International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

1

, Anil Kumar Choudhary2

1PG Student, Department of Civil Engineering, Galgotias University, Gr. Noida, Uttar Pradesh

2 Assistant Professor, Department of Civil Engineering, Galgotias University, Gr. Noida, Uttar Pradesh. ***

Abstract - Waste management is very needed for the utilization of wastage of plastic to use this wastage in replacement of the current disposal technique. To reduce the wastage of plastic and minimize the impact on the environment waste utilization and recycling of plastic is the best way.

The construction field according to the new innovation is growing very rapidly. It faces new different difficulties and solves them very smartly. According to the application of variousmaterials,ithasmanynumbersofdifferentoptions to use as a material. The Behaviors and high performance of a special concrete depend upon its own properties and its similarity requirements. With the help of regular materials and conventional maxing, we cannot gain always higher performance. In this paper, we will find the behavior and properties of concrete when we partially replace the coarse aggregate with wastage plastic. In this investigation, we cast theconcretecubeswithdifferentcompositionsofreplacement of coarse aggregate with different percentages (5,10, and 20%). All cubes are cast analysis for the compressive and tensile strength. The wastage of plastic is used as a coarse aggregate for the improvement of the behavior and strength with respect to the normal concrete. This type of concrete which partially replaces the coarse aggregate with wastage plastic is used in a building that is non-load bearing building

Key Words: WastePlastic;Cement;sand,CoarseAggregate; FineAggregate;E-Waste.

Insomepreviousyears,concretetechnologyisgrowingvery rapidly.Theemissionofpollutedgasisveryproblemfullfor thehuman bodyandourenvironment. TheAggregateis a major part of the concrete that gets from the rock which decreasesdaybyday.Limestoneisusedfortheproduction ofcementwhichisanimportantmaterialfortheconcrete. Forthefineaggregate,washingandgrindingarenecessary to get fine materials and reduce the impurities from the materials.Rawmaterialswillfindfromtheexcavation.Soit is very dangerous for the earth and our environment. We partiallyreplacethecoarseaggregatetoreducethesetypes ofnaturaleffects.

In the conventional study, the coarse summations are produced from recycled plastic wastage in solid waste,

therebyfurnishingasupportablevolition tocompactwith the plastic wastage. There are several recovering plastic wastagemanufactoriesacrosstheworld,butstill,asmultiple momentstheplasticwastagetacklearerecovered;theytend tomisplacetheirpower.Hence,theseplasticswillfinishup as dumps. accordingly, it's concluded to articulate plastic wastageasanaggregateandtousethisaggregateforpartial relief of course aggregate. Plastic is a raw material that consists of either synthetic or semi-synthetic things like organiccompositesinabroadrangethatthey'replasticand sotheycanbemouldedintohardlandthings.Steelfilaments areappliedtoconcretetohelpsnapintheconcretedueto plastic drying loss. They similarly dwindle the concrete permeabilityandthereforerefusewaterbleedingfromthe concreteexterior.

The challenge of setting up and handling hard waste accoutrements inall nations hasgottenoneof the biggish natural,provident,andsocialeffects.Aperfectwastecontrol systemcontainingorigindeduction,utilization,recovering, landfill, and incineration needs to be applied to hold the addingwastagedumpingchallenges.Generally,plasticisn't recoveredintotheevenkindofplasticproductionsproduced from recycled plastics are frequently not recyclable. The applicationofbiodegradableplasticsisincreasing.However, therecoveredplasticisn'trecyclablebecauseofthefriction inparcelsandmelttemperatures,ifsomeofthesegetmixed inthedifferentplasticsforrecycling

To know the Behavior of concrete when partially replacingthecoarseaggregatewithplastic.

To compare the compressive strength of that concretetonormalconcrete.

Toknowthetensilestrengthofthatconcrete.

Toknowitsuseintheconstructionfields.

To compare the physical properties of Plastic Aggregateconcretewithnaturalconcrete.

Toproducelightweightconcreteforthelightweight structure.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Itisthemainaspectofconcrete'smanufacturingprocess.It has the property of sticking to any different raw cloth introducedintheconcrete'sinstructionmethod,especially when exposed to water and subsequently producing a properpaste.Itismainpartofconcreteithasthebanding properties.FormakingtheconcreteasperIS12269:1987 OPCgrade53isused.Itisusewithlessamountofcement wegotthehighstrength

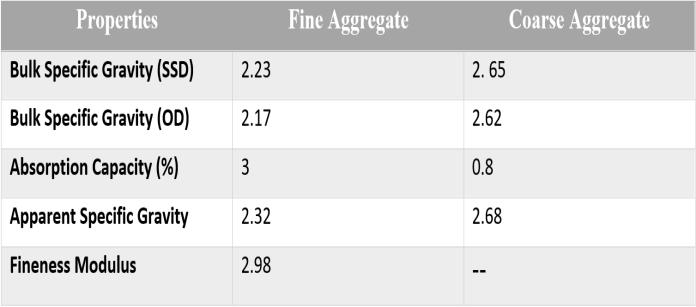

CleanRiversandisutilizedasfineaggregate.Thesizeofit's lesserthan2.36mm.Thepeculiargravenessandsmallness modulus of this fine total where set up to be2.66 and2.56 independently.Thechanceofendiswithinthelimitationsas perIS383-1970.Zone-I,II,III&IV.Inthiswork,Zone-IIsand isselectedwhosehabitatsaregiveninthetablebelow.

Thecoarseaggregateutilizedthing’s20mminsize,crushed angularshapeandfreefromdust.Thespecificgravenessand littleness modulus of this fine aggregate where set up to be2.6and2.98independentlyandthecollisionvaluationwas setuptobe12.Thechanceofendiswithinthelimitation.

Arecycledplasticwasutilizedtototaketheplaceofcoarse aggregates for manufacturing concrete samples. These aggregates were accessible in there being not of the same kindsize.

Mix design is carted out as per Indian Standard Code Method( IS 10262 – 2009) for concreting the experiment instance.ThegradeofconcretewhichweespousedisM20 withthewatercementrateOf0.45.

a)Theminimalcompressivestrengthneededfromstructural consideration

b)Theacceptable plasticitynecessaryforfull contraction withthecompactingoutfitavailable.

c)Maximumwater-cementrateand/ormaximumcement contenttogiveacceptablecontinuityfortheparticularpoint conditiontomeetthepointconditionandmeetstrength.

d)Maximumcementcontenttoavoidlosscrackingdueto temperaturecycleinmassconcrete.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Concretecubesamples(150mmx150mmx150mm)were castedforcalculatingcompressivestrength.Thespherical samples( periphery- 150 mm and length- 300 mm) were castedtodeterminespilttensilestrengthofconcrete.Allthe sampleswerecuredforaperiodof28daysbeforetest.Total twentyfoursamplesforeachtestwerecasted.

All test of the concrete is performed as perils. Code( IS 10262- 2009). The Concrete grade is espoused M20 with a0.45water-cementrate.

Samplesofconcretecellsofsize15cmx15cmx15cmwere poured to calculate the compressing strength of concrete. Spherical samples dia. - 15 cm and length- 30 cm were molderedtofindtheconcreteflexiblestrength.Theperiodof curingis28days.

Thestrategyespousedforthisstudyistoshakehandsand incorporate enough blenders ina11.42.40.5 wc ratefor a blendingrateof0.5.E-plasticphrasingsincludemeasuresof 0, 10, 20, and 30 percent by weight of the concrete in the blend.Theformwasaddedupanddulysmoothedprevious to blending for easy junking of the solid cement. Was. 3D places of size 15 cm x 15 cm x 15 cm, 15 cm X 30 cm cylindersareusedforthetestgovernance.Theassemblywas replaced motelywith an excavationoutfituntil the plastic positionwasreachedandretardationtestswereperformed to track the W/ C rate of the admixture and latterly to concentrateitintoaoiledcastironform.Thestrategywas espoused.Wentforwatertreatment.Sufficient3Dplacesof sizeweregiven24hourstosetbeforemaking.They'realso filledintoarelieftanktoplysufficient,advancehydration strength,dodownwithloss,andingestthehydrationraise until the age of the test. The 3D shape and cells were restored for days 7, 28, and 56. Concrete cylinders & cell wereladderedprevioustotesting,whiletheconsistenceof theconcretecellswasestimatedatdifferenttestingseasons. Before testing, the illustration was formerly again saved fromthetreatmenttank,whichwasleftoutdoorsforroughly 3hoursbeforebeingcrushed.Thecompressivestrengthof solidshapeswastriedoutasperMixDesign(IS102921982) usingaUniversalTestingMachine.

Testing hardened concrete plays an important role in controllingandconformingthequalityofcementconcrete work. The main factor in favour of the use of concrete in structuresisitscompressivestrength.Oneoftheimportant properties of the hardened concrete is its strength which represents its ability to resist forces. The compressive strength of the concrete is considered to be the most important and is often taken as an index of the overall qualityofconcrete.Thecompressivestrengthofconcreteis definedastheloadwhichcausesthefailureofspecimenper unit cross section on compression under given rate of loading.

TheCube ofM25 strengthistested byusing UTMandthe popularinstanceweresampledandthereliefweredoneby

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

10,20and30%cementsubstitutelevelbyPlasticWaste,fly ashandsuperplasticizerissupplementaltothecomposites.

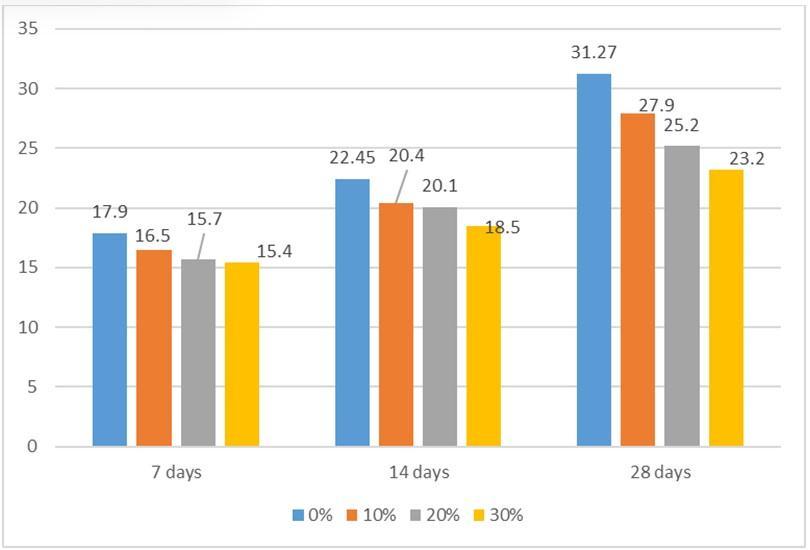

Compressivestrengthofplastictotaketheplaceofconcrete iscomparedwithconventionalconcrete.Fromgraphit'sset upthatacompressivestrengthupto80isachievedforamix of Waste plastic up to 30( as a relief for coarse total) in concrete.

The reduction in compressive strength of plastic replaced concrete is due to deficient cling of plastic grains in the matrix.

% Granules added

Figure 5: Compressivestrengthtest

Compressive Strength (MPa)

7th days 14th days 28th days 0% 18.60 22.45 31.27 17.90 22.27 32.15 10% 16.50 20.40 27.90 16.20 22.30 27.20 20% 15.70 20.10 25.20 14.80 19.40 26.60 30% 15.40 18.50 22.80 15.20 16.90 23.20

Table 2: Compressivestrengthtest

8.2

Graph 1: Compressivestrengthtest

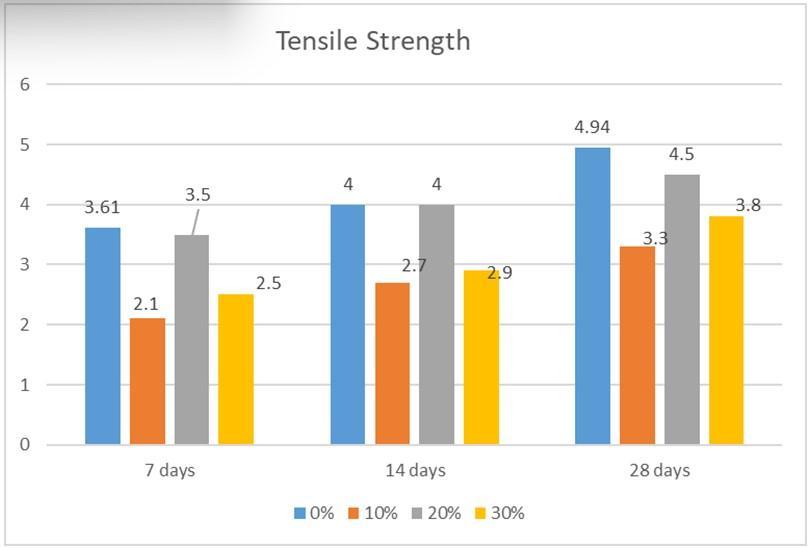

Concrete isn't generally anticipated to repel the direct pressure because of its low tensile strength and brittle nature. still the determination of tensile strength is necessary to determine the cargo at which the concrete members may crack. The cracking is a form of tensile failure.Splittensilestrengthupto70isscoredforablendof Wasteplasticupto90(asareliefforcoarseaggregate)in concrete.

The reduction in strength of plastic to take the place of concreteisduetodeficientbondingofplasticgrainsinthe matrix.

Table 3: SplitTensileTest

% Granules added

Tensile Strength (MPa)

7th days 14th days 28th days

0% 3.61 4.00 4.94 3.57 3.94 4.80 10% 2.10 2.70 3.30 2.30 3.00 3.40 20% 3.50 4.00 4.50 2.80 3.70 4.40 30% 2.50 2.90 3.80 2.70 3.30 3.90

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

[2] “Thermal insulation enhancement in concretes by addingwastePETandrubberpieces”:B.Yesilata,Y. Isker,P.Turgut,.Constr.Build.Mater.23(5)(2009) 1878–1882.doi:10.1016/j.conbuildmat.2008.09.014

[3] “Use of post-consumer plastic wastes in cementbased composites”: S.S. Singh, T.R. Naik, B.S. Brodersen,C.O.Huber.CementConcreteRes.26(10) (1996) 1489–1492. doi:10.1016/00088846(96)00135-4

[4] “Use of waste plastic in concrete mixture as aggregatereplacement”:Z.Z.Ismail,E.A.Al-Hashmi,. Waste Manag. 28(11) (2008) 2041–2047. doi:10.1016/j.wasman.2007.08.023

[5] “Behaviour of Concrete by Partial Replacement of Coarse Aggregate with Recycled Plastic Granules”: SuryakantaPanigrahi(2021)

The experimental results have shown the use of Waste plastic material in making concrete/ mortar can give an indispensableresulttominimizetheenvironmentalimpact duetounscientificdisposalofWasteplastic.Thefollowing conclusionsweredrawn

• The parcels of concrete containing colorful chance of plastic(0,10,20,and30)weretestedforitsphysicalparcels andcompressivestrength.

•TheWasteplasticusedfortrialsisofwasteplastic,5-12 mmsizeandspecificgravenessofWasteplasticissetupto be0.92.

• The compressive strength of test concrete is compared with plain concrete and it's set up that the compressive strengthupto80isachievedforablendofWasteplasticup to 30( as a relief for coarse total) in concrete. Hence it's recommendedforlightweightconcretestructures.

•Themechanicalparcelsofthetestconcretedidnotdisplay anynotabledifferencesdependingonthecoloroftheplastic waste.

• This exploration also has implicit operation for the productoffeatherlightconcrete,forminimizingthequantum ofpolymerwastesintips,andthecreationofornamental, seductivelandscapingproducts.

[1] “Effects of waste PET bottles aggregate on the properties of concrete”: Y.W. Choi, D.J. Moon, J.S. Chung,S.K.Cho,.CementConcreteRes.35(4)(2005) 776–781.doi:10.1016/j.cemconres.2004.05.014

[6] “Experimental investigation on the properties of concretecontainingpost-consumerplasticwasteas coarse aggregate replacement”: Zasiah Tafheem, RakibulIslamRakib(2018)

[7] ]“Experimental Study on Concrete by Partial Replacement of Cement with Human Hair, Glass Fiber and Course Aggregate with Plastic Chips”: ShailjaSharma(2021)

[8] “Wastepolyethyleneterephthalateasanaggregate inconcrete”:N.Saikia,J.deBrito,.Mater.Res.16(2) (2013).doi:10.1590/S1516-14392013005000017.

[9] “Development Of Energy-Efficient Concrete Buildings Using Recycled Plastic Aggregate”: M. Elzafraney1,P. Soroushian And M. Deru, 10.1061/_Asce_1076-0431_2005

[10] "Properties Of Hpc With Recycled Aggregates”, CementAndConcreteResearch,:Tsung-Yueh,YuenYeunchen,Chao-LungHwang(2006),Vol:36,Pp943950..

[11] ”Mechanicalpropertiesandabrasionbehaviourof concretecontainingshreddedPETbottlewasteasa partialsubstitutionofnaturalaggregate”:N.Saikia,J. de Brito,. Constr. Build. Mater. 52(2014) 236-244. doi:10.1016/j.conbuildmat.2013.11.049

[12] “Useofplasticwasteasaggregateincementmortar andconcretepreparation:Areview.Constr.Build.”: N. Saikia, J. de Brito, Mater. 34(2012) 385-401. doi:10.1170.2012.020.67.

[13] Use of recycled plastic in concrete: A review”: R. Siddique, J. Khatib, I. Kaur,. Waste Manag. 28(10) (2008) 1835– 1852. doi:10.1016/j.wasman.2007.09.011

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1401

Graph 2: SplitTensileTestInternational Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

[14] Comprehensive literature review on use of waste productinconcrete”:B.V.Bahoria,ResearchScholar, CivilEngg.Dept.,YCCE,Nagpur,

[15] Partial replacement of fine aggregates with waste plastic in concrete”: K.Balakrishna, C Sukesh, P.S.Teja, M.T.Meher, International Journal of Civil Engineering Research, Vol.3, No:2,2012, page no:105-113.1.

[16] AninvestigationontheuseofshreddedwastePET bottles as aggregate in lightweight concrete”: S. Akçaözoğlu,CDAtiş,KAkçaözoğlu,.WasteManag. 30(2) (2010) 285–290. doi:10.1016/j.wasman.2009.09.033

[17] Use of plastic aggregate in cement mortor and concretepreparation”:NabajyotiSaikiaandJorgede Brito, Construction and Building materials,Vol:34, 2012,pageno:385-401.

[18] Is456-2000SpecificationsForPlainAndReinforced Concrete

[19] Is 10262:2009 recommended Guidelines For ConcreteMixDesign,Bis.NewDelhi,2009.

[20] Is: 383-1970,Specification For Fine and Coarse Aggregates(SecondRevision)

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1402