International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

1M.Tech Student, Dept. of Civil Engineering, St. Josephs College of Engineering and Technology, Palai, Kerala, India

2Assistant Professor, Dept. of Civil Engineering, St. Josephs College of Engineering and Technology, Palai , Kerala, India ***

Abstract - Geopolymer is a sustainable binding material having similar binding property to ordinary Portland cement.it can be produced from fly ash, granulated blast furnaceslaglikealuminosilicatematerialitcanbeactivated by alkaline solution. Geopolymer concrete having higher mechanicalstrengththanordinaryPortlandcement.Alkaline activators can improve strength and durability of geopolymerconcrete.Thegeopolymerconcretetechnology reduceglobalcarbondioxideemission.

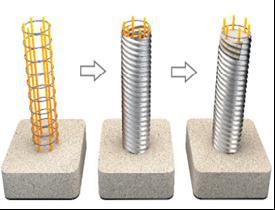

TheConcretefilledcorrugatedsteeltubehavethe same working mechanism as tube confined concrete columnsbecauseofitshighlateralstiffness andcorrosion resistanceofcorrugatedsteelpipeandcorrugatedsteelpipe providestrongconfinementeffect.Concretefilledcorrugated steel tube offers advantages such as ease of construction, highductility,confinementeffect,stronginterlockingeffect betweencorrugatedsteelpipeandconcreteandloadbearing capacity. So Geopolymer filled corrugated steel tube has benefit of both geopolymer concrete and concrete filled corrugatedsteeltube.

Key Words: geopolymerconcrete,flyash,alkalinesolution, corrugatedsteelpipe,loadbearingcapacity.

Inthisworldoneofthemostlyusedconstructionmaterialis concrete,butthereisalsohavesomeenvironmentalissues becauseofhighlyusageofconcrete.Mainreasoniscontent of Portland cement in concrete, which cause massive productionofcarbondioxideemissioninenvironment,it’s around7%oftotalhumaninducedcarbondioxideemission in every year. For example, for the production of one ton Portlandcementaround1.5tonsofrawmaterialneeded,for thisprocessleadstoeliminationofaroundonetonofcarbon dioxide. ConstructersareusingGeopolymercements,which producing from GGBS and Fly ash with alkali activator solution[1].TheordinaryPortlandcement-basedconcretes have high internal energy than geopolymer cement. ProductionofOPCleadstohighamountofgreenhousegasin atmosphere. Ordinary Portland cement-based concert are notthatmuchdurableinmanyenvironmentalconditions.In thissituationOPCcanreplacewithGeopolymerconcrete[2].

andalkalineactivatorsareeffectthemechanicalproperties of the Geopolymer concrete. There have some suitable materialsareacknowledgeforgeopolymermaterialssuchas classF Flyash(FA),SilicaandAlumina composition,even though the problem of generation of the F classs Fly ash based Geopolymer materials can be cured only high temperature.CuringofGPCatsurroundingtemperatureslag isnormallyadded.Mainlygroundgranulatedblastfurnace slagisused[3].

Experimentalandresearchshowsthatsubstitution offlyashwith GGBSimprovethecompressivestrength of concrete regardless of type of curing. The thing is more alkaline content improves strength of the concrete up to some range. Mix design is process that selecting suitable ingredientsusedinaparticularconcreteandidentifytheir relative proportions to reach given target strength and workability.TheBindercontent,amountoffineandcoarse aggregateusedinthemixalsomatterofthestrengthofGPC. Basically more in the binder content, the compressive strengthofGPCalsoincrease[14].

Wang et al [5] state that Concrete filled galvanized corrugatedsteeltubularcolumnisanewcompositemember toreducetheanticorrosionmaintenancecostandimprove the corrosion resistance of concrete filled steel tubular structure and it has advantages such as high load bearing capacity,freeofmaintenance,andgoodductility.Corrugated steelpipearemadefromcold-formedgalvanizedsteelsheet afterthecrimpingandmechanicalpressing.Concretefilled corrugated steel tube fabricated from concrete filled galvanized corrugated steel pipe. Steel is protected by cathodicprotectionduetoZincoxidefilmonthesurfaceof the structure. In addition, cladding layer is difficult to remove which reduces periodic maintenance cost. Anticorrosivepipeusedasbridges,rainwaterpipe,culvert, channel etc. service life of corrugated pipe depend on selectionofappropriatecoating.Concretefilledcorrugated column will perform well under lateral cyclic loading and compressionbecauseofstronginterlockingeffectbetween concrete and corrugated steel pipe due to corrugation of corrugatedsteelpipe[5].

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Fangetal[6]statethatconcretefilledcorrugatedsteeltube structure shows excellent local stability and post peak behaviour even it is not configured with transverse reinforcementduetoeffectiveconfinementprovidedbythe corrugated steel pipe. Test result shows that ductile behaviour of concrete columns is improved due to corrugated steel sleeves. Concrete filled corrugated steel tube column embedded with steel structure have good seismicbearingCapacity.Itsconstructioniseasierand economical than or same as that of SRC column. Corrugatedsteelpipeenhancetheconfinementofthe structuralsteelandinternalconcrete,sowegetenough bearing capacity and ductility. The Stud on the structural steel do not make significant effect to the axialbehaviouroftheconcretefilledcorrugatedsteel tube.Structuralsteelratioandconfinementfactorhelp toincreasingtheaxialmechanicalperformanceofthe concretefilledcorrugatedsteeltube.

Kumar et.al [9] studied the ingredient of Geopolymer concreteareFlyash,GGBS,Fineaggregate,Courseaggregate, Alkaline activator Solution. Alkaline activator Solution is combination of Sodium hydroxide, Sodium silicate and water. The Sodium hydroxide solution are made by dissolving sodium hydroxide pellet in to distilled water. Molarity of sodium hydroxide solution depend on concentration of Sodium hydroxide per liter. The sodium hydroxide solution was prepared 24 hour before use, because huge amount of heat generated when sodium hydroxide pellet mix with water. Flyash is collected from combustionofcoalinpowerplant.

Super plasticizer are added in to Geopolymer concreteforattaininggood workableconcrete.Commonly NaphthaleneSulphonatebasedSuperplasticizerisusedfor increasingworkabilityofGPC.Excesswatercanreducethe strength of Geopolymer concrete. Average density of GeopolymerconcreteissimilartoordinaryPortlandcement concrete.RatioofFlyashandGGBSeffectthecompressive strengthofconcrete.GroundGranulatedBlastFurnaceSlag isaby-productofslagofironfromBlastfurnaces.

Che Chou et al [7] state that concrete column confined by FRP frapped spiral corrugated tube have coupled surface between concrete and FRP. Steel tube provide confining effecttotheconcretecolumnithelptoimprovingstructural performancesuchasductility,stiffness.TheFRPwrapped spiralcorrugatedtubeprovidebothconfinementandshear strengthtotheconcretecolumn.Convexsurfaceofthespiral corrugated tube help to increase the interlocking effect of corrugatedtubeandconcrete.ConcretefilledGFRPwrapped spiralcorrugatedtubehavegoodstrengthanddeformation capacity.ConcretecolumnreinforcedwithFWSCTenhance the seismic performance. The FWSCT prevent the shear crack inside the confinement tube, hence plastic hinge is developedwithintheunwrappedregion.

Yang et.al [8] state that The Corrugated steel pipe gives strong confinement because of hoop stress. Ductility and loadbearingcapacityofconcretefilledgalvanizedsteeltube issimilartoidealTRCcolumn.Thehollowcorrugatedsteel pipe is not good for carrying axial load without in filled concrete and longitudinal bars. No noticeable buckling in CFGCSThoweverlittlebitverticalcrackformedinsidethe concrete.

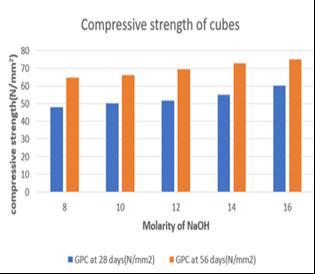

Dandaet.al[2]statethatratioofsodiumsilicatesolutionto sodiumhydroxidesolutionwasvarying.Commonly2.5ratio are adopted. Commonly 8M, 10M, 12M and 14M concentration of NaoH are prepared for Geopolymer concrete. Sodium hydroxide prepared before 24 hour of casting. At the time of casting both sodium hydroxide solutionandsodiumsilicatesolutionaremixed.

The ratio of sodium silicate to sodium hydroxide taken in this study is 2.5.The compressive strength of geopolymer concrete is directly proportional to molarity of sodium hydroxidesolution.Fig3explainthathighmolaritysodium hydroxideshowhighercompressivestrengthat28and56 day[2].

Chart-1:compressivestrengthofGPCvs. Molarityof NaoH

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Firstputthecourseaggregateintomixerandmixwithsmall quantityofwaterforfewminutetoreducedustcontent.Add specificamountoffineaggregateintomixerandrotatethe mixerforanothertwominute.LaterspecificamountofGGBS and fly ash add in to mixer followed by alkaline activator solution with particular amount of super plasticizer. The rotation of mix was allowed to another five minute for thorough mixing of reactive solid and alkaline activator solution.Geopolymerconcreteareharshandstiffer.Soextra waterandsuperplasticizerareessentialforgoodworkable concrete[11].

Neupane et.al [12] Studied that Concrete cubes, cylinders andbeamswithparticulardimensionwerecasttofindthe propertyofGeopolymerconcrete.3specimenweremadefor eachtest.After24hourofcasting,thedemoldedspecimen placedforcuringatambienttemperatureinlaboratory.After 28days,testwerecarriedout.

Workability of Geopolymer concrete was determined by slump test. Factors depending the workability of Geopolymerconcretearewatercontent,ratioofGGBSand Flyash,Molarityofalkalinesolution,sizeofaggregate,super plasticizer.WorkabilityofGeopolymerconcretedecreases with increase of GGBS content and workability of GeopolymerconcretedecreaseswithincreaseofMolarityof sodiumhydroxidesolution.Becausehighmolaritysodium hydroxidesolutionarehighviscous.Appropriateamountof super plasticizer help to improve the workability of the Geopolymerconcrete.21%-30%ofOPCreplacedbyflyash helptoimprovetheworkabilityofconcretebecauseround shape of Fly ash. Higher percentage of Fly ash based geopolymerconcretehavelesser waterdemandthan OPC concrete. Geopolymer concrete showed less segregation [12].

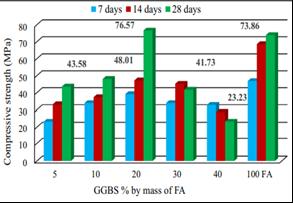

Poloju.et.al [4] studied about ambient and oven cured concreteanditscompressivestrengthofGPC. Ovencured concreteshowshighercompressivestrengththanambient curedgeopolymerconcrete.Becauseofearlypolymerization in the high temperature curing. Increasing strength of ambientcuredGPCbyaddingGGBScontent.

Inthismethodtestiscarriedoutinambienttemperature of 210-250C. Demoulded specimen were kept at ambient temperature for 7 or 28 days [10]. In Flyash based Geopolymer concrete, high temperature is necessary for initiateGeopolymerizationreaction.ThepresenceofGGBSis essential for ambient cured Geopolymer concrete with sodium hydroxide solution and sodium silicate solution,

otherwise heat curing is necessary. GGBS improve mechanical and micro structural property of geopolymer [11].

Gholampouret.al(2017)studiedthatlessamountofwater andaircontentingeopolymerconcreteenhancethedensity and durability of GPC than OPC concrete. Density of geopolymer increases with GGBS content and size of aggregateeffectthedensityofgeopolymerconcrete[13].

Concrete cubes are used for conducting compressive test. Minimum 3 cubes were made for compressive test. GGBS contentingeopolymerconcreteenhancetheearlystrength ofconcreteandcompressivestrength.BecauseGGBSconsist ofhigheramountofcalciumthanflyash.Thisleadstomix producemorecalciumsilicategelwiththealuminasilicate. Dueto thisreasonGGBS geopolymerisless workableand stiffer. Methodofcuringeffectthecompressivestrengthof geopolymer concrete. Heat cured specimen have higher compressive strength than ambient cured geopolymer concrete.Flyashpartiallyreplacedbysilicafumesincrease thecompressivestrength[11].

Compressive strength increases with GGBS but higher amount of GGBS effect the setting time of geopolymer concrete. Higher amount of GGBS leads to decreasing of setting time. Oven cured slag blended fly ash geopolymer give high early strength. Amount of fine and course aggregate,bindercontent,molarityofalkalinecontentalso effectthecompressivestrength[14].

Saranyaet.al[15]statethatGeopolymerconcretegained 95% of compressive strength within 7 days and OPC concreteattainedonly50%ofcompressivestrengthwithin 7days.GeopolymerattainearlystrengththanOPC.

Bouaissi. et.al [16] State that large amount of GGBS impact negatively on strength development. Compressive strengthofflyash-GGBSbasedgeopolymerpasteincreases inthebeginningandcompressivestrengthdecreaseswith large amount of GGBS replacement. Replacement of GGBS become40%,thecompressivestrengthreducedwithtime.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

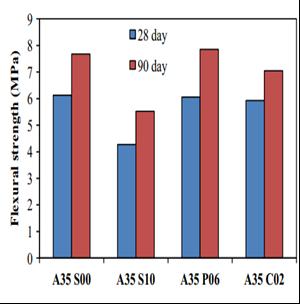

In fig. 2 shows that 35% alkaline activator and different ingredientsofmixturescompared.A35S10have30%lower compressive strength than A35 S00 mixture. Because presence of extra water with additive cause negative consequence on flexural strength of GPC concrete. Compressivestrengthincreaseswithadditivesbutaddition of more additives after a certain range effect the rate of tensile strength, when geopolymer cured in ambient condition. Percentage of calcium silicate hydrate gel increases with increase of additive in mixture. So tensile capacity of geopolymer concrete increase. Presence of additional waterintheplaceofalkalineactivatorsolution effectthestrengthofconcrete.

Minimum 3 cylinder are used for conducting split tensile strengthtest.TensilestrengthincreaseswithGGBScontent andmolarityofSodiumhydroxidesolution.Combinationof silica fumes, fly ash, GGBS shows low tensile strength. Combinationofflyash-GGBSbasedgeopolymershowshigh tensile strength than Flyash only geopolymer concrete. Because GGBS make rough surface between paste and aggregatethansphericalshapeofFlyashcomponent.Alkali activatorbindontheaggregatesurfaceontheGPCconcrete help to increase bond strength and it help to increase the tensilestrength.Alumina-silicategelprecipitationandalkali dissolution in the geopolymer play an important factor to attain good tensile strength. Split tensile strength of GPC concrete is 8%-12% greater than OPC concrete of same grade[11].

Nathet.al[17]statethatFlexuralstrengthofbothGPCand OPC shows higher value than split tensile strength of GPC andOPCconcrete.FlexuralstrengthincreaseswithGGBSor calcium hydroxide blended with fly ash geopolymer concrete.

Flexuralstrengthofgeopolymerconcreteisgreater thanOPCconcretewithsamegrade.Flexuralstrengthofgeo polymerconcreteincreaseswithage.Heatcuredgeopolymer concreteshowshigherflexuralstrengththanOPCconcrete [18].

Based on literature review it is concluded that concrete filled corrugated steel tubular column have higher load bearing capacity and confinement effect than ordinary concretefilledtubularcolumn.Geopolymerfilledcorrugated steeltubularcolumngetadvantageofbothcorrugatedsteel tubular column and geopolymer concrete. Geopolymer concreteshowhigherstrengththanOPCConcrete.Durability ofGPCgreaterthanOPCconcrete.Ovencuredgeopolymer concrete have higher strength than ambient cured geopolymerconcrete.TensileandflexuralstrengthofGPC havefarbetterthanOPCconcrete.

[1]Akdumana.S,Kocaera.O,AldemiraA,Mustafa,ahmarana, YıldırımaG,AlmahmoodbH.“Experimentalinvestigationson the structural behaviour of reinforced geopolymer beams producedfromrecycledconstructionmaterials”.Journalof BuildingEngineering.Turkey,2021.

[2] DandaU.K,KumarSY, KumarSH.“Experimentalstudy on reinforced geopolymer concrete columns using GGBS”. MaterialsToday:Proceedings.India

[3] Hadi M. N. S, Zhang H, Parkinson S. “Optimum mix designofgeopolymerpastesandconcretescuredinambient conditionbasedoncompressivestrength,settingtimeand workability”JournalofBuildingEngineering.

[4]Poloju.K.K,Srinivasu.K.“ImpactofGGBSandstrength ratio on mechanical properties of geopolymer concrete under ambient curing and oven curing”. Materials Today: Proceedings.2021,PP.962-968.

Chart-3:comparisonofflexuralstrengthofGPCcontain 35%alkalineactivator(Nathet.al)

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

[5]WangY,YangL,YangH(2019)“Behaviourofconcretefilled corrugated steel tubes under axial compression”. Engineeringstructures.PP.475-495.

[6] Fang. Y, Liu. C, Yang. H, Yang .L. “Axial behaviour of concrete-filledcorrugatedsteeltubularcolumnembedded with structural steel”. Journal of Constructional Steel Research,2020

[7]ChechouC,LeeC,WuK “Developmentandvalidationof a FRP-wrapped spiral corrugated tube for seismic performanceofcircularconcretecolumns”.Constructionand BuildingMaterials,2018.PP498-511.

[8]YangL,WangY,ElchalakaniM“Experimentalbehaviorof concrete-filledcorrugatedsteeltubularshortcolumnsunder eccentric compression and non-uniform confinement”. EngineeringStructures,2020.

[9] Kumar S. C, Ramesh K, “Analytical Study on Flexural Behavior of Reinforced Geopolymer Concrete Beams by ANSYS”. IOP Conference Series: Materials Science and Engineering.2018.

[10]HadiM.N,ZhangH,ParkinsonS, “Optimummixdesign of geopolymer pastes and concretes cured in ambient conditionbasedoncompressivestrength,settingtimeand workability”.JournalofBuildingEngineering,2019

[11]ZannerniG.M,FattahK.P,Tamimi A.“Ambient-cured geopolymer concrete with single alkali activator”. SustainableMaterialsandTechnologies,2019

[12] Neupane .k, Hadigheh.S.A. “Sodium hydroxide-free geopolymerbinderforprestressedconcreteapplications”. ConstructionandBuildingMaterials,2021.

[13] Gholampour .A, Ozbakkaloglu.T. “Performance of SustainableConcretesContainingVeryHighVolumeClass-F FlyAshandGroundGranulatedBlastFurnaceSlag”.Journal ofCleanerProduction,2017.

[14]Rao.G.M,Rao.T.D.“Aquantitativemethodofapproach indesigningthemixproportionsofflyashandGGBS-based geopolymer concrete”. Australian Journal of Civil Engineering,2018.2204-2245.

[15] Saranya.P, Nagarajan.P, Shashikala.A.P. “Behaviour of GGBS-dolomite geopolymer concrete short column under axialloading”.JournalofBuildingEngineering.

[16]Bouaissi.A,Li.L.Y,Abdullah.M.M,Bui.Q.B.“Mechanical propertiesandmicrostructureanalysisofFA-GGBS-HMNS based geopolymer concrete”. Construction and Building Material,2019.pp.198-209.

[17] Nath .P, Sarkar. P. K. “Flexural strength and elastic modulus of ambient-cured blended low-calcium fly ash

geopolymerconcrete”.ConstructionandBuildingMaterials, 2016.

[18] Farhan .N.A, Sheikh .M. N, Hadi. M. “Investigation of engineeringpropertiesofnormalandhighstrengthflyash based geopolymer and alkali-activated slag concrete compared to ordinary Portland cement concrete”. ConstructionandBuildingMaterials.2019,PP:26-42.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page