International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

NR Lohith1, Kumar Prashanth2, T Raghavendra3

1 PG Student, RV College of Engineering, Bengaluru, India.

2 PG Student, RV College of Engineering, Bengaluru, India. 3 Associate Professor, RV College of Engineering, Bengaluru, India. ***

Abstract - Whenweconsiderastructureorabuilding,there is a possibility of uncertainties or variability in material propertiesandloading.Thisreviewpapershowsthestudiesof acomplete review of literatureonreinforcedconcrete beams which is based on structural reliability analysis and is solved by different probability-based design methods. The probability-baseddesignapproachhaswidespreadacceptance and is a more precise and accurate way of treating uncertaintiesandvariabilitiesinastructure.Usingstructural engineering, reliability in a structure is a performance or functionality that can be measured. The methods which are reviewed in this paper are FORM (First Order Reliability Method), Monte-Carlo Simulation, TCM (Three-Term Conjugate Map), Fault Tree Analysis, and Hasofer-Lind Method.

Key Words: First Order Reliability Method, Three-Term Conjugate Method, Fault Tree Analysis, Hasofer-Lind method, Structural Reliability.

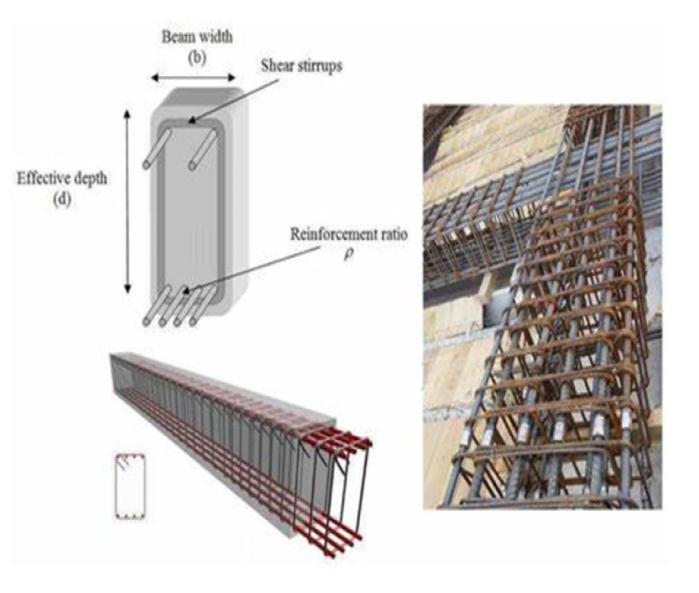

In a structure, there are many individual structural components,oneoftheimportantstructuralelementsisa beamwhichcarriestheloadfromthewallsandismadeto cause bending, shear, and torsion and they are always dependent on the parameters such as depth, length, materials,andcross-sectionalshapes.Analysisofreinforced concrete beams is designed by BS5950 (1990) and it was explainedbyFORM,attheserviceabilityandultimatelimit states.Arandomandstochasticapproachisconsideredfor designvariablessuchasspan,loadratio,andintensityoflive loads. The serviceability limit state tells us that the appearance, cracking, vibration, exposure condition, and thermal resistance whereas the ULS tells us about the loading form in bending and shear. Steel beams transfer transverse loads by flexural action into a column in a structure.Thefunctionofseveralvariables,mostofthemare randomvariableshasaresistanceinthestructuralmember and the applied loads. Hence, the probabilistic approach enables the use of the design of structural safety to be treatedmorerationally.

Reliabilitymethodsareprobability-basedapproachesthat are used in assessing the performance and safety of structural components or systems. When the probabilitybasedcomponentsorthesystemforaspecificperiodmeets

some specified demands under specified environmental conditionsaredefinedasReliability.Therefore,Reliability has the ability of the structural system to fulfill its design purpose for a specific time duration. The probability approachesinthereliabilityanalysistakeintoaccountthe uncertaintiesinthestructuralcomponentvariablesorthe system as a whole. Uncertainties are inherent in the componentstrength,randomvariables,andcorresponding loading effects. Reliability may also be defined as the structure that can be applied without any damage for a certainamountoftimeundersomeprobabilisticsituations.

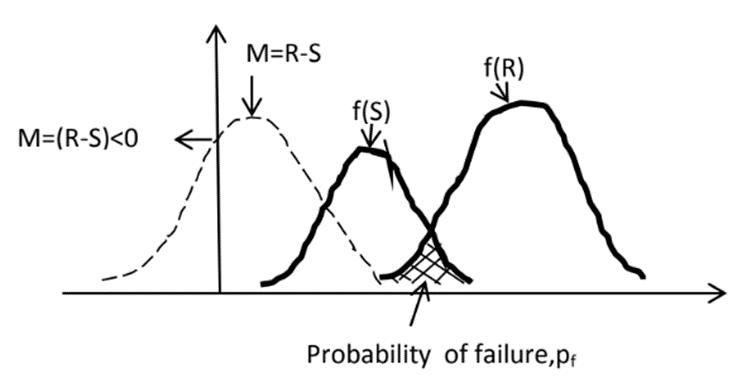

Ps + Pf = 1

Fig -1: GraphicalrepresentationofProbabilityoffailure (Pf)andMarginofSafety(M)

Duetothepresenceofmorestructuralcomponentsinthe system,thereisapossibilityoffailure.Afailuremodeinthe systemisconsideredbycombiningthestructuralelements thatleadtothefailureofthestructuralsystem.Identifying thefailuremodesinastructuralsystemisimportantforthe appropriate design and maintenance of the structural system. Reinforced concrete beams are subjected simultaneouslytotorsion,shear,andbendingwhichisthe case for a system reliability analysis is required when a whole structure or just a structural element has many modes.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Fig -2: TypicalrepresentationoftheReinforcedconcrete beam(Source–Internet).

Structural Reliability is the modern and best way to deal withorhandleuncertaintiesinengineeringdesign.FORM, SORM, HL Method, Point Estimate method, Monte-Carlo Simulation, Three-Term Conjugate Map (TCM), MVFOSM, andFaultTreeAnalysisarethedifferenttypesofreliability approachesthatcanbeusedtofindouttheSafetyIndex(ß), andProbabilityofFailure(Pf).

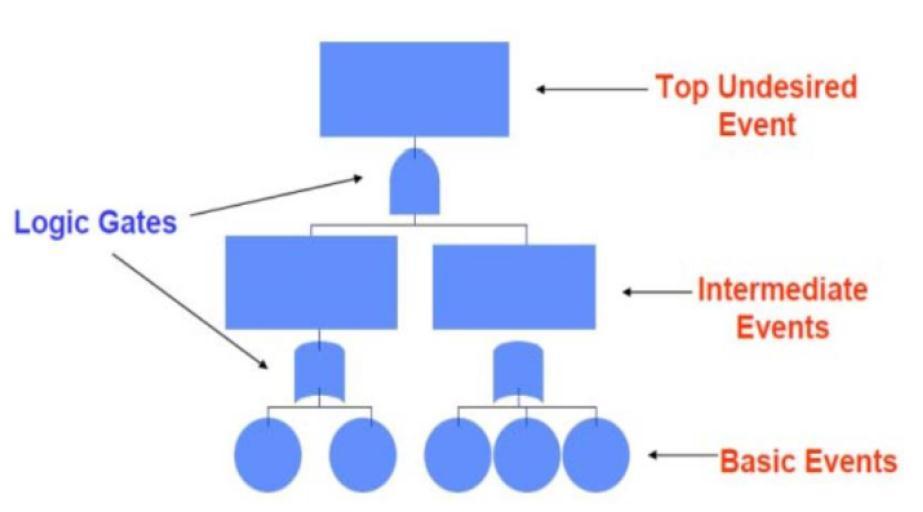

2.1 Fault Tree Analysis: Afaulttreecanbeexplainedbya graphical logical flowchart that describes the interrelationships of the basic structural components that are composing the system and leads to the occurrence of a predefined undesired top event in the tree. For structural engineeringsystems,theundesiredtopeventisdefinedas structural system failure. The fault tree analysis identifies the failures (faults) that can tend to unintended work. Therefore, the fault tree shows the different modes (the sequence of basic component failures) that lead to the systemfailure.

Theapproximateandrigorousresultsareprovidedwhich mightconsiderthestructuralbuildingasasinglesystemora unit which will be emphasized because of the reliability whichwasutilizedintheanalysisinsteadofthestructural reliability.

2.2 First Order Reliability Method (FORM): Thereliability ofstructuralelementscanbeassessedandutilizedbybasic design approaches. For a perfect solution for the safety factor and probability of failure, the input is given as standard deviation values, mean values, load values, and resistancevaluesincertainlimitstates.

Itisvastlyusedinapplicationsof estimation ofstructural reliability.Taylorexpansionisinvolvedinthisprocedureto find the equations in the limit state, which cannot be explainedbytheaveragevaluesinthefunctions.Normally distributedvariablesarestudiedinthispaper.

UsingtheRosenblatttransformation,themethoddealswith theconversion whichisexcluding normal variablestothe normal variables which give standard values and it is inclusiveofzeroaveragevaluethatisthemeanvalue,and thevarianceisalwayskeptequaltoone.Themainagendais tofindthefailurepointwhichisdefinedasthedistancefrom theoriginofthereducedvaluesandtheminimumdistance ofthelimitstatesurfaceofthereducedvariables.

One of the performance equations formulated for the reinforcedconcretebeamis, Z=R-S ……(R-ResistanceandS-Effectofloads)

Probability of Failure, Pf = ø (-ß)

Forareinforcedconcretebeam,whenalltheparametersare considered involving the effect of loads, and hence the equationisenumeratedas,

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

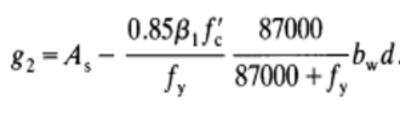

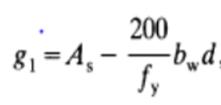

Where,areaoftensionsteel,As(mm2)

Yieldstrengthofsteel,fy (N/mm2)

Beanwidth,b(mm)

Lengthofthebeam,L(mm)

Compressivestrengthofconcrete,fcu (N/mm2)

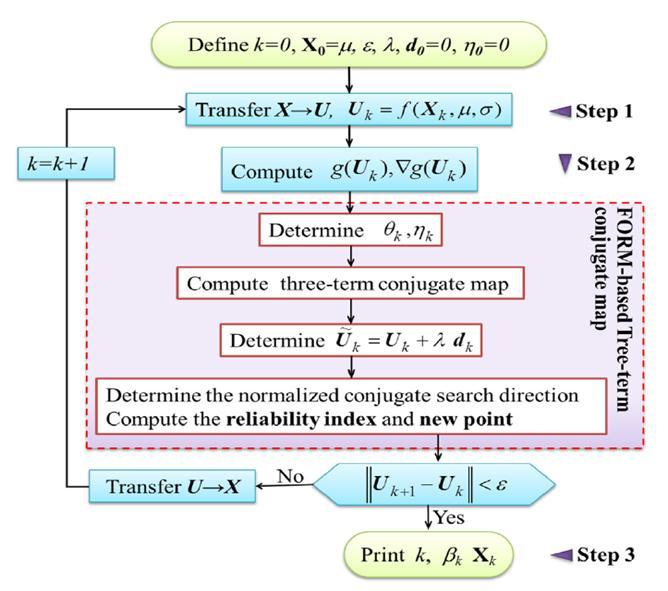

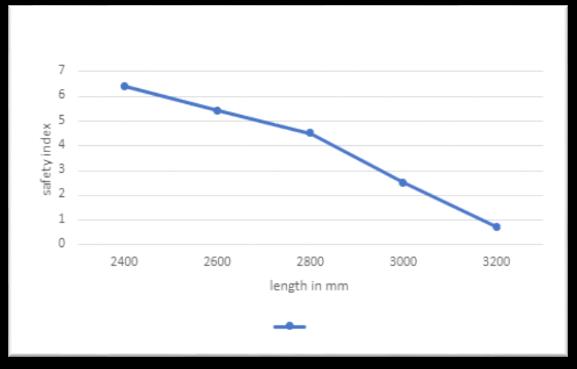

Thereliabilityindexandprobabilityofsuccessforvarious steel beams were determined using the probability-based reliability of the analysis. The developed model with differentparameterslikelength,depth,andstrengthwasa stochastic model. Different dimensions of concrete beams were constructed and built with varying dimensions like depth,length,andthickness.Itprovesthatifthesafetyindex increases it will increment along the depth and a slight decrease in the probability of failure, which automatically increasestheprobabilityofsuccess.Forevery2mincrement inthelengthofthebeam,thereisadecrementinthesafety factor.ThePfalwaysremainsconstantwhenthesafetyindex is directly proportional to the characteristic strength of beams.

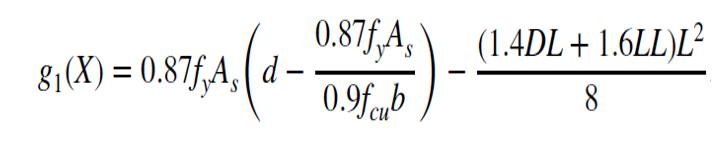

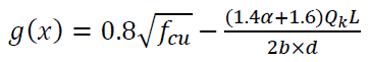

In one of the studies, it was found that the performance equationsforeveryfailuremodesuchasshearfailuremode, bendingfailure,anddeflectionmode.

2.3 Monte Carlo Simulation: Some of the simulation methodsisveryhelpfulforfindingasolutionforthesafety indexinastructure.Simulationistheprocessofconducting experiments on a model instead of applying experiments directlytothesystemorthecomponents.Amodel,physical or mathematical, is a representation of the system or the components to study its performance. Monte Carlo simulationisthemostcommonsimulationtechnique.MCS dealswiththenon-probabilisticmethodstoprobabilistically assessoutputvariablesofinterest.Theuncertaintiesinthe materialproperties,loads,geometry,andvariousmodelsare taken into consideration for evaluating the probability of failureandsafetyindex.

Aparticularreliabilityindexisfoundusingvaryinglengths, depth, and characteristic strength, and changes in the probabilityoffailurewereobserved.

Bendingfailuremode:

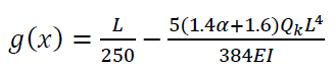

Deflectionfailuremode: Shearfailuremode: Where,Lengthofthebeam,L(mm) αistheDL-LLratio Compressivestrengthoftheconcrete,fy (N/mm2)

FORMusesthecombinationofanalyticalandapproximate valuesanditsolvestheproblemsateachstage.Firstly,the parameters have been defined as Normal, Log-normal, or Gumbeldistributionwhichmayormaynotbeindependent of each other. The limit state which was the original limit stateisnowconvertedintothesurfaceofthenewlimitstate.

Where,d–effectivedepthofthebeam Bw –widthifthebeam As –areaoftensionreinforcement f’ c –compressivestrength fy –yieldstrengthofsteel

Itwasclearthat,whenarelativelylowvalueofMonteCarlo simulation,itcanbeveryaccuratetopredicttheprobability of success in the pre-defined limit state. The Pf values are lowerthan105forMCSandvarysignificantlyintherandom variables, degrees of freedom, and complications in the problem.

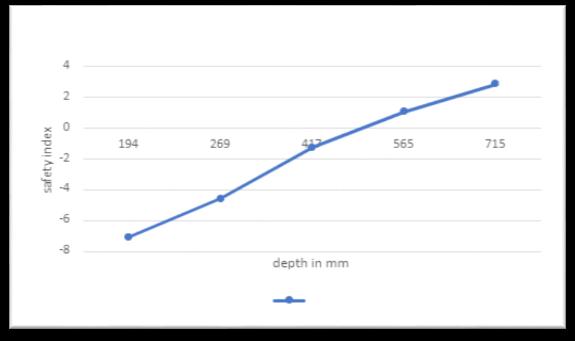

2.4 Three-term Conjugate Map (TCM): Itisbasedonone oftheimportantmethodsinthereliabilityapproachwhichis thebasicprobability-baseddesignapproach.Thefinitesteplengthconceptisusedforaformulationthatwasextracted from a non-linear conjugate map and is called the Threeterm Conjugate Finite Step-Length Method (TCFS). The sensitivityvectorconsistsofthreetermswhicharenamely the first term will be the gradient vector, the conjugate gradientintheintermediateterm,andfinallythelastisthe previousgradientvectorinthesucceedingevent.Identifying themulti-storybuildingfailureofreinforcedconcretebeams isoneofthemainapplicationsoftheTCMmethodwhichis plotted against many formulations in the structural reliabilityofFORMmethods.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

FORM method may or may not provide stable results without the variations in solution by non-linear formulations.Usingtheprobability-basedapproaches,TCM approachesastructuralanalysisofreinforcedconcretebeam whichistestedinbothformsofcorrosionvariationsnamely pitting corrosion and uniform corrosion, in this case, a specialbrittlefailuremodeisincludedfortheformulations oftheperformanceequation.

The distance between the reinforcement and the compressivefiberoftheextremelayerandthewidthofthe sectionincreasesdirectlythevalueofthesystemreliability ofthesystemanditalsoimpliesotherparameters.

Someuncertaintiesinthedesignarenotconsistent which are in a deterministic approach and have failedtoputintoconsiderationthemeasuringsafety factorssuchasloadfactorandthefactorofsafety.

The increment in the depth increases the safety index factor which automatically decreases the probabilityoffailure.Thisisexplainedgraphically inchart-1bytakingthevaluesofthedepthandthe safetyindex.

Fig -4: FlowchartforTCFSprocedure.

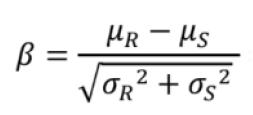

2.5 Hasofer-Lind Method: Thereliabilityindex(ß)canbe explained as the ratio of the average value of a particular event to the deviation of the same particular event. It can also be explained as the minimum length from the failure regiontotheoriginofadesignpoint.Thiscanbeexplained byacommonequation,

Z=R-S

ß = µ / σ

ItalsoexplainshowthereliabilityindexisdefinedbyMean ValueFirstOrderSecondMoment(MVFOSM)methodbythe termsRandSwhichistheresistanceandtheeffectofloads. WecantellthatitisalmostsimilartoMVFOSMifboththe variablesthatareRandSarenormallydistributed.

Chart -1: GraphicalrepresentationofSafety indexvsDepthinmm.

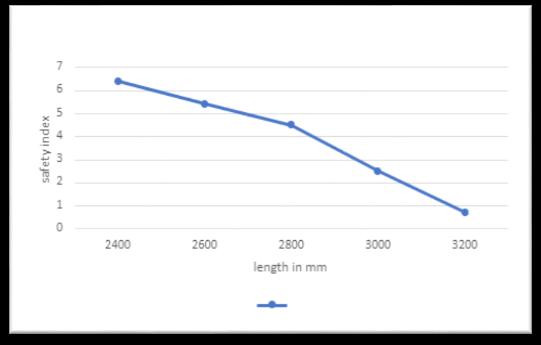

Wecanseefromfigno.6thatthelongerthelength ofthebeam,itisunsafeforthereinforcedconcrete beamwhichalsoincreasesthetendencytofail.The length of the beam is increased by 2m each up to 10m to show that the safety index is inversely proportionaltothelengthofthebeam.

Chart -2: SafetyindexvsLength(mm)

Whenthegraphisplottedagainstthecharacteristic strengthandthesafetyindex,itshowsthatitvaries linearly that is it is directly proportional to each

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

other and the probability of failure remains constant.Thisisshowninchart-3.

when compared to some of the probability-based designapproaches.

[1] Daniel Ndakuta Kolo, James Isiwu Aguwa, Theophilus Yisa Tsado, Mohammed Abdullahi, Abdulazeez Yusuf, Sikiru Folahan Oritola1 “Reliability Studies On ReinforcedConcreteBeamSubjectedToBendingForces WithNaturalStoneAsCoarseAggregate”AsianJournal ofCivilEngineering(2021).

[2] O J Aladegboye, D A Opeyemi, O D Atoyebi1, S L AkingbonmireandEMIbitogbe“ReliabilityAnalysisOf Reinforced Concrete Beam Using Varying Properties” 2020 EarthandEnvironmentalScience.

Chart -3: SafetyindexvsCharacteristicstrength (kN/m2)

The probability of failure (Pf) remains constant when the safety index is directly proportional to characteristicstrength.

[3] Marin Grubiši´c, Jelena Ivoševi´c, and Ante Grubiši´s “Reliability Analysis of Reinforced Concrete Frame by Finite Element Method with Implicit Limit State Functions”2019,www.mdpi.com/journal/buildings.

[4] U.Hamza,A.Aboshio,M.T.AbdulwahabandA.Suleiman “Reliability Assessment of Reinforced Concrete Panelled-Beams”2021.

Probabilityoffailurehasaconstantwholenumber of1.0,whenthereisadecrementinthereliability indexwhichautomaticallyshowsanincrementin boththeparametersnamelycharacteristicstrength anddepth.

[5] A.U. Barambu, O.A.U. Uche, and M.T. Abdulwahab “Reliability-BasedCodeCalibrationforLoadandSafety Factors for the Design of a Simply Supported Steel Beam” SEP: Journal of Research Information in Civil Engineering,Vol.14,No.1,2017.

The distance between the reinforcement and the compressive fiber of the extreme layer and the widthofthesectionincreasesdirectlythevalueof the system reliability of the system and it also impliesotherparameterslikecompressivestrength ofconcreteandspecifiedstrengthofthebeams.

[6] Behrooz Keshtegar, Shun-Peng Zhu “Three-Term ConjugateApproachforStructuralReliabilityAnalysis” journalhomepage:www.elsevier.com/locate/apm

[7] Dimitri V. Val “Deterioration of Strength of RC Beams DueToCorrosionandItsInfluenceonBeamReliability” 2007.

When the Hasofer-Lind method is used, the calculationswerecalculatedforcapacity,durability, and serviceability to find the reliability of the structuraldesigninreinforcedconcretebeams.

[8] MohamedElAmineBenSeghier,BehroozKeshtegarand HussamMahmoud“Time-DependentReliabilityAnalysis Of Reinforced Concrete Beams Subjected To Uniform AndPittingCorrosionAndBrittleFracture”.

Fromtheabovereviewpapers,itcanbeconcluded thatwhenweneedtodecreasethefailureratethe cross-sectionalareaofthebeamandsteelshouldbe increased.

To produce more accurate results the system’s reliabilityhasitsmeritsinpredictingthelifeperiod of the building, but it can be costly and timeconsuming.

[9] HasanAKamal,IbrahimAAssakkaf,HasanJKaramand Naser O Al-Enzi “Reliability Assessment of Existing ReinforcedConcreteStructures”2013.

[10] Z I Syed, M Kewalramani and E S Hejah “Structural Reliability Of Dapped End Beams With Different Reinforcement Layouts Under Dynamic Loading” IOP Conf. Series: Materials Science and Engineering 75 (2019)012003,2018.

The Three-term Conjugate Finite Step-Length methodshowsveryaccurateresultsfornon-linear structural components and is also more efficient

[11] S O A Olawale, O P Akintunde, M O Afolabi1 and O A Agbede“ComparisonofReliability-BasedDesign(Rbd) With Eurocode 2 for A Singly Reinforced Concrete

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Beam” IOP Conf. Series: Materials Science and Engineering.

[12] Paolo Castaldo, Diego Gino, Gabriele Bertagnoli, Giuseppe Mancini “Resistance Model Uncertainty in Non-LinearFiniteElementAnalysesOfCyclicallyLoaded Reinforced Concrete Systems” Engineering Structures 211(2020)110496.

[13] Structural Reliability and Durability Assessment of ReinforcedConcreteStructures.

[14] AbubakarIdrisandPiusEdache“ReliabilityAnalysisof Simply Supported Steel Beams” Australian Journal of Basic and Applied Sciences, 1(1): 20-29, 2007 ISSN 1991-8178.

[15] Renjian Lu, Yuanhui Luo, Joel P. Conte “Reliability Evaluation of Reinforced Concrete Beams” Structural Safety14(1994)277-298.

[16] P.Hari Prasad, T.Sumathi Uma Maheswari “Reliability AnalysisoftheSectionalBeamsDueToDistributionof Shearing Stress” Research Inventory: International JournalofEngineeringandScienceVol.6,Issue4(April 2016), PP -83-90 Issn (e): 2278-4721, Issn (p):2319648.

[17] A. S. Nowak, Chan-Hee Park, J.R. Casas “Reliability Analysis of Prestressed Concrete Bridge Girders: Comparison of Eurocode, Spanish Norma Iap, And Aashto lrfd”8th ASCE Specialty Conference on ProbabilisticMechanicsandStructuralReliability.

[18] Reliability-based analysis and design for civil engineering-DevarajVandRavindraR.

[19] Ditlevsen, O. and Madsen, H. O. (2005). Structural ReliabilityMethods.JohnWiley&Sons,Chichester.

[20] GouthamDRandManjunathK2016“ReliabilityAnalysis of Grid Floor Slabs” International Research Journal of EngineeringandTechnology(IRJET),3(6).E-ISSN:2395 -0056,www.irjet.netp-ISSN:2395-0072.

[21] ChoiSK, Grandhi R andCanfieldRA2006“ReliabilityBasedStructuralDesign”SpringerScienceandBusiness.

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |