International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Abstract - Plastic recycling industry is one of the most necessary industries in today’s age. The amount of plastic being used per day in India is 3.5 million tonnes. Plastic granules are one of the recycled products from this industry. Differenttypesofplasticsaresegregatedandprocessedbased upon their density. The types most widely used are HDPE, LDPE and PP. Each type has their own properties. A mixture between HDPE and LDPE is sought so as to achieve optimal strength ratio and better material flow index. Special machinery is required to manufacture each plastic’s type of granules, such as crusher, agglomerator, extruder. One such industry is taken as the subject of the study and a novel agglomeratorhasbeendesignedandmanufacturedaccording to the industry’s requirements. This paper presents optimization of mixture strength ratio between low density and high-density plastics as well as incorporating a novel agglomerator which can process both types so as to increase the overall efficiency of the process

Key Words: Agglomerator, Plastic recycling, granules, HDPE,LDPE

This paper is subjected towards improving the overall efficiencyofaplasticgranulefactorywhichrecyclesdifferent typesofplastics.Plasticgranulemanufacturingisadifficult process when you consider the types of plastics to be recycled.ThereareHighdensitypolypropylene(HDPE),low densitypolypropylene(LDPE)andpolyethylene.Thestages ofplasticgranulemakingbeginfromthesegregationoftypes ofplasticsbasedoftheirdensityandthentheyarecrushed inthecrusher.Thescrapsarethensenttotheagglomerator, which acts as a preheater and also helps to remove the moisturecontentfromtheplastics.Itisanimportantprocess whichisfollowedbyextrusion,wherethescrapsareputinto theextruder.Thescrapsaremeltedandextrudedthrougha filterandthencutintogranulesbyapalettecutter.Granules ofhigh-andlow-densitypolyethylenearemanufacturedand stored separately. This is done because the properties of both types differ a lot but some of them are important in making plastic products from the granules such as pipes, wireinsulations,etc.Thispapertargetstwoaspectsofthe

plasticgranuleindustry-1)designingandmanufacturinga novelagglomeratorwhichcanprocessplasticofalldensities atalargervolume,butinacost-effectiveway2)obtainingan optimummixtureratioofHDPEandLDPEwhichresultsin enhancedtensilestrengthandmeltflowindex.

Thedesigningofthemajorpartsoftheagglomeratoristobe done,whichisdueconsideringthestrengthofthematerial usedtomanufactureitandalsofactorofsafety.

The optimum mixture ratio of plastic is to be obtained by mixingHDPEandLDPEinvariousratios,inordertoobtain only the desirable properties of each type and then performing various tests on them to obtain the highest tensilestrengthandmeltflowindexofeachmixture.

Agglomerator is a device used in plastic recycling process whichisusedtodehumidifytheplasticrawmaterialcoming from washing unit and according to the requirements of injectionMouldingmachineplasticscrapisreducedinsize.

AgglomeratoriscomposedofElectricmotor,Gearreduction unit,Transmissionshaft,Impellorblades,Tank,Beltpulley system,BearingandShaft.Thecomponentsdesignedrevolve aroundthefactorslike torque, speed,strength,shaftloads andtransmissionunits.

Steps-

Selectionofdrum(tank)dimensions

Impellorbladedesign

Powerrequirementandmotorselection

Powertransmission

Thetankdesignedistoallowacapacityof100kgsofplastics to be processed per cycle. The material used should be

HDPE

granules and incorporating a novel agglomerator to process1Student, Mechanical Engineering, Government College of Engineering, Karad, Maharashtra India. 2Assistant Professor, Department of Production Engineering, Government College of Engineering, Karad, Maharashtra ***

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

strong enough to withstand the bombarding of plastic granulesrotatingataround800to1000rpm.Let,

DT = Diameterofthetank

H = Heightofthetank

Da = Impellordiameter

V = Volumeofthetank

M = Massoftherawmaterial=100kg

δ = Densityofplastic=920kg/m3

Weknowt V=M/δ =0.108m3

Therefore,volumeoftheplastic=108m3 Assuming,DT=1/2H V=π/4.DT2 .H H=0.82m

Afterdueconsiderations,tankdimensionsare: H=1.25m D=0.8m

2.2

Impellor blade design consists of 3 sets of blades. Consideringthemassofplastictobeprocessedandheightof thetank3setsofbladesaretobedesigned.

Parametersconsidered: Bladethickness Speed Diameter

Let, dbethediameteroftheimpellorandDbethediameterof thedrum

Therefore, d=0.9D d=0.9m

Widthoftheblades=w=d/10=0.9m

Thicknessoftheblades=0.009m 0.01m

Bladematerial=Steelalloy12 Numberofblades=n=3

Assumingrotorspeedof800rpm,stressinbladesgivenbyLet,ς=Shearforceontheblades

F=Shearforceontheblades

A=Bladearea

WhereF=Mixingforce/Shearforce =100x9.81

=981Nwithaspeedof800rpm

Therefore,

ς= =588kNm2

Shearforceontheblade=588kNm2

Therefore,thebladesareconsideredsafe.

The 3 Phase DC Electric Motor used for power. It uses a standard unit called power number to determine power required.

Total power required = Power required by 1st impellor + Power required by2ndimpellor +Powerrequiredby3rd impellor

Powerrequiredtodrive1stimpellorbladeset–P1=Npxρxω3xd5

Where, Np is power number obtained against Reynolds numberingraph

Np=1.9 [5] P1=Npxρxω3 xd5 =5530.2watts

Similarly,P2&P3willalsobe5530.2wattsrespectively.

Totalpowerrequired, P=P1+P2+P3+Losses(10%) =18249.6

Whichisequalto18250/746=24.46hp

Wecanusemotorof25to30HPforsafeoperationrunning at1440rpm.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

A belt and pulley system is used with a V belt due to its anti-slip feature, high power transmission efficiency and easyavailability.

SpeedRatio=N2/N1=D1/D2 800/1440=15/D2

ThereforeD2=27cm(Agglomeratorpulley)

Centredistance=2(D1+D2)=57cmand

beltlength=L=2C+ L=1.8m

Beltcontactangle= =6.03

Belttension= T1=415N T2=69N

Forreductionofshippage,3beltsof2.5cmwidthmadeupof syntheticrubberareused.

Powerofmotorused=30HP

Hence,theTransmissionsystemisdesigned.

Volumeofdrum=108m3

HeightofDrum=1.2m

DiameterofDrum=0.8m

WidthofBlade=0.9m

ThicknessofBlade=0.01m

BladeimpellerDiameter=0.72m

UltimateTensileStrengthofBladematerial=588kN/m2

PowerRequiredfor3setsofBladeImpeller=25HP

C-CDistanceBetweenTwoPulleyis0.57m

LengthofVBeltis1.88m

BeltTensionT1=415N,T2=69N

Hencethedesignofagglomeratoriscompleted.

HighdensitypolyethyleneandLow-densitypolyethyleneare twomaintypesofpolyethyleneidentificationofthesetypes of plastic is done by simple testing method, where plastic rawmaterialispouredincontainerfilledwithwateranddue tothedensitydifference,lowdensityplasticfloatsonwater andhigh-densitypolyethylenesettledowninthecontainer. These plastics are separately processed because of their followingproperties.

LDPEhasverylesstensilestrength

LDPEpropertieschangeafter20o C

HDPE is rigid and gets brittle after recycling, thereforedifficulttomachine

HDPEhasverylowyoung’smodulus

Toincreaseoveralltensilestrength,young’smodulus,impact strengthandtomaintainmeltflowindexLDPEandHDPEis usedtogethertoproducegranulesofimprovedproperties. DifferentpercentagesofLDPEandHDPEaretobemixedand optimumratioistobedetermined.

The requirement for most applications such as pipes manufacturing, wire insulations, etc. is that the granules shouldhavemaximummeltflowindex0.8gm/min.So,after producinggranulesofvariouscompositions,meltflowindex ofeachcompositionarecheckedonMFImachine.Followings aretheresultsafterconductingmeltflowindextestonMFI machine for various composition of HDPE and LDPE mixtures.

MFI for each composition of LDPE and HDPE respectively 1. 90-10 0.381gm/min 2 80-20 0.563gm/min 3 70-30 0.767gm/min 4 60-40 0.987gm/min 5 40-60 1.002gm/min 6. 20-80 1.531gm/min

GranuleswithMeltFlowIndexbelow0.8gm/minofvarious composition of LDPE and HDPE are tested for tensile strength on polymer UTM, in order to obtain the mixture withmaximumtensilestrength.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Fig1Strandsofvariousgranulescompositionproducedin MFImachine.

GranulesofvariousmixturecompositionsaretestedinMFI machine for checking the melt flow index and strands produced by test are measured in terms of gm/min in densitytester.

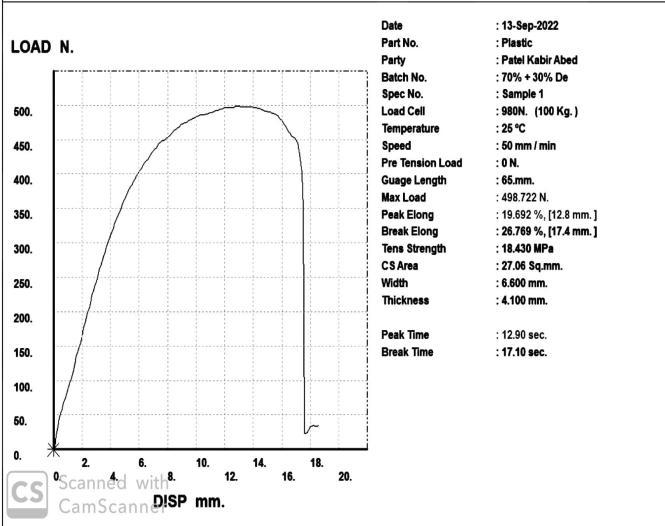

Graph1Tensilestrengthtestresultsof70-30%ofLDPE andHDPE

Intensilestrengthtestofgranulescomposition70-30%of LDPEandHDPEthetensilestrengthis18.430MPaandthe Meltflowindexis0.706gm/min.

Fig2Tensilestrengthofstrandsofvariousgranules compositionofLDPEandHDPE.

Tensile strength and displacement of strands of various compositionofgranulesismeasuredandplottedonagraph withappliedloadonYaxis andDisplacement inmmon X axis.Itwillhelpdeterminevariousstrengthsofthemixtures, suchasyieldstrength,ultimatetensilestrengthandYoung’s modulus.

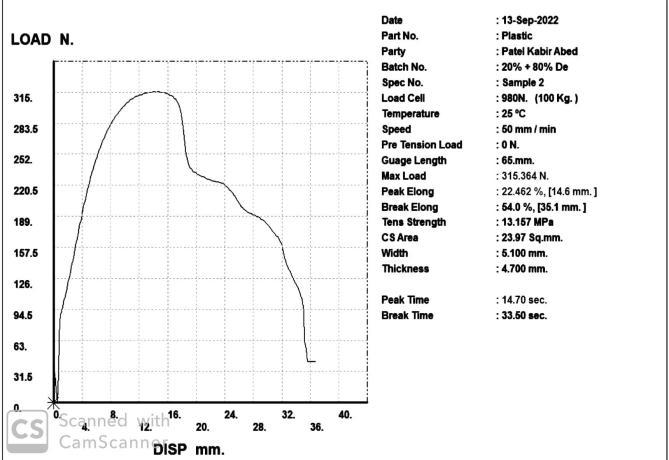

Graph2Tensilestrengthtestresultsof80-20%ofLDPE andHDPE

Intensilestrengthtestofgranulescomposition80-20%of LDPEandHDPEthetensilestrengthis13.157MPaandthe Meltflowindexis0.563gm/min.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Resilient moduli and strength characteristics." Construction and building materials 147(2017):639-647.

4. Cheng,H. J.,andS.S.Hsiau."Thestudyofgranular agglomerationmechanism." Powdertechnology 199, no.3(2010):272-283.

5. Joshis’sProcessEquipment Design,Fourthedition, M.VJoshi,V.V.Mahajani,S.B.Umarji,2009

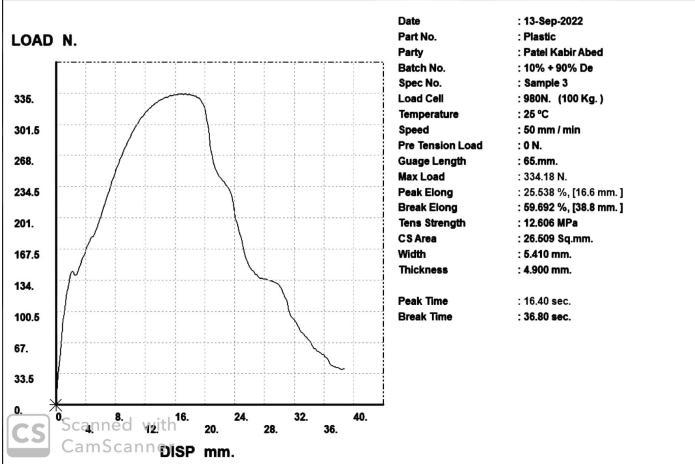

Intensilestrengthtestofgranulescomposition90-10%of LDPEandHDPEthetensilestrengthis12.606MPaandthe Meltflowindexis0.381gm/min.

From the test results it is observed that with increase in percentage of HDPE in LDPE the melt flow index and the tensilestrengthalsoincreases.

Thisstudydemonstratesinformationofagglomeratormixer anditscomponents.Studiedandimplementedisthedesign procedure for agglomerator and parameter like tank dimension, power calculation, power transmission and impellor blade design are calculated. A working model of saidagglomeratorisinthemaking.

Also, from this study it is observed that increase in proportion of HDPE in LDPE the melt flow index and the tensile strength also increases and flexibility decreases. Hencetheapplicationofplasticgranuleslikegardenpipes and electric wire insulation jacket where flexibility more importantthegranulesshouldbeproducedwithLDPEwith certainamountofHDPEtoimprovethetensilestrengthas well.

1. Shen, Li, and Ernst Worrell. "Plastic recycling." In Handbook of recycling, pp. 179-190. Elsevier, 2014

2. Singh,Gurjeet,andAjayVerma."ABriefReviewon injection moulding manufacturing process." Materials Today: Proceedings 4, no. 2 (2017):1423-1433.

3. AruArulrajah,Arul,EhsanYaghoubi,YatChoyWong, andSuksunHorpibulsuk."Recycledplasticgranules and demolition wastes as construction materials: