International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Kritesh Kumar1 , Prof. Anil Kumar Sahu2

1B.tech, Dept. of Civil Engineering, Delhi Technological University, Delhi, India 2Professor, Dept. of Civil Engineering, Delhi Technological University, Delhi, India ***

Abstract - Concrete is a major product which is widely used in every construction site and being used as per strength required for the given element of structure. The modern scenario the concrete industry is towards gaining more strength and durability of concrete tomeet thedemands ofthe current construction works. Hence, Varieties ofadmixtures has been used so far to improve its properties, i.e. Compressive strength, Split Tensile strength & durability etc. There has been a substantial growth in the use of glass fibre in concrete for refining its properties suchas Compressivestrength, tensile strength and durability that is the reason why the glass fibre concrete is generally used in concrete and mortar for retrofitting in present concrete structures.

Hence, In this studies we attempt to investigation the effect of glass fibre in concrete with different variations of 0%, 0.25%, 0.5%, 0.75%, 1.0% & 1.5% to determine the effect in its properties such as Compressive strength, Split tensileStrength and durability. The cubes were cured in ordinary tap water and the solution of Sulphuric acid of N/50 Normality also.

Key Words: Concrete, Glass fibre, Compressive strength, Split tensile strength, Cured, Sulphuric acid.

Concreteisa majorproduct infieldofcivil engineering to constructstructure&itsdemandisupsurgingdaybyday.It is a second most used item in the world after water. Nowadays,Structuresaregettingcomplex,So,Wehaveto develop better products which are more reliable and stronger which help in making thin structural frames and making structure economical where development of any product is a major aspect in any field. Various fibers are usually used in concrete for prevent of drying, shrinkage, crackingandplasticshrinkagecrackingwhichgivesthema plus point to it. Some fibers generate higher resistance to impact, shatter and abrasion in the concrete which is remarkably good. Moreover, they also lower down the penetrationaswellaspermeabilityinconcretewhichatlast leads to the diminishing the bleeding of water. Fibers are thinorsmall pieceof reinforcingcomponentforconcrete, possessingcertaincharacteristics.Lowfibrecontentupto 0.3% of concrete mix has found effective in floor slab application.

GFRCisanimprovedformofconventionalconcrete.Itisa fusion of cement, fine sand, water, Coarse aggregate, admixturesandglassfibreinwhichshortlengthglassfibers

aredispersed.Glassfibreoptsgoodresistance fortension which is the reason why Glass fibre is chosen as reinforcement for concrete industries. Glass fibre is a featherweight and impressively strong substance which improvethepropertyofconcrete[10].Thetensilestrength of concrete is pretty much less as compares to its compressive strength, The effect of the fibers in this composite leads to growth the mechanical properties of concrete and mortar [1]. FRC is a form multipurpose buildingconstructionmaterialwhichhasbeenavailableto construction industry. The rising demand in composite producthavingglassfibre.Duetothis,theannualmarket has been reached an turnover in 1000 of millions USD annually[23]ComparedtoordinaryPortlandconcrete,ithas a bit different properties because of its special structure. Different parameters such as water–cement ratio, void ratio(porosity), product density, inter filler content, substantialcontent,orientationlengthoffibre&technique of cure affect the properties and performance of GFRC as well asprecision ofproductionmethodarealsoanaspect [12].

Thepresentscenarioinconcreteindustryisinthedirection ofgrowingthestrengthanddurabilityofconcretetomeetthe demandsofthepresentconstructionworldatminimalcost. Thesefactorscanbeachievedinconcretebymixingdesirable naturalorartificialfiber.IntheresearchbyK.ChawlaandB. Tekwani[5]observedtheAR-GFRC filamentsand detailed thattheidealamountofGFthatshouldbemixinconcreteis 0.33%ofthetotalmixtureweightofproducttoimproveits property.Likewise,theynoticethatthisamountofGFrisethe compressiveresistanceandtheflexuralstrengthby36.7% and 129.15 % compared to the conventional concrete respectivelyafter28daysofcuring.

Ontheotherhand,In2016,Kariappaetal.[18]experiment onconcretegradeofM20inwhichhefindthatthepresence of0.4%toitstotalmixtureweightARGFfilamentscausedin the maximum resistance values in mechanical properties suchastheflexural,compressiveandtensilestrengths,and the increase rate gaining to 33.21%, 54% and 58.24%, respectivelyaftercuringfor28days.InstudyofGlassfibre reinforced polymer specimens retrofitted the flexural strengthwasincreasedupto23%inextremeheatexposure where ordinary concrete losses its strength up to 23%.C. SelinRavikumarandT.S.Thandavamoorthy[17]observeda noticeable growth in the use of fibers in concrete for

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

enhancingitspropertiessuchastensilestrengthandductility that is reason the fiber concrete is commonly used in retrofitting in modern structures for better and improved aesthetic appearance. Nevertheless, GFRC is a recent introductioninthefieldofconcreteindustry.

Instudyofreinforcedshearwalls,thedosageabout0.3%of alkali-resistant glass fibre enhancing best ductility on the specimen.Neverthelesswhenthecontentwasabout0.4% indicateinadequateeffectsonthepostponingofthebearing capacitydegradationofthemodel[24].Inadditionofthat,the thermalconductivityunderhightemperatureisreducedby addingGlassfibrehavingalongitudinallengthof0.6cmwith increasingamountofglassfibreandifthelengthoftheglass fibrewillbeincreasethethermalconductivitywasfounded reduced[25].

The GFRC was used on Telecommunication tower with carbonfiberandintheobservationIwasfoundtheweightof thestructurereducedandbetterdurabilitywereobserved.In the outcome the average mean values were: 41 MPa in compressionstrength,3.7MPaintensionstrength&initial Young modulus was 16.5 GPa. [11]. GFRC displayed noteworthyperformanceonfireresistance,sincetheuseof GFRCsisforarchitecturalbuildingpanels.Inthesebuildings, fireresistancebecomesanimportantaspectindesignofthe structure.

Sample paragraph, The entire document should be in cambria font. Type 3 fonts must not be used. Other font typesmaybeusedifneededforspecialpurposes.Theentire documentshouldbeincambriafont.Type3fontsmustnot beused. Otherfonttypesmaybeusedifneededforspecial purposes.

ThecementwhichisusedforprojectwasOPCof43grade manufacturedbyAmbujacementhadamanufacturingin3rd weekofJanuary2022andgenerallyavailableinlocalmarket .Inexaminationofcementthematerialwasfoundfitforuse asperIS8112andhavingaspecificgravityof3.14

S. No. Test Any specificati on Observ ed Value

Requirem entasPer IS:2692015

3 Soundness (mm) IS:4031(Part-3)

(A) Le-Chatelier 3mm 10mm max. Yes

4 Compressive Strength(N/m m2) IS:4031(Part-6)

(B) 7Days 38 33.00Min Yes

(C) 28Days 48 43.0Min Yes

Weusedriversandasfineaggregatewhosesourceisfrom Kothputli which is locally available in market of zone II categoryasperIS383,itwasfreefromdeleteriousmaterials &havingthespecificgravityofsandwas2.68.

S. No Nameof Parameters Observ ed Value TestasPerIS: Requirement asPerIS 383:2016

1 SpecificGravity 2.68 2386(Part. 3)1963

2 Water absorption(%) 2.46 2386(Part3)1963

3 Deleterious Materials

A Coal&Lignite (%) Nil 2386(Part2)1964 1.00max.

B Claysand Lumps Nil 2386(Part. 2)1963 1.00max.

C Siltcontent 5.6 2386(Part1)1963 15.00max.

D Total%OfAll Deleterious Materials Nil 2386(Part. 5)1963 2.00max.

6 SieveAnalysis (%)2386(Part7)1963

Sieve Size

Conform ity

1 Fineness Is:4031(Pa rt-2) 0.69% Lessthan 10% Yes

2 SettingTime (Minutes) IS:4031(Part-5)

A Initial 136 30min. Yes

B Final 262 600Max. Yes

IsLimit 383-2016 Zone-II Sample One Sample 2 Sample 3

%ofpassing Average passing in%

4.75 0 0 0 0 90-100 2.36 94.3 96.6 93.7 94.9 75-100 1.18 76.8 72.9 70.7 73.8 55-90 600 56.2 57.9 58.3 57.4 35-59 300 20.6 16.4 17.3 18.1 8-30 150 6.2 3.7 7.6 5.8 0-10

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

We used crushed angular particles whose source was Kothputli (Rajasthan) which is locally available in market andfreefromdeleteriousmaterialsThespecificgravitywas 2.70, the coarse aggregate used have 60% of 20mm aggregateand40%of10mmaggregateproportionintotal coarseaggregate.

S. No Test Observ ed Value TestMethod AsPerIS: Requirement AsPerIs:3832016

1 SpecificGravity 2.70 2386(Part-3)

2 OrganicMatter Nil 2386(Part-2)

3 WaterAbsorption 2.53 2386(Part-3)

4 FlakinessIndex(%) andelongation index(%) 126 2386(Part-1) Max 40%

5 DeleteriousMaterials

(A) MaterialFinerThan 75Micron(%) 0.08 2386(Part-1) 1.0Max

(B) Clay&Lump(%) Nil 2386(Part-2) 1.0Max

(C) Coal&Lignite Nil 2386(Part-2) 1.0Max

(D) SoftFragment Nil 2386(Part-2) 3.0Max. TotalDeleterious Materials 0.08 2386(Part-2) 2.0Max

6 ImpactValue(%) 195 2386(Part-4) 30Max. Wearing Surface

7 Moisturecontent (%) 0.14 2386(part-3) Max3%

S. no. Typeoftests

Result Permissible limit as per IS456:2000

1 Volumeof0.02NH2SO4 requiredto neutralize100mlsampleusingmixed indicator 21.6 Max25ml

2 Volumeof0.02NNaOHrequiredto neutralize 100ml sample using phenolphthaleinindicator 1.7 Max5ml

3 Organicsolid(mg/l) 82 Max. 200mg/l

4 Inorganicsolids(mg/l) 622 Max. 3000mg/l

5 SulphatesasSO4(mg/l) 84 Max. 400mg/l

6 Chlorides(mg/l) 120 Max. 2000 mg/l

7 Suspendedmatter(mg/l) Negligible Max.2000 mg/l

8 PHlevel 7.6 Not less than6

WegettheglassfibrefromlocalwarehouseinDelhiwhere theycurtailthefibreasperdesiredlengthof50.8mmwhich havingdiameterof14microns.

The proportion for the mix design was 0.40: 1: 1.84: 3.31 [Water:cement:F.A.:C.A]withvariationofdosageof0,0.25, 0.5,0.75,1.0&1.5%withrespectofweightofcementwhere theproportionoftheingredientsmixdesignwascalculated byperIS10262:2016.

Sieve Size

PercentagePassing Average Percentage Passing

LimitAs Per IS:383:2016 Sample 1 Sample 2 Sample 3 25mm 100 100 100 100 100 20mm 9655 9174 9281 9369 85To100 10mm 5.58 6.74 7.26 6.50 0To20 4.75mm 0.13 0.26 0.24 0.21 0To5 Pan 0.14 0.04 0.06 0.08

Thetapwaterofcollageusedintheprojectwaswithinthe permissiblelimitasperrecommendationsofIS456-2000.

The Sulphuric acid of Normality of N/50 was prepared by dilutingthe98%concentratedH2SO4inwaterinproportion or dosage of 55.14 ml per 10 litre of water with testing (normalising with Na2OH 10 ml and phenolphthalein (C20H14O4)indicator).

TheCompressiveStrengthtestwasconductedonthecube specimen 15cm of Cast iron moulds were used to cast the cubes having leak proof metal base plate. The Split tensile strength test was conducted on the cylindrical specimen diameterof150mmand300mminlength.

During the pouring the concrete into moulds the vibrating table and tamping rod were used to compact the concrete eachtime,themouldswerewellpolishedwithshutteringoil beforethepouringandaftertheremovingofspecimenfrom the mould. The specimens were marked with date of manufacturingandpercentageoffibres.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

ThespecimenswerecuredwithtapwaterandH2SO4water solution of 0.02 normality for 7 and 28 days. The NondestructivetestlikeUPVTandReboundhammertestwere conducted on the cubical and cylindrical specimens.The surface of specimen were rubbed with porous stones to perform UPVT by direct method. On the other hand, the Reboundnumbersofspecimensgetbyreboundhammerin whichthepointofimpactsweremorethan15mmawayfrom itscorner.

The temperature during the blending the ingredient was nearly 26℃.The Compressive strength and Split tensile strengthwereperformedwithcompressivetestingmachine whichhavingcapacityof2MNwheretheloadwasincreasing gradually.

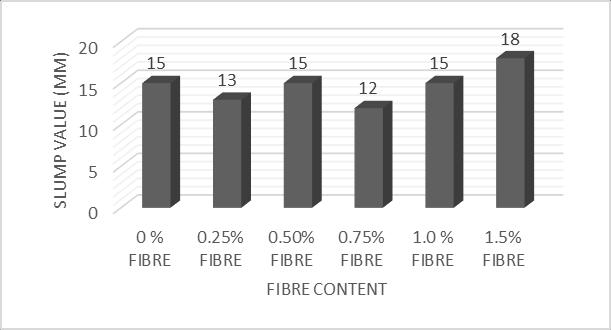

Therewerenonoticeablechangeinwetconcreteproperties such as slump value of concrete and its temperature with variationofpercentageoffibreduringtheexperiments.The concretehavingalowslumpvaluewhichdidnotvaryand thetemperatureofconcretewasalsodidnotchangeinsuch magnitude.

Table 7

Fibrecontent(%) Slumpvaluein mm Temperaturein℃ 0 15 30.3 0.25 13 30.5 0.50 15 30.5 0.75 12 30.6 1.0 15 30.8 1.5 18 30.3

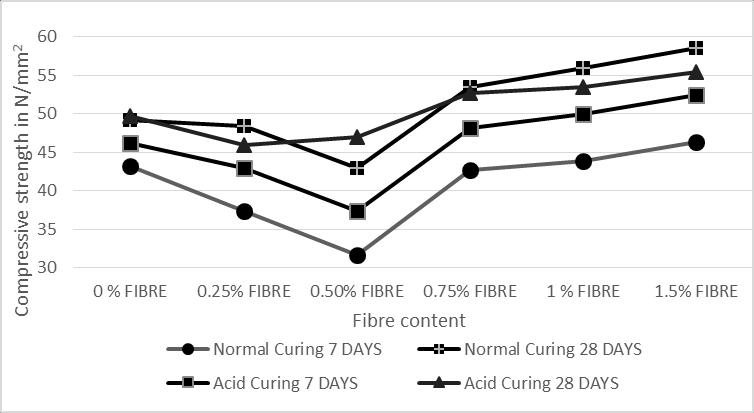

Overall, There was a reduction in compressive strength whenthepercentageoffibreincubeswhere0.25&0.5after thatextenttherewasgrowthinstrengthincaseofnormal watercuringaswellasacidwatercuring(H2SO4ofN/50).

Therewas 6.92%,10.42%,11.53%,7.03%,9.11%&4.44%of compressive strength was increased in acid cuing for 0,0.25,0.5,0.75,1.0&1.5respectively%ofglassfibrecontent forthe7daysspecimens.However,Insamemannersafter examine the specimen of 28 days it was found that the Compressive was decreased nearly 1.08%,5.20%,2.14%,1.55%,4.59%&5.35%.

Thecompressivestrengthwasdecreaseforspecimenwhich having0.25%and0.5%ofglassfibrecontentineverycase withrespectofageofconcrete.Inadditionofthatfor1.0% and1.5glassfibersspecimenshadgetincreaseinstrength which were 1.6% and 7.37% for normal curing condition, 3.84and4.88%foracidcuringafter7days.Furthermore, there was 13.88% and 18.99% % for normal curing condition,9.70%and13.70%foracidcuringafter28days.

Table 8 Compressive strength of concrete cubes with normal and acid curing conditions.

Fibre conte nt(%)

Normal curing7 days (N/mm2)

Normal curing28 days (N/mm2)

Acid curing7 days (N/mm2)

Acid curing28 days (N/mm2)

0 43.16 49.14 46.15 48.67

0.25 37.33 48.42 40.23 45.90

0.50 31.65 42.94 35.30 42.02

0.75 42.66 53.50 45.08 52.67

1.0 43.89 55.96 47.92 53.39 1.5 46.34 58.47 48.40 55.34

Figure 1 slump value of mixes (in mm)

Figure 2 Comparison of compressive strength after 7 & 28 days with normal and acid curing condition

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

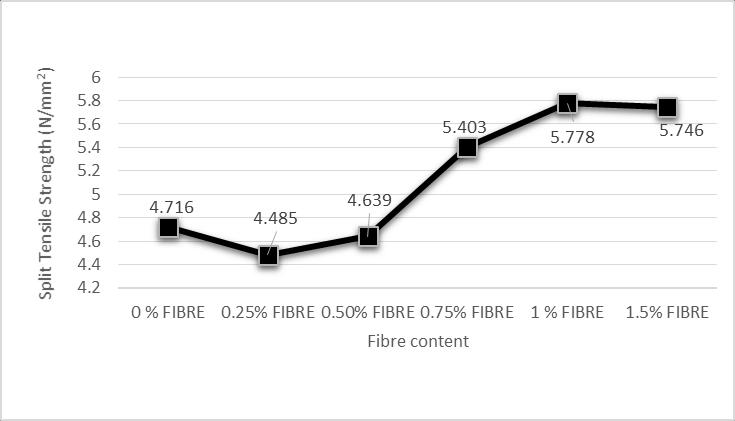

The tensile strength was follow same trend where the strengthofglassfibrespecimenshaving0.5%contenthaving lowerstrengthascompareto0%ofglassfibrespecimens. Nevertheless,thesplittensilestrengthwasroughlyaround 10%ofitscompressivestrength&increasedupto20%at 1.5%ofGlassfibrecontent.

Table 9 Split tensile strength of cylinders after 28 days

Fibre content (%)

AveragemeanLoadat failure(KN) Split Tensile StrengthinN/mm2

0 333.3333 4.716

0.25 317.000 4.485

0.50 327.9333 4.639

0.75 381.9333 5.403 1.0 408.4333 5.778 1.5 406.1667 5.746

1.0 4.47 4.20 4.45

1.5 4.37 4.28 4.46

Figure 3 Comparison of Split tensile strength of cylinders with variation of fibre content.

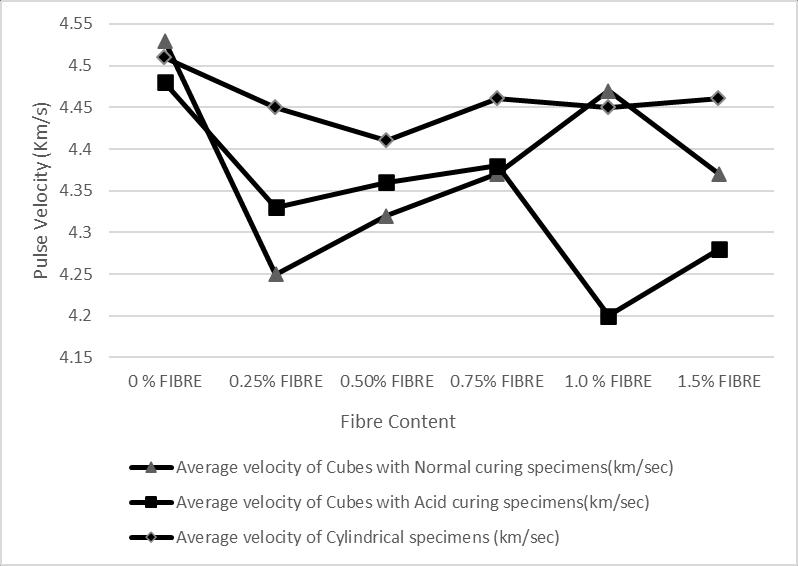

The ultra-sonic pulse velocity of cubes and cylinder was between4.25-4.53Km/swhichdefineasgoodtoExcellent ConcretequalityGradingasperIS13311(part1):1992

Fibre Content (%)

Averagevelocityof CubeswithNormal curing specimens(km/sec)

Averagevelocityof CubeswithAcid curing specimens(km/sec)

Figure 4 Comparison of pulse velocity of cubes and cylinders with variation of fibre content

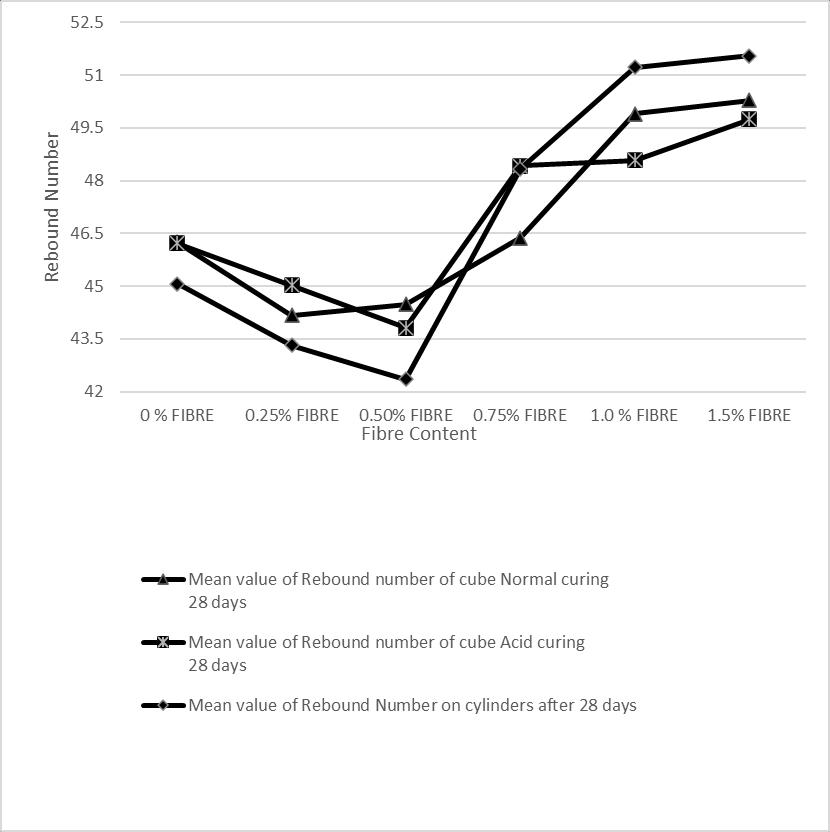

Therewasnonoticeablevariationwithrespecttovariation inconcrete.However,thequalitysurfacewasrecognizedas verygoodhardlayerasperIS13311(2)-1992.

Table 11 Rebound number of cubes (acid and normal curing after 28 days) and cylinders

Fibrecontent (%)

Meanvalueof reboundnumber ofcubenormal curing 28days

Meanvalueof rebound numberof cubeacid curing 28days

Meanvalueof rebound numberon cylinders after28days

0 46.25 46.22 45.06

0.25 44.17 45.02 43.32 0.50 44.49 43.82 42.35

Average velocityof Cylindrical specimens (km/sec)

0 4.53 4.48 4.51

0.25 4.25 4.33 4.45

0.50 4.32 4.36 4.41

0.75 4.37 4.38 4.46

0.75 46.37 48.43 48.34 1.0 49.9 48.58 51.22 1.5 50.28 49.75 51.55

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Figure 5 Comparison of rebound number with fibre content

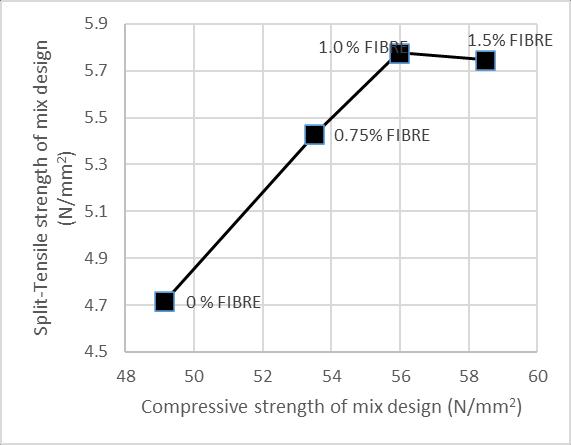

5.2.5 Relationship between Compressive strength and Split-tensile strength

The given figure shows the relationship between the split tensilestrengthandcompressivestrengthofmixdesignand it was found that an equation developed which for 0%,0.75%,1.0% & 1.5% of fibre content. This equation is y=0.1177x-0.9679. this equation is based upon linear assumption,whereslopeis0.1177,interceptis-0.7679,yis Splittensilestrengthandxiscompressivestrengthofdesign mix

Table no.12 Relationship between Compressive strength and Split-tensile strength

Fibrecontent (%)

Figure 6 relationship between compressive strength with tensile strength of different variation in fibre content.

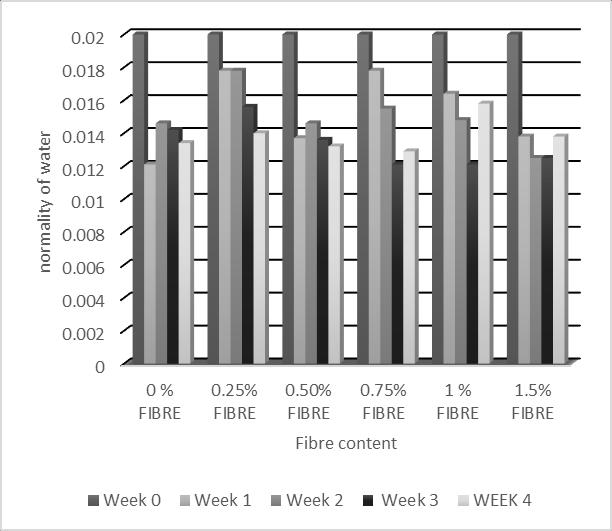

5.2.6 Normality of water

Thereisnonoticeableoutcomewithrespecttopercentage offibreinconcreteassamemannerwithrespecttoageof concretethereisnoclearthinkoccurs,Overall,the reductionwasabout11-39.5%.

Table 12 Normality of water used for acid curing

Fibre content (%) Week1 Week2 Week3 WEEK4

Compressivestrength ofcubesafter28days (normalcuring)

Splittensilestrength ofcylindersafter28 days(normalcuring) 0 49.14 4.716 0.75 53.5 5.43 1.0 55.96 5.778 1.5 58.47 5.746

0 0.0121 0.0146 0.0142 0.0134 0.25 0.0178 0.0178 0.0156 0.0140 0.50 0.0138 0.0146 0.0136 0.0132 0.75 0.0178 0.0155 0.0121 0.0129 1.0 0.0164 0.0148 0.0121 0.0158 1.5 0.0138 0.0125 0.0125 0.0138

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

ABDULLAH, M. M. and JALLO, E. K., (2012), “Mechanical properties of glass fibre reinforced Concrete”.Al-RafadainEngineeringJournal,Vol.20, No.5.

Arnon Bentur and Sidney Mindess, “Fibre Reinforced Cementitious Composites”, Second Edition2007,Chapter8,(pp278)

Banthia, N, Yan, C.B, Lee W.Y, (1997) “Restrained shrinkagecrackinginfibrereinforcedconcretewith polyolefin fibres”, Fifth International Concrete on Structural Failure, Durability Retrofitting, Singapore,November27-28,pp.456-463

Chandramouli,K,SrinivasaRao,P,Pannirselvam,N, SeshadriSekhar,T,andSravana,Priyadrashini,T.P, (2010),“ Strengthand durabilitycharacteristic of glass fibre concrete”, International Journal of MechanicsofSolids,Vol.5,No.1,pp.15-26

Figure 7 Variation of normality of after every week

Intheconclusionofthisreportwiththereferringthedata occurring in the result these are specific things are to be enlightenintheconclusionofthestudy:-

I. Thecompressivestrengthofconcretehaddecreased when the extent of amount of Glass Fibre was lower than 0.5%ofCementcontent.Incontrast,thespecimenshad1.0 % and 1.5 % given noticeable increment in compressive strengthnearly1.6%and7.37%fornormalcuringcondition, after7days.Furthermore,therewas13.88%and18.99%% fornormalcuringconditionafter28days.

II. Ontheotherhand,thespecimenshad1.0%and1.5 % given noticeable increment in compressive strength nearly 3.84 and 4.88% for acid curing after 7 days , for normalcuringcondition,9.70%and13.70%foracidcuring after28days.

III. The split tensile strength shows similar fashion havingabout10%ofitscompressivestrength.

IV. The pulse velocity by cross probe was4.25-4.53 km/swhichisdefinesthequalitygradingwasgoodtovery goodasperIS113311(2).

V. Normality of water during acid curing were diminisharound11-39.5%wherethereisnosignificantwas notedtoconcludethattheeffectofreactionwithspecimens.

VI. There is no significance effect on slump and temperatureofconcretewithvariationofglassfibrewhichis low.

K.Chawla and B. Tekwani, “Studiesof GlassFiber Reinforced Concrete Composites,” Int. J. Struct. & CivilEngg.Res.,vol.2,no.3,pp.176–182,2013

IS 13311-1 (1992): Method of Non-destructive testingofconcrete,Part1:Ultrasonicpulsevelocity [CED2:CementandConcrete]

IS 383 (2016): Specification for Coarse and Fine AggregatesfromNaturalSourcesforConcrete[CED 2:CementandConcrete]

IS456(2000):PlainandReinforcedConcrete-Code ofPractice[CED2:CementandConcrete].

IS8112(1989):Specificationfor43gradeordinary Portlandcement[CED2:CementandConcrete]

K.M.TajneandP.S.Bhandari,“EffectofGlassFibre on Ordinary Concrete,” International Journal of Innovative Research in Science, Engineering and Technology (An ISO Certified Organization), vol. 3297,no.11,pp.17632–17634,2014.

J.G. Ferreira, F.A. Branco 2005, “Structural applicationofGRCintelecommunicationtowers”, Construction and Building Materials Journal, PublishedAugust2005.

MuhammedİSKENDER &BekirKARASU,(2018),” GlassFibreReinforcedConcrete(GFRC)”El-Cezerî Journal of Science and Engineering Vol: 5, No: 1, 2018(136-162)

Siddique, R, (1997), “Properties of concrete reinforcedwithlowpercentageofsyntheticfibres”,

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

FifthInternationalConcreteonStructuralFailure, DurabilityRetrofittingSingaporeNovember27-28, pp.448-455

Sinha, D.A, Varma, A.K and, Prakash, K.B, (2013), “Propertiesofternaryblendedsteelfibrereinforced concrete”, The Indian Concrete Journal, Vol- 87, August,pp.26-30.

Wei-ChienWang,Her-YungWang,Kao-HaoChang, Shao-Yu Wang “Effect of high temperature on the strength and thermal conductivity of glass fiber concrete”

Elsevier, https://doi.org/10.1016/j.conbuildmat.2020.11838 7

IS10262(2009):Guidelinesforconcretemixdesign proportioning[CED2:CementandConcrete]

V. Mane and C. Markad, “An overview of glass fibers,”TextileToday,FIBER&POLYMER,pp.1–12, 2015.

Perumelsamy N. Balaguru and Surendra P. Shah, “Fibre reinforced cement composites”, February 1992.

C. Selin Ravikumar and T. S. Thandavamoorthy, “GlassFibreConcrete:InvestigationonStrengthand Fire Resistant Properties,” IOSR Journal of MechanicalandCivilEngineering,vol.9,no.3,pp. 2320–334.

M.KariappaandG.Shete,“Experimentalstudyon the performance of alkali resistant glass fiber reinforced concrete,” International journal of scientific development and research, vol. 1, no. 5, pp.127–133,2016.

IS 13311-2 (1992): Method of non-destructive testingofconcret-methodsoftest,Part2:Rebound hammer[CED2:CementandConcrete].

IS2386-1(1963):MethodsofTestforAggregates forConcrete,PartI:ParticleSizeandShape[CED2: CementandConcrete].

IS10262(2009):Guidelinesforconcretemixdesign proportioning[CED2:CementandConcrete].

IS2386-3(1963):Methodsoftestforaggregatesfor concrete, Part 3: Specific gravity, density, voids, absorption and bulking [CED 2: Cement and Concrete].

Singh,J.,M.Kumar,S.Kumar,andS.K.Mohapatra. 2017.“Propertiesofglass-fiberhybridcomposites: Areview.”Polym.Plast.Technol.Eng.56(5):455–469. https://doi.org/10.1080/03602559.2016.1233271.

Shaochun Ma, Dongfeng Hou, Peng Bao, Dongtao Wang “Influence of alkali-resistant glass fiber on seismicperformanceofprecastceramsiteconcrete sandwich wall panels” Elsevier, structure Volume 38, April 2022, Pages 94-107 https://doi.org/10.1016/j.istruc.2022.01.081.

Kritesh Kumar, completed his B.Tech in Civil Engineering from Delhi Technological University in 2022.

Prof. Anil Kumar Sahu, He is currentlyworkingasaprofessorin departmentofCivilEngineeringin Delhi Technological University, Delhi.Completedhis mastersand bachelors of technology from Allahabad University, Uttar PradeshandreceivedhisPhDfrom BundelkhandUniversity.Heisthe member of Professional Bodies: American Society of Civil Engineers(M-411489),Institution of Engineers (AM63307), Indian Geotechnical Society (M-2866), Institution of Civil Engineers, Indian Society of Technical Education, Indian Society of Rock Mechanics & Tunneling Technology(LM-177)andLifetime Member of Indian Society of ConstructionMaterials&Structure (LM22625)

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal