International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | September 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | September 2022 www.irjet.net p-ISSN: 2395-0072

Rohmat1, Sularjdaka2, Achmad Widodo2

1-2 Department of Mechanical Engineering, Faculty of Engineering, Diponegoro University Jl. Prof. Sudharto, SH, Tembalang, Semarang +62 247460059 ext. 101 ***

Abstract – Research has been carried out on the sound absorption properties of sound-absorbing materials made from Pineapple Leaf Fiber, PUF, and Banana Trunk Fiber with the resin matrix. Absorbent in the ratio of 2:1, 1:1, and 1:2 . The research method was carried out first by making samples by taking pineapple leaf fiber and banana fiber, and decomposing the alkaline treatment fiber with4%NaOHfor4 hours. Rinse with aquades until clean then dry. Composite molding was carried out with a Hot Press for 240 seconds at a temperature of 1100C. Then the sound absorption test was carried out using a signal generator and sound level meter concerning the principle of the E-1050 impedance tube method, at a ratio of fiber: matrix 2:1 capable of absorbing sound at a frequency of 400 Hz at = 300 Hz.

For the last decades, it has been studied with natural ingredients by researchers. Experimental products made from natural materials as noise absorbers have been published, such as cellulose tiles, mineral fiber, rock wool [2], glass wool [3], and pineapple leaf fiber [4]–[6], wood fibers, sawdust [7], felt (felt), sisal, coconut fiber and sugarcane[8]–[14],hair,carpets,cellulose,grainfromtires [15], cigarette filters [16] and waste fabrics and their compositesusedfornoisecontrolaredistinguishedfortheir highefficiencyinsoundabsorption.

Words: COMPOSITE, SOUND ABSORPTION, POLYURETHANE FOAM, Pineapple FIBER, BANANA FIBER

WASTEistheresidualwastefromaproductionprocess,both fromhouseholdandindustrialresidues,wheremostpeople live,therearevarioustypesofwaste,especiallyintheBelik Mountains area, Pemalang Regency, there are a lot of agricultural residues namely waste pineapple leaves and bananastems.Solidwastefrompineappleleavesandbanana stemsisknownasgarbagebecauseithasnoeconomicvalue. The presence of waste can harm the surrounding environment,especiallyhumanhealthduetonoise,soitis necessarytohandlethewaste.

The silencer [1] is a tool to control noise generated from home and industrial activities, one way to reduce it is by emittingsoundenergythathitsthewallthroughtheviscothermal effect. Its application is commonly found in buildingstocontroltheacousticqualityinroomswherethe clarity of speech. The absorbers commonly found in their manufacture are derived from porous materials such as foam,cotton,andwool.Itisknownthatsuchmaterialshave sound absorption at low to high frequencies where the thickness of the absorber is equal to a quarter of a wavelength. In addition to dampers, resonance-based dampers are also used which are effective for reducing acousticenergyatlowerfrequencieswithlimitedabsorption bandwidth.

In the study[17], the PU composite foam including CaCO3 fillerafterchemicaltreatmentwitholeicacidwasmadeto check the sound absorption resulting in a high sound absorptioncoefficientandthehighestvalueat6wt%filler content.

Pineapple leaf fiber has the highest sound absorption coefficientamongothertypesoffiber.Smalleranduniform fiberdiameterhasanimportantroletoabsorbsoundenergy inpineapplefiber[12]

Theresearchmethodwascarriedoutbytakingbananastem fibers,makingcomposites,andtestingthesoundabsorption propertiesofbananastemfiberpolyestercomposites.The stemfiberwastakenthroughadecompositionprocesswith 5%NaOHsolutionfor14hoursanddriedinthesuntodry, thenchoppedwithablender.Thefibersobtainedwerethen madeintocompositeswithfibervolumefractionsof30,40, and50%.Eachfibervolumefractioninthecompositewas pressed until it hardened with a time of ± 5 hours. The compositeattenuationtestwascarriedoutonaKundtsTube Impedance device equipped with speakers, amplifiers, power supplies, laptops, oscilloscopes, and sound level meters,withinputfrequenciesof200,400,and600Hz.The results of the attenuation study of polyester composites reinforcedwithbananastemfibershavethehighestsound absorptioncoefficientof0.72at50%fibervolumefraction withaninputfrequencyof 200Hzandthelowestvalueis 0.54at30%fibervolumefractionwithaninputfrequencyof 400 Hz. Overall, the specimen can be used as a damping materialbecauseithasasoundabsorptioncoefficientvalue >0.30[18].

Based on the background of various uses in the field of sound-dampeningcomposites,itwilltrytomakecomposites

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | September 2022 www.irjet.net p-ISSN: 2395-0072

derived from natural fibers. Natural fibers used in the manufacture of composite materials are pineapple fiber, polyurethane foam, and banana fiber. This study used pineapple fiber and banana fiber which had been treated witha5%NaOHsolution[14].Theimmersionofpineapple fiberandbanana fiberusing NaOHsolutionisintended to improve the adhesion between the fiber and the resin. In addition,theresultsofresearchwithalkalinetreatmentcan improvesoundabsorption.Soundattenuationtestingisby theASTME1050standard.Themorphologyofthematerial was investigated and evaluated using SEM and Fourier transforminfraredspectroscopy.

Pineapplefiberandbananafiberareeasilyobtainedfrom local agricultural products in Indonesia because of the abundantingredients.Thefibersweresoakedin5%NaOH solutionfor4hoursandthefiberswerewashedwithdistilled wateranddriedinthesuntodry.EpoxyresinbrandALFand Epoxy hardener brand ALF as adhesive for making composites.Anothermatrixmaterialusedisbi-component rigidpolyurethanefoam.Thepolyolcomponentofthefoam mixtureincludespolyol,(polyol:density=1.09g/cm3at26 °C,viscosity=560mPaat26°C).Theisocyanatecomponent includesthepolymerMDI(methylenediphenyldiisocyanate) (isocyanate: density = 1.24 g/cm3 at 26 °C, viscosity = 170÷250mPaat26°C).

In the manufacture of Polyurethane Foam, weighing 55% polyether polyol and 45% isocyanate, then the polyether polyolisstirredfor120secondsthentheisocyanatematerial ispouredandstirredfor90seconds,whenfinishedpourin thecontainerprovidedwithroomtemperature260C.Wait untilapprox.of4hours.

The tools used include molds, digital scales, calipers, and hydraulicjacks.Compositemanufacturebypressmoldwith a length, width, and width of 70 mm x 70 mm x 10 mm. Compositemanufacturebycoatingthemoldwithamixture ofepoxyresinhardenerplacingbananafiber,andgivingthe surfaceoffiberswithamixerofresinandhardener.Thenext stepistoputthepolyurethanefoamfiber,mixerofresinand hardener, and cut pineapple fiber on it while coating the resin hardener mixture to an even thickness of 10 mm. CompositesusingaHotPressmachinefor240secondsata temperature of 110 C, samples were cut with an average diameterof40mmandanaveragethicknessof10mm.The manufactureofasamplecylinderwithadiameterof20mm isintendedsothatthesamplecanbepreciselyinsertedinto animpedancetubetomeasureitsabsorptioncoefficient.An impedance tube made of aluminum pipe with an inner diameterof40mmwasusedtocovermeasurementsinthe frequency range from 200 Hz to 3000 Hz. The impedance

tube is designed according to ASTM E-1050. Sound absorptiontestspecimenismadebycuttingthecomposite according to the tube diameter. Dimensions of the test sampleandtestmethodaccordingtostandardE-1050.[16] SEM (Scanning Electron Microscopy) to determine the compositemechanismandFTIR.

Drawing1.20mmdiameterspecimen(left)and40mm diameterspecimen(right)

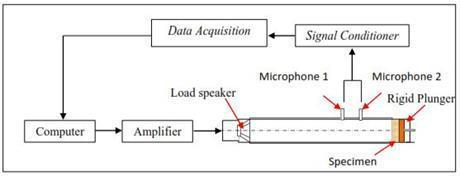

First,theimpedancetubeiscalibratedwithadensityof45 kg/m3 and a thickness of 40mm. The sound absorption coefficientiscalculatedusingthetransferfunctiongenerated from the two microphones. The experimental set-up is illustratedinDrawing2.

Thesoundabsorptioncoefficientwastestedaccordingtothe ISO10534standardtubeimpedanceshowninthefigure.2. Thetestsamplesizeisabout20mm&40mmdiameterfor lowerfrequencyandhigherfrequencyrespectively.Inthis methodthespeakerisusedtogeneratethefrequencyand themicrophonepicksupthesignalfromtheincidentwave andreflectedwave.Thetransferfunctionbetweenthesetwo signals gives you the value of the sound absorption coefficient determined using a 1/3 octave signal from a frequencyof100to6300Hz.

FTIRspectroscopywithattenuatedtotalreflectionaccessory wasusedtoexaminethechemicalfunctionofNaOHonthe surface.FTIRspectraobtainedwithanaverageof16scans witharesolutionof4cm1.Scanningelectronmicroscopy (SEM,SNE-3000M,SEC)wasusedat15kVtoexaminethe fillersurfaceandcellmorphologyofPUcompositefoam.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | September 2022 www.irjet.net p-ISSN: 2395-0072

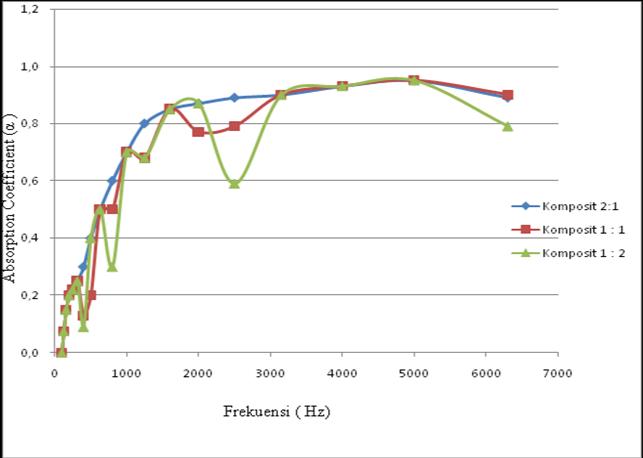

Frekuensi Comparis on matrix: fiber1:2

Comparis on matrix: fiber1:1

Comparison matrix:fiber 2:1

100 0,000 0,000 0,000

125 0,075 0,075 0,075

160 0,150 0,150 0,150

200 0,200 0,200 0,200

250 0,220 0,220 0,220 315 0,250 0,250 0,250

400 0,300 0,130 0,090

500 0,400 0,200 0,400 630 0,500 0,500 0,500 800 0,600 0,500 0,300 1000 0,700 0,700 0,700

1250 0,800 0,680 0,680

1600 0,850 0,850 0,850 2000 0,870 0,770 0,870 2500 0,890 0,790 0,590 3150 0,900 0,900 0,900 4000 0,930 0,930 0,930 5000 0,950 0,950 0,950 6300 0,890 0,900 0,790

Theresultsofthesoundabsorbingtestonthesamplewitha matrixandfiberratioof2:1aftertheexperimentshowed thatatafrequencyof5000Hzwithacoefficientvalueof0.90 thedensityofthematerialgaveamoredominantinfluence ontheabsorptioncoefficientcomparedtothethicknessof thetestobject.Higherdensityandhigherthicknessincrease theabsorptioncoefficient.Morefiberscreatemoretrapped acoustic pressure energy in the material. Material with a thicknessof10mmand0.1978gr/cm3densitycanabsorb sound,amaximumof90%at3000Hzfrequency,andmay still increase at higher frequencies. In addition, other specimens also have a higher probability of sound absorptionatfrequenciesover3000Hz.Itisalsoshownthat thecompressionofthefibrousmaterialdecreasesthesound absorptionproperties.Undercompression,variousfibersin the material are brought closer to each other without deformationorchangeinfibersize.

The fibers used in this study were pineapple fiber and bananafiber.TheresultsoftheFTIRtestofpineapplefiber andbananafiberthathavebeensoakedinNaOHfor4hours. Fromthetestresultsonpineapplefiber,itwasfoundthat therewasanidentificationofstretchingoftheO-Hbondsof the alkane group with a wave peak at 3319.26 cm-1 . Meanwhile, the bond between C and OH in the hydroxyl group occurs at the peak of the 572.06 cm-1 waves. Furthermore,atthepeakof1267.78cm-1 waveabsorption occurswhichcausesstretchdeformationintheC-Hbond.At the peak of the 1033.99 cm-1 waves, there was the absorptionoftheCObondfromthealkaligroup.

In the banana fiber test, it was found that there was an identification of stretching of the O-H bonds of the alkane group with a wave peak at 3322.07 cm-1. Meanwhile, the bondbetweenCandOHinthehydroxylgroupoccursatthe peakofthe557.03cm-1 waves.Furthermore,atthepeakof the wave at 1317.04 cm-1, wave absorption occurs which causesstretchdeformationintheC-Hbond.Atthepeakof the1034.67cm-1 waves,therewastheabsorptionoftheCO bondfromthealkaligroup.

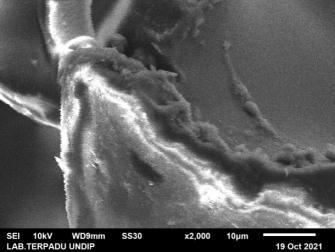

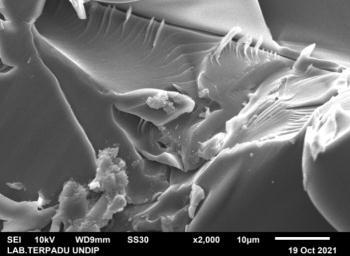

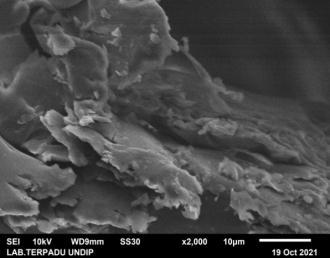

The fibers used in this study were pineapple fiber and bananafiber.Figure4.1showstheresultsoftheFTIRtestof pineapplefiberandbananafiberthathavebeensoakedin NaOHfor4hours.Fromthetestresultsonpineapplefiber,it wasfoundthatThemorphologyofpurepolyurethane-fiber composites was demonstrated by a Scanning Electron Microscopephotomicrograph.Thesemorphologicalresults werecarriedoutintheUndipTerpadulaboratory.TheSEM testspecimenwasmadewithdimensionsof10x10x10mm and then coated with an AuPd coating after that it was insertedintotheSEMtestequipment.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | September 2022 www.irjet.net p-ISSN: 2395-0072

The SEM results with 200x magnification. From the SEM observations, it can be seen that the morphology of the compositeswitharatioofMatrix:Fiber=1:2hasavisible fiber cell structure compared to other Matrix: Fiber composites. However, the difference in pore openness betweencompositesandtheratioofMatrix:Fiberisnottoo different.

glasswool,stainlesswool danfibre glassterhadap tingkat kebisingan pada sepeda motor empat langkah,”2013.

[4] N. H. N. Do et al., “Heat and sound insulation applications of pineapple aerogels from pineapple waste,” Mater. Chem. Phys., vol. 242, no. October 2019, p. 122267, 2020, doi: 10.1016/j.matchemphys.2019.122267.

[5] A. Kusuma Riza Pawestri, W. Hasanah, and A. Murphy, “Studi karakteristik komposit serat daun nanas,” Teknol. Bahan Alam, vol. 2, no. 2, p. 113, 2018.

[6] A.Putra,K.H.Or,M.SelamatZulkefli,andM.Jailani Mohd Nor, “Sound absorption of extracted pineapple-leaf fi bres,” elsevier, vol. 136, pp. 9–15, 2018,doi:10.1016/j.apacoust.2018.01.029.

[7] A. E. Tiuc, O. Nemeş, H. Vermeşan, and A. C. Toma, “Newsoundabsorbentcompositematerialsbasedon sawdust and polyurethane foam,” Compos. Part B Eng., vol. 165, no. November 2018, pp. 120–130, 2019,doi:10.1016/j.compositesb.2018.11.103.

Drawing4matrix:Fiber1:1(a),SEMmatrix:Fiber1:2 (b)andSEMmatrix:fiber2:1(c)

Compositescanabsorbsoundwellatmediumfrequencies (400Hz),withasoundabsorptioncoefficientvalueof0.3for compositeswithmorefiberwhileathighfrequencies(5000) thecoefficientvalueis0.95.Thisshowsthatthe composite can absorb sound well for low and medium frequencies, followingtheE-1050standardwheretheacousticmaterial's soundabsorptioncoefficientisatleast=0.15.

Theresultsoftheresearchshowthatthereishopeforthe developmentofcompositesassound-absorbingmaterials. However,itstillhasseveralmoresteps,furtherresearchis needed including porosity testing, and flammability resistancerelatedtoitsapplicationasasoundabsorber.

[1] N.C.LoureiroandJ.L.Esteves,Greencompositesin automotiveinteriorparts:Asolutionusingcellulosic fibers.ElsevirLtd,2018.

[2] A.Katherina,Sudarno,andE.Sutrisno,“Perancangan pengendalianbisingdenganpemasanganrockwool pada ruang pegawai di dipo lokomotif Semarang poncol,” Tek. Lingkung.,vol.5,no.2,pp.1–14,2016.

[3] H. M. dan D. F. Hasan, Akhabun Ari, “Analisa perbandingan penggunaan bahan Peredam suara

[8] E. Apriani and J. A. Malik, “Pembuatan kertas daur ulang dari limbah serat kelapa muda dan kertas bekas,” Pros. Konf. Nas. Eng. Perhotelan X,vol.2019, pp.242–247,2019.

[9] Y. M. Kartikaratri, A. Subagio, and H. Widiyandari, “Pembuatan komposit serat serabut kelapa dan resin,” Fisika,vol.15,no.3,pp.87–90,2012.

[10] A. Kirana, “Efek penambahan serat gelas pada komposit polyurethane terhadap nilai koefisien absorpsi suara dan sifat mekanik komposit doorpanel,”2016.

[11] Y. Rianto, “Pengaruh komposisi campuran filler terhadap kekuatan bending komposit ampas tebuserbukkayudalammatrikpolyester,”2011.

[12] M. Rusli, M. Irsyad, H. Dahlan, Gusriwandi, and M. Bur,“Soundabsorptioncharacteristicsofthenatural fibrous material from coconut coir, oil palm fruit bunches,andpineappleleaf,” IOPConf.Ser.Mater.Sci. Eng., vol. 602, no. 1, 2019, doi: 10.1088/1757899X/602/1/012067.

[13] C.C.B.DaSilva,F.J.H.Terashima,N.Barbieri,andK. F.DeLima,“Soundabsorptioncoefficientassessment ofsisal,coconuthuskandsugarcanefibersforlow frequenciesbasedonthreedifferentmethods,” Appl. Acoust., vol. 156, pp. 92–100, 2019, doi: 10.1016/j.apacoust.2019.07.001.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1231

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | September 2022 www.irjet.net p-ISSN: 2395-0072

[14] Suriadi, R. Balaka,and L. Hasanuddin, “Pembuatan kompositseratserabutkelapa Danresin polyester sebagaimaterialperedamakustik,” J. Ilm. Mhs. Tek. Mesin,vol.3,no.1,pp.1–10,2018.

[15] K. L. Putra, R. Y. Prakoso, and Z. Muchtar, “PENGARUHPENAMBAHANLIMBAHSERBUKBAN SEBAGAIPENGGANTIAGREGATHALUSTERHADAP STABILITASLAPISANAC-WC,”vol.14,no.01,pp.9–14,2019.

[16] A.I.Candra,E.Gardjito,Y.Cahyo,andG.A.Prasetyo, “PemanfaatanLimbahPuntungRokokFilterSebagai Bahan Campuran Beton Ringan Berpori,” UKaRsT, vol. 3, no. 1, p. 82, 2019, doi: 10.30737/ukarst.v3i1.365.

[17] H. Choe, J. H. Lee, and J. H. Kim, “Polyurethane composite foams including CaCO 3 fillers for enhanced sound absorption and compression properties,” Compos. Sci. Technol., vol. 194, no. March, p. 108153, 2020, doi: 10.1016/j.compscitech.2020.108153.

[18] K. Khotimah, S. -, and H. Soeprianto, “Sifat Penyerapan Bunyi Pada Komposit Serat Batang Pisang(Sbp)–Polyester,” J. Penelit.Pendidik.IPA,vol. 1, no. 1, pp. 91–101, 2015, doi: 10.29303/jppipa.v1i1.9.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal