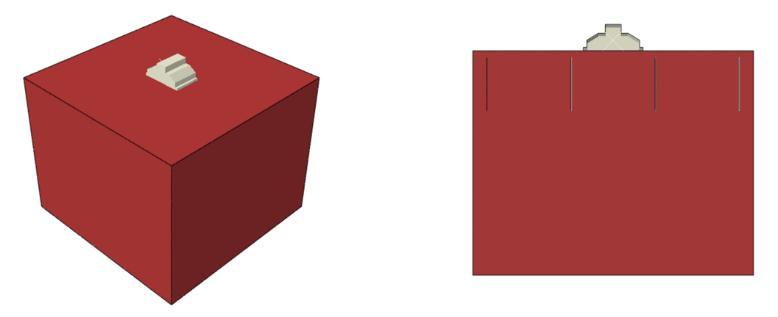

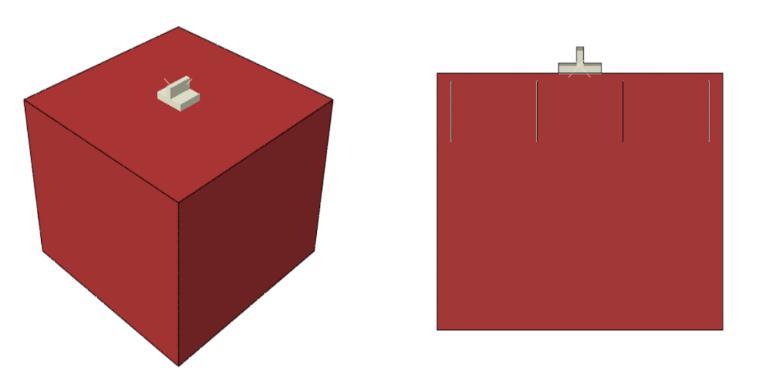

Anappliedpressureof600kPaisappliedatthetopsurface of the conical shell footing. The assembled model and section view of conical shell footing reinforced with onelayergeocellisgivenbelow;

Fig -4 Assembledmodelandsectionviewofgeocell reinforcedconicalshellfooting

- - -

17.6 17.6 -Dimension 0.8mx 0.8mx 0.64m

Cellsize (mm) - - - 240x 210x 150

The base of the footing is provided with fixed support condition and all the other four sides are provided with rotation or displacement. A contact tie is given to the footing and soil bed in order to provide smooth flow of loadtothefoundationsoil.

2.3 Analysis

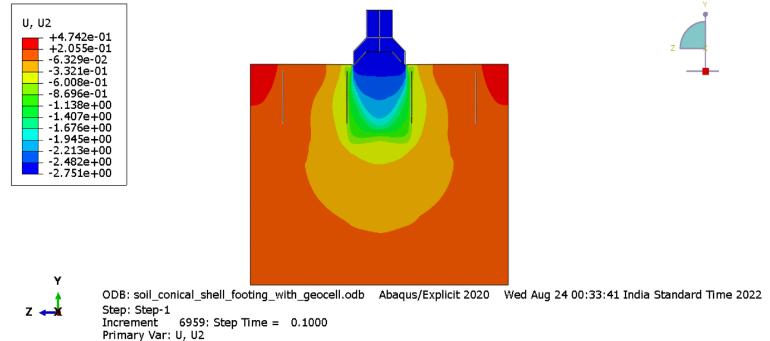

of one-layer geocell reinforced conical shell footing

-5

The analysis result shows that by applying one-layer geocell to the conical shell footing give an ultimate settlement value of 2.75mm and an upward soft lift of4.742mm. this result shows that, when an applied pressureisappliedtothefootingonlyasmallsettlementis noticed while comparing with unreinforced conical shell footing.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

2.4

Thegeocellsareplacedintwolayers.Theheightofthesoil istakenas0.32m,ie;2D(2x0.16).Sameappliedpressure, meshingandboundaryconditionsareprovidedwiththis.

Fig 8 shows the assembled model and section view of singlelayergeocellreinforcedconicalshellfooting.

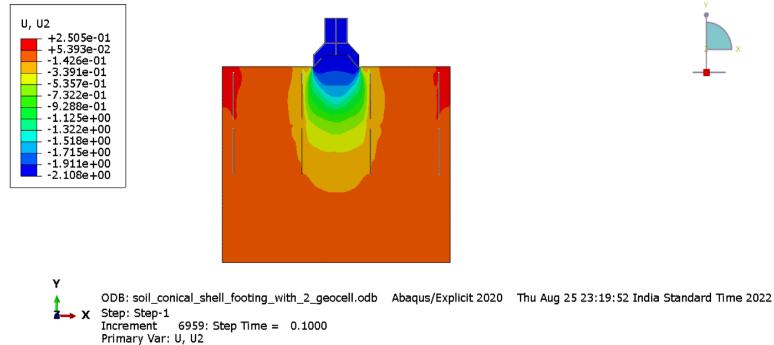

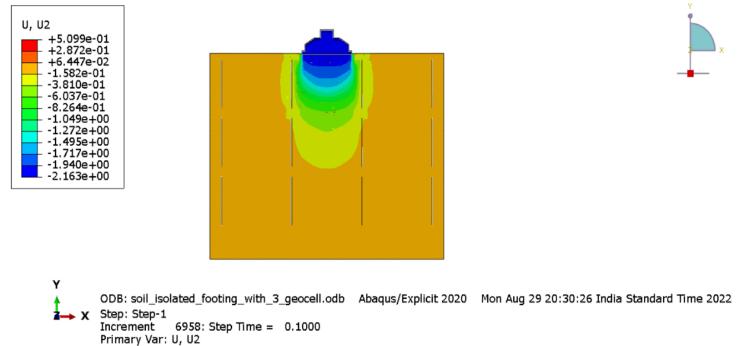

2.7 Analysis result of three-layer geocell reinforced conical shell footing

Fig -6 Assembledviewandsection

The figure shows the assembled view and section view of two-layergeocellreinforcedconicalshellfooting.

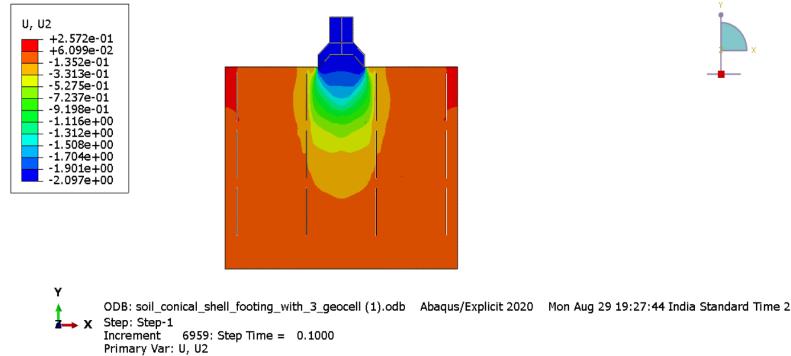

2.5 Analysis result of two-layer geocell reinforced conical shell footing

Fig - 9 Settlementanalysisresultofthree-layergeocell reinforcedconicalshellfooting

The settlement result concluded that, there shows an ultimate minimum settlement of 2.09mm and minimum soil uplift of -0.257mm. thus, when soil settlement is reducing on increasing number of layers, the bearing capacitycanbeincreased.

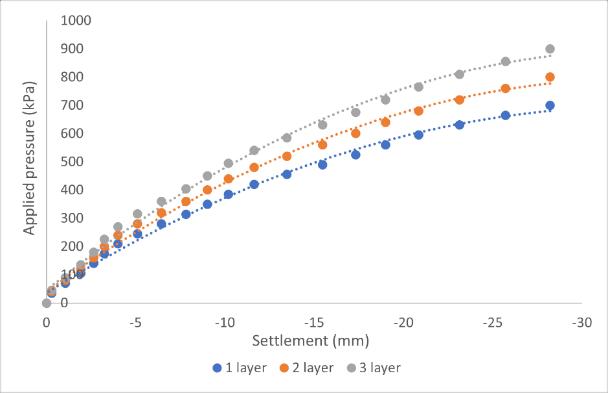

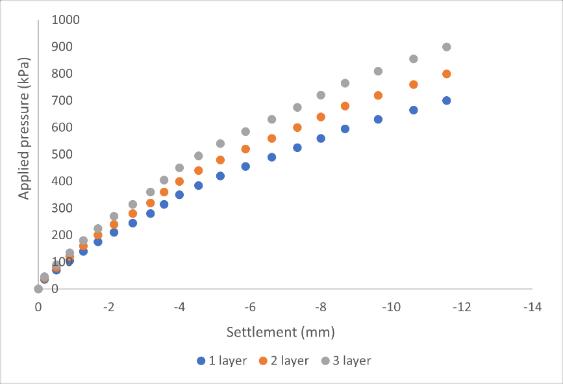

2.8 Comparison of single and multilayer geocell reinforced conical shell footing

Table – 2 Comparisonresultofone-layer,two-layerand three-layergeocellreinforcedconicalshellfooting

Fig - 7 Settlementanalysisresultofone-layergeocell reinforcedconicalshellfooting

The analysis result shows that the two-layer geocell reinforcedconicalshellfootingonappliedpressureshows an ultimate maximum settlement of 2.108mm and an upwardsoilliftof-0.250mm.thisshowsthatonincreasing the number of layers of geocell, the settlement of the footingreducedtoanoticeablelimit.

2.6 Two-layer geocell reinforced conical shell footing

Geocelllayer Umax(mm) Umin(mm) Onelayer 2.75 -0.474 Twolayers 2.10 -0.250 Threelayers 2.09 -0.257

Fig -8 Assembledmodelandsectionview

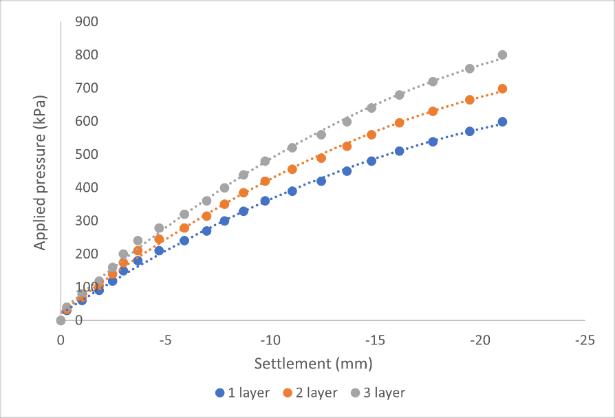

Chart - 1 Comparisonresultonthebearingcapacityof multilayergeocellreinforcedconicalshellfooting

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

The analysis result concluded that, three-layer geocell reinforced conical shell footing offers good minimum settlement result. Thus, three-layer geocell below footing helps in reducing the settlement and bearing capacity of footingcanbereduced.

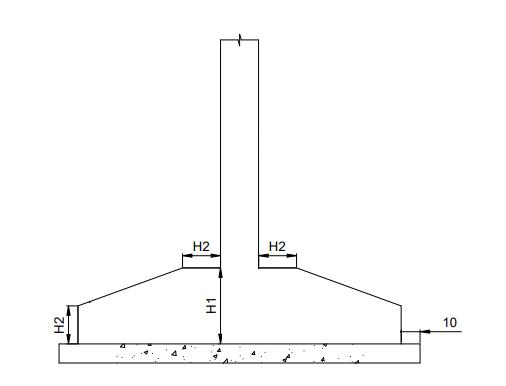

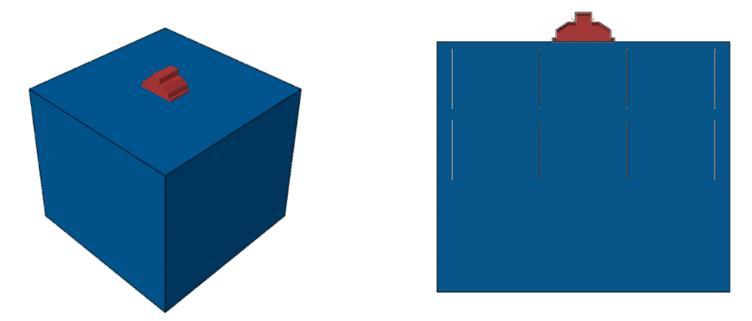

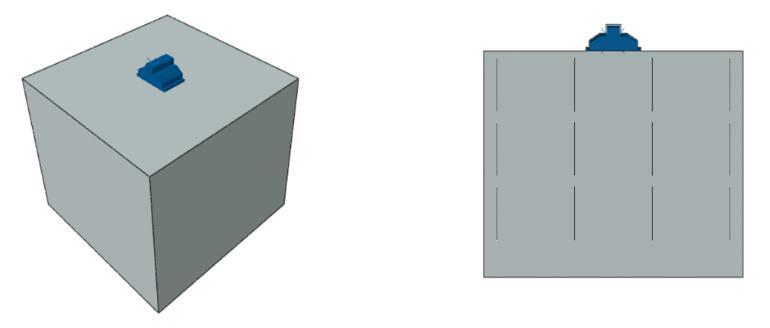

In this section, geocell reinforced in single and multilayer geocell is applied to the isolated footing. One of the most commonlyadoptedshallowfootingisisolatedfooting.This directly transfer heavy loads to the foil in a much wider area. This footing is provided with same pressure, boundary conditions and soil material properties same as the conical shell footing. The fig 10 shows the detailed dimensions of isolated footing, where H1 is 40cm, H2 is 20cmandsizeis170cmx110cm.

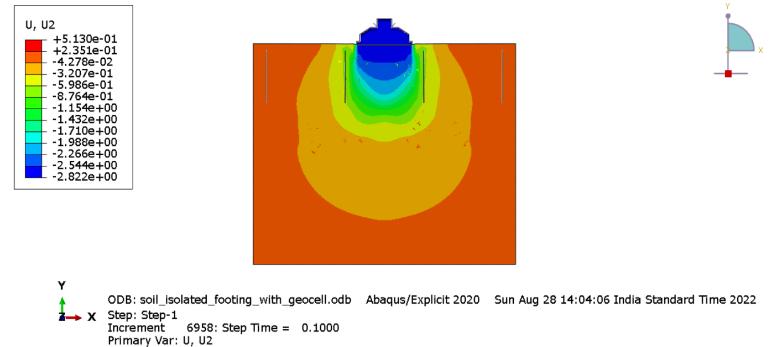

3.2 Analysis result of one-layer geocell reinforced isolated footing

Fig – 10 Isolatedfooting

3.1 One-layer geocell reinforced isolated footing

Fig - 12 Settlementanalysisresultofone-layergeocell reinforcedisolatedfooting

Fig 12 shows the settlement analysis result of on-layer geocell reinforced isolated footing. From the analysis result, the maximum ultimate settlement occurred due to the applied pressure is 2.822mm and minimum upward soilliftof-0.513mm

3.3 Two-layer geocell reinforced isolated footing

Fig 13 shows the assembled model and section view of geocell reinforced on two layers isolated footing. Providing two-layers of geocell helps in reducing the settlement compared to one-layer geocell. this is an effectivewaytoreducethesettlementduetoheavyloads.

Fig -13 Assembledmodelandsectionview

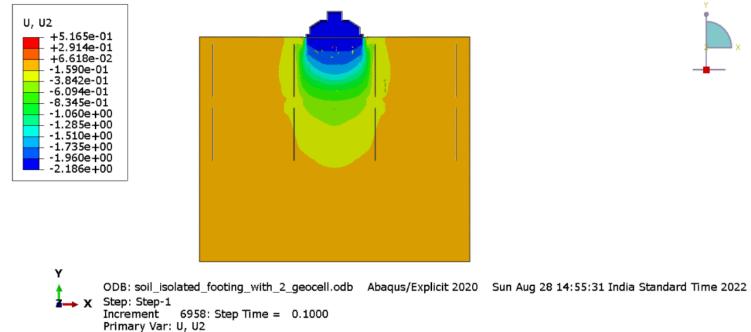

3.4 Analysis result of two-layer geocell reinforced isolated footing

Fig -11 Assembledmodelandsectionview

Fig 11 shows the assembled model and section view of isolatedfooting reinforced withone-layer geocell.Footing isprovidedwithsameappliedpressure samegiventothe conicalshellfooting.

Fig - 14 Settlementanalysisresultoftwo-layergeocell reinforcedisolatedfooting

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Settlement result of two-layer geocell reinforced isolated footing is shown in fig 14. The analysis results concluded that, there shows an ultimate maximum settlement of 2.186mmandminimumsoftupliftof-0.516mmisnoted.

3.5 Three-layer geocell reinforced isolated footing

Geocellsareplacedonthreelayersasshowninfig15.This gives additional strength to the weak soil. Same pressure, boundaryconditionsareappliedtothissoilbed.

On comparing the results, three layers of geocell give minimum settlement on comparing with one-layer and two-layer geocell. And this shows only a minimum uplift value.Thus,thebearingcapacityofthesoilisincreased.

Fig -15 Assembledmodelandsectionview

3.6 Analysis result of three-layer geocell reinforced isolated footing

Theanalysisresultshowsthat,thereoccurredamaximum ultimate settlement of 2.163mm and minimum soil uplift of-0.509mm.

Chart – 2 Comparisonresultonthebearingcapacityof multilayergeocellreinforcedisolatedfooting

Fig - 16 Settlementanalysisresultofthree-layergeocell reinforcedisolatedfooting

2.8 Comparison of single and multilayer geocell reinforced isolated footing

Table – 3 Comparisonresultofone-layer,two-layerand three-layergeocellreinforcedisolatedfooting

Geocelllayer Umax(mm) Umin(mm)

Onelayer 2.822 -0.513

Twolayers 2.186 -0.516

Threelayers 2.163 -0.509

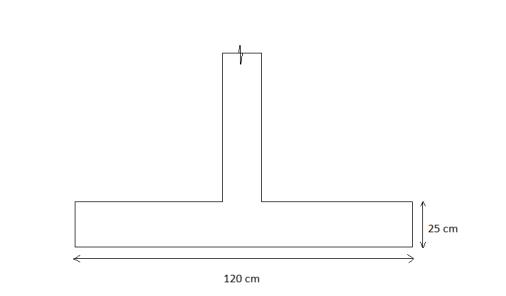

Fig - 17 Stripfooting

One of the most commonly adopted shallow footing is stripfooting.Thisfootinghelpsindirectlytransferringthe heavyloadsthroughthewallstothefootingtothesoil.

4.1 One-layer geocell reinforced strip footing

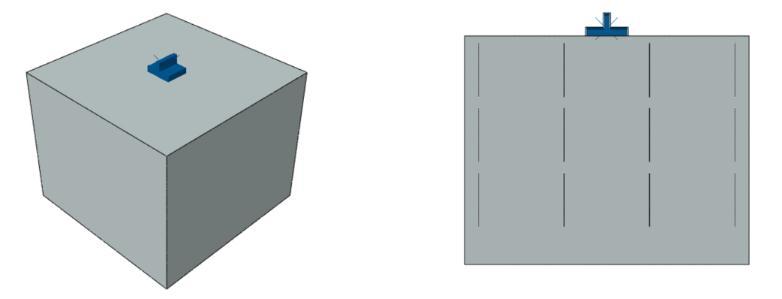

Fig -18 Assembledmodelandsectionview

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page511

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Fig 18 shows the assembled model and section view of stripfootingreinforcedinone-layer.

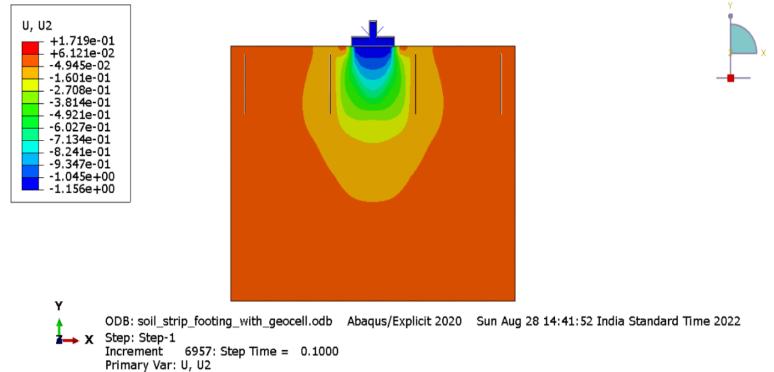

4.2 Analysis result of one-layer geocell reinforced strip footing

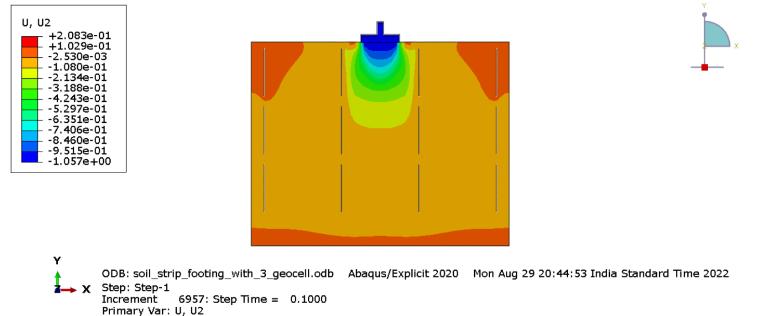

The settlement analysis result shoes that, the ultimate maximum settlement of 1.055mm and minimum upward soil lift of -0.201mm was noticed. Compared to one-layer geocell two-layer geocell reinforced strip footings show bettersettlementreduction.

4.5 Three-layer geocell reinforced strip footing

Fig - 19 Settlementanalysisresultofone-layergeocell reinforcedstripfooting

The analysis result concluded that, there shows a maximum ultimate settlement of 1.156mm and minimum soilupliftof-0.171mm.

4.3

The geocell layers are placed on two layers below the footing. This way, the settlement can be reduced for a weaksoilbase.

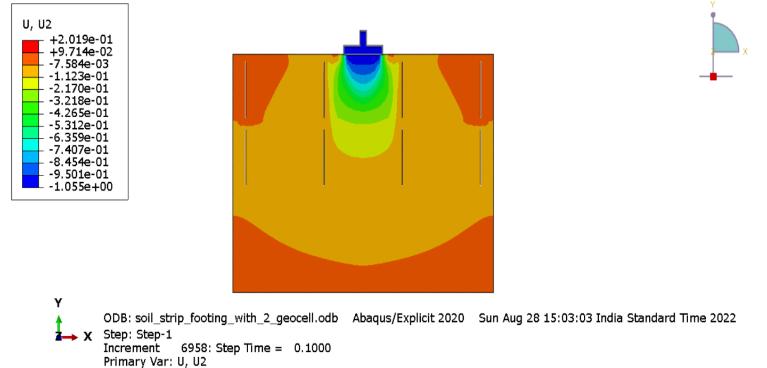

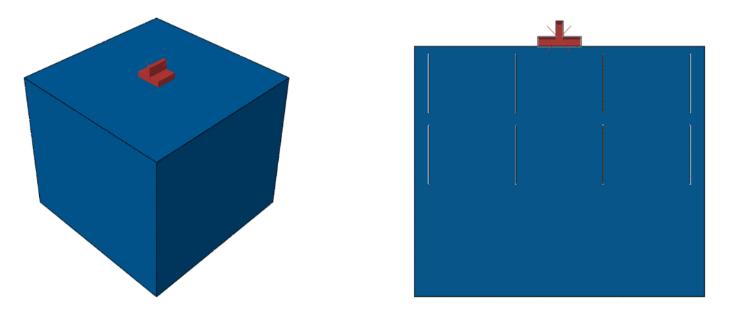

Fig -22 Assembledmodelandsectionview

Fig 22 shows the assembled model and section view of three-layer geocell reinforced strip footing. Geocells are placedinthree-layersbelowthefooting.

4.6 Analysis result of three-layer geocell reinforced strip footing

Fig -20 Assembledmodelandsectionview

4.4 Analysis result of two-layer geocell reinforced strip footing

Fig - 23 Settlementanalysisresultofthree-layergeocell reinforcedstripfooting

Theresultoftheanalysisshows,theultimatemaximum settlementobservedis1.057mmandminimumupward soilliftis-0.208mm.

4.7 Comparison of single and multilayer geocell reinforced strip footing

Table – 4 Comparisonresultofone-layer,two-layerand three-layergeocellreinforcedstripfooting

Geocelllayer Umax(mm) Umin(mm) Onelayer 1.156 -0.171 Twolayers 1.055 -0.201 Threelayers 1.057 -0.208

Fig - 21 Settlementanalysisresultoftwo-layergeocell reinforcedstripfooting

Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Chart – 3 Comparisonresultonthebearingcapacityof multilayergeocellreinforcedstripfooting

Oncomparingtheresultsofone-layer,two-layerandthree later geocell reinforced strip footing, three-layer geocell reinforcedstripfootingoffersbettersettlementreduction. Thus, by reducing the settlement, the bearing capacity of thesoilisincreased.

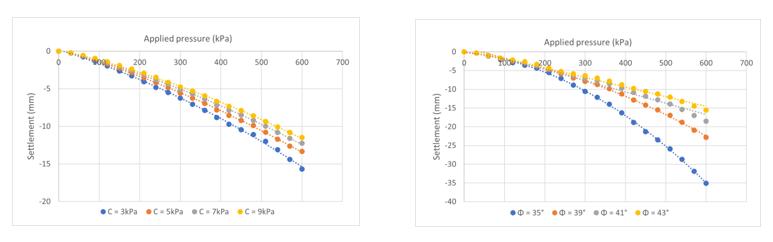

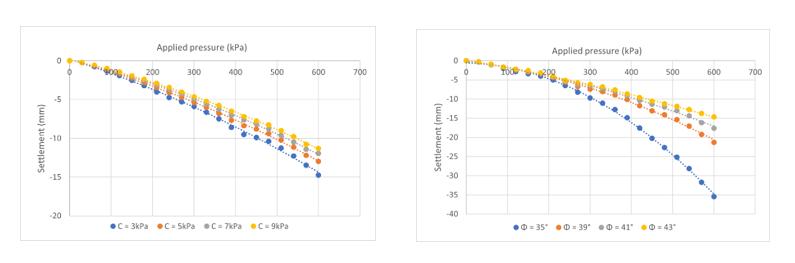

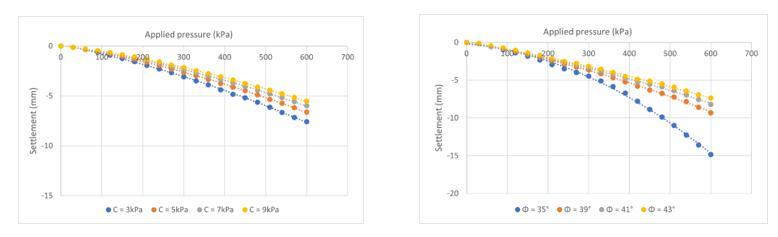

5 EFFECT OF COHESION AND FRICTION ANGLE OF CONICAL SHELL FOOTING, ISOLATED FOOTING AND STRIP FOOTING REINFORCED WITH ONELAYER GEOCELL

On varying the value of cohesion and friction angle of conical shell footing, isolated footing and strip footing reinforced with single layer geocell, we can find whether this is feasible for construction or not on different soil conditions.

Table – 5 Effectofvaryingcohesionandfrictionangle valueonconicalshellfootingreinforcedinone-layer

Umax(mm) Umin(mm) Cohesion

3kPa 1.480 -0.023 5kPa 1.303 0 7kPa 1.198 0 9kPa 1.133 0

Frictionangle

35° 3.560 -0.718 39° 2.151 -0.296 41° 1.783 -0.180 43° 1.481 -0.109

Chart – 4 Effectofvariationofcohesionandfrictionangle onbearingcapacityofconicalshellfootingreinforcedin one-layer

Table – 6 Effectofvaryingcohesionandfrictionangle valueonisolatedfootingreinforcedinone-layer

Umax(mm) Umin(mm) Cohesion

3kPa 1.568 -0.320 5kPa 1.334 -0.248 7kPa 1.225 -0.197 9kPa 1.148 -0.159 Frictionangle 35° 3.509 -0.704 39° 2.281 -0.393 41° 1.849 -0.267 43° 1.555 -0.211

Chart – 5 Effectofvariationofcohesionandfrictionangle onbearingcapacityofisolatedfootingreinforcedinonelayer

Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Table – 7 Effectofvaryingcohesionandfrictionangle valueonstripfootingreinforcedinone-layer

Umax(mm) Umin(mm)

Cohesion

3kPa 0.758 -0.031 5kPa 0.661 0 7kPa 0.593 0 9kPa 0.533 0

Frictionangle 35° 1.483 -0.371 39° 0.933 -0.067 41° 0.820 -0.015 43° 0.738 0.005

[1] K. Rajagopal, N.R. Krishnaswamy and G. M. Latha, “Behaviour of sand confined with single and multiple geocells”, Geotextiles and Geomembranes, vol. 17, 1999,pp171-184

[2] [2] S. K. Dash, N.R. Krishnaswamy and K. Rajagopal, “Bearing capacity of strip footings supported on geocell-reinforced sand”, Geotextiles and Geomembranes,vol.19,2001,pp235-256

[3] [3] S. Sireesh, T.G. Sitharam and S. K. Dash, “Bearing capacity of circular footing on geocell–sand mattress overlying clay bed with void”, Geotextiles and Geomembranes,vol.27,2009,pp89-98

[4] [4]S.K.Pokharel,J.Han,D.Leshchinsky,R.L.Parsons and I. Halahmi, “Investigation of factors influencing behavior of single geocell-reinforced bases under static loading”, Geotextiles and Geomembranes, vol. 28,2010,pp570-578

[5] [5] S.N. M. Tafreshi and A.R. Dawson, “Behaviour of footings on reinforced sand subjected to repeated loading–Comparinguseof3Dandplanargeotextile”, GeotextilesandGeomembranes,vol.28,2010,pp434447

[6] [6] L. Zhang, M. Zhao, C. Shi and H. Zhao, “Bearing capacity of geocell reinforcement in embankment engineering”, Geotextiles and Geomembranes, vol. 28, 2010,pp475-482

Chart – 6 Effectofvariationofcohesionandfrictionangle onbearingcapacityofstripfootingreinforcedinone-layer

Geocell helps in reducing the settlement in a much effective way. On providing geocell to the weak soil base, thesoilbecomemuchstiffer,strongerandtherebybearing capacity of the soil can be increased. Providing geocell in multilayershelpsinincreasingthebearingcapacityofsoil compared to single later geocell reinforcement, thus, the settlement can be reduced in an effective way. On comparing one-layer, two-layer and three-layer geocell to a soil base, three-layer geocell reinforcement offers a reduction in settlement for conical shell footing, isolated footing and strip footing systems. On increasing the value ofcohesionandfrictionangleofsoil,theshearstrengthof thesoil can be increased,thus the bearingcapacity ofsoil increasesandsettlementreduces.

[7] [7]S.N.M.TafreshiandA.R.Dawson,“Acomparisonof static and cyclic loading responses of foundations on geocell-reinforced sand”, Geotextiles and Geomembranes,vol.32,2012,pp 55-68

[8] [8]S. K. Dashand M.C.Bora,“Improved performance of soft clay foundations using stone columns and geocell-sand mattress”, Geotextiles and Geomembranes,vol.41,2013,pp26-35

[9] [9] T.G. Sitharam and A. Hegde, “Design and construction of geocell foundation to support the embankment on settled red mud”, Geotextiles and Geomembranes,vol.41,2013,pp55-63

[10] [10] A. M. Hegde and T.G. Sitharam, “Effect of infill materials on the performance of geocell reinforced soft clay beds”, Geomechanics and Geoengineering, 2014

[11] [11] T.G. Sitharam and A. Hegde, “Design and construction of geocell foundation to support the embankment on settled red mud”, Geotextiles and Geomembranes,vol.41,2013,pp55-63

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page514

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

[12] [12] S.N. M. Tafreshi, T. Shaghaghi, T. Mehrjardi, A.R. Dawson and M. Ghadrdan, “A simplified method for predictingthesettlementofcircularfootingsonmultilayered geocell-reinforced non-cohesive soils”, GeotextilesandGeomembranes,2015,pp1-13

[13] [13] Q. Chenn and M. Abu-Farsakh, “Ultimate bearing capacity analysis of strip footings on reinforced soil foundation”, Soils and Foundations vol. 55, 2015, pp 74-85

[14] [14] T. Mehrjardia, R. Behrada and S.N. M. Tafreshi, “Scale effect on the behavior of geocell-reinforced soil”,GeotextilesandGeomembranes,vol.47,2019,pp 154-163

[15] [15]M.Abdel-Rahman,“Lateral loadingresistancefor shell foundations”, HBRC Journal, vol. 16, 2020, pp 227-241

[16] [16] K. Halder and D. Chakraborty, “Influence of soil spatial variability on the response of strip footing on geocell-reinforcedslope”,ComputersandGeotechnics, vol.122,2020,103533

[17] [17] P. F. Dehkordia , M. Ghazavib and U. F. A. Karim, “Bearingcapacity-relativedensitybehaviorofcircular footingsrestingongeocell-reinforcedsand”European JournalofEnvironmentalandCivilEngineering,2021, DOI: https://doi.org/10.1080/19648189.2021.1884901

[18] [18]A.AriandG.Misir,“Three-dimensionalnumerical analysis of geocell reinforced shell foundations”, GeotextilesandGeomembranes,vol.49,2021,pp963975

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal