International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Abstract - Foamed concrete is the future commercial material in construction industry due to its light weight nature The physical and mechanical properties of foamed concrete varies from type of mixture and its composition Fly ash and grounded granulated blast furnace slag are industrial waste and generally used as mineral admixture in concrete blend to enhance the property of hardened concrete. In our work we have used fly ash, grounded granulated blast and alkaline solution which acts as an activator is used to develop foamed geopolymer concrete and parameters effecting compressive strength of the foamed concrete were studied Fly ash is usedas fine aggregate and grounded granulated blast furnace slag helps in improving strength of concrete. Rice husk ash and micro silica are also used to improve the density andstrength of our concrete Compression strength test was conductedto study the mechanical strength of concrete and water absorption test was also carried out. Trial and error approach is used and every mix proportion of material and quantity offoam is varied.

Key Words: Flyash,FoamedConcrete,GGBS,Compressive strength,Geo-polymerConcrete,RiceHusk.

Afterwater,concreteisthemostwidelyusedmaterialby the community and in the construction world, around 15 billiontonnesofconcreteisusedannually.OrdinaryPortland Cement (OPC) is primarily used binder for production of concrete,thereisenvironmentalissuefortheproductionof OPC,weburnCaCO3inkilnattemperatureofabout1400C0 duringthislime(Cao)andCO2isproducedbyprocesscalled calcination.5CaCO3+SiO2→(3CaO,SiO2)(2CaO,SiO2)+5CO2

InthisprocessCO2isemittedintheatmospherewhichisa greenhousegas.Indiaiscontributing7.1%oftotalgreenhouse gas emission Olivier and peters,2018) [24]. Silica containingmaterialisaddedtothelimewhichproducesan intermediateproductcalledclinkerthenclinkeriscooland small amount of gypsum is added to produce ordinary Portlandcement.ForproductionofOPC,fossilfuelgenerally coalisusedwhichproducesCO2.1tonofcement produces around0.95tonnesCO2(Davidovits,2015)[8].

Developmentininfrastructureleadstoriseindemandof cement concrete. Global production of concrete is

approximately15Billiontonnesand1cubicmeterperperson per year is already achieved (Gartner, 2004)[10]. India is second largest manufacturer of cement after China and producesaround330milliontonnescement(Governmentof India,2017)[11].WecanreducetheGHGsemissionbyusing supplementary cementitious material such as fly ash, blast furnaceslag,silicafumeetc

In India coal based thermal power plant is used for electricitygeneration,whichproduceswastematerialflyash asbyproductofburningcoal.Flyashiseffectivelyusedfor making cement concrete, by using this waste, reduces environmentalimpactandincreasesthetechnicalpropertyof concrete .Other waste material like rice husk, Ground GranulatedBlastFurnaceSlag(GGBFS)byproductofironand steelmaking.ItcanbeblendedwithPortlandcementwhich increase concrete workability, durability, density, and resistancetoalkalisilicareaction.

Therearetwomainconstituentofgeopolymerconcrete sourcematerialand alkalinesolution.Sourcematerialshould beenrichwithSilicon(Si),Aluminium(Al).Thesecanbebyproductsuchasflyash,GGBFS,Silicafume,ricehuskash,red mud etc. and can be natural mineral like clay, kaolinite. Selectionofmaterialdependsupontheavailability,cost,type of application, and specific demand of end user .The most commonly used alkaline solution are sodium hydroxide (NaOH), potassium hydroxide (KOH), and sodium silicate (Na2SiO3),potassiumsilicate(K2O3Si).

Slagbasedgeopolymerconcrete:Inthisconcrete,blast furnaceslagisusedassecondarybinderandsilicafume asprimarybinderwithalkaliactivator

Rockbasedgeopolymerconcrete:Thematerialsused in this concrete are crushed volcanic tuff (type of volcanic rock ejected from volcanic eruption), and minetailing(leftovermaterialfrommines)withsilica fumeandalkaliactivator

Fly ash based geopolymer concrete: Fly ash from thermalpowerplantsisusedasprimarybinderwith furnace slag as secondary binder is used and alkali activator.Recentstudieshaveshownthatthisconcrete canbemadeby100%flyashasbinder.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Ferro-isolatebasedgeopolymerconcrete:Thisconcrete is similar to rock based concrete, but the rocks used havehigherironoxidecontent.Thuspolymerformed inthisconcretehaveiron(Fe)atoms

Mohd & Samidi, 1997 Aerated concrete can be classified basedoncuringmethodandbasedonporeformationmethod. Sobasedoncuringmethodaeratedconcretecanbeclassified as autoclaved aerated concrete (AAC) and non-autoclaved aeratedconcrete(NAAC).similarlybasedonporeformation method it can be classified as “gas concrete” and “foamed concrete”

Zhang, Liu, Yan, Qin, 2016 Weproducedgeopolymerfoamed concretebyentrainingairintoit.Whentheaircontentvaries 2 to 6 % the number closed micro pores in the hardened concrete increases space between air void and diameter of voiddecreasessoprovidinggoodfrostresistanceproperty

Rashad, A. (2014) Thedevelopmentofnewbinders,asan alternativetoPortlandcement(PC),byalkalineactivation,isa currentresearchersinterest.Alkali-activatedflyash(AAFA) binder isobtained bya manufacturing process less energyintensive than PC and involves lower greenhouse gasses emission.UtilizingAAFAsystemasbindermaterialcanlimit the consumption of virgin materials (limestone and sand) requiredinPCmanufacture.AAFAbelongstobeprospective material inthefieldofCivil Engineeringwhereitcanresist aggressiveacids,resistsulfateattacks,resistaggregatealkali reaction,andresistelevatedtemperatures.Researchershave employed different fibers, chemical admixtures, mineral admixtures, additives and other materials in AAFA system aimingtomodifyspecialpropertiesofthissystem

Ali Hansberger et al (2012) Globally,thecementindustry accounts for approximately 5 percent of current anthropogeniccarbondioxide(CO2)emissions.Worldcement demandandproductionareincreasingsignificantly,leadingto an increase in this industry’s absolute energy use and CO2 emissions. Development of new energy-efficiency and CO2 emission-reductiontechnologiesandtheirdeploymentinthe marketwillbekeyforthecementindustry’smid-andlongtermclimatechangemitigationstrategies.

OrdinaryPortlandcement(OPC)of“ULTRATECH”brandedof grade 53 confirming toIS:12269 was used for our study. It waskeptinadryenvironmentwithproperstoragefacility53 grade of OPC is used because of its optimum particle size distributionandsuperiorcrystallizedstructureoffersastrong and durability of structure. It has high early strength as comparedtoanyothergradeofcementbutbecauseofearly strengthitdoesnotincreasemuchafter28days.

Low Calcium Class F fly ash used for our work. fly ash was obtainedfromtheSpatThermalpowerplantatBilaspurIndia and it is used as basic material for making concrete. The physicalpropertiesofflyashareaccordingtoIS1727(1967).

Micro silica used for this study has been obtained from Nagpur.Itisknowntobeextremelypozzalanicinnatureand is used as concrete additive .Addition of micro silica to concreteandgeopolymerhaveshownbetterpackingability andimprovethestrength.Itisalsoknownassilicafumeand is obtained as by product of silicon or ferro-silicon alloy developmentfromelectricalarcfurnace(EAF).

GGBFS used in our work was obtained from Uttam Galva,Wardha . It is used in combination with standard Portland cement or other pozzolanic materials to produce durableconcretestructures.GGBSbasedconcretesetsslower thanconcretemadeofordinaryPortlandcementItreduces hydrationandlowertemperaturesmakingiteasiertoavoid cold joints but also effects building schedules where fast setting is required. It also reduces the risk of alkali-silica reaction offers higher chloride intrusion resistance and reduces the risk of corrosion reinforcements and offers greaterresistancetosulphateandotherchemicalattacks

RicehuskashusedinthisprojectisobtainedfromNagpur.It is produced from rice milling industry as agro-industrial waste.Burningprocessandtemperatureaffectthechemical composition of RHA. The amount of silica increases when temperatureisincreased.RHAcontainsamorphousandvery cellularsilicawithasurfaceareaof50-1000m2/g.Ithasbeen observedthatuseofRHAreducesheatdevelopment,thermal cracking and plastic shrinkage also increases strength of hydratedcement paste which modifies porestructuresand blocking the large voids in the pozzolanic reaction. Indian standardIS456:2000recommendstheuseofRHAinconcrete and reinforced concrete but does not specify the quantity whichcanbeusedinmixeddesign.

There is no standard available for making geopolymer foamed concrete, so trial and error method is adopted and numerous sample were made. Identifying the appropriate quantityoffoamed,proportionofvariousfillermaterialand their effect on fresh and hardened properties, air void characteristicsoffoamedconcreteweredealt.Thereisvery fewstudyavailableonuseofgeopolymerfoamedconcreteso

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

presentstudywasfocusedonthis.Preliminaryworkwasdone toknowtheeffectoffoamingagentongeopolymerfoamed concreteasthereisverylessstudyavailablewithfoamand geopolymer.Proportionofvariousconstituentsmateriallike flyash,GGBFS,lime,ricehuskweredeterminedandbehaviour withgeopolymersolutionwerestudiedformakingthevarious trialmixes.

At beginning geopolymer solution was prepared 1 day before to give maturity of 24 hour. NaOH is used in pallets form.Accordingtothemolarityofgeopolymersolutionmass ofNaOHisselectedandmassofNa2SiO3isselectedaccording toratioofNaOH:Na2SiO3.ThenNaOHandNa2SiO3isadded inwater.Thissolutioniskeptforonedayandnextdayused forpreparationoffoamedconcrete.Forsometrialfoamedwas generatedinwaterandaddedintothesolutionandforsome trialfoamedisgeneratedingeopolymersolution.

Foam is generated by using hand mixer with rpm ( RevolutionperMinute)1000asfoamgeneratormachinewas notavailableinlaboratory.Thenfoamingagentquantitywas selected according to volume of geopolymer solution. Consistencyoffoamgetchangedifmixingtimeisvary,soto get a properconsistencyoffoam,itismixedfora specified timesothateverytimewegetsameconsistency.Ifwemixed the foam for more time air induced in it will increases, however longer mixing lead to air loss by lowering the air content.Aftersometrialmaturityperiodgiventosolutionwas removedinsistofitafteraddingtheconstituentssolutionwas mixedbyhandmixeruntilitgetturnedbrownish.

Hand mixer was used to produce geopolymer foamed concreteinlaboratoryasthevolumeislessbutincommercial practicevolumewillbehighforthatrotarydrumcanbeused forproduction,boththecasesmixingprocedurewillbesame. Forpreparationofspecimenfirstallthedryconstituentslike flyash,GGBFS,lime,ricehusk,cementandotherfinematerial is collected. Then according to required proportion each is mixedinacontainer.Forgettinghomogeneousmixedofthis dry constituent, it is mixed by hand mixer for 1-2 minute. Geopolymer solution is prepared according to point and accordingtovolumeofitfoamingagentquantityismixedin solution.Togetrequiredconsistencyfoamingagentismixed for 10-15 minutes. If foam is generated in water, then it is mixedindryconstituentandmixedfor2-3minutesuntilfoam getuniformlydistributed,incorporated,whichwecannotice duringmixing.Toincreasetheworkabilityofconcretewecan usesuperplasticizer.Afterthatindryconstituentthisprepare solution is mixed until we get required consistency then concretemixispouredinmouldsof100*100*100.After24hour demoulding was done and concrete cube is kept for curingeitherovencuringorwatercuring.

Thetestresultsarepresentedanddiscussedinthischapter. Eachdata pointforthecompressivestrengthtestshownin differentgraphsorindifferenttablescorrespondstothemean compressionvalue.theeffectofdifferentparametersonthe compressive strength of geopolymer foamed concrete is discussed.Alongwithcompressivestrength,otherparameters likewaterabsorption,andefflorescencevaluesoftheconcrete arealsodiscussed.Theparametersconsideredareasfollows:

Ratio of sodium hydroxide solution to sodium silicate solution

Curingtime(ovenheating)

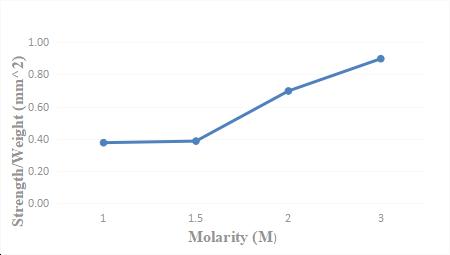

Molarityofthealkalinesolution

Mixingtime

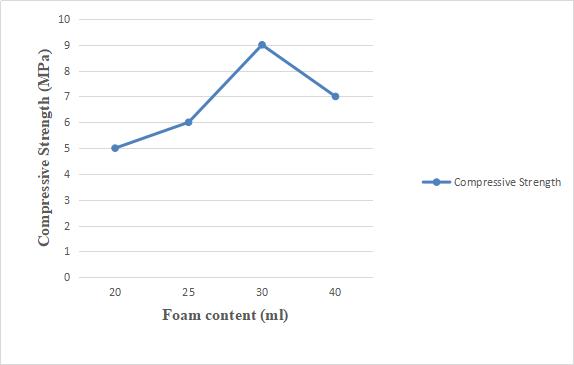

Concentrationoffoaminmix

EffectofGGBSincompressivestrength

Variationofcompressivestrengthwithdrydensity

It is observed that compressive strength of geopolymer NAACisproportionaltothemolarityofsolutionanditcanbe ascertained that molarity is the function of compressive strength.Higherthemolarityhigherwillbethecompressive strength.OnhighermolarityfreeSimoleculesareproduced whichincreasesC-S-Hgelisproducedwhichgivesstrengthto theconcrete.Alsoworkabilityofconcretedecreasesasmore C-S-Hgel isproduced.Trialsofhighermolaritywhichwere curedinovenshowedincreaseincompressivestrengthafter onedayofdemoulding.Insteadoftakingcompressivestrength directly,compressivestrengthtoweightofthecubeistaken becausestrengthisdirectlyproportionaltoweight.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Itisobservedfromthegraphinitiallycompressivestrengthof foam concrete increases uptoa certain point and then decreasesthestrengthofblocksooptimumcontentischosen whichisshowningraph

TRIAL 1 Samp leno.

Ceme nt GGB S Flyas h Foa m Aura+T E A+SP5 00+

Molar ity Age at test Compr es sive strengt h

dry dens ity

mea n dens ity (gm) (gm)(gm)(ml)HVF (ml) (M) (day) (Mpa) (kg/ m3) (kg/ m3) 1 600 600 180015 3+3+3 +3 1

After demou lding 1.8 1087 1029 2 3 3.1 1040 3 7 3.8 962

In this chapter futurescopeof work is discussed inline with present work. As we know that cement industry contributesmoreingreenhousegasemission,soinpresent workcementshouldbecompletelyremovefromtheGFCAs we know that density of GFC depend on quantity of foam contentandpropertiesoffoamcontent,inthisworkprotein basedfoamingagentisusedinfutureworkdifferenttypeof foamingagentwithdifferentquantityshouldbetry,thisarea needs to be explored more. Strength of foamed content dependsonGGBFScontentsomoreinvestigationshouldbe done to find out the optimum quantity of GGBFS and also investigate the potential use of fibre in aerated concrete to overcometheproblemofreinforcement.Toconfirmthelong termuseoffoamedconcrete,infutureworkmoretestshould bedonetotestthedurability.

Aimofthisprojectwastocreateageopolymerlightweight foamed concrete alkaline solution as an activator that will address environmental issues and retain their structural properties.Maximumcompressivestrength9MPawasnoted at density 1324 Kg/M3 at following percentage of content 10%cement,20%GGBFS,60%flyash,5%ricehusk5%lime, 2MalkalinesolutionEfflorescencetestwasalsoconducton GFC,resultofthistestwasNil.TheproductionprocessofGFC differ from production process of bricks, blocks in which controlling factor is water/cement ratio whereas GFC is divided into several sub-tasks, main controlling factor was mean target density therefore so there is need to develop design mix strategy for aerated block with air entraining agent. Certain consistency in terms of water content is required for air-entraining otherwise bubbles of foam will reachthesurfaceandescapeoutoritcanbebrokenduring mix phase. The main controlling factor that influences the designmixareGGBFS,Flyash,foamcontent,andplasticizers Due to complex nature of air entrainment trial and error methodwasadoptedfoamcontentwaschosensuchthatitwill give target density, during trial-and-error procedure it was foundthatifwegeneratefoaminwateritdoesnotgivegood consistencybutwhenitismixedwithalkalinesolutiongood consistencywasfoundandcompressivestrengthresultswas alsogood.Mixingtimeoffoamingagentplaysanimportant rolemoretimemixingproducesmorefoamcontentsointhis testmixingtimewaskeptconstantasforaspossible Itwas foundthatcompressivestrengthofGFCisfunctionofalkaline solution (NaOH) higher the molarity higher compressive strengthwasobserved.Secondaimofwastoanalysetheeffect of properties GGBFS, lime and rice husk on density and compressivestrengthofGFC.

[1] AlaaM.Rashad,Acomprehensiveoverviewaboutthe influence of different admixtures and additives on the propertiesofalkali-activatedflyash,MaterialsandDesign 53(2014)1005-1025.

[2] AliHasanbeigia,n,LynnPricea,ElinaLin,Emerging energy-efficiencyandCO2emission-reductiontechnologies for ceent and concrete production: A technical review, Renewable and Sustainable Energy Reviews 16 (2012) 6220-6238.

[3]Amer Hassan , Mohammed Arif , M. Shariq, Use of geopolymer concrete for a cleaner and sustainable environment- A review of mechanical properties and microstructure,JournalofCleanerProduction223(2019).

[4]Curan, Ma.A., 1996. Environmental life cycle assessment. The international journal of Life Cycle Assessment.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

[5]D.Aldridge (2005) Introduction to foamed concrete: What,Why,How?

[6]D.Falliano,D.DeDomenico,G.Ricciardi,E.Gugliandolo, Experimentalinvestigationonthecompressivestrengthof foamedconcrete:effectofcuringconditions,cementtype, foamingagentanddrydensity,Constr.Build. Mater.165 (2018)735–749.

[7]Davidovits J. Geopolymers, Inorganic polymeric new materials, Journal of Thermal analysis ,Vol 37 (1991), 1633-1656.

[8]Davidovits J. 2015, GEOPOLYMER: Chemistry and Application4th ed.InstituteGeopolymer.

[9]E.P.Kearsleya,P.J.Wainwright,Theeffectofhighflyash contentonthecompressivestrengthoffoamedconcrete, CementandConcreteResearch31(2001)105-112.

[10] GartnerE.,2004Industriallyinterestingapproaches to“low-CO2”cements’.Con.Res.34,1489-1498

[11]Government of India, 2017. Report on Fly Ash Generation at Coal / Lignite base Power Station andits UtilizationinIndiaforYear2016-2017.

[12]Gunasekara,C.,Law,D.W.,Setunge,S.,2016.Longterm permeation properties of different fly ash geopolymer concretes.Constr.Build.Mater.124,352-362.

[13]HuaXuandJannieS.J.vanDeventer,Effectofsource materialsongeo-polymeirzation,ACSPublicationInd.Eng. Chem.Res.(2003),42,8,1698–1706.

[14]HuaXu, J.S.J. Van Deventer, The repolymerization of alumina-silicateminerals,InternationalJournalMineral. Process.59_2000.247–266.

[15]Klopffer, W., 1997. Life Cycle Assessment: From the beginningtothecurrentstate.Environ.Sci.Pollut.Res.4, 223-228

[16]Kumar, S., Kumar, R. &Mehrotra, S.P. Influence of granulatedblastfurnaceslagonthereaction,structureand propertiesofflyashbasedgeopolymer. J Mater Sci45,607–615(2010).

[17]MR Jones,AMaCarthy, Behaviorandassessmentof foamedconcreteforconstructionapplication(2005).

[18]McCaffrey, R.,2002. Climate Change and Cement Industry. Global Cement and Lime Magazine (EnvironmentalSpecialIssue):15-19.

[19]McLellan,B.C.,Williams,R.P.,Lay,bJ.,VanRiessen,A., Corder, G.D., 2011. Costs and carbon emission for

geopolymer paste in comparison to ordinary Portland Cement.J.Clean.Prod.19,1080-1090.

[20]Mehta,P.K.,2002.GreeningoftheConcreteIndustry forSustainableDevelopment.ACIConcreteInternational, 24(7):23-28

[21]MohdRojiSamadi,(1997).Firstreportresearchproject on lightweight concrete, UniversitiTeknologi Malaysia, Skudai,JohorBahru.

[22]NALloydandBVRangan,Geopolymerconcretewith fly ash , Second international conference on sustainable constructionmaterialandtechnologies,2010.

[23]Nisbet, M.A., Marceau , M.L., Vangeem, M.G., 2002. Environmental Life Cycle Inventory ofPortland Cement Concrete,Report2137a.

[24]OlivierJGJ,SchureKM,PetersJ,2018Trendsinglobal CO2andtotalgreenhousegasemission;2018Report.

[25]Panesar,D.K.,Seto,K.E.,Churchill,C.J.,2017.Impact of the selection of functional unit on the life cycle assessment of green concrete. Int. J. Life Cycle Assess. 22,1969-1986

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page243